Research and Education in Robotics: A Comprehensive Review, Trends, Challenges, and Future Directions

Abstract

1. Introduction

- Main Contributions

- It presents a multi-dimensional taxonomy of robotics technologies encompassing AI, soft robotics, quantum robotics, IoRT, and neuromorphic computing, framed through recent advancements and real-world implementations.

- It systematically connects these technological developments to evolving educational practices at all levels, from K–12 to postgraduate research, highlighting instructional innovations such as digital twins, remote laboratories, and AI-driven tutoring.

- It offers a comparative analysis of educational tools, platforms, and curricula supported by detailed tables and figures.

- It outlines forward-looking, feasible future directions that incorporate technological, ethical, sustainable, and inclusive principles across robotics research and pedagogy.

- It introduces a curriculum-level case study from the German Jordanian University (GJU), showcasing a structured robotics integration across undergraduate coursework, project-based learning, capstone design, and competitive activities. This example demonstrates a scalable, practice-driven educational model that bridges theory and application within an industry-aligned academic framework.

2. Review Methodology

2.1. Literature Search Strategy

2.2. Search Terms and Keywords

- “robotics research” AND “technological trends”

- “robotics education” OR “educational robotics” AND “STEM learning”

- “robot manipulation” AND “grasping techniques”

- “human-robot interaction” OR “collaborative robotics”

- “robotics curriculum” AND “university education”

2.3. Inclusion and Exclusion Criteria

- Focused on robotics technologies, education, applications, or pedagogical tools.

- Peer-reviewed publications or reputable white papers.

- Published in English between 2010 and 2025.

- Relevance to core themes, such as HRI, perception, motion planning, curriculum design, and educational tools.

- Duplicate records or inaccessible full texts.

- Studies not directly related to robotics or educational implementations.

- Publications in non-peer-reviewed outlets lacking technical or empirical contributions.

2.4. Thematic Organization

3. Robotics

3.1. A Journey Through Time: The Evolution of Robotics

3.1.1. The Dawn of Automata: Early Civilizations and the Greek Legacy [22]

3.1.2. The Golden Age of Islamic Civilization: Al-Jazari, the Father of Robotics [23,24]

3.1.3. The Renaissance and Industrial Revolution: Mechanical Marvels and Rise of Automation [26]

3.1.4. The 20th Century: The Birth of Modern Robotics [27]

3.1.5. The Digital Age: [3,28,29]

3.2. A Taxonomy of Robotics

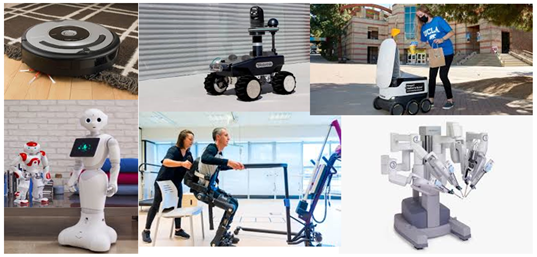

3.2.1. By Functionality (Application) [18,31]

3.2.2. By Level of Autonomy [32]

3.2.3. By Physical Configuration [34,35]

3.2.4. Domain-Based Classification of Robots [4,37]

3.2.5. By Enabling Technology [3]

- (i)

- Advanced Sensor Integration: Modern robotic systems rely on multi-modal sensor arrays to achieve environmental cognition. Cutting-edge technologies, including LiDAR, stereoscopic vision systems, and biomimetic tactile sensors, enable millimeter-scale spatial resolution and multispectral perception [38,39].

- (ii)

- Industry 4.0 and smart factories: Industry 4.0 integrates robotics with AI, IoT, and big data to enable real-time analytics, predictive maintenance, and adaptive automation in smart factories [40,41]. Collaborative robots (cobots) enhance flexibility and safety by working alongside humans in precise and ergonomically demanding tasks.

- (iii)

- AI-driven robotics leverages machine learning, computer vision, and decision-making algorithms to enhance adaptability. AI-driven robots can interpret sensor data, recognize patterns, and adapt to changing scenarios [42].

- (iv)

- IOT: The Internet of Robotic Things (IoRT) merges robotics with IoT for real-time data exchange, remote control, and predictive analytics in logistics and smart infrastructure [43]. 5G and blockchain enhance latency and data security, whereas Fog Robotics reduces cloud reliance and hardware costs in distributed simultaneous localization and mapping (SLAM) [44].

- (v)

- Soft Robotics: Soft robotics uses compliant materials such as elastomers and hydrogels, for safe and adaptive interaction with complex environments [45]. Ideal for medical, assistive, and rehabilitation applications, it also supports inspection and repair in hazardous settings such as nuclear facilities and aero-engines [46].

- (vi)

- (vii)

- Sustainable Robotics: Robotics supports the UN SDGs through innovations such as AI-powered waste-sorting robots that enhance recycling and promote circular economies [49]. In smart cities, IoT-integrated robots enable energy optimization, traffic control, air quality monitoring, and driving data-informed urban sustainability [50].

- (viii)

- Agricultural Robotics [51,52]: Robotic systems are transforming agriculture by enabling precision farming, a data-driven method that boosts productivity while reducing environmental impact. Throughout the crop lifecycle, from soil preparation to harvesting, autonomous tractors, drones, and robotic sprayers leverage sensors, GPS, and AI for targeted operations. For instance, drones detect diseases or pests early, whereas robot seeders and sprayers precisely deliver inputs and minimize waste.

4. Robotics in Research

4.1. Grasping and Manipulation [55,56,57,58]

4.2. Motion Planning and Control [59,60,61]

4.3. Robot Vision, Sensing, and Perception [62,63]

4.4. Human–Robot Interaction [64,65,66,67]

4.5. Sensing and Actuation Technologies [69,70,71]

4.5.1. Sensors

- Proprioceptive sensors, such as encoders, IMUs, electromyography (EMG), and force-torque sensors, provide internal state feedback (e.g., joint angles, orientation, andmotor loads).

- Exteroceptive sensors, such as LiDAR, stereo cameras, depth sensors, radar, and tactile arrays, deliver information about the external environment.

- Event-based vision sensors capture pixel changes with microsecond latency, ideal for fast dynamic tasks like drone flight or sports robotics.

- Quantum sensors, including atomic interferometry-based accelerometers and magnetometers, offer unmatched precision in inertial navigation and SLAM.

- Neuromorphic sensors mimic biological sensing and are optimized for energy-efficient edge perception in swarm and micro-robotics applications.

- Flexible e-skin sensors enable conformal surface sensing for wearable robots and safe human–robot interaction.

4.5.2. Actuators

- Electric actuators, particularly brushless DC motors and servos, are dominant in industrial arms and mobile platforms owing to their precision and efficiency.

- Pneumatic and hydraulic actuators offer high power density and are often used in legged or bioinspired robots where compliance and strength are required.

- Soft actuators, made of elastomers, shape-memory alloys, and dielectric elastomers, are used in rehabilitation, surgical robotics, and wearable systems.

4.5.3. Recent Trends and Research

4.5.4. Future Outlook

- Self-healing actuators and sensors for long-term operation in remote or hazardous environments.

- Biohybrid systems, integrating living tissues with artificial components.

- Integrated perception–action chips, which co-locate sensing, computation, and actuation for real-time responsiveness in microrobotics.

- Microactuators, as robotic systems continue to evolve toward higher precision, miniaturization, and bio-integration, the development of micro-actuators is gaining considerable momentum. These actuators are often based on electroactive polymers (EAPs), shape-memory alloys (SMAs), piezoelectric materials, or even microfluidics and offer high responsiveness and adaptability at the micro/nano and sub-scales. Their compact form makes them particularly suitable for minimally invasive surgical tools, micro-grippers, bio-inspired robots, and implantable robotic systems.

4.6. Quantum Robotics

4.7. Neural Morphology Computing

4.8. Applications

5. Robotics in Education

5.1. K-12 Education [89,90]

5.1.1. Educational Robotics Tools and Platforms

5.1.2. Software and Programming Platforms

5.2. Higher Education

5.2.1. Undergraduate Robotics Education [16,17,91]

- Curriculum Structure

- Key Components

- Core Foundations: Mathematics, physics, computer science, and systems engineering provide the analytical basis for robotics. These are typically covered during the first two years [92].

- Core Robotics Courses: Covering robot kinematics, dynamics, control systems, and AI, these modules emphasize lab work with tools such as ROS, MATLAB, and Arduino [17].

- Electives: Depending on the institutional offerings, students may specialize in areas such as soft robotics, HRI, or IoT-based systems. Interdisciplinary tracks include ethics, design, or business modules [91].

- Capstone Project: This final-year experience involves designing a full robotic system, such as autonomous drone or robotic arm, often in collaboration with industry or university laboratories. The deliverables include documentation, prototypes, and seminar presentations [16].

- Industry Collaboration and Internships

5.2.2. Postgraduate Robotics Education [87,88]

- Curriculum and Specialization

- Research and Thesis Integration

- Industry Collaboration and Applied Research

- Academic Development and Professional Skills

- Research methods and scientific writing.

- Presentation skills and conference participation.

- Ethics in robotics research.

- Grant writing and innovation management.

6. Career Prospects in Robotics

6.1. Industry Roles and Sectors

- Manufacturing and Industrial Automation: Development of robotic arms, assembly automation, and smart factories using Industry 4.0.

- Healthcare and Medical Robotics: Design of surgical robots, rehabilitation devices, prosthetics, and assistive technologies.

- Autonomous Vehicles and Drones: Roles in perception, navigation, and control of land, aerial, and underwater autonomous systems.

- Agriculture and Environmental Robotics: Automation of precision farming, crop monitoring, and conservation applications.

- Logistics and Warehouse Automation: Robotics solutions for inventory management, package handling, and autonomous delivery.

- Consumer Robotics and AI Assistants: Development of domestic robots, smart devices, and embodied AI interfaces.

6.2. Academic and Research Careers

- Fundamental research in robotic perception, control, learning, and human–robot interaction.

- Development of novel robotic systems and algorithms for scientific exploration or societal benefit.

- Contribution to interdisciplinary initiatives in neuroscience, cognitive science, or ethics.

- Mentorship and teaching in robotics, engineering, and computer science programs.

6.3. Entrepreneurship and Startups

- Service robotics (e.g., elder care, cleaning, delivery).

- Robotic platforms for education and STEM training.

- Niche automation tools for vertical industries (e.g., mining, construction).

- AI-enhanced robotics software and simulation tools.

6.4. Global Demand and Emerging Markets

- Germany’s Industrie 4.0.

- Japan’s Robot Strategy.

- Republic of Korea’s Fourth Intelligent Robot Basic Plan.

