1. Introduction

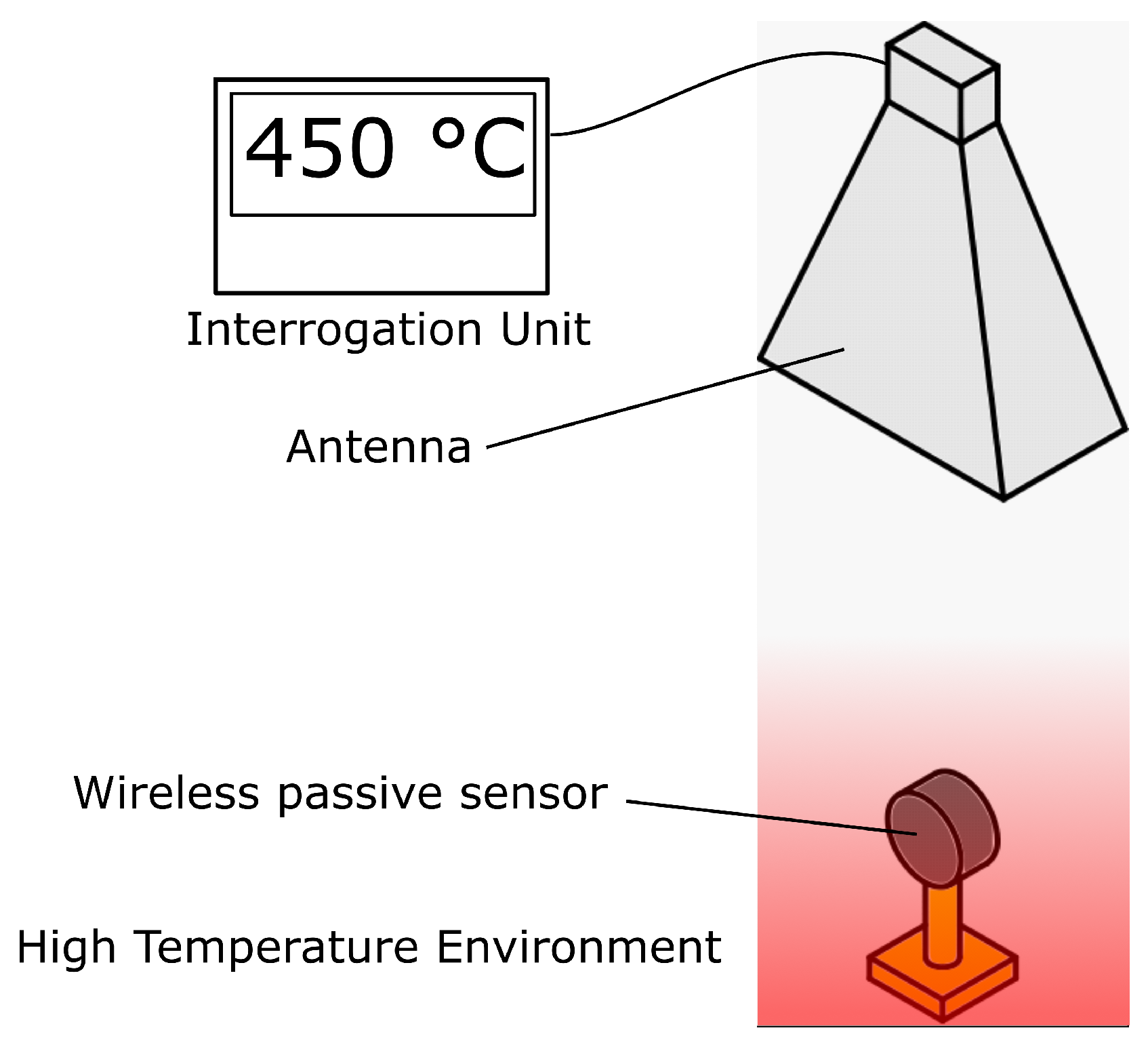

Sensors are essential components of any control system. For many applications, the size of the sensor matters; for ubiquitous sensing, the financial and environmental costs per sensor must be minimized. In aerospace, automotive, or process control industries, sensors often have to be installed in harsh environments. Wireless sensors, called transponders, are used in moving or rotating control points, on or in living beings, in harsh conditions, and where wiring would be expensive. Chipless passive transponders enable measurements without integrated circuits, wiring, or battery installation at the measuring point, thus increasing the robustness, functionality, and lifetime of the system under test. Such a transponder system consists of two parts: (i) a reader; (ii) passive transponders that act as cooperative targets. Both parts are connected via a wireless connection, usually a radio link, as shown in

Figure 1.

Three types of chipless passive transponders are presented in the literature: delay lines, resonators, and mixers [

1]. This article focuses on transponders made of dielectric resonators with a high overall quality factor

Q (see

Appendix A), where temperature changes the resonator’s resonance frequency. To excite the passive transponder, the reader sends a read signal to the transponder via a radio channel. This signal is received there and excites an oscillation in the resonator. After the read signal is switched off, the oscillation decays exponentially. Part of the energy stored in the oscillation is sent back to the reader as a backscattered signal, where it is received, sampled, and evaluated. The resonance frequency can be extracted if the oscillation’s decay time is long enough to separate it from the read signal and all larger ambient echoes of the radio channel. To achieve high resolution with a large reading range, the overall quality factor

Q must be in the range of several hundred to several thousand [

2].

Due to the low complexity of chip-less passive transponders and the operation without any battery or electronic circuity, the instrumentation technique is considered to be maintenance-free, robust, and can be operated in harsh environments. Systems with chipless passive transponders usually outperform radio frequency identification (RF-ID)-based transponder systems in terms of both temperature load and reading distance. Their maximum operating temperature is limited only by the assembly technology and the temperature resistance of the conduction lines. Since they are linear time-invariant systems, their reading distance is only limited by receiver noise, which blocks the detection of a response signal from distances beyond the maximum reading distance.

