Investigation of Twelve Significant Mycotoxin Contamination in Nut-Based Products by the LC–MS/MS Method

Abstract

:1. Introduction

2. Results

3. Discussion

4. Materials and Methods

4.1. Samples Collection

4.2. Sample Preparation

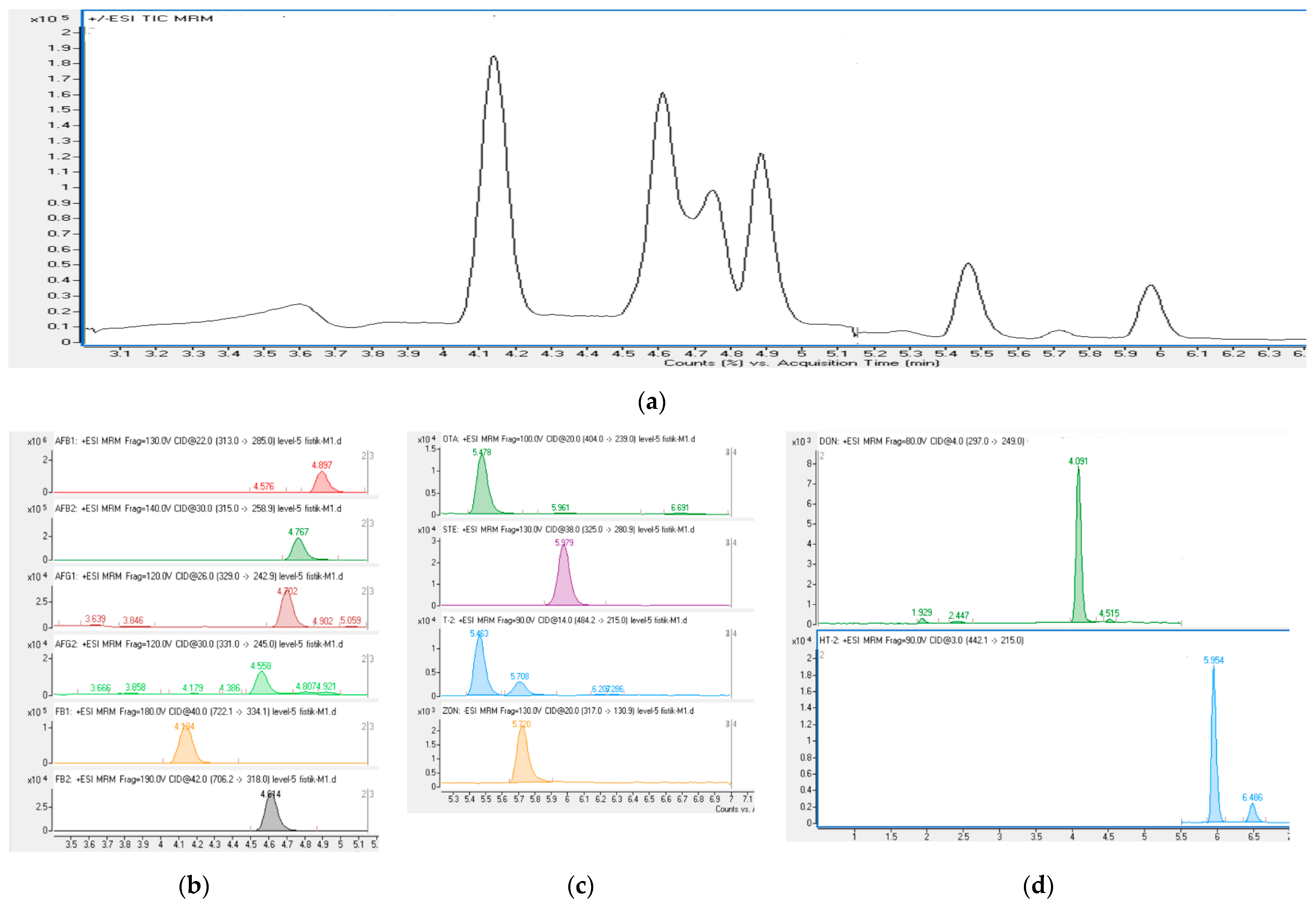

4.3. LC–MS/MS Procedure

4.4. Total Aerobic Mesophilic Bacteria (TAMB) Analysis

4.5. Statistical Analyses

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cunha, S.C.; Sa, S.V.; Fernandes, J.O. Multiple mycotoxin analysis in nut products: Occurrence and risk characterization. Food Chem. Toxicol. 2018, 114, 260–269. [Google Scholar] [CrossRef]

