A Heterogeneous Inductive Power Transfer System for Electric Vehicles with Spontaneous Constant Current and Constant Voltage Output Features

Abstract

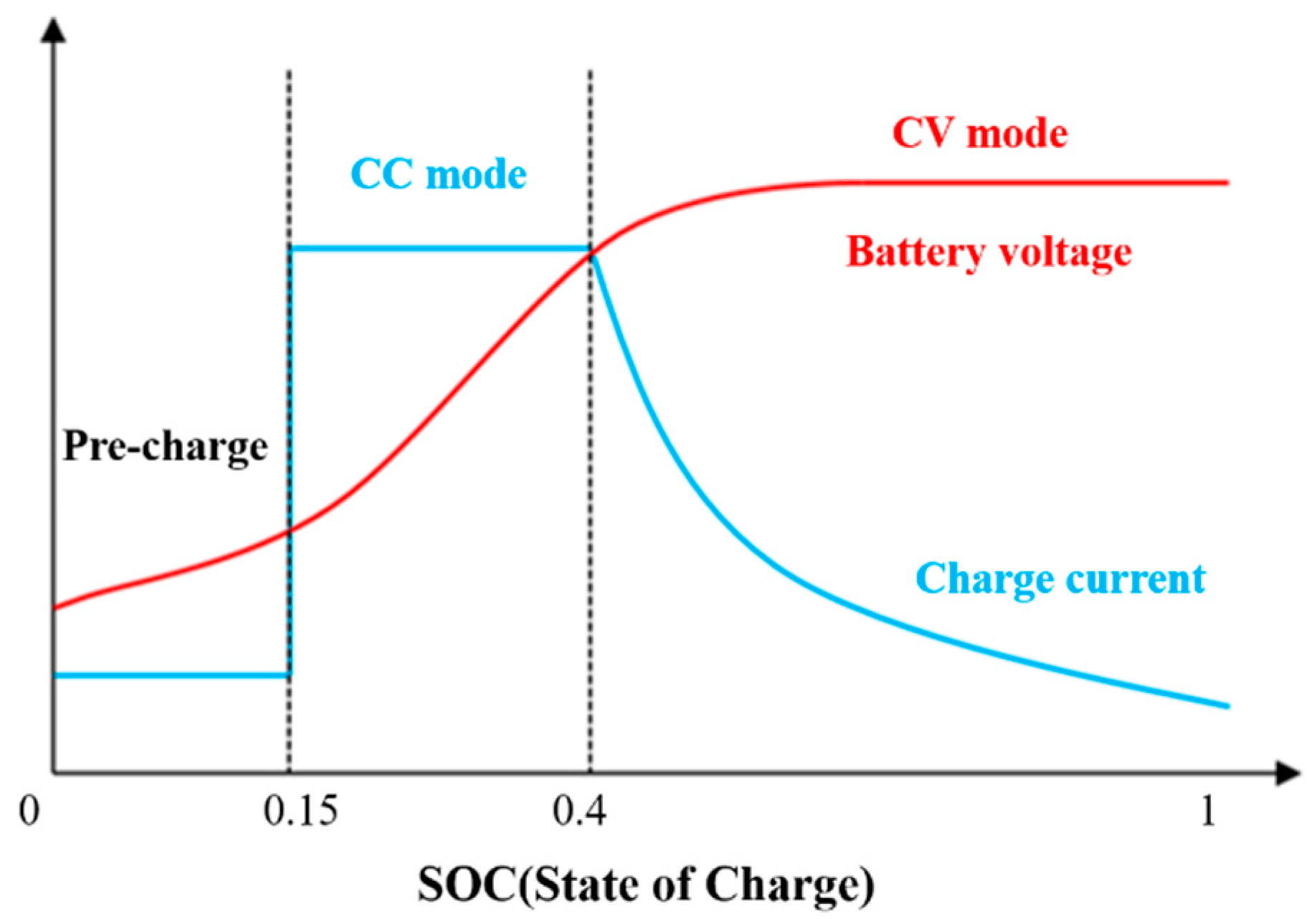

:1. Introduction