Contemporary passive wireless temperature sensors are often based on surface acoustic wave (SAW) devices [

1,

3]. However, their size is not determined by the small SAW chip but by the bulky antenna. They have shown a reliable operating range up to 350 °C and, in exceptional cases, even significantly higher [

4]. A dielectric resonator could enable a simpler, smaller, and more heat-resistant chipless passive transponder.

Dielectric resonators have been used in microwave-integrated circuits, antenna systems, and communication applications for many years. They were discovered in 1939 when it was shown that non-metallic dielectric objects are similar to metal cavities in their ability to confine electromagnetic fields [

5,

6]. However, due to high material dielectric loss and low temperature stability, dielectric resonators were rarely applied for several decades [

7]. This changed in the 1980s when new ceramic technology provided low-loss and temperature-stable materials for dielectric resonators [

8,

9,

10]. An example of such a highly stable ceramic, zirconium tin titanate,

, is used in this study.

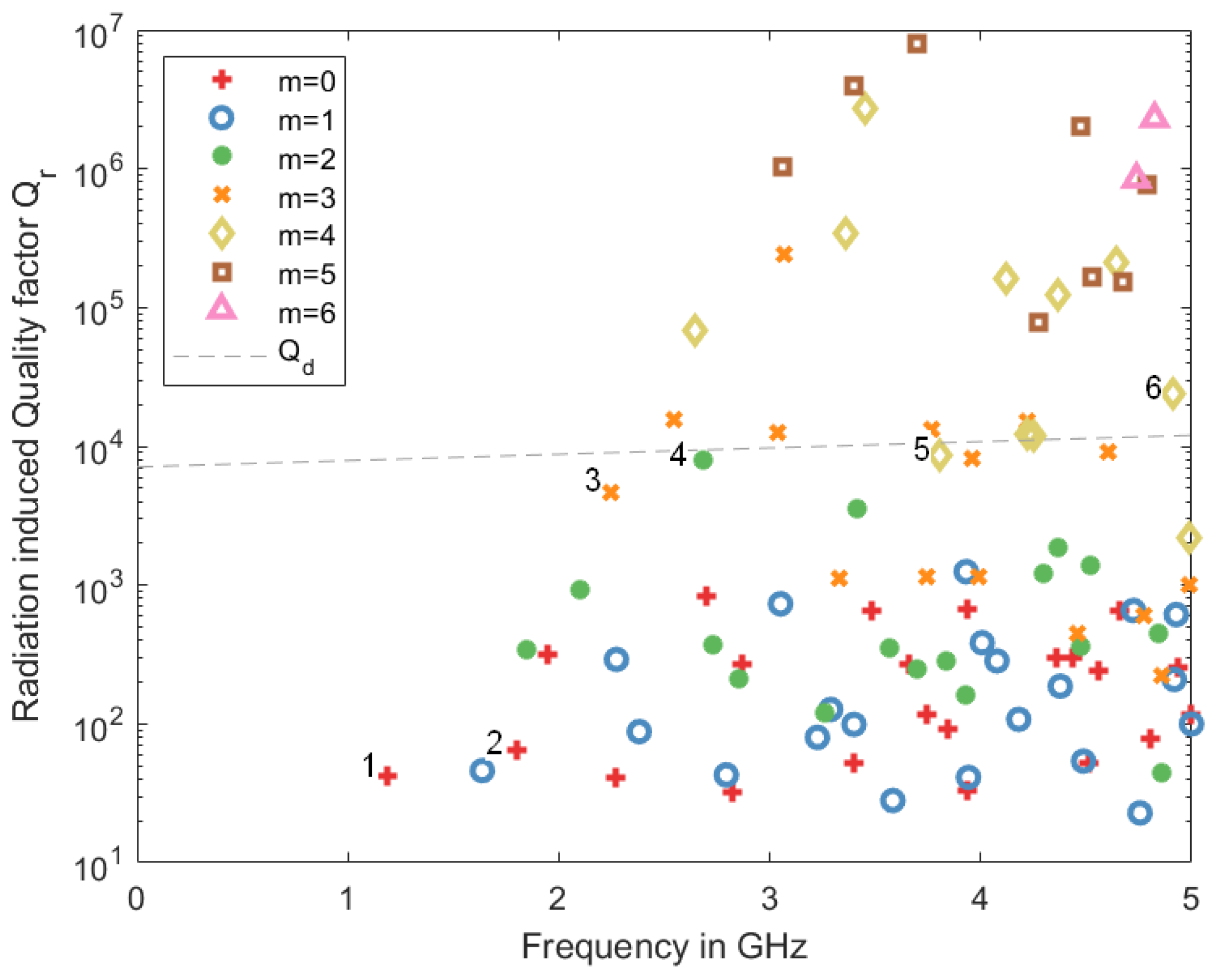

The use of a dielectric resonator as a sensor allows the combination of the functions of a resonator and an antenna in a single element. The dielectric resonator does not completely encapsulate the standing electromagnetic wave but rather exhibits low leakage. The overall quality factor

Q is thus determined by two factors (see

Appendix A): the dissipative and the radiation-induced Q-factor. To maximize the signal-to-noise ratio, the radiation-induced Q-factor should be similar to the dissipative Q-factor, and both should be high [

2].

The transponder then consists of just one single small element that functions as both a resonator and antenna. This not only makes the transponder unbeatably small but also greatly increases its robustness against mechanical and thermal stress. Since the resonator also acts as an antenna, it is sensitive to conductive materials in its environment.

Ceramic dielectric resonators have been presented in the scientific literature for measuring temperature [

11,

12,

13,

14,

15,

16,

17]; however, most applications include some metallic housings and additional antennas. The use of a bare-die dielectric resonator as a wireless passive chipless transponder is rare [

18,

19,

20,

21,

22]. This work continues the work reported in [

18] and extends it both simulatively and experimentally.

