A Low-Cost Monitoring System and Operating Database for Quality Control in Small Food Processing Industry

Abstract

1. Introduction

- a tool that uses different approaches for a posteriori analysis of process data, the extraction of information useful for optimizing conduction and/or improving product quality (HQ-Pro);

- a tool for the complete traceability of process conditions in the production of different lots (HQ-Track);

- a tool for analyzing the migration of pollutants from packaging to food (HQ-Pack).

2. Materials and Methods

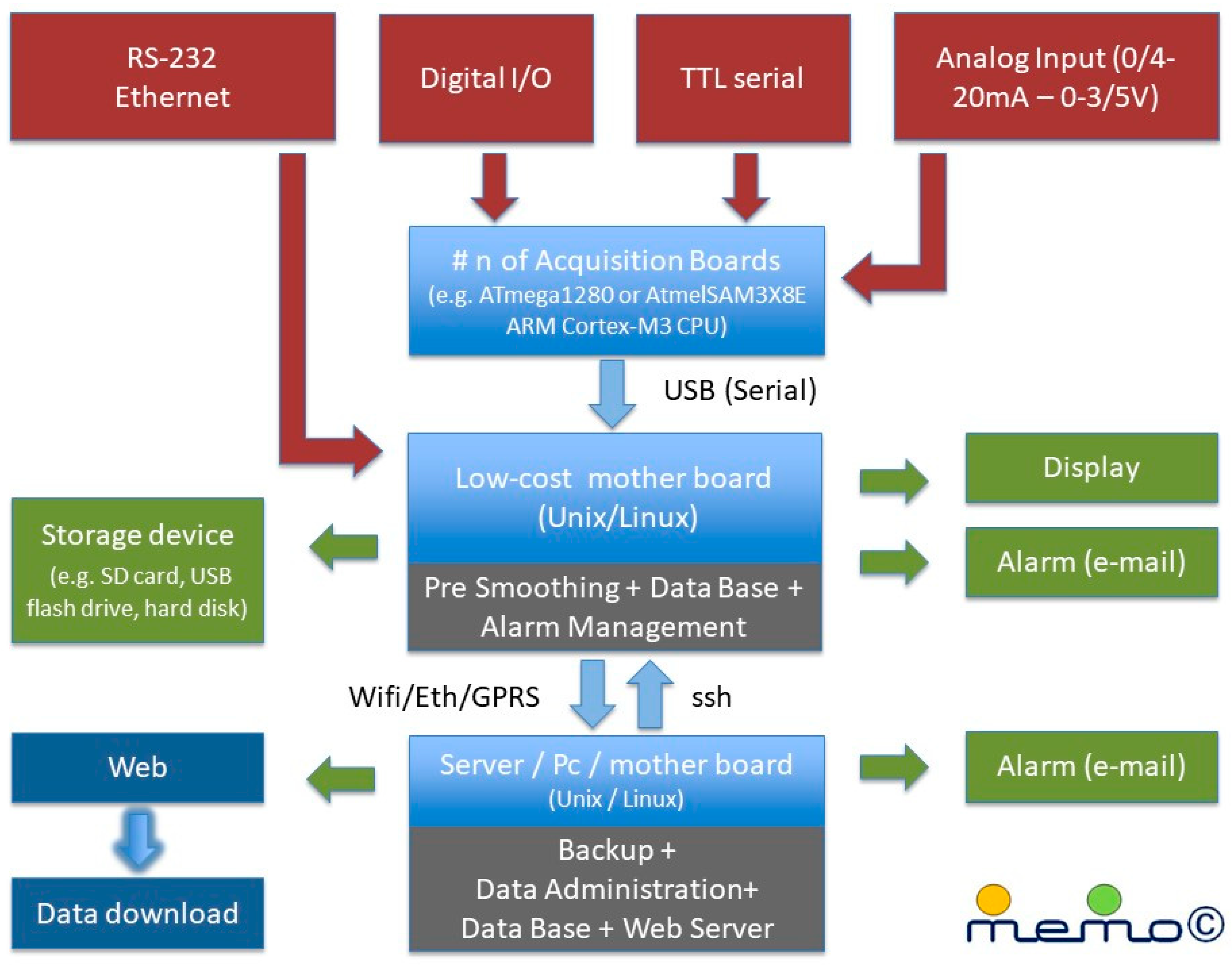

