Impacts of Array Orientation and Tilt Angles for Photovoltaic Self-Sufficiency and Self-Consumption Indices in Olive Mills in Spain

Abstract

1. Introduction

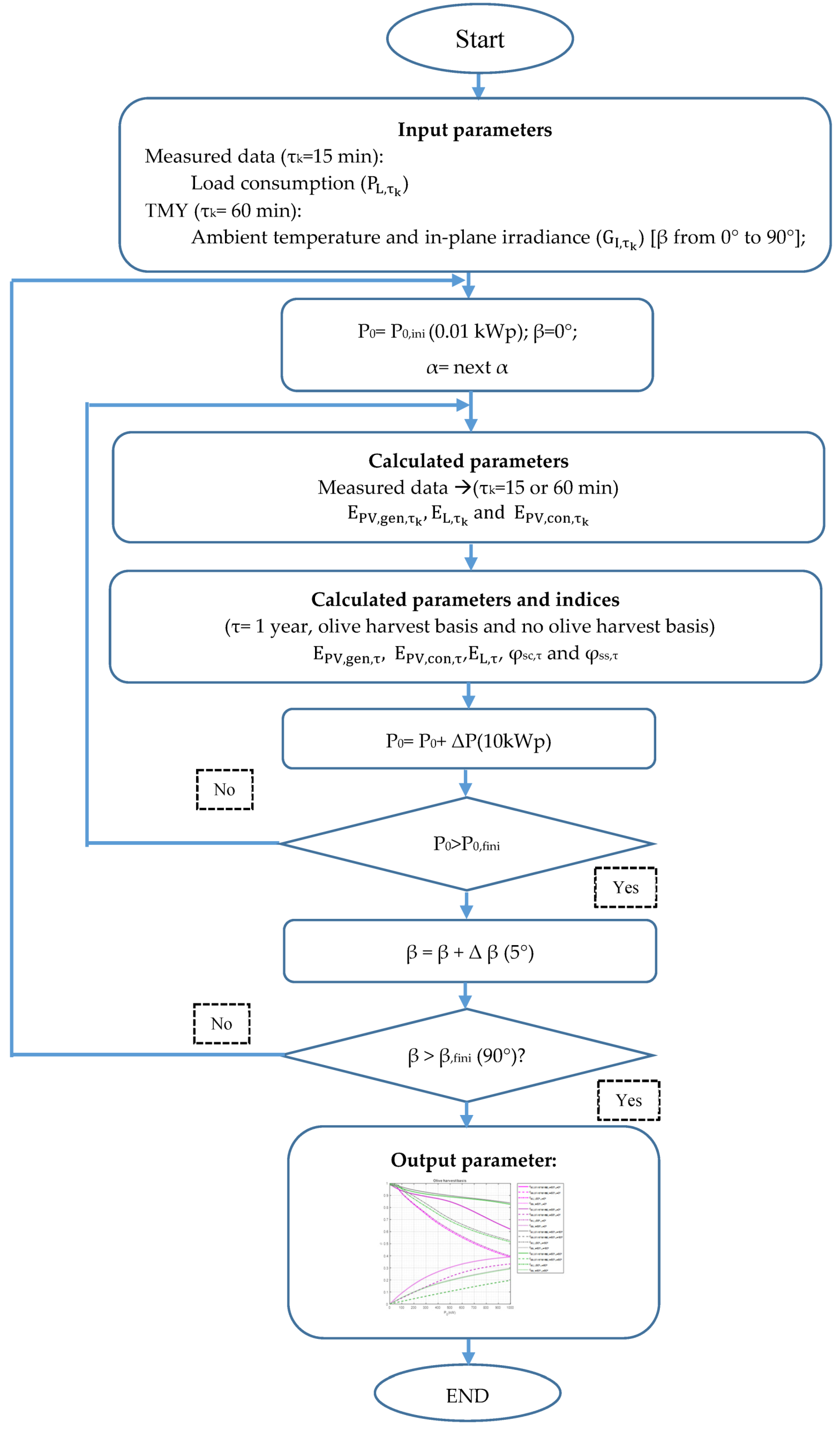

2. Materials and Methods

2.1. Input Data: Irradiance Profiles

2.2. The Photovoltaic Generation Profile.

2.3. Input Data: Load Consumption Profile

2.4. Photovoltaic Energy Consumed, Self-Consumption, and Self-Sufficierncy Indices.

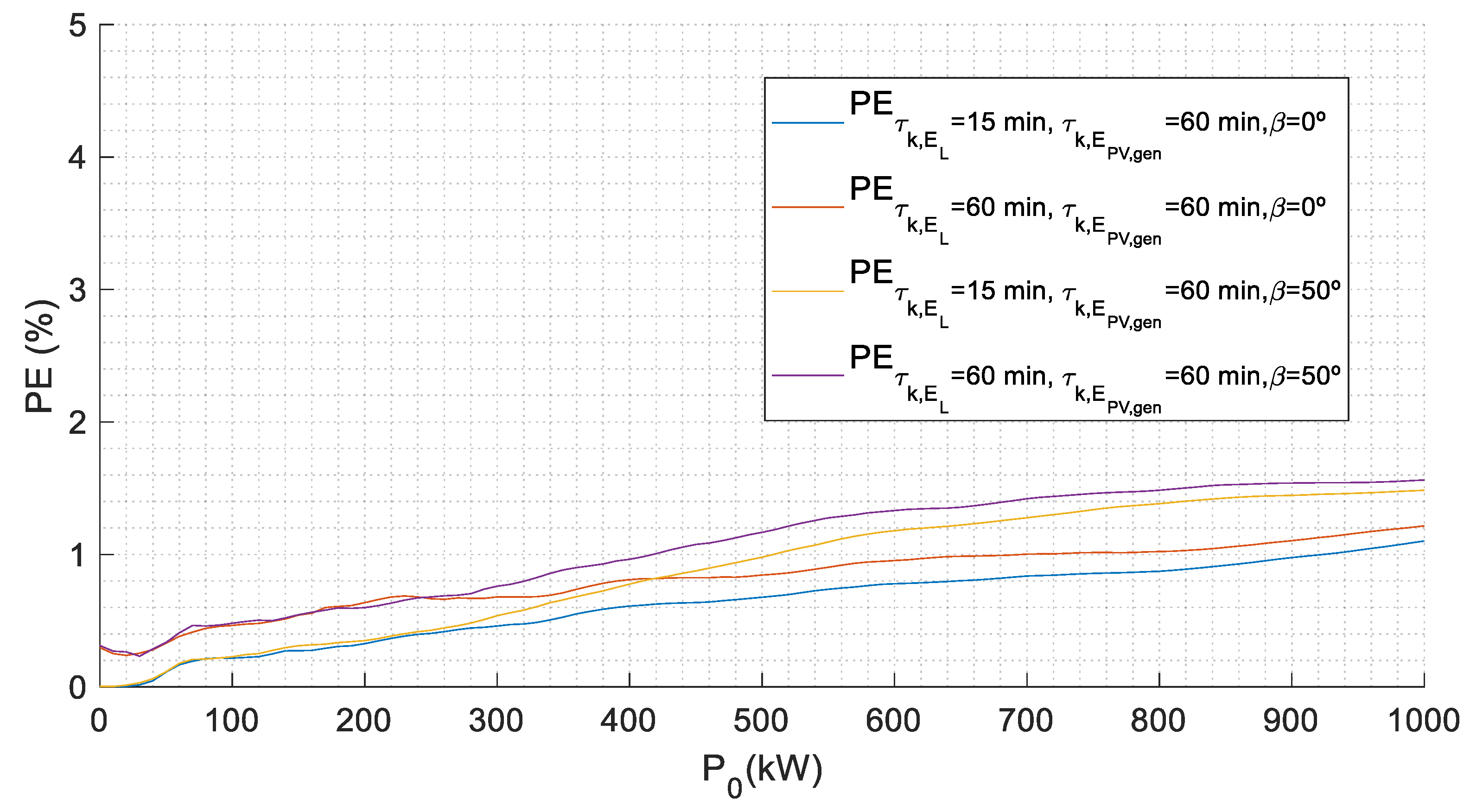

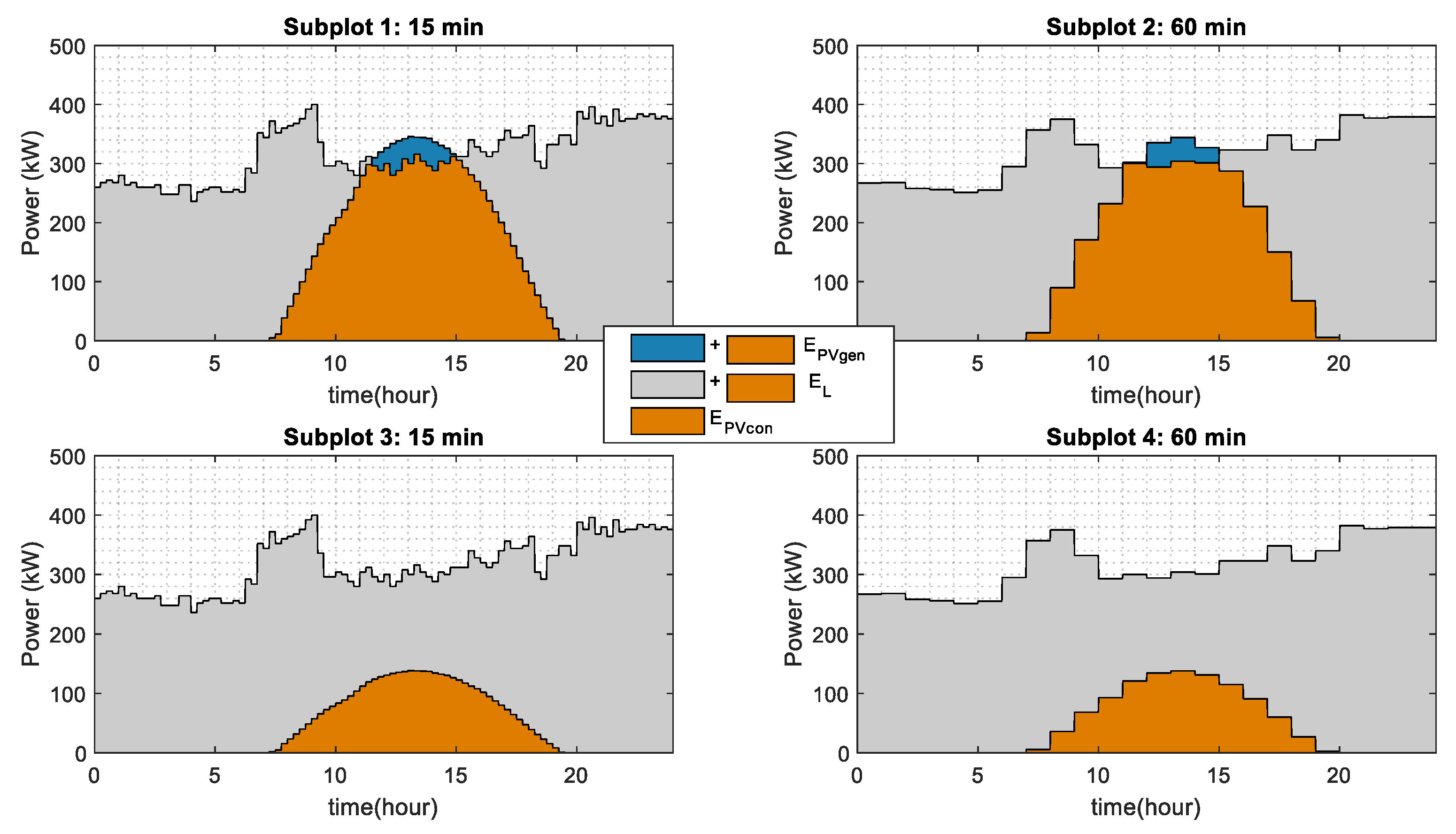