Due to its availability as unpacked dielectric resonators from the development of base station filters, its relatively high dielectric constant of

, and its high temperature resistance, a dielectric resonator made of zirconium tin titanate (ZST) was chosen for this study. The dielectric resonator is modeled using the finite element method (FEM) in the commercial program COMSOL 5.2 Multiphysics

® [

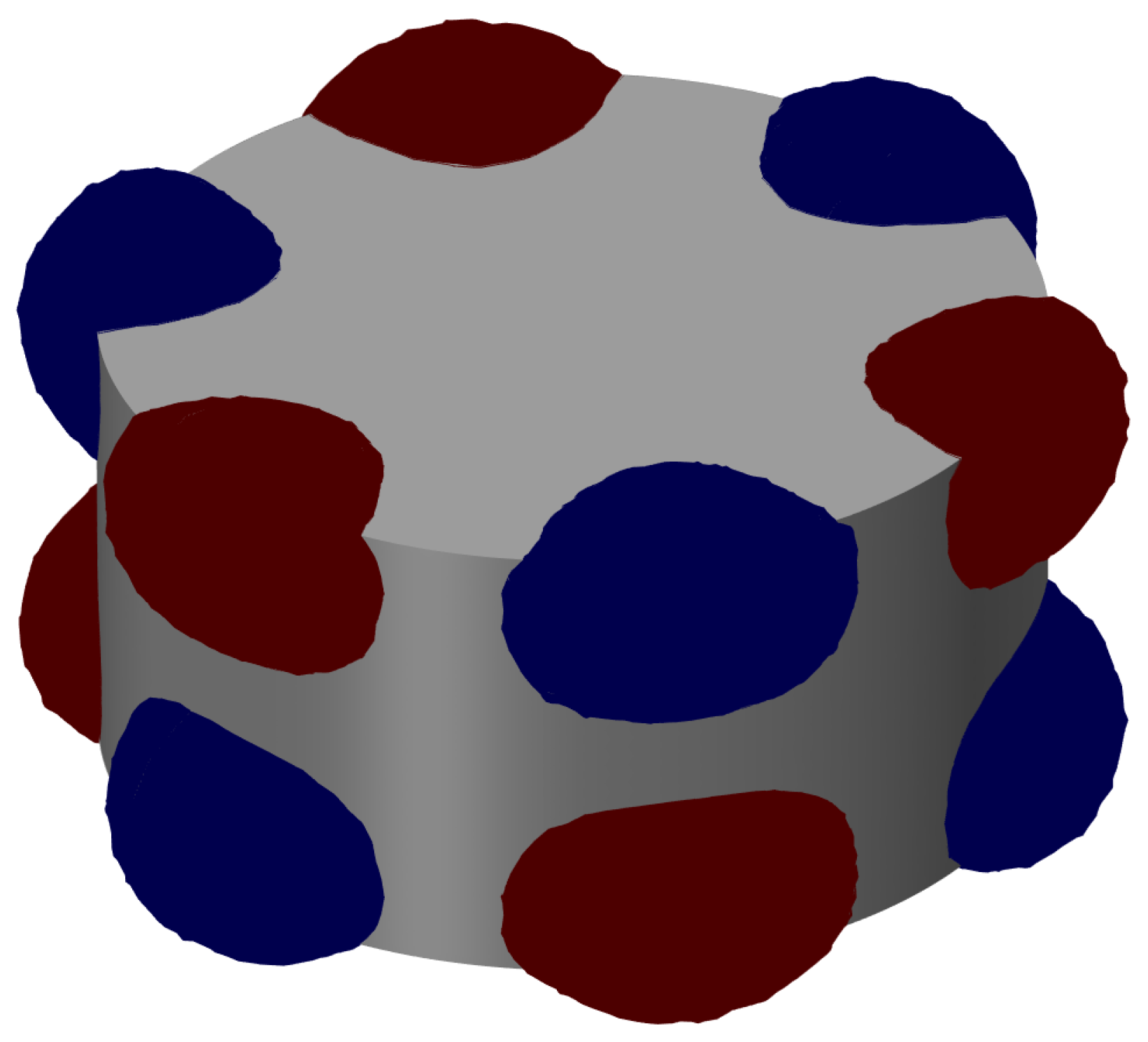

23]. The fundamental mode radiates very strongly electromagnetically and, thus, features a low overall Q-factor. However, some higher modes, such as the

mode, combine a good balance between radiative coupling and energy storage within the resonator and are, therefore, ideally suited for use as a passive chipless transponder.

For an experimental verification of the simulations, we placed isolated dielectric resonators with high radiation Q-factors on a low-loss, low permittivity ceramic holder and measured their radiation properties in the far field. The radiation patterns investigated in the laboratory and outdoors agree well with the simulations. The resulting radiation patterns show a directivity of approximately 7.5 dBi at 2.5 GHz. The sensor was then heated in a ceramic furnace. The readout antenna was located outside at room temperature. Wireless temperature measurements up to 700 °C, with a resolution of 0.5 °C, experimentally prove the outstanding performance of dielectric resonators for practical applications.

3. Measurement of the Electromagnetic Radiation Pattern of a Dielectric Resonator

To verify the vertical radiation pattern of the dielectric resonator calculated in

Section 2.2, the experimental setup shown in

Figure 9 was chosen. A dual-polarized, high-gain broadband horn antenna [

27] with a frequency range of 0.7–7 GHz and a maximum gain of 15 dBi is installed horizontally on an antenna holder. In the beam of the antenna, an isolated dielectric resonator is placed on the edge of a low-loss, low permittivity ceramic holder, which is mounted on top of an electronically controlled turntable. The axis of rotation of the turntable is parallel to the vertical polarization and perpendicular to the axis of symmetry of the dielectric resonator.

A motion controller with an optical encoder for feedback is implemented and connected via RS-232 to a data acquisition and control computer running a LabView program. An Agilent 5071B network analyzer (NWA) is also connected via the IEEE bus to the computer. The setup is controlled by a finite state machine with two main states: (1) rotate the turntable; (2) trigger the NWA measurement. The transition from state 1 to 2 will start when zero angular velocity is measured by the optical encoder, and the transition from state 2 to 1 is made when the measurement data transfer to the program is complete. We carried out a 1–5 GHz 2 port measurement with a frequency step of 50 kHz and an IF bandwidth of 15 kHz for each angle and both polarizations of the horn antenna. Additional cross-polarization data were also collected in the S21 and S12 columns. In order to suppress reflections from the environment, all the measurements were performed outdoors in a grass field, and the high-gain antenna suppressed possible ground reflections. In the post-processing algorithm, the resonance peaks were isolated and gated in the time domain to remove further environmental effects.

