A Survey on Active Fault-Tolerant Control Systems

Abstract

1. Introduction

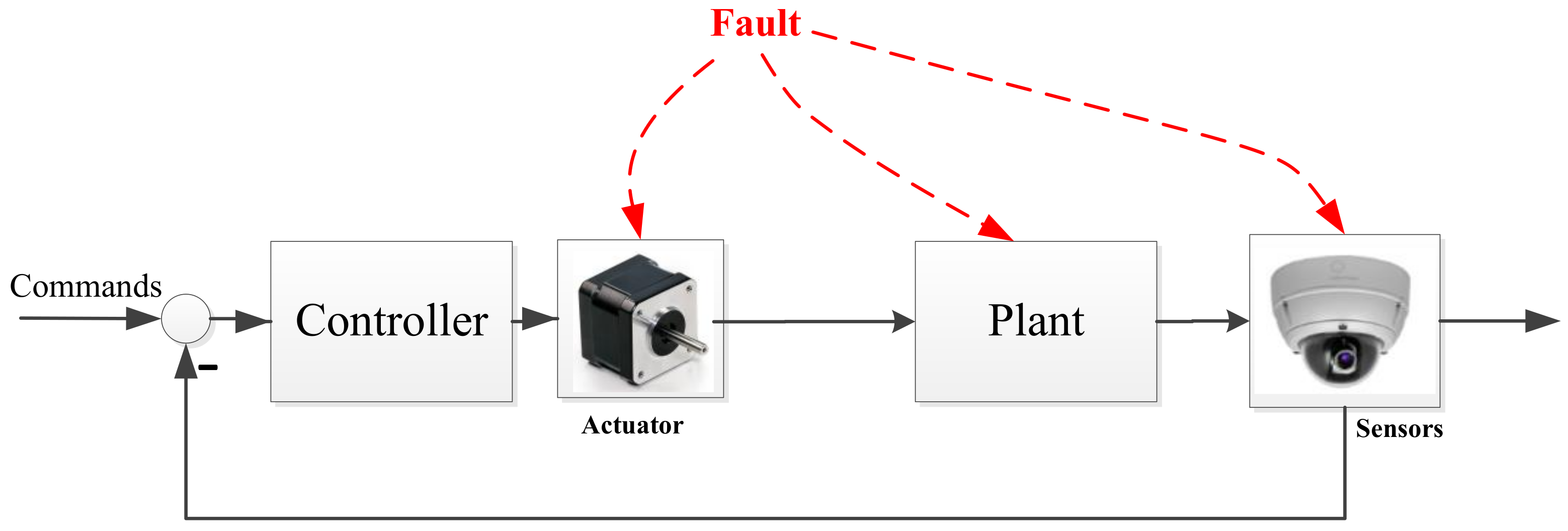

2. Fault Definition, Causes, and Types

2.1. Fault Types and Causes

- Interruptions in communication between the actuator/sensor and the control unit due to severe vibration, improper connections, metal flakes separating, and short circuit.

- Noise effect on the actuator/sensor due to environmental noise like a magnetic field.

- A fall in a supply voltage/current of the electrical actuator/sensor since they normally need a separated power supply [21].

- Actuator runaway/hardover where the control surface moves at its maximum rate limit and reaches its saturation limit. The actuator runaway can occur due to failure in an electronic component which leads to sending a random large signal to the actuators causing the actuator to be deflected at its maximum rate to its maximum deflection. This kind of failure has been reported as the main reason for several aircraft crashes such as Flight 85 (B-747, Alaska, 2002) [30] (where the lower rudder runaway led to full left deflection and caused the excessive roll of the aircraft).

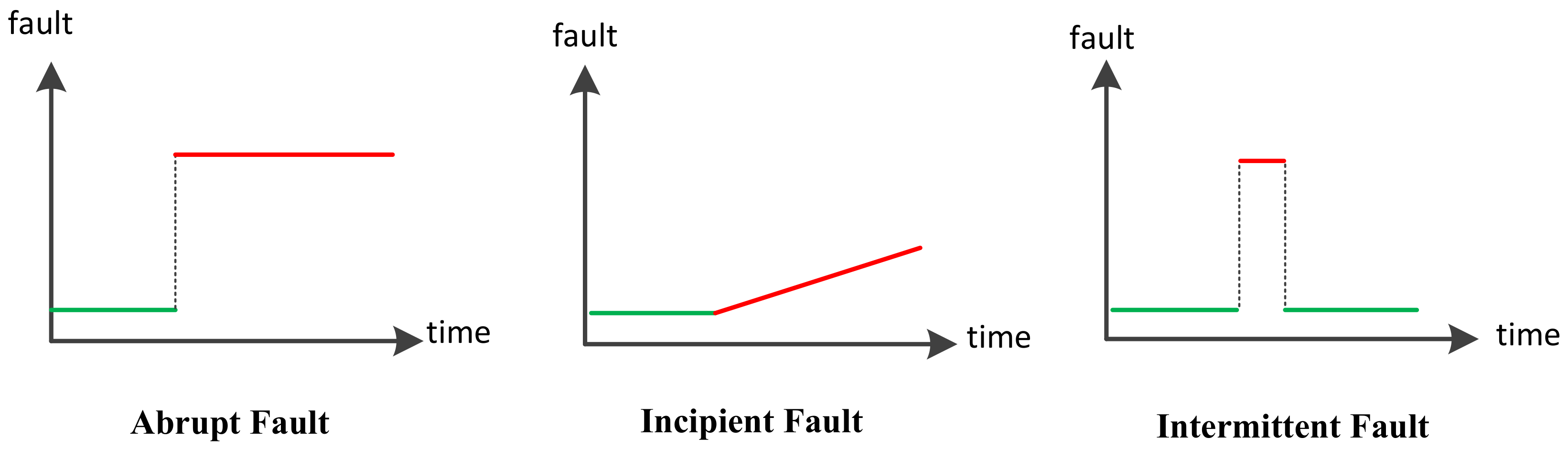

- Abrupt Faults: Abrupt faults can be defined as changes in parameter values, which are faster than the nominal dynamic process. Since tracking fast changes is a difficult process based on residuals, the ability to detect these abrupt changes is a great challenge for most of the fault detection algorithms [17]. Reference [31] considered the occurrence of three types of abrupt faults, severe vibrations, metal flakes separating, and short circuit.

- Incipient Faults: The problem with incipient faults is their small effects on the residuals, which could be hidden from the detection system. The sources of these faults are sensor/actuator inaccuracy or partial failure.

- Intermittent Fault: This kind of fault is a malfunction that occurs at irregular intervals. This kind of fault, common in most systems, can be caused by various contributing factors, i.e., improper connection of electrical wires to the sensors, actuators, etc. The complexity of the system increases the chance of the occurrence of intermittent faults. Due to the inconsistent nature of the intermittent faults, their detection is a great challenge for most of the detection algorithms. Figure 2 presents a graphical description of abrupt, incipient, and intermittent faults in the system.

