Optimized Dual-Battery System with Intelligent Auto-Switching for Reliable Soil Nutrient Monitoring in Remote IoT Applications

Abstract

1. Introduction

2. Related Works

3. System Model

- Power Monitoring Module: Measures voltage and current with ±0.1% accuracy at 1 Hz sampling.

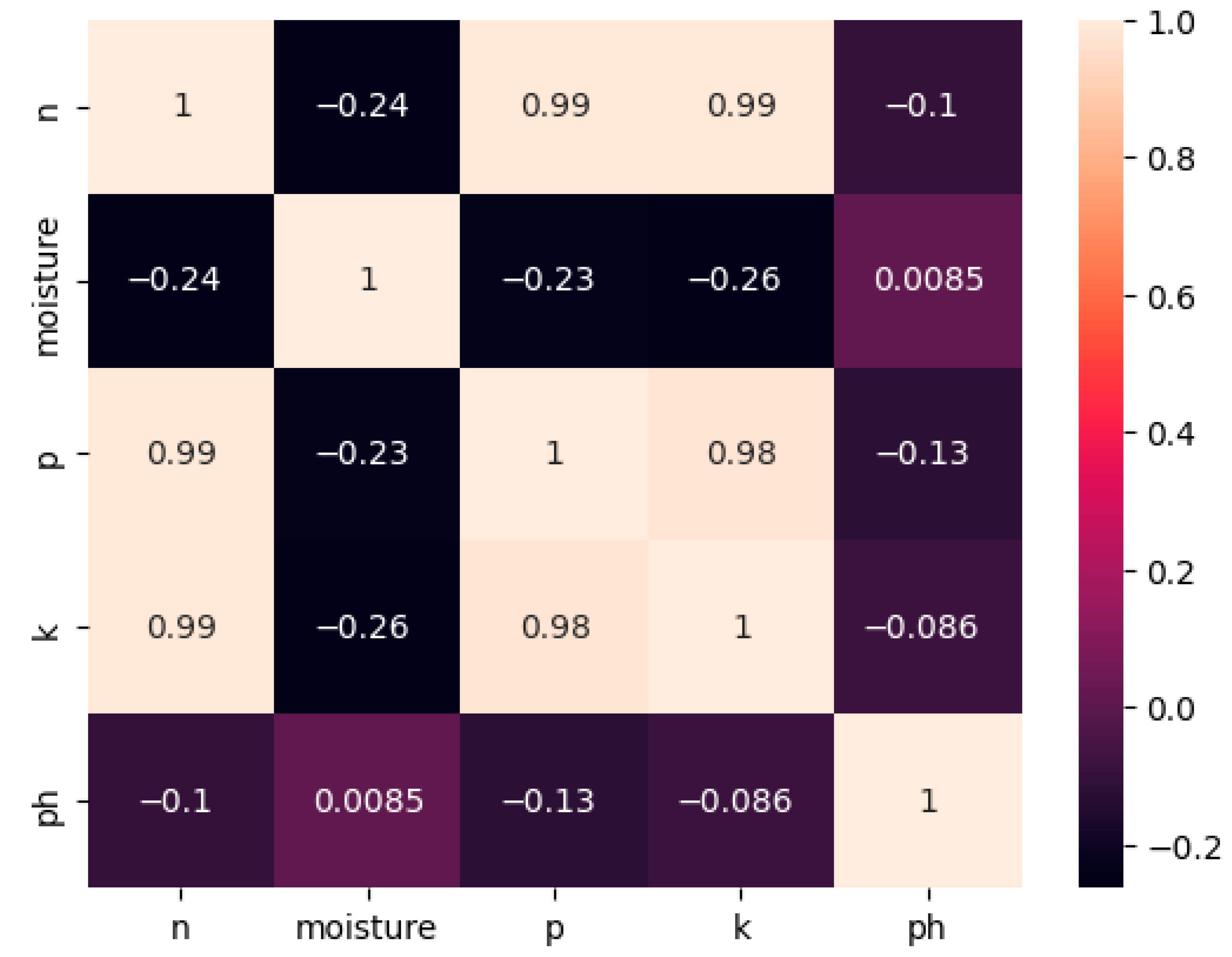

- Soil Monitoring Module: Detects soil nutrients (nitrogen, phosphorus, potassium), pH (0–14), moisture (0–100%), and temperature (0–50 °C).

- Battery 1 (Primary): A 5 V, 5000 mAh Lithium-Sulphur (Li-S) cell, optimised for high energy density and prolonged lifespan.

- Battery 2 (Backup): A 5 V, 4000 mAh Lithium-Ion (Li-Ion) cell, designed to ensure redundancy and maintain operational continuity during critical voltage thresholds.

- Over-voltage (OVP) and under-voltage (UVP) protection;

- Automatic battery switching triggered at a 4.5 V threshold;

- Voltage regulation and current limitation, with a maximum output of 2 A.

- Power Monitoring Module: Measures voltage (3.7–5.2 V) and current (0–3 A) in real time at a 1 Hz sampling rate, facilitating detailed performance analysis and energy profiling.

- Soil Monitoring Module: Employs sensors to measure soil nutrient levels (nitrogen, phosphorus, and potassium), pH (0–14), moisture content (0–100%), and temperature (0–50 °C).