- Sharma, R.; Ragavan, K.V.; Thakur, M.S.; Raghavarao, K.S.M.S. Recent advances in nanoparticle based aptasensors for food contaminants. Biosens. Bioelectron. 2015, 74, 612–627. [Google Scholar] [CrossRef]

- Molyneux, R.J.; Mahoney, N.; Kim, J.H.; Campbell, B.C. Mycotoxins in edible tree nuts. Int. J. Food Microbiol. 2007, 119, 72–78. [Google Scholar] [CrossRef] [PubMed]

- Scarpino, V.; Reyneri, A.; Blandino, M. Development and comparison of two multiresidue methods for the determination of 17 Aspergillus and Fusarium mycotoxins in cereals using HPLC-ESI-TQ-MS/MS. Front. Microbiol. 2019, 10, 361. [Google Scholar] [CrossRef] [PubMed]

- Steyn, P.S. Mycotoxins, general view, chemistry and structure. Toxicol. Lett. 1995, 82, 843–851. [Google Scholar] [CrossRef]

- Eskola, M.; Kos, G.; Elliott, C.T.; Hajšlová, J.; Mayar, S.; Krska, R. Worldwide contamination of food-crops with mycotoxins: Validity of the widely cited ‘FAO estimate’of 25%. Crit. Rev. Food Sci. Nutr. 2020, 60, 2773–2789. [Google Scholar] [CrossRef]

- Capriotti, A.L.; Caruso, G.; Cavaliere, C.; Foglia, P.; Samperi, R.; Lagana, A. Multiclass mycotoxin analysis in food, environmental and biological matrices with chromatography/mass spectrometry. Mass Spectrom. Rev. 2012, 31, 466–503. [Google Scholar] [CrossRef] [PubMed]

- Flores-Flores, M.E.; Lizarraga, E.; de Cerain, A.L.; González-Peñas, E. Presence of mycotoxins in animal milk: A review. Food Control 2015, 53, 163–176. [Google Scholar] [CrossRef]

- Al Juhaimi, F.; Özcan, M.M.; Ghafoor, K.; Babiker, E.E.; Hussain, S. Comparison of cold-pressing and soxhlet extraction systems for bioactive compounds, antioxidant properties, polyphenols, fatty acids and tocopherols in eight nut oils. J. Food Sci. Technol. 2018, 55, 3163–3173. [Google Scholar] [CrossRef]

- Abdulkadar, A.H.W.; Al-Ali, A.A.; Al-Kildi, A.M.; Al-Jedah, J.H. Mycotoxins in food products available in Qatar. Food Control 2004, 15, 543–548. [Google Scholar] [CrossRef]

- Dohlman, E. Mycotoxin Hazards and Regulations, Impacts on Food and Animal Feed Crop Trade; International Trade and Food Safety/AER-828; USDA: Washington, DC, USA, 2003; pp. 97–108. Available online: https://www.ers.usda.gov/webdocs/publications/41603/15640_aer828h_1_.pdf?v=0 (accessed on 8 December 2021).

- Liao, C.D.; Wong, J.W.; Zhang, K.; Yang, P.; Wittenberg, J.B.; Trucksess, M.W.; Hayward, D.G.; Lee, N.S.; Chang, J.S. Multi-mycotoxin analysis of finished grain and nut products using ultrahigh-performance liquid chromatography and positive electrospray ionization–quadrupole orbital ion trap high-resolution mass spectrometry. J. Agric. Food Chem. 2015, 63, 8314–8332. [Google Scholar] [CrossRef] [PubMed]

- Uçkun, O.; Var, I. Microbiological quality of peanuts: From field to consumption. Sustain. Food Prod. 2018, 4, 31–39. [Google Scholar] [CrossRef] [Green Version]

- Chang, A.S.; Sreedharan, A.; Schneider, K.R. Peanut and peanut products: A food safety perspective. Food Control 2013, 32, 296–303. [Google Scholar] [CrossRef]

