Abstract

Recent technological advances enable gripper-equipped robots to perform many tasks traditionally associated with the human hand, allowing the use of grippers in a wide range of applications. Depending on the application, an ideal gripper design should be affordable, energy-efficient, and adaptable to many situations. However, regardless of the number of grippers available on the market, there are still many tasks that are difficult for grippers to perform, which indicates the demand and room for new designs to compete with the human hand. Thus, this paper provides a comprehensive review of robotic arm grippers to identify the benefits and drawbacks of various gripper designs. The research compares gripper designs by considering the actuation mechanism, degrees of freedom, grasping capabilities with multiple objects, and applications, concluding which should be the gripper design with the broader set of capabilities.

1. Introduction

The ability to grip and manipulate objects has been central to the advancement of robots [1,2,3,4,5,6,7,8,9,10]. Manufacturers can use end-effector tooling for picking, placing, and packing objects using advances in gripper technology to reap the benefits of precision, performance, and productivity [11]. Grippers are classified depending on their design, how they are powered, and their application. For example, when considering industrial grippers, one of the simplest designs is the parallel motion two-jaw gripper, commonly used to lift objects [12,13,14,15]. Several other design types include the O-ring gripper [16], and the needle gripper [17]. Industrial grippers can be hydraulic, pneumatic, or electric, depending on the application requirements [2,18,19]. However, although the number of grippers currently available on the market has been increasing over the years, this does not change the fact that there are still many complex tasks that robots cannot accomplish.

A limitation of robotic grippers occurs when holding fragile objects with the correct force [3,6,8,9,10]. For example, a gripper handling fruit or food must grasp the fruit firmly enough so it will not slip out of their grasp but be gentle so the fruit will not get damaged, while human fingers are soft and can conform to objects, this is not inherent in a robotic gripper, typically made of metal or other materials with a hard surface. To mitigate this issue, designers developed grippers with softer materials, allowing robotic grippers to handle fragile objects, creating the subject of soft robotics. Soft robotics is a sub-field of robotics that features robots made with soft materials similar to living organisms, such as an octopus’ tentacles or a human’s fleshy finger. Recent advancements in soft robotics allow robots to overcome traditional challenges and expand into new fields [20,21].

Another challenge for gripper design is dexterity. Many traditional gripper designs have two or three fingers made of rigid material. Even though they can do pick and place tasks effectively, they are not suited to more complex manipulation activities [22,23]. For the design to be functional and successful, it needs to generate complex geometries, mechanically adapt to the shape of an object, specialize in grasping and manipulating with ultra-sensitive touch sensors, and have a low impact energy to achieve close resemblance to a human hand [24].

This article explores grippers’ most recent industrial and research designs to answer the question: What gripper design can handle most objects independently of their fragility, shape, and weight? Thus, we classified the grippers considering the type of mechanical design, number of degree of freedom (DOF), the type of actuation, and the form of the grasping objects, concentrating our study on analyzing which gripper yields the best handling capabilities.

The article is organized as follows: Section 2 presents the classification of grippers based on their degrees of freedom and design, focusing on the advantages and limitations of each gripper design. Section 3 shows the organization of the grippers considering their grasping capability in terms of the size, the shape, and the material of the handled object. Section 4 presents the conclusions. Finally, the Appendix A presents the methodology for selecting and organizing the articles for review.

2. Design Configurations for Robotic Arm Grippers

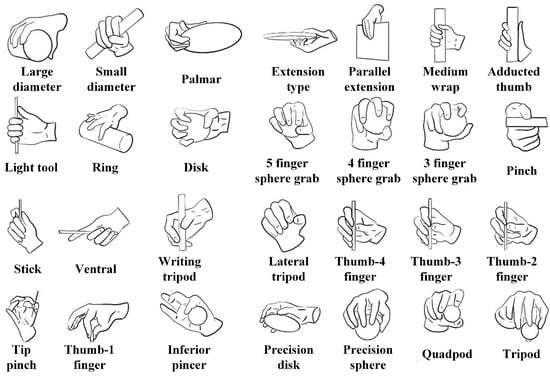

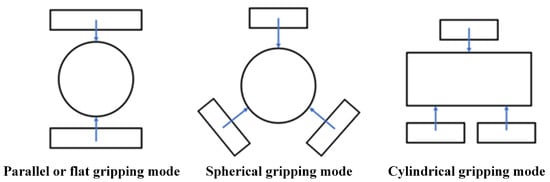

To understand how grippers are designed, first understand how humans interact with, hold, and move objects during daily activities. A Max Planck Institute for Intelligent Systems study trained computers to understand, model, and synthesize human grasping [25]. The analysis of the study includes complex 3D object shapes, detailed contact information, hand pose and shape, and 3D body motion. Similar analyses were conducted in [26,27], in which the types of grips used were classified based on the type of object, its shape, and its weight. Figure 1 shows different grasping types. According to what was previously stated, gripping modes are also classified based on the object’s shape, dividing them into three broad categories [28], which are shown in Figure 2: parallel or flat gripping mode, cylindrical gripping mode, and spherical gripping mode [29]. Other categories derived from these three, such as Tip mode, Hooke mode, and Lateral mode, are presented as subsets of the main categories. Lateral mode, for example, is a subset of parallel mode in which the object’s thickness is hundreds of times less than its perpendicular area. Based on the mobility of the robotic grippers, exists three main categories that classify the design of the grippers: Completely constrained, underconstrained, and deformable. Inside those categories, there are various subdivisions based on the actuation mechanisms, as presented in Table 1. This study reviews each group of robot arm grippers, focusing on the advantages and disadvantages of each classification.

Figure 1.

Categorization of grasping considering the required power and precision for different object shapes and wrap types.

Figure 2.

Generalized classification of gripping modes based on the object shapes.

Table 1.

Categories of robotic grippers based on design configurations and actuation mechanism.

2.1. Completely Constrained Gripper Mechanism

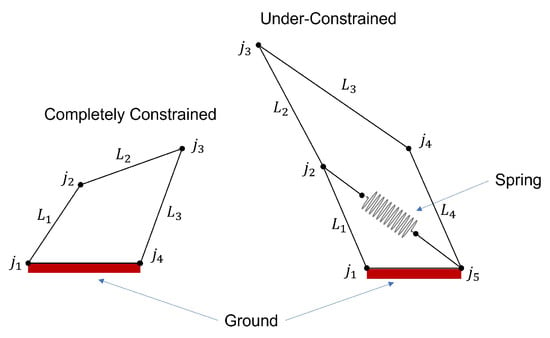

Completely constrained finger mechanisms are devices with a DOF equivalent to their number of actuators, which allows the trajectory of the tip of the finger to follow a predefined path. Note that the number of DOF is computed using the Gruebler-Kutzbach [77] equation presented below:

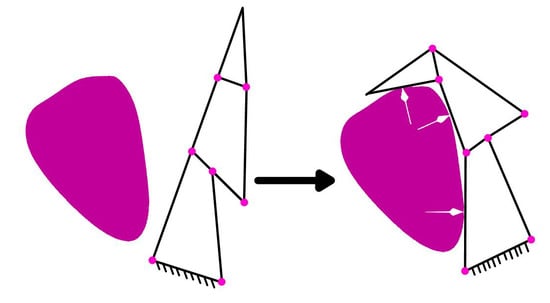

where M is the total DOF; L is the number of links, and J is the number of joints. Then, consider the completely constrained mechanism presented in Figure 3, with three links () and four joints(); applying Equation (1), the total number of DOF is one. Thus, this robot only needs one actuator to generate motion. This property permits the device to generate high output torque, allowing the gripper to hold heavy-weight objects [30,35]. Most of these devices use 1 DOF to control the motion of the gripper, which limits the complexity of the items that the gripper can handle [33]. To solve this issue, researchers have included more DOF in the grippers to enhance their ability to handle complex objects at the expense of their output torque [37]. Based on their design, completely constrained finger mechanisms have two classifications: compliant mechanisms and rigid links.

Figure 3.

Comparison of a fully constrained mechanism with an underconstrained mechanism.

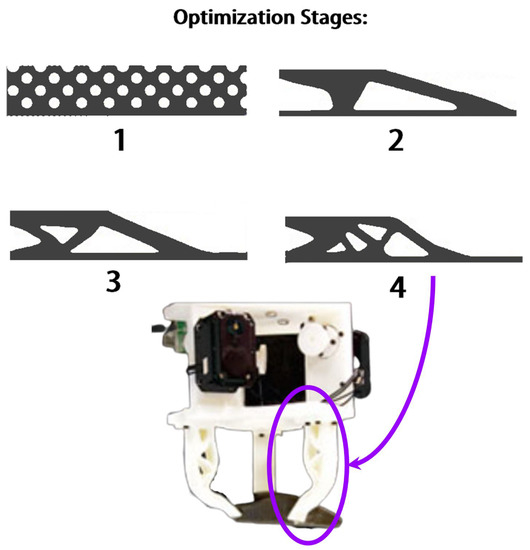

2.1.1. Compliant Mechanism

A compliant mechanism is a flexible mechanism that transmits force and motion through elastic deformations. Compliant mechanisms have a reduced number of moving parts which makes them light. Besides, friction impacts compliant mechanisms more than rigid links because they require fewer assembly parts. Moreover, the fewer assembly parts reduce undesirable nonlinear effects like backlash and noise on compliant mechanisms. Compliant mechanisms are usually of 3D printed materials, reducing their manufacturing cost. However, since the links are flexible, their considerably weaker than rigid links, reducing the output torque capabilities [78]. A usual design strategy for compliant mechanisms is topological optimization as proposed in [6] for a gripper of 3-flexible fingers. The principal purpose of the optimization was to facilitate the modeling of interactions between the gripper and the objects. Figure 4 presents the stages of optimization for the gripper design. The optimization model considers the loading pressure and traction frictions for this case to obtain the objective function. The obtained device uses pulleys and cables for actuation.

Figure 4.

Topological optimization stages of the finger compliant mechanism. Reprinted with permission from ref. [6]. Copyright 2018 IEEE.

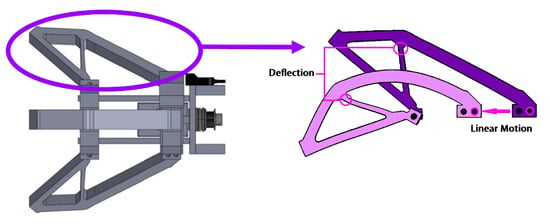

Another example of a compliant mechanism is used for each finger of a 3-finger flexible gripper in [1]. The finger mechanism performs linear motions as presented in Figure 5. The finger mechanism was fabricated with a thermoplastic elastomer (TPE) and was optimized for interactions with unpredictable environments and to handle delicate objects of different sizes. Additionally, the gripper mechanism has only one linear actuator to actuate the three fingers simultaneously, which generates the same displacement on each finger.

Figure 5.

Flexible finger performing linear motion. Reprinted with permission from ref. [1]. Copyright 2020 IEEE.

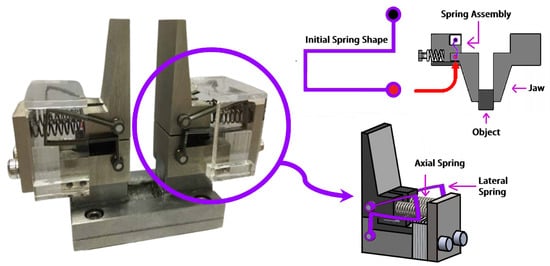

A similar design was proposed in [30], focusing on the optimal design of a 3D-printed constant force-compliant finger. This finger mechanism uses a force regulation strategy for high-speed handling of fragile objects. Details of the regulation strategy are presented in [31]. Figure 6 shows the gripper actuation system, including the jaw and the FRM. The gripper mechanism uses pneumatic actuation and has two complaint mechanisms acting as springs.

Figure 6.

Actuation system of a gripper including the jaw and FRM. Reprinted with permission from ref. [31]. Copyright 2018 IEEE.

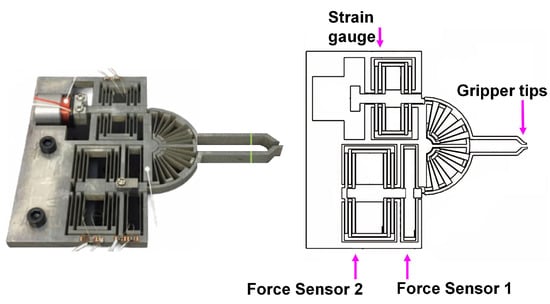

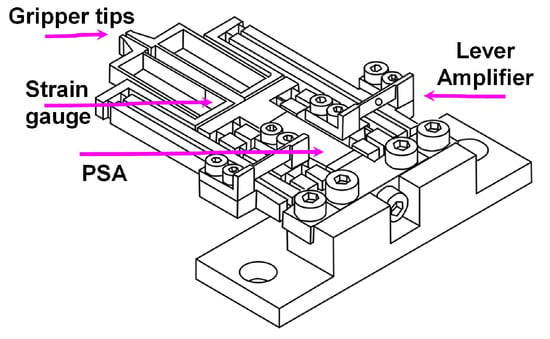

Other grippers integrate sensors in the design of the compliant gripper, as in [32]. This compliant gripper uses an integrated position and grasping/interaction force sensor for automated micro-assembly tasks. However, the integrated sensor limits the workspace to 2.2 mm with a grasping force of 16 mN. Although, this may not be an impending feature for the particular application of this gripper. Figure 7 presents the complaint mechanism with the integrated position and force sensors and a piezoresistive strain gauge for controlling the end-effector. This gripper mechanism also uses finite elements topological optimization. The author compared the results from the optimization with an experimental setup, validating the feasibility of this procedure.