2.2. Definition of Fault-Tolerant Controller

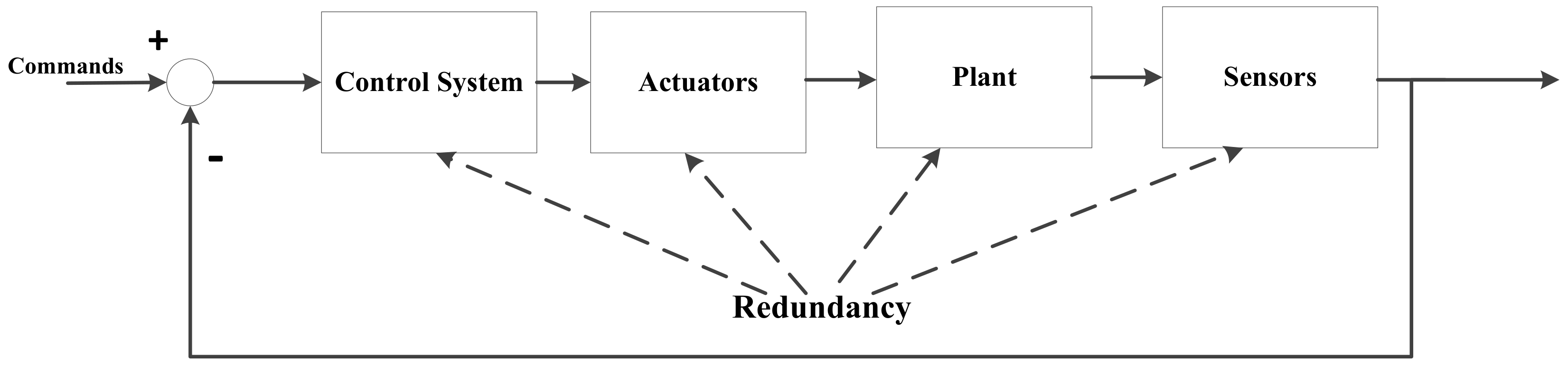

3. Passive and Active FTC

3.1. Passive FTC

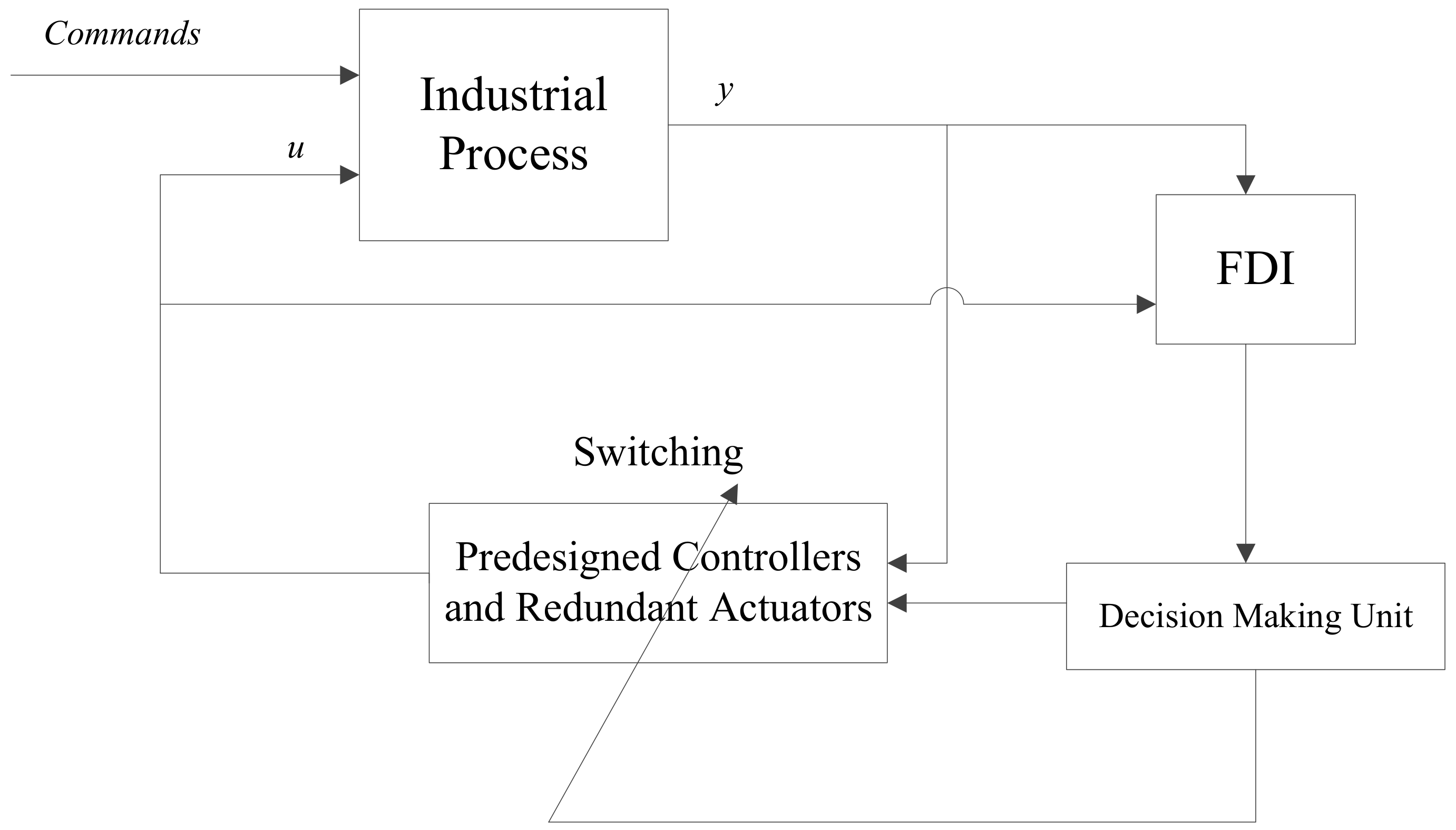

3.2. Active FTC

3.2.1. Switching-Based Active FTC

3.2.2. Hierarchical Structure Active FTC

3.2.3. Safe Parking Active FTC

3.2.4. Analytical Feedback Compensation Active FTC

3.2.5. Hybrid FTC

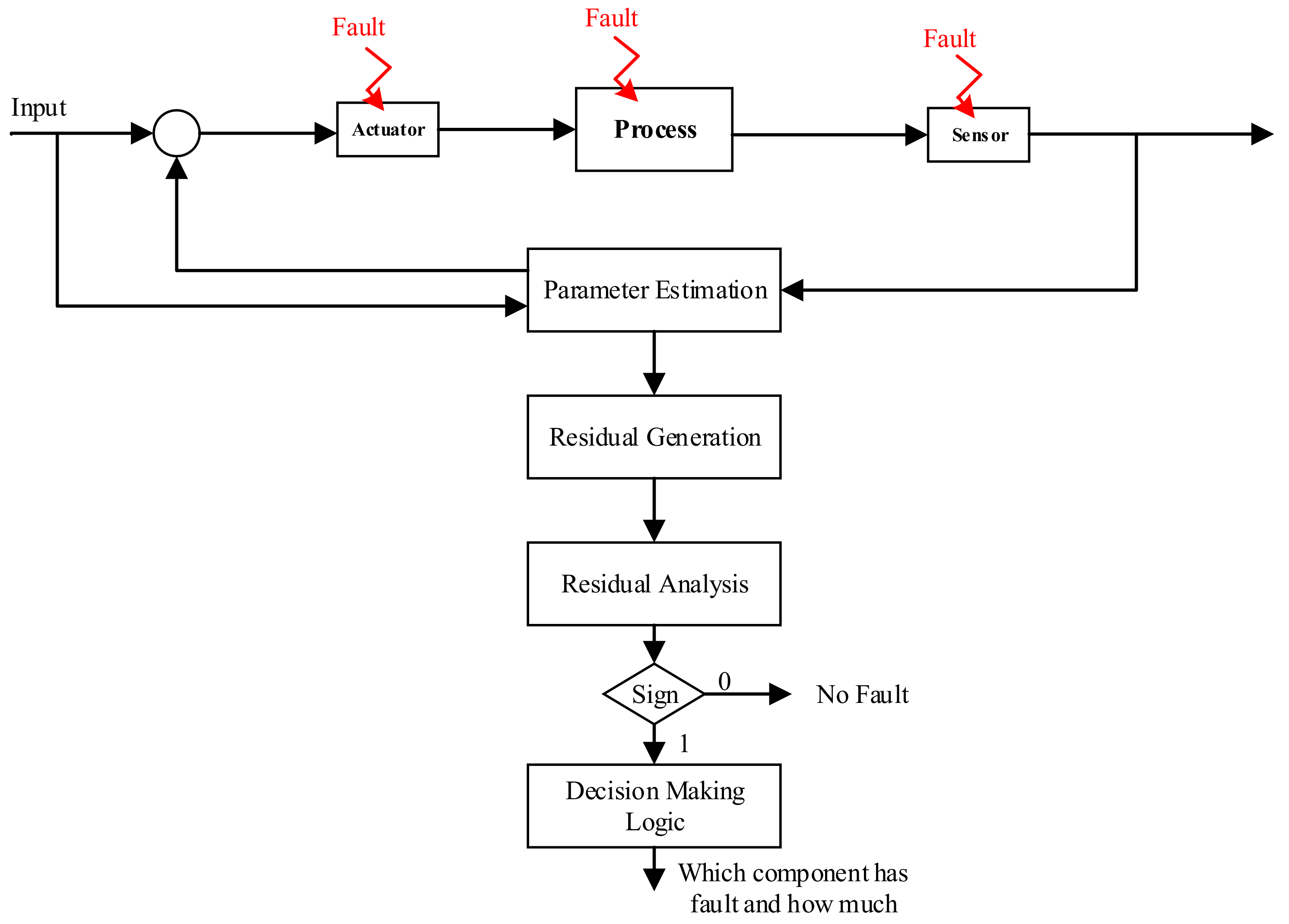

4. Fault Detection and Isolation

4.1. Model-Based FDI

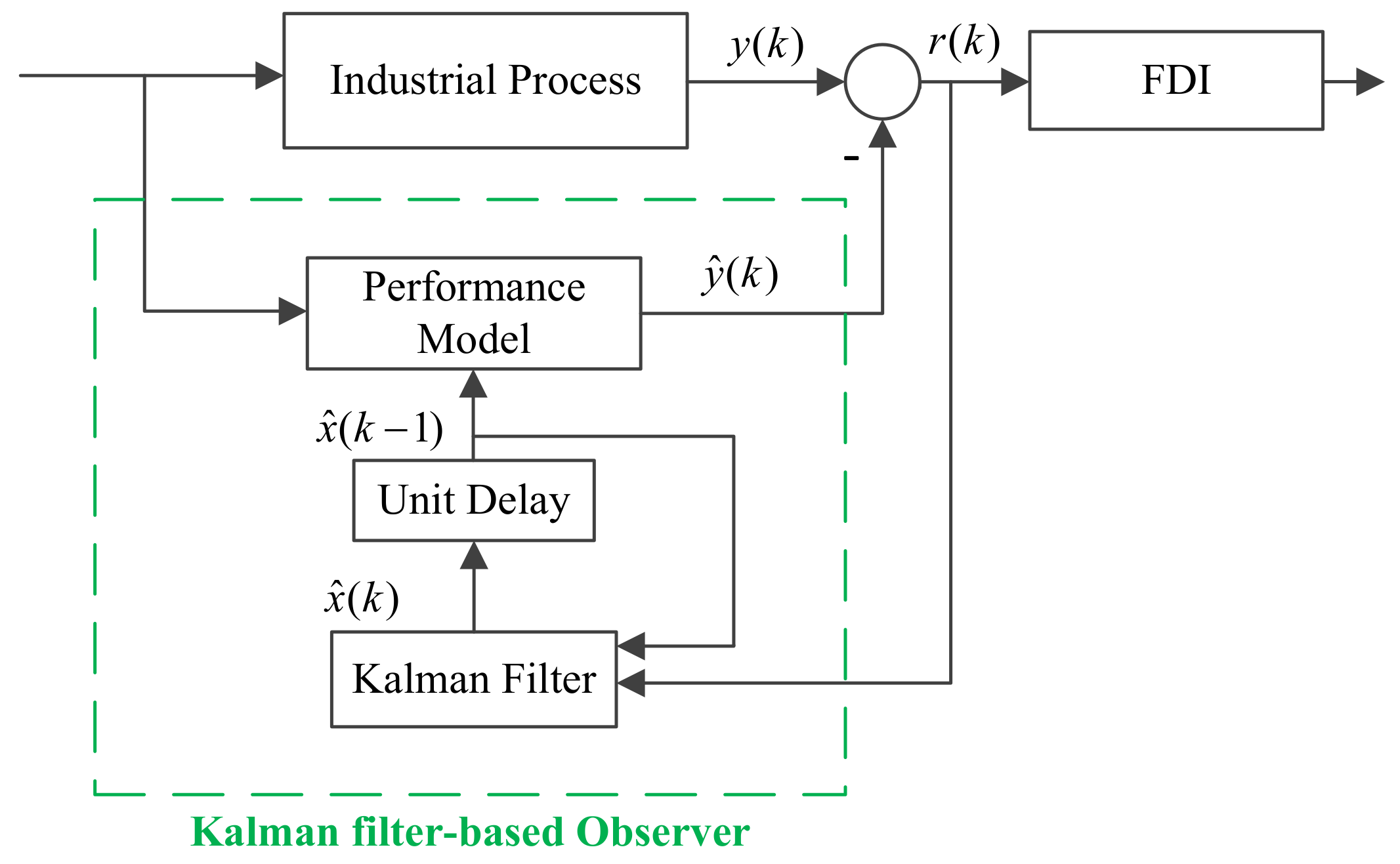

4.1.1. Kalman Filter-Based

4.1.2. Unknown Input Observers

4.1.3. Robust Fault Detection

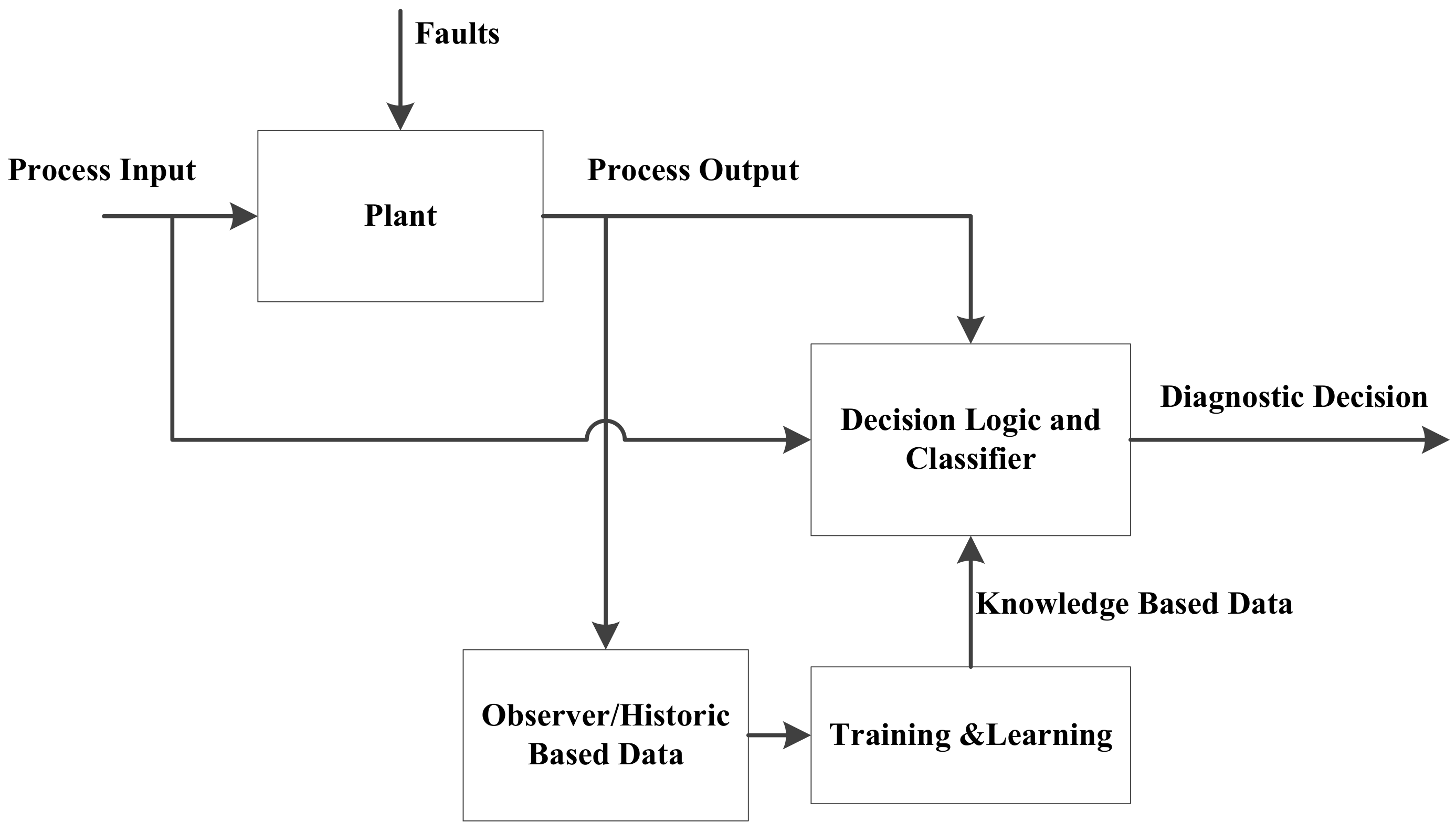

4.2. Knowledge-Based Approaches

4.2.1. Statistical-Analysis-FDI

4.2.2. Non-Statistical-Analysis-FDI

4.3. Combined Model-Knowledge-Based Approach

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stengel, R.F. Intelligent failure-tolerant control. IEEE Control Syst. 1991, 11, 14–23. [Google Scholar]

- Patton, R.J. Fault-tolerant control: The 1997 situation. IFAC Proc. Vol. 1997, 30, 1029–1051. [Google Scholar] [CrossRef]

- Lunze, J.; Richter, J.H. Reconfigurable fault-tolerant control: A tutorial introduction. Eur. J. Control 2008, 14, 359. [Google Scholar] [CrossRef]

- Alwi, H.; Edwards, C.; Tan, C.P. Fault tolerant control and fault detection and isolation. In Fault Detection and Fault-Tolerant Control Using Sliding Modes; Springer: Berlin/Heidelberg, Germany, 2011; pp. 7–27. [Google Scholar]

- Zhang, Y.; Jiang, J. Bibliographical review on reconfigurable fault-tolerant control systems. Annu. Rev. Control 2008, 32, 229–252. [Google Scholar] [CrossRef]

- Jiang, J.; Yu, X. Fault-tolerant control systems: A comparative study between active and passive approaches. Annu. Rev. Control 2012, 36, 60–72. [Google Scholar] [CrossRef]