2.5. Effect of Averaging Irradiance Time-Series in Photovoltaic Direct Self-Consumption in Olive Mills

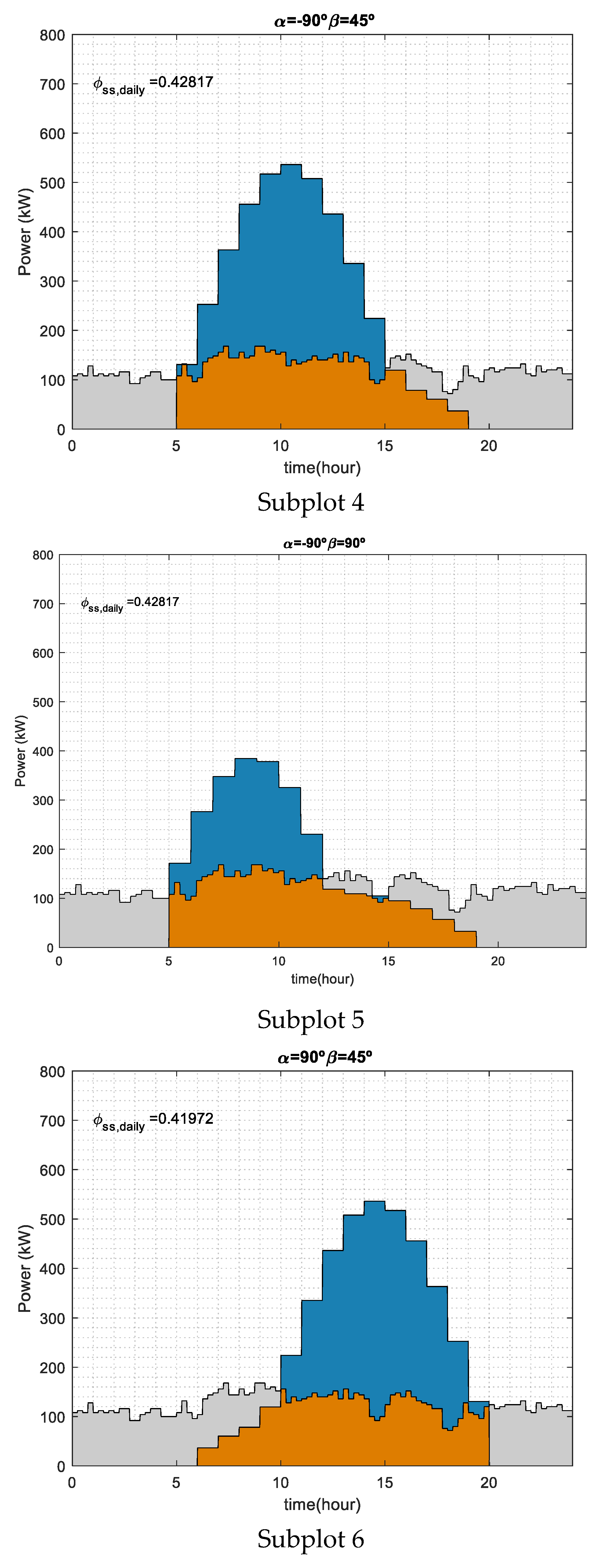

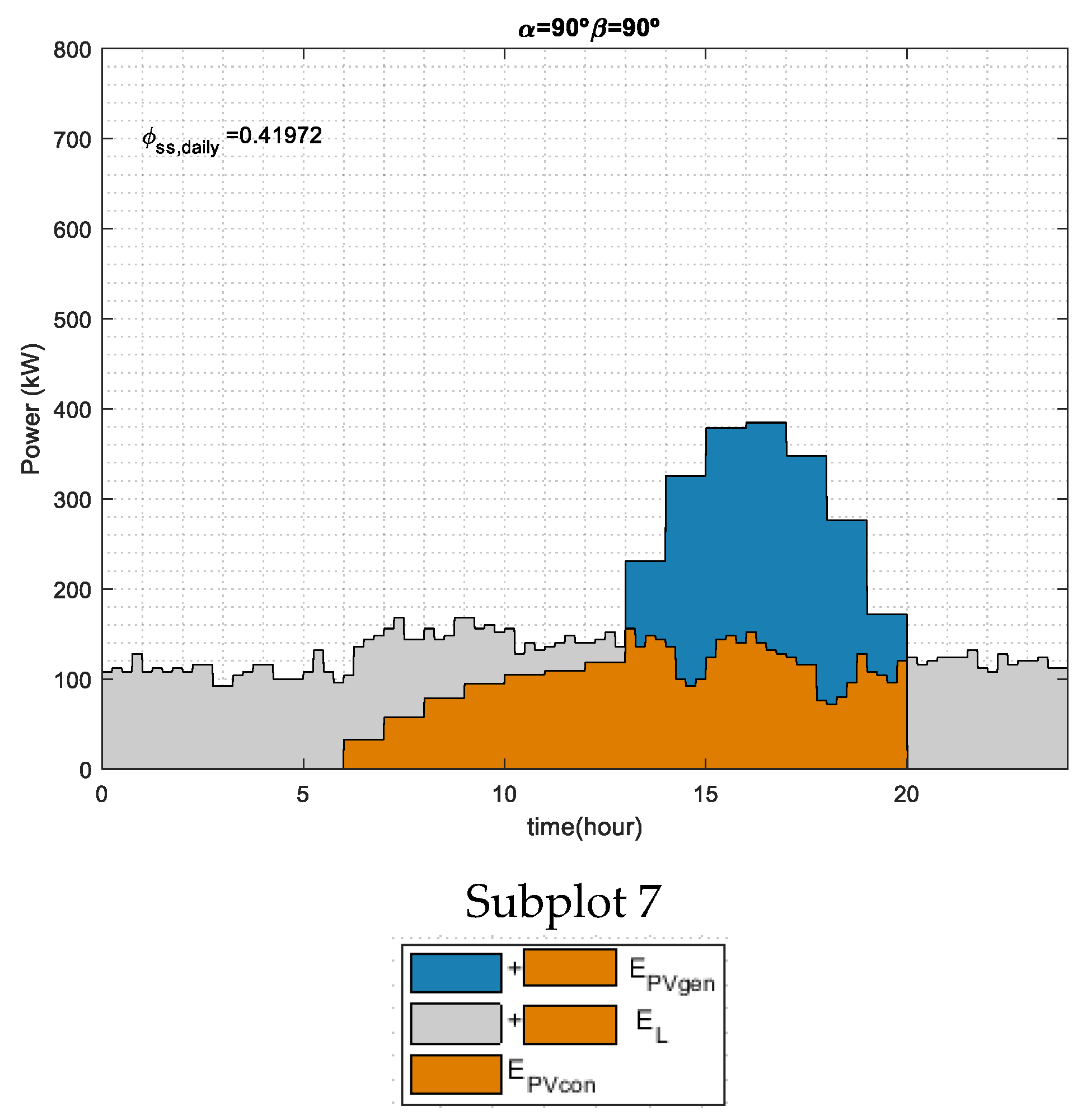

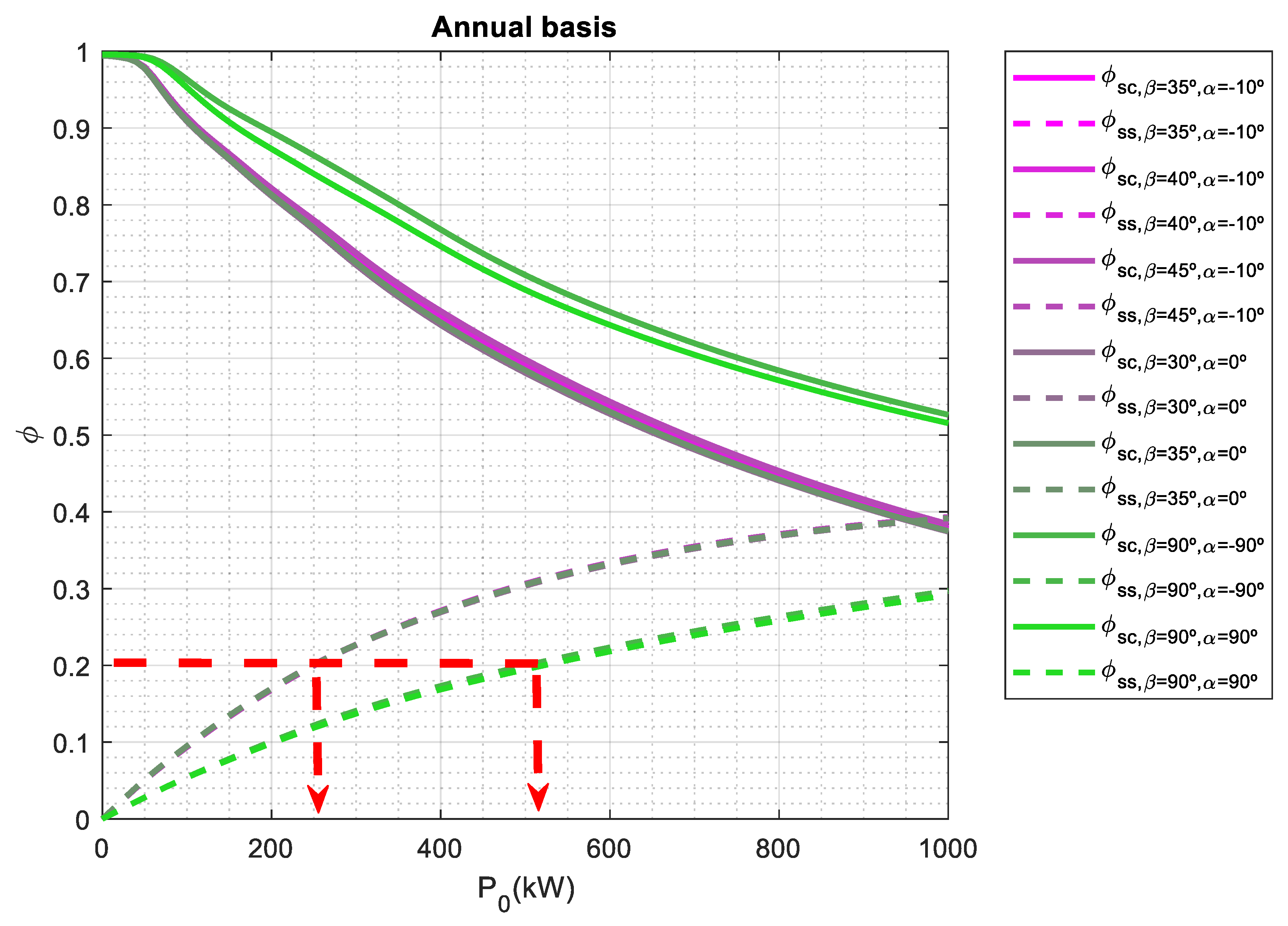

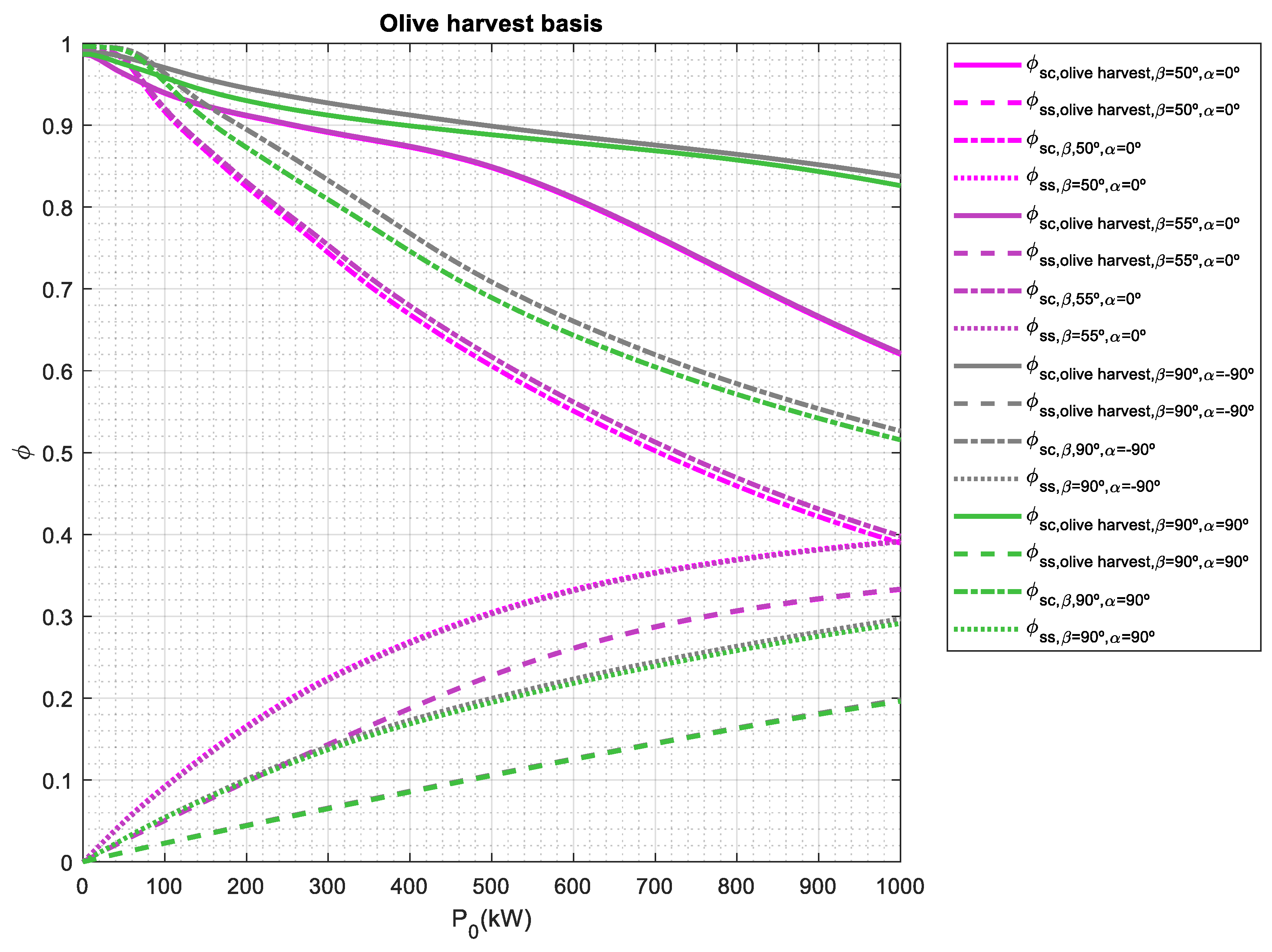

3. Results and Discussion

3.1. Impact of Recording Time in Self-Consumption Analisys

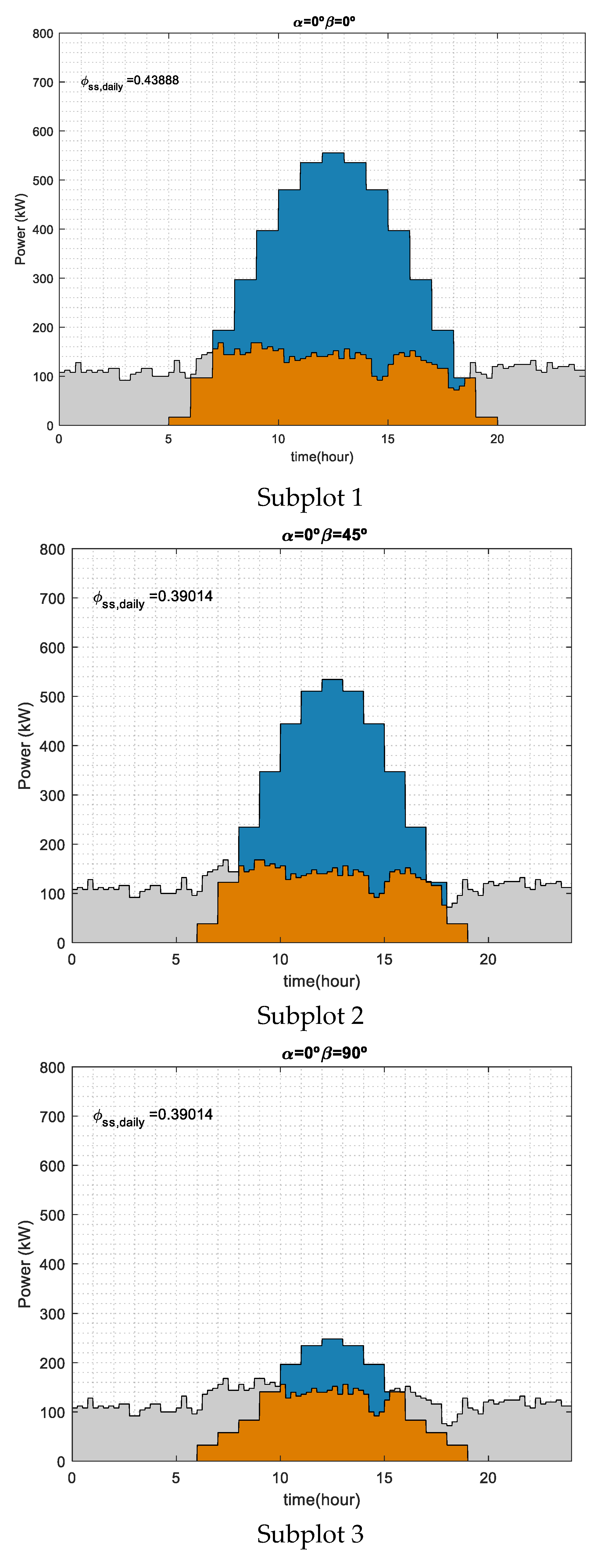

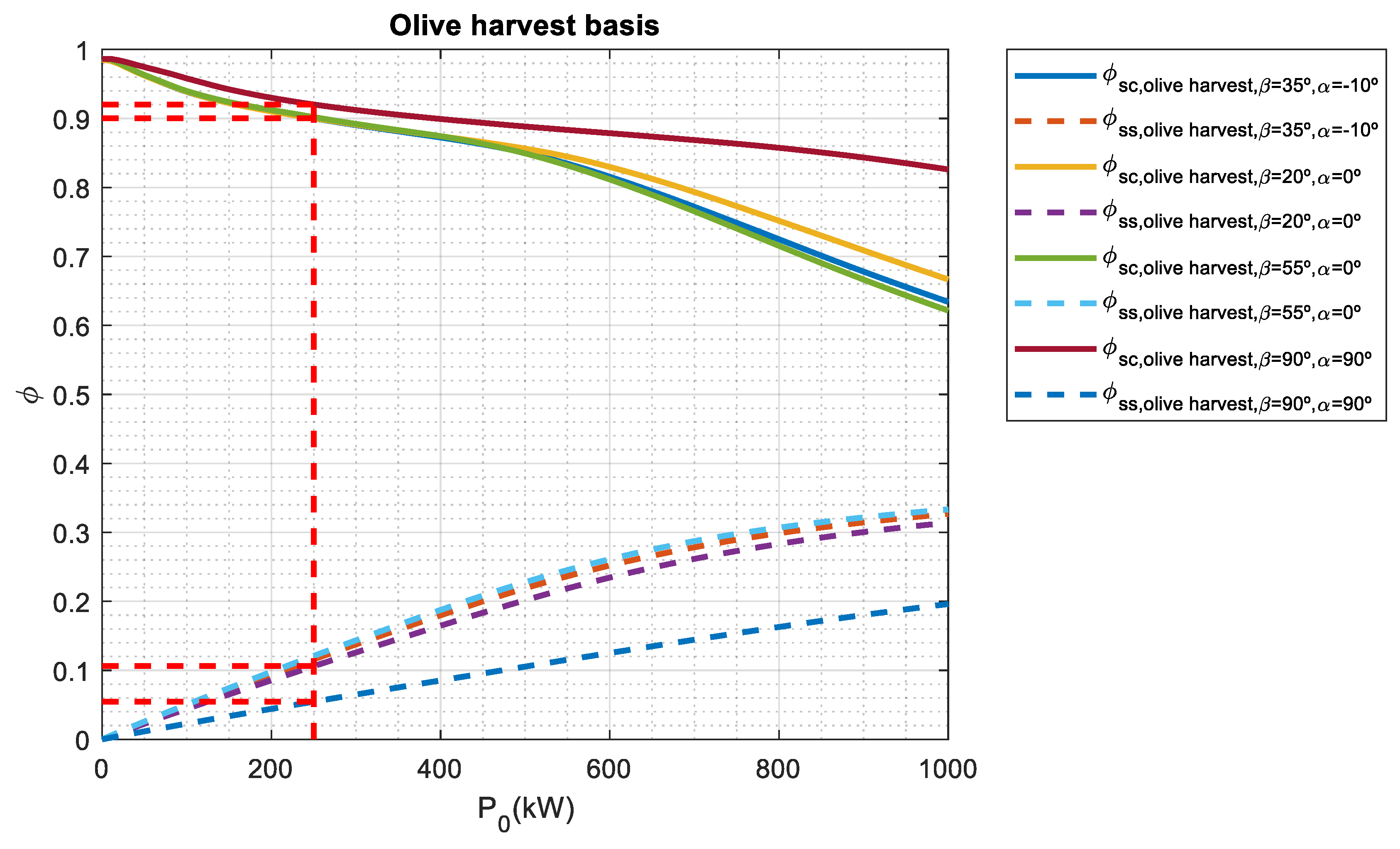

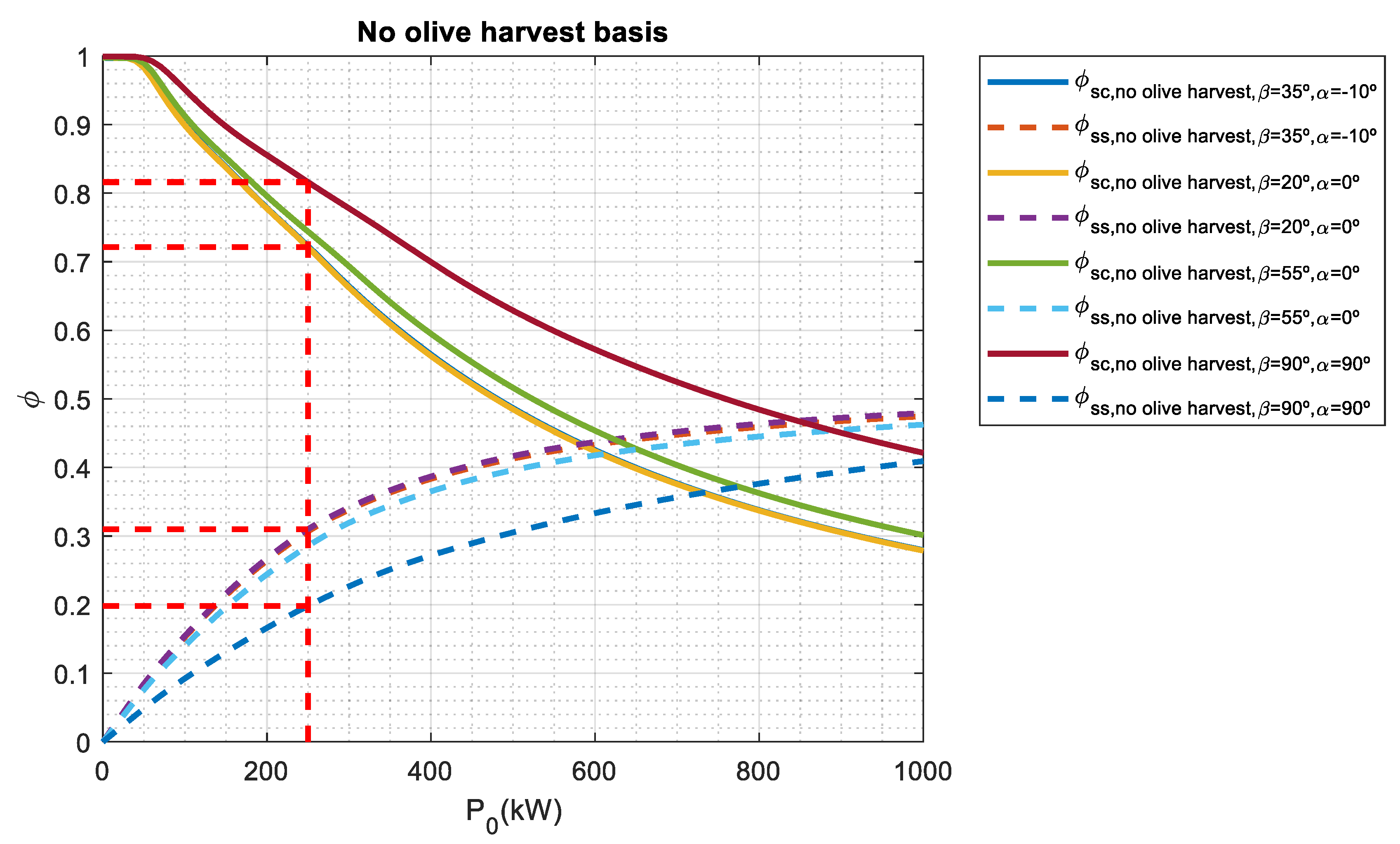

3.2. Influence of Array Tilt and Orientation Angles in Self-Consumption and Self-Sufficiency Indices.