- Godočiková, L.; Ivanišová, E.; Kačániová, M. Microbiological stability and subsequent hygienic quality of Slovak chocolates. In Proceedings of the Scientific Researches in Food Production—3rd Meeting of Young Researchers from V4 Countries, Debrecen, Hungary, 7 September 2018; pp. 12–16. [Google Scholar]

- Turkish Food Codex. Türk Gıda Kodeksi Bulaşanlar Yönetmeliği. Resmî Gazete Tarihi: 29.12.2011 Resmî Gazete Sayısı: 28157 (3.Mükerrer). Available online: https://www.mevzuat.gov.tr/mevzuat?MevzuatNo=15692&MevzuatTur=7&MevzuatTertip=5 (accessed on 9 November 2021).

- Buchanan, R.L.; Oni, R. Use of microbiological indicators for assessing hygiene controls for the manufacture of powdered infant formula. J. Food Prot. 2012, 75, 989–997. [Google Scholar] [CrossRef]

- Er Demirhan, B.; Demirhan, B. The investigation of mycotoxins and Enterobacteriaceae of cereal-based baby foods marketed in Turkey. Foods 2021, 10, 3040. [Google Scholar] [CrossRef] [PubMed]

- Perrone, G.; Ferrara, M.; Medina, A.; Pascale, M.; Magan, N. Toxigenic fungi and mycotoxins in a climate change scenario: Ecology, genomics, distribution, prediction and prevention of the risk. Microorganisms 2020, 8, 1496. [Google Scholar] [CrossRef]

- García-Díaz, M.; Gil-Serna, J.; Vázquez, C.; Botia, M.N.; Patiño, B. A comprehensive study on the occurrence of mycotoxins and their producing fungi during the maize production cycle in Spain. Microorganisms 2020, 8, 141. [Google Scholar] [CrossRef] [Green Version]

- Copetti, M.V.; Iamanaka, B.T.; Pereira, J.L.; Lemes, D.P.; Nakano, F.; Taniwaki, M.H. Co-occurrence of ochratoxin A and aflatoxins in chocolate marketed in Brazil. Food Control 2012, 26, 36–41. [Google Scholar] [CrossRef] [Green Version]

- Naz, N.; Kashif, A.; Kanwal, K.; Ajaz, H. Incidence of mycotoxins in local and branded samples of chocolates marketed in Pakistan. J. Food Qual. 2017, 2017, 1947871. [Google Scholar] [CrossRef] [Green Version]

- Kabak, B. Aflatoxins and ochratoxin A in chocolate products in Turkey. Food Addit. Contam. Part B Surveill. 2019, 12, 225–230. [Google Scholar] [CrossRef]

- Younis, Y.M.; Malik, K.M. TLC and HPLC assays of aflatoxin contamination in Sudanese peanuts and peanut products. Kuwait J. Sci. Eng. 2003, 30, 79–93. [Google Scholar]

- Yentür, G.; Er, B.; Özkan, M.G.; Öktem, A.B. Determination of aflatoxins in peanut butter and sesame samples using high-performance liquid chromatography method. Eur. Food Res. Technol. 2006, 224, 167–170. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, Y.; Shao, S.; Cai, Z.; Feng, L.; Pan, H.; Wang, Z. Simultaneous determination of multi-component mycotoxin contaminants in foods and feeds by ultra-performance liquid chromatography tandem mass spectrometry. J. Chromatogr. A 2007, 1143, 48–64. [Google Scholar] [CrossRef] [PubMed]

- Kumagai, S.; Nakajima, M.; Tabata, S.; Ishikuro, E.; Tanaka, T.; Norizuki, H.; Itoh, Y.; Aoyama, K.; Fujita, K.; Kai, S.; et al. Aflatoxin and ochratoxin A contamination of retail foods and intake of these mycotoxins in Japan. Food Addit. Contam. 2008, 25, 1101–1106. [Google Scholar] [CrossRef]

- Leong, Y.H.; Ismail, N.; Latif, A.A.; Ahmad, R. Aflatoxin occurrence in nuts and commercial nutty products in Malaysia. Food Control 2010, 21, 334–338. [Google Scholar] [CrossRef]