Figure 7.

Structure of the complaint mechanism with integrated sensors. Reprinted with permission from ref. [32]. Copyright 2017 IEEE.

2.1.2. Rigid Links

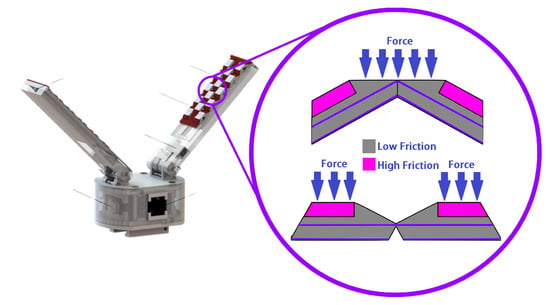

Opposite to compliant mechanisms, rigid links can generate a high output torque while maintaining their stiffness. However, this gripper mechanism requires force sensors to avoid damaging the handling objects. This architecture is presented in [39], which proposes a cable-driven adaptive multi-DOF finger with a mechanical sensor integrated to control the position and output torque. This finger mechanism is made of Acrylonitrile Butadiene Styrene (ABS) and can generate motions in a single plane. The design of this finger mechanism maximizes the output forces in a predefined path, obtaining a gripper mechanism that can hold objects of 55mm in diameter and 800 grams in weight. Figure 8 presents the kinematical diagram of the gripper mechanism for the design trajectory. Another rigid gripper example with similar capabilities is in [4]. This rigid gripper is a 4-finger hand gripper, each finger with three DOFs and actuated by cables. The hand gripper’s fingers have like dimensions and are composed of two phalanges. Other rigid grippers include variable friction surfaces which increase the manipulability dexterity of the gripper [40]. The texture of this gripper is a compound of Polylactic Acid (PLA) and TPU, and its friction changes by the actuation of two pulleys attached to DC motors as described by Figure 9.

Figure 8.

Kinematical diagram of the finger mechanism for the design trajectory [39].

Figure 9.

System of friction changing surface. Reprinted with permission from ref. [40]. Copyright 2020 IEEE.

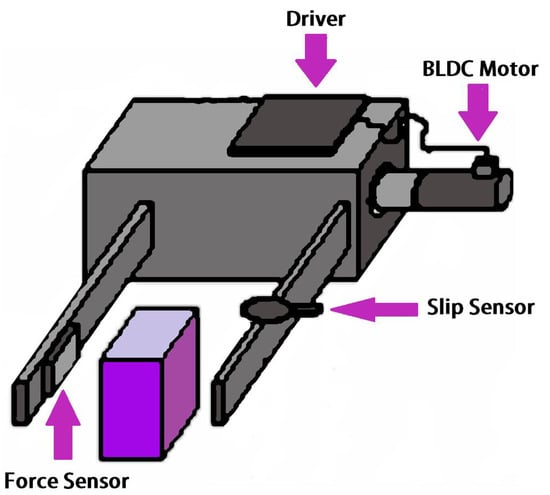

One limitation of rigid links is the need for an accurate control strategy. This feature is complex to obtain because of the nature of the force sensor. Thus, some authors use a fuzzy logic controller to approximate the experimental results into an accurate control strategy [34]. Figure 10 presents the experimental setup used by the author to verify the behavior of this approach. Other rigid link designs use closed-loop links [79]. This finger gripper has two parallel grippers composed of symmetric parallelograms, as seen in Figure 11.

Figure 10.

Gripper configuration with one movable finger (with force sensor) and one fixed finger (with slip sensor) to ease the control [34].

Figure 11.

Finger gripper composed of two parallel grippers of symmetric parallelograms. Reprinted with permission from ref. [79]. Copyright 2019 IEEE.

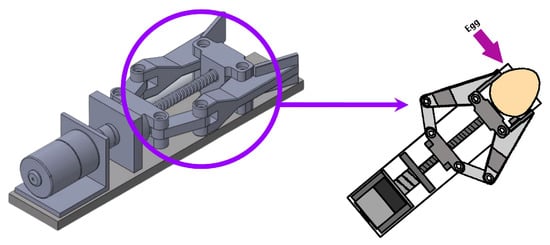

The advantage of this kinematical design is that the model is simpler to implement, ensuring that the tool reacts well relative to the gripping forces and the spring stiffness. Moreover, to increase the accuracy, some rigid links grippers use lead screws examples of this approach are in [33,35]. The former uses a gripper inspired by a chuck clamping device, as presented in Figure 12. This gripper has a closing motion mechanism that provides the position of objects. The latter uses a slider-crank-mechanism as shown in Figure 13. This rigid link mechanism can handle items up to 5kg or fragile objects like eggs. Both gripper mechanisms have the advantage of self-locking, which reduces energy consumption because the motors do not need to be active all the time. However, this type of gripper has a slow-motion issue because of its high mechanical advantage.

Figure 12.

Assembly and operation of the chuck type system. Reprinted with permission from ref. [35]. Copyright 2018 IEEE.

Figure 13.

Representation of the gripper holding an egg without breaking it. Reprinted with permission from ref. [33]. Copyright 2018 IEEE.

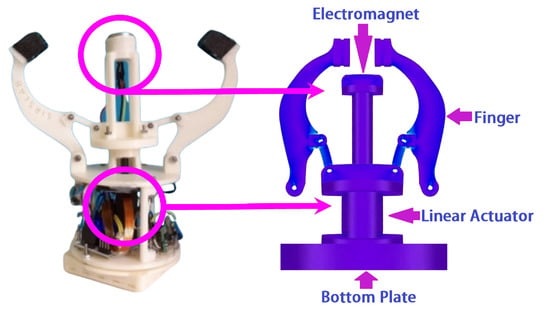

Other designs use electromagnets to actuate rigid links. For example, in [41] is proposed an electromagnet actuated gripper for the manipulation of fabrics. As presented in Figure 14, the gripper uses a slider-crank mechanism. More complex electromagnet-actuated grippers use multiobjective genetic algorithms for optimal design. An example is presented in [42] of this optimization strategy. For this purpose, the authors modeled the actuator as a stack consisting of individual actuator elements arranged in series and parallel arrays in four combinations. As a result of this optimization process, the gripper has increased accuracy compared with others grippers of the same type. However, using electromagnets demands a high energy input, making them unsuitable for autonomous applications.

Figure 14.

Electromagnet actuated gripper. Reprinted with permission from ref. [41]. Copyright 2020 IEEE.

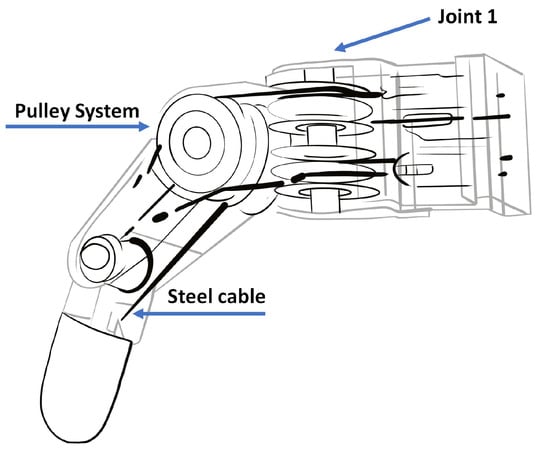

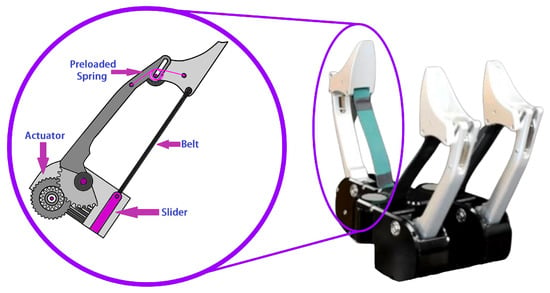

The Salisbury hand [80] shown in Figure 15 was the first successful humanoid robot hand built as a sophisticated end-effector for grasping investigations. Each finger on this hand has three joints, allowing it to mimic the dexterous gripping of the human hand to some extent. Steel wires that pass through Teflon-coated flexible tubes activate the fingers. Each cable is tensioned by a DC brush-type motor that works through a gear reducer. The flexible conduit that allows wires to be routed around the wrist allows the actuator package to be mounted on the robot’s forearm.

Figure 15.

Finger joints of Salisbury hand.

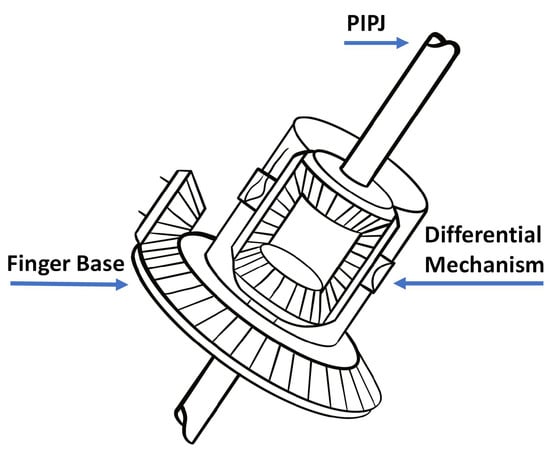

The DHL Hand [81] is an open skeleton hand made of aluminum and steel that can manipulate a variety of objects with great dexterity and accuracy. Three separate joints in each finger are controlled by their own actuators. Brushless dc motors, tooth belts, harmonic drive gears, and bevel gears at the base joint are used in all actuation systems. As shown in Figure 16, the base joint is a differential bevel gear type, allowing for two independent motions. The two actuators can be used to their full capacity, allowing the joint to flex or extend as needed.

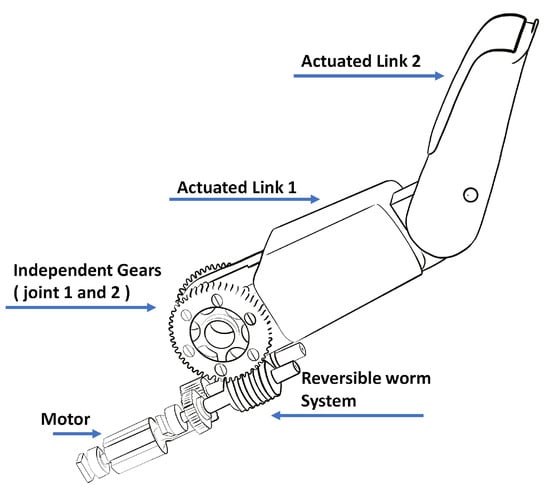

Figure 16.

Actuation systems use brushless dc motors, tooth belts, harmonic drive gears, and bevel gears at the base joint to control three finger joints of DHL hand.

The Barrett hand [82] is a popular example of a hand used in industry and for grasping and manipulation research. Each Barrett Hand’s finger shown in Figure 17 is powered by a motor, and each motor controls two joint axes. Torque is applied to these joints via a Torque switch mechanism. When a fingertip makes contact with an object for the first time, it locks both joints, deactivates motor currents, and waits for further instructions from the microprocessors.

Figure 17.

Mechanism of a Barrett hand’s finger.

2.2. Underconstrained Mechanism

2.3. Compliant Mechanism

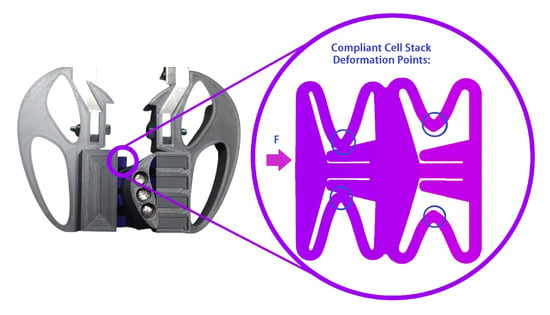

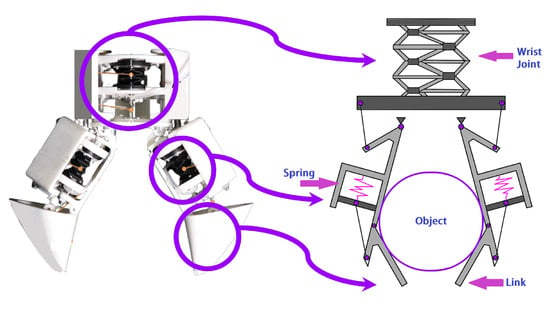

Underconstrained mechanisms allow a broader motion capability compared to completely constraints. The higher motion is due to the DOF, which is higher than the number of actuators, adding more flexibility to handle irregular shape objects. The extra DOF is usually passively actuated by springs for maintaining the structure, as presented in Figure 3, in which a 2-DOF under-constrained mechanism is presented. However, as is in the case of underconstrained compliant mechanisms, the shape of the gripper can include the effects of the spring without adding it. An example of this kind of mechanism is presented by the authors in [43], which developed a robotic gripper with compliant cell stacks for industrial part handling, shown in Figure 18.

Figure 18.

Robotic gripper with compliant cell stacks mechanism [43].