- Yu, X.; Jiang, J. A survey of fault-tolerant controllers based on safety-related issues. Annu. Rev. Control 2015, 39, 46–57. [Google Scholar] [CrossRef]

- Moor, T. A discussion of fault-tolerant supervisory control in terms of formal languages. Annu. Rev. Control 2016, 41, 159–169. [Google Scholar] [CrossRef]

- Fekih, A. Fault diagnosis and fault tolerant control design for aerospace systems: A bibliographical review. In Proceedings of the 2014 American Control Conference (ACC), Portland, OR, USA, 4–6 June 2014; pp. 1286–1291. [Google Scholar]

- Yin, S.; Xiao, B.; Ding, S.X.; Zhou, D. A review on recent development of spacecraft attitude fault tolerant control system. IEEE Trans. Ind. Electron. 2016, 63, 3311–3320. [Google Scholar] [CrossRef]

- Qi, X.; Qi, J.; Theilliol, D.; Zhang, Y.; Han, J.; Song, D.; Hua, C. A review on fault diagnosis and fault tolerant control methods for single-rotor aerial vehicles. J. Intell. Robot. Syst. 2014, 73, 535–555. [Google Scholar] [CrossRef]

- Campos-Delgado, D.; Espinoza-Trejo, D.; Palacios, E. Fault-tolerant control in variable speed drives: A survey. IET Electr. Power Appl. 2008, 2, 121–134. [Google Scholar] [CrossRef]

- Bourogaoui, M.; Sethom, H.B.A.; Belkhodja, I.S. Speed/position sensor fault tolerant control in adjustable speed drives—A review. ISA Trans. 2016, 64, 269–284. [Google Scholar] [CrossRef]

- Pillai, D.S.; Rajasekar, N. A comprehensive review on protection challenges and fault diagnosis in PV systems. Renew. Sustain. Energy Rev. 2018, 91, 18–40. [Google Scholar] [CrossRef]

- Song, Y.; Wang, B. Survey on reliability of power electronic systems. IEEE Trans. Power Electron. 2013, 28, 591–604. [Google Scholar] [CrossRef]

- Mirafzal, B. Survey of Fault-Tolerance Techniques for Three-Phase Voltage Source Inverters. IEEE Trans. Ind. Electron. 2014, 61, 5192–5202. [Google Scholar] [CrossRef]

- Gao, Z.; Cecati, C.; Ding, S.X. A survey of fault diagnosis and fault-tolerant techniques—Part I: Fault diagnosis with model-based and signal-based approaches. IEEE Trans. Ind. Electron. 2015, 62, 3757–3767. [Google Scholar] [CrossRef]

- Cecati, C. A survey of fault diagnosis and fault-tolerant techniques—Part II: Fault diagnosis with knowledge-based and hybrid/active approaches. IEEE Trans. Ind. Electron. 2015, 62, 1. [Google Scholar]

- Sargolzaei, A.; Yen, K.K.; Abdelghani, M.N. Preventing time-delay switch attack on load frequency control in distributed power systems. IEEE Trans. Smart Grid 2016, 7, 1176–1185. [Google Scholar] [CrossRef]

- Ducard, G.; Geering, H.P. Efficient nonlinear actuator fault detection and isolation system for unmanned aerial vehicles. J. Guid. Control. Dyn. 2008, 31, 225–237. [Google Scholar] [CrossRef]

- Abbaspour, A.; Yen, K.K.; Forouzannezhad, P.; Sargolzaei, A. A Neural Adaptive Approach for Active Fault-tolerant Control Design in UAV. IEEE Trans. Syst. Man Cybern. Syst. 2018, 50, 3401–3411. [Google Scholar] [CrossRef]

- Abbaspour, A.; Yen, K.K.; Noei, S.; Sargolzaei, A. Detection of fault data injection attack on UAV using adaptive neural network. Procedia Comput. Sci. 2016, 95, 193–200. [Google Scholar] [CrossRef]

- Ao, W.; Song, Y.; Wen, C. Adaptive cyber-physical system attack detection and reconstruction with application to power systems. IET Control Theory Appl. 2016, 10, 1458–1468. [Google Scholar] [CrossRef]

- Deng, R.; Xiao, G.; Lu, R. Defending against false data injection attacks on power system state estimation. IEEE Trans. Ind. Inform. 2017, 13, 198–207. [Google Scholar] [CrossRef]

- Ghanavati, M.; Chakravarthy, A.; Menon, P.P. Analysis of Automotive Cyber-Attacks on Highways using Partial Differential Equation Models. IEEE Trans. Control. Netw. Syst. 2017, 5, 1775–1786. [Google Scholar] [CrossRef]

- Sargolzaei, A.; Yen, K.; Abdelghani, M.; Abbaspour, A.; Sargolzaei, S. Generalized attack model for networked control systems, evaluation of control methods. Intell. Control Autom. 2017, 8, 164. [Google Scholar] [CrossRef]

- Sargolzaei, A.; Yazdani, K.; Abbaspour, A.R.; Crane, C.D.; Dixon, W. Detection and Mitigation of False Data Injection Attacks in Networked Control Systems. IEEE Trans. Ind. Inform. 2019, 16, 4281–4292. [Google Scholar] [CrossRef]

- Fisher, J.R. Aircraft Control Using Nonlinear Dynamic Inversion in Conjunction with Adaptive Robust Control. Ph.D. Thesis, Texas A&M University, Uvalde, TX, USA, 2005. [Google Scholar]

- Burcham, F.W., Jr.; Maine, T.A.; Burken, J.J.; Bull, J. Using Engine Thrust for Emergency Flight Control: MD-11 and B-747 Results. 1998. Available online: https://www.nasa.gov/centers/dryden/pdf/88576main_H-2232.pdf (accessed on 15 August 2020).

- Burcham, F.W., Jr.; Fullerton, C.G.; Maine, T.A. Manual Manipulation of Engine Throttles for Emergency Flight Control. 2004. Available online: https://www.nasa.gov/centers/dryden/pdf/88776main_H-2547.pdf (accessed on 15 August 2020).

- Safarinejadian, B.; Kowsari, E. Fault detection in non-linear systems based on GP-EKF and GP-UKF algorithms. Syst. Sci. Control Eng. Open Access J. 2014, 2, 610–620. [Google Scholar] [CrossRef]

- Tabbache, B.; Rizoug, N.; Benbouzid, M.E.H.; Kheloui, A. A control reconfiguration strategy for post-sensor FTC in induction motor-based EVs. IEEE Trans. Veh. Technol. 2013, 62, 965–971. [Google Scholar] [CrossRef][Green Version]

- Zhang, G.; Zhang, H.; Huang, X.; Wang, J.; Yu, H.; Graaf, R. Active fault-tolerant control for electric vehicles with independently driven rear in-wheel motors against certain actuator faults. IEEE Trans. Control Syst. Technol. 2016, 24, 1557–1572. [Google Scholar] [CrossRef]

- Cristofaro, A.; Johansen, T.A. Fault tolerant control allocation using unknown input observers. Automatica 2014, 50, 1891–1897. [Google Scholar] [CrossRef]

- Chen, M.; Shi, P.; Lim, C.C. Adaptive neural fault-tolerant control of a 3-DOF model helicopter system. IEEE Trans. Syst. Man Cybern. Syst. 2016, 46, 260–270. [Google Scholar] [CrossRef]

- Abbaspour, A.; Sargolzaei, A.; Yen, K. Detection of false data injection attack on load frequency control in distributed power systems. In Proceedings of the IEEE Power Symposium (NAPS), 2017 North American, Morgantown, WV, USA, 17–19 September 2017; pp. 1–6. [Google Scholar]

- Li, X.J.; Yang, G.H. Neural-network-based adaptive decentralized fault-tolerant control for a class of interconnected nonlinear systems. IEEE Trans. Neural Netw. Learn. Syst. 2016, 29, 144–155. [Google Scholar] [CrossRef] [PubMed]

- Abbaspour, A.; Sargolzaei, A.; Yen, K.K. A Neural Network Based Resilient Control Design for Distributed Power Systems Under Faults and Attacks. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I& CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–6. [Google Scholar]

- Gao, H.; Song, Y.; Wen, C. Backstepping design of adaptive neural fault-tolerant control for MIMO nonlinear systems. IEEE Trans. Neural Netw. Learn. Syst. 2017, 28, 2605–2613. [Google Scholar] [CrossRef] [PubMed]

- Yin, S.; Yang, H.; Gao, H.; Qiu, J.; Kaynak, O. An adaptive NN-based approach for fault-tolerant control of nonlinear time-varying delay systems with unmodeled dynamics. IEEE Trans. Neural Netw. Learn. Syst. 2017, 28, 1902–1913. [Google Scholar] [CrossRef] [PubMed]