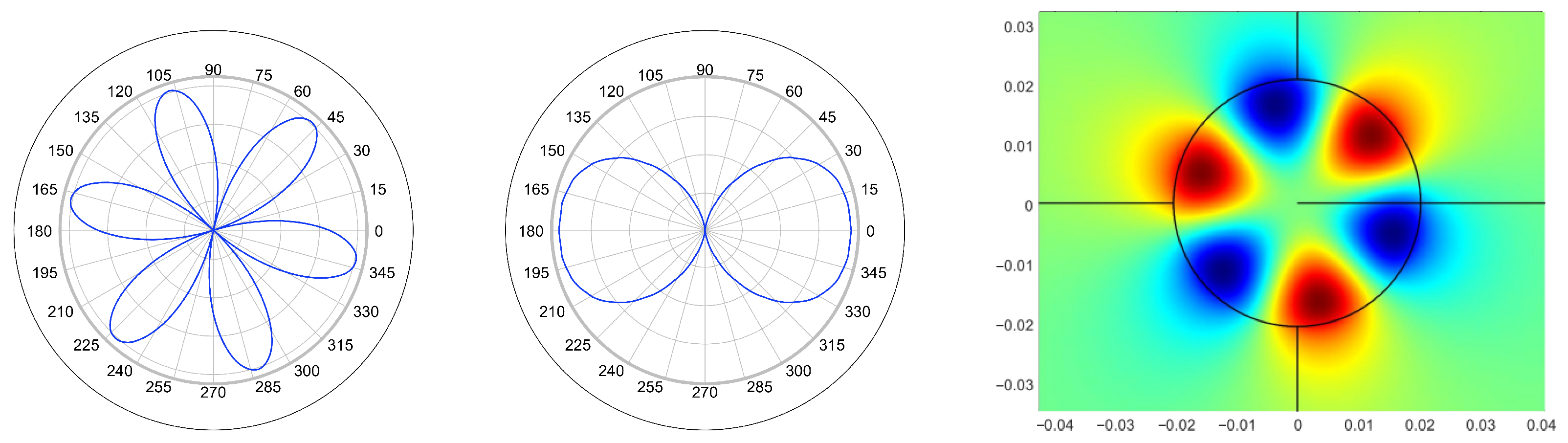

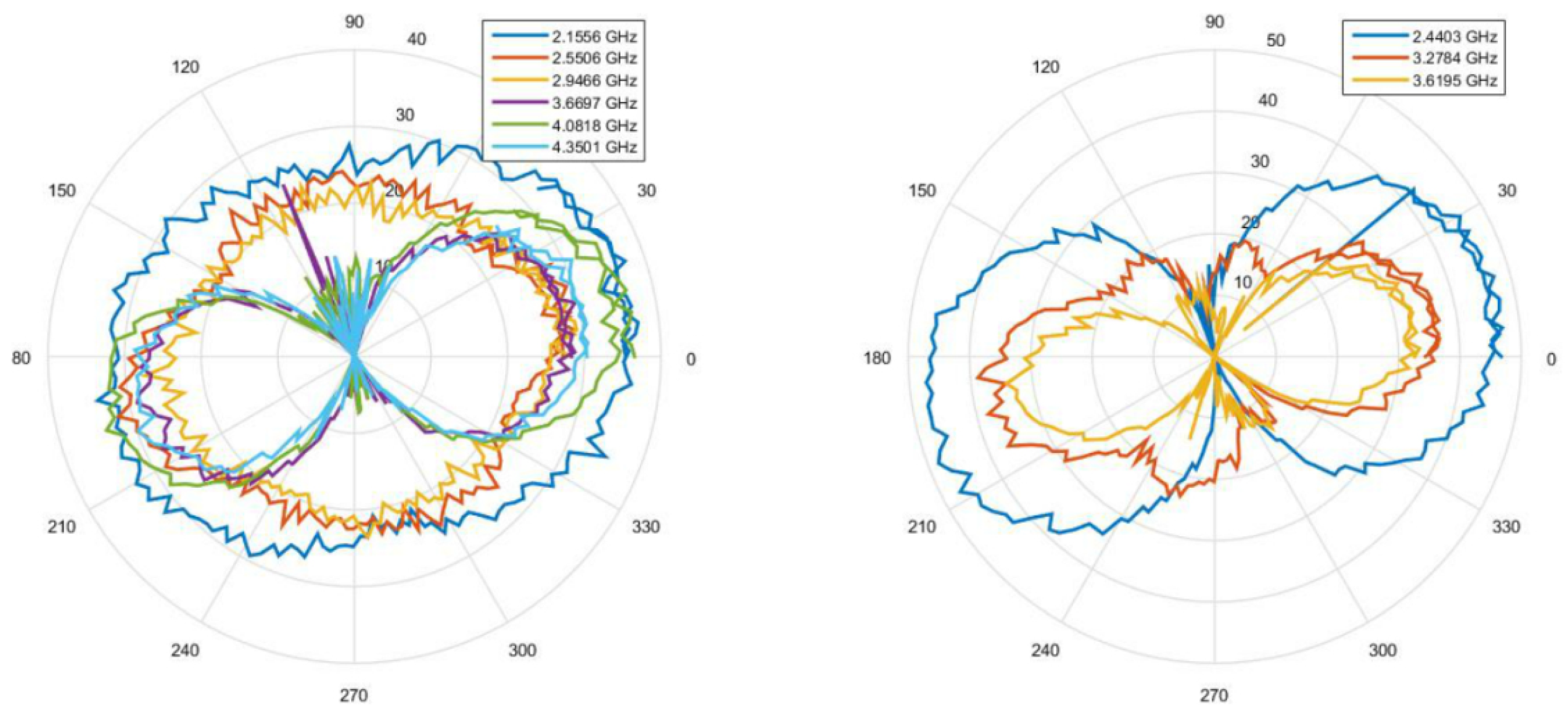

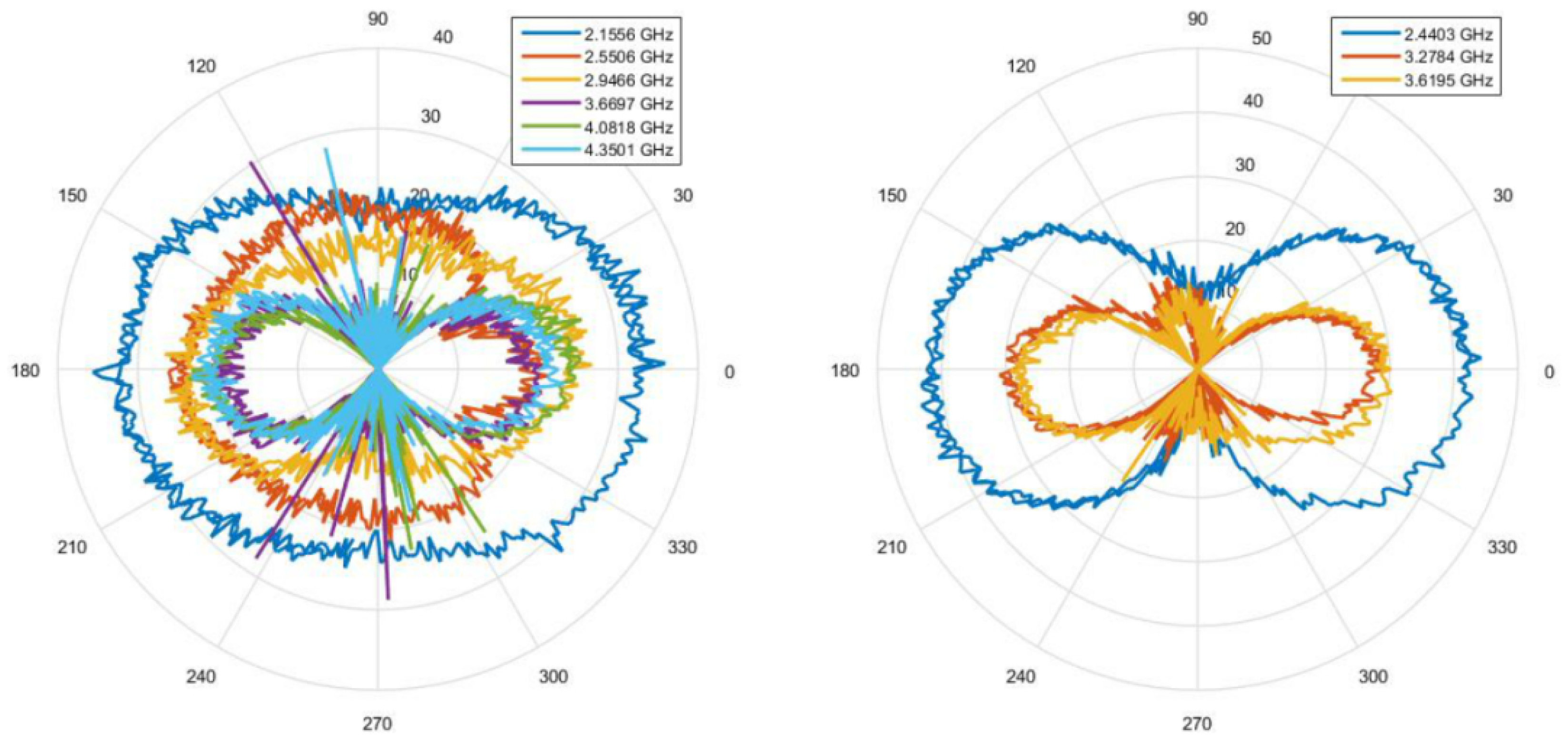

The amplitude of the resonance signal of the

as a function of the turntable angle is shown in

Figure 10 and

Figure 11.

Figure 10 shows the modes of the resonator that were excited and detected by the vertically polarized radiation of the horn antenna, and