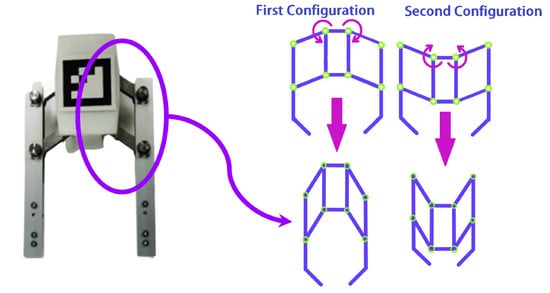

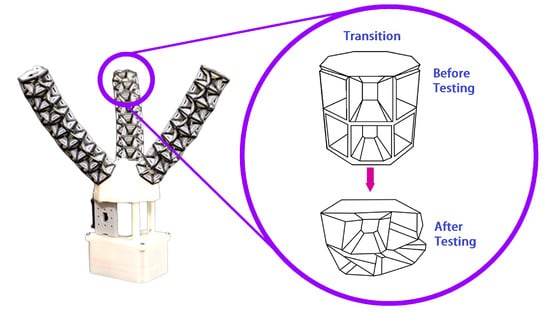

Another example is presented in [44], who developed an underactuated robotic gripper of three fingers inspired by an origami twisted tower shown in Figure 19. Each of the fingers of the gripper uses cable-driven actuation controlled by a central servomotor. Although the gripper mechanisms can handle objects with complex shapes, their payload capacity is limited to 1.5 N at most. Other examples with the same issue include the works of the authors of [47], who developed a passive-compliant piezo actuated micro-gripper (Figure 20); and the designs in [45], which presents a 3D printed Gripper for Cloth Manipulation and position control (Figure 21). However, the latter implemented a variable friction finger surface, controlled by a small motor that pushes the high friction surface at the tip of the top finger, incrementing the payload capacity.

Figure 19.

Underactuated robotic gripper of three fingers inspired in an origami twisted tower [44].

Figure 20.

Passive-compliant piezo actuated micro-gripper. Reprinted with permission from ref. [47]. Copyright 2021 IEEE.

Figure 21.

3D printed Gripper for Cloth Manipulation. Reprinted with permission from ref. [45]. Copyright 2020 IEEE. The figure shows the motors used to change the friction in the gripper.

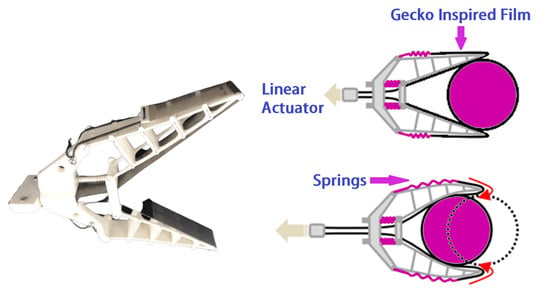

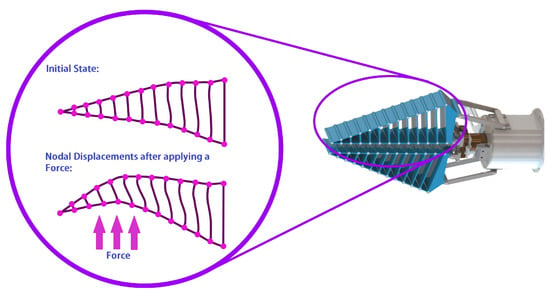

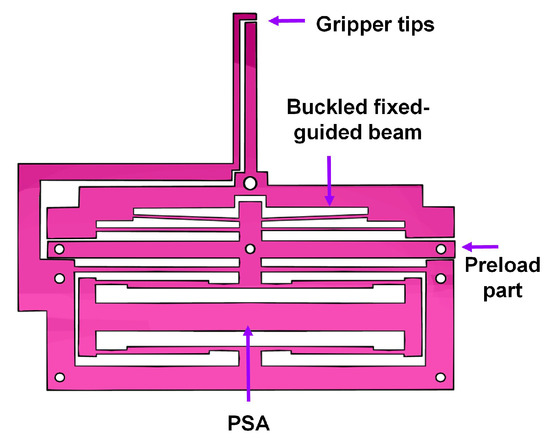

Another limitation of this type of gripper is the need for a force sensor capable of measuring the distribution of forces on a surface. To this end, the authors developed a gecko-inspired gripper that uses ABS polyimide or mylar polyester with a metalized surface for the sensors (Figure 22). The sensor is fabricated in situ with thin adhesive films on each finger and measures the change in capacitance when a region of adhesive makes contact with a surface. Another sensor is developed by the authors of [46] for a compliant adaptive gripper, which integrated an implicit force. The gripper can measure the output force by knowing the deformations on the gripper itself. To compute the deformation of the system, the authors used a general numerical network model (NTM). The NTM calculates the node coordinates of the mechanism using a hand-eye camera (Figure 23). Then, using the node information, the NTM computes the grasping force of the gripper. The proposed mechanism is the first fin-ray-based gripper that simultaneously achieves adaptive grasping and intrinsic force-sensing without any force sensor. A gripper with similar capabilities is presented in [48], who developed a novel compliant constant-force gripper based on buckled fixed-guided beams (Figure 24). The gripper has a passive type of compliant constant-force mechanism. The gripper can generate a constant-force output using a combination of positive and negative stiffness mechanisms. The negative stiffness mechanism is a bi-stable buckled fixed-guided beam.

Figure 22.

Movement sequence to perform a full grasping. Reprinted with permission from ref. [14]. Copyright 2019 IEEE.

Figure 23.

Representation of the theoretical deformation of the gripper given by the general numerical network model. Reprinted with permission from ref. [46]. Copyright 2021 IEEE.

Figure 24.

Compliant mechanism structure model.

Rigid Links

Underconstrained rigid gripper mechanisms have more load capacity compared to underconstrained compliant mechanisms. However, their load capacity is still low compared to totally constrained gripper mechanisms with rigid links. Thus, they are capable of mean output load capacity. Furthermore, most underconstrained grippers designs consider optimization methods to increase the kinematic capabilities. An example of an optimized gripper is presented in [55] the authors proposed a geometric design of three-phalanx underactuated fingers. In this study, the stability of two classes of three-phalanx cable-driven underactuated fingers is under analysis. Moreover, the theory for the optimal design of the gripper is presented, including an objective function that maximizes the forces normal to the contact trajectory while avoiding loss of contact and ejection (Figure 25). Another optimization example is found in [15], which presents a multi-modal adaptive gripper with the optimal design of a re-configurable finger developed for improving robotic manipulation without sacrificing grasping efficiency (Figure 26). The optimization problem maximizes the workspace volume for a wide range of objects using a parallel multi-start search algorithm. This algorithm uses all possible positions of the items during the in-hand manipulation; to compute the dexterous manipulation workspace. All the configurations are clustered in a set of points by the algorithm generating a planar point cloud. The bounding volume of the point cloud is calculated using the alpha-Shape method, which formalizes the abstract shape of the given set of points using Delaunay triangulation.

Figure 25.

Clamping sequence for an object preventing ejection from the gripper design [55].

Figure 26.

Multimodal adaptive gripper with the optimal design of a reconfigurable finger [15].

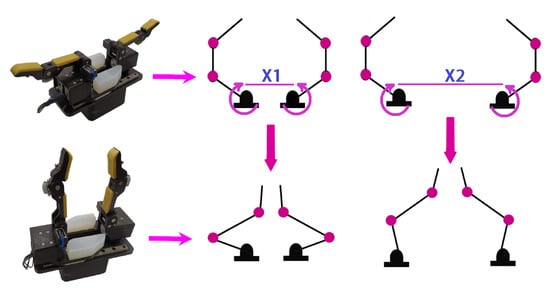

Other approaches add spines to increase the clamping capabilities of a gripper. For example, the authors in [5] presents a passive spine gripper that can hold rough rocky surfaces designed for a climber robot. This gripper has six fingers, making it suitable for spatial exploration in unknown environments. The mechanism (Figure 27) has dual spines that allow it to clamp to different surfaces. The finger part connects to a preload spring inside the gripper. A servomotor-pulley actuator controls the finger mechanism. Furthermore, to release or detach the gripper from the surface, a nylon gut attached to each fingertip is easily pulled by a servo motor. The gripper has a range of 120 () degrees and can hold 4.7 N. The author identified the stiffness of the spring by energy methods.

Figure 27.

Dual spines that allow the mechanism to clamp to different surfaces. Reprinted with permission from ref. [5]. Copyright 2021 IEEE.

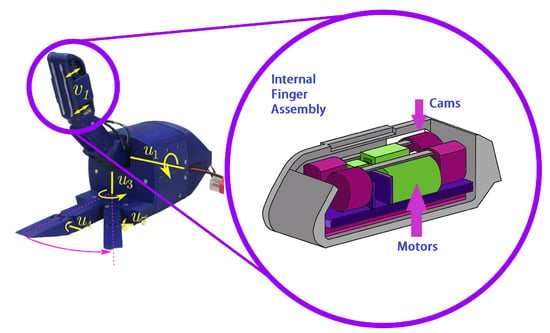

A limitation of rigid links is that they require more rigid links than completely constrained mechanisms. Thus, some gripper mechanisms may suffer from bulkiness. Some authors implemented cable-driven actuation to avoid this issue. Consider the design for an open-loop gripper shown in [12], the device is a two-fingers underactuated hand with cable-driven actuation (Figure 28). Each finger is tendon-driven with a 21-mm pulley diameter attached to an MX-28 Dynamixel servo, producing a stall torque of 2.5 Nm at 12 V. The gripper can hold square and circular objects. The authors tested the gripper using an Ascension trakSTAR sensor to measure the displaced position and orientation at the center of the gripper. The sensor can track 6-DOF with a spatial resolution of 0.5mm and 0.002 rad. Moreover, the gripper has a total stroke from 0 to 103 mm and a holding grip force at the fingertips of 8.9 ± 0.35 N. The article is limited to presenting the design, not the mathematical consideration. However, in [83], according to the authors, introduces a library for developing underactuated grippers. The Schunk SVH hand [84] shown in Figure 29 is one of the most compact designs ever created. The humanoid Schunk hand’s motors are all housed in the wrist, saving a lot of space for the mechanisms. The human hand has 20 individual joints, and the majority of the SVH’s joints are controlled by leadscrew mechanisms, which convert linear motion to rotational motion. There are 22 joints in total, but only 9 of them are fully actuated, turning this hand into an underactuated mechanism.

Figure 28.

Internal gripper assembly. Reprinted with permission from ref. [12]. Copyright 2016 IEEE.

Figure 29.

Schunk SVH hand.

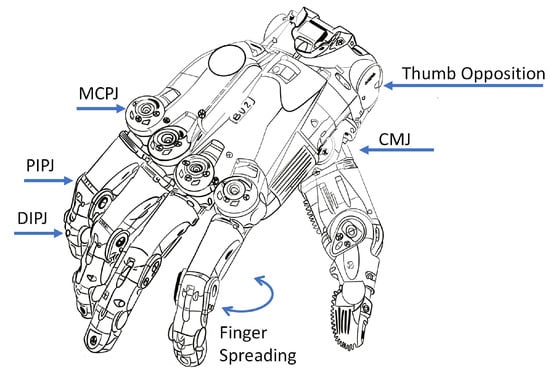

Another design is found in [13], which presents another similar two-fingers underactuated mechanism with cable-driven actuation and active tactile manipulation. The tip contact objects of the fingers are of a rubber-like material skin, with white pins (1 mm diameter) on its inside surface. The tip is entirely 3D-printed using a multi-material 3D-printer (Stratasys Objet 260 Connex), with the rigid parts printed in Vero White material and the compliant skin in the rubber-like TangoBlack+. An acrylic lens separates the electronic components from the tip, filled with RTV27905 silicon gel for compliance. A circuit of 6 LEDs illuminates the rubber pins, which protrude from inside the tip surface (Figure 30). The full range of object orientations depends on object size and shape, ranging from to for the 20 mm diameter cylinder to to for the 35 mm cylinder.

Figure 30.

Layers used to use the LEDs as sensors at the tip of the gripper [13].

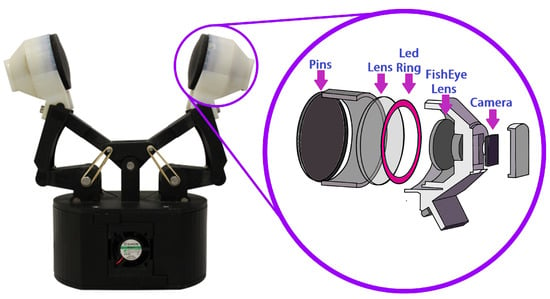

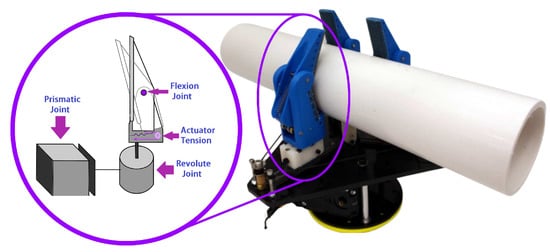

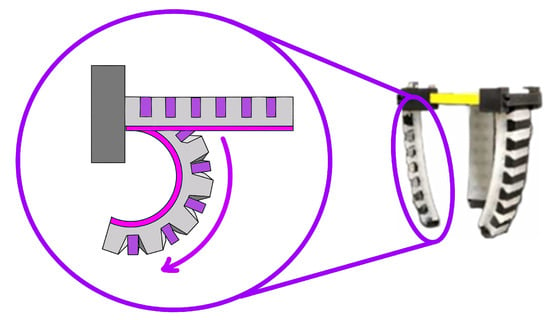

The authors of [58] designed an adaptive gripper with transition capabilities between a precise pinch and compliant grasp for interaction with an unexpected environment. Each finger has a minimum number of components using one rigid link, one belt, one fingertip frame, and one motor (40 Watt ECX16 motor) for flexion motion (Figure 31). The finger structure enables precise parallel pinching and highly compliant stable grasping with evenly distributed pressure. The gripper is composed of flexible belt materials with high stiffness while the fingers of ABS. The grasping force of the gripper is near 13 N, and it can hold a wide range of objects like a driller, a baseball ball, a hammer, a cup, tape, etc. The optimization of the ginger is based on the kinematic; finding the lengths for an optimal Compliant Grasping Pose.

