Photovoltaic Degradation Rate Affected by Different Weather Conditions: A Case Study Based on PV Systems in the UK and Australia

Abstract

1. Introduction

- United States of America (USA): The USA is placed on the top five countries leading the PV technology worldwide [6]. In 1977, the Department of Energy established the Solar Energy Research Institute in Golden, Colorado. In 1991, it was renamed as the NREL. Outdoor testing of modules and sub-modules started at the Solar Energy Research Institute in 1982. When amorphous silicon (a-Si) modules first became commercially available, NREL began to report degradation rate that were considerably higher than −1.0%/year [7]. In [8] and [9], similar results of the PV degradation were found in small (<10 kWp) size PV installations, followed by a yearly degradation rate of approximate −0.8% to −1.25%/year.

- Europe: The terrestrial focus of PV industry in Europe can be traced to the oil crisis of the 1970s. The development and institution of PV sites can be divided into publicly and privately funded projects. The publicly funded portion in Europe can be additionally divided into the umbrella organization of the Commission of the European Communities and individual national programs. Never the less, various references indicate that the annual degradation rate in Spain and Italy is between −0.8% to −1.1%/year [10,11,12], in Germany between −0.5% to −0.7%/year [13,14], in Cyprus between −0.8% to −1.1%/year [15], in Greece between −0.9% to −1.13%/year [16], and finally in Poland is always greater than −0.9%/year [17].

- Asia: Chandel et al. [18] studied the degradation rate in India based on 28 year filed exposes mono crystalline PV modules, with the degradation rate found to be −1.4%/year. Similar results were found by Thotakura et al. [19]. In this study, the degradation rate in southern India is observed at −1.3%/year. Furthermore, in Thailand, the degradation rate was widely different, ranging between −0.5% to −4.9%/year [20]. However, C. Dechthummarong et al. [21] found that the degradation rate based on 15 years of PV exposure in northern Thailand is equal to −1.5%/year. The degradation rate of PV modules in many other countries such as Japan, Singapore, and Republic of Korea are reported in [22,23,24], the PV degradation rate is equal to −1.15%/year in Japan [22], −2.0%/year in Singapore [23], and −1.3%/year in Republic of Korea [24].

- Encapsulate browning—may be similar at low and high irradiance levels

- Series resistance increase—will be worse at high irradiance conditions

- Shunt resistance decrease—will be worse at low irradiance conditions

- Random failures such as faulty bypass diodes—will give an even higher variability between PV installations

2. Methodology

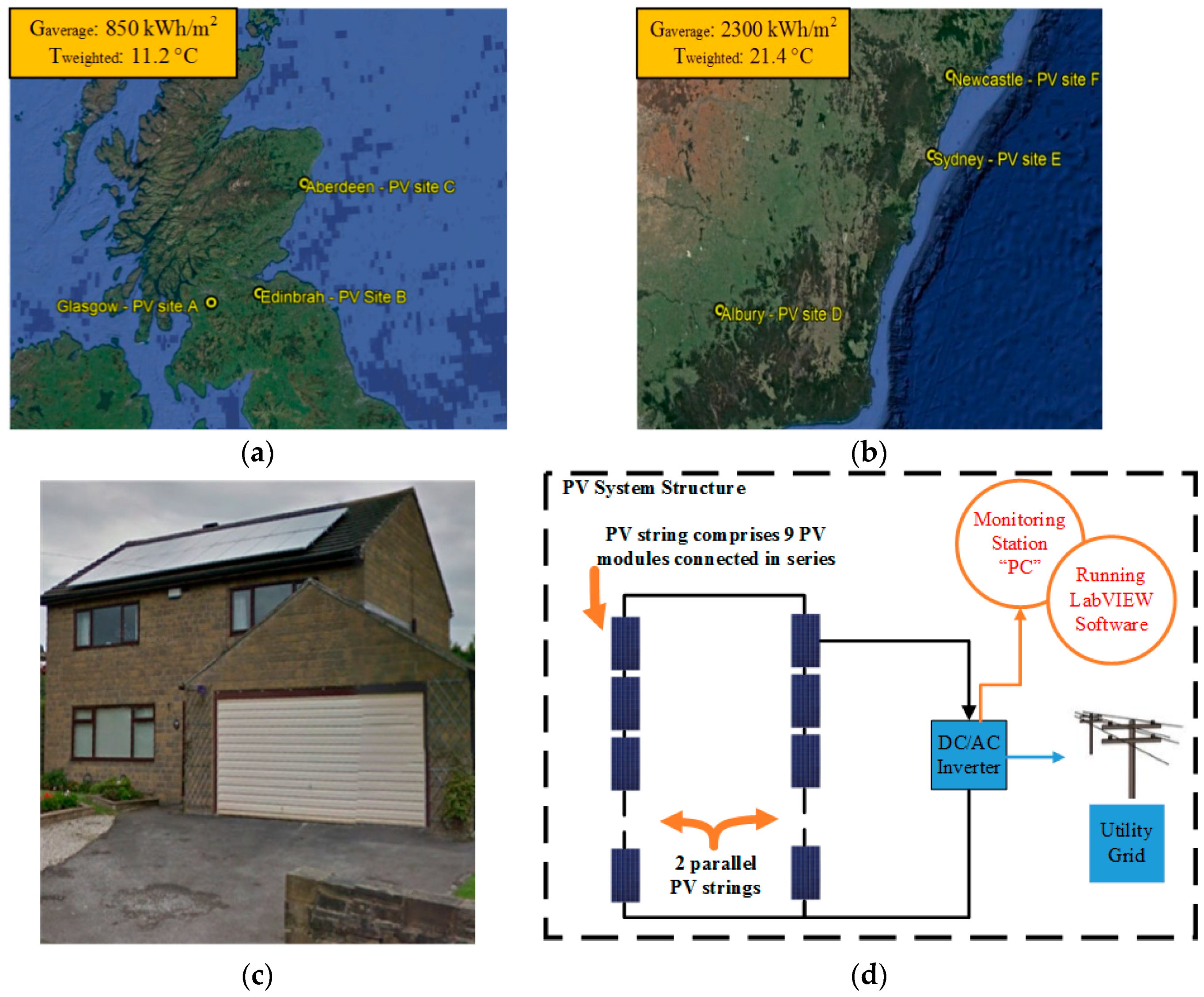

2.1. Description of the Examined PV Systems

2.2. Year-On-Year (YOY) Degradation Analysis Technique

- Import data and preliminary calculations: at this step, the time series of the energy yield, PV temperature, and solar irradiance will be processed.