Figure 11 shows the modes that were excited and detected by the horizontally polarized radiation of the horn antenna.

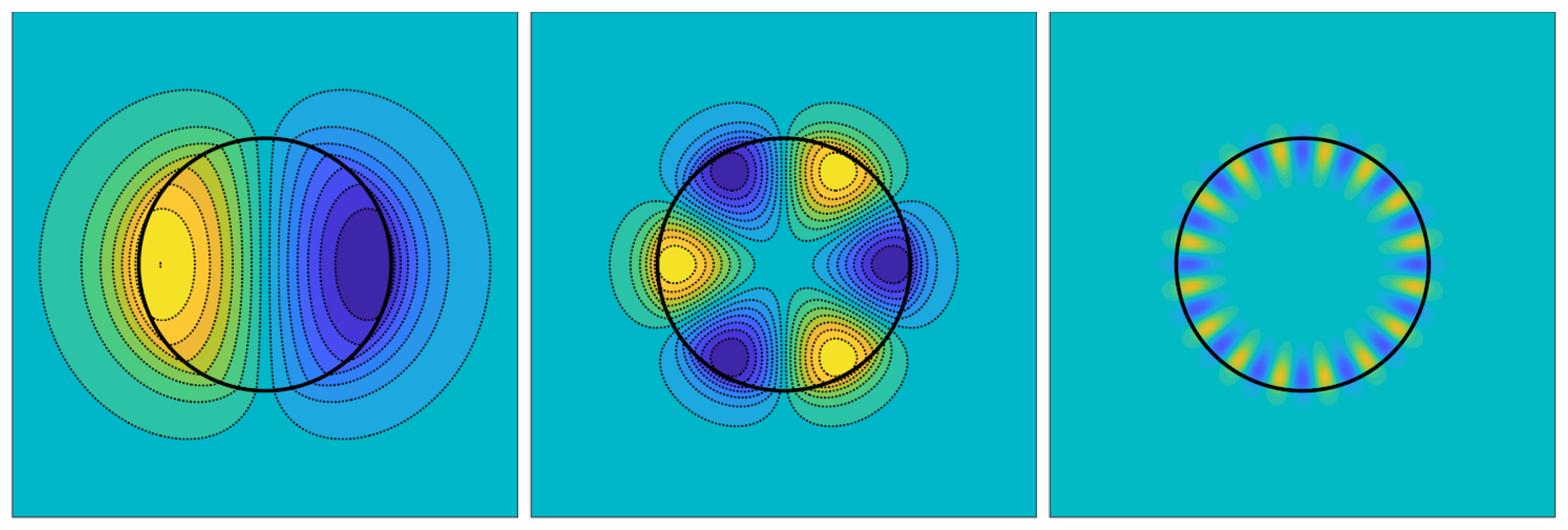

The center graph of

Figure 6 depicts the calculated radiation pattern of the

mode, which rings at 2.4403 GHz for the dimensions of the resonator under test. The corresponding measured radiation pattern is shown in blue color in the right graphs of

Figure 10 and

Figure 11. Other modes of different orders also have dipole characteristics.

