Energy Harvesting Backpacks for Human Load Carriage: Modelling and Performance Evaluation

Abstract

1. Introduction

2. Methods

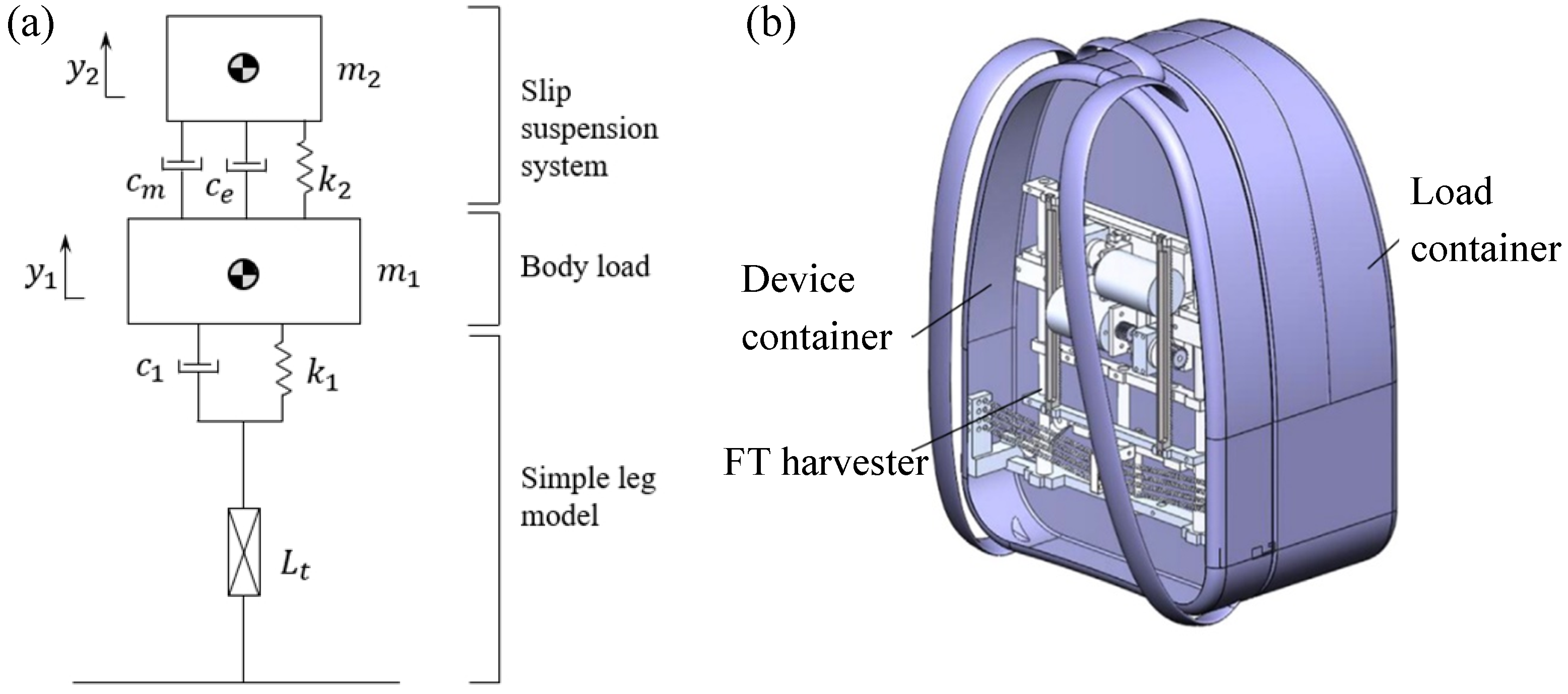

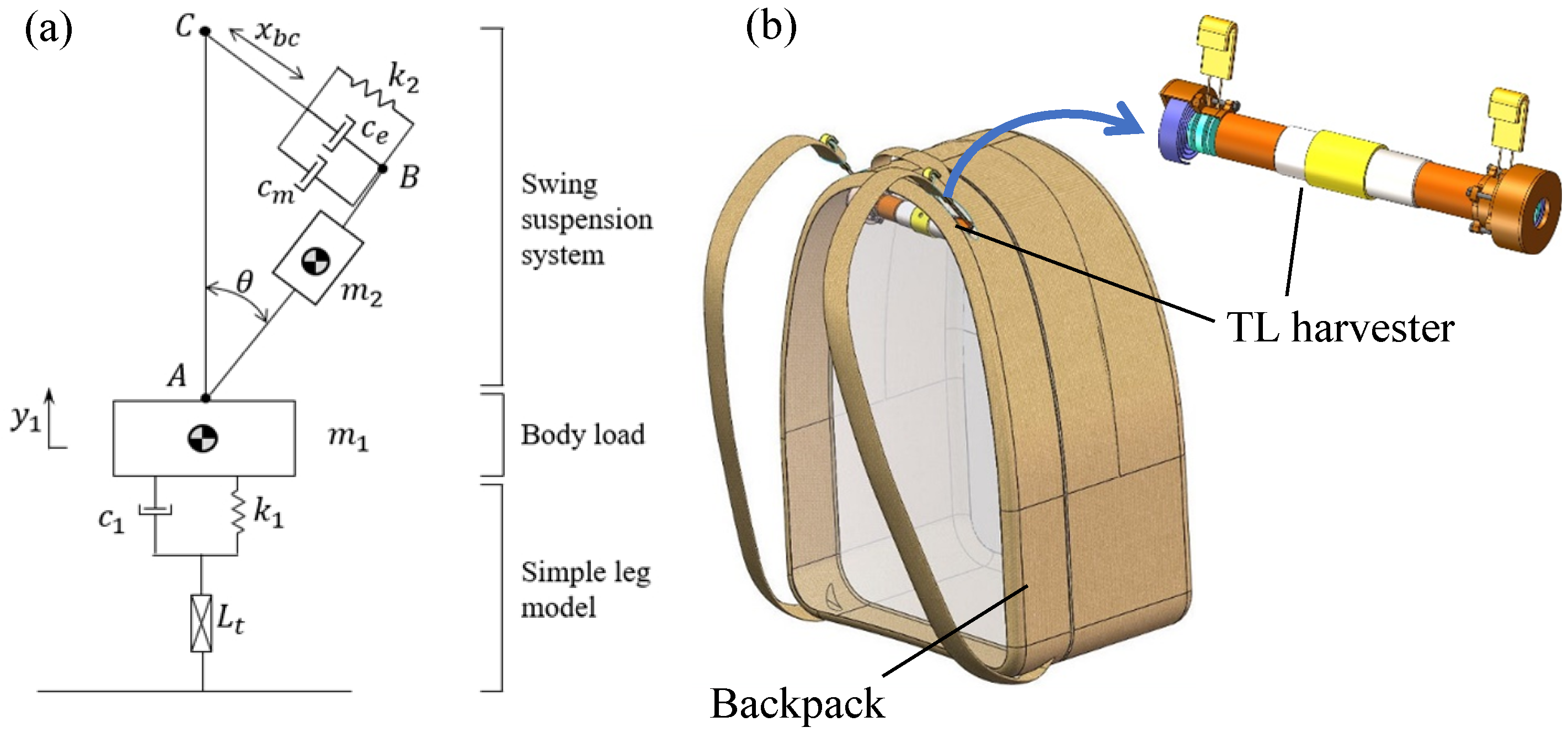

2.1. Dynamic Model of the System

2.1.1. Spring-Mass-Damper Slip Model

2.1.2. Spring-Mass-Damper Swing Model

2.2. Electrical Power Generation

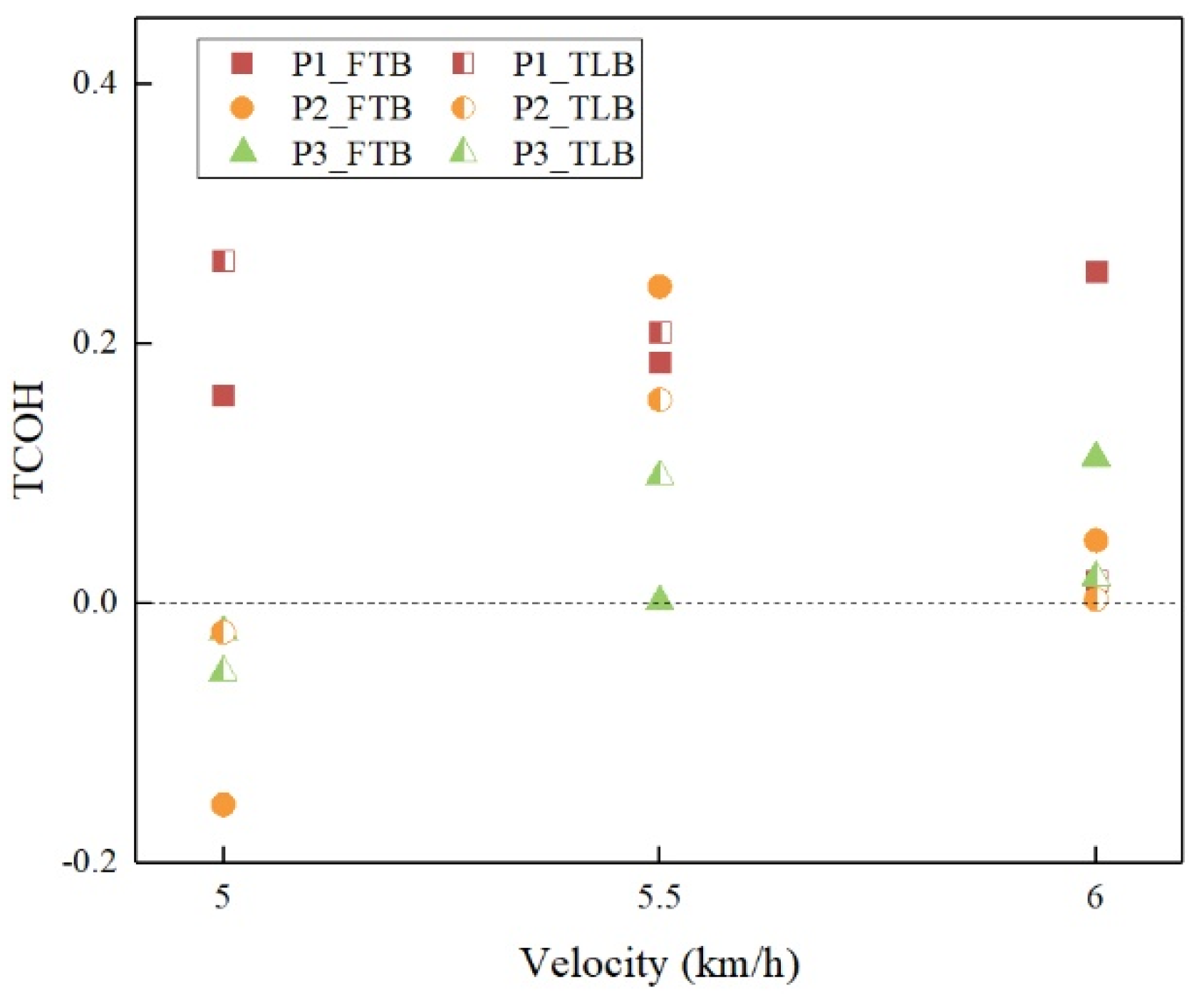

2.3. Human Net Metabolic Power and TCOH Calculation

3. Experimental Validation

3.1. Human Walking Experimentation

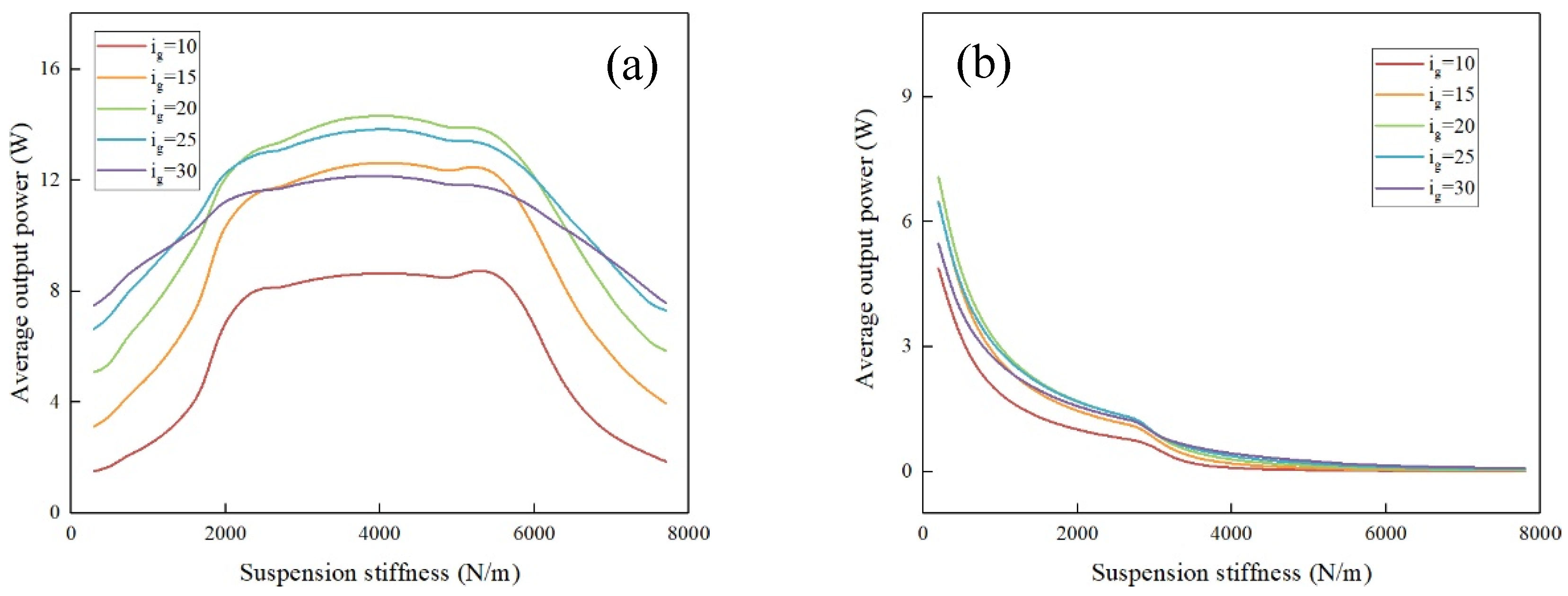

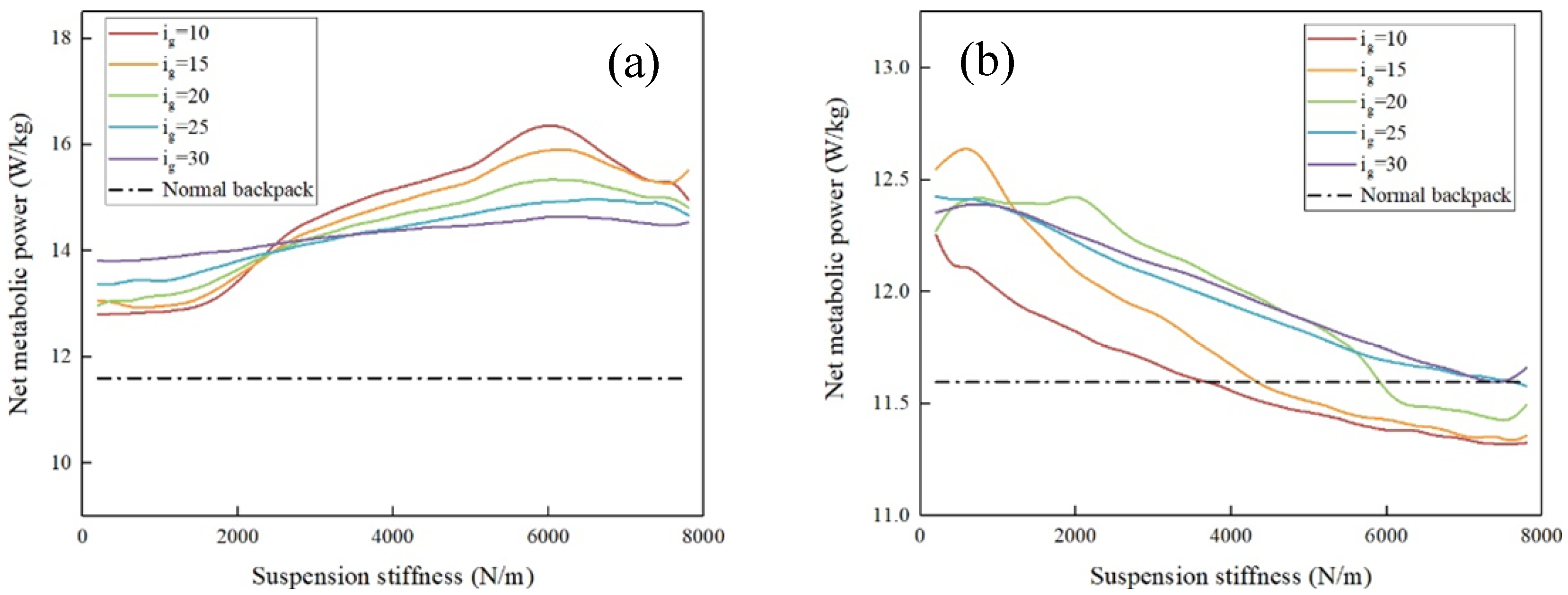

3.2. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bastien, G.J.; Willems, P.A.; Schepens, B.; Heglund, N.C. Effect of load and speed on the energetic cost of human walking. Eur. J. Appl. Physiol. 