- Abbaspour, A.; Sanchez, M.; Sargolzaei, A.; Yen, K.; Sornkhampan, N. Adaptive Neural Network Based Fault Detection Design for Unmanned Quadrotor under Faults and Cyber Attacks. In Proceedings of the 25th International Conference on Systems Engineering, Las Vegas, NV, USA, 22–23 August 2017. [Google Scholar]

- Fekih, A. Fault tolerant control design for complex systems: Current advances and open research problems. In Proceedings of the 2015 IEEE International Conference on Industrial Technology (ICIT), Seville, Spain, 17–19 March 2015; pp. 1007–1012. [Google Scholar]

- Alwi, H.; Edwards, C.; Stroosma, O.; Mulder, J. Fault tolerant sliding mode control design with piloted simulator evaluation. J. Guid. Control. Dyn. 2008, 31, 1186–1201. [Google Scholar] [CrossRef]

- Qinglei, H.; Zhang, Y.; Xing, H.; Bing, X. Adaptive integral-type sliding mode control for spacecraft attitude maneuvering under actuator stuck failures. Chin. J. Aeronaut. 2011, 24, 32–45. [Google Scholar]

- Wang, R.; Wang, J. Passive actuator fault-tolerant control for a class of overactuated nonlinear systems and applications to electric vehicles. IEEE Trans. Veh. Technol. 2013, 62, 972–985. [Google Scholar] [CrossRef]

- Yang, Z.; Blanke, M.; Verhaegen, M. Robust control mixer method for reconfigurable control design using model matching. IET Control Theory Appl. 2007, 1, 349–357. [Google Scholar] [CrossRef]

- Shen, H.; Park, J.H.; Wu, Z.G. Finite-time reliable 2-∞/∞ control for Takagi–Sugeno fuzzy systems with actuator faults. IET Control Theory Appl. 2014, 8, 688–696. [Google Scholar] [CrossRef]

- Shen, H.; Su, L.; Park, J.H. Reliable mixed H∞/passive control for T–S fuzzy delayed systems based on a semi-Markov jump model approach. Fuzzy Sets Syst. 2017, 314, 79–98. [Google Scholar] [CrossRef]

- Staroswiecki, M.; Yang, H.; Jiang, B. Progressive accommodation of parametric faults in linear quadratic control. Automatica 2007, 43, 2070–2076. [Google Scholar] [CrossRef]

- Wu, H.N. Reliable LQ fuzzy control for continuous-time nonlinear systems with actuator faults. IEEE Trans. Syst. Man Cybern. Part B (Cybern.) 2004, 34, 1743–1752. [Google Scholar] [CrossRef] [PubMed]

- Zeghlache, S.; Kara, K.; Saigaa, D. Fault tolerant control based on interval type-2 fuzzy sliding mode controller for coaxial trirotor aircraft. ISA Trans. 2015, 59, 215–231. [Google Scholar] [CrossRef] [PubMed]

- Benosman, M.; Lum, K.Y. Passive actuators’ fault-tolerant control for affine nonlinear systems. IEEE Trans. Control Syst. Technol. 2010, 18, 152–163. [Google Scholar] [CrossRef]

- Luo, Y.; Serrani, A.; Yurkovich, S.; Oppenheimer, M.W.; Doman, D.B. Model-predictive dynamic control allocation scheme for reentry vehicles. J. Guid. Control. Dyn. 2007, 30, 100–113. [Google Scholar] [CrossRef]

- Johansen, T.A.; Fossen, T.I. Control allocation—A survey. Automatica 2013, 49, 1087–1103. [Google Scholar] [CrossRef]

- Hua, M.D.; Ducard, G.; Hamel, T.; Mahony, R.; Rudin, K. Implementation of a nonlinear attitude estimator for aerial robotic vehicles. IEEE Trans. Control Syst. Technol. 2014, 22, 201–213. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, L.; Zhang, H.; Xiao, G. Fault-tolerant controller design for a class of nonlinear MIMO discrete-time systems via online reinforcement learning algorithm. IEEE Trans. Syst. Man Cybern. Syst. 2016, 46, 611–622. [Google Scholar] [CrossRef]

- Ye, D.; Yang, G.H. Adaptive fault-tolerant tracking control against actuator faults with application to flight control. IEEE Trans. Control Syst. Technol. 2006, 14, 1088–1096. [Google Scholar] [CrossRef]

- Alwi, H.; Edwards, C. Fault tolerant longitudinal aircraft control using non-linear integral sliding mode. IET Control Theory Appl. 2014, 8, 1803–1814. [Google Scholar] [CrossRef]

- Yu, X.; Jiang, J. Hybrid fault-tolerant flight control system design against partial actuator failures. IEEE Trans. Control Syst. Technol. 2012, 20, 871–886. [Google Scholar] [CrossRef]

- Lu, P.; Van Eykeren, L.; van Kampen, E.J.; de Visser, C.; Chu, Q. Double-model adaptive fault detection and diagnosis applied to real flight data. Control Eng. Pract. 2015, 36, 39–57. [Google Scholar] [CrossRef]

- Gao, Z.; Jiang, B.; Shi, P.; Qian, M.; Lin, J. Active fault tolerant control design for reusable launch vehicle using adaptive sliding mode technique. J. Frankl. Inst. 2012, 349, 1543–1560. [Google Scholar] [CrossRef]

- Bateman, F.; Noura, H.; Ouladsine, M. Fault diagnosis and fault-tolerant control strategy for the aerosonde UAV. IEEE Trans. Aerosp. Electron. Syst. 2011, 47, 2119–2137. [Google Scholar] [CrossRef]

- Park, P.; Khadilkar, H.; Balakrishnan, H.; Tomlin, C.J. High confidence networked control for next generation air transportation systems. IEEE Trans. Autom. Control 2014, 59, 3357–3372. [Google Scholar] [CrossRef]

- Nazarnia, H.; Sarmasti, H. Characterizing infrastructure resilience in disasters using dynamic network analysis of consumers’ service disruption patterns. Civ. Eng. J. 2018, 4, 2356–2372. [Google Scholar] [CrossRef]

- Abbaspour, A.; Sargolzaei, A.; Forouzannezhad, P.; Yen, K.K.; Sarwat, A.I. Resilient Control Design for Load Frequency Control System under False Data Injection Attacks. IEEE Trans. Ind. Electron. 2019, 67, 7951–7962. [Google Scholar] [CrossRef]

- Colaneri, P. Dwell time analysis of deterministic and stochastic switched systems. In Proceedings of the 2009 IEEE European Control Conference (ECC), Budapest, Hungary, 23–26 August 2009; pp. 15–31. [Google Scholar]

- Allerhand, L.I.; Shaked, U. Robust switching-based fault tolerant control. IEEE Trans. Autom. Control 2015, 60, 2272–2276. [Google Scholar] [CrossRef]

- Yang, H.; Jiang, B.; Staroswiecki, M. Supervisory fault tolerant control for a class of uncertain nonlinear systems. Automatica 2009, 45, 2319–2324. [Google Scholar] [CrossRef]

- Zhang, X.; Polycarpou, M.M.; Parisini, T. Adaptive fault diagnosis and fault-tolerant control of MIMO nonlinear uncertain systems. Int. J. Control 2010, 83, 1054–1080. [Google Scholar] [CrossRef]

- Perk, S.; Shao, Q.; Teymour, F.; Cinar, A. An adaptive fault-tolerant control framework with agent-based systems. Int. J. Robust Nonlinear Control 2012, 22, 43–67. [Google Scholar] [CrossRef]

- Izadi, H.A.; Gordon, B.W.; Zhang, Y. Hierarchical decentralized receding horizon control of multiple vehicles with communication failures. IEEE Trans. Aerosp. Electron. Syst. 2013, 49, 744–759. [Google Scholar] [CrossRef]

- Gandhi, R.; Mhaskar, P. A safe-parking framework for plant-wide fault-tolerant control. Chem. Eng. Sci. 2009, 64, 3060–3071. [Google Scholar] [CrossRef]

- Du, M.; Nease, J.; Mhaskar, P. An integrated fault diagnosis and safe-parking framework for fault-tolerant control of nonlinear systems. Int. J. Robust Nonlinear Control 2012, 22, 105–122. [Google Scholar] [CrossRef]

- Paoli, A.; Sartini, M.; Lafortune, S. Active fault tolerant control of discrete event systems using online diagnostics. Automatica 2011, 47, 639–649. [Google Scholar] [CrossRef]

- Abbaspour, A.; Yen, K.K.; Forouzannezhad, P.; Sargolzaei, A. An Adaptive Resilient Control Approach for Pressure Control in Proton Exchange Membrane Fuel Cells. IEEE Trans. Ind. Appl. 2019, 55, 6344–6354. [Google Scholar] [CrossRef]