- Elzupir, A.O.; Salih, A.O.; Suliman, S.A.; Adam, A.A.; Elhussein, A.M. Aflatoxins in peanut butter in Khartoum State, Sudan. Mycotoxin Res. 2011, 27, 183–186. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.C.; Liao, C.D.; Lin, H.Y.; Chiueh, L.C.; Shih, D.Y.C. Survey of aflatoxin contamination in peanut products in Taiwan from 1997 to 2011. J. Food Drug Anal. 2013, 21, 247–252. [Google Scholar] [CrossRef] [Green Version]

- Mupunga, I.; Lebelo, S.L.; Mngqawa, P.; Rheeder, J.P.; Katerere, D.R. Natural occurrence of aflatoxins in peanuts and peanut butter from Bulawayo, Zimbabwe. J. Food Prot. 2014, 77, 1814–1818. [Google Scholar] [CrossRef]

- Keskin, Z.S.; Gürsoy, N. Investıgatıon of natural mycoflora and aflatoxin formation in hazelnuts and products. Cumhur. Sci. J. 2019, 40, 967–977. [Google Scholar]

- Da Silva, N.; Taniwaki, M.H.; Junqueira, V.C.A.; Silveira, N.F.A.; Okazaki, M.M.; Gomes, R.A.R. Basic plate count techniques for enumeration of microorganisms. In Microbiological Examination Methods of Food and Water; CRC Press: London, UK, 2018. [Google Scholar]

- Da Silva, N.; Taniwaki, M.H.; Junqueira, V.C.A.; Silveira, N.F.A.; Okazaki, M.M.; Gomes, R.A.R. Aerobic plate count. In Microbiological Examination Methods of Food and Water; CRC Press: London, UK, 2018. [Google Scholar]

- Odu, N.N.; Okonko, I.O. Bacteriology quality of traditionally processed peanut butter sold in Port Harcourt metropolis, Rivers State, Nigeria. Researcher 2012, 4, 15–21. [Google Scholar]

- El-Sisy, T.T.; Ali, J.B. Processing of a Nutrient-Rich Cereal Butter an Alternative to Peanut Butter. Asian Food Sci. J. 2021, 20, 25–39. [Google Scholar] [CrossRef]

- Jasem Kit. Food Safety & Quality. 2021. Available online: https://jasem.com.tr/en/products/food-safety-quality/ (accessed on 9 November 2021).

- Halkman, A.K. Merck Applications of Food Microbiology; Başak Matbaacılık ve Tanıtım Hizmetleri Ltd., Şti.: Ankara, Turkey, 2005; pp. 135–238. [Google Scholar]

- Daniel, N.W. Bioistatistic: A Foundation for Analysis in the Health Sciences; Wiley: New York, NY, USA, 1991; p. 5. [Google Scholar]