2005, 94, 76–83. [Google Scholar] [CrossRef] [PubMed]

- Holewijn, M. Physiological strain due to load carrying. Eur. J. Appl. Physiol. Occup. Physiol. 1990, 61, 237–245. [Google Scholar] [CrossRef] [PubMed]

- Birrell, S.A.; Hooper, R.H.; Haslam, R.A. The effect of military load carriage on ground reaction forces. Gait Posture 2007, 26, 611–614. [Google Scholar] [CrossRef] [PubMed]

- Tilbury-Davis, D.C.; Hooper, R.H. The kinetic and kinematic effects of increasing load carriage upon the lower limb. Hum. Mov. Sci. 1999, 18, 693–700. [Google Scholar] [CrossRef]

- Hadid, A.; Belzer, N.; Shabshin, N.; Zeilig, G.; Gefen, A.; Epstein, Y. The effect of mechanical strains in soft tissues of the shoulder during load carriage. J. Biomech. 2015, 48, 4160–4165. [Google Scholar] [CrossRef] [PubMed]

- Hadid, A.; Katz, I.; Haker, T.; Zeilig, G.; Defrin, R.; Epstein, Y.; Gefen, A. Effect of Load Carriage on Upper Limb Performance. Med. Sci. Sports Exerc. 2017, 49, 1006–1014. [Google Scholar] [CrossRef]

- Xie, L.; Du, R. Harvest human kinetic energy to power portable electronics. J. Mech. Sci. Technol. 2012, 26, 2005–2008. [Google Scholar] [CrossRef]

- Von Buren, T.; Mitcheson, P.D.; Green, T.C.; Yeatman, E.M.; Holmes, A.S.; Troster, G. Optimization of inertial micropower generators for human walking motion. IEEE Sens. J. 2006, 6, 28–38. [Google Scholar] [CrossRef]