- U.S. National Robotics Initiative.

- China’s Made in China 2025.

- Government Labs: Opportunities at NASA, CERN for large-scale robotics projects.

7. Robotics Education: Tools and Platforms for Experiential Learning

7.1. Software Tools

7.2. Hardware Platforms

7.3. Educational Robotics Kits

7.4. ROS

8. Curriculum-Level Robotics Integration: Insights from the German Jordanian University

8.1. Class Projects and Laboratory Work

- Embedded Systems: Students program microcontrollers such as Arduino or Raspberry Pi to execute basic robotic tasks, including line-following and obstacle-avoidance robots.

- Control Systems: Student teams design and implement PID and state-space controllers for dynamic systems such as balancing inverted pendulums or stabilizing twin-rotor drones.

- AI: Students develop and deploy path-planning and decision-making algorithms using ROS on mobile robot platforms.

- Computer-Aided Engineering Courses: Courses involving MATLAB, Simulink, Simscape, LabVIEW, Python, and CAD tools support simulation, modeling, and robotic system design.

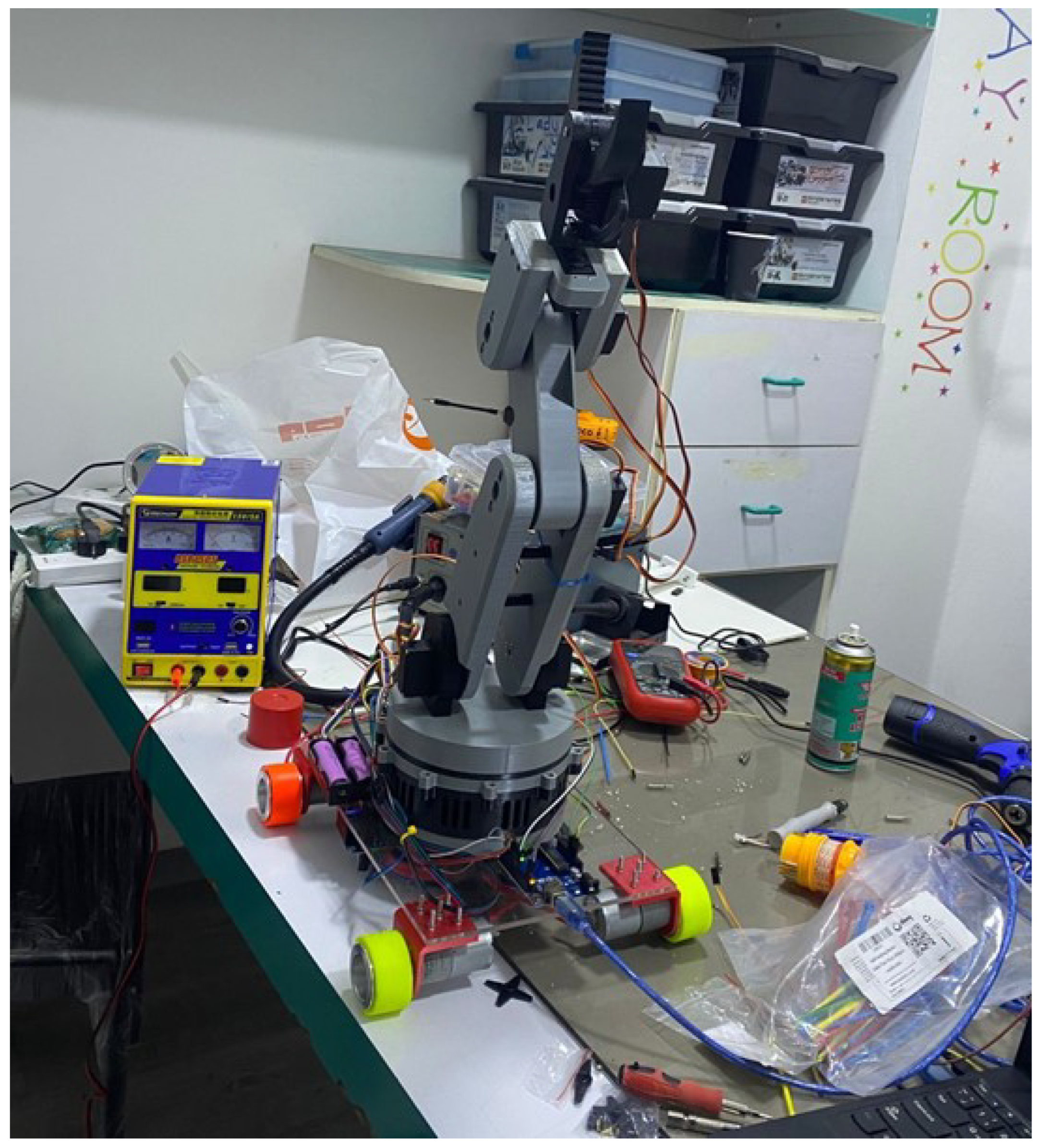

- Mechatronics Laboratories: Students integrate sensors, actuators, and microcontrollers to build functional robotic systems such as robotic arms.

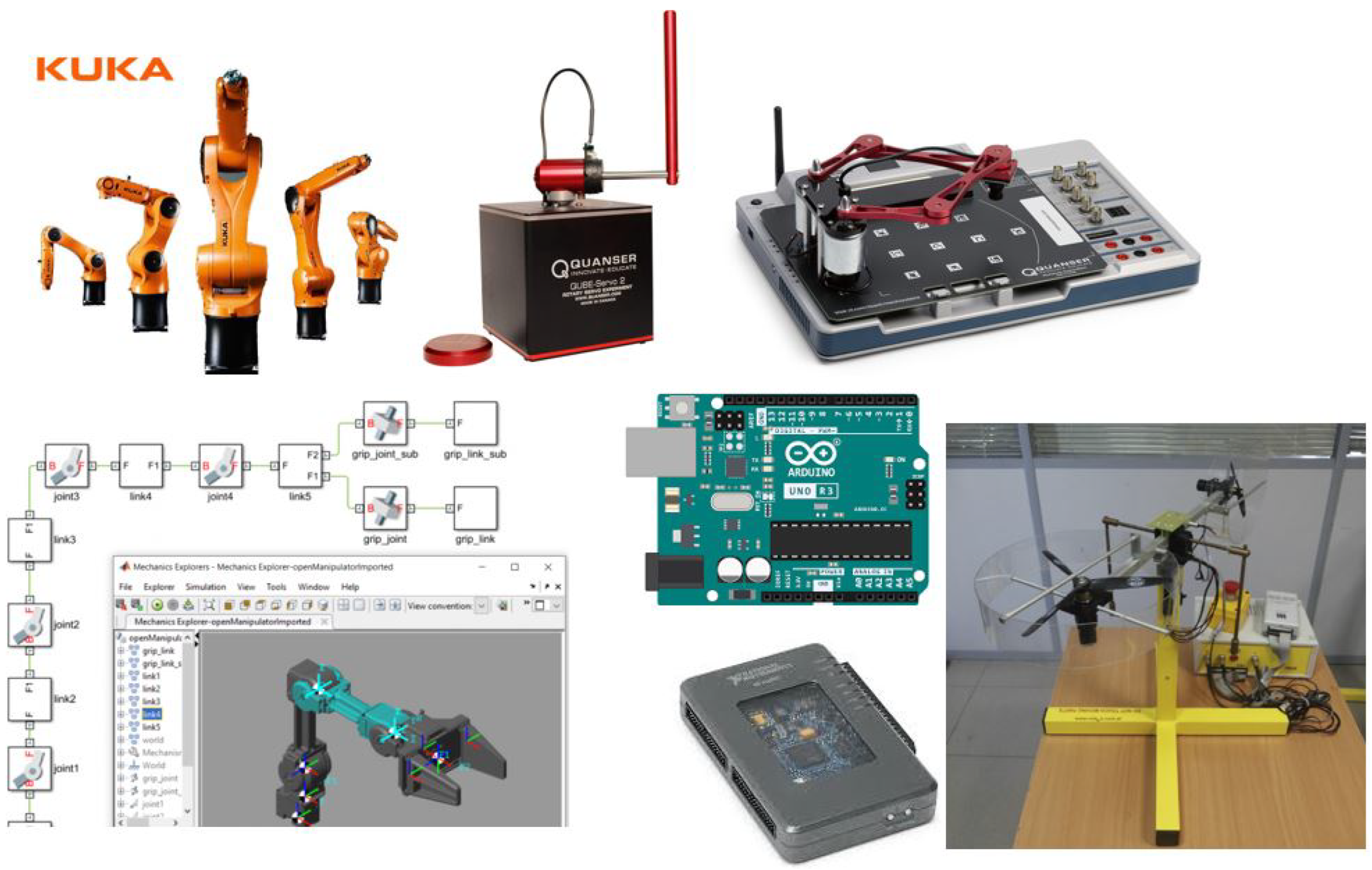

- Industrial Robot Programming: Students gain hands-on experience programming various robotic manipulators, including KUKA, Mitsubishi, and Quanser.