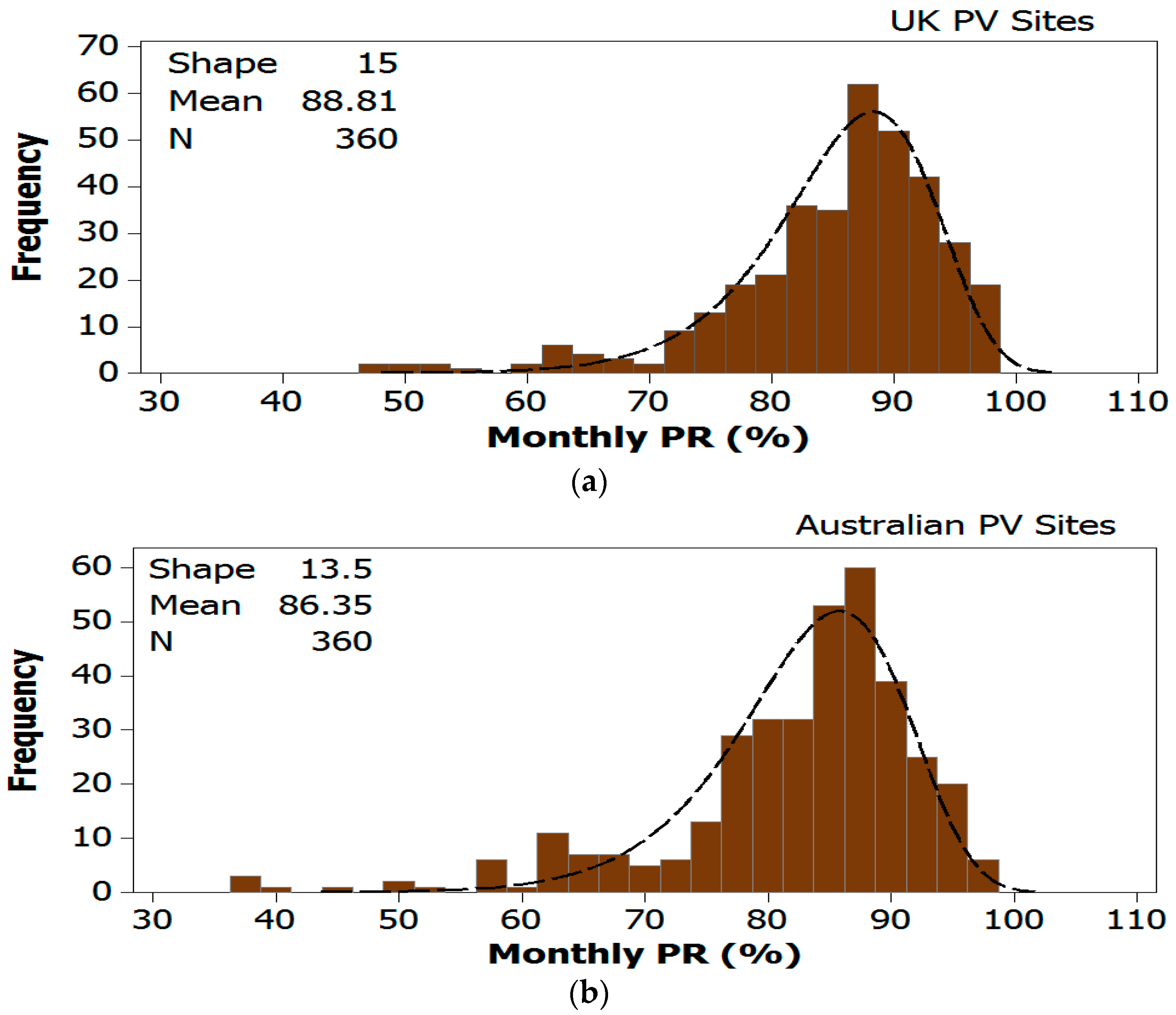

- Normalization: since PV data is randomly distributed, normalization process is required in order to transform the data into a normal distribution mode. This step calculated a unitless performance ratio (PR) metric with less variability than raw power production data. The PR is typically based on the rated power of the PV system, measured PV power, and site irradiance (measured by weather station). The normalization is done using the following Equation [27]:where P is the measured dc or ac power of the PV systems in watts, PSTC,rated is the rated dc or ac power of the PV system in watts, Gpoa is the plane-of-array irradiance, Gref is the reference irradiance 1000 W/m2, γ is the maximum power temperature coefficient in relative %/°C, TPV is the PV system temperature in °C, and Tref is the PV system reference temperature 25 °C.