Figure 31.

Double actuated gear and belt system of the gripper. Reprinted with permission from ref. [58]. Copyright 2020 IEEE.

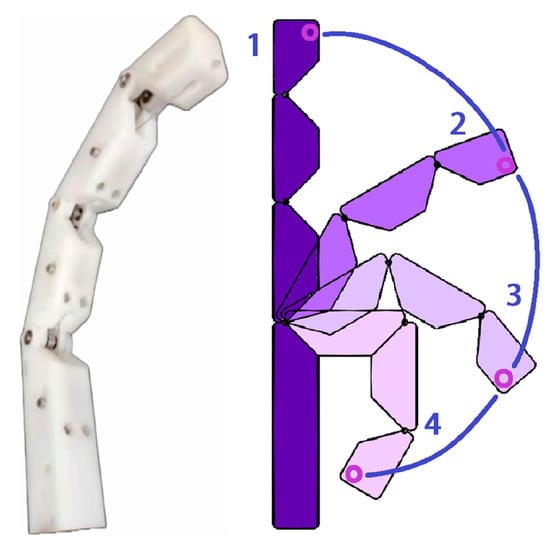

Moreover, the authors in [59] presented an underactuated origami gripper for changing the stiffness of the gripper joints (Figure 32). This two-fingers gripper is of shape memory polymers, actuated by a tendon-driven system with adjustable stiffness joints. The controllable compliance of the fingers limits the contact forces at the desired magnitude without requiring any Feedback without a control strategy. Thus, the gripper does not need a sensor, becoming the control easier and allowing it to grasp delicate and small objects such as an egg, foam, and a coin. The minimum diameter held by the gripper was a coin of 31.5 mm with a maximum load bearing capacity of the joint of 0.97 Nm. The authors correlated the tension in the tendon with the joint angle by considering the system energy.

Figure 32.

Underactuated origami gripper for changing the stiffness of the gripper joints. Reprinted with permission from ref. [59]. Copyright 2017 IEEE.

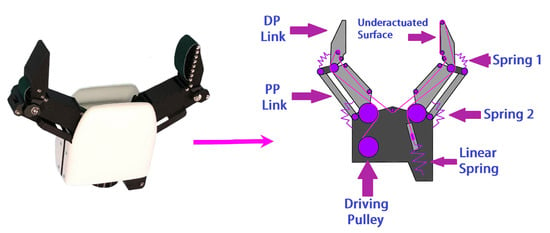

Another cable-driven robot gripper with a passively switchable underactuated surface is shown in [60], including a physic simulation based on parameter optimization for its design. The author proposed a gripper with an underactuated surface on the fingertip (Figure 33). With the spring-loaded passive switching mechanism, the actuation of a single motor generates three grasp modes in series: approaching the object as a standard parallel gripper, pulling items inside the hand with actuated fingertip crawler, and power grasping the object as an underactuated gripper. The authors experimentally showed that a prototyped gripper with the proposed structure successfully picked a 3-mm thin sheet and a softcover book from a flat surface. Moreover, the gripper can lift cylindrical-shaped objects from surface to end with an enveloping grasp. The workspace for this gripper is around 200 mm, with a grasping force that is flat against the object size and exceeds 20 N.

Figure 33.

Cable-driven robot gripper with a passively switchable underactuated surface. Reprinted with permission from ref. [60]. Copyright 2020 IEEE.

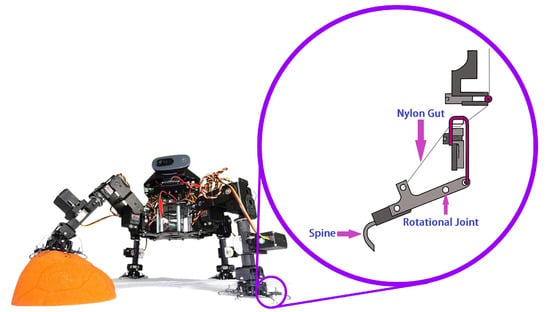

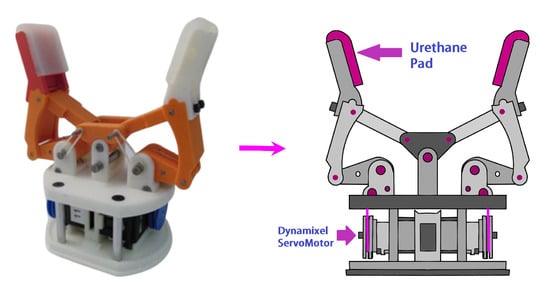

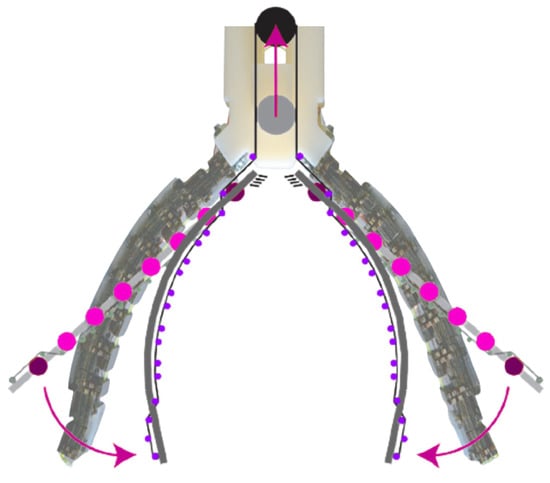

The article presented in [9] shows an adaptive three-fingers prismatic gripper with passive rotational joints (Figure 34). The body of the hand is made with laser-cut 3 mm Delrin and 3D-printed ABS components (printed on a Fortus 250mc). The fingers are also 3D-printed, and the finger pads are from a cast using Smooth-On VytaFlex 30 urethane rubber. Each finger consists of a single joint finger connected to the prismatic joint via a perpendicular passive rotational joint to the palm. The rotational joints allow the fingers to passively switch between spherical and cylindrical grasps, while the finger joint allows the fingers to wrap about the grasped object. According to the article, the gripper can hold items from 17.4 mm to 145 mm, a set of washers ranging in size from 9.8 mm to 50.8 mm, a credit card, various tools, and other items.

Figure 34.

Adaptive three-fingers prismatic gripper with passive rotational joints. Reprinted with permission from ref. [9]. Copyright 2016 IEEE.

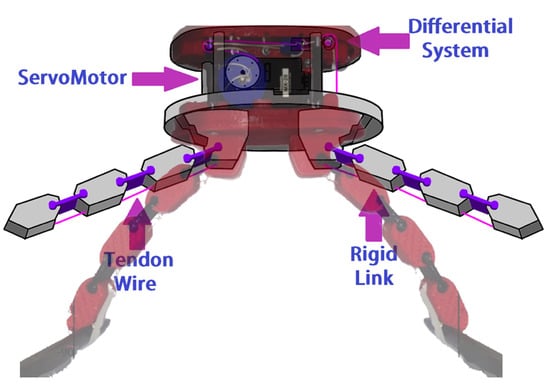

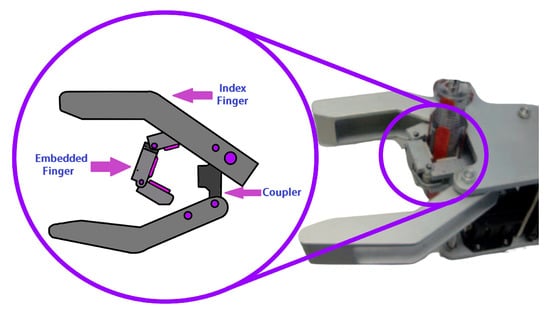

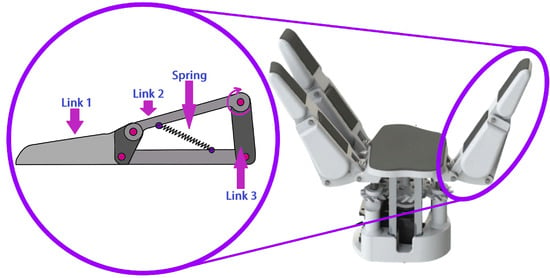

The authors of [61] present an underactuated gripper exploiting joint compliance with an efficient mathematical representation of soft robotic fingers based on screw theory (Figure 35). The mathematical model enables the gripper designer to analyze the influence of specific properties such as the trajectory of the fingertips, the overall stiffness, the distribution of contact force, etc. The gripper ranges 85 mm for cylindrical and spherical objects like a cup, tennis ball, small box, etc. Moreover, the material of the gripper is ABS and can hold 43 N. Lastly, the design and analysis of a novel robotic gripper integrated with a three-phalanx finger for medical applications are shown in [62]. The mechanism works like two grippers in one, a small one for grasping small objects (the embedded one) (Figure 36) and a bigger one for handling wide items. This novelty allows the gripper to reach more activities of daily living.

Figure 35.

Underactuated gripper exploiting joint compliance. Reprinted with permission from ref. [61]. Copyright 2018 IEEE.

Figure 36.

Novel robotic gripper integrated with a three-phalanx finger for medical applications. Reprinted with permission from ref. [62]. Copyright 2005 ASME.

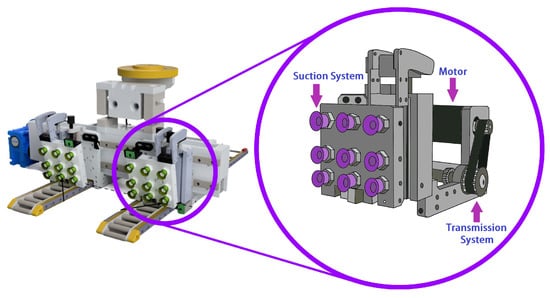

Other approaches use rigid links with linear actuators in [50], where the authors presented a re-configurable gripper for robotic autonomous depalletizing for supermarket logistics. The depalletizing gripper has two extendable forks that can slide along a rail and two suction systems endowed with suction cups controlled by a closed-loop controller (Figure 37). The gripper can hold objects of a size between 15 and 50 cm and a weight of 43 N.

Figure 37.

Depalletizing gripper with rigid links and linear actuators. Reprinted with permission from ref. [50]. Copyright 2020 IEEE.

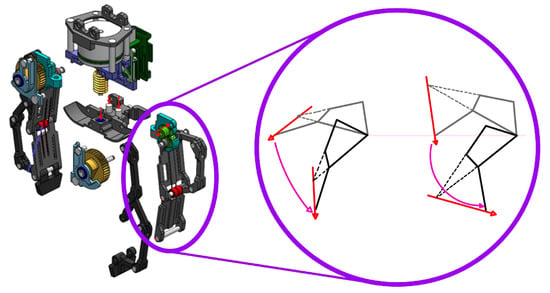

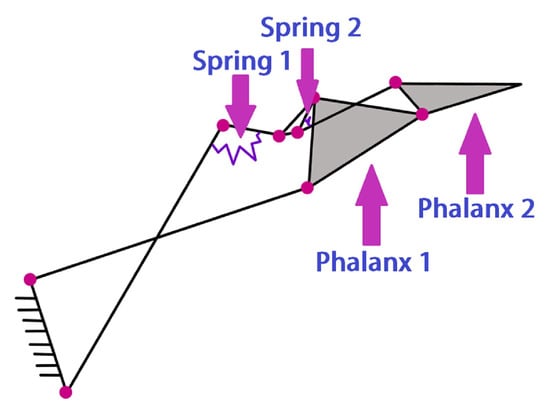

Another type of actuation implemented in rigid links is rotary actuators. In [10], an underactuated four-bar linkage (Figure 38) is proposed. The gripper is actuated using a single actuator (Maxon EC45 70-W) that performs a robust pinch under various environmental constraints. The fingertips can slide on sloped surfaces of objects ranging from 11 mm to 85 mm in diameter. The gripper is also capable of handling lightweight objects. The research also analyzes the kinematic and static using the Plücker coordinates to determine the operation principle of the actuator. The results were used for the dimensional synthesis of the linkage according to several criteria for sliding and lifting. Furthermore, the design proposed in [52] uses rotary actuators, proposing a 3D-printed robot hand with three linkage-driven underactuated fingers with the capacity to reorient two or three of its fingers (Figure 39). The mechanism of each finger is made of a chain of rigid links, making three phalanges for each finger. The gripper design can interact with objects of different sizes and shapes, e.g., cylinders with dimensions up to 81 × 19 mm and spheres with diameters up 70 mm, while maintaining a contact force of 15 N. The gripper includes springs for recovering the initial position. The dimensions of the mechanism were obtained by implementing a grasping optimization for different objects.

Figure 38.

Underactuated four-bar linkage based gripper. Reprinted with permission from ref. [10]. Copyright 2021 IEEE.

Figure 39.

Kinematic representation of one of the three linkage-driven under-actuated fingers [52].