8.2. Project-Based Courses

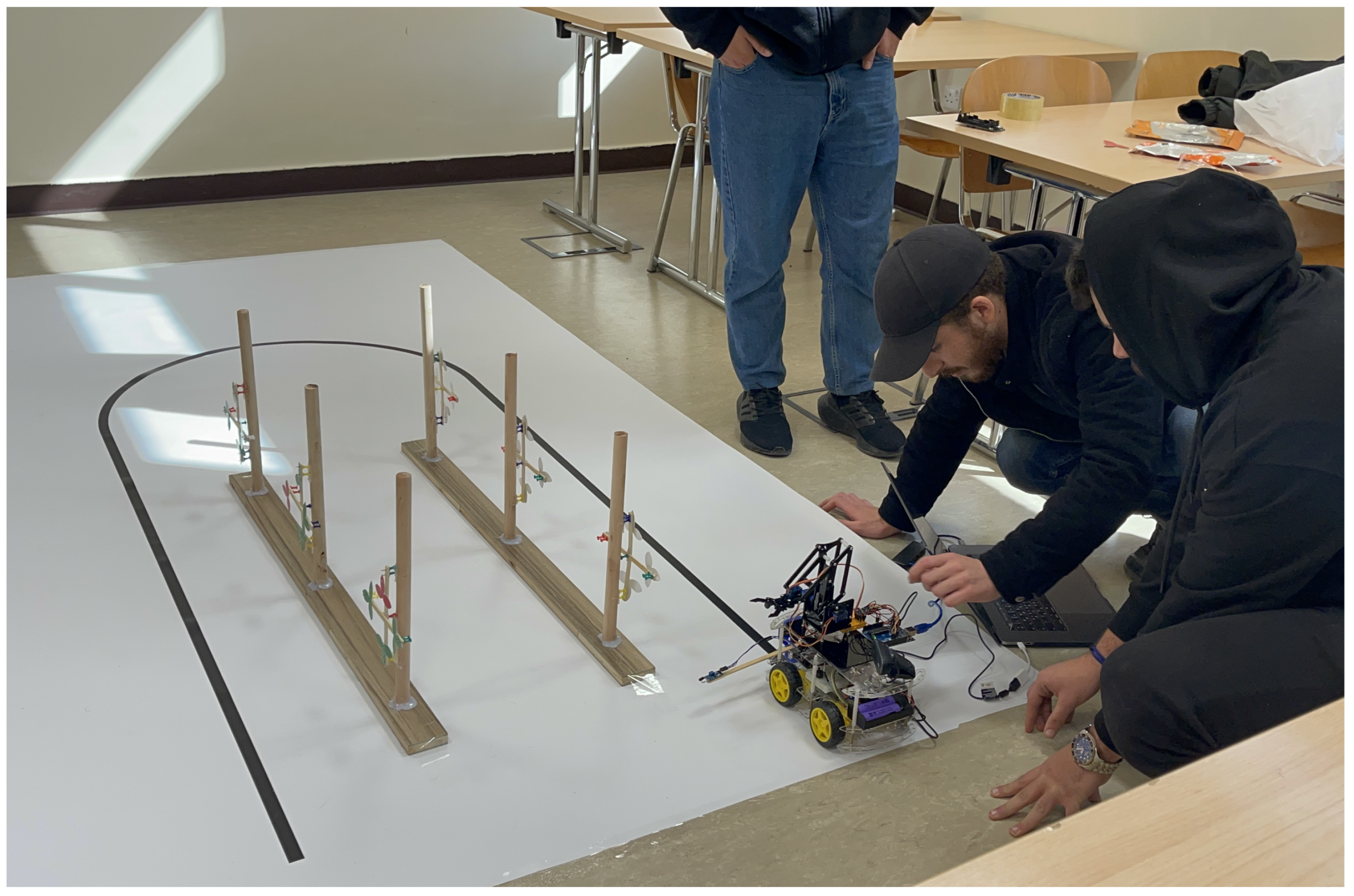

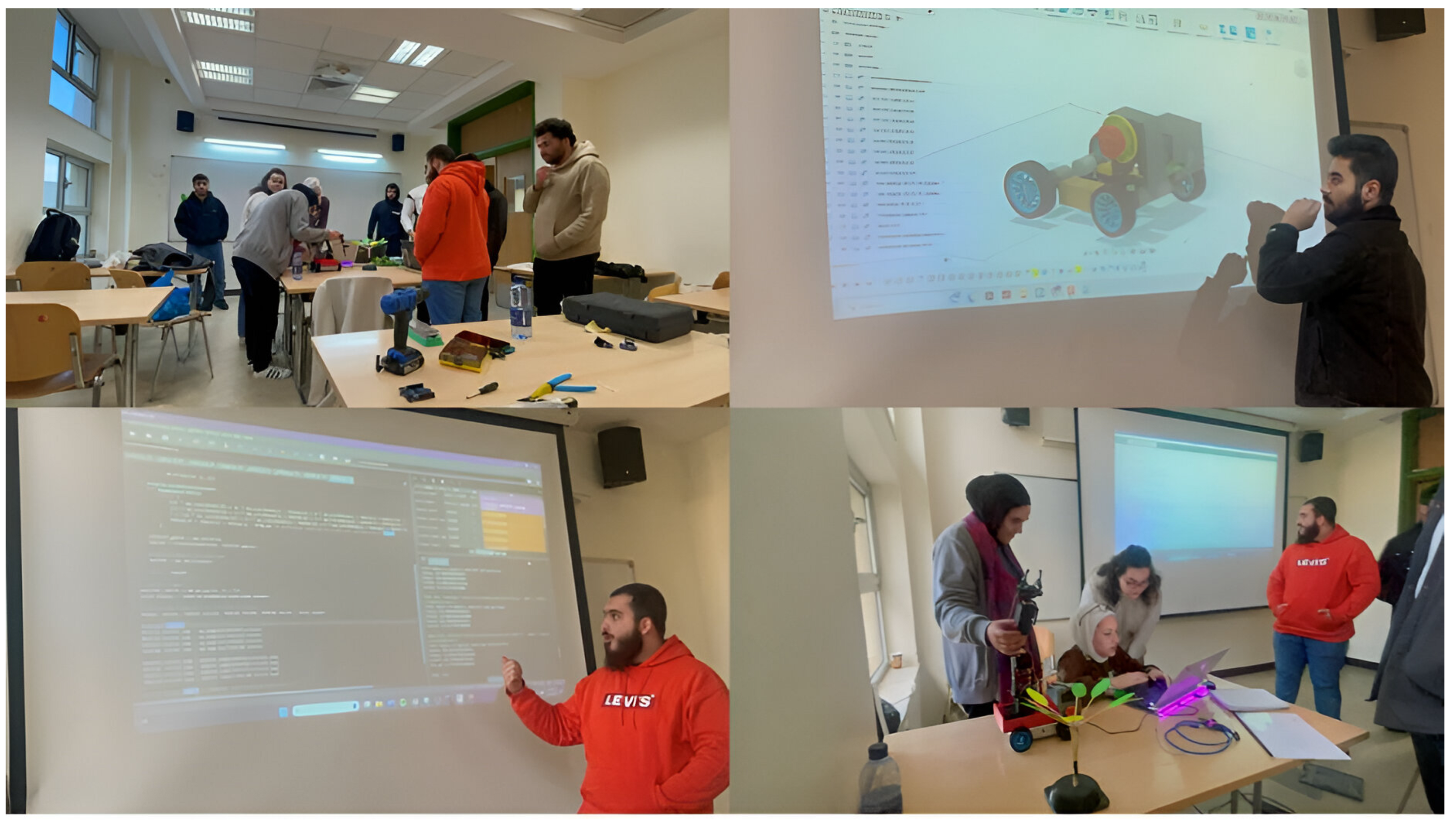

- Robotics Design Course: This course challenges students in designing and building autonomous robotic systems capable of operating in obstacle-rich environments. Emphasis is placed on hardware/software co-design, sensor integration, and real-time embedded control. An exemplary project involves the creation of agricultural robots that merge mobile platforms with robotic arms for tasks such as crop monitoring and leaf picking. These robots incorporate 3D-printed components, machine vision systems, and AI-based decision-making algorithms. As depicted in Figure 2 and Figure 3, students performed iterative testing of an autonomous agricultural robot, integrating line-following capabilities, manipulator control, and sensor–actuator feedback loops. This hands-on experience cultivates essential competencies in embedded systems, control theory, and precision agriculture—core pillars of contemporary robotics education.

- Quanser Autonomous Vehicles Research Studio: As shown in Figure 4, this specialized lab supports immersive, project-based learning in swarm and cooperative robotics. Students design and deploy multi-agent systems using autonomous ground vehicles and aerial drones. The platforms are equipped with high-resolution vision systems and precision sensors, enabling real-time experimentation with coordination strategies, distributed control algorithms, and collective intelligence. This environment fosters a hands-on understanding of complex system dynamics, scalability, and emergent behavior in swarm robotics applications.

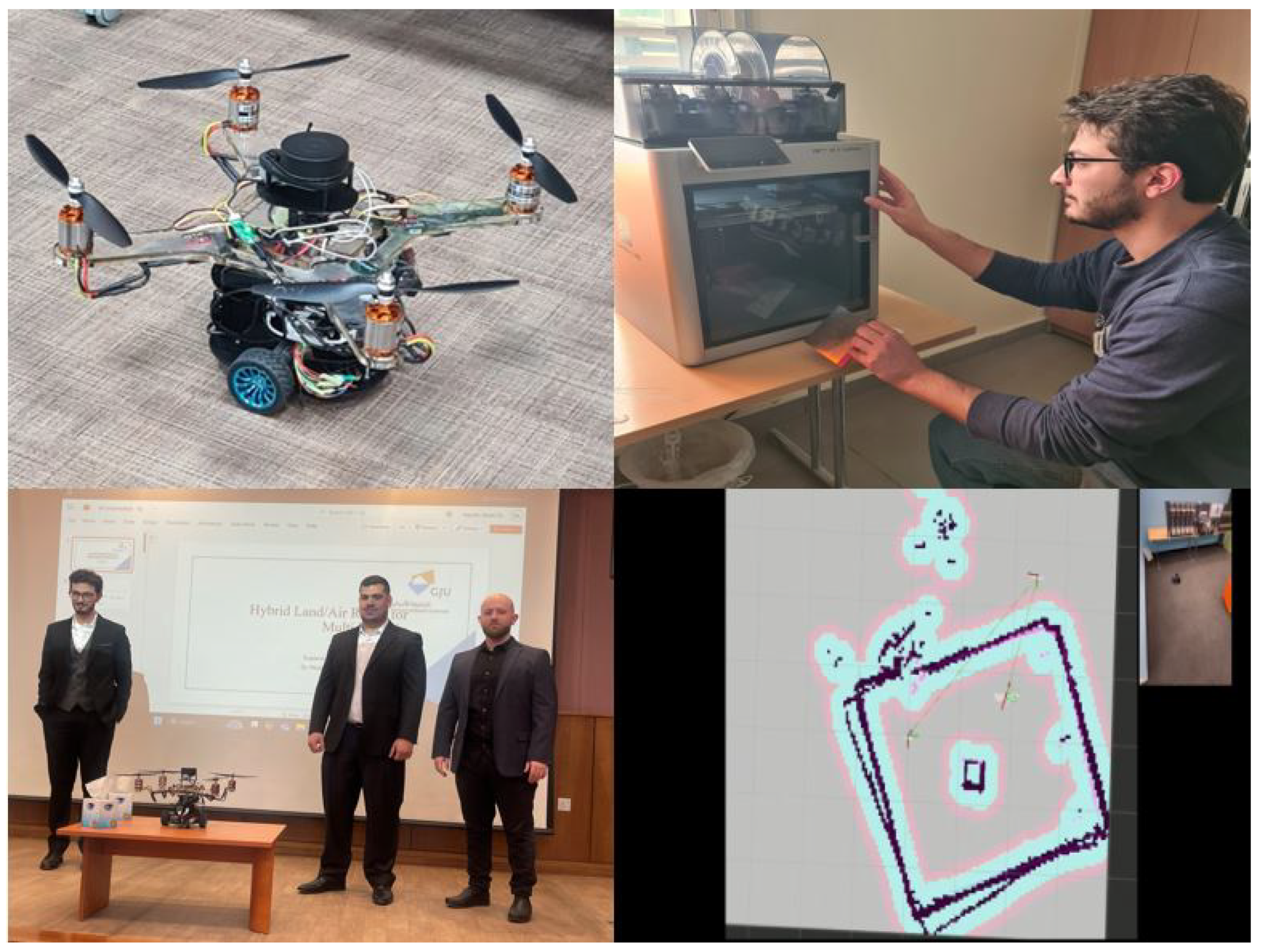

8.3. Capstone Projects

- Hybrid Ground/Aerial Robot: This project involved the development of a dual-modality robotic platform designed for long-endurance autonomous mobility across heterogeneous environments. As shown in Figure 6, the system integrates a wheeled ground vehicle with a quadrotor drone, thereby enabling terrain-adaptive navigation and aerial surveillance. Constructed using lightweight 3D-printed components and powered by an NVIDIA Jetson platform running ros2, the robot supports real-time SLAM, LiDAR-based localization, and multi-sensor fusion for perception-driven autonomy. This project exemplifies the advanced capabilities of embedded systems, multi-modal locomotion, and autonomous environmental mapping.