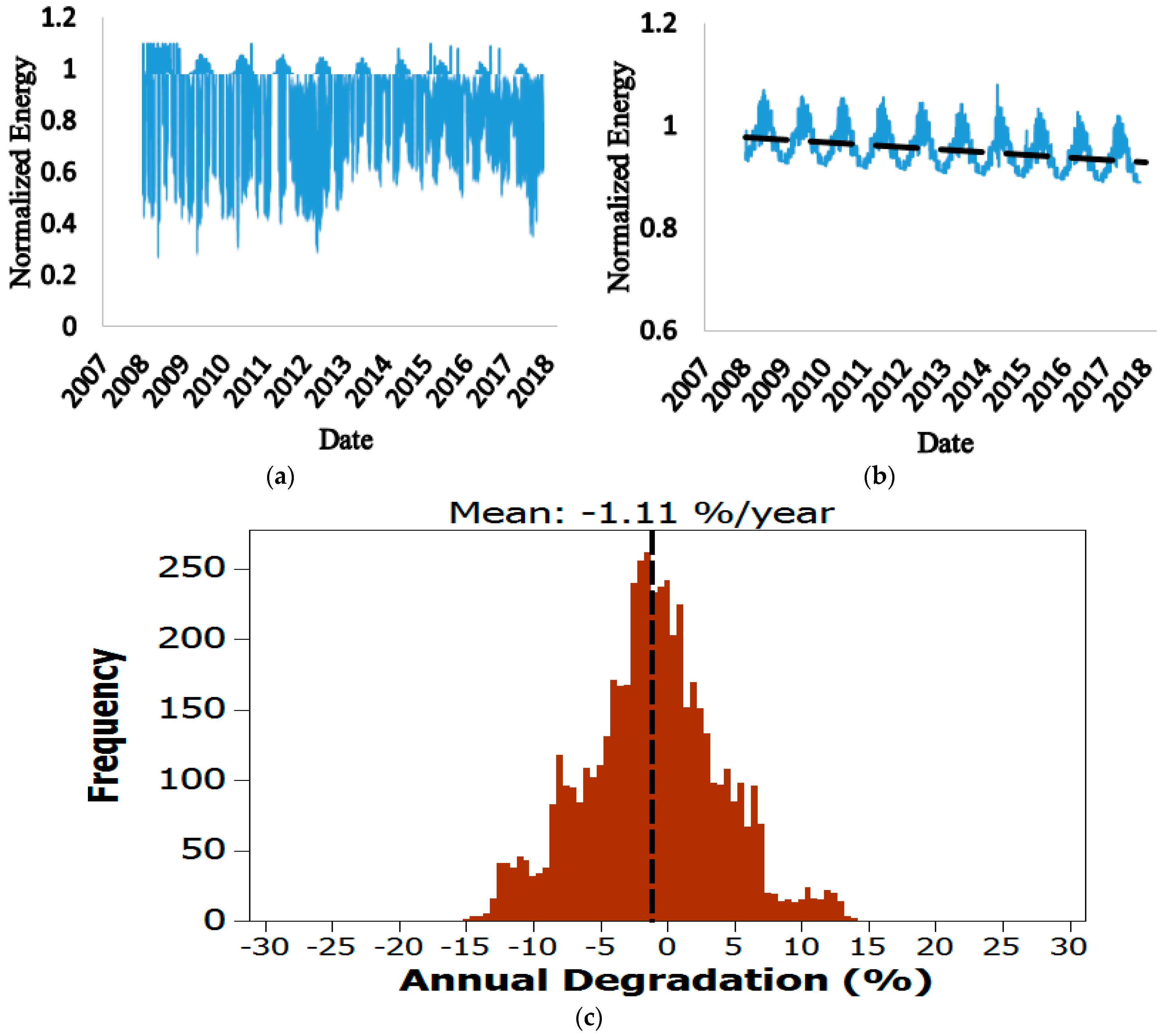

- Data Filtering: PV data filtering is used to exclude data points that represents invalid data, create bias in the analysis, or introduce significant noise. Often, low irradiance conditions are associated with night-time data or with errors due to PV components startup such as the MPPT unit. An example of the data filtering output is shown in Figure 2a.

- Aggregation: PV data is aggregated with an irradiance and temperature weighted average. This step reduces the impact of high-error data points in the morning and evening time. The aggregation time-period was selected at one day period. Therefore, the final yield data has a resolution of 1 day. An example of output aggregation is shown in Figure 2b.