- Romero, E.; Warrington, R.O.; Neuman, M.R. Body motion for powering biomedical devices. In Proceedings of the 2009 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Minneapolis, MN, USA, 3–6 September 2009; pp. 2752–2755. [Google Scholar]

- Paradiso, J.A.; Starner, T. Energy scavenging for mobile and wireless electronics. IEEE Pervasive Comput. 2005, 4, 18–27. [Google Scholar] [CrossRef]

- Granstrom, J.; Feenstra, J.; Sodano, H.A.; Farinholt, K. Energy harvesting from a backpack instrumented with piezoelectric shoulder straps. Smart Mater. Struct. 2007, 16, 1810. [Google Scholar] [CrossRef]

- Martin, J.-P.; Li, Q. Design, model, and performance evaluation of a biomechanical energy harvesting backpack. Mech. Syst. Signal Process. 2019, 134, 106318. [Google Scholar] [CrossRef]

- Elvin, N.G.; Elvin, A.A. Vibrational energy harvesting from human gait. IEEE/ASME Trans. Mechatron. 2012, 18, 637–644. [Google Scholar] [CrossRef]

- Kuang, Y.; Ruan, T.; Chew, Z.J.; Zhu, M. Energy harvesting during human walking to power a wireless sensor node. Sens. Actuators A Phys. 2017, 254, 69–77. [Google Scholar] [CrossRef]

- Ando, B.; Baglio, S.; Marietta, V.; Pistorio, A.; Bulsara, A.R. Preliminary investigation of a mixed inductive-piezoelectric energy harvester from human walking. In Proceedings of the IEEE Sensors Applications Symposium, Glassboro, NJ, USA, 13–15 March 2017. [Google Scholar]