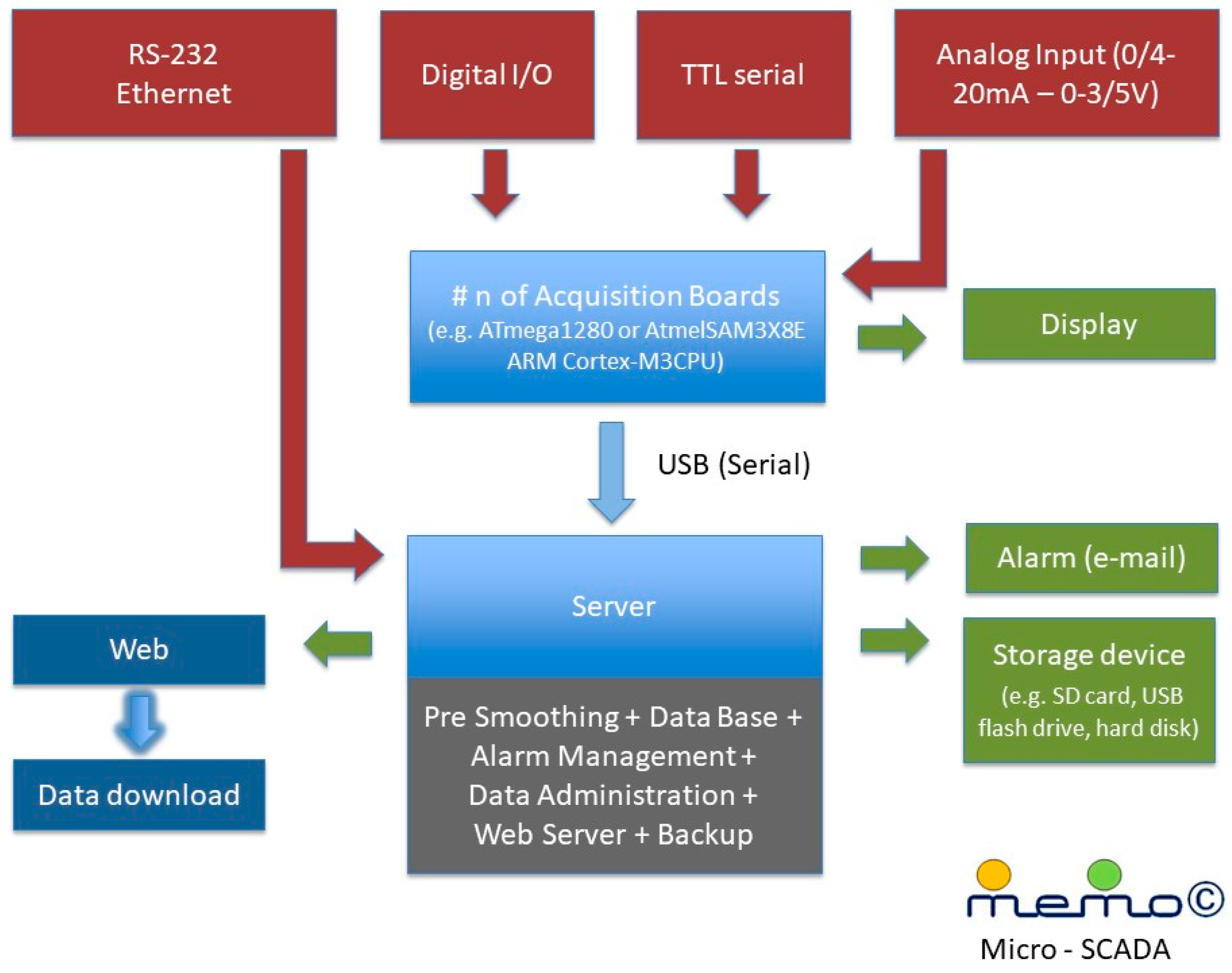

2.1. System Architecture

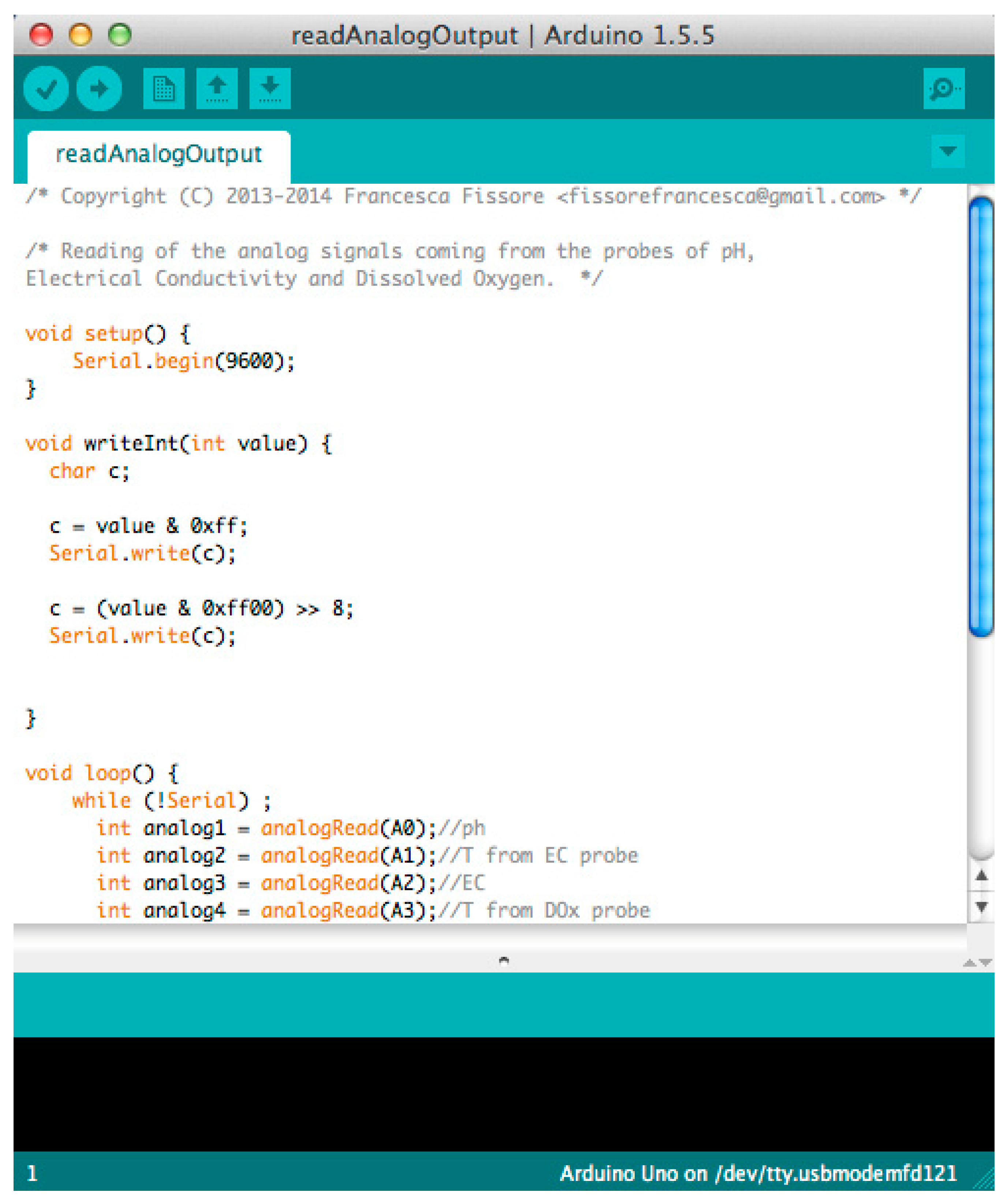

2.2. Hardware

2.3. Software Schema

- work with long-time monitoring processes;

- accelerate the visualization of the time series on the web page devoted to this service.

2.3.1. HQ-Pro

- The calculation of the first and the second derivative of the monitored variable. As an example, if the temperature is the process variable whose dynamics requires particular attention, early warning is sent when:where and are respectively the reactor temperature and the coolant temperature.