- Smart Factory Cyber-Physical System: Another capstone project focused on building a smart manufacturing prototype aligned with Industry 4.0. As depicted in Figure 7, the team designed an integrated cyber-physical platform that combine industrial automation, edge computing, and cloud-based monitoring. The key components included a KUKA KR 6 sixx R900 (Augsburg, Germany) industrial manipulator, Siemens PLC (Munich, Germany), vision-based inspection module, and web-connected interface. The robot was programmed using the KUKA Robot Language (KRL), and cloud integration was achieved via IBM Watson IoT using MQTT and REST protocols. This setup enabled automated drilling, inspection, and remote diagnostics. This project highlighted robotics as the central actuator within a smart factory environment, executing high-precision manipulation, responding to cyber-level decisions, and interacting with the physical production process. This demonstrated the students’ ability to implement secure, interoperable, and intelligent robotic systems in modern industrial contexts.

8.4. Robotics Competitions

8.5. Discussion: The Role of Key Instructional Components in Robotics Education

8.5.1. Class Projects

8.5.2. Laboratory Work

8.5.3. Project-Based Courses

8.5.4. Capstone Projects

8.5.5. Robotics Competitions

8.5.6. Cumulative and Incremental Skill-Building

- Resource Limitations: The acquisition and maintenance of advanced hardware and software platforms can be cost-prohibitive. Strategic partnerships with industry leaders such as NVIDIA, Boston Dynamics, and Quanser are essential to provide access to state-of-the-art technologies and funding opportunities.

- Interdisciplinary Coordination: Robotics inherently spans multiple domains, including mechanical design, control systems, artificial intelligence, and embedded computing. Aligning learning outcomes and content delivery across departments requires an intentional collaborative curriculum planning.

- Rapid Technological Evolution: With continuous advancements in areas such as AI, soft robotics, and edge computing, curricula and laboratory infrastructure must be updated regularly to remain relevant and forward-looking.

- Industry–Academia Partnerships: Collaborations with industry not only provide mentorship and funding, but also expose students to real-world problem statements, tools, and workflows, enhancing the relevance of their education.

- Modular Curriculum Design: Structuring the curriculum in modular blocks facilitates progressive skill development, ranging from introductory topics, such as kinematics and embedded systems, to advanced subjects such as multi-agent autonomy and machine vision.

- Utilization of Open Source Tools: Leveraging open source platforms such as ROS, Gazebo, and TensorFlow democratizes access to robotics education and fosters a culture of experimentation and innovation.

9. Conclusions and Future Directions

9.1. Conclusions

9.2. Future Directions

9.2.1. Embodied AI and Neuromorphic Computing

9.2.2. Human-Centric Collaborative Robotics

- Developing multi-modal perception systems (vision, force, voice) for real-time human–robot interaction [115].

- Incorporating affective computing for emotional recognition [116].

- Establishing trust calibration protocols across user demographics and cultural contexts through user studies and human trials.

9.2.3. Sustainable Robotics Ecosystem

9.2.4. Challenges and Future Prospects in University Robotics Education

- Resource Inequality: Many institutions, especially in low-income regions, lack access to modern robotics infrastructure, which limits experiential learning.

- Curricular Discontinuity: Robotics remains fragmented across disciplines (e.g., mechanical engineering, computer science), lacking cohesive, interdisciplinary curricula.

- Insufficient Industry Alignment: Educational programs often lag behind industrial trends, leaving graduates underprepared for evolving job market demands.

- Limited Undergraduate Research Exposure: Few opportunities exist for undergraduates to participate in real research, which stifles early critical thinking and innovation.

- Co-designed Curricula: Partnering with industry to develop course content, capstone projects, and internships ensures alignment with emerging technological needs.

- Research-Integrated Teaching: Embedding active faculty research projects into undergraduate coursework fosters deeper learning and innovation.

- Remote and Cloud Robotics Labs: Digital twin systems and remote-access labs democratize access to high-quality robotics education across geographical and economic boundaries.

- Ecosystem Integration: Robotics programs should be embedded within innovation ecosystems such as incubators, smart factories, and research centers to enhance translational skills and entrepreneurship.

9.2.5. Quantum-Enhanced Robotics

- Deploying quantum sensors in field robotics for high-precision localization, particularly in GPS-denied environments [128].

- Testing hybrid quantum-classical systems in simulation environments before transitioning to physical robot control.

9.2.6. Ethical and Regulatory Foundations

- Integration of robot ethics modules into core engineering curricula, promoting awareness of bias, safety, and fairness.

- Adoption of international safety and performance standards during design and certification, such as

- -

- ISO/TC 299, the International Organization for Standardization Technical Committee on Robotics.

- -

- IEEE IAB/SCSA), IEEE Industry Activities Board/Standards Coordinating Subcommittee on Autonomous Systems [129].

- Establishment of interdisciplinary ethics boards for large-scale robotics research projects, especially those involving AI or artificial general intelligence (AGI) [130].

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Choset, H.; Lynch, K.M.; Hutchinson, S.; Kantor, G.; Burgard, W.; Kavraki, L.E.; Thrun, S. Principles of Robot Motion: Theory, Algorithms, and Implementations; MIT Press: Cambridge, MA, USA, 2005. [Google Scholar]

- Siciliano, B.; Khatib, O. (Eds.) Springer Handbook of Robotics, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Licardo, J.T.; Domjan, M.; Orehovački, T. Intelligent Robotics—A Systematic Review of Emerging Technologies and Trends. Electronics 2024, 13, 542. [Google Scholar] [CrossRef]

- Niku, S.B. Introduction to Robotics: Analysis, Control, Applications, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Ren, M.; Chen, N.; Qiu, H. Human-machine Collaborative Decision-making: An Evolutionary Roadmap Based on Cognitive Intelligence. Int. J. Soc. Robot. 2023, 15, 1101–1114. [Google Scholar] [CrossRef]

- Song, Q.; Zhao, Q. Recent Advances in Robotics and Intelligent Robots Applications. Appl. Sci. 2024, 14, 4279. [Google Scholar] [CrossRef]

- Sheridan, T.B. Human–Robot Interaction: Status and Challenges. Hum. Factors 2016, 58, 525–532. [Google Scholar] [CrossRef] [PubMed]

- Ryalat, M.; Franco, E.; Elmoaqet, H.; Almtireen, N.; Al-Refai, G. The Integration of Advanced Mechatronic Systems into Industry 4.0 for Smart Manufacturing. Sustainability 2024, 16, 8504. [Google Scholar] [CrossRef]

- Harashima, F.; Suzuki, S. Intelligent mechatronics and robotics. In Proceedings of the 2008 IEEE International Conference on Emerging Technologies and Factory Automation, Hamburg, Germany, 15–18 September 2008; pp. xviii–xix. [Google Scholar]

- Yang, Y.; Bartolozzi, C.; Zhang, H.H.; Nawrocki, R.A. Neuromorphic electronics for robotic perception, navigation and control: A survey. Eng. Appl. Artif. Intell. 2023, 126, 106838. [Google Scholar] [CrossRef]

- Sut, D.J.; Sethuramalingam, P. Soft manipulator for soft robotic applications: A review. J. Intell. Robot. Syst. 2023, 108, 10. [Google Scholar] [CrossRef]

- Lepuschitz, W.; Koppensteiner, G.; Balogh, R.; Obdržálek, D. Robotics in Education; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Vrochidou, E.; Manios, M.; Papakostas, G.A.; Aitsidis, C.N.; Panagiotopoulos, F. Open-Source Robotics: Investigation on Existing Platforms and Their Application in Education. In Proceedings of the 2018 26th International Conference on Software, Telecommunications and Computer Networks (SoftCOM), Split, Croatia, 13–15 September 2018; pp. 1–6. [Google Scholar]

- Chevalier, M.; Giang, C.; Piatti, A.; Mondada, F. Fostering computational thinking through educational robotics: A model for creative computational problem solving. Int. J. STEM Educ. 2020, 7, 39. [Google Scholar] [CrossRef]

- Phan, M.H.; Ngo, H.Q.T. A Multidisciplinary Mechatronics Program: From Project-Based Learning to a Community-Based Approach on an Open Platform. Electronics 2020, 9, 954. [Google Scholar] [CrossRef]

- Evripidou, S.; Georgiou, K.; Doitsidis, L.; Amanatiadis, A.A.; Zinonos, Z.; Chatzichristofis, S.A. Educational Robotics: Platforms, Competitions and Expected Learning Outcomes. IEEE Access 2020, 8, 219534–219562. [Google Scholar] [CrossRef]

- Rosillo, N.; Montés, N.; Alves, J.P.; Ferreira, N.M.F. A generalized Matlab/ROS/Robotic platform framework for teaching robotics. In Proceedings of the Robotics in Education: Current Research and Innovations 10, Vienna, Austria, 10–12 April 2020; Springer: Berlin/Heidelberg, Germany, 2020; pp. 159–169. [Google Scholar]

- Internation Federation of Robotics, I.F. World Robotics Report 2023: Industrial and Service Robots. Available online: https://ifr-org.webpkgcache.com/doc/-/s/ifr.org/img/worldrobotics/2023_WR_extended_version.pdf (accessed on 15 February 2025).

- World Economic Forum. Search Results for “Robot”. Available online: https://ifr.org/ (accessed on 15 February 2025).