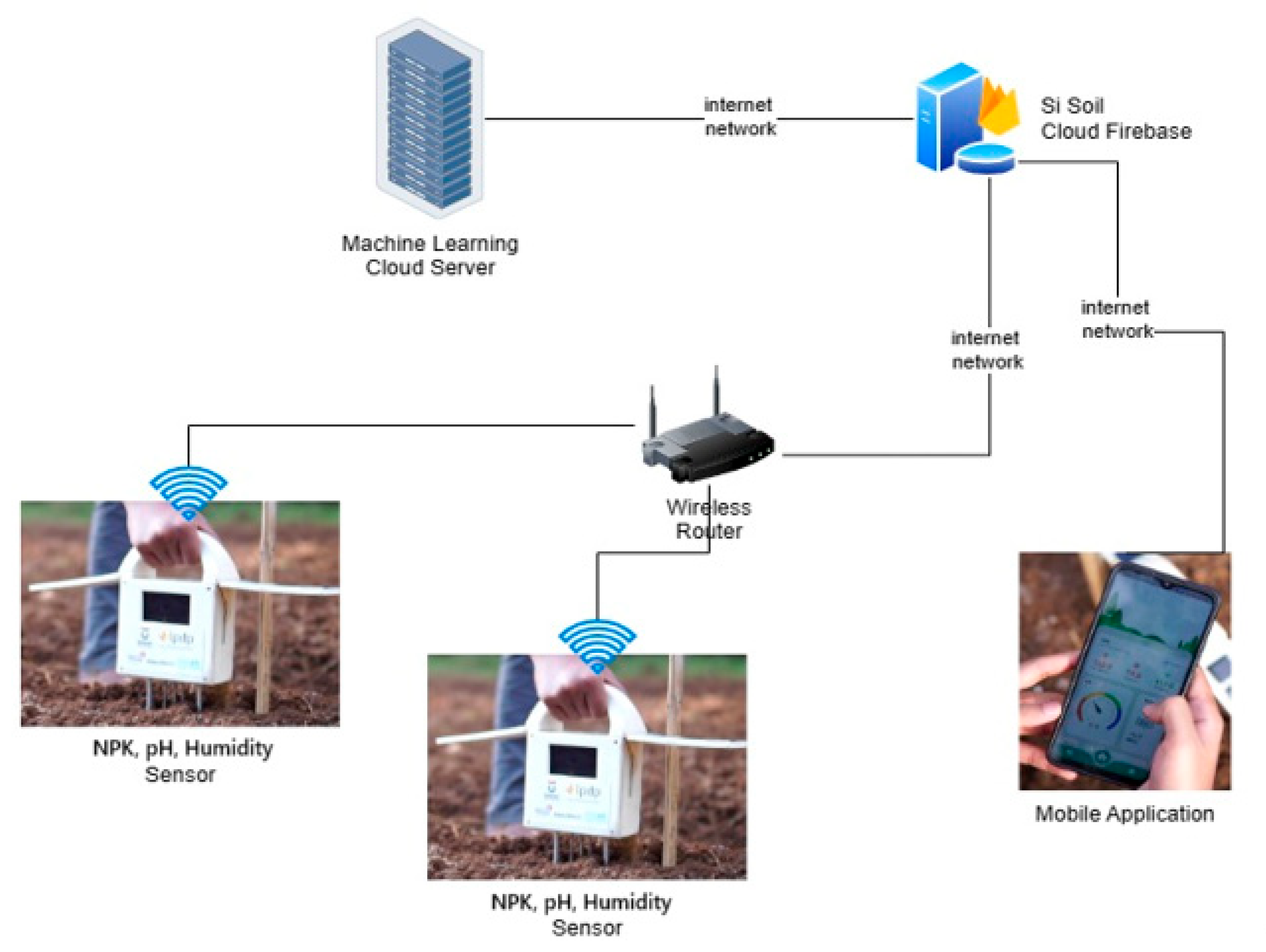

- IoT Gateway: Acts as a communication hub supporting WiFi, Bluetooth Low Energy (BLE), and Ethernet for cloud connectivity, transmitting data from the monitoring modules at 60 s intervals with an average power consumption of 0.5 W.

3.1. Soil Monitoring: Step 1

3.2. Description of the Si-Soil Measurement Tool: Step 2

- Measurement Range:

- ○

- Moisture: 0% to 100%;

- ○

- Temperature: –20 °C to 60 °C;

- ○

- pH: 3.0 to 10.0;

- ○

- NPK Detection Sensitivity: 0 to 500 mg/L.

- Sensor Accuracy:

- ○

- Moisture: ±3%;

- ○

- Temperature: ±0.5°C;

- ○

- pH: ±0.2 units.

- Communication Interface: Wi-Fi-based data transmission.

- Power Source: Dual-battery system with automatic switching to enhance operational longevity.

- IoT Node Setup

- 2.

- Power Management System

- 3.

- Data Collection Protocol

- 4.

- Calibration and Validation

3.3. IoT Node Power Consumption: Step 3

- Active Monitoring State: The node used an average of 280 milliamperes (mA) at 5 volts (V) during continuous data collection and transmission, with transient spikes during transmission bursts reaching 310 mA.

- Standby State: Power consumption dropped to about 70 mA at 5 V in a low-power state (when sensors were kept in an active state).