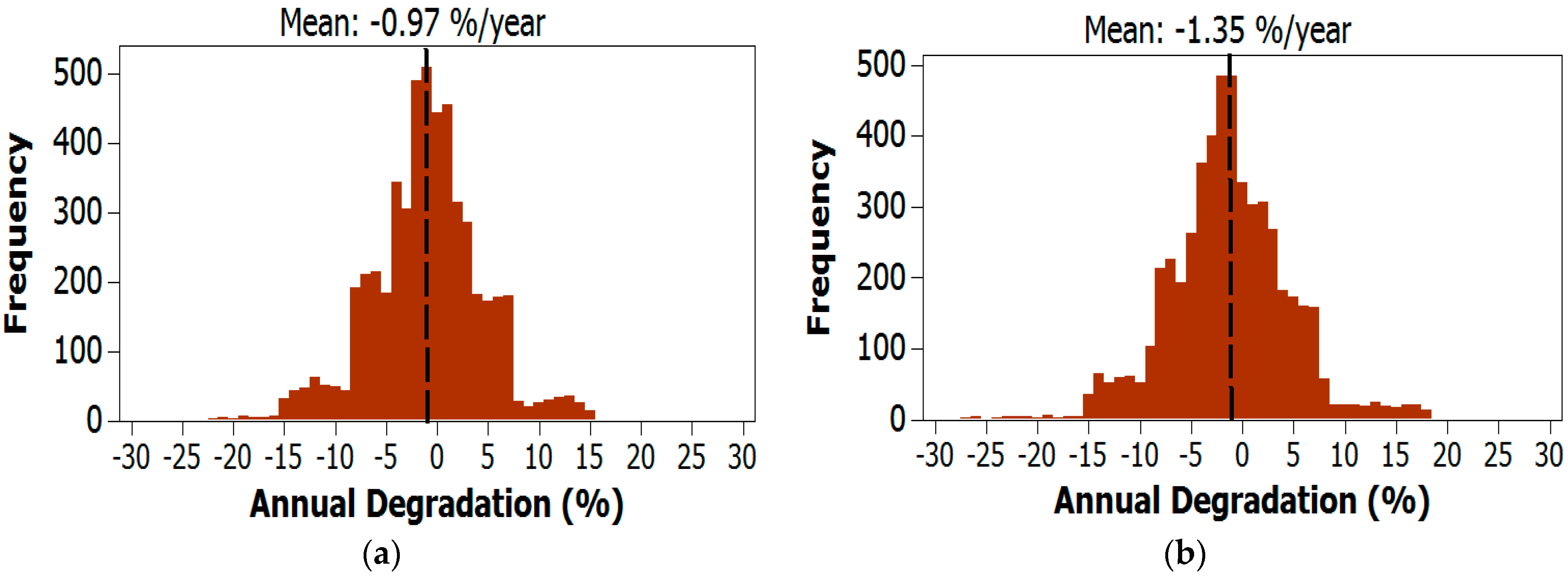

- Degradation analysis: the degradation analysis step processes the remaining data to compute a degradation rate based on year-on-year method. The rate of change is calculated between two points at the same time in subsequence years. Calculating such a rate of change for all data points and all years, results in a histogram (as shown in Figure 2c) of rates of change, the central tendency of which representing the overall system performance.