In the measurements, we observed that low-order dipoles exhibit a low radiation Q-factor. This phenomenon is in good agreement with the simulation results in

Section 2.2 as, due to field confinement, an increase in the radiation Q-factor for higher order modes is also observed numerically. The far-field radiation pattern will exhibit the same symmetry as the field pattern of the resonance modes.

The resonator operating on the mode is used as wireless passive transponder for high temperature measurements in the next section.

4. High Temperature Measurements

The resonator operating on the combines both functionalities; it provides a high Q-factor of oscillation with dielectric losses nearly equal to radiation losses, and it couples well with free space electromagnetic radiation, eliminating the need for any additional antenna. No conductive boundary to encapsulate the electromagnetic fields of the resonator is needed. This allows for an extremely high temperature load on the transponder and keeps the high overall Q-factors even at elevated temperatures of more than 500 °C.

Figure 12 illustrates the schematic setup of a wireless high temperature measurement experiment. A high-gain antenna is installed outside the high temperature area and aligned with a dielectric resonator sensor. Radiation from one or more of the HEM modes shown in the simulation results in

Figure 5 couple to the antenna via electromagnetic waves. As described in

Figure 1, a reader detects the resonant frequency and compares it with a pre-calibrated lookup table defined by a second-order polynomial to calculate the temperature at the sensor. The experimental setup for such a high temperature wireless measurement is shown in

Figure 13. The dielectric resonator is placed on a low permittivity dielectric holder within a high temperature oven. The sides of the oven are metallic and the top and bottom are a low permittivity ceramic material, thus top and bottom of the over are transparent to EM microwaves.

A PID controller with a PT-100 reference element is used to control the temperature in the oven and, thus, the temperature on the dielectric resonator. The PID controller is connected via RS-232 to the data acquisition and control computer running a LabView program. The dual-polarized horn antenna is connected to two ports of the Agilent 5071B NWA, which is also connected to the laptop via the IEEE bus. The PID controller is programmed with a linear temperature ramp from room temperature to 700 °C over a duration of 15 h. The LabView program regularly collects the current temperature from the PT100 element and measurement data from the NWA and stores it with a time stamp.

The multi-mode resonator is irradiated by radio waves generated from an NWA that is used as a stepped frequency continuous wave radar. From the frequency domain sampling, all multiple resonant frequencies can be extracted. A Short Time Fourier Transform is performed on the zero-padded frequency domain data, and a spectrogram is produced as depicted in the left graph of

Figure 14. Every resonance produces a long reverberation and, thus, a long tail in the time domain. The higher the overall Q-factor, the longer the reverberation.

To separate the individual resonant frequency bands shown in the right-hand graph, the time domain from 0 to 300 ns is gated out, and the remaining signal components are transformed into the frequency domain. Three dominant modes with different overall Q-factors and different radiation couplings between the dielectric resonator and the antenna emerge. The noise floor of the measurement is −105 dB, and the strongest peak features a signal-to-noise ratio of 40 dB at a distance of over 50 cm between the antenna and the resonator and with the radio waves attenuated twice by the ceramic cover.

