IoT-Based Adaptive Lighting Framework for Optimizing Energy Efficiency and Crop Yield in Indoor Farming

Abstract

1. Introduction

- A growth model for stage-specific lighting adaptation.

- Two novel efficiency metrics: Light Use Efficiency at Growth stage Canopy Level (LUEP) and Lamp-Level Efficiency (LUEL), linking energy input to photosynthetic output.

- A scalable IoT architecture tested on lettuce (Lactuca sativa L.), as a light-sensitive model crop, designed for seamless adaptation to other CEA systems.

2. Literature Review and Research Gaps

- Lavanya et al. [19]:

- Goap et al. [20]:

- Khanna and Kaur [21]:

- Bodunde et al. [22]:

- Foughali et al. [23]:

- Zhang et al. [3]:

- Benyezza et al. [24]:

- Raghuvanshi et al. [25]:

- Chataut et al. [26]:

- Javaid et al. [27]:

- Seesaard et al. [28]:

3. Materials and Methods

3.1. System Architecture and Hardware Setup

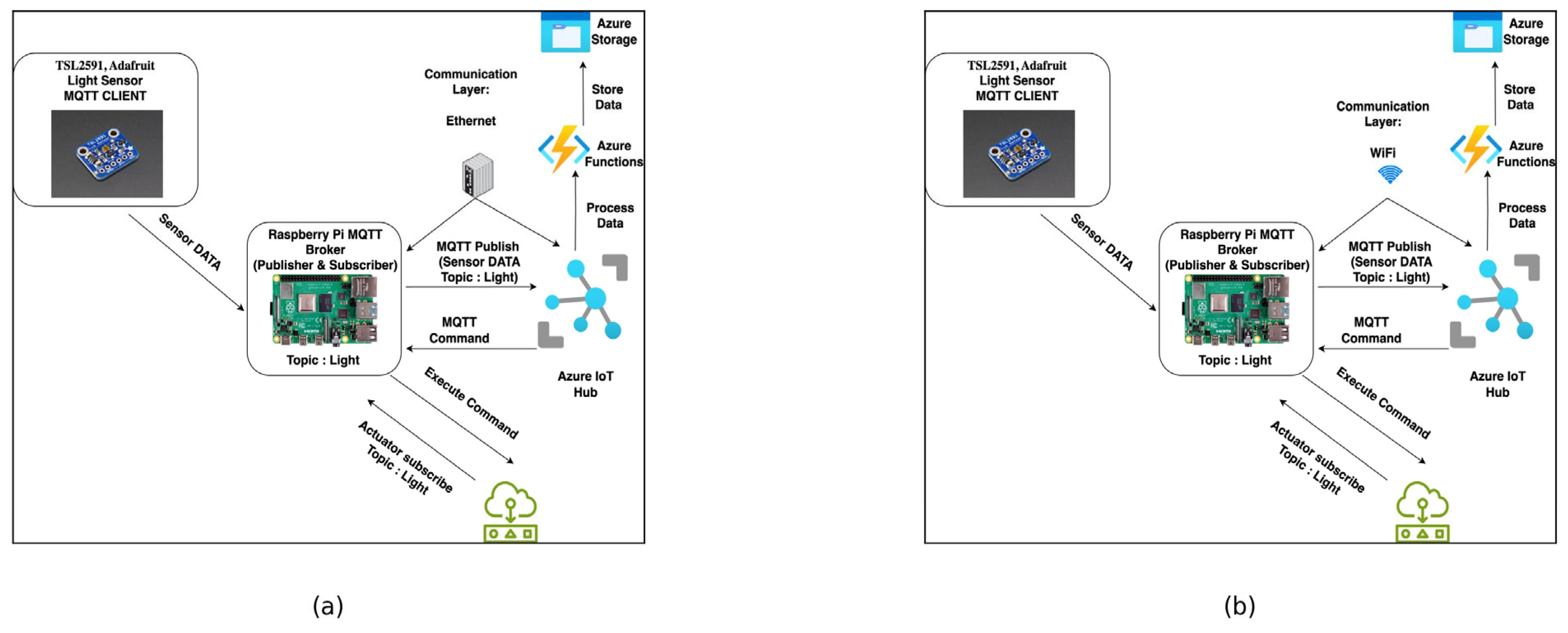

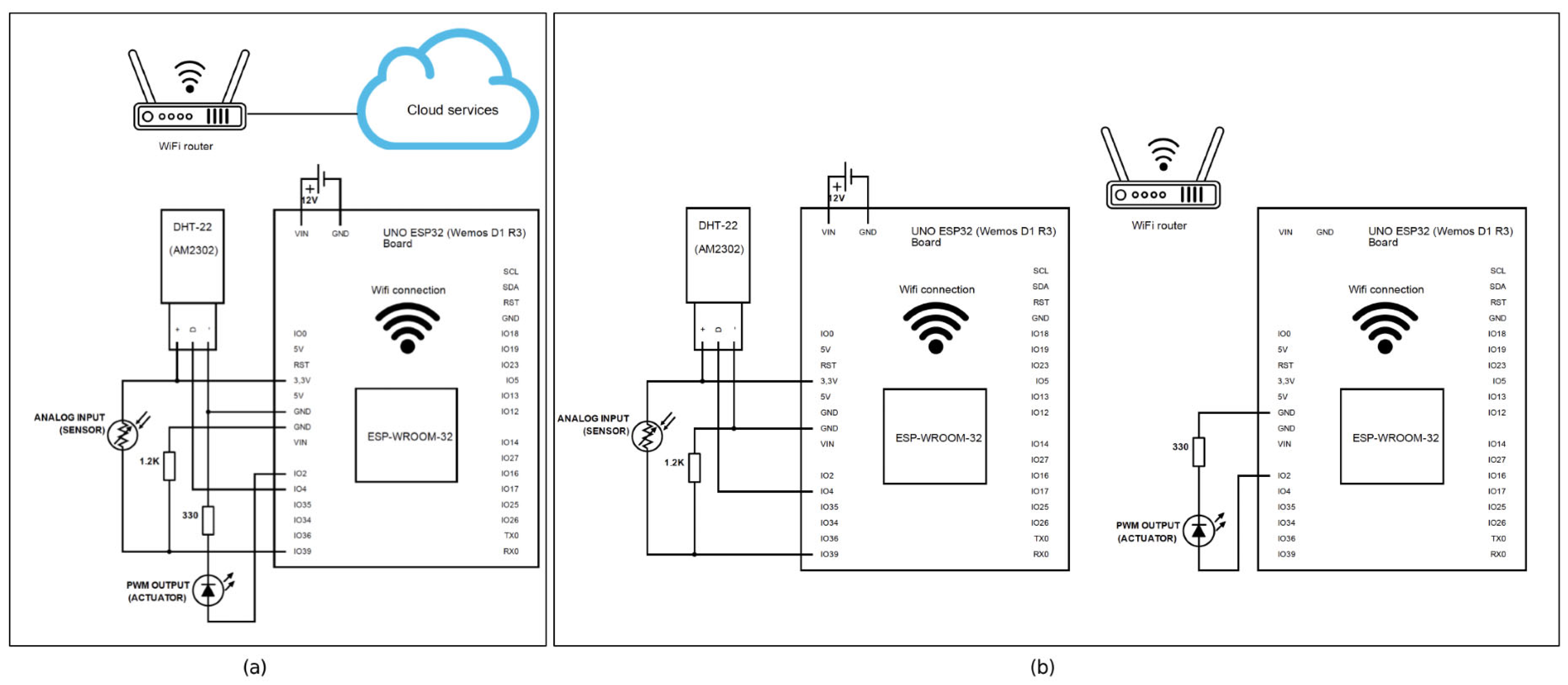

3.2. Wired Sensor Network

3.3. Wireless Sensor Network

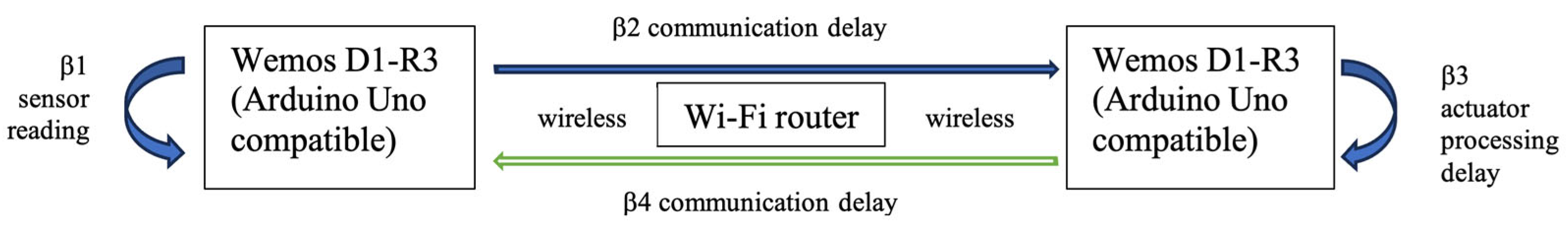

3.4. Analysis of Time Responsiveness in IoT Communication

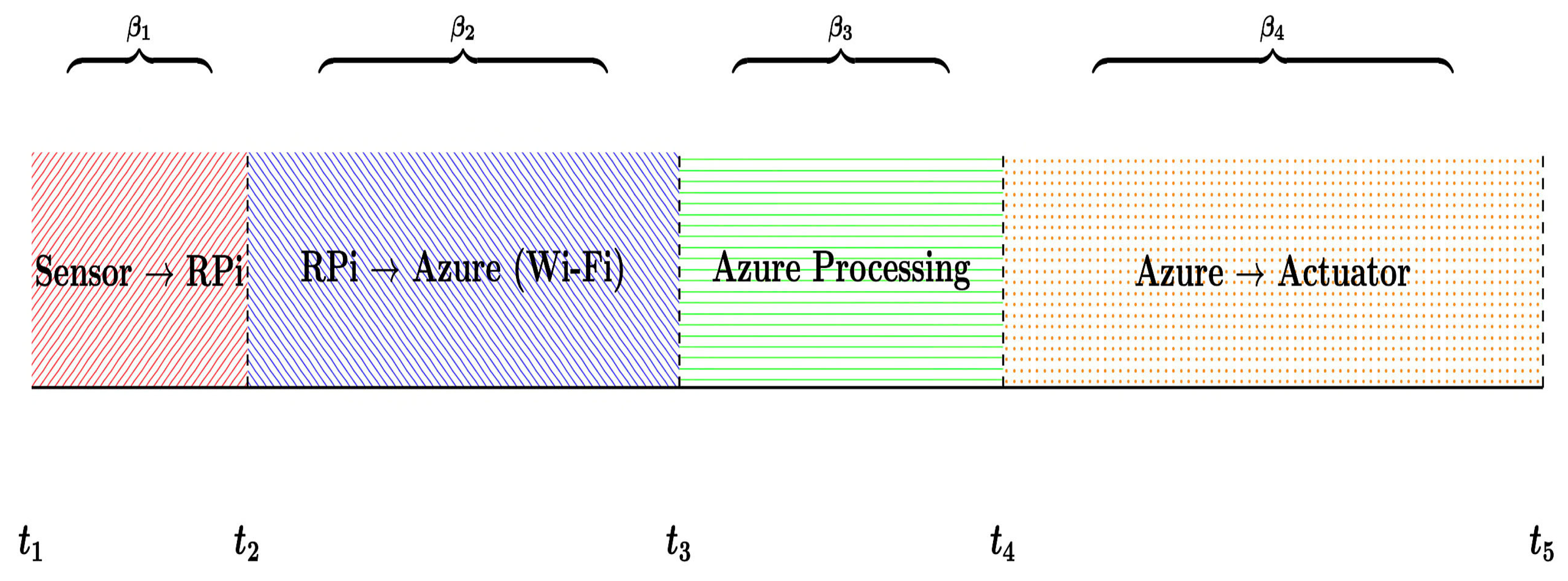

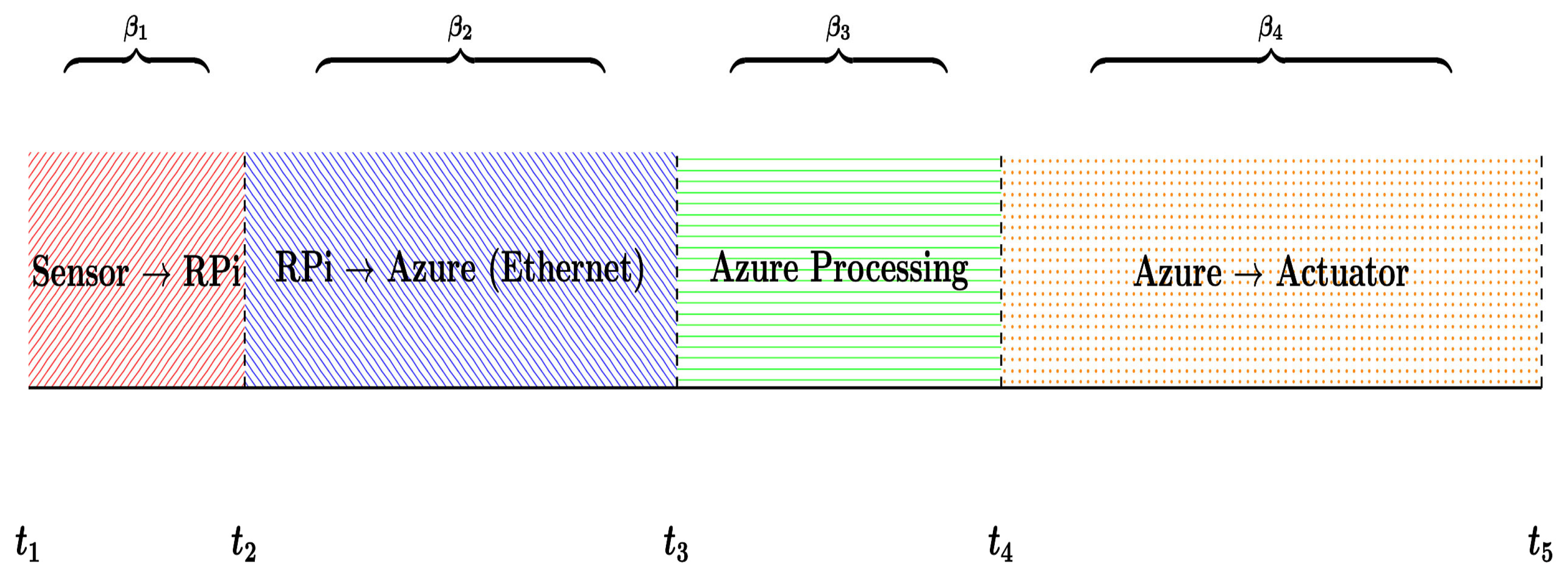

3.4.1. Time Responsiveness in Wi-Fi vs. Ethernet in MQTT-Based IoT System

3.4.2. Time Responsiveness in Point-to-Point vs. Cloud in HTTP-Based IoT System

3.4.3. Technology Trade-Offs in IoT Responsiveness

3.5. Lighting Configuration and Feedback Control

- I: Current light intensity (measured in μmol/m2/s);

- Lower threshold for light intensiy (200 μmol/m2/s);

- Upper threshold for light intensity (400 μmol/m2/s).

- Light intensity at time t;

- Command output at time t;

- : Change in light intensity resulting from the command.