- Statista. Forecast of the Robotics Market Worldwide; Statista: Hamburg, Germany, 2025. [Google Scholar]

- Dixon, J.; Hong, B.; Wu, L. The Robot Revolution: Managerial and Employment Consequences for Firms. Manag. Sci. 2021, 67, 5586–5605. [Google Scholar] [CrossRef]

- Rosheim, M.E. Robot Evolution: The Development of Anthrobotics; John Wiley & Sons: Hoboken, NJ, USA, 1994. [Google Scholar]

- Al-Jazari, I. The Book of Knowledge of Ingenious Mechanical Devices; Springer: Berlin/Heidelberg, Germany, 1974; Originally Written in 1206. [Google Scholar]

- Herath, D.; St-Onge, D. Foundations of Robotics: A Multidisciplinary Approach with Python and ROS; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Elices, J. Ismail al-Jazari, the Muslim Inventor whom Some Call the Father of Robotics. Available online: https://www.nationalgeographic.com/history/history-magazine/article/ismail-al-jazari-muslim-inventor-called-father-robotics (accessed on 30 January 2025).

- Herman, D. A Renaissance Robot. Mech. Eng. 1998, 120, 80–82. [Google Scholar] [CrossRef]

- Gasparetto, A.; Scalera, L. A brief history of industrial robotics in the 20th century. Adv. Hist. Stud. 2019, 8, 24–35. [Google Scholar] [CrossRef]

- Kose, T.; Yamano, H.; Sakata, I. Detecting Emerging Complex Technological Fields in Robotics. In Proceedings of the Portland International Conference on Management of Engineering and Technology, Portland, OR, USA, 25–29 August 2019; pp. 1–12. [Google Scholar]

- Soori, M.; Dastres, R.; Arezoo, B.; Karimi Ghaleh Jough, F. Intelligent robotic systems in Industry 4.0: A review. J. Adv. Manuf. Sci. Technol. 2024, 2024007. [Google Scholar] [CrossRef]

- Isaka, S. A Taxonomic Classification and Identification System for Robots: Abstract. In Proceedings of the 2024 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Kuching, Malaysia, 6–10 October 2024; pp. 3799–3800. [Google Scholar]

- Ben-Ari, M.; Mondada, F. Robots and Their Applications. In Elements of Robotics; Springer: Cham, Switzerland, 2018; pp. 1–20. [Google Scholar]

- Beer, J.M.; Fisk, A.D.; Rogers, W.A. Toward a framework for levels of robot autonomy in human-robot interaction. J. Hum. Robot Interact. 2014, 3, 74–99. [Google Scholar] [CrossRef] [PubMed]

- Basañez, L.; Nuño, E.; Aldana, C.I. Teleoperation and Level of Automation. In Springer Handbook of Automation; Nof, S.Y., Ed.; Springer: Berlin/Heidelberg, Germany, 2023; pp. 457–482. [Google Scholar]

- Rubio, F.; Valero, F.; Llopis-Albert, C. A review of mobile robots: Concepts, methods, theoretical framework, and applications. Int. J. Adv. Robot. Syst. 2019, 16, 1729881419839596. [Google Scholar] [CrossRef]

- Mobed, D.A.O.; Wodehouse, A.; Maier, A. The aesthetics of robot design: Towards a classification of morphologies. Proc. Des. Soc. 2024, 4, 2413–2422. [Google Scholar] [CrossRef]

- Paul, C. Morphological computation: A basis for the analysis of morphology and control requirements. Robot. Auton. Syst. 2006, 54, 619–630. [Google Scholar] [CrossRef]

- Yang, G.; Hu, S. Review of Robotics Technologies and Its Applications. In Proceedings of the 2023 International Conference on Advanced Robotics and Mechatronics (ICARM), Sanya, China, 8–10 July 2023; pp. 322–329. [Google Scholar]

- Luo, J.; Zhou, X.; Zeng, C.; Jiang, Y.; Qi, W.; Xiang, K.; Pang, M.; Tang, B. Robotics Perception and Control: Key Technologies and Applications. Micromachines 2024, 15, 531. [Google Scholar] [CrossRef] [PubMed]

- Che, C.; Zheng, H.; Huang, Z.; Jiang, W.; Liu, B. Intelligent Robotic Control System Based on Computer Vision Technology. arXiv 2024, arXiv:2404.01116. [Google Scholar] [CrossRef]

- Huang, Z.; Shen, Y.; Li, J.; Fey, M.; Brecher, C. A Survey on AI-Driven Digital Twins in Industry 4.0: Smart Manufacturing and Advanced Robotics. Sensors 2021, 21, 6340. [Google Scholar] [CrossRef] [PubMed]

- Tantawi, K.H.; Sokolov, A.; Tantawi, O. Advances in Industrial Robotics: From Industry 3.0 Automation to Industry 4.0 Collaboration. In Proceedings of the 2019 4th Technology Innovation Management and Engineering Science International Conference (TIMES-iCON), Bangkok, Thailand, 11–13 December 2019; pp. 1–4. [Google Scholar]

- Soori, M.; Arezoo, B.; Dastres, R. Artificial intelligence, machine learning and deep learning in advanced robotics, a review. Cogn. Robot. 2023, 3, 54–70. [Google Scholar] [CrossRef]

- Ray, P.P. Internet of Robotic Things: Concept, Technologies, and Challenges. IEEE Access 2016, 4, 9489–9500. [Google Scholar] [CrossRef]

- Tanwani, A.K.; Mor, N.; Kubiatowicz, J.; Gonzalez, J.E.; Goldberg, K. A Fog Robotics Approach to Deep Robot Learning: Application to Object Recognition and Grasp Planning in Surface Decluttering. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 4559–4566. [Google Scholar]

- Treratanakulchai, S.; Franco, E.; Garriga-Casanovas, A.; Minghao, H.; Kassanos, P.; y Baena, F.R. Development of a 6 DOF Soft Robotic Manipulator with Integrated Sensing Skin. In Proceedings of the 2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Kyoto, Japan, 23–27 October 2022; pp. 6944–6951. [Google Scholar]

- Wang, L.; Chen, K.; Franco, E. Robust and Adaptive Control of a Soft Continuum Manipulator for Minimally Invasive Surgery. Robotics 2024, 13, 162. [Google Scholar] [CrossRef]

- Cheraghi, A.R.; Shahzad, S.; Graffi, K. Past, Present, and Future of Swarm Robotics. In Proceedings of the Intelligent Systems and Applications; Arai, K., Ed.; Elsevier: Cham, Switzerland, 2022; pp. 190–233. [Google Scholar]

- Dabass, V.; Sangwan, S. Strategic allocation: Exploring optimization techniques in multi-robot systems. Int. J. Intell. Robot. Appl. 2025. [Google Scholar] [CrossRef]

- Rivera, R.; Amorim, M.; Reis, J. Robotic Services in Smart Cities: An Exploratory Literature Review. In Proceedings of the 2020 15th Iberian Conference on Information Systems and Technologies (CISTI), Seville, Spain, 24–27 June 2020; pp. 1–7. [Google Scholar]

- Roldán-Gómez, J.J.; Garcia-Aunon, P.; Mazariegos, P.; Barrientos, A. SwarmCity project: Monitoring traffic, pedestrians, climate, and pollution with an aerial robotic swarm. Pers. Ubiquitous Comput. 2022, 26, 1151–1167. [Google Scholar] [CrossRef]

- Oliveira, L.F.P.; Moreira, A.P.; Silva, M.F. Advances in Agriculture Robotics: A State-of-the-Art Review and Challenges Ahead. Robotics 2021, 10, 52. [Google Scholar] [CrossRef]

- Rose, D.C.; Lyon, J.; de Boon, A.; Hanheide, M.; Pearson, S. Responsible development of autonomous robotics in agriculture. Nat. Food 2021, 2, 306–309. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.Z.; Bellingham, J.; Dupont, P.E.; Fischer, P.; Floridi, L.; Full, R.; Jacobstein, N.; Kumar, V.; McNutt, M.; Merrifield, R.; et al. The grand challenges of Science Robotics. Sci. Robot. 2018, 3, 7650. [Google Scholar] [CrossRef] [PubMed]

- Billard, A.; Asfour, T.; Khatib, O. Robotics Research; Springer: Berlin/Heidelberg, Germany, 2023; Volume 27. [Google Scholar]

- Sun, Y.; Falco, J.; Roa, M.A.; Calli, B. Research Challenges and Progress in Robotic Grasping and Manipulation Competitions. IEEE Robot. Autom. Lett. 2022, 7, 874–881. [Google Scholar] [CrossRef]

- Babin, V.; Gosselin, C. Mechanisms for Robotic Grasping and Manipulation. Annu. Rev. Control. Robot. Auton. Syst. 2021, 4, 573–593. [Google Scholar] [CrossRef]

- Hernandez, J.; Sunny, M.S.H.; Sanjuan, J.; Rulik, I.; Zarif, M.I.I.; Ahamed, S.I.; Ahmed, H.U.; Rahman, M.H. Current Designs of Robotic Arm Grippers: A Comprehensive Systematic Review. Robotics 2023, 12, 5. [Google Scholar] [CrossRef]

- Billard, A.; Kragic, D. Trends and challenges in robot manipulation. Science 2019, 364, eaat8414. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Huang, B.; Fränti, P. A review of motion planning algorithms for intelligent robots. J. Intell. Manuf. 2022, 33, 387–424. [Google Scholar] [CrossRef]

- Rybczak, M.; Popowniak, N.; Lazarowska, A. A Survey of Machine Learning Approaches for Mobile Robot Control. Robotics 2024, 13, 12. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, T.; Ma, N.; Li, Z.; Ma, H.; Meng, F.; Meng, M.Q.H. A survey of learning-based robot motion planning. IET Cyber Syst. Robot. 2021, 3, 302–314. [Google Scholar] [CrossRef]

- Yang, J.; Wang, C.; Jiang, B.; Song, H.; Meng, Q. Visual Perception Enabled Industry Intelligence: State of the Art, Challenges and Prospects. IEEE Trans. Ind. Inform. 2021, 17, 2204–2219. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, B.; Xu, N.; Zhou, J.; Shi, J.; Diao, Z. Vision-based navigation and guidance for agricultural autonomous vehicles and robots: A review. Comput. Electron. Agric. 2023, 205, 107584. [Google Scholar] [CrossRef]

- Rodríguez-Guerra, D.; Sorrosal, G.; Cabanes, I.; Calleja, C. Human-Robot Interaction Review: Challenges and Solutions for Modern Industrial Environments. IEEE Access 2021, 9, 108557–108578. [Google Scholar] [CrossRef]

- Gervasi, R.; Barravecchia, F.; Mastrogiacomo, L.; Franceschini, F. Applications of affective computing in human-robot interaction: State-of-art and challenges for manufacturing. Proc. Inst. Mech. Eng. B Part J. Eng. Manuf. 2023, 237, 815–832. [Google Scholar] [CrossRef]