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- DNV GL. Energy Transition Outlook 2018 Oil and Gas; DNV GL: Oslo, Norway, 2018. [Google Scholar]

- Sampaio, P.; González, M. Photovoltaic solar energy: Conceptual framework. Renew. Sustain. Energy Rev. 2017, 74, 590–601. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Chen, J. Assessment of the ecological niche of photovoltaic agriculture in China. Sustainability 2019, 11, 2268. [Google Scholar] [CrossRef]

- Chen, J.; Liu, Y.; Wang, L. Research on coupling coordination development for photovoltaic agriculture system in China. Sustainability 2019, 11, 1065. [Google Scholar] [CrossRef]

- Bey, M.; Hamidat, A.; Benyoucef, B.; Nacer, T. Viability study of the use of grid connected photovoltaic system in agriculture: Case of Algerian dairy farms. Renew. Sustain. Energy Rev. 2016, 63, 333–345. [Google Scholar] [CrossRef]

- Gómez-Lorente, D.; Rabaza, O.; Aznar-Dols, F.; Mercado-Vargas, M.J. Economic and environmental study of wineries powered by grid-connected photovoltaic systems in Spain. Energies 2017, 10, 222. [Google Scholar] [CrossRef]

- Moustafa, K. Toward Future Photovoltaic-Based Agriculture in Sea. Trends Biotechnol. 2016, 34, 257–259. [Google Scholar] [CrossRef]

- Rabaza, O.; Contreras-Montes, J.; García-Ruiz, M.J.; Delgado-Ramos, F.; Gómez-Lorente, D. Techno-economic performance evaluation for olive mills powered by grid-connected photovoltaic systems. Energies 2015, 8, 11939–11954. [Google Scholar] [CrossRef]

- Aceite de Oliva. Available online: https://www.mapa.gob.es/es/agricultura/temas/producciones-agricolas/aceite-oliva-y-aceituna-mesa/aceite.aspx (accessed on 18 December 2019).