- Sleep Mode: A deep-sleep mode lowered power consumption to 15 mA at 5 V during prearranged inactivity periods.

3.4. Energy Harvesting and Auto-Switching: Step 4

- Energy Harvesting Component:

- A 5 V, 10 W photovoltaic module was integrated to harvest solar energy during daylight hours.

- The solar panel charged the primary Lithium-Ion battery through a charge controller, which stabilised input voltage and prevented overcharging.

- Automatic Switching Circuit:

- A voltage monitoring system continuously evaluated the voltage levels of both the primary and secondary batteries.

- When the primary battery’s voltage fell below a predefined threshold of 4.5 V, the circuit promptly disconnected it and engaged the secondary lithium-polymer battery.

- The switching mechanism was engineered to occur instantaneously, ensuring uninterrupted data collection and system operation without downtime.

- Battery Management System (BMS):

- This system continuously monitored key parameters, including voltage, current, temperature, and state of charge (SoC), for both batteries.

- Safety protocols were implemented to prevent overcharging, deep discharge, and thermal runaway, thereby extending the operational lifespan of the batteries.

3.5. Dynamic Load Balancing (DLB) with Power Allocation Optimisation (PAO)

- and = Power allocated from the primary and secondary batteries.

- and = State of Charge for each battery.

- and = Power efficiency for each battery.

- = System power load, which must be optimally distributed.

- State of Charge (SoC) of Each Battery:

- If is significantly higher than , the system prioritises the use of the primary battery to prevent uneven power depletion.

- If and are approximately equal, the system distributes power proportionally to optimise and extend the operational lifespan of both batteries.

- Real-Time Power Load:

- During high-load conditions, the system implements load-sharing to allocate power between both batteries, thereby mitigating excessive strain on any single unit.

- Under low-load conditions, the system utilises a single battery, maintaining the other in an inactive state to reduce charging cycles and prolong its operational lifespan.

- Power Efficiency of Each Battery:

- 4.

- Optimal Load Allocation for Each Battery:

- 5.

- Switching Process and Load Balancing

3.6. System Implementation

3.7. IoT Network Topology

4. Performance Results

- Type: High-Density Lithium-Ion;

- Capacity: 5000–6000 mAh;

- Voltage: 5 V;

- Operational Time: 24 × 7 h (1 week).

- Type: Lithium Polymer (LiPo);

- Capacity: 4000–5000 mAh;

- Voltage: 5 V;

- Switchover Capability: Immediate Activation.

4.1. Simulation Methodology

- Assess the endurance and uptime of various battery configurations.

- Analyse the switching behaviour and control logic under varying load conditions.

- Quantify battery usage efficiency and system-level fault tolerance.

- Evaluate the impact of optimisation algorithms (PAO and GA) on the longevity of the power system.

4.2. System Components and Modelling Approach

- Primary Battery (Li-S): Modelled with custom discharge characteristics derived from empirical studies and recent datasheets, featuring a nominal voltage of 3.6 V and a capacity of 5000 mAh.

- Secondary Battery (Li-Ion): Simulated using Simscape’s built-in Lithium-Ion module, with parameters adjusted to a nominal voltage of 3.7 V and a capacity of 2200 mAh.

- Switching Controller: Implemented as a state machine, governed by threshold-based voltage feedback with hysteresis to prevent oscillatory switching. Thresholds were set at 3.0 V for the Li–S battery and 3.2 V for the Li-Ion battery.

- System Load Profile: Based on a real-world ESP32 workload, comprising periodic sensing and data transmission: 180 mA for 2 s (active), followed by 0.8 mA for 58 s (sleep), yielding an average consumption of approximately ~4.93 mAh/hour.