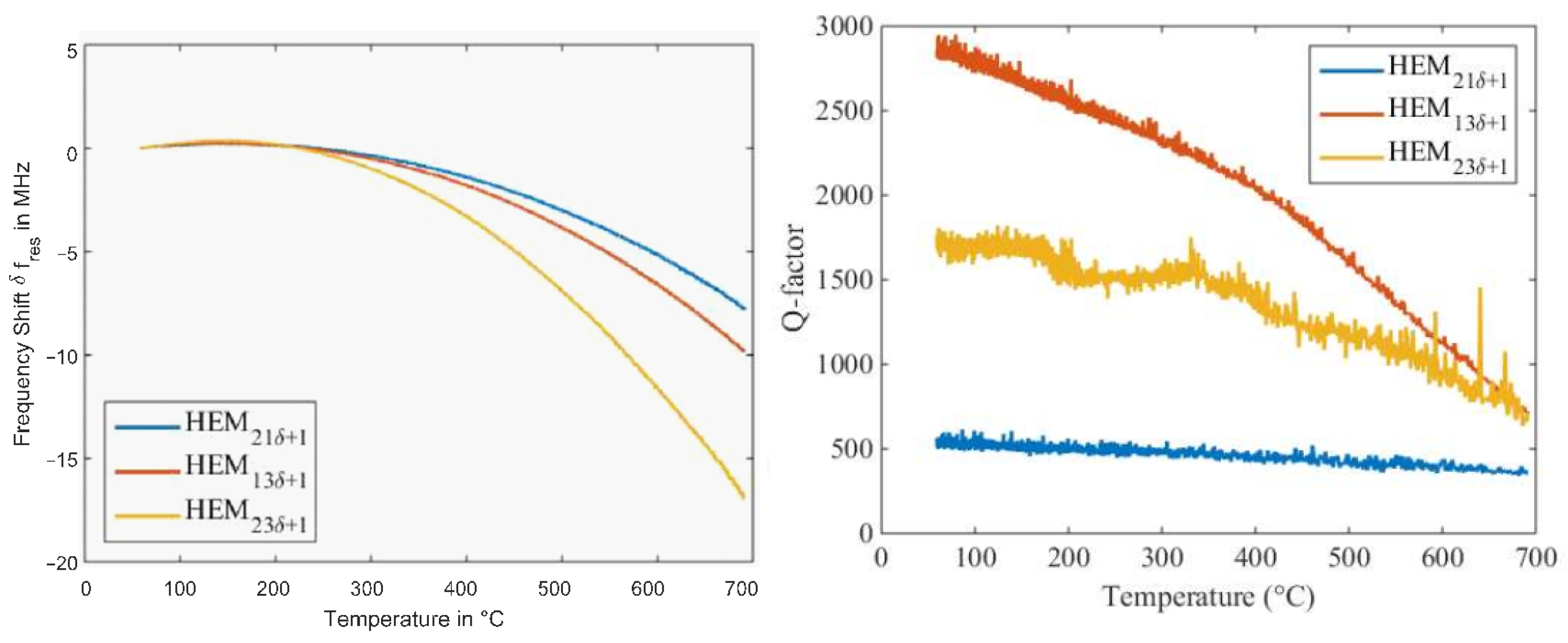

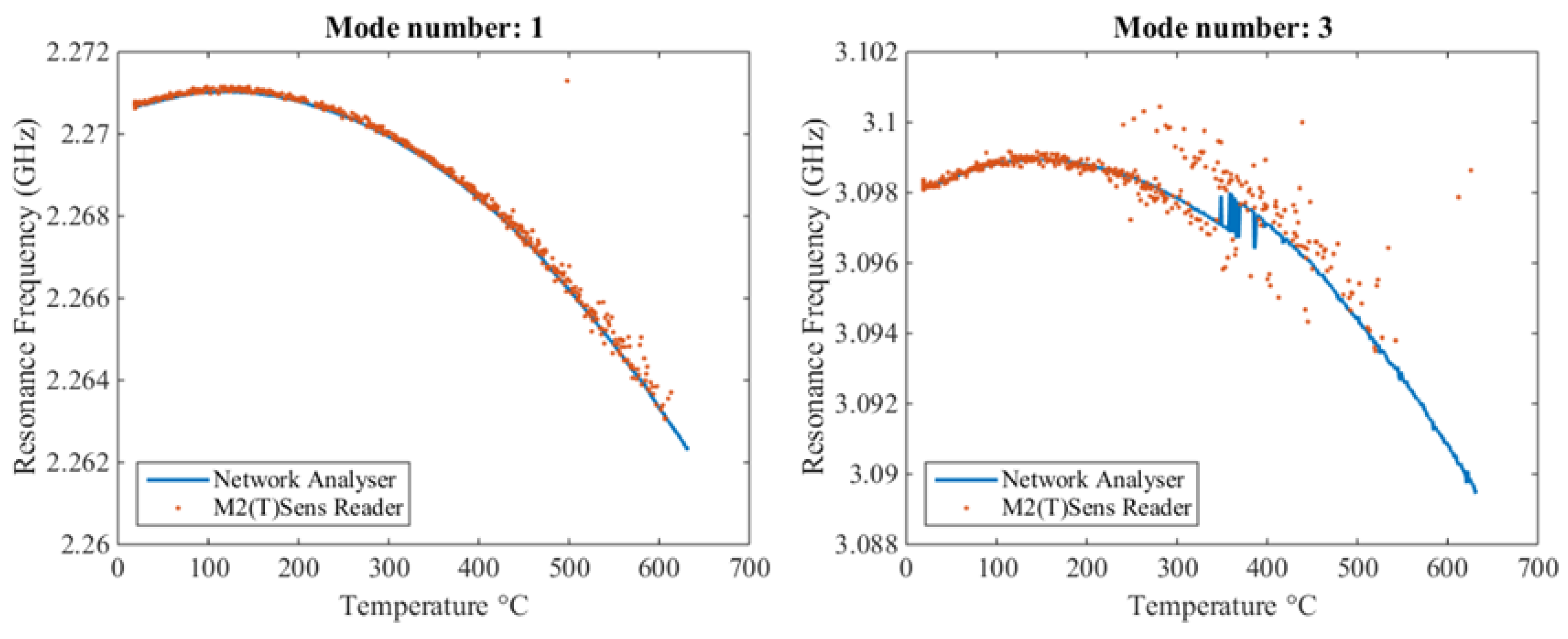

The frequencies of the three resonances shown in

Figure 14 were then monitored as a function of temperature.

Figure 15 shows their frequency shift and Q-factor variation as a function of temperature. The inflection points of the temperature sensitivity for the material used here lie between room temperature and 200 °C. The three modes exhibit three different negative square temperature coefficients of the resonance frequency, which can be used for more precise temperature determination.

The overall Q factor shows a monotonically decreasing function of temperature due to increasing dielectric losses in the materials. Increasing losses at high temperatures in the radio channel of the experimental setup might also contribute to the lowered Q factor: The radio waves pass through the fire clay of the oven, which has a small but non-negligible electrical conductivity at high temperatures, resulting in an increase in absorption of the radio waves two times for a single measurement. In addition, the ceramic holder on which the resonator is located can also exhibit increased conductivity and, thus, increased damping at higher temperatures.