- Wang, J.S.; Yang, G.H. Data-driven output-feedback fault-tolerant compensation control for digital PID control systems with unknown dynamics. IEEE Trans. Ind. Electron. 2016, 63, 7029–7039. [Google Scholar] [CrossRef]

- Salimifard, M.; Talebi, H.A. Robust output feedback fault-tolerant control of non-linear multi-agent systems based on wavelet neural networks. IET Control Theory Appl. 2017, 11, 3004–3015. [Google Scholar] [CrossRef]

- Hu, Q.; Niu, G.; Wang, C. Spacecraft attitude fault-tolerant control based on iterative learning observer and control allocation. Aerosp. Sci. Technol. 2018, 75, 245–253. [Google Scholar] [CrossRef]

- Gertler, J. Fault Detection and Diagnosis; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Willsky, A.; Jones, H. A generalized likelihood ratio approach to the detection and estimation of jumps in linear systems. IEEE Trans. Autom. Control 1976, 21, 108–112. [Google Scholar] [CrossRef]

- Beard, R.V. Failure Accomodation in Linear Systems through Self-Reorganization. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1971. [Google Scholar]

- Blanke, M.; Kinnaert, M.; Lunze, J.; Staroswiecki, M.; Schröder, J. Diagnosis and Fault-Tolerant Control; Springer: Berlin/Heidelberg, Germany, 2006; Volume 2. [Google Scholar]

- Ding, S.X. Model-Based Fault Diagnosis Techniques: Design Schemes, Algorithms, and Tools; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Venkatasubramanian, V.; Rengaswamy, R.; Kavuri, S.N.; Yin, K. A review of process fault detection and diagnosis: Part III: Process history based methods. Comput. Chem. Eng. 2003, 27, 327–346. [Google Scholar] [CrossRef]

- Isermann, R. Model-based fault-detection and diagnosis–status and applications. Annu. Rev. Control 2005, 29, 71–85. [Google Scholar] [CrossRef]

- Zhong, M.; Xue, T.; Ding, S.X. A survey on model-based fault diagnosis for linear discrete time-varying systems. Neurocomputing 2018, 306, 51–60. [Google Scholar] [CrossRef]

- Habibi, H.; Howard, I.; Simani, S. Reliability improvement of wind turbine power generation using model-based fault detection and fault tolerant control: A review. Renew. Energy 2019, 135, 877–896. [Google Scholar] [CrossRef]

- Manandhar, K.; Cao, X.; Hu, F.; Liu, Y. Detection of faults and attacks including false data injection attack in smart grid using kalman filter. IEEE Trans. Control Netw. Syst. 2014, 1, 370–379. [Google Scholar] [CrossRef]

- Pourbabaee, B.; Meskin, N.; Khorasani, K. Sensor Fault Detection, Isolation, and Identification Using Multiple-Model-Based Hybrid Kalman Filter for Gas Turbine Engines. IEEE Trans. Control Syst. Tech. 2016, 24, 1184–1200. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B. Iterative Residual Generator for Fault Detection with Linear Time-Invariant State–Space Models. IEEE Trans. Autom. Control 2017, 62, 5422–5428. [Google Scholar] [CrossRef]

- Lu, P.; van Kampen, E.J.; de Visser, C.; Chu, Q. Nonlinear aircraft sensor fault reconstruction in the presence of disturbances validated by real flight data. Control Eng. Pract. 2016, 49, 112–128. [Google Scholar] [CrossRef]

- Liu, Z.; He, H. Sensor fault detection and isolation for a lithium-ion battery pack in electric vehicles using adaptive extended Kalman filter. Appl. Energy 2017, 185, 2033–2044. [Google Scholar] [CrossRef]

- Rahimi, A.; Kumar, K.D.; Alighanbari, H. Enhanced adaptive unscented Kalman filter for reaction wheels. IEEE Trans. Aerosp. Electron. Syst. 2015, 51, 1568–1575. [Google Scholar] [CrossRef]

- Zhong, M.; Liu, S.; Zhao, H. Krein space-based H∞ fault estimation for linear discrete time-varying systems. Acta Autom. Sin. 2008, 34, 1529–1533. [Google Scholar] [CrossRef]

- Aouaouda, S.; Chadli, M.; Shi, P.; Karimi, H.R. Discrete-time H_/H∞ sensor fault detection observer design for nonlinear systems with parameter uncertainty. Int. J. Robust Nonlinear Control 2015, 25, 339–361. [Google Scholar] [CrossRef]

- Dong, H.; Wang, Z.; Bu, X.; Alsaadi, F.E. Distributed fault estimation with randomly occurring uncertainties over sensor networks. Int. J. Gen. Syst. 2016, 45, 662–674. [Google Scholar] [CrossRef]

- Li, X.; Liu, H.H.; Jiang, B. Parametrization of optimal fault detection filters. Automatica 2015, 56, 70–77. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, H.; Li, T. Krein space-based H∞ adaptive smoother design for a class of Lipschitz nonlinear discrete-time systems. Appl. Math. Comput. 2016, 287, 134–148. [Google Scholar] [CrossRef]

- Zhang, K.; Jiang, B.; Yan, X.G.; Mao, Z. Sliding mode observer based incipient sensor fault detection with application to high-speed railway traction device. ISA Trans. 2016, 63, 49–59. [Google Scholar] [CrossRef]

- Djeghali, N.; Djennoune, S.; Bettayeb, M.; Ghanes, M.; Barbot, J.P. Observation and sliding mode observer for nonlinear fractional-order system with unknown input. ISA Trans. 2016, 63, 1–10. [Google Scholar] [CrossRef]

- Castillo, I.; Edgar, T.F.; Fernández, B.R. Robust model-based fault detection and isolation for nonlinear processes using sliding modes. Int. J. Robust Nonlinear Control 2012, 22, 89–104. [Google Scholar] [CrossRef]

- Bøgh, S. Multiple hypothesis-testing approach to FDI for the industrial actuator benchmark. Control Eng. Pract. 1995, 3, 1763–1768. [Google Scholar] [CrossRef]

- Nikiforov, I.; Varavva, V.; Kireichikov, V. Application of statistical fault detection algorithms to navigation systems monitoring. Automatica 1993, 29, 1275–1290. [Google Scholar] [CrossRef]

- Simon, D.L.; Borguet, S.; Léonard, O.; Zhang, X.F. Aircraft engine gas path diagnostic methods: Public benchmarking results. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013; American Society of Mechanical Engineers: New York, NY, USA, 2013; p. V004T06A014. [Google Scholar]

- Haykin, S. Kalman Filtering and Neural Networks; John Wiley & Sons: Hoboken, NJ, USA, 2004; Volume 47. [Google Scholar]

- Wan, E.A.; Van Der Merwe, R. The unscented Kalman filter for nonlinear estimation. In Proceedings of the IEEE 2000 Adaptive Systems for Signal Processing, Communications, and Control Symposium AS-SPCC, Lake Louise, AB, Canada, 4 October 2000; pp. 153–158. [Google Scholar]

- Chen, J.; Patton, R.J. Robust Model-Based Fault Diagnosis for Dynamic Systems; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; Volume 3. [Google Scholar]

- Khalghani, M.R.; Solanki, J.; Solanki, S.; Khooban, M.H.; Sargolzaei, A. Resilient Frequency Control Design for Microgrids Under False Data Injection. IEEE Trans. Ind. Electron. 2020. [Google Scholar] [CrossRef]

- Karimi, H.R.; Zapateiro, M.; Luo, N. A linear matrix inequality approach to robust fault detection filter design of linear systems with mixed time-varying delays and nonlinear perturbations. J. Frankl. Inst. 2010, 347, 957–973. [Google Scholar] [CrossRef]

- Hassanabadi, A.H.; Shafiee, M.; Puig, V. UIO design for singular delayed LPV systems with application to actuator fault detection and isolation. Int. J. Syst. Sci. 2016, 47, 107–121. [Google Scholar] [CrossRef]

- Behzad, H.; Casavola, A.; Tedesco, F.; Sadrnia, M.A. A fault-tolerant sensor reconciliation scheme based on LPV Unknown Input Observers. In Proceedings of the 2016 IEEE 55th Conference on Decision and Control (CDC), Las Vegas, NV, USA, 12–14 December 2016; pp. 2158–2163. [Google Scholar]

- Li, S.; Wang, H.; Aitouche, A.; Tian, Y.; Christov, N. Robust unknown input observer design for state estimation and fault detection using linear parameter varying model. J. Phys. Conf. Ser. 2017, 783, 012001. [Google Scholar] [CrossRef]