- The practical application of the Lyapunov exponents criterion. The Lyapunov exponents of a dynamic system at a point give the measure of how significantly the orbits of the system are dependent on the initial data (sensitivity on input data) and are therefore indicators of the presence of the complex and not predictable dynamics. They measure the average velocity of departing of the orbits of the points near the point from the orbit of , for sufficiently long times. In a dynamic system with a dimensions phase space, it is possible to monitor the evolution of a -sphere of infinitesimal dimensions (around point ) that will become an ellipsoid over time. The -th Lyapunov exponent is defined in terms of the length of the -th axis of the ellipsoid at time as:

2.3.2. HQ-Track

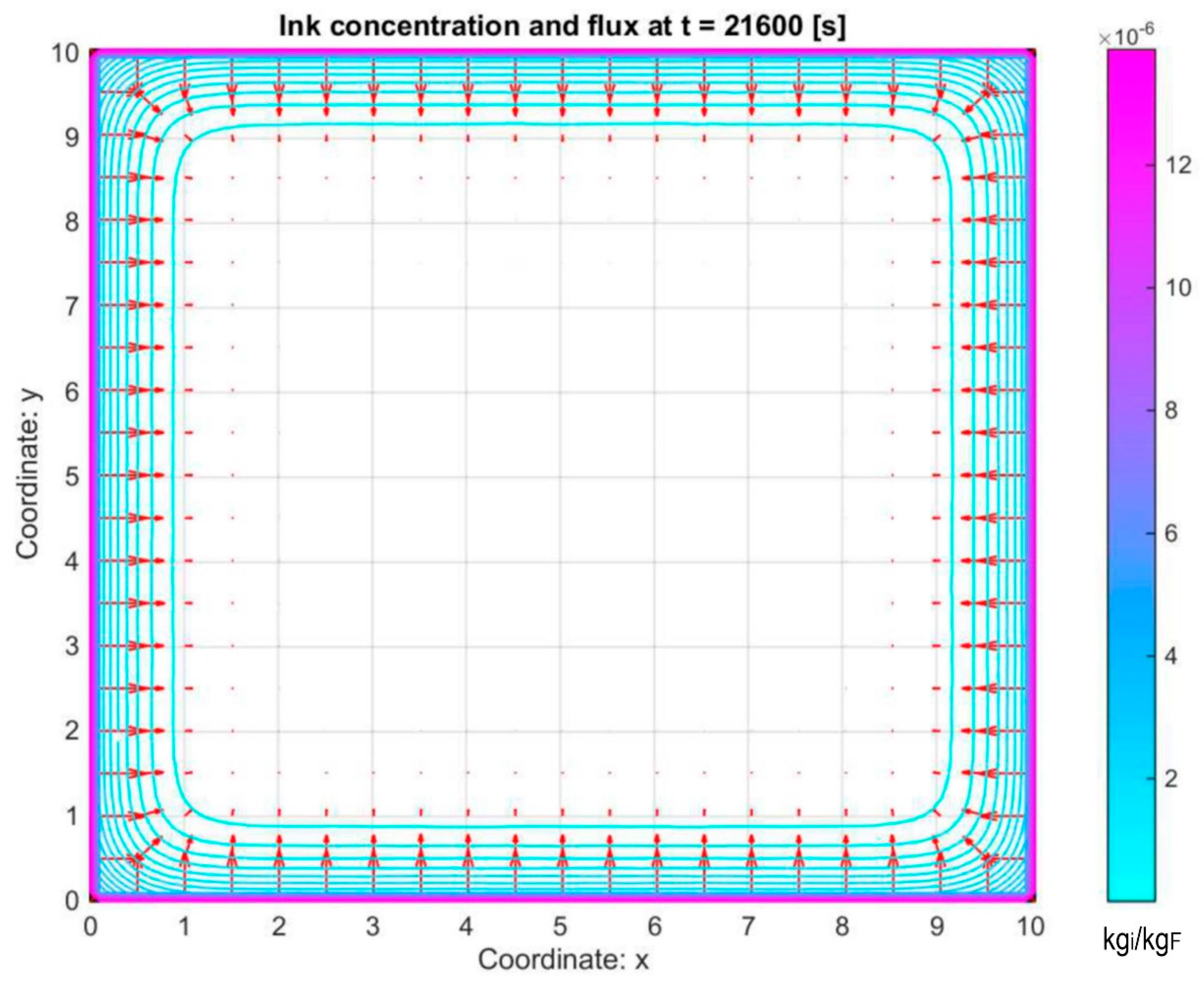

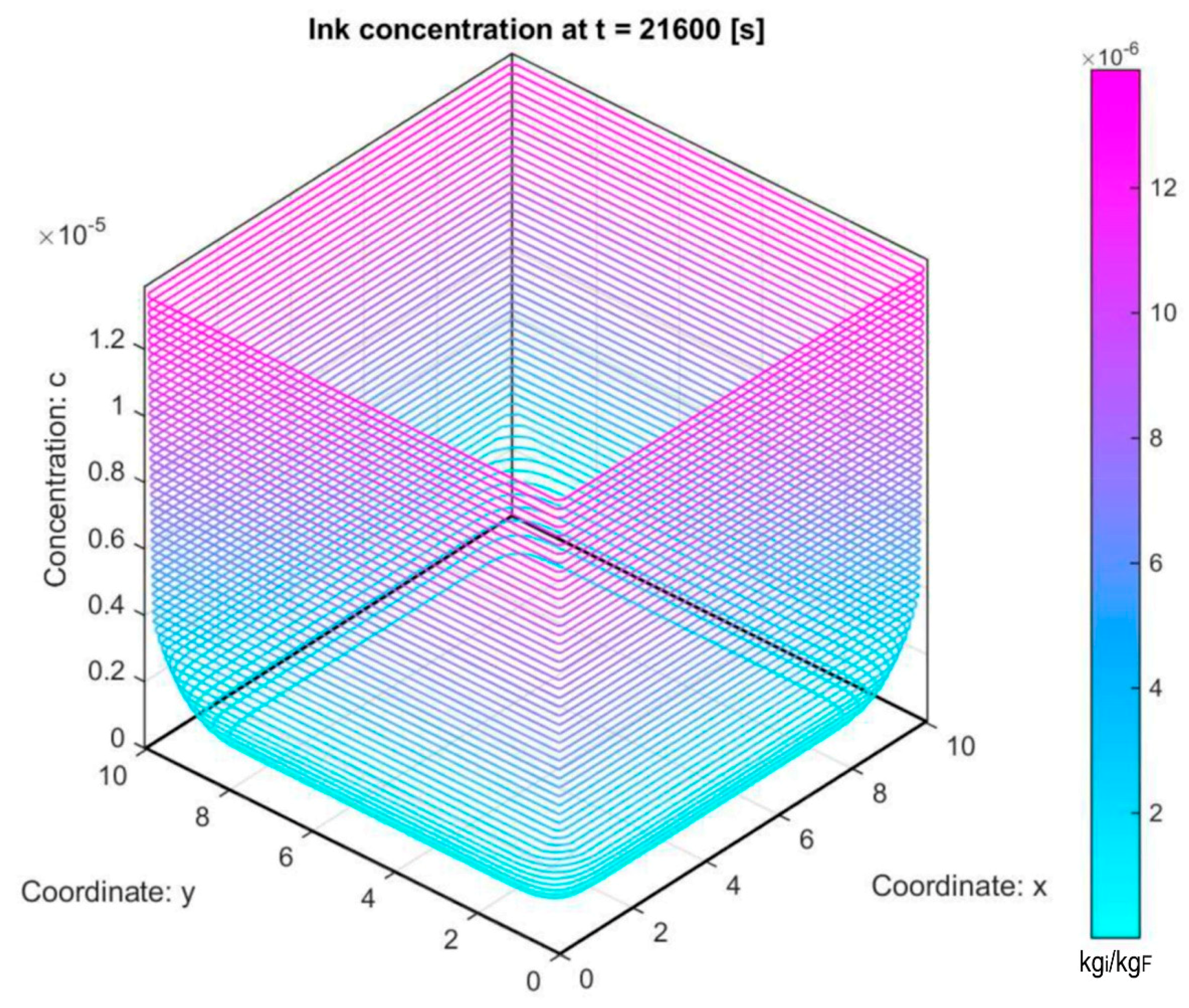

2.3.3. HQ-Pack

- a database with the following data:

- Commission Regulation (EU) No 10/2011 of 14 January, 2011 on plastic materials and articles intended to come into contact with food and related Annexes [15];

- List of substances (migrants) of Annex 1 [15];

- Specific Migration Limits of Annex 1 on Group restrictions [15];

- Food simulants of Annex 2 [15];

- Contact time Annex V and the contact temperature Annex V [15];

- The values of the diffusion coefficients of the main migrants into the most used plastic materials (polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), high-density polyethylene (HDPE), low-density polyethylene (LDPE), polystyrene (PS), polyethylene terephthalate (PET));

- Partitioning coefficients of the main migrants from the most used plastic materials to the food simulants of Annex 2.

- The analytical solutions, if they are available, of some diffusion problems under different initial and boundary conditions, that can be used to model the migration process.The two solutions under the hypothesis of migration controlled by diffusion in the packaging material, valid respectively for the limit condition and [27,28] and the solution under the hypothesis of migration with diffusion in the packaging material and boundary layer resistance in the food simulant (valid for high Biot number), are currently implemented [29,30,31].

- The possibility to exploit an external link in order to obtain numerical solutions for the migration problem in case of migration with diffusion in both the packaging material and the food simulant, migration with the interaction between the packaging material and the food simulant, complex geometry and multilayered packaging.