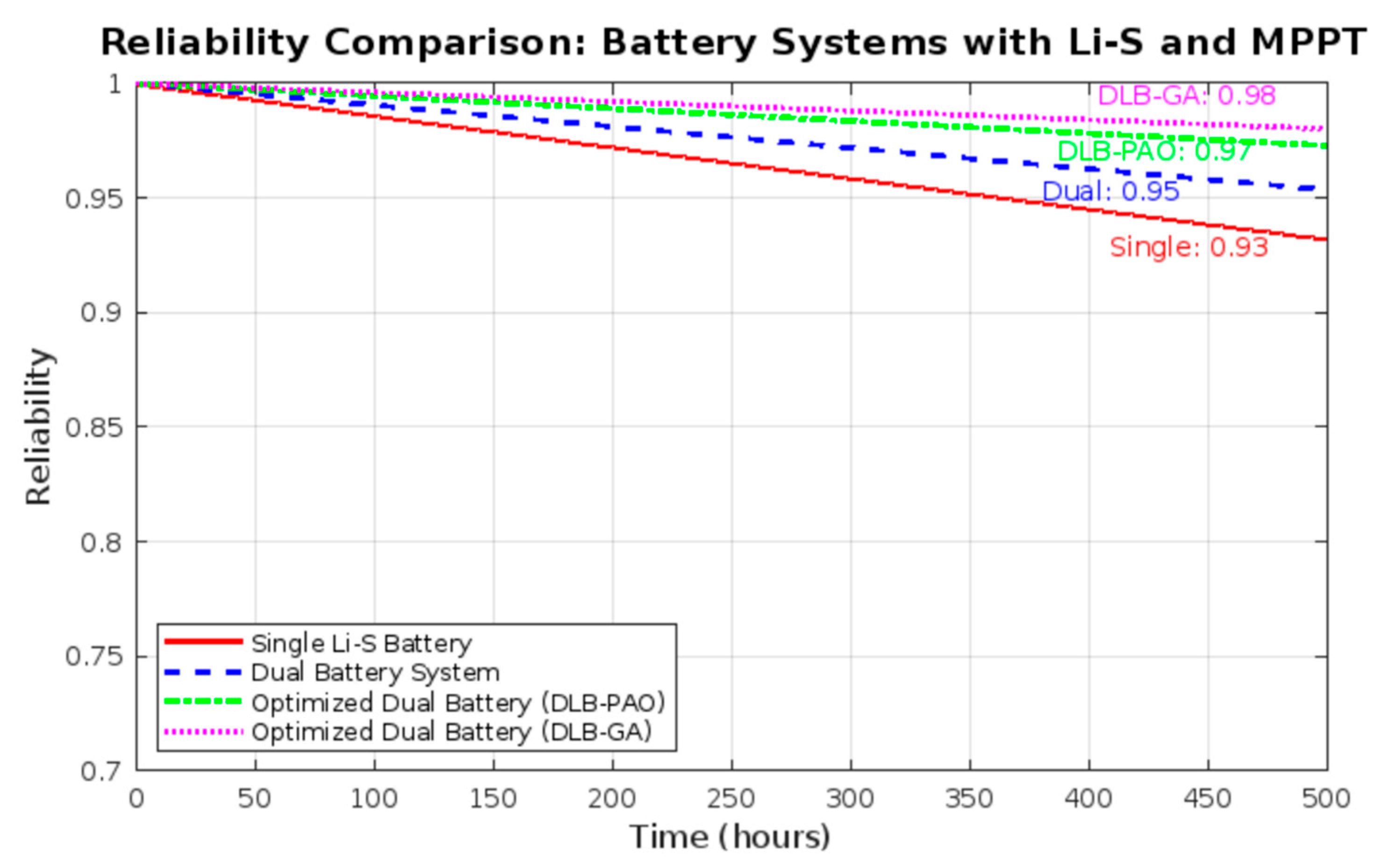

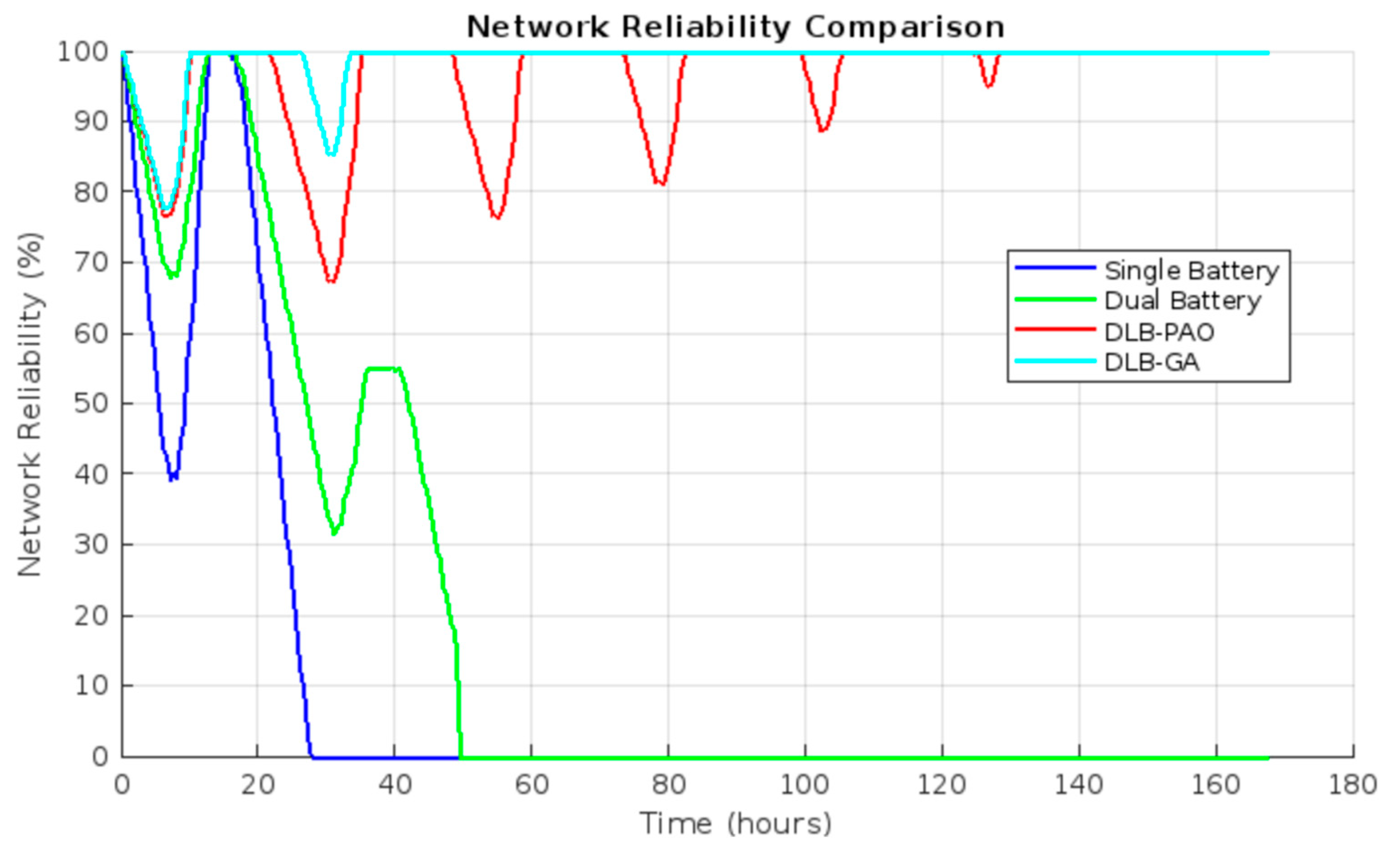

4.3. Simulation Scenarios

- C1—Single Battery (Li-S) without switching;

- C2—Dual battery (Li-S + Li-Ion) with fixed-threshold switching;

- C3—Optimised dual battery using Pattern-Adaptive Optimisation (DLB–PAO);

- C4—Optimised dual battery using Genetic Algorithm (DLB–GA).

4.4. Optimisation Framework

- The PAO algorithm dynamically adjusts switching thresholds in response to historical load patterns and voltage decay gradients.