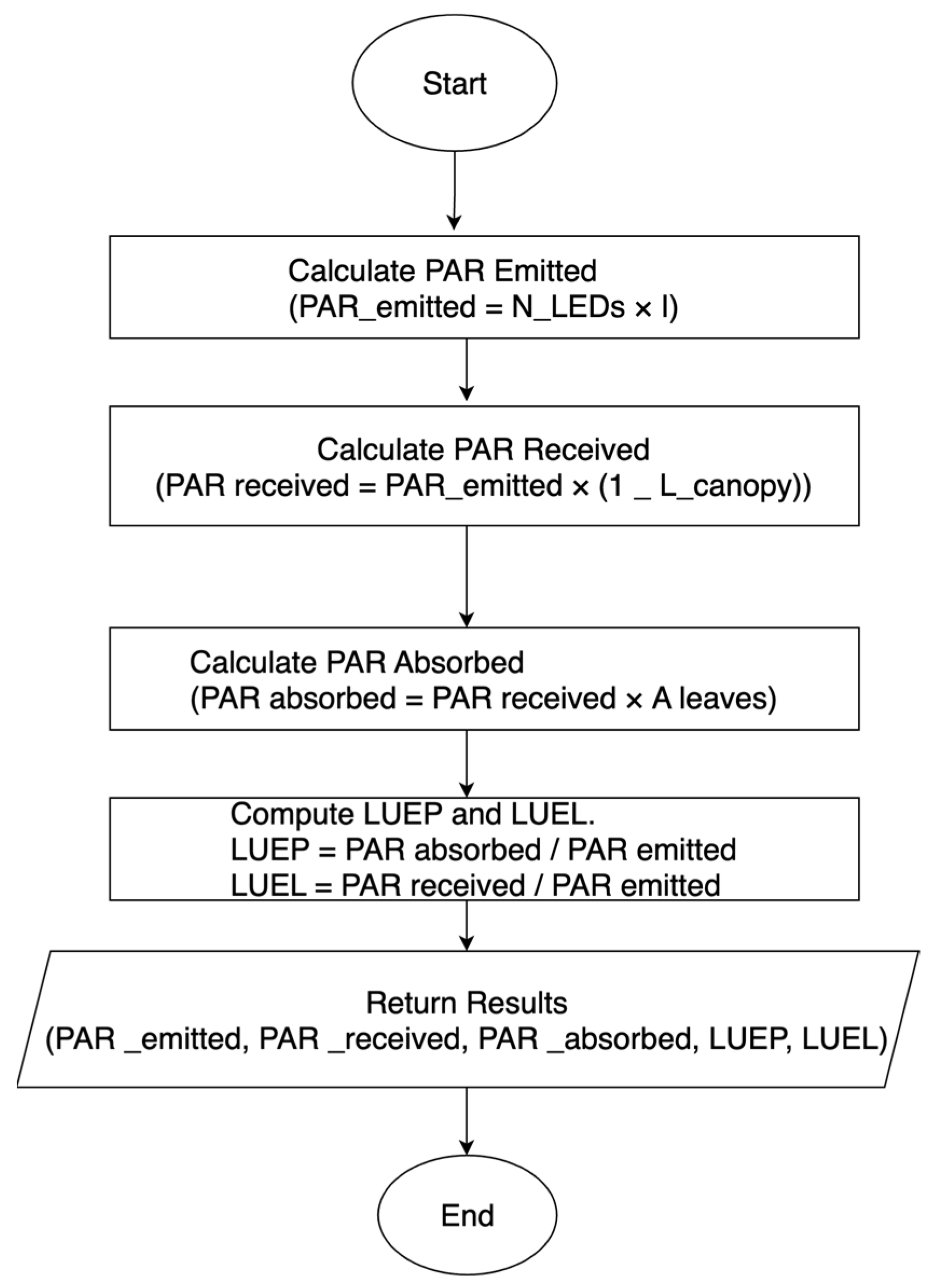

3.6. Metrics for Light and Energy Efficiency

3.6.1. Light Use Efficiency

3.6.2. System-Level Energy Efficiency

- Electrical Input: Measured in real time via smart meters integrated with the Raspberry Pi control system.

- PAR Output: Quantified using calibrated quantum sensors at canopy height.

- Adaptive Optimization: The IoT framework dynamically adjusted LED intensity to maintain optimal efficiency (300–400 µmol/m2/s) while reducing power waste.

3.7. Lighting Configuration for Light Efficiency Simulation

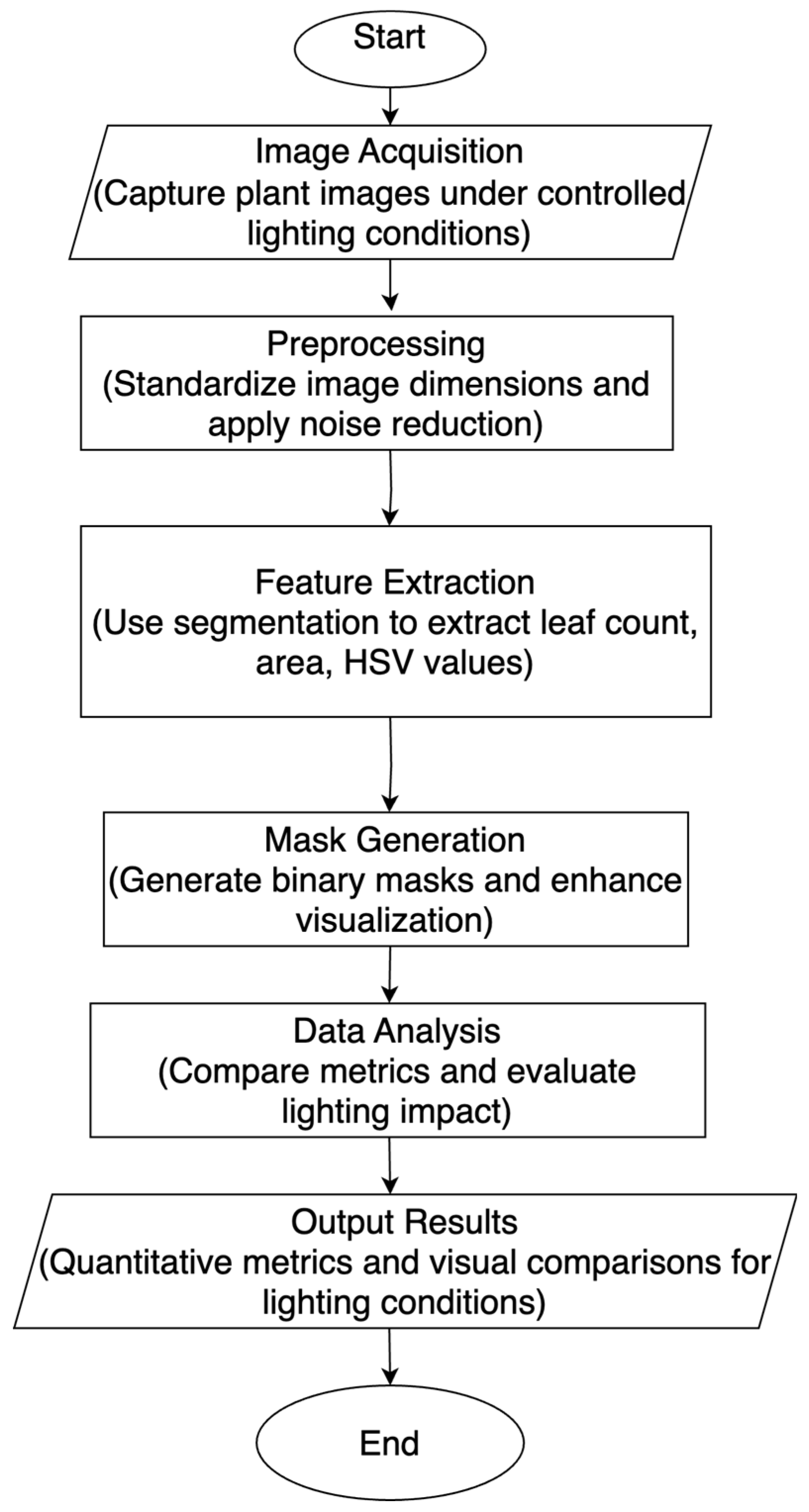

3.8. Image Analysis

- ○

- Brighter Images: Created by increasing brightness (β = +50) and contrast (α = 1.2) via linear transformation.

- ○

- Darker Images: Created by decreasing brightness (β = −50) with the same contrast (α = 1.2).

3.9. Security, Reliability, and Robustness Considerations

4. Results

4.1. IoT Framework Performance

4.1.1. Comparative Delay Analysis: Wi-Fi and Ethernet Using MQTT Communication

- Darker colors indicate lower correction accuracy, typically for larger deviations and longer response times.

- Lighter colors represent higher correction accuracy (>97%), achieved for smaller deviations and shorter response times.

4.1.2. Comparative Delay Analysis: Wi-Fi Sensor-Based HTTP Point-to-Point vs. Cloud Communication

4.1.3. Comparative Time Responsiveness

4.1.4. Analysis of Light Intensity

- Darker colors indicate lower growth rates, typically observed at lower light intensities or shorter time periods.

- Lighter colors represent higher growth rates, achieved when the light intensity is near the optimal range and sustained over time.