2.4. Testing

3. Results and Discussion

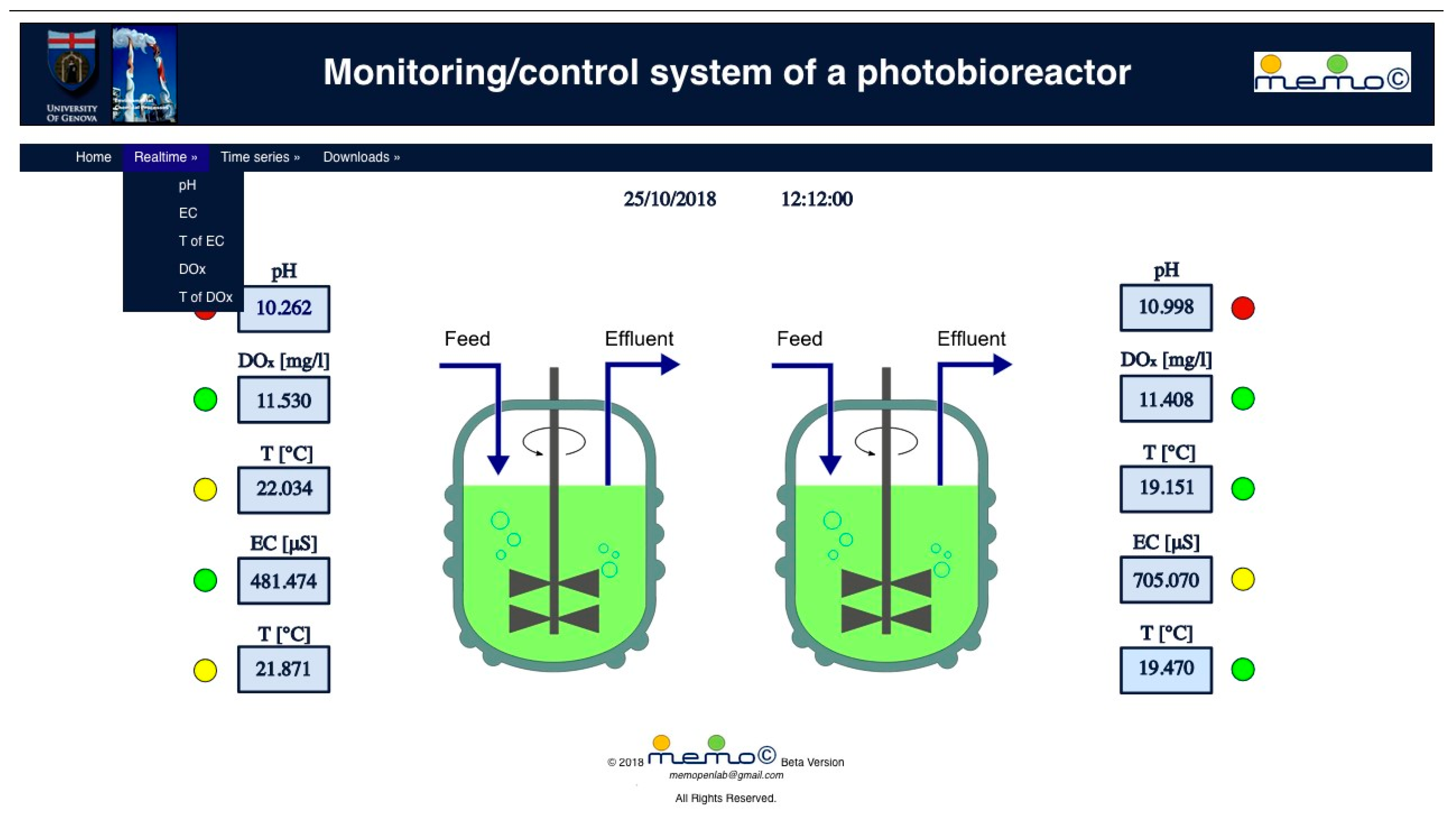

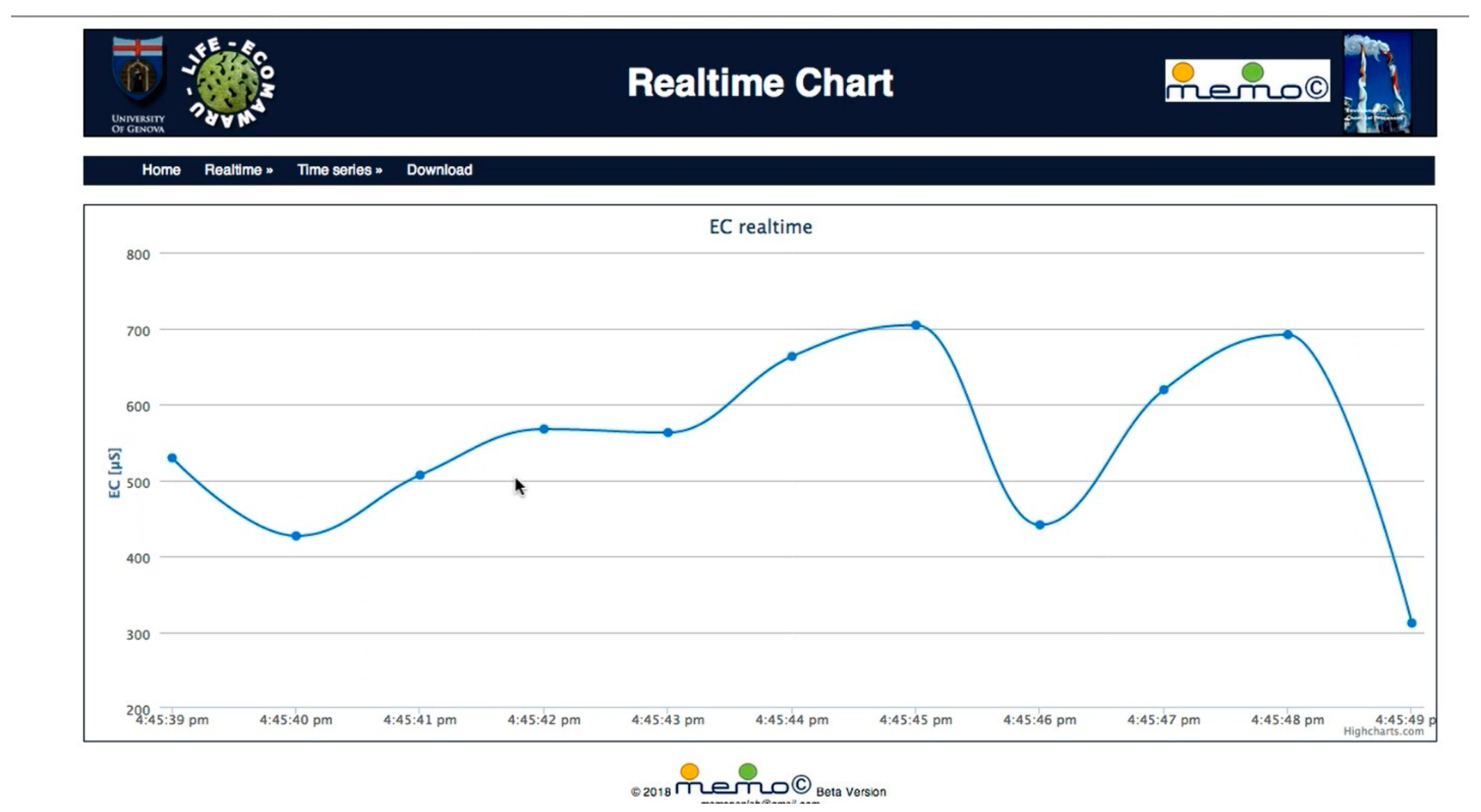

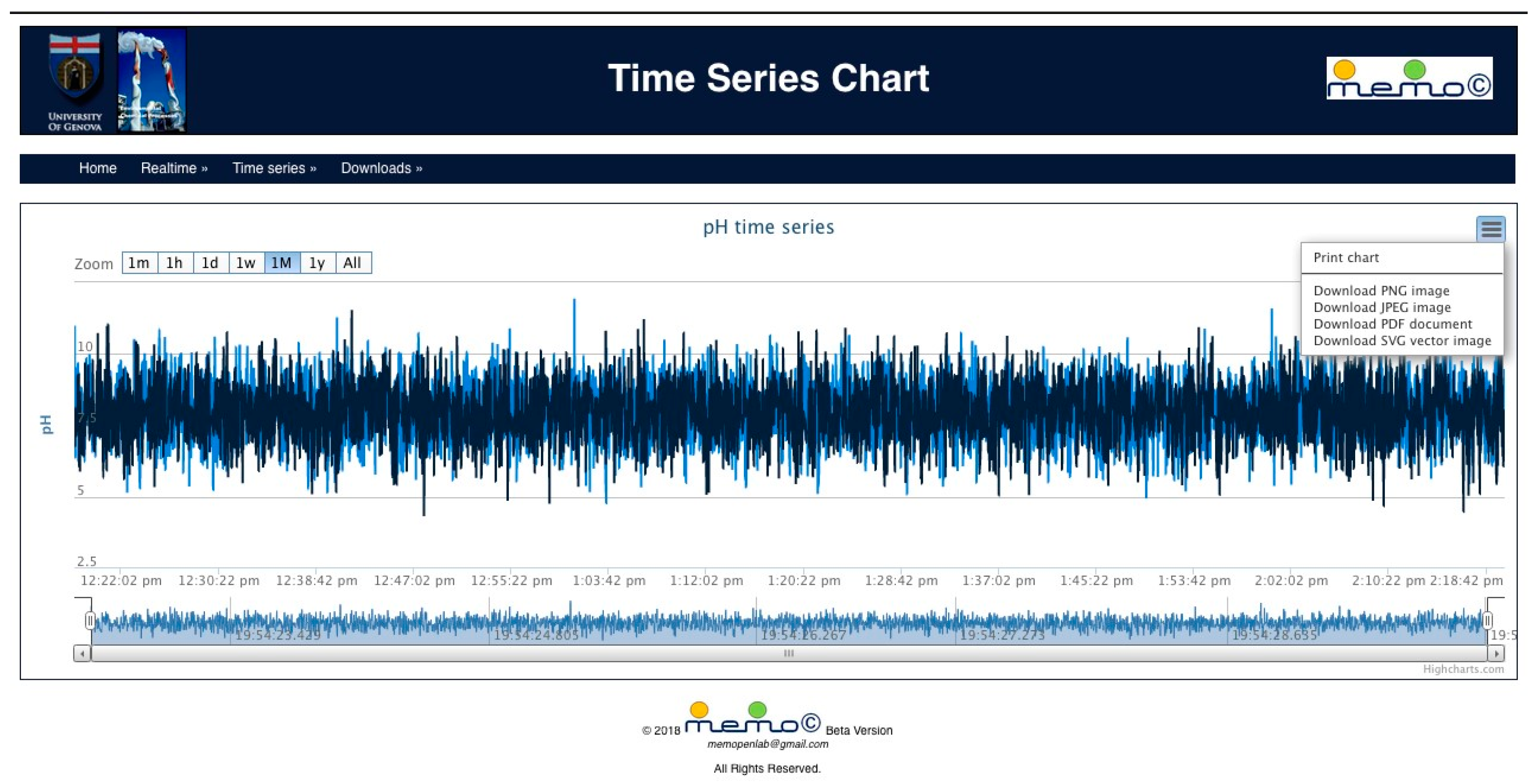

3.1. MEMO-HQ

- It is developed according to the needs of the food industry;

- The human-machine interface (HMI) can be consulted via the web and from any machine or smart device;

- The user can choose the system version (data reside on proprietary machines) or the service version (data are sent to servers owned by external providers);

- It uses public domain algorithms as far as possible, in order to keep low costs;

- The connection to the sensors is both via open HW or commercial/proprietary HW;

- The acquisition of signals from programmable logic controllers (PLCs) or microcontrollers, if already existing on the plant, is envisaged;

- The data can be received from the sensors via general packet radio service (GPRS) if the network is not available (for example, fish farming in marine tanks);