Lastly, another rotary actuator gripper is found in [51]. This research presents an underactuated adaptive 3D printed robotic gripper for interactions with unpredictable environments. The gripper has three fingers; each finger has an underactuated mechanism composed of 5 joints and one spring (Figure 40). The gripper materials are thermoplastic elastomer (TPE), PLA, and ABS. Furthermore, the gripper can hold different objects of daily living such as pencils, bottles, and whiteboard erasers, including spherical objects up to 75mm and a weight of 2.5 kg. The authors also presented a kinematic and quasi-static analysis of the finger for selecting the spring [53].

Figure 40.

Underactuated adaptative 3D printed robotic gripper for interactions with unpredictable environments. Reprinted with permission from ref. [51]. Copyright 2014 IEEE.

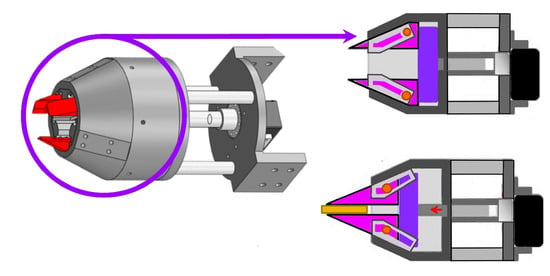

Other designs use pneumatic actuators, as is the case of [63]. The authors presented the design of a high-payload hybrid robotic gripper with soft origamic actuators. The proposed actuator has one DOF linear translation along its axis. The repetitive trapezoid facets lead to the simple design of geometric parameters for customization and stable linear movement (Figure 41). Both the actuator body and the bottom cover are molded using polypropylene rubber. An air vent at the top of the actuator is designed to connect to pneumatic fittings. The gripper consists of two main components: a soft-actuator joint and rigid supporting structures with motion constraints. An analytical model of the actuator is derived based on the geometric parameters to capture the relations between the output force, inner pressure, and axial displacement.

Figure 41.

High-payload hybrid robotic gripper with soft origamic actuators. Reprinted with permission from ref. [63]. Copyright 2020 IEEE.

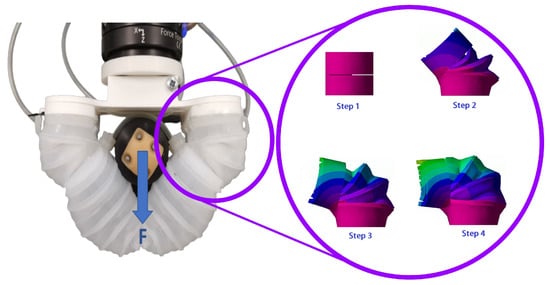

2.4. Deformable Grippers

2.4.1. Single Mass Gripper

Single mass grippers handle items by deforming their shape. This kind of gripper does not have a straightforward relationship between the deformation and the actuator mechanism, as with completely-constrained or underconstrained grippers. Thus, single mass grippers deform until wrapping the desired object. This type of gripper uses pneumatic or cable-driven actuation, covering the broader scope of objects, independent of their shape. However, despite their abilities to manipulate objects, the use of pneumatic actuation limits the mobility of the gripper [8], which presents a prestressed soft gripper with three fingers for food handling. The actuator has 3D printed in two parts: a soft chamber with a rigid connector and a sealed cover. The soft chamber is prestressed by stretching and gluing a non-stretched cover (Figure 42). The gripper can realize a large contact area while grasping with a wide initial opening without deflating the soft actuators. The fingers/actuators are of Rubber-like material. The authors used an air compressor (JUN-AIR 3-4) and an electro-pneumatic regulator (SMC ITV2030) to pressurize the actuator. The soft actuator has a length of 87 mm and can pick up objects of 75.2 g with an accuracy of 80%. The author did a finite element simulation to obtain the optimal dimensions.

Figure 42.

The prestressed soft gripper with three fingers for food handling has a soft chamber with a rigid connector and a sealed cover. Reprinted with permission from ref. [8]. Copyright 2017 IEEE.

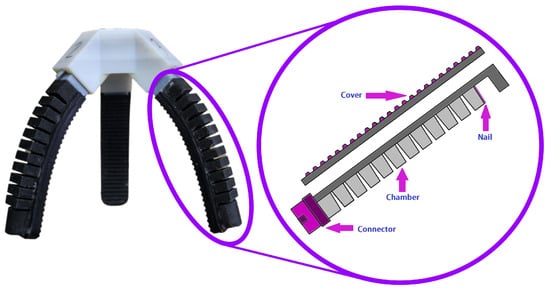

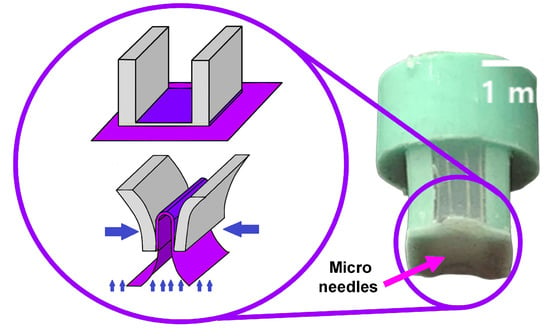

Other authors have similar issues [64], which presents a single mass soft robotic gripper embedded with Microneedles for handling delicate fabrics. The gripper material is of the elastomer kind. The gripper hooks the delicate fabrics using four microneedles. The actuator of the gripper is a vacuum pump that deforms the elastomer once it is in position for handling the fabrics (Figure 43). Although the author does not use any sensor for controlling the pressure, some solutions include embedding soft pressure sensors at the tip of the gripper. Besides its bulkiness, the vacuum pump requires more energy than a regular air compressor. Likewise, an origami-inspired gripper controlled by an SMA actuator is designed [11] for picking objects with variable shapes and sizes. The design of the gripper takes inspiration from a reconfigurable suction gripper (Figure 44). Constructed from rigid and soft components and driven by compact shape memory alloy actuators, the gripper can effectively self-fold into three shape modes. The main objective is to pick large and small, flat, narrow, cylindrical, triangular, and spherical objects ranging from 2 mm to 43 mm in diameter and less than 5.2 N of weight.

Figure 43.

Single mass soft robotic gripper embedded with Microneedles for handling delicate fabrics. Reprinted with permission from ref. [64]. Copyright 2020 IEEE.

Figure 44.

Origami-inspired gripper controlled by an SMA actuator and the possible forms that the gripper can take due to the SMA actuators that it has inside [11].

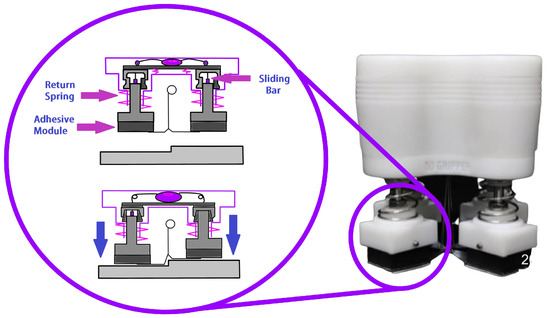

Other approaches use cable-driven actuation to reduce energy consumption and increase manipulability. However, controlling the gripper motion becomes an issue because of the complexity of the deformation model. The authors of [65] present an example of this kind of gripper. The authors developed a multi-legged gripper inspired by a gecko with a controllable adhesion parameter. The gripper can manipulate flat and curve objects by a self-adaptive dry adhesion system. The system consists of four symmetric adhesive units, each modulated by two adaptive-locking mechanisms for compression and rotation, respectively, and one peeling mechanism. The two adaptive-locking mechanisms can adapt to surfaces with height and curvature differences to ensure intimate contact with the objects (Figure 45). Moreover, the lock adaption configuration enables equal load sharing for a firm attachment. The peeling mechanism rapidly peels the adhesive surfaces from the substrate for easy detachment.

Figure 45.

Multi-legged gripper inspired by a gecko with a controllable adhesion parameter generating a firm grip thanks to the adaptability of the gripper. Reprinted with permission from ref. [65]. Copyright 2021 IEEE.

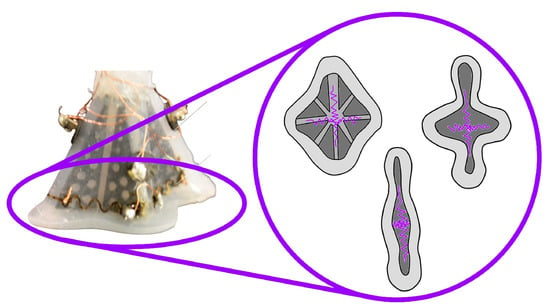

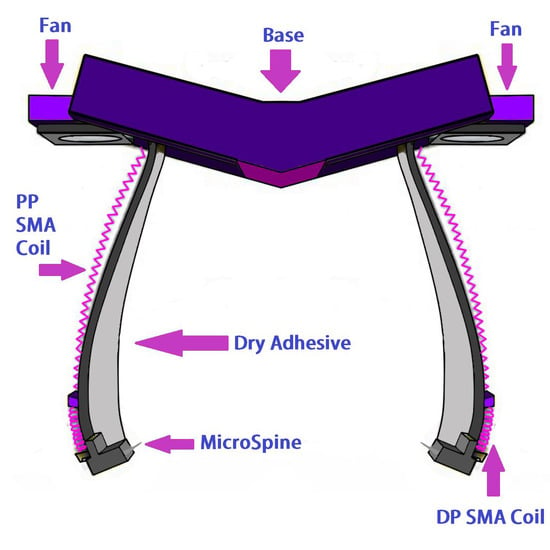

Another flat dry adhesive soft gripper was presented in [66], integrating a soft actuator, micro spine, and a bioinspired design based on a gecko’s toe and a cat’s foot. The soft gripper has an improved design that enhances the comprehensive grasping ability of the soft gripper on smooth or rough surfaces. The design emulates two phalanges, proximal and distal, using SMA coils (Figure 46). The SMA coils are on the backside of the base layer opposite an adhesive layer. A flexible sensor measures the force inside the finger between the two layers. The fingers have micro-needles for increased grasping ability. The viscoelastic mechanics model is used to formulate the preloading process of the adhesive relating the stress encountered by the adhesive with the contact area considered during the preloading process.

Figure 46.

System composed of the SMA actuators, the structure and the cooling system for the soft gripper. Reprinted with permission from ref. [66]. Copyright 2021 IEEE.

2.4.2. Single Mass Finger

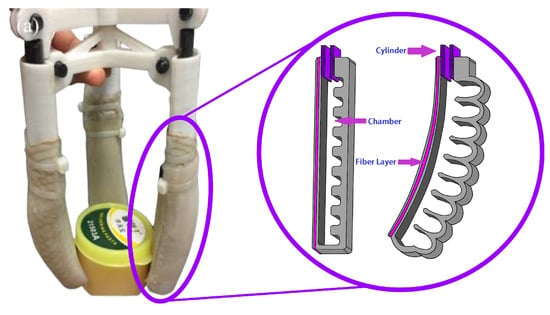

Single mass fingers deform their shape to actuate each of their fingers. This gripper mechanism can hold objects of different forms because of the actuation of the fingers, having similar advantages and disadvantages to single mass grippers. Among the benefits, using multiple grippers facilitates controlling the gripper; an increase in the number of grippers allows a better distribution of the forces generated, relaxing the dependency on an accurate control strategy. However, for this kind of grippers, the issue of bulkiness is more notorious because the actuator requires to deform multiple fingers instead of only one structure. To present some examples, The soft robotic gripper shown in [7] uses a particle transmission and has three fingers. The fingers can grasp a wide range of objects such as a nipper plier, tape, haptic device, and an electric screwdriver. Moreover, the gripper has a vertical force gauge that measures a grasping force of around 20 N at the tip. The authors modeled the system using mass conservation and the principle of incompressible homogenous neo-Hookean materials [85]. Moreover, the authors used molded silicone rubber reinforced by double-stranded woven fiberglass thread and PLA to make the actuators (Figure 47). The proposed actuator design is a slightly modified model of the widely researched fiber-reinforced soft pneumatic actuator [86].

Figure 47.

Soft robotic gripper actuated by particle transmission. Reprinted with permission from ref. [7]. Copyright 2019 IEEE.

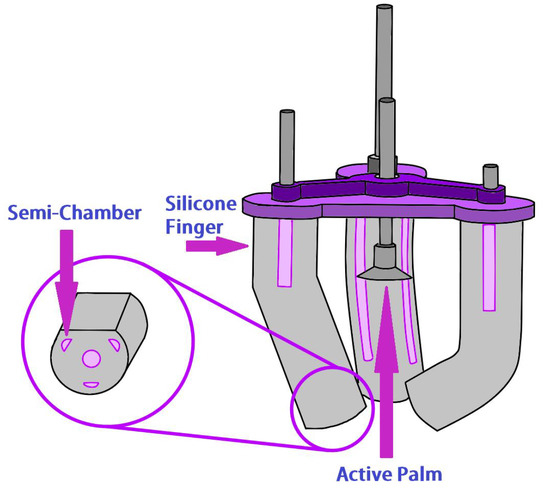

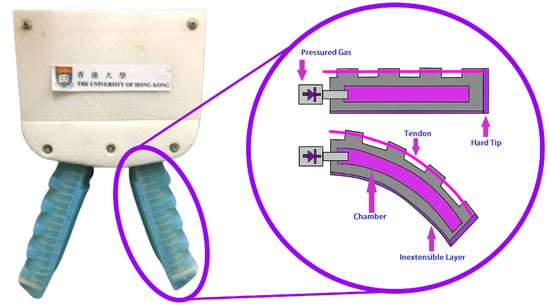

Moreover, a soft robotic gripper with an active palm and reconfigurable fingers is presented in [68] performing complex motions such as rolling a pen or pouring a glass of water. The gripper performs in multiple applications, such as robotic manipulation, medical applications, mobility, rehabilitation, or assistive robotics. The fingers of the gripper are of silicone elastomers EcoFlex. Stepper motors, micropumps, and solenoids control the position of the fingers (Figure 48). Each finger has three pneumatic chambers, which are independent, giving each finger a wide range of mobility. Optimization over a previous iteration is mentioned but not explained. However, the author performs a workspace analysis to determine the total active area. Additionally, the soft gripper shown in [67] is based on pre-charged pneumatic soft actuators. The gripper has a pre-charged pneumatic (PCP) with a silicone chamber with one air tube for pressurizing it (Figure 49). A check valve controls the pressure inside the silicone chamber. When the fingers are pressurized, their shape is corrected using tensile cables or tendons. The actuator body material is silicone rubber with an inextensible layer attached to the bottom of the actuator with a range of 150 mm and capable of holding soft objects like tomatoes or eggs.