- Vilar Hernández, J. Presente y Futuro del Mercado Internacional del Aceite de Oliva; AES: Malaga, España, 2017. [Google Scholar]

- AICA: Agencia de Información y Control Alimentarios. Available online: http://www.aica.gob.es/ (accessed on 18 December 2019).

- FAECA. Manual de Ahorro y Eficiencia Energética del Sector; FAECA: Madrid, España, 2015. [Google Scholar]

- Singh, H.; Sirisamphanwong, C.; Santhi Rekha, S.M. Effect of Tilt and Azimuth Angle on the Performance of PV Rooftop System. Appl. Mech. Mater. 2016, 839, 159–164. [Google Scholar] [CrossRef]

- Dhimish, M.; Silvestre, S. Estimating the impact of azimuth-angle variations on photovoltaic annual energy production. Clean Energy 2019, 3, 47–58. [Google Scholar] [CrossRef]

- Mehleri, E.D.; Zervas, P.L.; Sarimveis, H.; Palyvos, J.A.; Markatos, N.C. Determination of the optimal tilt angle and orientation for solar photovoltaic arrays. Renew. Energy 2010, 35, 2468–2475. [Google Scholar] [CrossRef]

- Kaldellis, J.; Kavadias, K.; Zafirakis, D. Experimental validation of the optimum photovoltaic panels’ tilt angle for remote consumers. Renew. Energy 2012, 46, 179–191. [Google Scholar] [CrossRef]

- Yadav, A.K.; Chandel, S.S. Tilt angle optimization to maximize incident solar radiation: A review. Renew. Sustain. Energy Rev. 2013, 23, 503–513. [Google Scholar] [CrossRef]

- Morcos, V.H. Optimum tilt angle and orientation for solar collectors in Assiut, Egypt. Renew. Energy 1994, 4, 291–298. [Google Scholar] [CrossRef]

- Jafarkazemi, F.; Saadabadi, S.A. Optimum tilt angle and orientation of solar surfaces in Abu Dhabi, UAE. Renew. Energy 2013, 56, 44–49. [Google Scholar] [CrossRef]

- Yakup, M.A.B.H.M.; Malik, A.Q. Optimum tilt angle and orientation for solar collector in Brunei Durassalam. Renew. Energy 2001, 24, 223–234. [Google Scholar] [CrossRef]

- Kacira, M.; Simsek, M.; Babur, Y.; Demirkol, S. Determining optimum tilt angles and orientations of photovoltaic panels in Sanliurfa, Turkey. Renew. Energy 2004, 29, 1265–1275. [Google Scholar] [CrossRef]

- Hussein, H.M.S.; Ahmad, G.E.; El-Ghetany, H.H. Performance evaluation of photovoltaic modules at different tilt angles and orientations. Energy Convers. Manag. 2004, 45, 2441–2452. [Google Scholar] [CrossRef]

- Yang, H.; Lu, L. The optimum tilt angles and orientations of PV claddings for Building-Integrated Photovoltaic (BIPV) applications. J. Sol. Energy Eng. Trans. ASME 2007, 129, 253–255. [Google Scholar] [CrossRef]

- Paciello, L.; Pedale, A.; Scaradozzi, D.; Conte, G. A design tool for modelling and sizing of energy production/storage home system. In Proceedings of the EESMS 2014—2014 IEEE Workshop on Environmental, Energy and Structural Monitoring Systems Proceedings, Naples, Italy, 17–18 September 2014; pp. 126–131. [Google Scholar]

- Vieira, F.M.; Moura, P.S.; de Almeida, A.T. Energy storage system for self-consumption of photovoltaic energy in residential zero energy buildings. Renew. Energy 2017, 103, 308–320. [Google Scholar] [CrossRef]

- Wolisz, H.; Schütz, T.; Blanke, T.; Hagenkamp, M.; Kohrn, M.; Wesseling, M.; Müller, D. Cost optimal sizing of smart buildings’ energy system components considering changing end-consumer electricity markets. Energy 2017, 137, 715–728. [Google Scholar] [CrossRef]

- Şenol, M.; Abbasoğlu, S.; Kükrer, O.; Babatunde, A.A. A guide in installing large-scale PV power plant for self consumption mechanism. Sol. Energy 2016, 132, 518–537. [Google Scholar] [CrossRef]

- Luthander, R.; Widén, J.; Nilsson, D.; Palm, J. Photovoltaic self-consumption in buildings: A review. Appl. Energy 2015, 142, 80–94. [Google Scholar] [CrossRef]

- Salvador, M.; Grieu, S. Methodology for the design of energy production and storage systems in buildings: Minimization of the energy impact on the electricity grid. Energy Build. 2012, 47, 659–673. [Google Scholar] [CrossRef]

- Castillo-Cagigal, M.; Caamaño-Martín, E.; Matallanas, E.; Masa-Bote, D.; Gutiérrez, A.; Monasterio-Huelin, F.; Jiménez-Leube, J. PV self-consumption optimization with storage and Active DSM for the residential sector. Sol. Energy 2011, 85, 2338–2348. [Google Scholar] [CrossRef]

- Al Garni, H.; Awasthi, A. Techno-Economic Feasibility Analysis of a Solar PV Grid-Connected System with Different Tracking Using HOMER Software. In Proceedings of the 2017 IEEE International Conference on Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 14–17 August 2017; pp. 217–222. [Google Scholar]

- Sinha, S.; Chandel, S.S. Review of software tools for hybrid renewable energy systems. Renew. Sustain. Energy Rev. 2014, 32, 192–205. [Google Scholar] [CrossRef]

- Ghiani, E.; Vertuccio, C.; Pilo, F. Optimal Sizing and Management of a Smart Microgrid for Prevailing Self-Consumption. In Proceedings of the 2015 IEEE Eindhoven PowerTech, Eindhoven, The Netherlands, 29 June–2 July 2015; pp. 1–6. [Google Scholar]

- Ghiani, E.; Giordano, A.; Nieddu, A.; Rosetti, L.; Pilo, F. Planning of a Smart Local Energy Community: The Case of Berchidda Municipality (Italy). Energies 2019, 12, 4629. [Google Scholar] [CrossRef]

- Martín-Chivelet, N.; Montero-Gómez, D. Optimizing photovoltaic self-consumption in office buildings. Energy Build. 2017, 150, 71–80. [Google Scholar] [CrossRef]

- Poulek, V.; Dang, M.; Libra, M.; Beránek, V.; Šafránková, J. PV Panel With Integrated Lithium Accumulators For BAPV Applications—One Year Thermal Evaluation. IEEE J. Photovoltaics 2020, 10, 150–152. [Google Scholar] [CrossRef]

- Yu, H.; Duan, J.; Du, W.; Xue, S.; Sun, J. China’s energy storage industry: Develop status, existing problems and countermeasures. Renew. Sustain. Energy Rev. 2017, 71, 767–784. [Google Scholar] [CrossRef]

- Lave, M.; Kleissl, J.; Arias-Castro, E. High-frequency irradiance fluctuations and geographic smoothing. Sol. Energy 2012, 86, 2190–2199. [Google Scholar] [CrossRef]

- Zawilska, E.; Brooks, M.J. An assessment of the solar resource for Durban, South Africa. Renew. Energy 2011, 36, 3433–3438. [Google Scholar] [CrossRef]

- Journée, M.; Müller, R.; Bertrand, C. Solar resource assessment in the Benelux by merging Meteosat-derived climate data and ground measurements. Sol. Energy 2012, 86, 3561–3574. [Google Scholar] [CrossRef]

- Gueymard, C.A.; Wilcox, S.M. Assessment of spatial and temporal variability in the US solar resource from radiometric measurements and predictions from models using ground-based or satellite data. Sol. Energy 2011, 85, 1068–1084. [Google Scholar] [CrossRef]

- Jiménez-Torres, M.; Rus-Casas, C.; Lemus-Zúñiga, L.G.; Hontoria, L. The importance of accurate solar data for designing solar photovoltaic systems-Case studies in Spain. Sustainability 2017, 9, 247. [Google Scholar] [CrossRef]