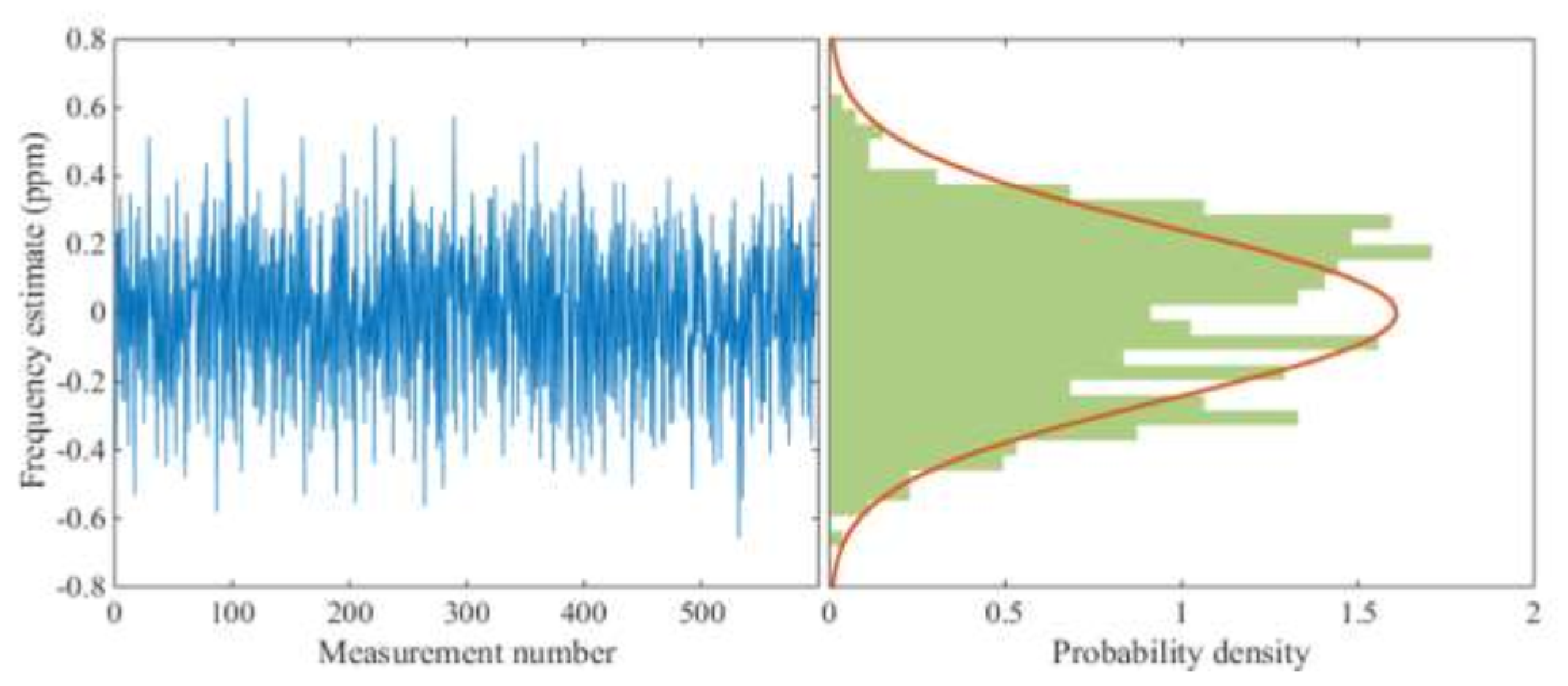

Figure 16 shows the variance of the resonance frequency of a mode for 600 consecutive measurements. The sensor is placed in the high temperature furnace, and the temperature is fixed at 500 °C. Slight fluctuations in the center frequency due to the furnace temperature control are visible in the time series. To compensate for these tiny deviations, a non-contact measurement of the actual temperature of the resonator with an accuracy of better than 0.1 °C at 500 °C would have been necessary, but this was beyond the capabilities of the laboratory.

On the right-hand side of

Figure 16, a histogram and an approximated Gaussian distribution are created from these data, resulting in a 1

standard deviation, which corresponds to a temperature uncertainty of 0.5 °C. This uncertainty can be reduced by filtering or averaging the raw signal. The actual uncertainty of temperature measurement with a dielectric resonator could be below 0.5 °C since the uncertainty shown in

Figure 16 is caused by the joint contributions of the furnace temperature control and the measurement accuracy. Furthermore, a sub-optimal parabolic fit was used to evaluate the resonance frequency [

2]. The authors assume that due to the influence of the furnace control loop, the distribution of the frequency deviations does not exactly follow a Gaussian distribution and, moreover, shows an asymmetric distribution of the frequency deviations.

A simple tracking algorithm might run into problems if two modes are very close in the frequency domain or if two crossing modes are tracked. Such a possible tracking failure is shown in

Figure 17. The simple tracking algorithm jumps between both modes depending on signal strength. This problem might be overcome by more advanced algorithms in the future.

5. Summary and Conclusions

This manuscript presents a theoretical and experimental study on the use of bare-die dielectric resonators as wireless, passive temperature sensors, which do not require integrated circuits, batteries, or antennas because the electromagnetic fields in the dielectric resonators are coupled to free-space electromagnetic waves. A resonator itself acts as an analog storage for the read signals, as a sensor, and as an antenna. For the fundamental mode and several higher modes of an isolated dielectric resonator based on Zirconium Tin Titanate (ZST, = 37), the resonance frequencies, quality factors, and couplings to electromagnetic waves were calculated using a finite element method in COMSOL Multiphysics. For the fundamental mode, the coupling to the far-field electromagnetic wave is so strong that the overall Q factor remains below 100, which is too low for a wireless passive sensor. Some higher modes, such as the mode, have a radiation Q factor, about half of the overall Q factor, which makes them ideal as wireless passive sensors.

To characterize the dielectric resonators, several experiments were conducted in which they were placed on a dielectric holder. The vertical radiation patterns of some higher modes agreed well with the simulation results, showing total Q factors of up to 3000 and a directivity of approximately 7.6 dBi at 2.44 GHz. For temperature measurements, the sensor was placed in a ceramic furnace, and the reading antenna was placed outdoors at room temperature. Wireless temperature measurements up to 700 °C were demonstrated with a resolution of 0.5 °C from a distance of 1 m.

Future research could investigate other well-suited or even better-suited materials, such as strontium titanate, for their suitability for high temperature measurement technology based on dielectric resonators. Material optimizations with regard to higher temperature tolerance, higher dielectric constant for size reduction, and higher quality factors in combination with reduced conductivity losses at high temperatures could also significantly advance the technology.

Radiating dielectric resonators act as small antennas. Conductive or magnetizable materials in the range of approximately two wavelengths change their radiation properties and also pull the resonant frequency. In a static setup with conductive or magnetizable materials, wireless measurement of the resonator temperature or temperature change is still feasible. In a dynamic setup, however, some components of the evanescent field must be shielded. This leads to additional conduction losses, especially at high temperatures.