| Mycotoxins | Chocolate Brands | ||

|---|---|---|---|

| A | B | ||

| AFB1 | N (Positive/Total) | 10/10 | nd |

| Mean ± S.E (μg/kg) | 0.18 ± 0.02 | nd | |

| Min (μg/kg) | 0.11 | nd | |

| Max (μg/kg) | 0.24 | nd | |

| AFG1 | N (Positive/Total) | 10/10 | nd |

| Mean ± S.E (μg/kg) | 0.23 ± 0.01 | nd | |

| Min (μg/kg) | 0.17 | nd | |

| Max (μg/kg) | 0.27 | nd | |

| OTA | N (Positive/Total) | 10/10 | 10/10 |

| Mean ± S.E (μg/kg) | 1.87 a ± 0.11 | 0.44 b ± 0.07 | |

| Min (μg/kg) | 1.20 | 0.13 | |

| Max (μg/kg) | 2.34 | 0.68 | |

| STE | N (Positive/Total) | 8/10 | nd |

| Mean ± S.E (μg/kg) | 1.01 ± 0.14 | nd | |

| Min (μg/kg) | 0.49 | nd | |

| Max (μg/kg) | 1.50 | nd | |

| ZON | N (Positive/Total) | 10/10 | nd |

| Mean ± S.E (μg/kg) | 3.11 ± 0.64 | nd | |

| Min (μg/kg) | 0.90 | nd | |

| Max (μg/kg) | 7.57 | nd | |

| DON | N (Positive/Total) | 1/10 | 10/10 |

| Mean ± S.E (μg/kg) | 29.52 | 29.81 ± 2.77 | |

| Min (μg/kg) | 29.52 | 11.81 | |

| Max (μg/kg) | 29.52 | 42.09 | |

| Mycotoxins | Hazelnut Butters | ||

|---|---|---|---|

| C | D | ||

| AFB1 | N (Positive/Total) | 4/10 | 6/10 |

| Mean ± S.E (μg/kg) | 1.03 ± 0.72 | 0.21 ± 0.07 | |

| Min (μg/kg) | 0.27 | 0.04 | |

| Max (μg/kg) | 3.18 | 0.49 | |

| AFB2 | N (Positive/Total) | 4/10 | 2/10 |

| Mean ± S.E (μg/kg) | 0.12 ± 0.03 | 0.08 ± 0.01 | |

| Min (μg/kg) | 0.06 | 0.07 | |

| Max (μg/kg) | 0.20 | 0.08 | |

| AFG1 | N (Positive/Total) | 2/10 | 5/10 |

| Mean ± S.E (μg/kg) | 0.17 ± 0.005 | 0.22 ± 0.05 | |

| Min (μg/kg) | 0.16 | 0.14 | |

| Max (μg/kg) | 0.17 | 0.40 | |

| OTA | N (Positive/Total) | 2/10 | 3/10 |

| Mean ± S.E (μg/kg) | 0.59 ± 0.35 | 0.05 ± 0.02 | |

| Min (μg/kg) | 0.24 | 0.01 | |

| Max (μg/kg) | 0.94 | 0.08 | |

| STE | N (Positive/Total) | 1/10 | 2/10 |

| Mean ± S.E (μg/kg) | 0.23 | 0.66 ± 0.44 | |

| Min (μg/kg) | 0.23 | 0.22 | |

| Max (μg/kg) | 0.23 | 1.09 | |

| T2 | N (Positive/Total) | 3/10 | 3/10 |

| Mean ± S.E (μg/kg) | 1.75 ± 0.19 | 2.09 ± 0.23 | |

| Min (μg/kg) | 1.41 | 1.77 | |

| Max (μg/kg) | 2.08 | 2.54 | |

| ZON | N (Positive/Total) | 2/10 | 3/10 |

| Mean ± S.E (μg/kg) | 2.41 ± 1.14 | 0.98 ± 0.48 | |

| Min (μg/kg) | 1.27 | 0.33 | |

| Max (μg/kg) | 3.55 | 1.91 | |

| HT2 | N (Positive/Total) | 2/10 | 2/10 |

| Mean ± S.E (μg/kg) | 7.01 b ± 0.07 | 7.42 a ± 0.02 | |

| Min (μg/kg) | 6.94 | 7.40 | |

| Max (μg/kg) | 7.07 | 7.43 | |

| Mycotoxins | Peanut Butter Brands | ||||

|---|---|---|---|---|---|

| E | F | G | H | ||

| AFB1 | N (Positive/Total) | 10/10 | 10/10 | 10/10 | 10/10 |

| Mean ± S.E (μg/kg) | 5.37 ± 2.20 | 13.35 a ± 2.37 | 8.11 b ± 1.56 | 0.94 c ± 0.24 | |

| Min (μg/kg) | 0.18 | 5.56 | 1.02 | 0.20 | |

| Max (μg/kg) | 22.97 | 27.37 | 15.67 | 2.89 | |

| AFB2 | N (Positive/Total) | 10/10 | 10/10 | 10/10 | 10/10 |

| Mean ± S.E (μg/kg) | 0.93 ± 0.36 | 2.53 a ± 0.60 | 1.54 b ± 0.28 | 0.20 c ± 0.03 | |