- Hontoria, L.; Rus-Casas, C.; Aguilar, J.D.; Hernandez, J.C. An improved method for obtaining solar irradiation data at temporal high-resolution. Sustainability 2019, 11, 5233. [Google Scholar] [CrossRef]

- Hirsch, T.; Schenk, H.; Schmidt, N.; Meyer, R. Dynamics of oil-based parabolic trough plants—Impact of transient behaviour on energy yields. In Proceedings of the SolarPACES 2010 Conference, Perpignan, France, 21–24 September 2010. [Google Scholar]

- Moreno-Tejera, S.; Silva-Pérez, M.A.; Lillo-Bravo, I.; Ramírez-Santigosa, L. Solar resource assessment in Seville, Spain. Statistical characterisation of solar radiation at different time resolutions. Sol. Energy 2016, 132, 430–441. [Google Scholar] [CrossRef]

- Sandia National Laboratories. Stand-Alone Photovoltaic Systems: A Handbook of Recommended Design Practices; Absorpt. Fluids Data Surv. Final Rep. Foreign Data; Sandia National Laboratories: Albuquerque, NM, USA, 1995; pp. 1–437. [Google Scholar]

- Carroquino, J.; Dufo-López, R.; Bernal-Agustín, J.L. Sizing of off-grid renewable energy systems for drip irrigation in Mediterranean crops. Renew. Energy 2015, 76, 566–574. [Google Scholar] [CrossRef]

- Radiación Solar. Available online: https://www.agenciaandaluzadelaenergia.es/Radiacion/radiacion1.php (accessed on 20 October 2019).

- Rus-Casas, C.; Aguilar, J.D.; Rodrigo, P.; Almonacid, F.; Pérez-Higueras, P.J. Classification of methods for annual energy harvesting calculations of photovoltaic generators. Energy Convers. Manag. 2014, 78, 527–536. [Google Scholar] [CrossRef]

- IEC. IEC 61724-1 Edition 1.0 2017-03 Photovoltaic System Performance—Part 1: Monitoring IEC, 1st ed.; IEC Publications: Geneva, Switzerland, 2017; ISBN 9782832239889. [Google Scholar]

- Jiménez-Castillo, G.; Muñoz-Rodriguez, F.J.; Rus-Casas, C.; Talavera, D.L. A new approach based on economic profitability to sizing the photovoltaic generator in self-consumption systems without storage. Renew. Energy 2020, 148, 1017–1033. [Google Scholar] [CrossRef]

- Talavera, D.L.; Muñoz-Rodriguez, F.J.; Jimenez-Castillo, G.; Rus-Casas, C. A new approach to sizing the photovoltaic generator in self-consumption systems based on cost–competitiveness, maximizing direct self-consumption. Renew. Energy 2019, 130, 1021–1035. [Google Scholar] [CrossRef]

- Mubarak, R.; Luiz, E.W.; Seckmeyer, G. Why PV Modules Should Preferably No Longer Be Oriented to the South in the Near Future. Energies 2019, 12, 4528. [Google Scholar] [CrossRef]

- Burgio, A.; Menniti, D.; Sorrentino, N.; Pinnarelli, A.; Leonowicz, Z. Influence and impact of data averaging and temporal resolution on the assessment of energetic, economic and technical issues of hybrid photovoltaic-battery systems. Energies 2020, 13, 354. [Google Scholar] [CrossRef]

- Guerra, T.A.; Guerra, J.A.; Tabernero, B.O.; De La Cruz García, G. Comparative energy performance analysis of six primary photovoltaic technologies in Madrid (Spain). Energies 2017, 10, 772. [Google Scholar] [CrossRef]

- Mondol, J.D.; Yohanis, Y.G.; Smyth, M.; Norton, B. Performance analysis of a grid-connected building integrated photovoltaic system. In Proceedings of the ISES 2003: ISES Solar World Congress 2003: Solar Energy for a Sustainable Future, Göteborg, Sweden, 14–19 June 2003. [Google Scholar]

- Šúri, M.; Huld, T.A.; Dunlop, E.D.; Ossenbrink, H.A. Potential of solar electricity generation in the European Union member states and candidate countries. Sol. Energy 2007, 81, 1295–1305. [Google Scholar] [CrossRef]

- Ransome, S.J.; Wohlgemuth, J.H. kWh/kWp dependency on PV technology and balance of systems performance. In Proceedings of the Conference Record of the Twenty-Ninth IEEE Photovoltaic Specialists Conference, New Orleans, LA, USA, 19–24 May 2002; pp. 1420–1423. [Google Scholar]

- Ruiz-Arias, J.A.; Terrados, J.; Pérez-Higueras, P.; Pozo-Vázquez, D.; Almonacid, G. Assessment of the renewable energies potential for intensive electricity production in the province of Jaén, southern Spain. Renew. Sustain. Energy Rev. 2012, 16, 2994–3001. [Google Scholar] [CrossRef]

- Almonacid, F.; Rus, C.; Hontoria, L.; Muñoz, F.J.; Fuentes, M.; Nofuentes, G. Characterisation of Si-crystalline PV modules by artificial neural networks. Renew. Energy 2009, 34, 941–949. [Google Scholar] [CrossRef]

- Almonacid, F.; Rus, C.; Pérez, P.J.; Hontoria, L. Estimation of the energy of a PV generator using artificial neural network. Renew. Energy 2009, 34, 2743–2750. [Google Scholar] [CrossRef]

- Tina, G.M.; Ventura, C.; Sera, D.; Spataru, S. Comparative Assessment of PV Plant Performance Models Considering Climate Effects. Electr. Power Components Syst. 2017, 45, 1381–1392. [Google Scholar] [CrossRef]

- Poulek, V.; Matuška, T.; Libra, M.; Kachalouski, E.; Sedláček, J. Influence of increased temperature on energy production of roof integrated PV panels. Energy Build. 2018, 166, 418–425. [Google Scholar] [CrossRef]

- Jiménez-Castillo, G.; Tina, G.-M.; Muñoz-Rodríguez, F.-J.; Rus-Casas, C. Smart meters for the evaluation of self-consumption in zero energy buildings. In Proceedings of the 2019 10th International Renewable Energy Congress (IREC), Sousse, Tunisia, 26–28 March 2019; pp. 1–6. [Google Scholar]

- Iqbal, M. An Introduction to Solar Radiation; Elsevier: Amsterdam, The Netherlands, 2012; ISBN 0323151817. [Google Scholar]

- Cao, S.; Sirén, K. Impact of simulation time-resolution on the matching of PV production and household electric demand. Appl. Energy 2014, 128, 192–208. [Google Scholar] [CrossRef]

- Ayala-Gilardón, A.; Sidrach-de-Cardona, M.; Mora-López, L. Influence of time resolution in the estimation of self-consumption and self-sufficiency of photovoltaic facilities. Appl. Energy 2018, 229, 990–997. [Google Scholar] [CrossRef]

- Wolf, P.; Včelák, J. Simulation of a simple PV system for local energy usage considering the time resolution of input data. J. Energy Storage 2018, 15, 1–7. [Google Scholar] [CrossRef]

- Wyrsch, N.; Riesen, Y.; Ballif, C. Effect of the fluctuations of pv production and electricity demand on the pv electricity self-consumption. In Proceedings of the 28th European Photovoltaic Solar Energy Conference and Exhibition, Villepinte, France, 30 September–4 October 2013; pp. 4322–4324. [Google Scholar]

- Jiménez-Castillo, G.; Muñoz-Rodríguez, F.J.; Rus-Casas, C.; Gómez-Vidal, P. Improvements in Performance Analysis of Photovoltaic Systems: Array Power Monitoring in Pulse Width Modulation Charge Controllers. Sensors 2019, 19, 2150. [Google Scholar] [CrossRef] [PubMed]