- It uses the methods for identifying patterns and for early warning detection coming from innovative research results.

- The processes do not involve the transformation of substances that can lead to high risk of pollution in the event of uncontrolled emissions (the reagents and the products are food or chemical substances suitable for treating food);

- The processes are mostly carried out in a liquid phase and the sensor costs necessary for the measurement of process variables such as temperature, pH, conductivity, dissolved gases, nitrates, ammonia, redox potential, etc. have considerably decreased in recent years;

- The problems related to information security (data secrecy) are not critical for high-quality micro/very small companies (they usually do not use patented additives, preservatives, etc.);

- The transients of the process variables are relatively slow and in all the process situations of the target industrial types the acquisition frequencies can be in the order of seconds (the smart-SCADA can easily manage acquisitions at 10 ms using open HW at low cost);

- In recent years, fast algorithms have been made available for data analysis and representation of data.

- It does not provide safe shut-down operations and therefore is not applicable to high-risk plants;

- If it operates as a control system in plants at high pressure, the transients may be at risk;

- It does not permit the implementation of high-level data protection procedures;

- It cannot be certified because it uses open HW/SW.

3.2. HQ-Pack

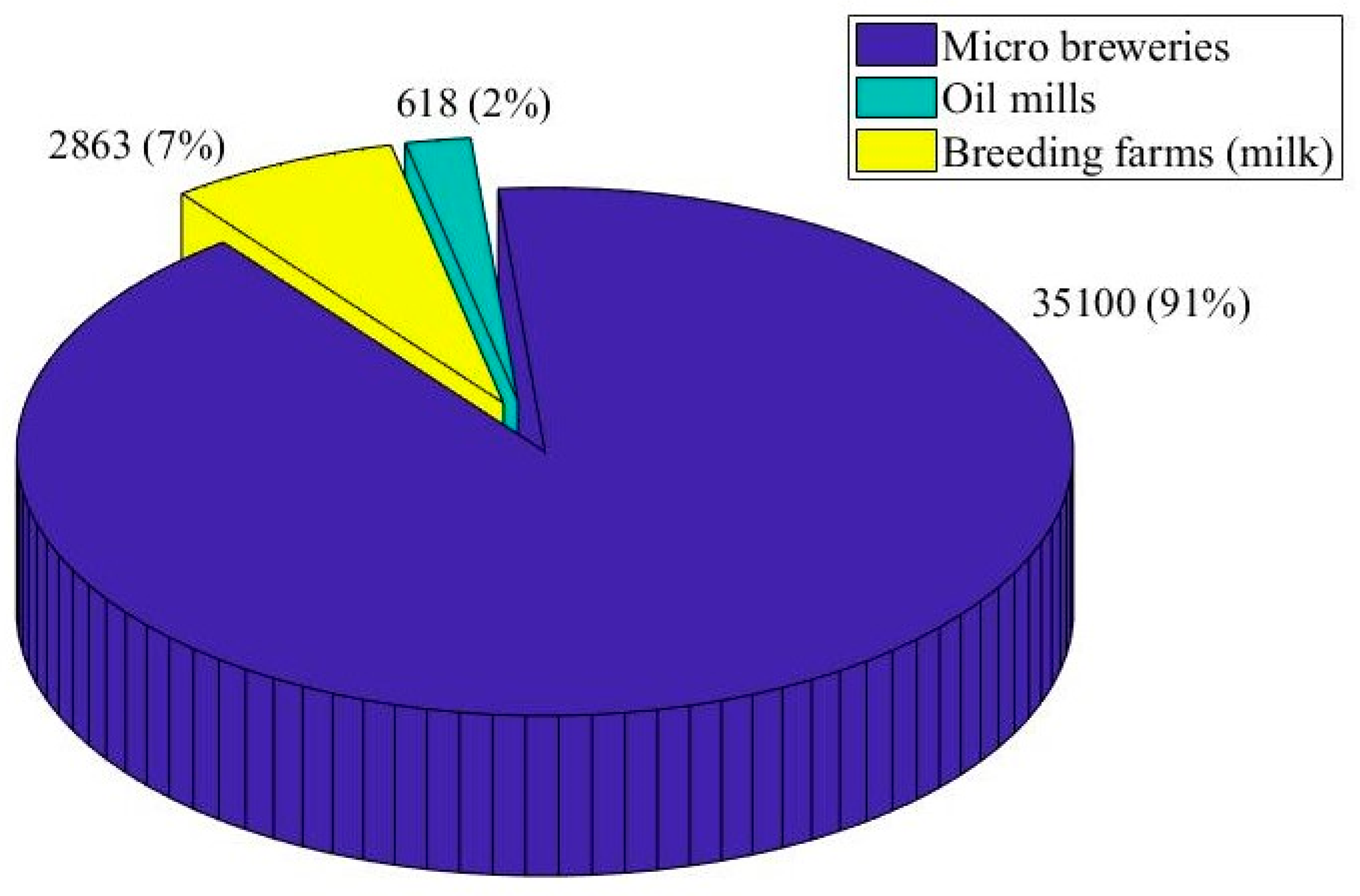

3.3. Market Analysis

- Product certification through the identification of process and product markers;

- Food safety of products with regard to biological and microbiological, chemical and physical contaminants;

- The interest in innovative products or traditional evolved ones (less thermal treatments, innovative conservation processes).