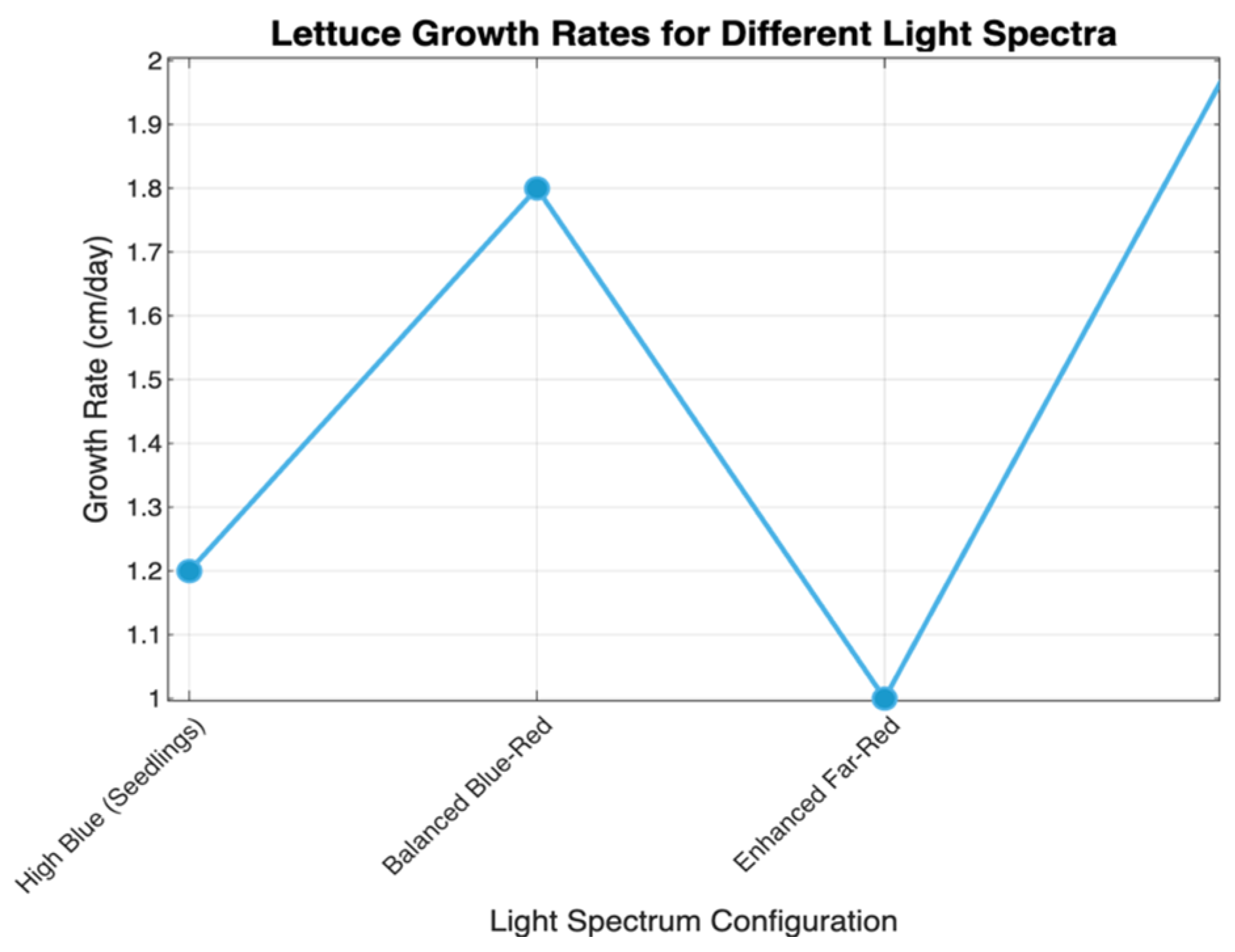

4.2. Growth Stage Growth Predictions

4.3. Optimal Configuration

4.4. Light Use Efficiency (LUE) Metrics

4.5. Image Analysis for Light Impact

- Brighter Condition: This overestimates growth stage area (11.4 M vs. 6.8 M pixels) and decreases saturation (37.2 vs. 53.9), likely due to reflectance from leaf surfaces causing false positives in segmentation.

- Darker Condition: This underestimates growth stage area (4.25 M vs. 6.8 M pixels) but detects more contours due to higher local contrast and noise misclassified as leaves.

- Hue Stability: Hue values remain stable (~41–42), supporting its reliability for monitoring pigmentation changes over time.

- Binary Threshold (120/255): Maintained segmentation uniformity.

- Morphological Operations: Erosion (3 × 3) and small-hole filling reduced artifacts and noise sensitivity.

- Lighting Simulation: Contrast-enhanced inputs replicated common spectral shifts in controlled agricultural setups.

4.6. Energy Efficiency Analysis

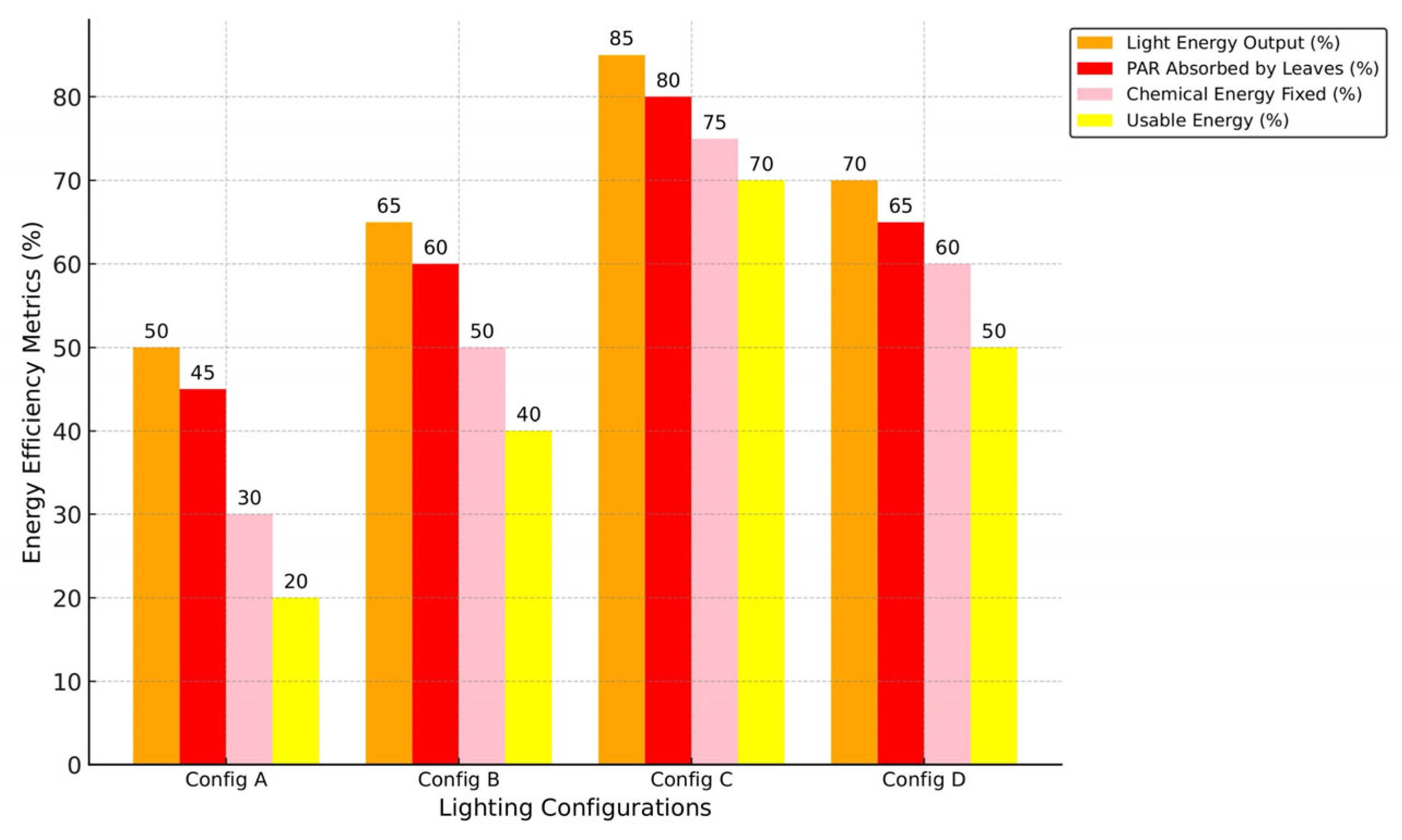

4.6.1. Metrics According to Lighting Configurations

- Light Energy Output (%): Efficiency of converting electrical energy to light.

- PAR Absorbed by Leaves (%): Efficiency of light absorption by growth stage leaves.

- Chemical Energy Fixed (%): Conversion of absorbed light into biomass.

- Usable Energy (%): Final energy contributing to salable growth stage parts.