- Subramanian, K.; Thomas, L.; Sahin, M.; Sahin, F. Supporting Human–Robot Interaction in Manufacturing with Augmented Reality and Effective Human–Computer Interaction: A Review and Framework. Machines 2024, 12, 706. [Google Scholar] [CrossRef]

- Mohebbi, A. Human-robot interaction in rehabilitation and assistance: A review. Curr. Robot. Rep. 2020, 1, 131–144. [Google Scholar] [CrossRef]

- Seyitoğlu, F.; Ivanov, S. Robots and emotional intelligence: A thematic analysis. Technol. Soc. 2024, 77, 102512. [Google Scholar] [CrossRef]

- Hao, Y.; Zhang, S.; Fang, B.; Sun, F.; Liu, H.; Li, H. A Review of Smart Materials for the Boost of Soft Actuators, Soft Sensors, and Robotics Applications. Chin. J. Mech. Eng. 2022, 35, 37. [Google Scholar] [CrossRef]

- Ogenyi, U.E.; Liu, J.; Yang, C.; Ju, Z.; Liu, H. Physical Human–Robot Collaboration: Robotic Systems, Learning Methods, Collaborative Strategies, Sensors, and Actuators. IEEE Trans. Cybern. 2021, 51, 1888–1901. [Google Scholar] [CrossRef] [PubMed]

- Raj, R.; Kos, A. Study of Human–Robot Interactions for Assistive Robots Using Machine Learning and Sensor Fusion Technologies. Electronics 2024, 13, 3285. [Google Scholar] [CrossRef]

- Bogue, R. Quantum technologies in robotics: A preliminary appraisal. Ind. Robot. Int. J. Robot. Res. Appl. 2025, 52, 1–8. [Google Scholar] [CrossRef]

- Taghavi, M. Quantum Computing and Neuromorphic Computing for Safe, Reliable, and explainable Multi-Agent Reinforcement Learning: Optimal Control in Autonomous Robotics. arXiv 2024, arXiv:2408.03884. [Google Scholar] [CrossRef]

- Du, Z.; Li, H. Research on Application of Improved Quantum Optimization Algorithm in Path Planning. Appl. Sci. 2024, 14, 4613. [Google Scholar] [CrossRef]

- Aitsam, M.; Davies, S.; Di Nuovo, A. Neuromorphic Computing for Interactive Robotics: A Systematic Review. IEEE Access 2022, 10, 122261–122279. [Google Scholar] [CrossRef]

- Paredes-Vallés, F.; Hagenaars, J.J.; Dupeyroux, J.; Stroobants, S.; Xu, Y.; de Croon, G.C.H.E. Fully neuromorphic vision and control for autonomous drone flight. Sci. Robot. 2024, 9, eadi0591. [Google Scholar] [CrossRef] [PubMed]

- Niedermeier, L.; Dutt, N.; Krichmar, J.L. An integrated toolbox for creating neuromorphic edge applications. Neuromorphic Comput. Eng. 2025, 5, 014003. [Google Scholar] [CrossRef]

- Arents, J.; Greitans, M. Smart industrial robot control trends, challenges and opportunities within manufacturing. Appl. Sci. 2022, 12, 937. [Google Scholar] [CrossRef]

- Ryalat, M.; ElMoaqet, H.; AlFaouri, M. Design of a Smart Factory Based on Cyber-Physical Systems and Internet of Things towards Industry 4.0. Appl. Sci. 2023, 13, 2156. [Google Scholar] [CrossRef]

- Dupont, P.E.; Nelson, B.J.; Goldfarb, M.; Hannaford, B.; Menciassi, A.; O’Malley, M.K.; Simaan, N.; Valdastri, P.; Yang, G.Z. A decade retrospective of medical robotics research from 2010 to 2020. Sci. Robot. 2021, 6, eabi8017. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Vaishnav, R.; Gautam, S.; Banerjee, S. Agricultural Robotics: A Comprehensive Review of Applications, Challenges and Future Prospects. In Proceedings of the 2024 2nd International Conference on Artificial Intelligence and Machine Learning Applications Theme: Healthcare and Internet of Things (AIMLA), Namakkal, India, 15–16 March 2024; pp. 1–8. [Google Scholar]

- Shamout, M.; Ben-Abdallah, R.; Alshurideh, M.; Alzoubi, H.; Kurdi, B.a.; Hamadneh, S. A conceptual model for the adoption of autonomous robots in supply chain and logistics industry. Uncertain Supply Chain. Manag. 2022, 10, 577–592. [Google Scholar] [CrossRef]

- Ajith, V.S.; Jolly, K. Unmanned aerial systems in search and rescue applications with their path planning: A review. J. Phys. Conf. Ser. 2021, 2115, 012020. [Google Scholar] [CrossRef]

- Scopus. Scopus Sources CiteScore. Available online: https://www.scopus.com/sources.uri (accessed on 10 February 2025).

- Scholar, G. Google Scholar: Top Publication. Available online: https://scholar.google.com/citations?view_op=top_venues&hl=en&vq=eng_robotics (accessed on 10 February 2025).

- Alam, A.; Mohanty, A. Integrated constructive robotics in education (ICRE) model: A paradigmatic framework for transformative learning in educational ecosystem. Cogent Educ. 2024, 11, 2324487. [Google Scholar] [CrossRef]

- Petraki, E.; Herath, D. Teaching and Learning Robotics: A Pedagogical Perspective. In Foundations of Robotics: A Multidisciplinary Approach with Python and ROS; Herath, D., St-Onge, D., Eds.; Springer: Singapore, 2022; pp. 43–62. [Google Scholar]

- Pozzi, M.; Prattichizzo, D.; Malvezzi, M. Accessible Educational Resources for Teaching and Learning Robotics. Robotics 2021, 10, 38. [Google Scholar] [CrossRef]

- López-Belmonte, J.; Segura-Robles, A.; Moreno-Guerrero, A.J.; Parra-González, M.E. Robotics in Education: A Scientific Mapping of the Literature in Web of Science. Electronics 2021, 10, 291. [Google Scholar] [CrossRef]

- Atman Uslu, N.; Yavuz, G.O.; Koccak Usluel, Y. A systematic review study on educational robotics and robots. Interact. Learn. Environ. 2023, 31, 5874–5898. [Google Scholar] [CrossRef]

- He, Y.; Liang, L. Application of Robotics in Higher Education in Industry 4.0 Era. Univers. J. Educ. Res. 2019, 7, 1612–1622. [Google Scholar] [CrossRef]

- Craig, J.J. Introduction to Robotics: Mechanics and Control, 4th ed.; Pearson: London, UK, 2017. [Google Scholar]

- Quigley, M.; Conley, K.; Gerkey, B.; Faust, J.; Foote, T.; Leibs, J.; Wheeler, R.; Ng, A.Y. ROS: An open-source Robot Operating System. In Proceedings of the ICRA Workshop on Open Source Software, Kobe, Japan, 12–17 May 2009. [Google Scholar]

- Macenski, S.; Foote, T.; Gerkey, B.; Lalancette, C.; Woodall, W. Robot Operating System 2: Design, architecture, and uses in the wild. Sci. Robot. 2022, 7, eabm6074. [Google Scholar] [CrossRef] [PubMed]

- MathWorks. MATLAB and Simulink for Robotics. 2023. Available online: https://www.mathworks.com/solutions/robotics.html (accessed on 3 March 2025).

- Corke, P. Robotics, Vision and Control: Fundamental Algorithms in MATLAB, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Koubaa, A. Robot Operating System (ROS): The Complete Reference; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Corke, P. Robotics, Vision and Control: Fundamental Algorithms in Python, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar] [CrossRef]

- OpenCV Team. OpenCV: Open Source Computer Vision Library. 2025. Available online: https://opencv.org/ (accessed on 28 February 2025).

- Farley, A.; Wang, J.; Marshall, J.A. How to pick a mobile robot simulator: A quantitative comparison of CoppeliaSim, Gazebo, MORSE and Webots with a focus on accuracy of motion. Simul. Model. Pract. Theory 2022, 120, 102629. [Google Scholar] [CrossRef]

- Lee, H.J.; Yi, H. Development of an Onboard Robotic Platform for Embedded Programming Education. Sensors 2021, 21, 3916. [Google Scholar] [CrossRef] [PubMed]

- NVIDIA Corporation. NVIDIA Jetson Orin: Embedded Systems for Autonomous Machines. 2025. Available online: https://www.nvidia.com/en-us/autonomous-machines/embedded-systems/jetson-orin/ (accessed on 28 February 2025).

- Castelli, K.; Giberti, H. Additive Manufacturing as an Essential Element in the Teaching of Robotics. Robotics 2019, 8, 73. [Google Scholar] [CrossRef]

- Yeong, D.J.; Velasco-Hernandez, G.; Barry, J.; Walsh, J. Sensor and Sensor Fusion Technology in Autonomous Vehicles: A Review. Sensors 2021, 21, 2140. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Liu, X. Common Sensors in Industrial Robots: A Review. In Proceedings of the Journal of Physics: Conference Series, Proceedings of the 3rd International Conference on Artificial Intelligence (ICAI 2019), Istanbul, Turkey, 26–28 October 2019; IOP Publishing: Bristol, UK, 2019; Volume 1267. [Google Scholar]

- Djuric, A.; Rickli, J.; Sefcovic, J.; Hutchison, D.; Goldin, M.M. Integrating Collaborative Robots in Engineering and Engineering Technology Programs. ASME Int. Mech. Eng. Congr. Expo. 2018, 5, V005T07A013. [Google Scholar]

- Quanser Inc. Quanser Academic Resources. 2025. Available online: https://www.quanser.com/resource-type/academic-resources/ (accessed on 28 March 2025).

- Clearpath Robotics. Husky Unmanned Ground Vehicle (UGV). 2025. Available online: https://clearpathrobotics.com/husky-a300-unmanned-ground-vehicle-robot/ (accessed on 28 March 2025).

- LEGO Education. SPIKE Prime and Mindstorms for Robotics Learning. 2025. Available online: https://spike.legoeducation.com/ (accessed on 28 March 2025).

- Cervera, E. Run to the Source: The Effective Reproducibility of Robotics Code Repositories. IEEE Robot. Autom. Mag. 2024, 31, 125–134. [Google Scholar] [CrossRef]

- Open Robotics. Open Robotics. ROS Developer Documentation. 2025. Available online: https://docs.ros.org/ (accessed on 3 April 2025).