3. Results

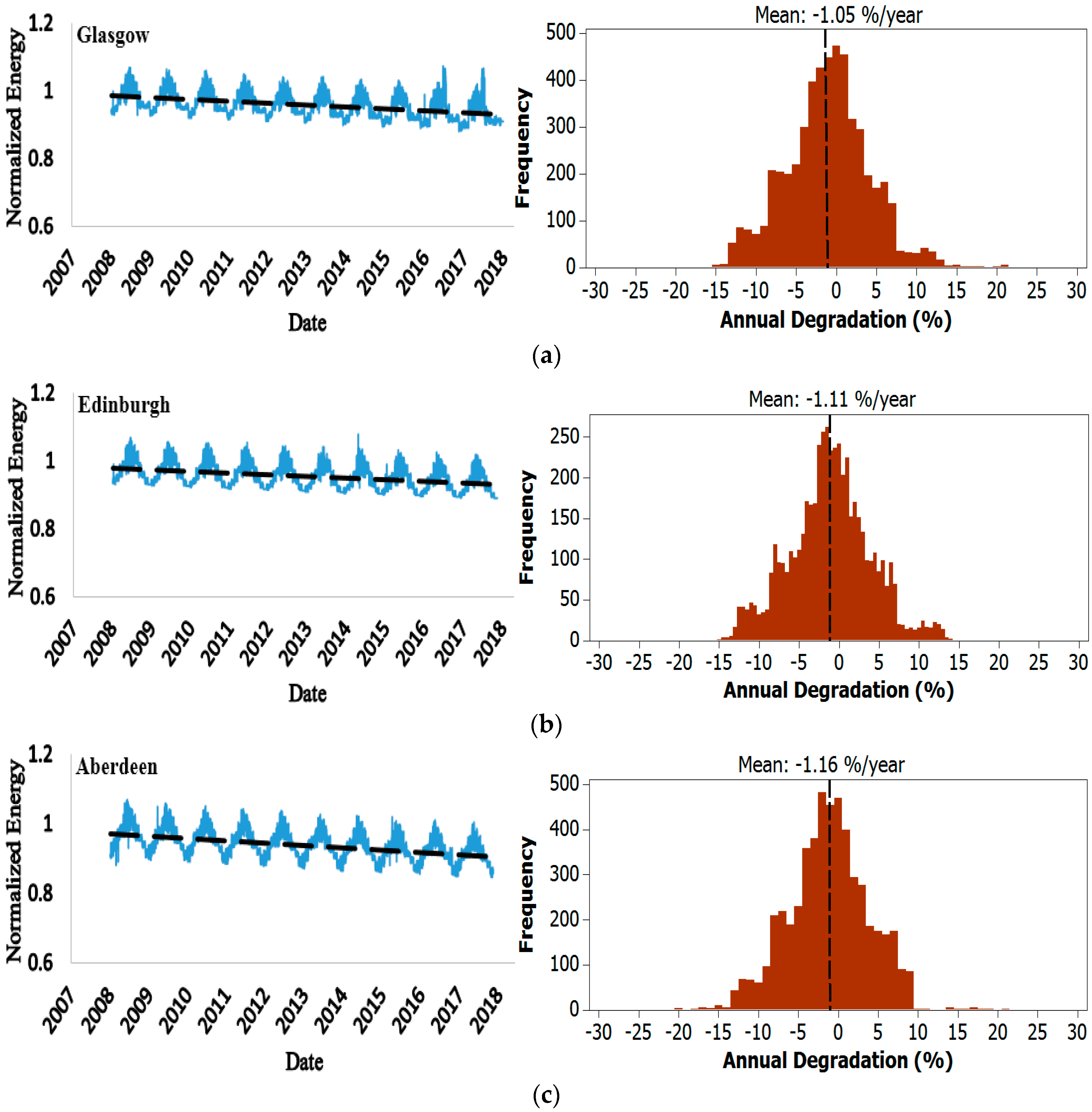

3.1. Degradation Rates in the UK PV Installations (A, B and C)

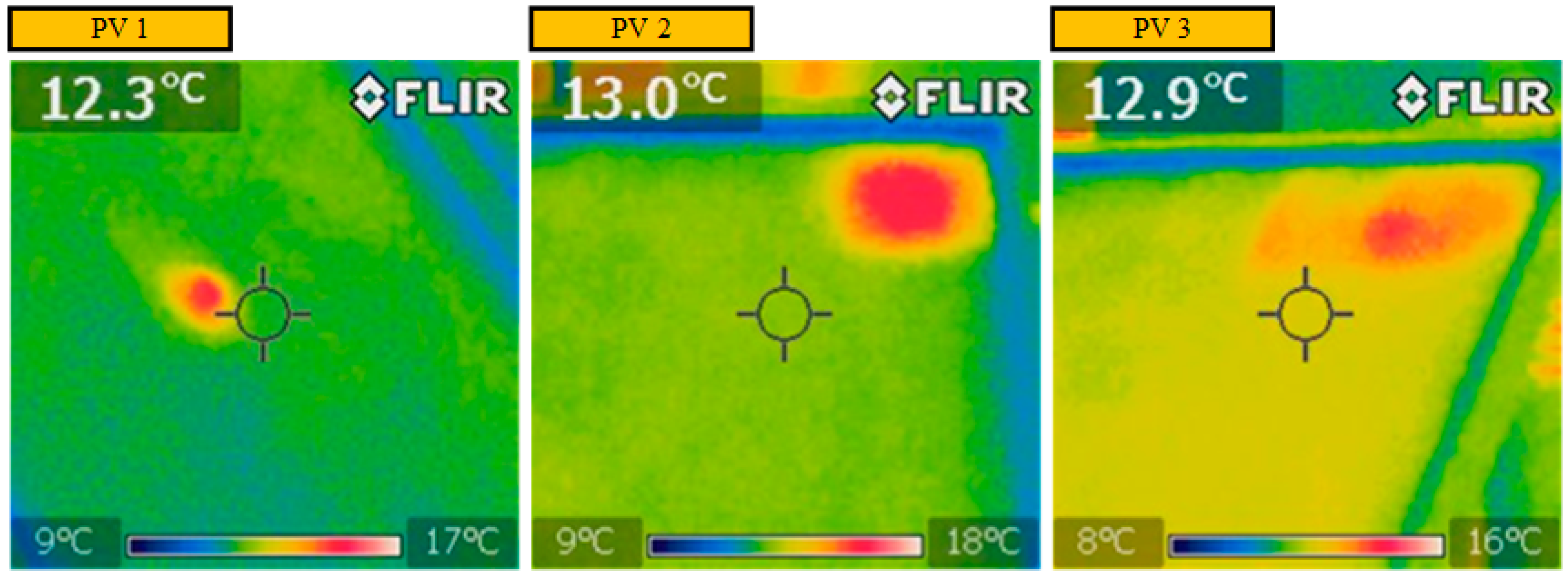

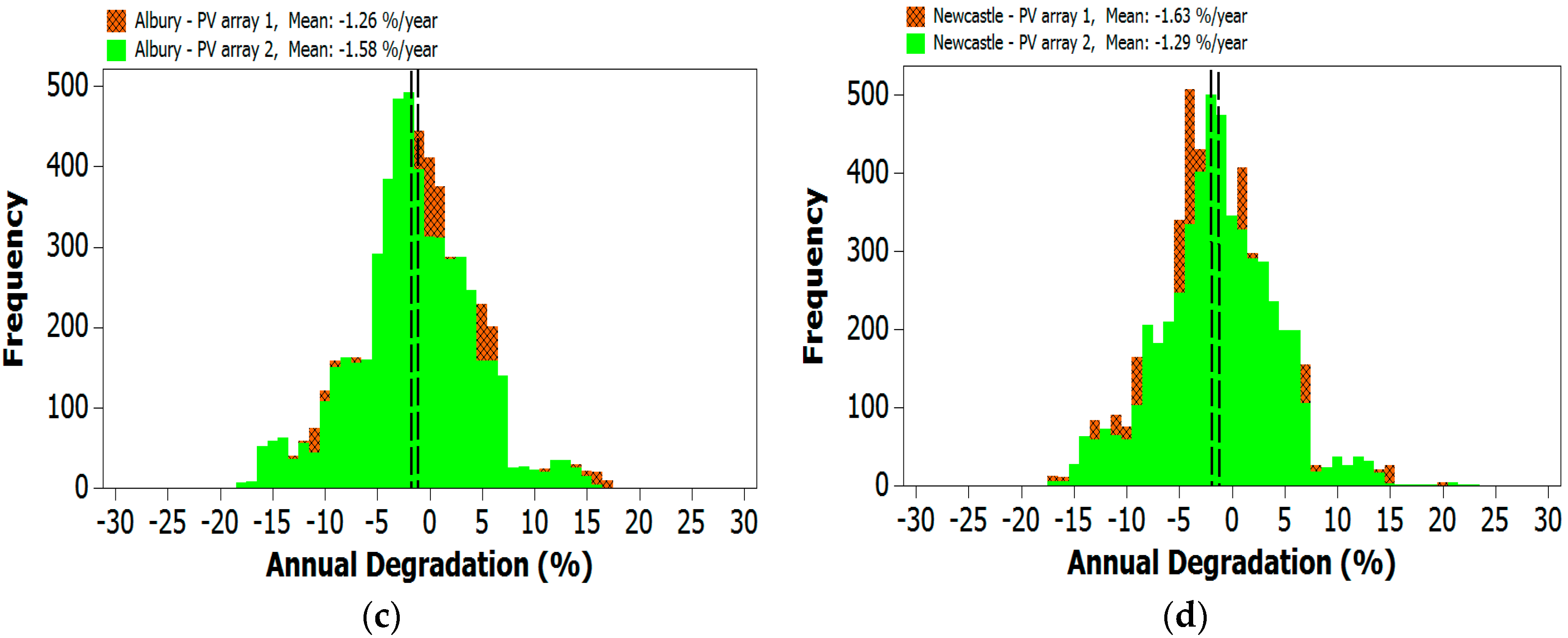

- First PV array: the PV array consists of 9 healthy PV modules; connected in series; all PV modules are not affected by hot-spots, or any other types of faults.