- The GA-based optimisation iteratively refines threshold values and sleep duty-cycle parameters over 50 generations, employing a population size of 20. A multi-objective fitness function prioritises maximising system uptime while minimising switching frequency.

4.5. Battery Configuration

4.6. Mathematical Modelling of System Reliability

4.7. Reliability Justification for Dual-Battery System

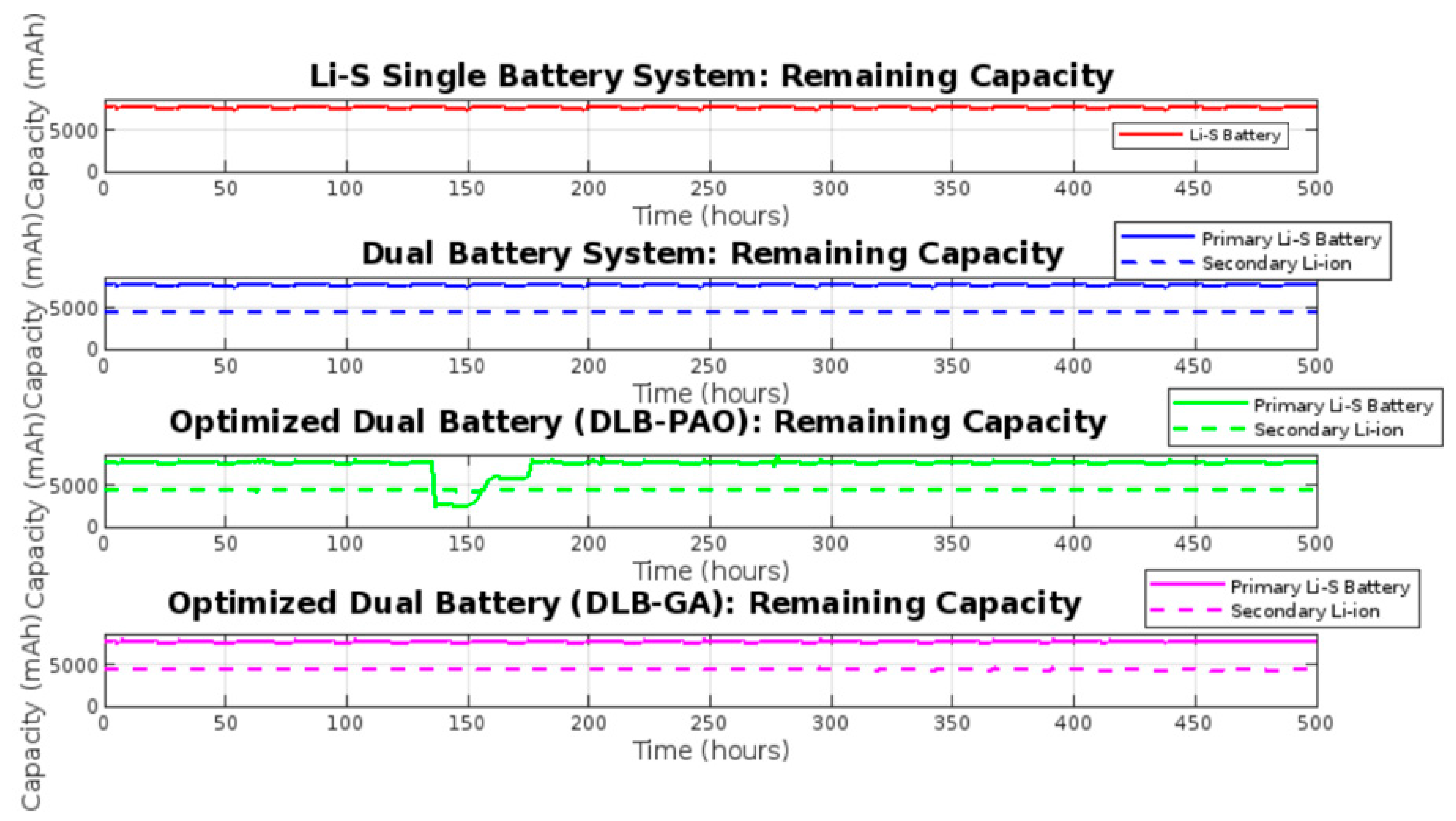

4.8. Remaining Capacity

4.8.1. Mathematical Model of Battery Capacity Degradation

- : Residual capacity at time .