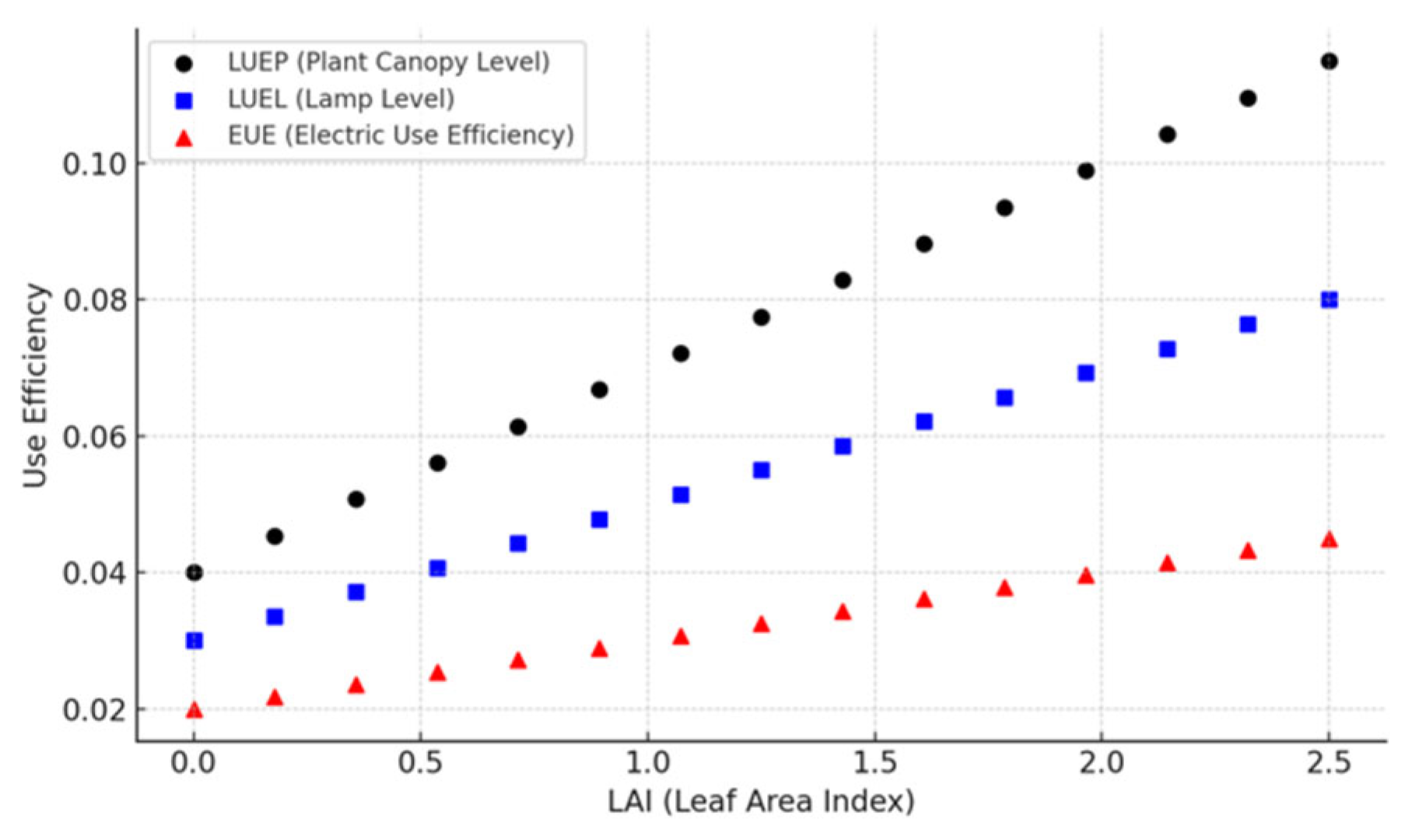

4.6.2. Leaf Area Index and Efficiency

- The fraction of PAR absorbed by the canopy for LUEP;

- The fraction of PAR transmitted to the canopy for LUEL.

- LUEP (Canopy-Level Efficiency):

- 2.

- LUEL (Lamp-Level Efficiency):

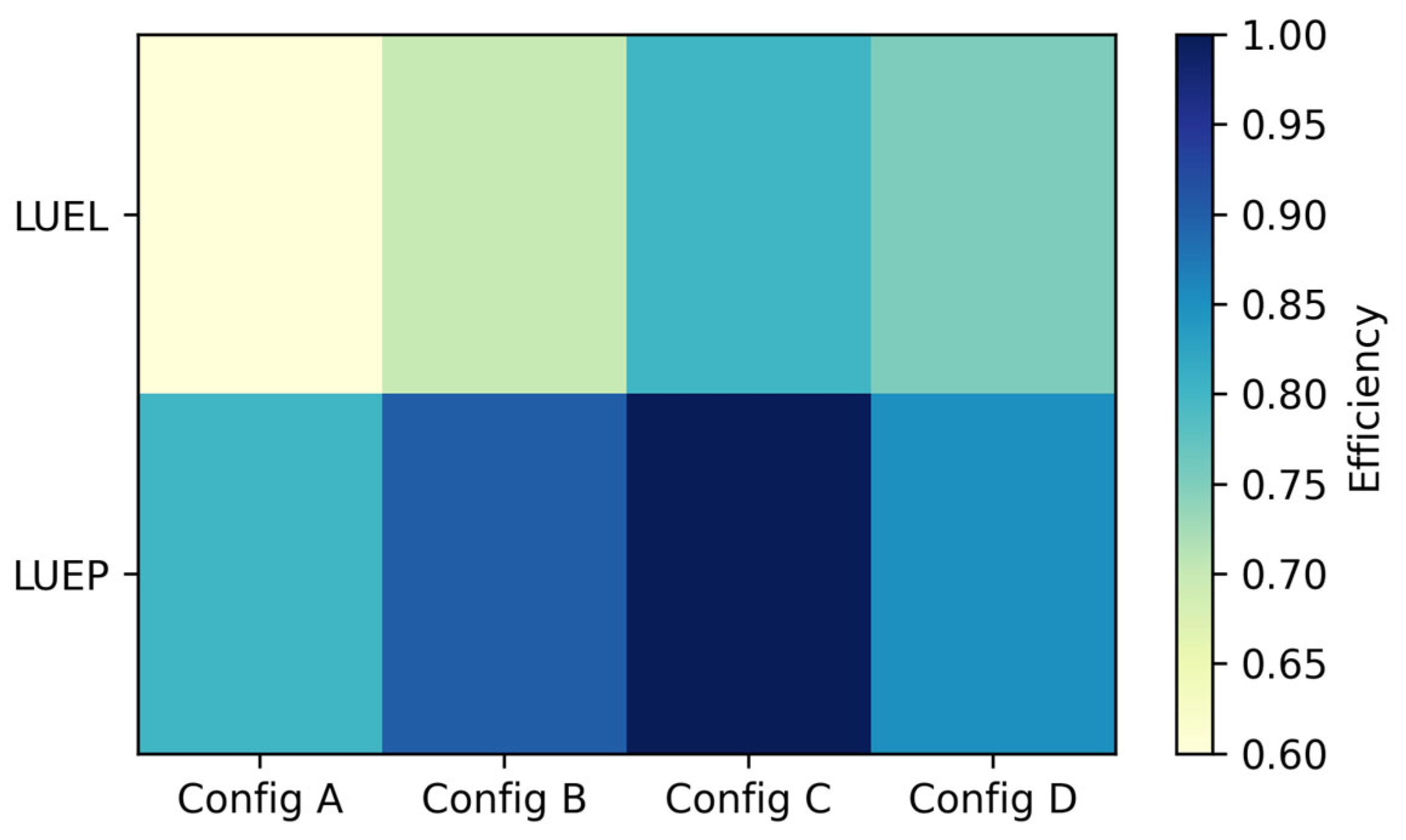

4.6.3. Heatmap Analysis

5. Discussions and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| HTTP | HyperText Transfer Protocol |

| JSON | JavaScript Object Notation data exchange |

References

- Bahar, N.H.A.; Lo, M.; Sanjaya, M.; Van Vianen, J.; Alexander, P.; Ickowitz, A.; Sunderland, T. Meeting the food security challenge for nine billion people in 2050: What impact on forests? Glob. Environ. Change 2020, 62, 102056. [Google Scholar] [CrossRef]