Figure 48.

Soft robotic gripper with an active palm and reconfigurable fingers. Reprinted with permission from ref. [68]. Copyright 2021 IEEE.

Figure 49.

Soft gripper using a tendon to pre-charge the soft pneumatic actuators. Reprinted with permission from ref. [67]. Copyright 2019 IEEE.

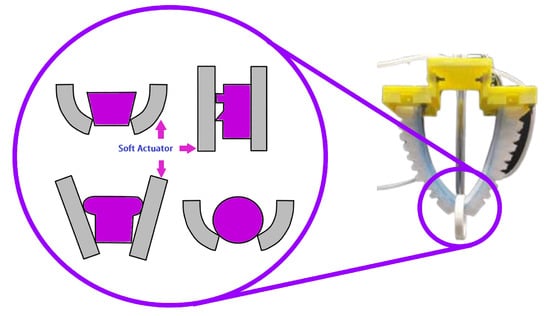

Another gripper is in [69], including rigid and soft materials. The gripper has a pressuring single internal chamber that controls the position. The authors proposed this design to improve the fingertip force and actuation speed simultaneously, optimizing parameters like the degree of bending, the ratio of the rigid structure, the longitudinal strain by modifying the shape of the chamber, and the relation between soft and rigid materials in the same finger (Figure 50). Furthermore, two pneumatic pumps (DAO-370A) control the gripper, allowing a broad workspace suitable for teleoperation. The gripper can hold objects like a drill driver, a coffee cup, and a banana with a maximum allowable weight of 28.7 N. The design parameters were optimized by the finite elements method (FEM) and a simulation based on the hyperrealistic Mooney-Rivlin model.

Figure 50.

Representation of the circular path that the fingertip travels when pressure is applied in its chamber for the soft gripper [69].

Other designs include a pneumatically driven gripper with retractable, telescopic fingers as developed in [70] for Medical applications. The authors used two low-pressure mini-air pumps to actuate this silicone rubber gripper. Additionally, the authors implemented an optical motion capture system composed of eight cameras to track the angular displacement of the gripper (Figure 51). The gripper has retroreflective markers at the top surface of the actuator to increase the accuracy of the measure. The range of motion of the soft actuator is 0 to 105 degrees. The gripper can hold objects like a medium mustard bottle, a water bottle, an egg, and a drill driver whit a grasp up to 14.53 N. A Finite Element Analysis (FEA) model of the soft actuator deformation was developed to understand the structure’s inflation behavior.

Figure 51.

Deformation sequence captured by a camera to track movement at specific points on the gripper. Reprinted with permission from ref. [70]. Copyright 2021 IEEE.

Similarly, the pneumatic two-finger soft robotic gripper shown in [71] can handle objects with enveloping and pinching grasping modes (Figure 52). This gripper consists of chambers and channels in a series arrangement. Moreover, the gripper includes a main body with a bottom both an inextensible elastomer. It combines two dual-module pneumatic actuators with a variable chamber height. The gripper has a workspace with a Bending angle of up to 250 degrees but a low payload of up to 4 N. A digital force gauge inside the finger measures the force at different chamber points. The pinching grasping mode was mainly analyzed by FE analysis and experiments.

Figure 52.

Different grip modes for the pneumatic two-finger soft robotic gripper and different shapes and objects. Reprinted with permission from ref. [71]. Copyright 2021 IEEE.

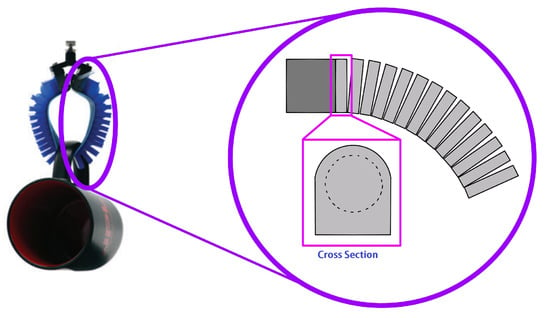

Other approaches use a soft robotic gripper with Gecko-inspired adhesive as proposed in [72], which can handle rocky or dirty surfaces where adhesion is limited. Gecko-inspired grippers use a combination of fluidic elastomer actuators as an actuation mechanism that goes through a circular cross-section (Figure 53). Gecko elastomer actuators provide improved control authority for manipulation tasks. The ability to achieve higher ultimate grip strengths on many objects allows manipulation of heavier objects and higher accelerations of objects during motion. This property is significant for pick and place operations, where speed is critical. The gecko elastomer actuator maintains a low energy input and a fast actuation since the actuators are optimized for these properties while using adhesion-enhanced friction for higher strength grips.

Figure 53.

Cross-sectional area used for elastomer actuation of gecko-inspired gripper. Reprinted with permission from ref. [72]. Copyright 2018 IEEE.

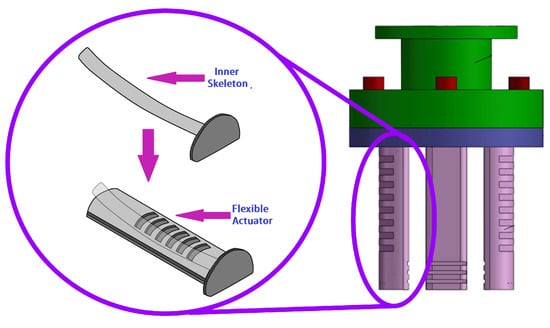

Lastly, an underwater gripper studying the deformation characteristics of water hydraulic flexible actuators is shown in [73]. The gripper has three fingers. Each of the fingers has an inner skeleton made of 3J1, 3J21, TC4, and Carbon fiber with a wall thickness of 1 mm and 30 mm for the first knuckle and 80 mm for the second knuckle. A nonlinear equation expresses the workspace. According to the equation, when the inlet pressure is 0 or 10 MPa, the minimum and maximum deformation of the flexible actuator are 0 mm and 0.20213 mm, respectively. The authors investigated using simulations the effects of different inlet pressure, knuckle length, wall thickness, and material of the inner skeleton and external surface on the deformation characteristics of the flexible actuator. Figure 54 shows the theoretical deflection of the internal bar of the gripper and its repercussion on the external coating. According to the authors, the wall thickness and the length between the knuckles significantly affect the gripper deformation.

Figure 54.

Theoretical deflection of the internal bar of the underwater gripper and its repercussion on the external coating [73].

2.4.3. Materials of the Deformable Grippers

Most single-mass grippers and single-mass fingers are of silicone or rubber-like materials. Rubber-like materials have elasticity, and structural compliance, which increases the safety and adaptability of the device when interacting with delicate or fragile objects [70]. However, rubber-like materials come with disadvantages; the fabrication of soft grippers often requires an iterated casting process, which is usually complex and time-consuming. Furthermore, the air bubbles within the material often result in significant individual differences, which limits the robot’s repeatability [8]. An example of rubber-like material is the commercial ECOFLEX silicone 00-30, which is easy and fast to actuate thanks to its flexibility [87]. Moreover, ECOFLEX silicone 00-30 has a high-power-to-weight ratio, which allows it to have large deformations with a small input [88]. However, the analysis and design of this rubber-like material are complex due to its highly nonlinear response. Thus, when analytical solutions are required, researchers use models similar to the neo-Hookean, which are limited in representing the material behavior at large stretches [88]. Thus, an option is using finite element (FE) analysis, especially when considering the response of silicone rubber actuators [86,87,89,90,91].

Other rubber-like materials include the Object Full cure 930 TangoPlus, which can be 3D printed. Although this material has a higher resistance than the ECOFLEX silicone 00-30, it has the limitation of less elongation break and more cost [88]. Another example of 3D printed rubber-like material is found in [92], NinjaFlex. Although this material has a high resistance, it has a high hardness, which is unsuitable for applications requiring low pressure or force.

Some rubber-like materials can be prepared with a wide range of cured stiffnesses; such materials include the Dragonskin 20, and VTV800 [93]. However, these materials may need an external force or vibrators to recover their initial shape [7].

Other materials include the Dielectric Elastomer Actuators (DEA) or smart material. This material can be used as an actuator for the gripper. Moreover, grippers with this material have reported good performance while grasping various objects [94]. Additionally, soft grippers with this technology report fast response while consuming very-low energy [95]. However, most DEA grippers require a rigid frame to pre-stretch the high elastomer, which is a complex process. Another issue is the reliability of the flexible electrode, which deteriorates with time. Lastly, DEA grippers are limited to low-weight objects because of limitations in the voltage [73].

3. Principal Findings

Table 2 summarizes our findings of the robotic arm grippers handling different sizes, shapes, and materials of objects. In the size category, this table groups the gripper by small, medium, and large size of the handling object. Additionally, this table considers the most common shapes to classify the handling objects, i.e., circular, square, and irregular. The last criteria of comparison consider the types of objects handled by the grippers as delicate, fabric, electronics, rocks and soils, and food. According to the findings presented in the table, the best grippers to handle irregular objects are deformable single-mass grippers; this is because of the adapting capabilities of those grippers. However, the most widely used gripper for daily objects is the underconstrained-rigid links; this is due to this type of gripper is easier to build, requiring a more available actuation system as is linear or rotary actuators. Finally, Table 3 presents the principal findings of each main design category of grippers. This table presents the principal qualities of each gripper type, the load capacity, the range capacity, and the type of objects that each category can hold.

Table 2.

Summary of the findings of actuation grippers for different sizes, shapes, and materials of objects.

Table 3.

Principal findings of each main design category of grippers.

4. Conclusions

The main contribution of this paper is the review of the majority of robotic grippers from the last four years. We classified the gripper according to the number of DOF, the actuation system, the design approach, and the shape of the grasping objects. For each classification criterion, a comparison of the advantages and disadvantages is presented, obtaining insights into which is the gripper design with the broader capabilities. Thus, the principal conclusions of our study are as follows:

- The sensing of the forces generated by the grasping is not accurate. Thus, to avoid breaking fragile objects, engineers use deformable grippers.

- Another issue is the glide of objects, which creates issues in the control strategy. Thus, a solution for this subject is variable friction in the gripper found in gecko-inspired grippers.

- The issue of the sensing forces is handled by completely constrained grippers which can exert greater forces with precision, especially in applications where heavy objects must be moved. However, it cannot be attached to different shapes with ease.

- Another option for deformable grippers is passive-compliant mechanisms that add an extra DOF to increase the manipulability. Passive-compliant mechanisms have the advantage of exerting a moderate amount of output force, adequate for handling objects with a moderate weight, especially if they are built using rigid links.

- Passive compliant mechanisms offers a balance between flexibility and strength. Possessing rigid joints, it can support heavy weights while adapting to most objects’ shapes. As a result, it is ideal for applications where the environment is uncontrolled or unpredictable

Thus, based on our analysis, we conclude that the gripper design with the best capabilities for handling objects of different weights and shapes is a passive-compliant mechanism with rigid links and a gecko-inspired surface. The only disadvantage of this application depends on the exposure to environmental contaminants that may deteriorate the capabilities of the gecko-inspired surface to graduate friction.

Author Contributions

Conceptualization, J.H., M.S.H.S. and J.S.; methodology, J.H. and M.S.H.S.; formal analysis, J.H., M.S.H.S. and J.S.; investigation, J.H., M.S.H.S., I.R., M.I.I.Z. and J.S.; resources, M.H.R.; writing—original draft preparation, J.H., M.S.H.S., I.R., M.I.I.Z. and J.S.; writing—review and editing, J.H., M.S.H.S., H.U.A., J.S. and M.H.R.; visualization, J.H. and M.S.H.S.; supervision, M.H.R.; project administration, M.H.R.; funding acquisition, M.H.R. and S.I.A. All authors have read and agreed to the published version of the manuscript.