- : Initial battery capacity.

- : Degradation coefficient.

- : Cumulative degradation function dependent on load profile, charge cycles, and temperature.

- Comparative System Analysis

- Single-Battery System (Li-S):

- b.

- Dual-Battery System:

- c.

- Optimised Dual-Battery (DLB–PAO):

- d.

- Optimised Dual Battery (DLB–GA):

4.8.2. Mathematical Implications for System Optimisation

4.8.3. Comprehensive Analysis

- System Efficiency

- 2.

- Harvesting Efficiency

- 3.

- Storage Utilisation

- 4.

- Waste Percentage

4.8.4. Advanced Mathematical Analysis

4.8.5. Mathematical Model of System Efficiency

- Superiority of the Dual-Battery System: Dual-battery systems (Dual Battery, DLB–PAO, DLB–GA) consistently outperform the single-battery system across all evaluated parameters, demonstrating statistically significant performance advantages.

- Homogeneity of DLB Variants: No statistically significant differences are observed between the DLB variants (DLB–PAO, DLB–GA) and the standard dual-battery system. This suggests that distinguishing factors such as implementation complexity, cost, or long-term durability may require analysis beyond the current parameter set.

- Efficiency–Waste Trade-off: The strong inverse correlation between system efficiency and waste percentage confirms that higher efficiency corresponds to reduced energy losses.

- Optimisation of Storage Utilisation: The most substantial relative improvement (27.8%) is observed in storage utilisation, underscoring the dual-battery configuration’s enhanced ability to maximise energy storage efficiency.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Selvakumar, R.B.; Vivekanandan, C.; Sharma, H.; Vekariya, V.; Varma, R.A.; Mohanavel, V.; Ramkumar, G.; Kumar, A.M.; Abdullah-Al-Wadud, M. Energy management of a dual battery energy storage system for electric vehicular application. Comput. Electr. Eng. 2024, 115, 109099. [Google Scholar] [CrossRef]

- Nyamathulla, S.; Dhanamjayulu, C. A review of battery energy storage systems and advanced battery management system for different applications: Challenges and recommendations. J. Energy Storage 2024, 86, 111179. [Google Scholar] [CrossRef]

- Liu, W.; Placke, T.; Chau, K.T. Overview of batteries and battery management for electric vehicles. Energy Rep. 2022, 8, 4058–4084. [Google Scholar] [CrossRef]

- Khare, V.; Khare, C.; Nema, S.; Baredar, P. Renewable energy system paradigm change from trending technology: A review. Int. J. Sustain. Energy 2021, 40, 697–718. [Google Scholar] [CrossRef]

- Šriupša, L.; Vaitkūnas, M.; Baronas, A.; Dosinas, J. Analysis of self-generated PV energy consumption profiles in prosumers microgrid. Int. J. Sustain. Energy 2023, 42, 1583–1602. [Google Scholar] [CrossRef]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Smart grid technologies and application in the sustainable energy transition: A review. Int. J. Sustain. Energy 2023, 42, 685–758. [Google Scholar] [CrossRef]

- Senapaty, M.K.; Ray, A.; Padhy, N. IoT-enabled soil nutrient analysis and crop recommendation model for precision agriculture. Computers 2023, 12, 61. [Google Scholar] [CrossRef]

- Swathi, T.; Rasiga, T.D.; Sudha, S. Design of an IoT Based Soil Monitoring System. In Proceedings of the 2023 International Conference on IoT, Communication and Automation Technology (ICICAT), Gorakhpur, India, 23–24 June 2023; pp. 1–6. [Google Scholar]

- Sayyad, S.B.; Shaikh, M.A.; Anpat, S.M.; Kolapkar, M.M. IoT based soil monitoring for precision agriculture. Remote Sens. Precis. Agric. 2024, 43–59. [Google Scholar] [CrossRef]

- Sharanappa, R. Nutrient availability in soil and crop response. Soil Fertil. Nutr. Manag. 2022, 9–14. [Google Scholar] [CrossRef]

- Perdana, D.; Doan, A. Performance analysis of LoRaWAN Class A and Class C in the measurement of nutrient content systems. Int. J. Intell. Eng. Syst. 2023, 16, 388–404. [Google Scholar]

- Kumar, N.; Saha, T.K.; Dey, J. Power electronics and solar panel: Solar panel design and implementation. Green Energy Sol. Energy Photovolt. Smart Cities 2020, 139–165. [Google Scholar]

- Horiba, T. Lithium-ion battery systems. Proc. IEEE 2014, 102, 939–950. [Google Scholar] [CrossRef]

- Kimura, S.A.; Wijanto, H.; Rafsanzani, F.F.A.; Prananditiya, H.; Ichwan, A.A. Development of the electronic power subsystem design for Tel-USAT. In Proceedings of the 2019 IEEE International Conference on Signals and Systems (ICSigSys), Bandung, Indonesia, 16–18 July 2019; pp. 120–125. [Google Scholar]