- Perrine, Z.; Negi, S.; Sayre, R.T. Optimization of photosynthetic light energy utilization by microalgae. Algal Res. 2012, 1, 134–142. [Google Scholar] [CrossRef]

- Huang, J.; Haider, F.U.; Huang, W.; Liu, S.; Mwangi, B.N.; Suba, V.; Sikuku, L.; Tang, X.; Zhang, Q.; Chu, G.; et al. Influence of photosynthetic active radiation on sap flow dynamics across forest succession stages in Dinghushan subtropical forest ecosystem. Heliyon 2024, 10, e37530. [Google Scholar] [CrossRef] [PubMed]

- Harun, H.; Ahmad, A.N.; Mohamed, N.; Ahmad, R.; Abdul Rahim, A.R.; Ani, N. Improved Internet of Things (IoT) monitoring system for growth optimization of Brassica chinensis. Comput. Electron. Agric. 2019, 164, 105046. [Google Scholar] [CrossRef]

- Boros, I.F.; Székely, G.; Balázs, L.; Csambalik, L.; Sipos, L. Effects of LED lighting environments on lettuce (Lactuca sativa L.) in PFAL systems—A review. Sci. Hortic. 2023, 321, 112351. [Google Scholar] [CrossRef]

- Orsini, F.; Carotti, L.; Souri, M.K.; Gianquinto, G. Optimizing Energy and Other Resource Use in Vertical Farms. In Advances in Plant Factories: New Technologies in Indoor Vertical Farming; Burleigh Dodds Science Publishing: Cambridge, UK, 2023; pp. 145–168. [Google Scholar] [CrossRef]

- Islam, S.; Reza, M.N.; Samsuzzaman; Ahmed, S.; Cho, Y.; Noh, D.; Chung, S.-O.; Hong, S. Machine Vision and Artificial Intelligence for Plant Growth Stress Detection and Monitoring: A Review. Precis. Agric. Sci. Technol. 2024, 6, 33–57. [Google Scholar] [CrossRef]

- Safira, M.; Yusuf, A.; Salim, T.I.; Alam, H.S. Design and Implementation of IoT-Based Monitoring System on Nanobubble-Based Hydroponics Farming. J. Tek. Pertan. Lampung 2023, 12, 470–483. [Google Scholar] [CrossRef]

- Casado-García, A.; del-Canto, A.; Sanz-Saez, A.; Pérez-López, U.; Bilbao-Kareaga, A.; Fritschi, F.B.; Miranda-Apodaca, J.; Muñoz-Rueda, A.; Sillero-Martínez, A.; Yoldi-Achalandabaso, A.; et al. LabelStoma: A tool for stomata detection based on the YOLO algorithm. Comput. Electron. Agric. 2020, 178, 105751. [Google Scholar] [CrossRef]

- Yu, J.; Zhao, J.; Sun, C.; Wei, X. A dual deep learning approach for winter temperature prediction in solar greenhouses in Northern China. Comput. Electron. Agric. 2025, 229, 109807. [Google Scholar] [CrossRef]

- Jung, A.; Szabó, D.; Varga, Z.; Lausch, A.; Vohland, M.; Sipos, L. Daily light integral maps for agriculture lighting design in Spain. Smart Agric. Technol. 2024, 9, 100681. [Google Scholar] [CrossRef]

- Soussi, E.; Zero, S.; Sacile, R.; Trinchero, D.; Fossa, M. Smart sensors and smart data for precision agriculture: A review. Sensors 2024, 24, 2647. [Google Scholar] [CrossRef] [PubMed]

- Mir, M.; Naikoo, N.; Kanth, R.; Bahar, F.; Bhat, M.; Nazir, N.; Mahdi, S.; Amin, Z.; Singh, L.; Raja, W.; et al. Vertical Farming: The Future of Agriculture: A Review. Agronomy 2022, 12, 3005. [Google Scholar] [CrossRef]

- Hadj Abdelkader, O.; Bouzebiba, H.; Pena, D.; Aguiar, A.P. Energy-Efficient IoT based Light Control System in Smart Indoor Agriculture. Sensors 2023, 23, 7670. [Google Scholar] [CrossRef]

- Afzali, S.; Mosharafian, S.; van Iersel, M.W.; Mohammadpour Velni, J. Development and implementation of an IoT-enabled optimal and predictive lighting control strategy in greenhouses. Plants 2021, 10, 2652. [Google Scholar] [CrossRef]

- Jiang, J.; Moallem, M.; Zheng, Y. An intelligent IoT-enabled lighting system for energy-efficient crop production. J. Daylighting 2021, 8, 86–99. [Google Scholar] [CrossRef]

- Ryu, J.H.; Subah, Z.; Baek, J. An Application of System Dynamics to Characterize Crop Production for Autonomous Indoor Farming Platforms (AIFP). Horticulturae 2023, 9, 1318. [Google Scholar] [CrossRef]

- Ting, Y.T.; Chan, K.Y. Optimising performances of LoRa based IoT enabled wireless sensor network for smart agriculture. J. Agric. Food Res. 2024, 16, 101093. [Google Scholar] [CrossRef]

- Lavanya, G.; Rani, C.; Ganeshkumar, P. An automated low cost IoT based Fertilizer Intimation System for smart agriculture. Sustain. Comput. Inform. Syst. 2020, 28, 100300. [Google Scholar] [CrossRef]

- Goap, A.; Sharma, D.; Shukla, A.K.; Rama Krishna, C. An IoT based smart irrigation management system using Machine learning and open source technologies. Comput. Electron. Agric. 2018, 155, 41–49. [Google Scholar] [CrossRef]

- Khanna, A.; Kaur, S. Evolution of Internet of Things (IoT) and its significant impact in the field of Precision Agriculture. Comput. Electron. Agric. 2019, 157, 218–231. [Google Scholar] [CrossRef]

- Bodunde, O.P.; Adie, U.C.; Ikumapayi, O.M.; Akinyoola, J.O.; Aderoba, A.A. Architectural design and performance evaluation of a ZigBee technology based adaptive sprinkler irrigation robot. Comput. Electron. Agric. 2019, 160, 168–178. [Google Scholar] [CrossRef]

- Foughali, K.; Fathallah, K.; Frihida, A. Using Cloud IoT for disease prevention in precision agriculture. Procedia Comput. Sci. 2018, 130, 575–582. [Google Scholar] [CrossRef]

- Tao, W.; Zhao, L.; Wang, G.; Liang, R. Review of the Internet of Things Communication Technologies in Smart Agriculture and Challenges. Comput. Electron. Agric. 2021, 189, 106352. [Google Scholar] [CrossRef]

- Raghuvanshi, A.; Singh, U.K.; Sajja, G.S.; Pallathadka, H.; Asenso, E.; Kamal, M.; Singh, A.; Phasinam, K. Intrusion Detection Using Machine Learning for Risk Mitigation in IoT-Enabled Smart Irrigation in Smart Farming. J. Food Qual. 2022, 2022, 3955514. [Google Scholar] [CrossRef]

- Chataut, R.; Phoummalayvane, A.; Akl, R. Unleashing the Power of IoT: A Comprehensive Review of IoT Applications and Future Prospects in Healthcare, Agriculture, Smart Homes, Smart Cities, and Industry 4.0. Sensors 2023, 23, 7194. [Google Scholar] [CrossRef] [PubMed]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Enhancing Smart Farming Through the Applications of Agriculture 4.0 Technologies. Int. J. Intell. Netw. 2022, 3, 150–164. [Google Scholar] [CrossRef]

- Seesaard, T.; Goel, N.; Kumar, M.; Wongchoosuk, C. Advances in Gas Sensors and Electronic Nose Technologies for Agricultural Cycle Applications. Comput. Electron. Agric. 2022, 193, 106673. [Google Scholar] [CrossRef]

- Kozai, T.; Niu, G.; Takagaki, M. Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production; Academic Press: Cambridge, MA, USA, 2015. [Google Scholar]

- Kharraz, N.; Szabó, I. Monitoring of water level in indoor precision vegetable production systems. J. Mech. Civ. Ind. Eng. 2022, 3, 85–91. [Google Scholar] [CrossRef]

- Kharraz, N.; Szabó, I. Monitoring of plant growth through methods of phenotyping and image analysis. Columella 2023, 10, 49–59. [Google Scholar] [CrossRef]

- Kharraz, N.; Szabó, I. Temperature sensor working protocol in the vegetable growing systems. Int. Res. J. Adv. Eng. Sci. 2023, 8, 78–82. [Google Scholar]