- Second PV array: the PV array consists of 9 PV modules connected in series, of which three are affected by hot-spots.

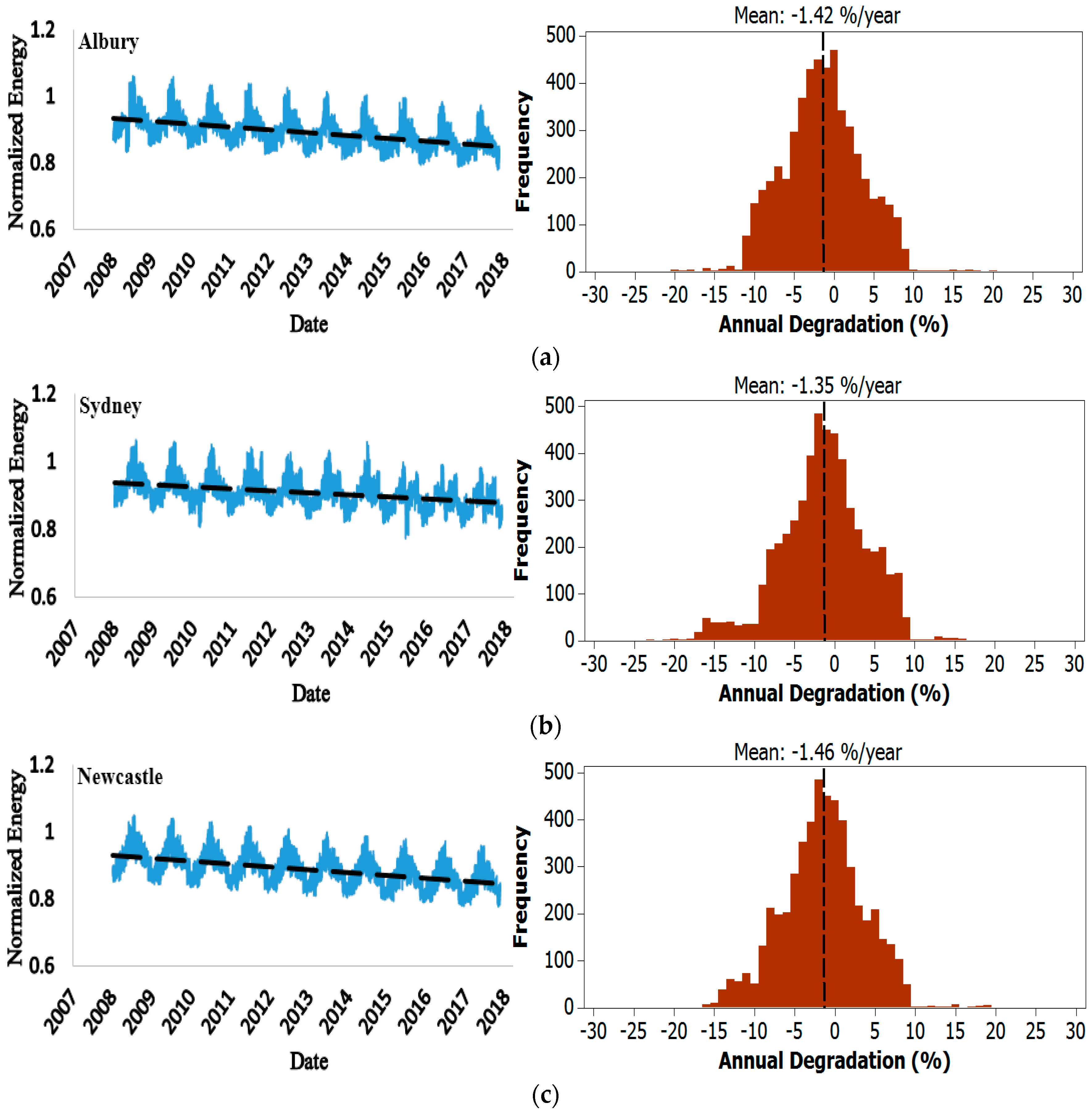

3.2. Degradation Rates in the Australian PV Installations (D, E and F)

- PV modules bypass diodes failure: from the examined PV sites in Australia, it was found that several PV modules had a faulty bypass diode. Two examples are shown in Figure 7a,b. A faulty bypass diode is found in a PV string, resulting an increase in the PV string temperature. In Figure 7a, the PV string has 7.9 °C increase in the temperature, whereas the PV string in Figure 7b has 9.1 °C increase in the PV string temperature due to the bypass diodes failure.

4. Discussion

- In cold weather conditions the PV degradation rate is less than the degradation rate of PV modules affected by hot weather conditions. Based on the analysis of three different PV sites, it was found that PV degradation rate in the UK is between −1.05% to −1.16%/year, whereas the PV degradation rate in Australia ranging from −1.35% to −1.46%/year.

- In cold weather conditions, there is high risk for glass broke due to hoarfrost, in addition, heavy snow is expected to impact the PV modules by various hot spots, which will reduce the output power generation of the PV modules.

- In hot weather conditions, it was found that faulty PV bypass diodes are expected to occur due to the high range of ambient temperature and uneven temperature and irradiance profiles affecting the PV modules. However, in cold weather conditions, none of the bypass diodes were damaged over the considered period; 10 years of operation.