- Räber, M.; Heinzelmann, A.; Taeschler, A. Beneficial effects of active charge balancing in lithium-ion battery systems. J. Clean Energy Technol. 2016, 4, 225–228. [Google Scholar] [CrossRef]

- Rakesh, N.; Santosh, T.; Malavya, U.; Rishikesh, D. Battery Management System for Solar PV Panel. In Proceedings of the International Conference on Innovative Mechanisms for Industry Applications (ICIMIA), Bengaluru, India, 21–23 February 2017. [Google Scholar]

- Venkatasetty, H.V.; Jeong, Y.U. Recent advances in lithium-ion and lithium-polymer batteries. In Proceedings of the Seventeenth Annual Battery Conference on Applications and Advances. Proceedings of Conference (Cat. No. 02TH8576), Long Beach, CA, USA, 18 January 2002; pp. 173–178. [Google Scholar]

- Wibowo, S.; Marcel, F. Performance Comparison of Time Scheduling Dual Axis Cartesian-Active Solar Panel and Static Solar Panel. In Proceedings of the 2023 International Conference on Electrical and Information Technology (IEIT), Malang, Indonesia, 14–15 September 2023; pp. 354–360. [Google Scholar]

- Udutalapally, V.; Mohanty, S.P.; Pallagani, V.; Khandelwal, V. sCrop: A novel device for sustainable automatic disease prediction, crop selection, and irrigation in Internet-of-Agro-Things for smart agriculture. IEEE Sens. J. 2020, 21, 17525–17538. [Google Scholar] [CrossRef]

- La Rosa, R.; Dehollain, C.; Costanza, M.; Speciale, A.; Viola, F.; Livreri, P. A battery-free wireless smart sensor platform with bluetooth low energy connectivity for smart agriculture. In Proceedings of the 2022 IEEE 21st Mediterranean Electrotechnical Conference (MELECON), Palermo, Italy, 14–16 June 2022; pp. 554–558. [Google Scholar]

- Chand, A.A.; Prasad, K.A.; Mar, E.; Dakai, S.; Mamun, K.A.; Islam, F.R.; Mehta, U.; Kumar, N.M. Design and analysis of photovoltaic powered battery-operated computer vision-based multi-purpose smart farming robot. Agronomy 2021, 11, 530. [Google Scholar] [CrossRef]

- Benzaouia, M.; Hajji, B.; Rabhi, A.; Mellit, A.; Benslimane, A.; Dubois, A.M. Energy management strategy for an optimum control of a standalone photovoltaic-batteries water pumping system for agriculture applications. In Proceedings of the 2nd International Conference on Electronic Engineering and Renewable Energy Systems: ICEERE 2020, Saidia, Morocco, 13–15 April 2020; pp. 855–868. [Google Scholar]

- Et-taibi, B.; Abid, M.R.; Boumhidi, I.; Benhaddou, D. Smart agriculture as a cyber physical system: A real-world deployment. In Proceedings of the 2020 Fourth International Conference on Intelligent Computing in Data Sciences (ICDS), Fez, Morocco, 21–23 October 2020; pp. 1–7. [Google Scholar]

- Hijriawan, M.; Arifin, Z.; Tjahjana, D.; Kuncoro, I. Performance analysis of flat winglet deflector on hybrid solar PV-Wind turbine system: Case study on twisted Savonius turbine. J. Appl. Eng. Sci. 2024, 22, 69–80. [Google Scholar] [CrossRef]

- Perdana, D.; Darmawan, D.; Ismardi, A.; Enriko, I.K.A.; Fathona, I.W.; Cahyono, O. Increasing the measurement of soil water content with the characterization of magnetic field induction sensors using model equations for the internet of thing application. J. Appl. Eng. Sci. 2022, 20, 137–144. [Google Scholar] [CrossRef]

- Oyinkanola, L.A. Performance assessment based on Intelligent power management for standalone PV system in remote area of Ibadan, Nigeria. J. Appl. Eng. Sci. 2019, 17. [Google Scholar]

- Moldabayeva, G.Z.; Suleimenova, R.T.; Akhmetov, S.M.; Shayakhmetova, Z.B.; Suyungariyev, G.E. The process of monitoring the current condition of oil recovery at the production fields in Western Kazakhstan. J. Appl. Eng. Sci. 2021, 19, 1099–1107. [Google Scholar] [CrossRef]

- Shayeghi, H.; Pourjafar, S.; Sedaghati, F. A Buck-Boost Converter; Design, Analysis and Implementation Suggested for Renewable Energy Systems. Iran. J. Electr. Electron. Eng. 2021, 17, 1862. [Google Scholar]

- Toodeji, H. A Hybrid Switching Technique for Single-Phase AC-Module PV System to Reduce Power Losses and Minimize THD. Iran. J. Electr. Electron. Eng. 2020, 16, 13–25. [Google Scholar]

- Masikana, S.B.; Sharma, G.; Sharma, S.; Bokoro, P.N.; Çelik, E. Solar PV focused LFC studies utilizing an SFS-optimized PID with fractional derivative (PIDDμ), and incorporating BESS and FESS applications. e-Prime—Adv. Electr. Eng. Electron. Energy 2024, 10, 100787. [Google Scholar] [CrossRef]