| Min (μg/kg) | 0.08 | 0.87 | 0.28 | 0.10 | |

| Max (μg/kg) | 3.86 | 6.19 | 3.02 | 0.46 | |

| AFG1 | N (Positive/Total) | nd | 2/10 | nd | nd |

| Mean ± S.E (μg/kg) | nd | 0.21 ± 0.03 | nd | nd | |

| Min (μg/kg) | nd | 0.18 | nd | nd | |

| Max (μg/kg) | nd | 0.24 | nd | nd | |

| FB2 | N (Positive/Total) | nd | nd | 5/10 | nd |

| Mean ± S.E (μg/kg) | nd | nd | 2.85 ± 0.04 | nd | |

| Min (μg/kg) | nd | nd | 2.73 | nd | |

| Max (μg/kg) | nd | nd | 2.93 | nd | |

| OTA | N (Positive/Total) | 10/10 | 10/10 | 10/10 | 8/10 |

| Mean ± S.E (μg/kg) | 2.87 ± 1.85 | 7.02 ± 3.39 | 4.43 ± 0.92 | 0.17 ± 0.05 | |

| Min (μg/kg) | 0.19 | 1.72 | 0.51 | 0.09 | |

| Max (μg/kg) | 19.20 | 37.26 | 9.26 | 0.47 | |

| STE | N (Positive/Total) | 5/10 | 10/10 | 3/10 | 0/10 |

| Mean ± S.E (μg/kg) | 0.40 b ± 0.11 | 1.23 a ± 0.19 | 0.57 ± 0.17 | nd | |

| Min (μg/kg) | 0.19 | 0.47 | 0.26 | nd | |

| Max (μg/kg) | 0.83 | 2.25 | 0.86 | nd | |

| ZON | N (Positive/Total) | nd | 2/10 | 1/10 | nd |

| Mean ± S.E (μg/kg) | nd | 0.08 ± 0.05 | 0.24 | nd | |

| Min (μg/kg) | nd | 0.03 | 0.24 | nd | |

| Max (μg/kg) | nd | 0.12 | 0.24 | nd | |

| TAMB | Positive Samples (%) | Number of Positive Samples | Mean ± S.E (log CFU/g) |

|---|---|---|---|

| Chocolates | 50 | 10 | 2.41 ± 0.08 |

| Hazelnut butters | 5 | 1 | 2.73 |

| Peanut butters | 80 | 32 | 2.74 ± 0.06 |

| Total | 53.75 | 43 | 2.66 ± 0.05 |

| TAMB | Peanut Butters | |||

| E | F | G | H | |

| N (Positive/Total) | 3/10 | 10/10 | 10/10 | 9/10 |

| Mean ± S.E (log CFU/g) | 2.23 c ± 0.04 | 2.90 a ± 0.09 | 2.89 b ± 0.10 | 2.57 ± 0.10 |

| Min (log CFU/g) | 2.15 | 2.54 | 2.48 | 2.15 |

| Max (log CFU/g) | 2.30 | 3.43 | 3.59 | 3.12 |

| TAMB | Chocolates | Nut Butters | ||

| A | B | C | D | |

| N (Positive/Total) | 7/10 | 3/10 | 0/10 | 1/10 |

| Mean ± S.E (log CFU/g) | 2.52 a ± 0.07 | 2.15 b ± 0.00 | <102 | 2.73 |

| Min (log CFU/g) | 2.24 | 2.15 | <102 | 2.73 |

| Max (log CFU/g) | 2.77 | 2.15 | <102 | 2.73 |

| Mycotoxins | Nut Butter | Chocolate | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| RSD (%) | Rec (%) | LOD (µg/kg) | LOQ (µg/kg) | R2 | RSD (%) | Rec (%) | LOD (µg/kg) | LOQ (µg/kg) | R2 | |