- Du, D.; Jiang, B. Actuator fault estimation and accommodation for switched systems with time delay: Discrete-time case. ISA Trans. 2016, 62, 137–144. [Google Scholar] [CrossRef] [PubMed]

- Hur, H.; Ahn, H.S. Unknown Input H∞ Observer-Based Localization of a Mobile Robot with Sensor Failure. IEEE/ASME Trans. Mechatron. 2014, 19, 1830–1838. [Google Scholar] [CrossRef]

- Ding, S.; Jeinsch, T.; Frank, P.; Ding, E. A unified approach to the optimization of fault detection systems. Int. J. Adapt. Control Signal Process. 2000, 14, 725–745. [Google Scholar] [CrossRef]

- Li, X.; Zhou, K. A time domain approach to robust fault detection of linear time-varying systems. Automatica 2009, 45, 94–102. [Google Scholar] [CrossRef]

- Zhong, M.; Zhou, D.; Ding, S.X. On Designing H∞ Fault Detection Filter for Linear Discrete Time-Varying Systems. IEEE Trans. Autom. Control 2010, 55, 1689–1695. [Google Scholar] [CrossRef]

- Hassibi, B.; Sayed, A.H.; Kailath, T. Indefinite-Quadratic Estimation and Control: A Unified Approach to H2 and H-Infinity Theories; SIAM: Philadelphia, PA, USA, 1999; Volume 16. [Google Scholar]

- Zhao, D.; Wang, Y.; Li, Y.; Ding, S.X. H∞ fault estimation for 2-D linear discrete time-varying systems based on Krein space method. IEEE Trans. Syst. Man Cybern. Syst. 2017, 48, 2070–2079. [Google Scholar]

- Luo, Y.; Wang, Z.; Wei, G.; Alsaadi, F.E. H∞ Fuzzy Fault Detection for Uncertain 2-D Systems Under Round-Robin Scheduling Protocol. IEEE Trans. Syst. Man Cybern. Syst. 2017, 47, 2172–2184. [Google Scholar] [CrossRef]

- Dong, H.; Wang, Z.; Ding, S.X.; Gao, H. On H-infinity estimation of randomly occurring faults for a class of nonlinear time-varying systems with fading channels. IEEE Trans. Autom. Control 2016, 61, 479–484. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, Z.; Wei, G. Fault detection for fuzzy systems with multiplicative noises under periodic communication protocols. IEEE Trans. Fuzzy Syst. 2017, 26, 2384–2395. [Google Scholar] [CrossRef]

- Zhou, Y.; Soh, Y.; Shen, J. High-gain observer with higher order sliding mode for state and unknown disturbance estimations. Int. J. Robust Nonlinear Control 2014, 24, 2136–2151. [Google Scholar] [CrossRef]

- Walcott, B.; Zak, S. State observation of nonlinear uncertain dynamical systems. IEEE Trans. Autom. Control 1987, 32, 166–170. [Google Scholar] [CrossRef]

- Edwards, C.; Spurgeon, S.K.; Patton, R.J. Sliding mode observers for fault detection and isolation. Automatica 2000, 36, 541–553. [Google Scholar] [CrossRef]

- Koshkouei, A.J.; Zinober, A.S. Sliding mode state observation for non-linear systems. Int. J. Control 2004, 77, 118–127. [Google Scholar] [CrossRef]

- Drakunov, S.; Utkin, V. Sliding mode observers. Tutorial. In Proceedings of the 1995 34th IEEE Conference on Decision and Control, New Orleans, LA, USA, 13–15 December 1995; Volume 4, pp. 3376–3378. [Google Scholar]

- Barbot, J.P.; Boukhobza, T.; Djemai, M. Sliding mode observer for triangular input form. In Proceedings of the 35th IEEE Conference on Decision and Control, Kobe, Japan, 13 December 1996; Volume 2, pp. 1489–1490. [Google Scholar]

- Veluvolu, K.C.; Soh, Y.C. High-gain observers with sliding mode for state and unknown input estimations. IEEE Trans. Ind. Electron. 2009, 56, 3386–3393. [Google Scholar] [CrossRef]

- De Loza, A.F.; Cieslak, J.; Henry, D.; Dávila, J.; Zolghadri, A. Sensor fault diagnosis using a non-homogeneous high-order sliding mode observer with application to a transport aircraft. IET Control Theory Appl. 2015, 9, 598–607. [Google Scholar] [CrossRef]

- Laghrouche, S.; Liu, J.; Ahmed, F.S.; Harmouche, M.; Wack, M. Adaptive second-order sliding mode observer-based fault reconstruction for PEM fuel cell air-feed system. IEEE Trans. Control Syst. Technol. 2015, 23, 1098–1109. [Google Scholar] [CrossRef]

- Galván-Guerra, R.; Fridman, L.; Dávila, J. High-order sliding-mode observer for linear time-varying systems with unknown inputs. Int. J. Robust Nonlinear Control 2017, 27, 2338–2356. [Google Scholar] [CrossRef]

- Ríos, H.; Punta, E.; Fridman, L. Fault detection and isolation for nonlinear non-affine uncertain systems via sliding-mode techniques. Int. J. Control 2017, 90, 218–230. [Google Scholar] [CrossRef]

- Wang, X.; Tan, C.P.; Zhou, D. A novel sliding mode observer for state and fault estimation in systems not satisfying matching and minimum phase conditions. Automatica 2017, 79, 290–295. [Google Scholar] [CrossRef]

- Chen, W.; Chowdhury, F.N. A synthesized design of sliding-mode and Luenberger observers for early detection of incipient faults. Int. J. Adapt. Control Signal Process. 2010, 24, 1021–1035. [Google Scholar] [CrossRef]

- Zhang, J.; Swain, A.K.; Nguang, S.K. Detection and isolation of incipient sensor faults for a class of uncertain non-linear systems. IET Control Theory Appl. 2012, 6, 1870–1880. [Google Scholar] [CrossRef]

- Wang, X.; Kruger, U.; Irwin, G.W.; McCullough, G.; McDowell, N. Nonlinear PCA with the local approach for diesel engine fault detection and diagnosis. IEEE Trans. Control Syst. Technol. 2008, 16, 122–129. [Google Scholar] [CrossRef]

- Jiang, B.; Xiang, J.; Wang, Y. Rolling bearing fault diagnosis approach using probabilistic principal component analysis denoising and cyclic bispectrum. J. Vib. Control 2016, 22, 2420–2433. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, B.; Lu, N.; Mao, Z. Deep PCA Based Real-time Incipient Fault Detection and Diagnosis Methodology for Electrical Drive in High-Speed Trains. IEEE Trans. Veh. Technol. 2018, 67, 4819–4830. [Google Scholar] [CrossRef]

- Wang, T.; Xu, H.; Han, J.; Elbouchikhi, E.; Benbouzid, M.E.H. Cascaded H-bridge multilevel inverter system fault diagnosis using a PCA and multiclass relevance vector machine approach. IEEE Trans. Power Electron. 2015, 30, 7006–7018. [Google Scholar] [CrossRef]

- Li, G.; Liu, B.; Qin, S.J.; Zhou, D. Quality relevant data-driven modeling and monitoring of multivariate dynamic processes: The dynamic T-PLS approach. IEEE Trans. Neural Netw. 2011, 22, 2262–2271. [Google Scholar]

- Ding, S.X.; Yin, S.; Peng, K.; Hao, H.; Shen, B. A novel scheme for key performance indicator prediction and diagnosis with application to an industrial hot strip mill. IEEE Trans. Ind. Inform. 2013, 9, 2239–2247. [Google Scholar] [CrossRef]

- Vitale, R.; de Noord, O.E.; Ferrer, A. A kernel-based approach for fault diagnosis in batch processes. J. Chemom. 2014, 28, S697–S707. [Google Scholar] [CrossRef]

- Yin, S.; Zhu, X.; Kaynak, O. Improved PLS focused on key-performance-indicator-related fault diagnosis. IEEE Trans. Ind. Electron. 2015, 62, 1651–1658. [Google Scholar] [CrossRef]

- Jiao, J.; Yu, H.; Wang, G. A Quality-Related Fault Detection Approach Based on Dynamic Least Squares for Process Monitoring. IEEE Trans. Ind. Electron. 2016, 63, 2625–2632. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, N.; Li, S. Fault isolation of nonlinear processes based on fault directions and features. IEEE Trans. Control Syst. Technol. 2014, 22, 1567–1572. [Google Scholar] [CrossRef]

- Guo, Y.; Na, J.; Li, B.; Fung, R.F. Envelope extraction based dimension reduction for independent component analysis in fault diagnosis of rolling element bearing. J. Sound Vib. 2014, 333, 2983–2994. [Google Scholar] [CrossRef]