- Bugbee, B.G.; Salisbury, F.B. Exploring the limits of crop productivity: I. Photosynthetic efficiency of wheat in high irradiance environments. Plant Physiol. 1988, 88, 869–878. [Google Scholar] [CrossRef] [PubMed]

- Kim, G.D.; Wheeler, H.-H.; Wheeler, R.M. Plant productivity in response to LED lighting. HortScience 2008, 43, 1951–1956. [Google Scholar]

- Minervini, M.; Scharr, H.; Tsaftaris, S.A. Image Analysis: The New Bottleneck in Plant Phenotyping. IEEE Signal Process. Mag. 2015, 32, 126–131. [Google Scholar] [CrossRef]

- Tsaftaris, S.A.; Minervini, M.; Scharr, H. Machine Learning for Plant Phenotyping Needs Image Processing. Trends Plant Sci. 2016, 21, 989–991. [Google Scholar] [CrossRef] [PubMed]

- Busemeyer, L.; Ruckelshausen, A.; Möller, K.; Melchinger, A.E.; Würschum, T. Precision Phenotyping of Biomass Accumulation in Triticale Using Image Analysis. Field Crops Res. 2013, 141, 67–76. [Google Scholar] [CrossRef]

- Mitchell, C.A.; Both, A.-J.; Bourget, C.M.; Burr, J.F.; Kubota, C.; Lopez, R.G.; Morrow, R.C.; Runkle, E.S. LEDs: The future of greenhouse lighting! Chron. Hortic. 2012, 52, 6–11. [Google Scholar]

- Dueck, T.A.; Grashoff, C.; Broekhuijsen, G.; Marcelis, L.F.M. Efficiency of light energy used by leaves situated in different levels of a sweet pepper canopy. Acta Hortic. 2006, 711, 201–205. [Google Scholar] [CrossRef]

- Hall, S.; Bhattarai, S.; Midmore, D. The effects of photoperiod on phenological development and yields of industrial hemp. J. Nat. Fibers 2014, 11, 87–106. [Google Scholar] [CrossRef]

- Malinovskyi, O.; Rahimnejad, S.; Stejskal, V.; Boňko, D.; Stará, A.; Velíšek, J.; Policar, T. Effects of different photoperiods on growth performance and health status of largemouth bass (Micropterus salmoides) juveniles. Aquaculture 2022, 548, 737631. [Google Scholar] [CrossRef]

- Petit, G.; Beauchaud, M.; Attia, J.; Buisson, B. Food intake and growth of largemouth bass (Micropterus salmoides) held under alternated light/dark cycle (12L:12D) or exposed to continuous light. Aquaculture 2003, 228, 397–401. [Google Scholar] [CrossRef]

- Saengtharatip, S.; Lu, N.; Takagaki, M.; Kikuchi, M. Productivity and Cost Performance of Lettuce Production in a Plant Factory Using Various Light-Emitting Diodes of Different Spectra. J. ISSAAS 2018, 24, 1–9. [Google Scholar]

- Garcillanosa, M.M.; Batino, Z.M., Jr.; Gabuyo, E.A.; Mojica, T.L.; Mundo, M.A.D.; Impelido, D.G.; Sison, M.P.A.A. Efficient and Low-Cost Method of Smart Indoor Vertical Farming for Lactuca sativa L. with Machine Learning. Chem. Eng. Trans. 2023, 106, 535–540. [Google Scholar] [CrossRef]

- Wang, L.; Ning, S.; Zheng, W.; Guo, J.; Li, Y.; Li, Y.; Chen, X.; Ben-Gal, A.; Wei, X. Performance Analysis of Two Typical Greenhouse Lettuce Production Systems: Commercial Hydroponic Production and Traditional Soil Cultivation. Front. Plant Sci. 2023, 14, 1165856. [Google Scholar] [CrossRef] [PubMed]

- Md Saad, M.H.; Hamdan, N.M.; Sarker, M.R. State of the art of urban smart vertical farming automation system: Advanced topologies, issues and recommendations. Electronics 2021, 10, 1422. [Google Scholar] [CrossRef]

- Poorter, H.; Niinemets, Ü.; Walter, A.; Fiorani, F.; Schurr, U. A method to construct dose–response curves for a wide range of environmental factors and plant traits by means of a meta-analysis of phenotypic data. J. Exp. Bot. 2010, 61, 2043–2055. [Google Scholar] [CrossRef]

- Katzin, G.; van Mourik, S.; van Straten, G.; van Henten, E.J. A Hierarchical Control System for Energy-Efficient Greenhouse Cultivation. Agric. Syst. 2021, 191, 103183. [Google Scholar] [CrossRef]

| Study | Primary Focus | Methodology | Multi-Parameter Control | Real-Time Adaptation | Security/IDPS | Energy Metrics | Latency | Key Innovation |

|---|---|---|---|---|---|---|---|---|

| Lavanya et al. [19] | Soil NPK monitoring | Colorimetric NPK sensor + CoAP/UDP | Limited to soil nutrients only; no coordination with other environmental factors | Lacks dynamic response; measurements are taken and sent without adaptive action | No intrusion detection or security protocols implemented | No measurement or optimization of energy usage | Approximately 300 ms | Affordable and compact NPK sensor integration |

| Goap et al. [20] | Irrigation optimization | ML-based irrigation using weather and soil data | Focused only on soil moisture and weather; does not integrate light or nutrient feedback | No real-time growth stage sensing; ML decisions are pre-trained and not plant-responsive | No discussion or handling of cybersecurity risks | Does not track energy use in pumping or communication | Approximately 300 ms | Predictive irrigation through ML modeling |

| Khanna and Kaur [21] | Survey of IoT gaps in precision agriculture and CEA | Literature review of top cited IoT studies in agriculture | Identifies lack of integration across systems | Highlights missing dynamic responsiveness | Notes security concerns but lacks implementation | Emphasizes absence of plant-level energy use metrics | Recognizes delays in feedback systems | Maps critical research gaps like LUE, energy waste, and lack of closed loop control |

| Bodunde et al. [22] | Mobile irrigation | ZigBee communication with mobile robot | Focuses solely on soil moisture distribution; no coordination with light or nutrient control | Partially adaptive to soil moisture maps but not fully autonomous or continuous | No security measures for robot control or data streams | No mention of power efficiency of mobile units | Around 100 ms | Water precision via robotic mobility |

| Foughali et al. [23] | Disease prevention | ZigBee-based sensing + cloud DSS | Addresses disease and climate but lacks integration with lighting, irrigation, or nutrients | Not responsive to growth stage conditions in real time; latency in cloud processing | No built-in protection against data interception or tampering | Energy consumption not assessed, despite continuous monitoring | Several minutes due to cloud processing | Early detection of growth stage disease via DSS |

| Zhang et al. [3] | Light intensity optimization | Static light control using fixed PAR values | Optimizes light but does not consider nutrient, water, or temperature interactions | Uses fixed values; no growth stage feedback or stage-based adjustment | No protection mechanisms for network or device security | Energy use implied but not analyzed in light energy terms | Not specified | Demonstrated improved growth from PAR tuning |

| Benyezza et al. [24] | Zoning irrigation | Fuzzy logic control with wireless sensors | Coordinates soil moisture and temperature in specific zones but excludes light or nutrient metrics | Adaptable zoning improves local responses but lacks real-time growth stage sensing | No security or encryption techniques used in WSN | Improves water efficiency, but no broader energy assessment | Less than 1 s | Intelligent irrigation zoning through FLC |

| Raghuvanshi et al. [25] | Cybersecurity in agriculture | Machine learning-based IDS for smart irrigation | Focused on network-layer threats; does not manage any growth stage or environmental parameters | No feedback from plants or sensors; strictly a cyber-layer solution | High-accuracy intrusion detection using SVM and Random Forest | Energy use of the IDS or system not considered | Not applicable | Strong threat detection for agricultural IoT |

| Chataut et al. [26] | Literature survey | Review of agricultural IoT trends and tools | Identifies challenges across multiple domains but lacks specific system implementation | Synthesizes past work rather than proposing adaptive strategies | Points out security gaps but does not propose or test solutions | Recognizes need for energy efficiency but lacks quantitative data | Not applicable | Comprehensive identification of research bottlenecks |

| Javaid et al. [27] | Agriculture 4.0 integration | Conceptual model combining AI, IoT, robotics, and blockchain | Promotes system-wide synergy but remains theoretical without deployment details | Predictive in concept, but no direct sensor–actuator implementation shown | Discusses blockchain potential but lacks direct experimentation | Energy efficiency assumed in abstract terms, not measured | Not applicable | Conceptual integration of next-gen agri-technologies |