- AlBatati, A.S.; Koubaa, A.; Abdelkader, M. ROS 2 in a Nutshell: A Survey. Preprints 2024. [Google Scholar]

- Kwon, T.; Palo, N.D.; Johns, E. Language Models as Zero-Shot Trajectory Generators. IEEE Robot. Autom. Lett. 2024, 9, 6728–6735. [Google Scholar] [CrossRef]

- Rizzardo, C.; Chen, F.; Caldwell, D. Sim-to-real via latent prediction: Transferring visual non-prehensile manipulation policies. Front. Robot. AI 2023, 9, 1067502. [Google Scholar] [CrossRef] [PubMed]

- Wong, C.Y.; Vergez, L.; Suleiman, W. Vision- and Tactile-Based Continuous Multimodal Intention and Attention Recognition for Safer Physical Human–Robot Interaction. IEEE Trans. Autom. Sci. Eng. 2024, 21, 3205–3215. [Google Scholar] [CrossRef]

- Cho, Y.J.; Cho, M.; Jang, M. Social Robot Intelligence Quotient to Measure Human-Robot Interaction Performance for Human-Care Service Robots. In Proceedings of the 2023 20th International Conference on Ubiquitous Robots (UR), Honolulu, HI, USA, 25–28 June 2023; pp. 616–621. [Google Scholar]

- Battarra, I.; Accorsi, R.; Lupi, G.; Manzini, R. Life cycle assessment of an automated multi-cellular case-picking system. J. Manuf. Syst. 2025, 79, 419–434. [Google Scholar] [CrossRef]

- Hartmann, F.; Baumgartner, M.; Kaltenbrunner, M. Becoming Sustainable, The New Frontier in Soft Robotics. Adv. Mater. 2021, 33, 2004413. [Google Scholar] [CrossRef] [PubMed]

- Hajra, S.; Panda, S.; Khanberh, H.; Vivekananthan, V.; Chamanehpour, E.; Mishra, Y.K.; Kim, H.J. Revolutionizing self-powered robotic systems with triboelectric nanogenerators. Nano Energy 2023, 115, 108729. [Google Scholar] [CrossRef]

- Halkiopoulos, C.; Gkintoni, E. Leveraging AI in E-Learning: Personalized Learning and Adaptive Assessment through Cognitive Neuropsychology—A Systematic Analysis. Electronics 2024, 13, 3762. [Google Scholar] [CrossRef]

- Khan, Z.H.; Mekid, S. Designing Remote Labs in Outcome-Based Education Using Digital Twin and Metaverse. Available online: https://teaching.ieee.org/designing-remote-labs-in-outcome-based-education-using-digital-twin-and-metaverse/ (accessed on 7 May 2025).

- Hu, J.; Huang, Z.; Li, J.; Xu, L.; Zou, Y. Real-time classroom behavior analysis for enhanced engineering education: An AI-assisted approach. Int. J. Comput. Intell. Syst. 2024, 17, 167. [Google Scholar] [CrossRef]

- Chen, Y.; Zou, Y. Enhancing education quality: Exploring teachers’ attitudes and intentions towards intelligent MR devices. Eur. J. Educ. 2024, 59, e12692. [Google Scholar] [CrossRef]

- Pujol, F.A.; Tomás, D. Introducing Sustainability in a Robotic Engineering Degree: A Case Study. Sustainability 2020, 12, 5574. [Google Scholar] [CrossRef]

- Chou, H.S.; Thong, L.T.; Chew, H.S.J.; Lau, Y. Barriers and Facilitators of Robot-Assisted Education in Higher Education: A Systematic Mixed-Studies Review. Technol. Knowl. Learn. 2023, 28, 477–516. [Google Scholar] [CrossRef]

- Van Scoy, B.; Jamieson, P.; Chidurala, V. On First-Principle Robot Building in Undergraduate Robotics Education in the Robotic System Levels Model. Robotics 2025, 14, 70. [Google Scholar] [CrossRef]

- Khobragade, P.; Dhankar, P.K.; Titarmare, A.; Dhone, M.; Thakur, S.; Saraf, P. Quantum-Enhanced AI Robotics for Sustainable Agriculture: Pioneering Autonomous Systems in Precision Farming. In Proceedings of the 2024 International Conference on Artificial Intelligence and Quantum Computation-Based Sensor Application (ICAIQSA), Nagpur, India, 20–21 December 2024; pp. 1–7. [Google Scholar]

- Hohenfeld, H.; Heimann, D.; Wiebe, F.; Kirchner, F. Quantum Deep Reinforcement Learning for Robot Navigation Tasks. IEEE Access 2024, 12, 87217–87236. [Google Scholar] [CrossRef]

- ISO/TC 299 Robotics; ISO: Geneva, Switzerland, 2025; Available online: https://committee.iso.org/home/tc299 (accessed on 1 May 2025).

- Fahad, M.; Basri, T.; Hamza, M.A.; Faisal, S.; Akbar, A.; Haider, U.; Hajjami, S.E. The Benefits and Risks of Artificial General Intelligence (AGI). In Artificial General Intelligence (AGI) Security: Smart Applications and Sustainable Technologies; El Hajjami, S., Kaushik, K., Khan, I.U., Eds.; Springer: Singapore, 2025. [Google Scholar]

| Category | Key Statistics |

|---|---|

| Global Market Size | Robotics market projected to reach USD 165 Billion by 2028 |

| Educational Robot Market Size | Valued at USD 1.37 Billion in 2024 and is estimated to grow at a CAGR of 28.8% from 2025 to 2030 |

| Industrial Robot Deployment | 4.28 million operational robots worldwide (2023) |

| Major Markets | China, Japan, US, Republic of Korea, and Germany (account for 74% of global robot installations) |

| Service Robotics | Expected to generate USD 40.6 Billion in revenue by 2025 |

| Economic Impact | Automation expected to displace 85M jobs and create 97 Million new roles by 2025 (WEF) |

| Wage Impact | Each robot added per 1000 workers decreases wages by 0.42% in the US |

| Future Projection | By 2030, 80% of humans expected to interact with robots daily |

| Class of Robots | Types | Examples |

|---|---|---|

| Industrial Robots |

|  |

| Autonomous Mobile Robots |

|  |

| Flying Robots, Drones, UAVs | Wing-Type

|  |

| Biologically Inspired |

|  |

| Service Robots |

|  |

| Journal Title | CiteScore | 2020–2023 Citations | % Cited | Publisher |

|---|---|---|---|---|

| Science Robotics | 30.6 | 9480 | 81 | American Association for the Advancement of Science |

| Annual Review of Control, Robotics, and Autonomous Systems | 28.3 | 2489 | 99 | Annual Reviews Inc. |

| Robotics and Computer-Integrated Manufacturing | 24.1 | 14,118 | 97 | Elsevier |

| International Journal of Robotics Research | 22.2 | 5921 | 84 | SAGE |

| Soft Robotics | 15.5 | 4976 | 88 | Mary Ann Liebert |

| Journal of Field Robotics | 15.0 | 4207 | 81 | Wiley |

| IEEE Transactions on Robotics | 14.9 | 11,685 | 84 | IEEE |

| Robotics: Science and Systems | 12.0 | 3230 | 94 | MIT Press |

| International Journal of Social Robotics | 9.8 | 4503 | 83 | Springer Nature |

| IEEE Robotics and Automation Letters | 9.6 | 44,648 | 83 | IEEE |

| Robotics and Autonomous Systems | 9.0 | 5741 | 84 | Elsevier |

| IEEE Robotics and Automation Magazine | 8.8 | 1673 | 76 | IEEE |

| Cognitive Robotics | 8.4 | 565 | 72 | KeAi Communications |

| IEEE Transactions on Medical Robotics and Bionics | 6.8 | 2483 | 81 | IEEE |

| Robotics | 6.7 | 3747 | 78 | MDPI |

| Frontiers in Robotics and AI | 6.5 | 7497 | 78 | Frontiers Media |

| Journal of Robotics and Control (JRC) | 6.3 | 1980 | 82 | Universitas Muhammadiyah Yogyakarta |

| Intelligent Service Robotics | 5.7 | 1001 | 78 | Springer Nature |

| Journal of Mechanisms and Robotics | 5.6 | 2510 | 87 | ASME |

| International Journal of Medical Robotics and Computer Assisted Surgery | 5.3 | 2631 | 83 | Wiley |

| Frontiers in Neurorobotics | 5.2 | 3968 | 70 | Frontiers Media |

| Advanced Robotics | 4.1 | 1747 | 69 | Taylor & Francis |

| Journal of Micro and Bio Robotics | 3.8 | 139 | 59 | Springer Nature |

| International Journal of Intelligent Robotics and Applications | 3.8 | 662 | 79 | Springer Nature |

| Journal of Robotics | 3.7 | 626 | 77 | Wiley |

| Biomimetic Intelligence and Robotics | 3.7 | 223 | 65 | Elsevier |

| IET Cyber-systems and Robotics | 3.7 | 407 | 66 | Wiley |

| International Journal of Humanoid Robotics | 3.5 | 350 | 75 | World Scientific |

| International Journal of Robotics and Control Systems | 3.1 | 476 | 72 | ASCEE |

| Springer Proceedings in Advanced Robotics | 2.6 | 1774 | 59 | Springer Nature |

| Journal of Robotics and Mechatronics | 2.2 | 1194 | 62 | Fuji Technology Press |

| Conference Name | Organizer | Focus | Frequency |

|---|---|---|---|

| IEEE International Conference on Robotics and Automation (ICRA) | IEEE Robotics and Automation Society | Robotics advancements, including AI, control, perception, and autonomous systems. | Annual |

| Robotics: Science and Systems (RSS) | RSS Foundation | Theoretical robotics, including ML, computer vision, and motion planning. | Annual |

| IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) | IEEE Robotics and Automation Society, RSJ | Intelligent systems, sensing, AI, robot manipulation, and multi-robot systems. | Annual |

| International Symposium on Robotics Research (ISRR) | RSJ, Springer | Advanced robotics methodologies and fundamental research. | Biennial |

| Conference on Robot Learning (CoRL) | ML and Robotics Community | Robotics and machine learning, including reinforcement learning, perception, and planning. | Annual |

| International Conference on Humanoid Robots (Humanoids) | IEEE Robotics and Automation Society | Humanoid robotics, locomotion, HRI, and social robotics. | Annual |

| International Conference on Automation Science and Engineering (CASE) | IEEE Robotics and Automation Society | Industrial automation, robotics systems, and smart manufacturing. | Annual |

| International Conference on Social Robotics (ICSR) | Springer, various institutions | Social robotics, human–robot interaction, and ethical concerns. | Annual |