Funding

The contents of this research were supported by a grant from the National Institute on Disability, Independent Living, and Rehabilitation Research (NIDILRR grant number 90DPGE0018-01-00). NIDILRR is a Center within the Administration for Community Living (ACL), Department of Health and Human Services (HHS). The contents of this research do not necessarily represent the policy of NIDILRR, ACL, or HHS, and you should not assume endorsement by the Federal Government.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| DOF | Degree of Freedom |

| TPE | Thermoplastic Elastomer |

| FRM | Flexible Redundant Robot Manipulators |

| ABS | Acrylonitrile Butadiene Styrene |

| PLA | Polylactic Acid |

| TPU | Thermoplastic polyurethane |

| BLDC | Brushless DC Motor |

| PID | Proportional-Integral-Derivative feedback control |

| NTM | Numerical Network Model |

| RTV | soft, adherent, clear silicone elastomer gel |

| 3J1 | Nickel-based high elastic alloy |

| 3J21 | Cobalt based high elastic alloy |

| TC4 | Titanium Alloy |

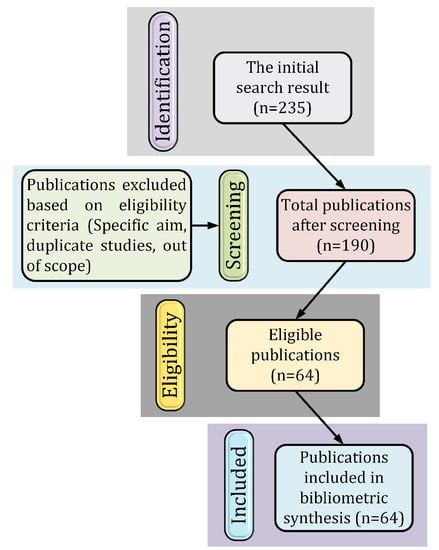

Appendix A. Journal Selection

Studies focused on current design and control approaches for the robotic arm gripper were chosen by performing a systematic electronic search in a handful of databases in January 2022. The timeline of the studies was limited to the last five years to focus on the recent advancement in this field to focus on the recent advances in this field, the study was restricted to the last five years. Keywords used to search include “robotic gripper”, “robotic hand”, “gripper design”, “robotic manipulation”, and “robotic grasping”. Several databases were searched for this research: Google Scholar, IEEE Xplore, ScienceDirect, Engineering Village, Microsoft academic search, Google Patent Search, Scopus, Springer, PubMed, MDPI, IOS Press, Hindawi, SAGE, PLOS, Frontiers in Robotics and AI, etc. Around 235 publications are identified for consideration in this search. However, after some initial screening, 190 studies were shortlisted for review. A few publications were excluded based on eligibility criteria (specific goals, duplication, review, etc.), which resulted in 64 studies being selected for an in-depth review. All the selected papers (n = 64) were reviewed, including abstracts, introductions, design approach, experiments, conclusions, and future work sections to identify any other noteworthy information, such as the addressed problem, contribution, control theory, applications, experiments, used material, and sensors. Figure A1 shows the systematic approach with inclusion and exclusion criteria for the selected studies.

Figure A1.

Inclusion and exclusion criteria of the selected studies.

References

- Liu, C.H.; Chung, F.M.; Chen, Y.; Chiu, C.H.; Chen, T.L. Optimal Design of a Motor-Driven Three-Finger Soft Robotic Gripper. IEEE/ASME Trans. Mechatron. 2020, 25, 1830–1840. [Google Scholar] [CrossRef]

- Birglen, L.; Schlicht, T. A statistical review of industrial robotic grippers. Robot. Comput.-Integr. Manuf. 2018, 49, 88–97. [Google Scholar] [CrossRef]

- Choi, B.; Choi, H.R.; Kang, S. Development of tactile sensor for detecting contact force and slip. In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, Edmonton, AB, Canada, 2–6 August 2005; pp. 2638–2643. [Google Scholar] [CrossRef]

- Cannata, G.; Maggiali, M. An embedded tactile and force sensor for robotic manipulation and grasping. In Proceedings of the 5th IEEE-RAS International Conference on Humanoid Robots, Tsukuba, Japan, 5–7 December 2005; pp. 80–85. [Google Scholar] [CrossRef]

- Nagaoka, K.; Minote, H.; Maruya, K.; Shirai, Y.; Yoshida, K.; Hakamada, T.; Sawada, H.; Kubota, T. Passive Spine Gripper for Free-Climbing Robot in Extreme Terrain. IEEE Robot. Autom. Lett. 2018, 3, 1765–1770. [Google Scholar] [CrossRef]

- Chen, F.; Xu, W.; Zhang, H.; Wang, Y.; Cao, J.; Wang, M.Y.; Ren, H.; Zhu, J.; Zhang, Y.F. Topology Optimized Design, Fabrication, and Characterization of a Soft Cable-Driven Gripper. IEEE Robot. Autom. Lett. 2018, 3, 2463–2470. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Yang, Y.; Li, Y. Soft Robotic Grippers Based on Particle Transmission. IEEE/ASME Trans. Mechatron. 2019, 24, 969–978. [Google Scholar] [CrossRef]

- Wang, Z.; Torigoe, Y.; Hirai, S. A Prestressed Soft Gripper: Design, Modeling, Fabrication, and Tests for Food Handling. IEEE Robot. Autom. Lett. 2017, 2, 1909–1916. [Google Scholar] [CrossRef]

- Backus, S.B.; Dollar, A.M. An Adaptive Three-Fingered Prismatic Gripper With Passive Rotational Joints. IEEE Robot. Autom. Lett. 2016, 1, 668–675. [Google Scholar] [CrossRef]

- Yoon, D.; Choi, Y. Analysis of Fingertip Force Vector for Pinch-Lifting Gripper With Robust Adaptation to Environments. IEEE Trans. Robot. 2021, 37, 1127–1143. [Google Scholar] [CrossRef]

- Zhakypov, Z.; Heremans, F.; Billard, A.; Paik, J. An Origami-Inspired Reconfigurable Suction Gripper for Picking Objects With Variable Shape and Size. IEEE Robot. Autom. Lett. 2018, 3, 2894–2901. [Google Scholar] [CrossRef]

- Rojas, N.; Ma, R.R.; Dollar, A.M. The GR2 Gripper: An Underactuated Hand for Open-Loop In-Hand Planar Manipulation. IEEE Trans. Robot. 2016, 32, 763–770. [Google Scholar] [CrossRef]

- Ward-Cherrier, B.; Rojas, N.; Lepora, N.F. Model-Free Precise in-Hand Manipulation with a 3D-Printed Tactile Gripper. IEEE Robot. Autom. Lett. 2017, 2, 2056–2063. [Google Scholar] [CrossRef]

- Hashizume, J.; Huh, T.M.; Suresh, S.A.; Cutkosky, M.R. Capacitive Sensing for a Gripper With Gecko-Inspired Adhesive Film. IEEE Robot. Autom. Lett. 2019, 4, 677–683. [Google Scholar] [CrossRef]

- Elangovan, N.; Gerez, L.; Gao, G.; Liarokapis, M. Improving Robotic Manipulation Without Sacrificing Grasping Efficiency: A Multi-Modal, Adaptive Gripper With Reconfigurable Finger Bases. IEEE Access 2021, 9, 83298–83308. [Google Scholar] [CrossRef]

- Brown, E.; Rodenberg, N.; Amend, J.; Mozeika, A.; Steltz, E.; Zakin, M.R.; Lipson, H.; Jaeger, H.M. Universal robotic gripper based on the jamming of granular material. Proc. Natl. Acad. Sci. USA 2010, 107, 18809–18814. [Google Scholar] [CrossRef]

- Makiyama, Y.; Wang, Z.; Hirai, S. A Pneumatic Needle Gripper for Handling Shredded Food Products. In Proceedings of the 2020 IEEE International Conference on Real-Time Computing and Robotics (RCAR), Hokkaido, Japan, 28–29 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 183–187. [Google Scholar]

- Zhang, B.; Xie, Y.; Zhou, J.; Wang, K.; Zhang, Z. State-of-the-art robotic grippers, grasping and control strategies, as well as their applications in agricultural robots: A review. Comput. Electron. Agric. 2020, 177, 105694. [Google Scholar] [CrossRef]

- Hughes, J.; Culha, U.; Giardina, F.; Guenther, F.; Rosendo, A.; Iida, F. Soft manipulators and grippers: A review. Front. Robot. AI 2016, 3, 69. [Google Scholar] [CrossRef]

- Wang, J.; Gao, D.; Lee, P.S. Recent Progress in Artificial Muscles for Interactive Soft Robotics. Adv. Mater. 2021, 33, 2003088. [Google Scholar] [CrossRef]

- Laschi, C.; Mazzolai, B.; Cianchetti, M. Soft robotics: Technologies and systems pushing the boundaries of robot abilities. Sci. Robot. 2016, 1, eaah3690. [Google Scholar] [CrossRef]

- Bicchi, A.; Kumar, V. Robotic grasping and contact: A review. In Proceedings of the 2000 ICRA. Millennium Conference. IEEE International Conference on Robotics and Automation. Symposia Proceedings (Cat. No. 00CH37065), San Francisco, CA, USA, 24–28 April 2000; IEEE: Piscataway, NJ, USA, 2000; Volume 1, pp. 348–353. [Google Scholar]

- Samadikhoshkho, Z.; Zareinia, K.; Janabi-Sharifi, F. A brief review on robotic grippers classifications. In Proceedings of the 2019 IEEE Canadian Conference of Electrical and Computer Engineering (CCECE), Edmonton, AB, Canada, 5–8 May 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–4. [Google Scholar]

- Mukhtar, M. Design, Modelling, and Control of an Ambidextrous Robot Arm. Ph.D. Thesis, Brunel University London, London, UK, 2020. [Google Scholar]

- Taheri, O.; Ghorbani, N.; Black, M.J.; Tzionas, D. GRAB: A dataset of whole-body human grasping of objects. In Proceedings of the European Conference on Computer Vision, Glasgow, UK, 23–28 August 2020; Springer: Cham, Switzerland, 2020; pp. 581–600. [Google Scholar]

- Cini, F.; Ortenzi, V.; Corke, P.; Controzzi, M. On the choice of grasp type and location when handing over an object. Sci. Robot. 2019, 4, eaau9757. [Google Scholar] [CrossRef]

- Feix, T.; Bullock, I.M.; Dollar, A.M. Analysis of human grasping behavior: Object characteristics and grasp type. IEEE Trans. Haptics 2014, 7, 311–323. [Google Scholar] [CrossRef]

- Prakash, B.; Veeregowda, B.; Krishnappa, G. Biofilms: A survival strategy of bacteria. Curr. Sci. 2003, 85, 1299–1307. [Google Scholar]

- Song, E.J.; Lee, J.S.; Moon, H.; Choi, H.R.; Koo, J.C. A Multi-Curvature, Variable Stiffness Soft Gripper for Enhanced Grasping Operations. Actuators 2021, 10, 316. [Google Scholar] [CrossRef]

- Liu, C.H.; Chung, F.M.; Ho, Y.P. Topology Optimization for Design of a 3D-Printed Constant-Force Compliant Finger. IEEE/ASME Trans. Mechatron. 2021, 26, 1828–1836. [Google Scholar] [CrossRef]

- Chen, C.C.; Lan, C.C. An Accurate Force Regulation Mechanism for High-Speed Handling of Fragile Objects Using Pneumatic Grippers. IEEE Trans. Autom. Sci. Eng. 2018, 15, 1600–1608. [Google Scholar] [CrossRef]

- Xu, Q. Design and Development of a Novel Compliant Gripper With Integrated Position and Grasping/Interaction Force Sensing. IEEE Trans. Autom. Sci. Eng. 2017, 14, 1415–1428. [Google Scholar] [CrossRef]

- Suebsomran, A. Development of Robot Gripper and Force Control. In Proceedings of the 2018 13th World Congress on Intelligent Control and Automation (WCICA), Changsha, China, 4–8 July 2018; pp. 433–437. [Google Scholar] [CrossRef]

- Zaki, A.M.; Soliman, A.M.; Mahgoub, O.A.; El-Shafei, A. Design and implementation of efficient intelligent robotic gripper. In Proceedings of the 2010 International Conference on Modelling, Identification and Control, Okayama City, Japan, 17–19 July 2010; pp. 710–716. [Google Scholar]

- Nishimura, T.; Tennomi, M.; Suzuki, Y.; Tsuji, T.; Watanabe, T. Lightweight, High-Force Gripper Inspired by Chuck Clamping Devices. IEEE Robot. Autom. Lett. 2018, 3, 1354–1361. [Google Scholar] [CrossRef]

- Nie, K.; Wan, W.; Harada, K. A Hand Combining Two Simple Grippers to Pick Up and Arrange Objects for Assembly. IEEE Robot. Autom. Lett. 2019, 4, 958–965. [Google Scholar] [CrossRef]

- Mahmoud, R.; Ueno, A.; Tatsumi, S. Dexterous mechanism design for an anthropomorphic artificial hand: Osaka City University Hand I. In Proceedings of the 2010 10th IEEE-RAS International Conference on Humanoid Robots, Nashville, TN, USA, 6–8 December 2010; pp. 180–185. [Google Scholar] [CrossRef]

- Wattanasiri, P.; Tangpornprasert, P.; Virulsri, C. Design of Multi-Grip Patterns Prosthetic Hand With Single Actuator. IEEE Trans. Neural Syst. Rehabil. Eng. 2018, 26, 1188–1198. [Google Scholar] [CrossRef]

- Wu, C.; Song, T.; Wu, Z.; Cao, Q.; Fei, F.; Yang, D.; Xu, B.; Song, A. Development and Evaluation of an Adaptive Multi-DOF Finger with Mechanical-Sensor Integrated for Prosthetic Hand. Micromachines 2021, 12, 33. [Google Scholar] [CrossRef]