- Rome, L.C.; Flynn, L.; Goldman1, E.M.; Yoo1, T.D. Generating Electricity While Walking with Loads. Science 2005, 309, 1725–1728. [Google Scholar] [CrossRef] [PubMed]

- Xie, L.; Cai, M. Increased energy harvesting and reduced accelerative load for backpacks via frequency tuning. Mech. Syst. Signal Process. 2015, 58–59, 399–415. [Google Scholar] [CrossRef]

- Talarico, M.K.; Haynes, C.A.; Douglas, J.S.; Collazo, J. Spatiotemporal and kinematic changes in gait while carrying an energy harvesting assault pack system. J. Biomech. 2018, 74, 143–149. [Google Scholar] [CrossRef] [PubMed]

- Yue, Y.; Liu, M.; Tai, W.C.; Lei, Z. Design and Treadmill Test of a Broadband Energy Harvesting Backpack With a Mechanical Motion Rectifier. J. Mech. Des. 2018, 140, 085001. [Google Scholar] [CrossRef]

- Rome, L.C.; Flynn, L.; Yoo, T.D. Rubber bands reduce the cost of carrying loads. Nature 2006, 444, 1023–1024. [Google Scholar] [CrossRef]

- Hoover, J.; Meguid, S. Performance assessment of the suspended-load backpack. Int. J. Mech. Mater. Des. 2011, 7, 111–121. [Google Scholar] [CrossRef]

- Foissac, M.; Millet, G.Y.; Geyssant, A.; Freychat, P.; Belli, A. Characterization of the mechanical properties of backpacks and their influence on the energetics of walking. J. Biomech. 2009, 42, 125–130. [Google Scholar] [CrossRef]

- Xu, X.; Hsiang, S.M.; Mirka, G.A. The effects of a suspended-load backpack on gait. Gait Posture 2009, 29, 151–153. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Ackerman, J.; Seipel, J. A model of human walking energetics with an elastically-suspended load. J. Biomech. 2014, 47, 1922–1927. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Li, T.; Li, Q.; Liu, T.; Yi, J. A simple model for predicting walking energetics with elastically-suspended backpack. J. Biomech. 2016, 49, 4150–4153. [Google Scholar] [CrossRef] [PubMed]

- Rubinshtein, Z.E.; Peretz, M.M.; Riemer, R. Biomechanical energy harvesting system with optimal cost-of-harvesting tracking algorithm. In Proceedings of the 2014 IEEE Applied Power Electronics Conference and Exposition-APEC 2014, Fort Worth, TX, USA, 16–20 March 2014; pp. 3105–3109. [Google Scholar]

- Chen, M.; Yang, Z.; Saad, W.; Yin, C.; Poor, H.V.; Cui, S. A joint learning and communications framework for federated learning over wireless networks. arXiv 2019, arXiv:1909.07972. [Google Scholar]

- Yang, Z.; Xu, W.; Pan, Y.; Pan, C.; Chen, M. Energy efficient resource allocation in machine-to-machine communications with multiple access and energy harvesting for IoT. IEEE Internet Things J. 2017, 5, 229–245. [Google Scholar] [CrossRef]

- Mi, J.; Xu, L.; Zhu, Z.; Liu, M.; Zuo, L. Design, modeling and testing of a one-way energy harvesting backpack. In Proceedings of the Active and Passive Smart Structures and Integrated Systems XII, Denver, CO, USA, 10 April 2018; p. 1059520. [Google Scholar]

- Xie, L.; Li, X.; Cai, S.; Huang, L.; Li, J. Increased energy harvesting from backpack to serve as self-sustainable power source via a tube-like harvester. Mech. Syst. Signal Process. 2017, 96, 215–225. [Google Scholar] [CrossRef]

- Khaligh, A.; Zeng, P.; Zheng, C. Kinetic energy harvesting using piezoelectric and electromagnetic technologies—State of the art. IEEE Trans. Ind. Electron. 2009, 57, 850–860. [Google Scholar] [CrossRef]

- Wei, C.; Jing, X. A comprehensive review on vibration energy harvesting: Modelling and realization. Renew. Sustain. Energy Rev. 2017, 74, 1–18. [Google Scholar] [CrossRef]

- Shepertycky, M.; Li, Q. Generating Electricity during Walking with a Lower Limb-Driven Energy Harvester: Targeting a Minimum User Effort. PLoS ONE 2015, 10. [Google Scholar] [CrossRef]