- Muñoz, F.J.; Jiménez, G.; Fuentes, M.; Aguilar, J.D.; Munoz, F.J.; Jimenez-Castillo, G.; Fuentes, M.; Aguilar, J.D. Power Gain and Daily Improvement Factor in Stand-Alone Photovoltaic Systems With Maximum Power Point Tracking Charge Regulators. Case of Study: South of Spain. J. Sol. Energy Eng. ASME 2013, 135, 1–9. [Google Scholar] [CrossRef]

- Rus-Casas, C.; Hontoria, L.; Fernández-Carrasco, J.; Jiménez-Castillo, G.; Muñoz-Rodríguez, F.J. Development of a Utility Model for the Measurement of Global Radiation in Photovoltaic Applications in the Internet of Things (IoT). Electronics 2019, 8, 304. [Google Scholar]

- Jiménez-Castillo, G.; Muñoz-Rodríguez, F.; Rus-Casas, C.; Hernández, J.C.; Tina, G. Monitoring PWM signals in stand-alone photovoltaic systems. Measurement 2019, 134, 412–425. [Google Scholar]

- Widén, J.; Wäckelgård, E.; Paatero, J.; Lund, P. Impacts of different data averaging times on statistical analysis of distributed domestic photovoltaic systems. Sol. Energy 2010, 84, 492–500. [Google Scholar] [CrossRef]

- Sørnes, K.; Fredriksen, E.; Tunheim, K.; Sartori, I. Analysis of the impact resolution has on load matching in the Norwegian context. Energy Procedia 2017, 132, 610–615. [Google Scholar] [CrossRef]

- Beck, T.; Kondziella, H.; Huard, G.; Bruckner, T. Assessing the influence of the temporal resolution of electrical load and PV generation profiles on self-consumption and sizing of PV-battery systems. Appl. Energy 2016, 173, 331–342. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. A comprehensive review on design of building integrated photovoltaic system. Energy Build. 2016, 128, 99–110. [Google Scholar] [CrossRef]

| Categories | Olive Oil Production (t) | Average Electricity Consumption (MWh) |

|---|---|---|

| Small | <1000 | 92 |

| Medium | 1000 < production < 5000 | 435 |

| Large | >5000 | 923 |

| Category | Period | Electricity Consumption (MWh) |

|---|---|---|

| Harvest | December to March | Cleaning and crushing the olives. Motor drives of conveyor belts, washings for olive, destemmers, grinding and mixing equipment centrifugal pumps Applications ancillary, such as air compressors, computer systems, lighting system |

| Annual | Full year | Applications ancillary, such as air compressors, computer systems, lighting system |

| Period | Monitoring Period (Year) | Electricity Consumption (kWh/Period) | Daylight/Total (%) | Monthly/Year (%) | Monthly/Year (%) (Daylight Hours) | ||

|---|---|---|---|---|---|---|---|

| Total Hours | Daylight Hours | Night Hours | |||||

| January | 2019 | 233352.0 | 91334.9 | 142017.1 | 39.1 | 16.6 | 13.4 |

| February | 2019 | 208175.0 | 92891.8 | 115283.2 | 44.6 | 14.8 | 13.6 |

| March | 2019 | 139263.0 | 79591.3 | 59671.7 | 57.2 | 9.9 | 11.7 |

| April | 2018 | 107102.0 | 60758.1 | 46343.9 | 56.7 | 7.6 | 8.9 |

| May | 2018 | 75133.0 | 50591.8 | 24541.2 | 67.3 | 5.3 | 7.4 |

| June | 2018 | 68283.0 | 43612.9 | 24670.1 | 63.9 | 4.9 | 6.4 |

| July | 2018 | 64509.0 | 45226.5 | 19282.5 | 70.1 | 4.6 | 6.6 |

| August | 2018 | 67635.0 | 38276.9 | 29358.1 | 56.6 | 4.8 | 5.6 |

| September | 2018 | 52970.0 | 27188.5 | 25781.5 | 51.3 | 3.8 | 4.0 |

| October | 2018 | 67194.0 | 27944.7 | 39249.3 | 41.6 | 4.8 | 4.1 |

| November | 2018 | 125344.0 | 47475.7 | 77868.3 | 37.9 | 8.9 | 7.0 |

| December | 2018 | 198244.0 | 77012.8 | 121231.2 | 38.8 | 14.1 | 11.3 |

| Year | 2018 | 1407204.0 | 681905.8 | 725298.2 | |||

| Reporting Period | Φss | β (°) | α (°) | P0 (kWp) |

|---|---|---|---|---|

| Annual basis | Max | 30 | 0 | [0.01–110) |

| 35 | 0 | [110–140) | ||

| 35 | −10 | [140–300) | ||

| 40 | −10 | [300–690) | ||

| 45 | −10 | [690–820) | ||

| 40 | −10 | [820–1000] | ||

| Min | 90 | −90 | [0.01–60) | |

| 90 | 90 | [60–1000] | ||

| Olive harvest basis | Max | 50 | 0 | [0.01–70) |

| 55 | 0 | [70–1000] | ||

| Min | 90 | −90 | [0.01–20) | |

| 90 | 90 | [20–1000] | ||

| No olive harvest basis | Max | 25 | 0 | [0.01–170) |

| 20 | 0 | [170–310) | ||

| 20 | −10 | [310–380) | ||

| 20 | −30 | [380–400) | ||

| 15 | −30 | [400–490) | ||

| 10 | −30 | [490–600) | ||

| 0 | 90 | [600–1000] | ||

| Min | 90 | 0 | [0.01–120) | |

| 90 | 90 | [120–1000] |

| P0 (kWp) | β (°) | α (°) | Reporting Period | Φsc | Φss |

|---|---|---|---|---|---|

| 250 | 35 | −10 | Annual basis | 0.7714 | 0.2012 |

| Olive harvest basis | 0.9002 | 0.1159 | |||

| No olive harvest basis | 0.7229 | 0.3069 | |||

| 20 | 0 | Annual basis | 0.7667 | 0.1971 | |

| Olive harvest basis | 0.9004 | 0.1060 | |||

| No olive harvest basis | 0.7212 | 0.3101 | |||

| 55 | 0 | Annual basis | 0.7918 | 0.1944 | |

| Olive harvest basis | 0.9020 | 0.1209 | |||

| No olive harvest basis | 0.7441 | 0.2855 | |||

| 90 | 90 | Annual basis | 0.8404 | 0.1187 | |

| Olive harvest basis | 0.9203 | 0.0546 | |||

| No olive harvest basis | 0.8161 | 0.1982 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiménez-Castillo, G.; Muñoz-Rodríguez, F.J.; Martinez-Calahorro, A.J.; Tina, G.M.; Rus-Casas, C. Impacts of Array Orientation and Tilt Angles for Photovoltaic Self-Sufficiency and Self-Consumption Indices in Olive Mills in Spain. Electronics 2020, 9, 348. https://doi.org/10.3390/electronics9020348

Jiménez-Castillo G, Muñoz-Rodríguez FJ, Martinez-Calahorro AJ, Tina GM, Rus-Casas C. Impacts of Array Orientation and Tilt Angles for Photovoltaic Self-Sufficiency and Self-Consumption Indices in Olive Mills in Spain. Electronics. 2020; 9(2):348. https://doi.org/10.3390/electronics9020348

Chicago/Turabian StyleJiménez-Castillo, Gabino, Francisco José Muñoz-Rodríguez, Antonio Javier Martinez-Calahorro, Giuseppe Marco Tina, and Catalina Rus-Casas. 2020. "Impacts of Array Orientation and Tilt Angles for Photovoltaic Self-Sufficiency and Self-Consumption Indices in Olive Mills in Spain" Electronics 9, no. 2: 348. https://doi.org/10.3390/electronics9020348

APA StyleJiménez-Castillo, G., Muñoz-Rodríguez, F. J., Martinez-Calahorro, A. J., Tina, G. M., & Rus-Casas, C. (2020). Impacts of Array Orientation and Tilt Angles for Photovoltaic Self-Sufficiency and Self-Consumption Indices in Olive Mills in Spain. Electronics, 9(2), 348. https://doi.org/10.3390/electronics9020348