- Rustam, M.A.; Khan, M.Y.A.; Abbas, T.; Khan, B. Distributed Secondary Frequency Control Scheme with A-Symmetric Time Varying Communication Delays and Switching Topology. e-Prime—Adv. Electr. Eng. Electron. Energy 2024, 9, 100650. [Google Scholar] [CrossRef]

- Bakare, M.S.; Abdulkarim, A.; Shuaibu, A.N.; Muhamad, M.M. Predictive Energy Control for Grid-Connected Industrial PV-Battery Systems using GEP-ANFIS. e-Prime—Adv. Electr. Eng. Electron. Energy 2024, 9, 100647. [Google Scholar] [CrossRef]

- Kumar, P.; Arya, S.R.; Kumar, S. Adaptive fuzzy integrated LMS based control strategy for voltage power quality enhancement. e-Prime—Adv. Electr. Eng. Electron. Energy 2024, 9, 100635. [Google Scholar] [CrossRef]

- Ihsan, D.; Fadlilah, U.; Kusban, M. Design and Development of Object Detection Radar with IoT-Based Matlab Software Visualization. Emit. J. Tek. Elektro 2024, 24, 154–156. [Google Scholar]

- Susanto, H.; Nurcahyo, A. Design and Implementation of a Smart Home Security System Using Voice Command and Internet of Things. Khazanah Inform. 2020, 6. [Google Scholar] [CrossRef]

| Works | Methods | Focuses | ||

|---|---|---|---|---|

| IoT-Based Monitoring | Soil Nutrient Monitoring | Dual-Battery Switching System | ||

| Selvakumar et al. [1] | Introduced a fuzzy logic controller-based energy management system for hybrid energy storage systems (HESSs), enhancing scalability and mitigating battery degradation through adaptive load distribution. | X | X | ✓ |

| Shaik et al. [2] | Performed a comparative evaluation of conventional versus advanced state-of-charge (SoC) estimation techniques, underscoring the necessity of intelligent battery management systems (BMSs) for EV applications. | X | X | ✓ |

| Sarvar et al. [3] | Conducted a critical review of emerging battery chemistries and alternative energy storage paradigms, forecasting the integration of high-energy-density batteries with interconnected data-energy networks. | X | X | ✓ |

| Khare et al. [4] | Investigated AI-driven IoT frameworks for renewable energy systems, emphasizing synergies between cloud computing, big data analytics, and solar/wind energy optimisation. | ✓ | X | ✓ |

| Laurynas et al. [5] | Analysed energy dissipation in prosumer photovoltaic (PV) systems, quantifying losses attributable to temporal mismatches between energy generation and consumption. | X | X | ✓ |

| Moses et al. [6] | Proposed a smart grid architecture to harmonise stakeholder objectives, enhance energy stability, and mitigate climate impacts through decentralised energy governance. | X | ✓ | X |

| The proposed Method | Innovative dual-battery auto-switching system integrating intelligent power allocation, IoT-enabled sensing, and adaptive threshold optimisation to ensure uninterrupted agricultural monitoring. | ✓ | ✓ | ✓ |

| Parameter (%) | Single Battery | Dual Battery | DLB–PAO | DLB–GA |

|---|---|---|---|---|

| System Efficiency | 86.7% | 100.0% | 100.0% | 100.0% |

| Harvesting Efficiency | 3.7% | 4.6% | 4.6% | 4.6% |

| Storage Utilisation | 59.3% | 75.8% | 75.8% | 75.8% |

| Waste Percentage | 91.5% | 81.5% | 81.5% | 81.5% |

| Configuration | Average Reliability (%) | Standard Deviation (%) |

|---|---|---|

| Single Battery | 31.2 | 26.4 |

| Dual Battery | 42.6 | 21.7 |

| DLB–PAO | 91.7 | 5.8 |

| DLB–GA | 99.1 | 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perdana, D.; Lorenz, P.; Aditya, B. Optimized Dual-Battery System with Intelligent Auto-Switching for Reliable Soil Nutrient Monitoring in Remote IoT Applications. J. Sens. Actuator Netw. 2025, 14, 53. https://doi.org/10.3390/jsan14030053

Perdana D, Lorenz P, Aditya B. Optimized Dual-Battery System with Intelligent Auto-Switching for Reliable Soil Nutrient Monitoring in Remote IoT Applications. Journal of Sensor and Actuator Networks. 2025; 14(3):53. https://doi.org/10.3390/jsan14030053

Chicago/Turabian StylePerdana, Doan, Pascal Lorenz, and Bagus Aditya. 2025. "Optimized Dual-Battery System with Intelligent Auto-Switching for Reliable Soil Nutrient Monitoring in Remote IoT Applications" Journal of Sensor and Actuator Networks 14, no. 3: 53. https://doi.org/10.3390/jsan14030053

APA StylePerdana, D., Lorenz, P., & Aditya, B. (2025). Optimized Dual-Battery System with Intelligent Auto-Switching for Reliable Soil Nutrient Monitoring in Remote IoT Applications. Journal of Sensor and Actuator Networks, 14(3), 53. https://doi.org/10.3390/jsan14030053