- Lu, Q.; Clark, A.B.; Shen, M.; Rojas, N. An Origami-Inspired Variable Friction Surface for Increasing the Dexterity of Robotic Grippers. IEEE Robot. Autom. Lett. 2020, 5, 2538–2545. [Google Scholar] [CrossRef]

- Marullo, S.; Bartoccini, S.; Salvietti, G.; Iqbal, M.Z.; Prattichizzo, D. The Mag-Gripper: A Soft-Rigid Gripper Augmented With an Electromagnet to Precisely Handle Clothes. IEEE Robot. Autom. Lett. 2020, 5, 6591–6598. [Google Scholar] [CrossRef]

- Datta, R.; Pradhan, S.; Bhattacharya, B. Analysis and Design Optimization of a Robotic Gripper Using Multiobjective Genetic Algorithm. IEEE Trans. Syst. Man Cybern. Syst. 2016, 46, 16–26. [Google Scholar] [CrossRef]

- Netzev, M.; Angleraud, A.; Pieters, R. Soft Robotic Gripper With Compliant Cell Stacks for Industrial Part Handling. IEEE Robot. Autom. Lett. 2020, 5, 6821–6828. [Google Scholar] [CrossRef]

- Lee, K.; Wang, Y.; Zheng, C. TWISTER Hand: Underactuated Robotic Gripper Inspired by Origami Twisted Tower. IEEE Trans. Robot. 2020, 36, 488–500. [Google Scholar] [CrossRef]

- Donaire, S.; Borràs, J.; Alenyà, G.; Torras, C. A Versatile Gripper for Cloth Manipulation. IEEE Robot. Autom. Lett. 2020, 5, 6520–6527. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, H.; Yuan, H.; Liang, B. A Compliant Adaptive Gripper and Its Intrinsic Force Sensing Method. IEEE Trans. Robot. 2021, 37, 1584–1603. [Google Scholar] [CrossRef]

- Chen, F.; Gao, Y.; Dong, W.; Du, Z. Design and Control of a Passive Compliant Piezo-Actuated Micro-Gripper With Hybrid Flexure Hinges. IEEE Trans. Ind. Electron. 2021, 68, 11168–11177. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.; Xu, Q. Design and Control of a Novel Compliant Constant-Force Gripper Based on Buckled Fixed-Guided Beams. IEEE/ASME Trans. Mechatron. 2017, 22, 476–486. [Google Scholar] [CrossRef]

- Birglen, L.; Gosselin, C. On the force capability of underactuated fingers. In Proceedings of the 2003 IEEE International Conference on Robotics and Automation (Cat. No.03CH37422), Taipei, Taiwan, 4–19 September 2003; Volume 1, pp. 1139–1145. [Google Scholar] [CrossRef]

- Fontanelli, G.A.; Paduano, G.; Caccavale, R.; Arpenti, P.; Lippiello, V.; Villani, L.; Siciliano, B. A Reconfigurable Gripper for Robotic Autonomous Depalletizing in Supermarket Logistics. IEEE Robot. Autom. Lett. 2020, 5, 4612–4617. [Google Scholar] [CrossRef]

- Telegenov, K.; Tlegenov, Y.; Shintemirov, A. An underactuated adaptive 3D printed robotic gripper. In Proceedings of the 2014 10th France-Japan/8th Europe-Asia Congress on Mecatronics (MECATRONICS2014-Tokyo), Tokyo, Japan, 27–29 November 2014; pp. 110–115. [Google Scholar] [CrossRef]

- Li, X.L.; Wu, L.C.; Lan, T.Y. A 3D-Printed Robot Hand with Three Linkage-Driven Underactuated Fingers. Int. J. Autom. Comput. 2018, 15, 593–602. [Google Scholar] [CrossRef]

- Tlegenov, Y.; Telegenov, K.; Shintemirov, A. An open-source 3D printed underactuated robotic gripper. In Proceedings of the 2014 IEEE/ASME 10th International Conference on Mechatronic and Embedded Systems and Applications (MESA), Senigallia, Italy, 10–12 September 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Telegenov, K.; Tlegenov, Y.; Shintemirov, A. A Low-Cost Open-Source 3-D-Printed Three-Finger Gripper Platform for Research and Educational Purposes. IEEE Access 2015, 3, 638–647. [Google Scholar] [CrossRef]

- Birglen, L.; Gosselin, C.M. Geometric Design of Three-Phalanx Underactuated Fingers. J. Mech. Des. 2005, 128, 356–364. Available online: http://xxx.lanl.gov/abs/https://asmedigitalcollection.asme.org/mechanicaldesign/article-pdf/128/2/356/5688285/356_1.pdf (accessed on 31 December 2022). [CrossRef]

- Birglen, L.; Gosselin, C. Kinetostatic analysis of underactuated fingers. IEEE Trans. Robot. Autom. 2004, 20, 211–221. [Google Scholar] [CrossRef]

- Melchiorri, C.; Vassura, G. Design of a Three-Finger Gripper for Intra-Vehicular Robotic Manipulation. In Proceedings of the IFAC Workshop on Space Robotics (SPRO’98), St-Hubert, QC, Canada, 19–22 October 1998; IFAC Proceedings Volumes. Volume 31, pp. 7–12. [Google Scholar] [CrossRef]

- Kim, Y.J.; Song, H.; Maeng, C.Y. BLT Gripper: An Adaptive Gripper With Active Transition Capability Between Precise Pinch and Compliant Grasp. IEEE Robot. Autom. Lett. 2020, 5, 5518–5525. [Google Scholar] [CrossRef]

- Firouzeh, A.; Paik, J. Grasp Mode and Compliance Control of an Underactuated Origami Gripper Using Adjustable Stiffness Joints. IEEE/ASME Trans. Mechatron. 2017, 22, 2165–2173. [Google Scholar] [CrossRef]

- Ko, T. A Tendon-Driven Robot Gripper With Passively Switchable Underactuated Surface and its Physics Simulation Based Parameter Optimization. IEEE Robot. Autom. Lett. 2020, 5, 5002–5009. [Google Scholar] [CrossRef]

- Hussain, I.; Renda, F.; Iqbal, Z.; Malvezzi, M.; Salvietti, G.; Seneviratne, L.; Gan, D.; Prattichizzo, D. Modeling and Prototyping of an Underactuated Gripper Exploiting Joint Compliance and Modularity. IEEE Robot. Autom. Lett. 2018, 3, 2854–2861. [Google Scholar] [CrossRef]

- Lee, W.C.; Wu, C.W. Design and analysis of a novel robotic gripper integrated with a three-phalanx finger. Proc. Inst. Mech. Eng. Part J. Mech. Eng. Sci. 2014, 228, 1786–1796. [Google Scholar] [CrossRef]

- Su, Y.; Fang, Z.; Zhu, W.; Sun, X.; Zhu, Y.; Wang, H.; Tang, K.; Huang, H.; Liu, S.; Wang, Z. A High-Payload Proprioceptive Hybrid Robotic Gripper With Soft Origamic Actuators. IEEE Robot. Autom. Lett. 2020, 5, 3003–3010. [Google Scholar] [CrossRef]

- Ku, S.; Myeong, J.; Kim, H.Y.; Park, Y.L. Delicate Fabric Handling Using a Soft Robotic Gripper With Embedded Microneedles. IEEE Robot. Autom. Lett. 2020, 5, 4852–4858. [Google Scholar] [CrossRef]

- Li, X.; Li, X.; Li, L.; Meng, Y.; Tian, Y. Load Sharing Design of a Multi-legged Adaptable Gripper With Gecko-Inspired Controllable Adhesion. IEEE Robot. Autom. Lett. 2021, 6, 8482–8489. [Google Scholar] [CrossRef]

- Hu, Q.; Dong, E.; Sun, D. Soft Gripper Design Based on the Integration of Flat Dry Adhesive, Soft Actuator, and Microspine. IEEE Trans. Robot. 2021, 37, 1065–1080. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Li, Y. Pre-Charged Pneumatic Soft Gripper With Closed-Loop Control. IEEE Robot. Autom. Lett. 2019, 4, 1402–1408. [Google Scholar] [CrossRef]

- Pagoli, A.; Chapelle, F.; Corrales, J.A.; Mezouar, Y.; Lapusta, Y. A Soft Robotic Gripper With an Active Palm and Reconfigurable Fingers for Fully Dexterous In-Hand Manipulation. IEEE Robot. Autom. Lett. 2021, 6, 7706–7713. [Google Scholar] [CrossRef]

- Park, W.; Seo, S.; Bae, J. A Hybrid Gripper With Soft Material and Rigid Structures. IEEE Robot. Autom. Lett. 2019, 4, 65–72. [Google Scholar] [CrossRef]

- Gao, G.; Chang, C.M.; Gerez, L.; Liarokapis, M. A Pneumatically Driven, Disposable, Soft Robotic Gripper Equipped With Multi-Stage, Retractable, Telescopic Fingers. IEEE Trans. Med. Robot. Bionics 2021, 3, 573–582. [Google Scholar] [CrossRef]

- Liu, S.; Wang, F.; Liu, Z.; Zhang, W.; Tian, Y.; Zhang, D. A Two-Finger Soft-Robotic Gripper With Enveloping and Pinching Grasping Modes. IEEE/ASME Trans. Mechatron. 2021, 26, 146–155. [Google Scholar] [CrossRef]

- Glick, P.; Suresh, S.A.; Ruffatto, D.; Cutkosky, M.; Tolley, M.T.; Parness, A. A Soft Robotic Gripper With Gecko-Inspired Adhesive. IEEE Robot. Autom. Lett. 2018, 3, 903–910. [Google Scholar] [CrossRef]

- Nie, S.; Liu, X.; Ji, H.; Ma, Z.; Yin, F. Simulation and Experiment Study on Deformation Characteristics of the Water Hydraulic Flexible Actuator Used for the Underwater Gripper. IEEE Access 2020, 8, 191447–191459. [Google Scholar] [CrossRef]

- Hwang, G.; Park, J.; Cortes, D.S.D.; Hyeon, K.; Kyung, K.U. Electroadhesion-Based High-Payload Soft Gripper With Mechanically Strengthened Structure. IEEE Trans. Ind. Electron. 2022, 69, 642–651. [Google Scholar] [CrossRef]

- Krahn, J.M.; Fabbro, F.; Menon, C. A Soft-Touch Gripper for Grasping Delicate Objects. IEEE/ASME Trans. Mechatron. 2017, 22, 1276–1286. [Google Scholar] [CrossRef]

- Li, L.; Jin, T.; Tian, Y.; Yang, F.; Xi, F. Design and Analysis of a Square-Shaped Continuum Robot With Better Grasping Ability. IEEE Access 2019, 7, 57151–57162. [Google Scholar] [CrossRef]

- Sanjuan, J.; Serje, D.; Pacheco, J. Closed form solution for direct and inverse kinematics of a US-RS-RPS 2-DOF parallel robot. Sci. Iran. 2018, 25, 2144–2154. [Google Scholar] [CrossRef]

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Wan, W.; Harada, K. Designing a Mechanical Tool for Robots With Two-Finger Parallel Grippers. IEEE Robot. Autom. Lett. 2019, 4, 2981–2988. [Google Scholar] [CrossRef]

- Pellerin, C. The salisbury hand. Ind. Robot. Int. J. 1991, 18, 25–26. [Google Scholar] [CrossRef]

- Butterfass, J.; Grebenstein, M.; Liu, H.; Hirzinger, G. DLR-Hand II: Next generation of a dextrous robot hand. In Proceedings of the 2001 ICRA. IEEE International Conference on Robotics and Automation (Cat. No.01CH37164), Seoul, Republic of Korea, 21–26 May 2001; Volume 1, pp. 109–114. [Google Scholar] [CrossRef]

- Townsend, W. The BarrettHand grasper–programmably flexible part handling and assembly. Ind. Robot. Int. J. 2000, 27, 181–188. [Google Scholar] [CrossRef]

- Tai, K.; El-Sayed, A.R.; Shahriari, M.; Biglarbegian, M.; Mahmud, S. State of the Art Robotic Grippers and Applications. Robotics 2016, 5, 11. [Google Scholar] [CrossRef]

- Ruehl, S.W.; Parlitz, C.; Heppner, G.; Hermann, A.; Roennau, A.; Dillmann, R. Experimental evaluation of the schunk 5-finger gripping hand for grasping tasks. In Proceedings of the 2014 IEEE International Conference on Robotics and Biomimetics (ROBIO 2014), Bali, Indonesia, 5–10 December 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 2465–2470. [Google Scholar]

- Ogden, R. Non-Linear Elastic Deformations, Courier Corporation; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 1984. [Google Scholar]

- Polygerinos, P.; Wang, Z.; Overvelde, J.T.; Galloway, K.C.; Wood, R.J.; Bertoldi, K.; Walsh, C.J. Modeling of soft fiber-reinforced bending actuators. IEEE Trans. Robot. 2015, 31, 778–789. [Google Scholar] [CrossRef]

- Wakimoto, S.; Suzumori, K.; Ogura, K. Miniature pneumatic curling rubber actuator generating bidirectional motion with one air-supply tube. Adv. Robot. 2011, 25, 1311–1330. [Google Scholar] [CrossRef]

- Steck, D.; Qu, J.; Kordmahale, S.B.; Tscharnuter, D.; Muliana, A.; Kameoka, J. Mechanical responses of Ecoflex silicone rubber: Compressible and incompressible behaviors. J. Appl. Polym. Sci. 2019, 136, 47025. [Google Scholar] [CrossRef]