- Ackerman, J.; Seipel, J. Energy efficiency of legged robot locomotion with elastically suspended loads. IEEE Trans. Robot. 2013, 29, 321–330. [Google Scholar] [CrossRef]

- Inman, V.T.; Eberhart, H.D. The major determinants in normal and pathological gait. JBJS 1953, 35, 543–558. [Google Scholar]

- Grieve, D.; Gear, R.J. The relationships between length of stride, step frequency, time of swing and speed of walking for children and adults. Ergonomics 1966, 9, 379–399. [Google Scholar] [CrossRef] [PubMed]

- Xu, X. An Investigation on the Interactivity between Suspended-Load Backpack and Human Gait. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2008. [Google Scholar]

- Zhang, L.; Xu, D.; Makhsous, M.; Lin, F. Stiffness and viscous damping of the human leg. In Proceedings of the 24th Annual Meeting of the American Society of Biomechanics, Chicago, IL, USA, 19–22 July 2000. [Google Scholar]

- Tzu-wei, P.H.; Kuo, A.D. Mechanics and energetics of load carriage during human walking. J. Exp. Biol. 2014, 217, 605–613. [Google Scholar]

- Margaria, R. Biomechanics and Energetics of Muscular Exercise; Oxford University Press: Oxford, MI, USA, 1976. [Google Scholar]

- Keren, R.; Or, Y. Energy performance analysis of a backpack suspension system with a timed clutch for human load carriage. Mech. Mach. Theory 2018, 120, 250–264. [Google Scholar] [CrossRef]

- Brockway, J.M. Derivation of formulae used to calculate energy expenditure in man. Hum. Nutr. Clin. Nutr. 1987, 41, 463–471. [Google Scholar] [PubMed]

- Ackerman, J.; Potwar, K.; Seipel, J. Suspending loads decreases load stability but may slightly improve body stability. J. Biomech. 2017, 52, 38–47. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Description | Values for Slip Model | Values for Swing Model |

|---|---|---|---|

| (m) | Leg length [17] | 0.95 | 0.95 |

| (km/h) | Walking speed [17] | 5.5 | 5.5 |

| (N/m) | Effective leg stiffness [38] | 28,500 | 28,500 |

| (N s/m) | Effective leg damping [38] | 950 | 950 |

| (N/m) | Suspension stiffness | Variable | Variable |

| (N s/m) | Suspension damping | Variable | Variable |

| (kg) | Body load [17,30] | 80 | 75 |

| (kg) | Backpack load [17,30] | 16.5 | 16.5 |

| Parameter | FT Harvester | TL Harvester |

|---|---|---|

| Generator | DCX26L, Maxon | DCX26L, Maxon |

| Gear ratio | 21 | 21 |

| External load resistance () | 2 | 2 |

| Stiffness (N/m) | 2800 | 1200 |

| Weight of the harvester (kg) | 1.5 | 1.5 |

| Weight of the framework (kg) | 5 | 0 |

| Participant | Gender | Age (years) | Height (cm) | Weight (kg) |

|---|---|---|---|---|

| 1 | Male | 27 | 173 | 62 |

| 2 | Male | 21 | 166 | 55 |

| 3 | Male | 22 | 174 | 65 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Wang, R.; Yang, Z.; Xie, L. Energy Harvesting Backpacks for Human Load Carriage: Modelling and Performance Evaluation. Electronics 2020, 9, 1061. https://doi.org/10.3390/electronics9071061

Huang L, Wang R, Yang Z, Xie L. Energy Harvesting Backpacks for Human Load Carriage: Modelling and Performance Evaluation. Electronics. 2020; 9(7):1061. https://doi.org/10.3390/electronics9071061

Chicago/Turabian StyleHuang, Ledeng, Ruishi Wang, Zhenhua Yang, and Longhan Xie. 2020. "Energy Harvesting Backpacks for Human Load Carriage: Modelling and Performance Evaluation" Electronics 9, no. 7: 1061. https://doi.org/10.3390/electronics9071061

APA StyleHuang, L., Wang, R., Yang, Z., & Xie, L. (2020). Energy Harvesting Backpacks for Human Load Carriage: Modelling and Performance Evaluation. Electronics, 9(7), 1061. https://doi.org/10.3390/electronics9071061