- Yang, T.; Pen, H.; Wang, Z.; Chang, C.S. Feature knowledge based fault detection of induction motors through the analysis of stator current data. IEEE Trans. Instrum. Meas. 2016, 65, 549–558. [Google Scholar] [CrossRef]

- Xu, Y.; Shen, S.Q.; He, Y.L.; Zhu, Q.X. A Novel Hybrid Method Integrating ICA-PCA with Relevant Vector Machine for Multivariate Process Monitoring. IEEE Trans. Control. Syst. Technol. 2018, 27, 1780–1787. [Google Scholar] [CrossRef]

- Widodo, A.; Yang, B.S. Support vector machine in machine condition monitoring and fault diagnosis. Mech. Syst. Signal Process. 2007, 21, 2560–2574. [Google Scholar] [CrossRef]

- Yin, S.; Gao, X.; Karimi, H.R.; Zhu, X. Study on support vector machine-based fault detection in tennessee eastman process. In Abstract and Applied Analysis; Hindawi: London, UK, 2014; Volume 2014. [Google Scholar]

- Namdari, M.; Jazayeri-Rad, H.; Hashemi, S.J. Process fault diagnosis using support vector machines with a genetic algorithm based parameter tuning. J. Autom. Control 2014, 2, 1–7. [Google Scholar]

- Yi, Z.; Etemadi, A.H. Line-to-line fault detection for photovoltaic arrays based on multiresolution signal decomposition and two-stage support vector machine. IEEE Trans. Ind. Electron. 2017, 64, 8546–8556. [Google Scholar] [CrossRef]

- Zidi, S.; Moulahi, T.; Alaya, B. Fault detection in wireless sensor networks through SVM classifier. IEEE Sens. J. 2018, 18, 340–347. [Google Scholar] [CrossRef]

- Tang, X.; Xie, X.; Fan, B.; Sun, Y. A Fault-Tolerant Flow Measuring Method Based on PSO-SVM with Transit-Time Multipath Ultrasonic Gas Flowmeters. IEEE Trans. Instrum. Meas. 2018, 67, 992–1005. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, Y.; Ding, S.X.; Zi, Y.; Wei, M. A Fault Detection and Health Monitoring Scheme for Ship Propulsion Systems using SVM Technique. IEEE Access 2018, 6, 16207–16215. [Google Scholar] [CrossRef]

- Shatnawi, Y.; Al-Khassaweneh, M. Fault diagnosis in internal combustion engines using extension neural network. IEEE Trans. Ind. Electron. 2014, 61, 1434–1443. [Google Scholar] [CrossRef]

- De Bruin, T.; Verbert, K.; Babuška, R. Railway track circuit fault diagnosis using recurrent neural networks. IEEE Trans. Neural Netw. Learn. Syst. 2017, 28, 523–533. [Google Scholar] [CrossRef]

- Bach-Andersen, M.; Rømer-Odgaard, B.; Winther, O. Deep learning for automated drivetrain fault detection. Wind Energy 2018, 21, 29–41. [Google Scholar] [CrossRef]

- James, J.; Hou, Y.; Lam, A.Y.; Li, V.O. Intelligent Fault Detection Scheme for Microgrids with Wavelet-based Deep Neural Networks. IEEE Trans. Smart Grid 2017, 10, 1694–1703. [Google Scholar]

- Panigrahi, B.K.; Ray, P.K.; Rout, P.K.; Mohanty, A.; Pal, K. Detection and classification of faults in a microgrid using wavelet neural network. J. Inf. Optim. Sci. 2018, 39, 327–335. [Google Scholar] [CrossRef]

- Zidani, F.; Diallo, D.; Benbouzid, M.E.H.; Naït-Saïd, R. A fuzzy-based approach for the diagnosis of fault modes in a voltage-fed PWM inverter induction motor drive. IEEE Trans. Ind. Electron. 2008, 55, 586–593. [Google Scholar] [CrossRef]

- Li, L.; Ding, S.X.; Qiu, J.; Yang, Y.; Xu, D. Fuzzy observer-based fault detection design approach for nonlinear processes. IEEE Trans. Syst. Man Cybern. Syst. 2017, 47, 1941–1952. [Google Scholar] [CrossRef]

- Li, L.; Ding, S.X.; Qiu, J.; Yang, Y. Real-time fault detection approach for nonlinear systems and its asynchronous T–S fuzzy observer-based implementation. IEEE Trans. Cybern. 2017, 47, 283–294. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Chadli, M.; Ding, S.X.; Qiu, J.; Yang, Y. Diagnostic Observer Design for T–S Fuzzy Systems: Application to Real-Time-Weighted Fault-Detection Approach. IEEE Trans. Fuzzy Syst. 2018, 26, 805–816. [Google Scholar] [CrossRef]

- Talebi, H.A.; Khorasani, K.; Tafazoli, S. A recurrent neural-network-based sensor and actuator fault detection and isolation for nonlinear systems with application to the satellite’s attitude control subsystem. IEEE Trans. Neural Netw. 2009, 20, 45–60. [Google Scholar] [CrossRef] [PubMed]

- Abbaspour, A.; Aboutalebi, P.; Yen, K.K.; Sargolzaei, A. Neural adaptive observer-based sensor and actuator fault detection in nonlinear systems: Application in UAV. ISA Trans. 2017, 67, 317–329. [Google Scholar] [CrossRef] [PubMed]

- Sheibat-Othman, N.; Laouti, N.; Valour, J.P.; Othman, S. Support vector machines combined to observers for fault diagnosis in chemical reactors. Can. J. Chem. Eng. 2014, 92, 685–695. [Google Scholar] [CrossRef]

- Muradore, R.; Fiorini, P. A PLS-based statistical approach for fault detection and isolation of robotic manipulators. IEEE Trans. Ind. Electron. 2012, 59, 3167–3175. [Google Scholar] [CrossRef]

- Rashid, M.M.; Yu, J. Hidden Markov model based adaptive independent component analysis approach for complex chemical process monitoring and fault detection. Ind. Eng. Chem. Res. 2012, 51, 5506–5514. [Google Scholar] [CrossRef]

| Approach | Advantage | Disadvantage |

|---|---|---|

| KF | Low computation load and guaranteed convergence for linear systems with noise | Cannot be applied to nonlinear systems or linear systems without Gaussian distribution |

| EKF | Can be applied to the nonlinear system. Robustness against the unmodeled dynamics, model uncertainties, and disturbances. | Heavier computation load than KF, and can be only implemented on systems with Gaussian distribution. Errors related to the linearization of EKF may reduce the estimation accuracy or can even result in filter divergence. |

| UKF | Can be applied to nonlinear systems and lower computation load than EKF | Similar to EKF may be unstable to highly nonlinear system |

| UIO | Its ability in the complete decoupling of the estimated states from the unknown inputs under certain conditions | Cannot be applied to highly nonlinear systems |

| Being robust against uncertainties and disturbances | Vulnerable to incipient faults. Cannot be applied to highly nonlinear systems | |

| SMO | Being robust against uncertainties and disturbances | Vulnerable to incipient fault |

| Approach | Advantage | Disadvantage |

|---|---|---|

| PCA | reducing the dimensionality of data, while keeping as much variation as possible | can be only applied to Gaussian distribution data |

| ICA | Can be applied to non-Gaussian distribution | The historical data must be statistically independent and must have non-Gaussian distributions |

| SVM | Ability with working with both of Gaussian distribution and non-Gaussian distribution | dependency to the kernel selection |

| ANN | Ability with working with both of Gaussian distribution and non-Gaussian distribution | Need for huge historical data of the system performance |

| Fuzzy | Being robust against uncertainties and disturbances. This observer is only sensitive to the fault signal, and other parameter variations and uncertainties cannot deteriorate the FD performance | Vulnerable to the incipient fault. Obtaining the fuzzy if-then rules needs extensive expert knowledge of the system. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbaspour, A.; Mokhtari, S.; Sargolzaei, A.; Yen, K.K. A Survey on Active Fault-Tolerant Control Systems. Electronics 2020, 9, 1513. https://doi.org/10.3390/electronics9091513

Abbaspour A, Mokhtari S, Sargolzaei A, Yen KK. A Survey on Active Fault-Tolerant Control Systems. Electronics. 2020; 9(9):1513. https://doi.org/10.3390/electronics9091513

Chicago/Turabian StyleAbbaspour, Alireza, Sohrab Mokhtari, Arman Sargolzaei, and Kang K. Yen. 2020. "A Survey on Active Fault-Tolerant Control Systems" Electronics 9, no. 9: 1513. https://doi.org/10.3390/electronics9091513

APA StyleAbbaspour, A., Mokhtari, S., Sargolzaei, A., & Yen, K. K. (2020). A Survey on Active Fault-Tolerant Control Systems. Electronics, 9(9), 1513. https://doi.org/10.3390/electronics9091513