- The number of PV hot spots found in UK PV sites are less than the number of hot spots found in the Australasian PV sites.

- The observed failure of the bypass diodes in the Australian PV systems are a result of the sudden drop in the output power of one of the three PV modules cell strings, this will activate the bypass diode in the shaded PV string, while other bypass diodes in the un-shaded strings remains switched-off. The repeated alternation in the switching (off/on) for the bypass diodes resulting in a possible failure. This is also the case in many investigated studies such as [28,29,30].

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Javed, K.; Ashfaq, H.; Singh, R.; Hussain, S.M.S.; Ustun, T.S. Design and Performance Analysis of a Stand-alone PV System with Hybrid Energy Storage for Rural India. Electronics 2019, 8, 952. [Google Scholar] [CrossRef]

- Liu, M.; Lu, W.; Xin, Y.; Wang, X.; Li, X.; Yao, S.; Guo, Q. Mechanism of Degradation Rate on the Irradiated Double-Polysilicon Self-Aligned Bipolar Transistor. Electronics 2019, 8, 657. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Mehrdadi, B.; Dales, M.; Mather, P. Output-Power Enhancement for Hot Spotted Polycrystalline Photovoltaic Solar Cells. IEEE Trans. Device Mater. Reliab. 2017, 18, 37–45. [Google Scholar] [CrossRef]

- Kyprianou, A.; Phinikarides, A.; Makrides, G.; Georghiou, G.E. Definition and Computation of the Degradation Rates of Photovoltaic Systems of Different Technologies with Robust Principal Component Analysis. IEEE J. Photovolt. 2015, 5, 1698–1705. [Google Scholar] [CrossRef]

- Kawai, S.; Tanahashi, T.; Fukumoto, Y.; Tamai, F.; Masuda, A.; Kondo, M. Causes of Degradation Identified by the Extended Thermal Cycling Test on Commercially Available Crystalline Silicon Photovoltaic Modules. IEEE J. Photovolt. 2017, 7, 1–8. [Google Scholar] [CrossRef]

- Chen, W.; Yang, M.; Zhang, S.; Andrews-Speed, P.; Li, W. What accounts for the China-US difference in solar PV electricity output? An LMDI analysis. J. Clean. Prod. 2019, 231, 161–170. [Google Scholar] [CrossRef]

- Jordan, D.; Kurtz, S.R.; VanSant, K.; Newmiller, J. Compendium of photovoltaic degradation rates. Prog. Photovolt. Res. Appl. 2016, 24, 978–989. [Google Scholar] [CrossRef]

- Bouaichi, A.; Merrouni, A.A.; Hajjaj, C.; Zitouni, H.; Ghennioui, A.; El Amrani, A.; Messaoudi, C. In-situ inspection and measurement of degradation mechanisms for crystalline and thin film PV systems under harsh climatic conditions. Energy Procedia 2019, 157, 1210–1219. [Google Scholar] [CrossRef]

- Ascencio-Vásquez, J.; Kaaya, I.; Brecl, K.; Weiss, K.-A.; Topič, M. Global Climate Data Processing and Mapping of Degradation Mechanisms and Degradation Rates of PV Modules. Energies 2019, 12, 4749. [Google Scholar] [CrossRef]

- Martínez, S.M.; Carretón, M.C.; Honrubia-Escribano, A.; Gómez-Lázaro, E. Performance evaluation of large solar photovoltaic power plants in Spain. Energy Convers. Manag. 2019, 183, 515–528. [Google Scholar] [CrossRef]

- Lovati, M.; Salvalai, G.; Fratus, G.; Maturi, L.; Albatici, R.; Moser, D. New method for the early design of BIPV with electric storage: A case study in northern Italy. Sustain. Cities Soc. 2019, 48, 101400. [Google Scholar] [CrossRef]

- Muttillo, M.; Nardi, I.; Stornelli, V.; De Rubeis, T.; Pasqualoni, G.; Ambrosini, D. On Field Infrared Thermography Sensing for PV System Efficiency Assessment: Results and Comparison with Electrical Models. Sensors 2020, 20, 1055. [Google Scholar] [CrossRef] [PubMed]

- Weu, A.; Kumar, R.; Butscher, J.F.; Lami, V.; Paulus, F.; Bakulin, A.A.; Vaynzof, Y. Energy Transfer to a Stable Donor Suppresses Degradation in Organic Solar Cells. Adv. Funct. Mater. 2019, 30, 1907432. [Google Scholar] [CrossRef]

- Seel, J.; Barbose, G.L.; Wiser, R.H. An analysis of residential PV system price differences between the United States and Germany. Energy Policy 2014, 69, 216–226. [Google Scholar] [CrossRef]

- Singh, R.; Sharma, M.; Rawat, R.; Banerjee, C. Field Analysis of three different silicon-based Technologies in Composite Climate Condition—Part II—Seasonal assessment and performance degradation rates using statistical tools. Renew. Energy 2020, 147, 2102–2117. [Google Scholar] [CrossRef]

- Gaglia, A.G.; Lykoudis, S.; Argiriou, A.; Balaras, C.; Dialynas, E. Energy efficiency of PV panels under real outdoor conditions–An experimental assessment in Athens, Greece. Renew. Energy 2017, 101, 236–243. [Google Scholar] [CrossRef]

- Jurasz, J.; Dąbek, P.B.; Campana, P.E. Can a city reach energy self-sufficiency by means of rooftop photovoltaics? Case study from Poland. J. Clean. Prod. 2020, 245, 118813. [Google Scholar] [CrossRef]

- Chandel, S.; Naik, M.N.; Sharma, V.; Chandel, R. Degradation analysis of 28 year field exposed mono-c-Si photovoltaic modules of a direct coupled solar water pumping system in western Himalayan region of India. Renew. Energy 2015, 78, 193–202. [Google Scholar] [CrossRef]