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Appendix A. MEMO Demo Version

- Create Virtual Environment

- Verify that you are at a level above the setup.py file;

- From the console run the following commands:

- pip install virtualenv

- virtualxenv ENV

- source ENV/bin/activate

In this way, the virtual environment is created and activated. - Install the MEMO application

- From the console type:

- pip install–e memo

In this way, all the Python libraries that are needed for MEMO operation are installed.

References

- Ilyukhin, S.V.; Haley, T.A.; Singh, R.K. A survey of automation practices in the food industry. Food Control 2001, 12, 285–296. [Google Scholar] [CrossRef]

- Mahalik, N.P.; Yen, M. Extending fieldbus standards to food processing and packaging industry: A review. Comput. Stand. Interfaces 2009, 31, 586–598. [Google Scholar] [CrossRef]

- Mahalik, N.P. Processing and packaging automation systems: A review. Sens. Instrum. Food Qual. Saf. 2009, 3, 12–25. [Google Scholar] [CrossRef]

- Arjona, R.; Ollero, P.; Vidal, B.F. Automation of an olive waste industrial rotary dryer. J. Food Eng. 2005, 68, 239–247. [Google Scholar] [CrossRef]

- Muzzio, C.R.; Díaz, R.J.; Dini, N.G. In-line measurement of sunflower oil color in the Lovibond scale using a low-cost robust device. J. Food Eng. 2014, 120, 88–93. [Google Scholar] [CrossRef]

- Holmes, J.F.; Russell, G.; Allen, J.K. 6 - Supervisory Control and Data Acquisition (SCADA) and related systems for automated process control in the food industry: An introduction. In Robotics and Automation in the Food Industry; Caldwell, D.G., Ed.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Cambridge, UK, 2013; pp. 130–142. ISBN 978-1-84569-801-0. [Google Scholar]

- Hosseinpour, S.; Ilkhchi, A.H.; Aghbashlo, M. An intelligent machine vision-based smartphone app for beef quality evaluation. J. Food Eng. 2019, 248, 9–22. [Google Scholar] [CrossRef]

- Cristani, M.; Demrozi, F.; Tomazzoli, C. ONTO-PLC: An ontology-driven methodology for converting PLC industrial plants to IoT. Procedia Comput. Sci. 2018, 126, 527–536. [Google Scholar] [CrossRef]

- Talavera, J.M.; Tobón, L.E.; Gómez, J.A.; Culman, M.A.; Aranda, J.M.; Parra, D.T.; Quiroz, L.A.; Hoyos, A.; Garreta, L.E. Review of IoT applications in agro-industrial and environmental fields. Comput. Electron. Agric. 2017, 142, 283–297. [Google Scholar] [CrossRef]

- Verdouw, C.; Sundmaeker, H.; Tekinerdogan, B.; Conzon, D.; Montanaro, T. Architecture framework of IoT-based food and farm systems: A multiple case study. Comput. Electron. Agric. 2019, 165, 104939. [Google Scholar] [CrossRef]

- García, L.; Parra, L.; Jimenez, J.M.; Lloret, J.; Lorenz, P. Practical Design of a WSN to Monitor the Crop and its Irrigation System. Netw. Protoc. Algorithms 2019, 10, 35–52. [Google Scholar] [CrossRef][Green Version]

- Strozzi, F.; Zaldívar, J.M.; Kronberg, A.E.; Westerterp, K.R. On-Line runaway detection in batch reactors using chaos theory techniques. AIChE J. 1999, 45, 2429–2443. [Google Scholar] [CrossRef]

- Zbilut, J.P.; Zaldivar-Comenges, J.-M.; Strozzi, F. Recurrence quantification based Liapunov exponents for monitoring divergence in experimental data. Phys. Lett. A 2002, 297, 173–181. [Google Scholar] [CrossRef]

- Sjöberg, J.; Zhang, Q.; Ljung, L.; Benveniste, A.; Delyon, B.; Glorennec, P.-Y.; Hjalmarsson, H.; Juditsky, A. Nonlinear black-box modeling in system identification: A unified overview. Automatica 1995, 31, 1691–1724. [Google Scholar] [CrossRef]

- EU Commission Regulation EU Commission Regulation No 10/2011 of 14 January 2011 on Plastic Materials and Articles Intended to Come into Contact with Food Text with EEA Relevance. Available online: https://eur-lex.europa.eu/eli/reg/2011/10/oj (accessed on 6 January 2018).

- Zaldívar, J.M.; Cano, J.; Alós, M.A.; Sempere, J.; Nomen, R.; Lister, D.; Maschio, G.; Obertopp, T.; Gilles, E.D.; Bosch, J.; et al. A general criterion to define runaway limits in chemical reactors. J. Loss Prev. Process Ind. 2003, 16, 187–200. [Google Scholar] [CrossRef]

- Bosch, J.; Strozzi, F.; Lister, D.G.; Maschio, G.; Zaldívar, J.M. Sensitivity Analysis in Polymerization Reactions Using the Divergence Criterion. Process Saf. Environ. Prot. 2004, 82, 18–25. [Google Scholar] [CrossRef]

- Bosch, J.; Strozzi, F.; Zbilut, J.P.; Zaldívar, J.M. On-line runaway detection in isoperibolic batch and semibatch reactors using the divergence criterion. Comput. Chem. Eng. 2004, 28, 527–544. [Google Scholar] [CrossRef]

- Ratto, M.; Paladino, O. Controllability of start-ups in CSTRs under PI control. Chem. Eng. Sci. 2001, 56, 1477–1484. [Google Scholar] [CrossRef]

- Scikit-Learn: Machine Learning in Python—scikit-Learn 0.21.3 Documentation. Available online: https://scikit-learn.org/stable/ (accessed on 19 August 2019).