| AFB1 | 3.84 | 96.15 | 0.03 | 0.09 | 0.997 | 2.95 | 98.38 | 0.02 | 0.18 | 0.998 |

| AFB2 | 3.23 | 94.62 | 0.02 | 0.08 | 0.997 | 3.94 | 88.92 | 0.03 | 0.32 | 0.998 |

| AFG1 | 2.44 | 95.15 | 0.02 | 0.06 | 0.998 | 4.87 | 101.88 | 0.02 | 0.18 | 0.993 |

| AFG2 | 11.24 | 101.55 | 0.09 | 0.29 | 0.993 | 3.51 | 101.55 | 0.01 | 0.11 | 0.995 |

| DON | 4.62 | 110.68 | 3.83 | 12.77 | 0.999 | 4.24 | 102.69 | 2.38 | 23.77 | 0.992 |

| FB1 | 3.81 | 74.13 | 2.12 | 7.07 | 0.999 | 5.22 | 53.18 | 0.65 | 6.51 | 0.998 |

| FB2 | 2.33 | 83.89 | 1.47 | 4.89 | 0.998 | 1.79 | 76.75 | 0.19 | 1.88 | 0.998 |

| HT2 | 3.19 | 111.40 | 2.66 | 8.88 | 0.999 | 12.63 | 86.54 | 1.43 | 14.31 | 0.997 |

| OTA | 6.32 | 95.20 | 0.01 | 0.15 | 0.995 | 4.3 | 98.91 | 0.02 | 0.19 | 0.997 |

| STE | 2.29 | 94.16 | 0.02 | 0.05 | 0.994 | 3.53 | 100.04 | 0.01 | 0.15 | 0.998 |

| T2 | 2.96 | 95.55 | 0.21 | 0.71 | 0.994 | 2.98 | 95.52 | 0.14 | 1.38 | 0.998 |

| ZON | 4.40 | 94.78 | 0.03 | 0.11 | 0.996 | 1.78 | 102.33 | 0.11 | 1.12 | 0.999 |

| Mycotoxins | RT | Parent Ion (m/z) | Fragment Ions | Concentration Range (µg/L) | Ion Mode | Fragmentor Voltage (V) | CE (V) | |

|---|---|---|---|---|---|---|---|---|

| AFB1 | 4.89 ± 0.01 | 313 | 285/240.9 | 0.05–1 | Positive | 130 | 22 | 38 |

| AFB2 | 4.76 ± 0.01 | 315 | 287/258.9 | 0.05–1 | Positive | 140 | 24 | 30 |

| AFG1 | 4.70 ± 0.03 | 329 | 242.9/200 | 0.05–1 | Positive | 120 | 26 | 38 |

| AFG2 | 4.55 ± 0.02 | 331 | 312.9/245 | 0.05–1 | Positive | 120 | 24 | 30 |

| DON | 4.09 ± 0.05 | 297 | 249/231 | 5–100 | Positive | 80 | 4 | 6 |

| FB1 | 4.13 ± 0.05 | 722.1 | 352.1/334.1 | 5–100 | Positive | 180 | 36 | 40 |

| FB2 | 4.61 ± 0.01 | 706.2 | 336.1/318 | 1.5–30 | Positive | 190 | 40 | 42 |

| HT2 | 5.95 ± 0.01 | 442.1 | 263/215 | 5–100 | Positive | 90 | 3 | 3 |

| OTA | 5.47 ± 0.01 | 404 | 358/239 | 0.05–1 | Positive | 100 | 10 | 20 |

| STE | 5.97 ± 0.02 | 325 | 309.9/280.9 | 0.05–1 | Positive | 130 | 24 | 38 |

| T2 | 5.46 ± 0.01 | 484.2 | 215/185 | 0.5–10 | Positive | 90 | 14 | 16 |

| ZON | 5.72 ± 0.01 | 317 | 174.9/130.9 | 0.5–10 | Negative | 130 | 12 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Er Demirhan, B.; Demirhan, B. Investigation of Twelve Significant Mycotoxin Contamination in Nut-Based Products by the LC–MS/MS Method. Metabolites 2022, 12, 120. https://doi.org/10.3390/metabo12020120

Er Demirhan B, Demirhan B. Investigation of Twelve Significant Mycotoxin Contamination in Nut-Based Products by the LC–MS/MS Method. Metabolites. 2022; 12(2):120. https://doi.org/10.3390/metabo12020120

Chicago/Turabian StyleEr Demirhan, Buket, and Burak Demirhan. 2022. "Investigation of Twelve Significant Mycotoxin Contamination in Nut-Based Products by the LC–MS/MS Method" Metabolites 12, no. 2: 120. https://doi.org/10.3390/metabo12020120

APA StyleEr Demirhan, B., & Demirhan, B. (2022). Investigation of Twelve Significant Mycotoxin Contamination in Nut-Based Products by the LC–MS/MS Method. Metabolites, 12(2), 120. https://doi.org/10.3390/metabo12020120