- Thotakura, S.; Kondamudi, S.C.; Xavier, J.F.; Quanjin, M.; Reddy, G.R.; Gangwar, P.; Davuluri, S.L. Operational performance of megawatt-scale grid integrated rooftop solar PV system in tropical wet and dry climates of India. Case Stud. Therm. Eng. 2020, 18, 100602. [Google Scholar] [CrossRef]

- Tongsopit, S.; Junlakarn, S.; Wibulpolprasert, W.; Chaianong, A.; Kokchang, P.; Hoang, N.V.; Julakarn, S.; Wibulpholprasert, W. The economics of solar PV self-consumption in Thailand. Renew. Energy 2019, 138, 395–408. [Google Scholar] [CrossRef]

- Dechthummarong, C.; Wiengmoon, B.; Chenvidhya, D.; Jivacate, C.; Kirtikara, K. Physical deterioration of encapsulation and electrical insulation properties of PV modules after long-term operation in Thailand. Sol. Energy Mater. Sol. Cells 2010, 94, 1437–1440. [Google Scholar] [CrossRef]

- Park, J.H.; Lee, H.D.; Tae, D.H.; Ferreira, M.; Rho, D.S. A Study on Disposal Diagnosis Algorithm of PV Modules Considering Performance Degradation Rate. J. Korea Acad. Ind. Coop. Soc. 2019, 20, 493–502. [Google Scholar]

- Teah, H.S.; Yang, Q.; Onuki, M. Incorporating External Effects into Project Sustainability Assessments: The Case of a Green Campus Initiative Based on a Solar PV System. Sustainability 2019, 11, 5786. [Google Scholar] [CrossRef]

- Jordan, D.C.; Deline, C.; Deceglie, M.; Silverman, T.J.; Luo, W. PV Degradation—Mounting & Temperature. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; pp. 0673–0679. [Google Scholar]

- Dhimish, M.; Mather, P. Exploratory evaluation of solar radiation and ambient temperature in twenty locations distributed in United Kingdom. Urban Clim. 2019, 27, 179–192. [Google Scholar] [CrossRef]

- Taylor, J.; Leloux, J.; Hall, L.M.; Everard, A.M.; Briggs, J.; Buckley, A. Performance of distributed PV in the UK: A statistical analysis of over 7000 systems. In Proceedings of the 31st European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany, 14–18 September 2015. [Google Scholar]

- Jordan, D.; Kurtz, S.R. Photovoltaic Degradation Rates-an Analytical Review. Prog. Photovolt. Res. Appl. 2011, 21, 12–29. [Google Scholar] [CrossRef]

- Dhimish, M.; Chen, Z. Novel Open-Circuit Photovoltaic Bypass Diode Fault Detection Algorithm. IEEE J. Photovolt. 2019, 9, 1819–1827. [Google Scholar] [CrossRef]

- Shin, W.; Ko, S.; Song, H.-J.; Ju, Y.; Hwang, H.; Kang, G.-H. Origin of Bypass Diode Fault in c-Si Photovoltaic Modules: Leakage Current under High Surrounding Temperature. Energies 2018, 11, 2416. [Google Scholar] [CrossRef]

- Alqaisi, Z.; Mahmoud, Y. Comprehensive Study of Partially Shaded PV Modules with Overlapping Diodes. IEEE Access 2019, 7, 172665–172675. [Google Scholar] [CrossRef]

- Jiménez-Castillo, G.; Muñoz-Rodriguez, F.; Martinez-Calahorro, A.J.; Tina, G.M.; Rus-Casas, C. Impacts of Array Orientation and Tilt Angles for Photovoltaic Self-Sufficiency and Self-Consumption Indices in Olive Mills in Spain. Electronics 2020, 9, 348. [Google Scholar] [CrossRef]

- Dhimish, M.; Mather, P.; Holmes, V. Evaluating Power Loss and Performance Ratio of Hot-Spotted Photovoltaic Modules. IEEE Trans. Electron Devices 2018, 65, 5419–5427. [Google Scholar] [CrossRef]

- Shao, J.; Zhang, H.; Chen, B. Experimental Study on the Reliability of PBGA Electronic Packaging under Shock Loading. Electronics 2019, 8, 279. [Google Scholar] [CrossRef]

| PV Module Parameter | Value |

|---|---|

| PV peak power | 220 W |

| One PV cell peak power | 3.6 W |

| Voltage at maximum power point (Vmpp) | 28.7 V |

| Current at maximum power point (Impp) | 7.67 A |

| Open Circuit Voltage (Voc) | 36.74 V |

| Short Circuit Current (Isc) | 8.24 A |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dhimish, M.; Alrashidi, A. Photovoltaic Degradation Rate Affected by Different Weather Conditions: A Case Study Based on PV Systems in the UK and Australia. Electronics 2020, 9, 650. https://doi.org/10.3390/electronics9040650

Dhimish M, Alrashidi A. Photovoltaic Degradation Rate Affected by Different Weather Conditions: A Case Study Based on PV Systems in the UK and Australia. Electronics. 2020; 9(4):650. https://doi.org/10.3390/electronics9040650

Chicago/Turabian StyleDhimish, Mahmoud, and Abdullah Alrashidi. 2020. "Photovoltaic Degradation Rate Affected by Different Weather Conditions: A Case Study Based on PV Systems in the UK and Australia" Electronics 9, no. 4: 650. https://doi.org/10.3390/electronics9040650

APA StyleDhimish, M., & Alrashidi, A. (2020). Photovoltaic Degradation Rate Affected by Different Weather Conditions: A Case Study Based on PV Systems in the UK and Australia. Electronics, 9(4), 650. https://doi.org/10.3390/electronics9040650