- mlpy–Machine Learning Python. Available online: http://mlpy.sourceforge.net/ (accessed on 19 August 2019).

- PyBrain. Available online: http://pybrain.org/ (accessed on 19 August 2019).

- Welcome to NeuroLab’s documentation!—NeuroLab 0.3.5 documentation. Available online: https://pythonhosted.org/neurolab/ (accessed on 19 August 2019).

- PyNeurGen. Available online: http://pyneurgen.sourceforge.net/ (accessed on 19 August 2019).

- Paladino, O.; Hodaifa, G.; Neviani, M.; Seyedsalehi, M.; Malvis, A. Chapter 11—Modeling in environmental interfaces. In Interface Science and Technology; Kyzas, G.Z., Mitropoulos, A.C., Eds.; Advanced Low-Cost Separation Techniques in Interface Science; Elsevier: Amsterdam, The Nertherland, 2019; Volume 30, pp. 241–282. [Google Scholar]

- Chen, S.-C.; Billings, S.A.; Luo, W. Orthogonal least squares methods and their application to non-linear system identification. Int. J. Control 1989, 50, 1873–1896. [Google Scholar] [CrossRef]

- Baner, A.; Brandsch, J.; Franz, R.; Piringer, O. The application of a predictive migration model for evaluating the compliance of plastic materials with European food regulations. Food Addit. Contam. 1996, 13, 587–601. [Google Scholar] [CrossRef]

- Begley, T.; Castle, L.; Feigenbaum, A.; Franz, R.; Hinrichs, K.; Lickly, T.; Mercea, P.; Milana, M.; O’Brien, A.; Rebre, S.; et al. Evaluation of migration models that might be used in support of regulations for food-contact plastics. Food Addit. Contam. 2005, 22, 73–90. [Google Scholar] [CrossRef]

- Chung, D.; Papadakis, S.E.; Yam, K.L. Simple models for assessing migration from food-packaging films. Food Addit. Contam. 2002, 19, 611–617. [Google Scholar] [CrossRef] [PubMed]

- Poças, M.F.; Oliveira, J.C.; Brandsch, R.; Hogg, T. Analysis of Mathematical Models to Describe the Migration of Additives from Packaging Plastics to Foods. J. Food Process Eng. 2012, 35, 657–676. [Google Scholar] [CrossRef]

- Poças, M.F.; Oliveira, J.C.; Oliveira, F.A.R.; Hogg, T. A Critical Survey of Predictive Mathematical Models for Migration from Packaging. Crit. Rev. Food Sci. Nutr. 2008, 48, 913–928. [Google Scholar] [CrossRef] [PubMed]

- Moresi, M.; Masi, P.; Massini, R. Industria Alimentare Italiana: Quali Prospettive di Ricerca e Sviluppo? Società Italiana di Scienze e Tecnologie Alimentari (SISTAL) c/o Dipartimento di Scienze e Tecnologie Agroalimentari (DISTA), Università degli Studi della Tuscia: Viterbo, Italy, 2008; pp. 1–30. [Google Scholar]

| Test | 1 | 2 | 3 |

| Plant scale | Lab-scale | Pilot-scale | Pilot-scale |

| Operation | Semi-continuous | Quasi-continuous | Continuous |

| Reactors | Stirred tanks | Airlifts | Tubular |

| Duration | 3 months | 3 months | 1 month |

| Measured Variables | T1, T2, pH, C, DOx (single probes inside the reactor); concentration (by UV-VIS) | T1, T2, pH, C, DOx (single probes inserted into the bottom collector); concentration (by UV-VIS) | T, pH/ORP, C, DOx, turbidity, chlorophyll, nitrates and ammonia (multi-parametric inserted probe into the recirculating tank) |

| Acquisition Interval | 100 ms | 100 ms | 1 s |

| Data pre-Treatment | Median each 10 values + mean each 60 values (by MEMO) | Median each 10 values + mean each 60 values (by MEMO) | Median each 10 values + mean each 6 values (by MEMO) |

| Controlled Variables | pH, DOx, microalgae concentration | pH, DOx, microalgae concentration, pressure (without MEMO) | pH, DOx, chlorophyll, nitrates, ammonia |

| Manipulated Variables | Feeding intervals; Feeding flowrate 1 (liquid medium with nutrients); Feeding flowrate 2 (air + CO2); Brought to volume | Feeding intervals; Feeding flowrate 1 (wastewater); Feeding flowrate 2 (air + CO2); Extracting intervals (extr. flowrate is fixed); Acid flowrate | Extracting flowrate (water + microalgae); Nutrients flowrate; Acid flowrate; (feeding flowrate is kept fixed since in exit from a WW treatment plant) |

| Manipulated Pumps | Gilson Minipuls 3 | Welko WP1100 | Welko WP1100; Industrial pneumatic (not manipulated by MEMO). |

| Probes/Sensors | Atlas scientific | B&C Electronics 7685 | YSI 6600/6920 V2 |

| Actuators | Arduino 1 +self-constructed (0–5 V) | Arduino + dedicated shield (0–5 V and 0–20 mA) | Arduino + dedicated shield (0–20 mA) |

| Mean Cost of Probes/Sensors + Actuators | 500 euros | 5000 euros | 25,000 euros |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paladino, O.; Fissore, F.; Neviani, M. A Low-Cost Monitoring System and Operating Database for Quality Control in Small Food Processing Industry. J. Sens. Actuator Netw. 2019, 8, 52. https://doi.org/10.3390/jsan8040052

Paladino O, Fissore F, Neviani M. A Low-Cost Monitoring System and Operating Database for Quality Control in Small Food Processing Industry. Journal of Sensor and Actuator Networks. 2019; 8(4):52. https://doi.org/10.3390/jsan8040052

Chicago/Turabian StylePaladino, Ombretta, Francesca Fissore, and Matteo Neviani. 2019. "A Low-Cost Monitoring System and Operating Database for Quality Control in Small Food Processing Industry" Journal of Sensor and Actuator Networks 8, no. 4: 52. https://doi.org/10.3390/jsan8040052

APA StylePaladino, O., Fissore, F., & Neviani, M. (2019). A Low-Cost Monitoring System and Operating Database for Quality Control in Small Food Processing Industry. Journal of Sensor and Actuator Networks, 8(4), 52. https://doi.org/10.3390/jsan8040052