| Seesaard et al. [28] | Gas sensing in agriculture | Review of gas sensor and E-nose technologies | Broad in sensor types but not integrated with environmental controls or decision systems | Provides sensing options but lacks discussion on automation or feedback loops | Focuses on sensor function; no attention to data privacy or network safety | Technical discussion of sensors only; no analysis of power use in context | Not applicable | Extensive catalog of E-nose and gas sensor evolution |

| Our System | LUE-based optimization | Logistic growth model + real-time sensor–actuator feedback | Integrates light, soil moisture, and canopy health for closed-loop control | Dynamically adjusts spectrum and intensity based on growth stage needs | Currently lacks built-in security layer; potential for future integration | Tracks energy efficiency using LUEP and LUEL | Under 2 s end-to-end | Real-time optimization of light use for biomass gain |

| Property | Details |

|---|---|

| LED Model | Programmable full-spectrum LED panels |

| Brightness (PAR) | 150–400 µmol/m2/s |

| Power | 25 W per LED panel |

| Temperature | Operating range: 22–25 °C |

| Control | Raspberry Pi + Arduino relay modules |

| Spectral Ratios | Seedling: High blue (0.3:0.7:0.0) |

| Vegetative: Balanced blue-red (0.2:0.7:0.1) | |

| Flowering: High red (0.1:0.8:0.1) |

| Configuration | Number of LEDs | Lighting Hours per Day | Light Intensity (µmol/m2/s) | Spectrum Ratio (Blue/Red/Far-Red) |

|---|---|---|---|---|

| Config A | 2 LEDs | 12 h | 150 | 0.3:0.7:0.0 |

| Config B | 3 LEDs | 16 h | 250 | 0.2:0.7:0.1 |

| Config C | 4 LEDs | 18 h | 350 | 0.2:0.6:0.2 |

| Config D | 5 LEDs | 20 h | 400 | 0.1:0.8:0.1 |

| Metric | Full Name | Formula | Focus | Scope | Suitability for Indoor Farming |

|---|---|---|---|---|---|

| LUEP | Light Use Efficiency at Growth stage Canopy Level | Measures absorbed PAR at canopy | Lighting + growth stage biomass | Highly suitable | |

| LUEL | Light Use Efficiency at Lamp Level | Measures canopy PAR reception | Lighting configuration | Highly suitable | |

| RUE | Radiation Use Efficiency | Conversion of intercepted PAR to biomass | Field and greenhouse systems | Limited indoors | |

| NPP | Net Primary Productivity | GPP: Total carbon assimilated Ra: Energy “cost” of lettuce metabolism | Net biomass production | All ecosystems | Indirect light focus |

| CYE | Crop Yield Efficiency | Yield-based productivity metric | Crop yield studies | Dependent on multiple factors |

| Step | Parameter | Value |

|---|---|---|

| Grayscale Conversion | LAB channel | L* |

| Binary Threshold | Threshold value | 120 (0–255) |

| Hole Filling | Max hole size | 100 pixels |

| Smoothing | Kernel size, iterations | 3 × 3, 1 |

| Brightness Adjustment | α (contrast), β (brightness) | 1.2, +50 (brighter)/−50 (darker) |

| Parameter | Wi-Fi | Ethernet |

|---|---|---|

| (Sensor Delay) | 5 ms | 5 ms |

| (Comm Delay) | 2.001 ms | 1.0001 ms |

| (Cloud Processing) | 10 ms | 10 ms |

| (Command Back) | 5 ms | 5 ms |

| (Ψ) | 22.001 ms | 21.0001 ms |

| (No Retries) | 0.95 | 0.99 |

| 23.158 ms | 21.212 ms |

| Parameter in Point-to-Point | Parameter in Cloud | Point-to-Point Average Delay (ms) | Cloud Average Delay (ms) |

|---|---|---|---|

| β1 (sensor reading) | β1 (sensor reading) | 0.06629 | 0.072008 |

| (β2 + β4)/2 (communication delay) | β2 + β4 (communication delay) | 138.685722 | 403.176788 |

| - | β3 (Cloud processing delay) | - | 75.5572 |

| β3 (evaluation and actuator processing delay) | β5 (actuator processing delay) | 0.163356 | 0.011846 |

| Total processing delay | 277.606808 | 478.812124 |

| Growth Stage | Light Spectrum | Light Intensity | Photoperiod | Key Benefits |

|---|---|---|---|---|

| Seedling Stage | High Blue Light | 200–300 μmol/m2/s | 14–16 h/day | Promotes compact growth and strong chlorophyll absorption. |

| Vegetative Stage | Balanced Blue-Red Light | 300–400 μmol/m2/s | 16–17 h/day | Maximizes photosynthesis efficiency and biomass growth. |

| Flowering Stage | High Red Light | 300–400 μmol/m2/s | 16–17 h/day | Enhances reproductive growth and biomass accumulation. |

| Configuration | PAR Emitted (μmol/m2/s) | PAR Received (μmol/m2/s) | PAR Absorbed (μmol/m2/s) | LUEP | LUEL |

|---|---|---|---|---|---|

| Config A | 300 | 240 | 216 | 0.73 | 0.78 |

| Config B | 750 | 600 | 540 | 0.72 | 0.79 |

| Config C | 1400 | 1120 | 1008 | 0.71 | 0.80 |

| Config D | 2000 | 1600 | 1440 | 0.70 | 0.81 |

| Condition | Leaf_Count | Plant_Area | Mean_Hue | Saturvvation | Value |

|---|---|---|---|---|---|

| Original | 279 | 6864455 | 41.02836009 | 53.94690467 | 127.1086289 |

| Brighter | 44 | 11432135 | 40.19186455 | 37.21804819 | 197.1930414 |

| Darker | 730 | 4250962 | 42.11890508 | 92.07262453 | 102.6295178 |

| Image Metric | Growth Proxy | Biological Interpretation |

|---|---|---|

| Leaf Count | Vegetative biomass, development | Higher counts suggest more foliage; sensitive to segmentation accuracy. |

| Growth stage Area | Canopy size, light interception | Indicates growth extent and potential photosynthetic surface area. |

| Hue | Chlorophyll content | Stable hue implies consistent pigmentation; shifts may indicate stress. |

| Saturation | Water content, senescence | Lower saturation may relate to dehydration or tissue aging. |

| Value | Light exposure, photoinhibition | High values can reflect overexposure; low values may suggest shading. |

| Study/System | Fresh Weight (g/Plant) | Productivity (g/m2/Day) | Electricity Productivity (g/kWh) | ROI |

|---|---|---|---|---|

| Our study (2025) | 600.0 | 285.0 | 95.0 | 65.0% |

| Saengtharatip et al. (2018) [43] | 180.0 | 120.0 | 30.0 | 20.0% |

| Garcillanosa et al. (2023) [44] | 270.0 | 54.0 | 86.5 | 27.2% |

| Wang et al. (2023)—HPS [45] | 228.0 | 22.7 * | 35.0 | 35.0% |

| Wang et al. (2023)—SBS [45] | 291.0 | 30.2 * | 75.0 | 18.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kharraz, N.; Revoly, A.; Szabó, I. IoT-Based Adaptive Lighting Framework for Optimizing Energy Efficiency and Crop Yield in Indoor Farming. J. Sens. Actuator Netw. 2025, 14, 59. https://doi.org/10.3390/jsan14030059

Kharraz N, Revoly A, Szabó I. IoT-Based Adaptive Lighting Framework for Optimizing Energy Efficiency and Crop Yield in Indoor Farming. Journal of Sensor and Actuator Networks. 2025; 14(3):59. https://doi.org/10.3390/jsan14030059

Chicago/Turabian StyleKharraz, Nezha, András Revoly, and István Szabó. 2025. "IoT-Based Adaptive Lighting Framework for Optimizing Energy Efficiency and Crop Yield in Indoor Farming" Journal of Sensor and Actuator Networks 14, no. 3: 59. https://doi.org/10.3390/jsan14030059

APA StyleKharraz, N., Revoly, A., & Szabó, I. (2025). IoT-Based Adaptive Lighting Framework for Optimizing Energy Efficiency and Crop Yield in Indoor Farming. Journal of Sensor and Actuator Networks, 14(3), 59. https://doi.org/10.3390/jsan14030059