| International Conference on Advanced Robotics (ICAR) | IEEE Robotics and Automation Society | Emerging and innovative concepts in robotics. | Biennial |

| European Robotics Forum (ERF) | EU Robotics Association | Robotics research, industry collaboration, and policy development. | Annual |

| Robotics in Education (RiE) | International RiE Committee | Educational robotics, curriculum design, pedagogical tools, STEAM education | Annual |

| Category | Course Field | Topics |

|---|---|---|

| Core Topics | Mathematics | Linear Algebra, Calculus (differential and integral), Probability and Statistics. |

| Physics | Mechanics, Electronics, Materials Science, | |

| Computer Science | Algorithms, Programming (Python, C++, ROS), AI and Machine Learning, Embedded Software | |

| Engineering Principles | Electrical Engineering, Mechanical Engineering, Systems Integration | |

| Specialized Topics | Robot Kinematics and Dynamics | Forward/Inverse Kinematics, Motion Planning, Multi-body Dynamics |

| Control Systems | Feedback Control (PID), Nonlinear/Adaptive Control, State Estimation, Kalman Filters | |

| Sensing and Actuating | Sensors (LiDAR, Cameras), Computer Vision, Sensor Fusion, motors, servos, pneumatics | |

| AI for Robotics | Path Planning (A*, RRT), Reinforcement Learning, NLP, Swarm Intelligence | |

| Human–Robot Interaction | User Interfaces, Collaborative Robots, Ethical and Social Considerations | |

| Embedded Systems | Microcontrollers (Arduino, Raspberry Pi), Real-Time Operating Systems (RTOS), communication | |

| Emerging Topics | Soft Robotics | Bio-Inspired Robotics, Design and Control of Soft Materials |

| Autonomous Systems | Autonomous Vehicles, Marine Robotics, Space Robotics, SLAM | |

| Robotics and AI Integration | Deep Learning, Cognitive Robotics, Ethical AI | |

| Additive Manufacturing | 3D Printing, Customizable Components | |

| Cybersecurity | Securing Robotic Systems, Cyberattack Prevention | |

| Research and Practical Skills | Hands-On Prototyping | Building and Programming Robots, Debugging, Testing, Capstone Projects |

| Simulation and Modeling | Robotics Simulators (Gazebo, Webots), Digital Twin Technology | |

| Communication and Teamwork | Collaborative Projects, Technical Writing, Multidisciplinary Team Management | |

| Ethical and Societal Topics | Ethical Design | Responsible Robotics, Ethical Use |

| Environmental Impact | Sustainability in Robotics | |

| Social Implications | Workforce Displacement, Addressing Societal Challenges |

| Aspect | Undergraduate Programs (BSc) | Graduate Programs (MSc) |

|---|---|---|

| Program Names | BSc in Robotics Engineering, Mechatronics, Automation and Robotics, or Computer Science (Robotics Focus) | MSc in Robotics, AI and Robotics, Autonomous Systems, or Mechatronics and Robotics |

| Focus Areas | Fundamentals of robotics, mechanical/electrical/software engineering, hands-on design and prototyping | Advanced robotics concepts, AI and machine learning in robotics, automation, control systems, and autonomy |

| Duration | 3–4 years | 1–2 years |

| Entry Requirements | High school diploma (background in math, physics, programming optional) | BSc in robotics, mechatronics, or related fields; sometimes GRE/GMAT, research experience, or portfolio required |

| Key Courses | Introduction to Robotics, Sensors and Actuators, Programming for Robotics, Robot Kinematics and Dynamics, Control Systems | Advanced Robotics Programming, Machine Learning for Robotics, Robot Perception, Advanced Mechatronic Design, Research Methodology |

| Skills Developed | Engineering fundamentals, programming, robot design, problem-solving, teamwork | Advanced research, AI and autonomy specialization, system integration, innovation |

| Career Opportunities | Entry-level roles: Robotics Technician, Automation Engineer, Embedded Systems Developer | Advanced roles: Robotics Scientist, AI Specialist, Control Systems Engineer, Researcher, Academic positions |

| Industries | Manufacturing, automotive, healthcare, logistics | Advanced R&D, aerospace, defense, high-tech healthcare robotics, academia |

| Research Component | Minimal; hands-on and coursework-focused | Strong emphasis on research; often requires a thesis or project |

| Capstone/Thesis | Capstone project with practical applications | Research thesis or advanced project contributing to the field |

| Global Popularity | High demand in developing nations and entry-level robotics markets | Preferred in research-intensive institutions and high-tech industries |

| Future Pathways | Further education (MSc) or immediate industry entry | Doctoral studies (PhD) or leadership roles in robotics research and innovation |

| Category | Textbook Title and Authors | Key Focus/Typical Use Cases |

|---|---|---|

| General Robotics | Introduction to Robotics: Mechanics and Control John J. Craig | Introductory textbook covering mechanical foundations, actuators, sensors, and basic control. Widely used in undergraduate courses. |

| Modern Robotics: Mechanics, Planning, and Control Kevin M. Lynch and Frank C. Park | Balanced coverage of theory and implementation, ideal for undergrad and grad courses. | |

| Robotics: Control, Sensing, Vision, and Intelligence K.S. Fu, R.C. Gonzalez, C.S.G. Lee | Comprehensive introduction to robotics, including control systems, sensors, vision, and artificial intelligence. Suitable for both beginners and advanced learners. | |

| Springer Handbook of Robotics Edited by Bruno Siciliano and Oussama Khatib | Comprehensive reference that spans foundational theories, robot kinematics, dynamics, control, sensing, learning, HRI, and ethics. Ideal for graduate-level study, multidisciplinary research. | |

| Robot Kinematics and Dynamics | Robotics: Modelling, Planning and Control Bruno Siciliano et al. | In-depth treatment of kinematics, dynamics, control, and trajectory planning; suitable for advanced learners. |

| Robot Dynamics and Control Mark W. Spong et al. | Focus on dynamic modeling and feedback control techniques. | |

| Autonomous Robots and Mobile Robotics | Introduction to Autonomous Mobile Robots Roland Siegwart, Illah Nourbakhsh, and Davide Scaramuzza | Core principles of mobility, navigation, localization, and perception for mobile robots. |

| Probabilistic Robotics Sebastian Thrun, Wolfram Burgard, and Dieter Fox | Covers probabilistic models, SLAM, Bayesian filtering; ideal for autonomous systems research. | |

| Computer Vision and Perception in Robotics | Computer Vision: Algorithms and Applications Richard Szeliski | Comprehensive guide to vision algorithms used in robotics and AI applications. |

| Multiple View Geometry in Computer Vision Richard Hartley and Andrew Zisserman | Focuses on 3D vision, structure from motion, stereo vision—used in advanced robotics perception. | |

| Robotics, Vision and Control: Fundamental Algorithms in MATLAB/Python Peter Corke | Practical integration of robotics and computer vision algorithms, with detailed implementations in MATLAB and Python. Covers kinematics, visual servoing, and perception pipelines. Widely used in labs, projects, and applied robotics courses. | |

| AI and Machine Learning for Robotics | Introduction to AI Robotics Robin R. Murphy | Broad AI textbook, foundational for reasoning, planning, and learning in robotics. |

| Artificial Intelligence: A Modern Approach Stuart Russell and Peter Norvig | Broad AI textbook, foundational for reasoning, planning, and learning in robotics. | |

| Hands-On Machine Learning with Scikit-Learn, Keras, and TensorFlow: Concepts, Tools, and Techniques to Build Intelligent Systems Aurélien Géron | Practical guide to implementing machine learning and deep learning algorithms using Python libraries. Covers neural networks, CNNs, RNNs, and reinforcement learning. Widely used in robotics projects involving perception, control, and adaptive behaviors. | |

| Cognitive Robotics | Cognitive Robotics Angelo Cangelosi and Minija Tamosiunaite | Explores cognitive architectures, learning, reasoning, and human–robot interaction. |

| University | Program | Partner Research Institutions/Focus Areas |

|---|---|---|

| Carnegie Mellon University (USA) | M.S./Ph.D. in Robotics | Robotics Institute, National Robotics Engineering Center; collaborations with NASA, DARPA, Google; focus on autonomous systems, HRI, soft robotics |

| ETH Zurich (Switzerland) | M.Sc. in Robotics, Systems, and Control | ETH Robotics Systems Lab, Autonomous Systems Lab; aerial robotics, legged robots, mechatronic systems |

| Technical University of Munich (Germany) | M.Sc. in Robotics, Cognition, Intelligence | Munich Institute of Robotics and Machine Intelligence (MIRMI); partnerships with Siemens, BMW; cognitive robotics, AI |

| University of Tokyo (Japan) | Graduate Program in Information Science | JSK Robotics Lab; cooperation with RIKEN, AIST; humanoid robotics, soft robotics |

| Imperial College London (UK) | M.Sc. in Medical Robotics | Hamlyn Centre for Robotic Surgery; NHS collaborations, Intuitive Surgical; surgical robotics, medical AI |

| National University of Singapore (NUS) | M.Sc./Ph.D. in Robotics | Advanced Robotics Centre; collaborations with A*STAR and global institutions; smart mobility, assistive robotics |

| Tsinghua University (China) | M.E./Ph.D. in Control Science and Engineering (Robotics Track) | Partners with the Institute of Automation, Chinese Academy of Sciences (CASIA); focus on intelligent robotics, computer vision, human–robot interaction |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryalat, M.; Almtireen, N.; Al-refai, G.; Elmoaqet, H.; Rawashdeh, N. Research and Education in Robotics: A Comprehensive Review, Trends, Challenges, and Future Directions. J. Sens. Actuator Netw. 2025, 14, 76. https://doi.org/10.3390/jsan14040076

Ryalat M, Almtireen N, Al-refai G, Elmoaqet H, Rawashdeh N. Research and Education in Robotics: A Comprehensive Review, Trends, Challenges, and Future Directions. Journal of Sensor and Actuator Networks. 2025; 14(4):76. https://doi.org/10.3390/jsan14040076

Chicago/Turabian StyleRyalat, Mutaz, Natheer Almtireen, Ghaith Al-refai, Hisham Elmoaqet, and Nathir Rawashdeh. 2025. "Research and Education in Robotics: A Comprehensive Review, Trends, Challenges, and Future Directions" Journal of Sensor and Actuator Networks 14, no. 4: 76. https://doi.org/10.3390/jsan14040076

APA StyleRyalat, M., Almtireen, N., Al-refai, G., Elmoaqet, H., & Rawashdeh, N. (2025). Research and Education in Robotics: A Comprehensive Review, Trends, Challenges, and Future Directions. Journal of Sensor and Actuator Networks, 14(4), 76. https://doi.org/10.3390/jsan14040076