2. Design of Loosely Coupled Transformers

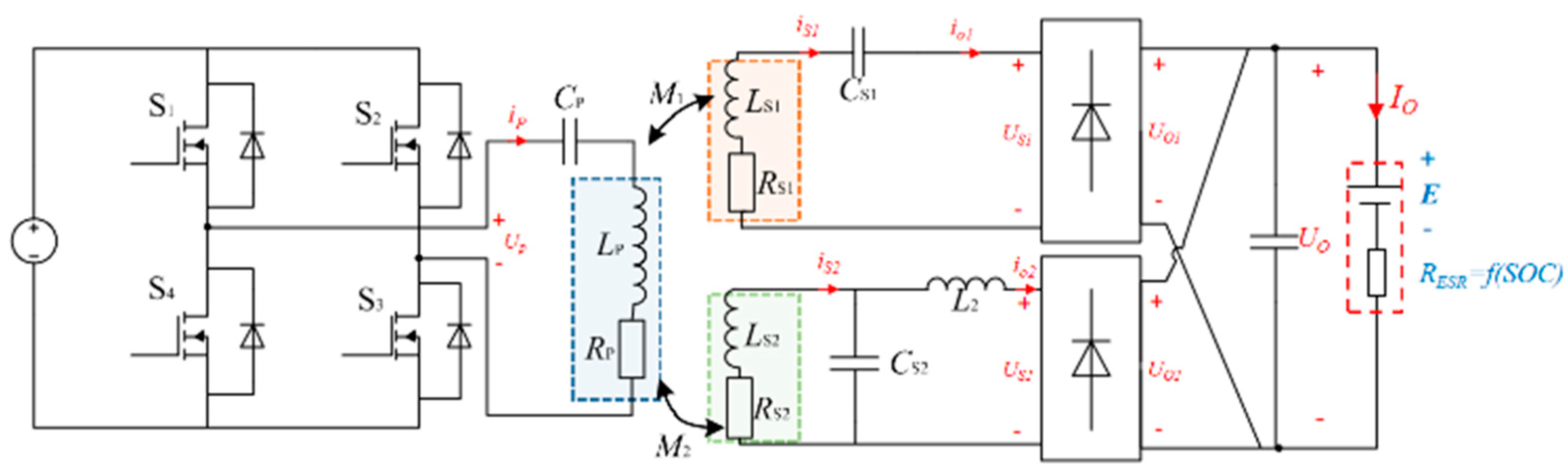

3. Heterogeneous Compensation Network

3.1. Basic Principles

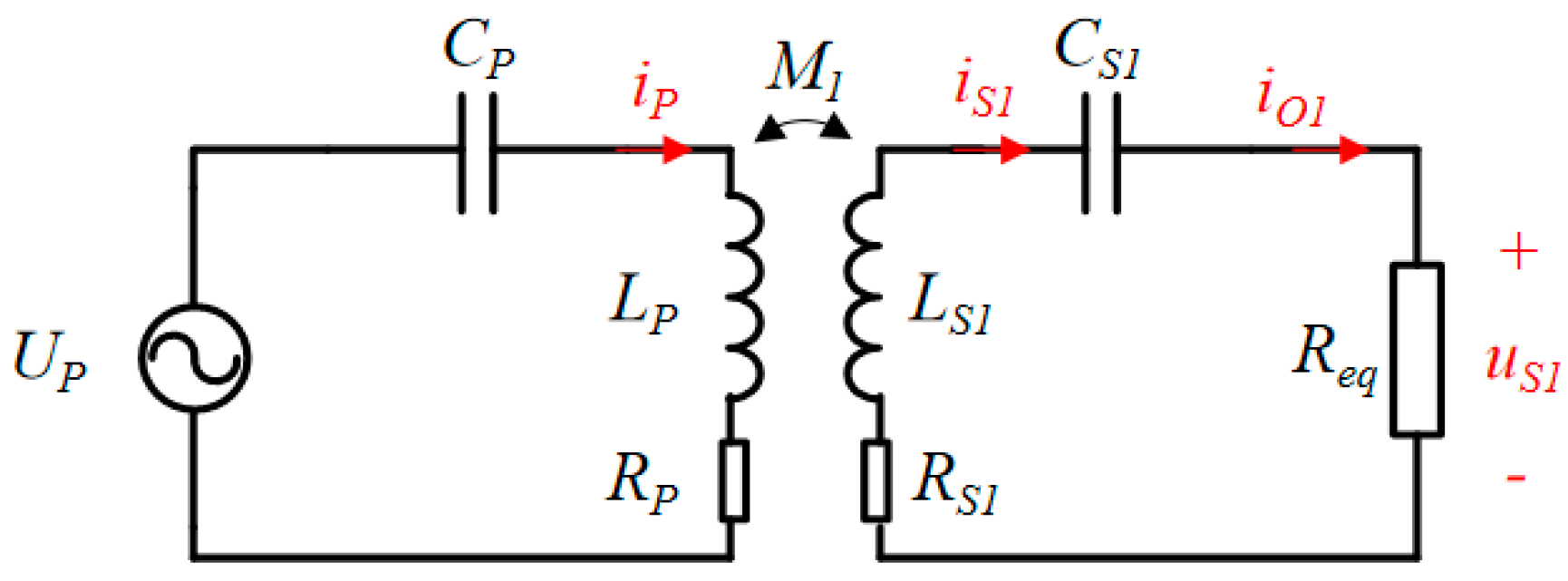

3.1.1. S-S Compensation Topology

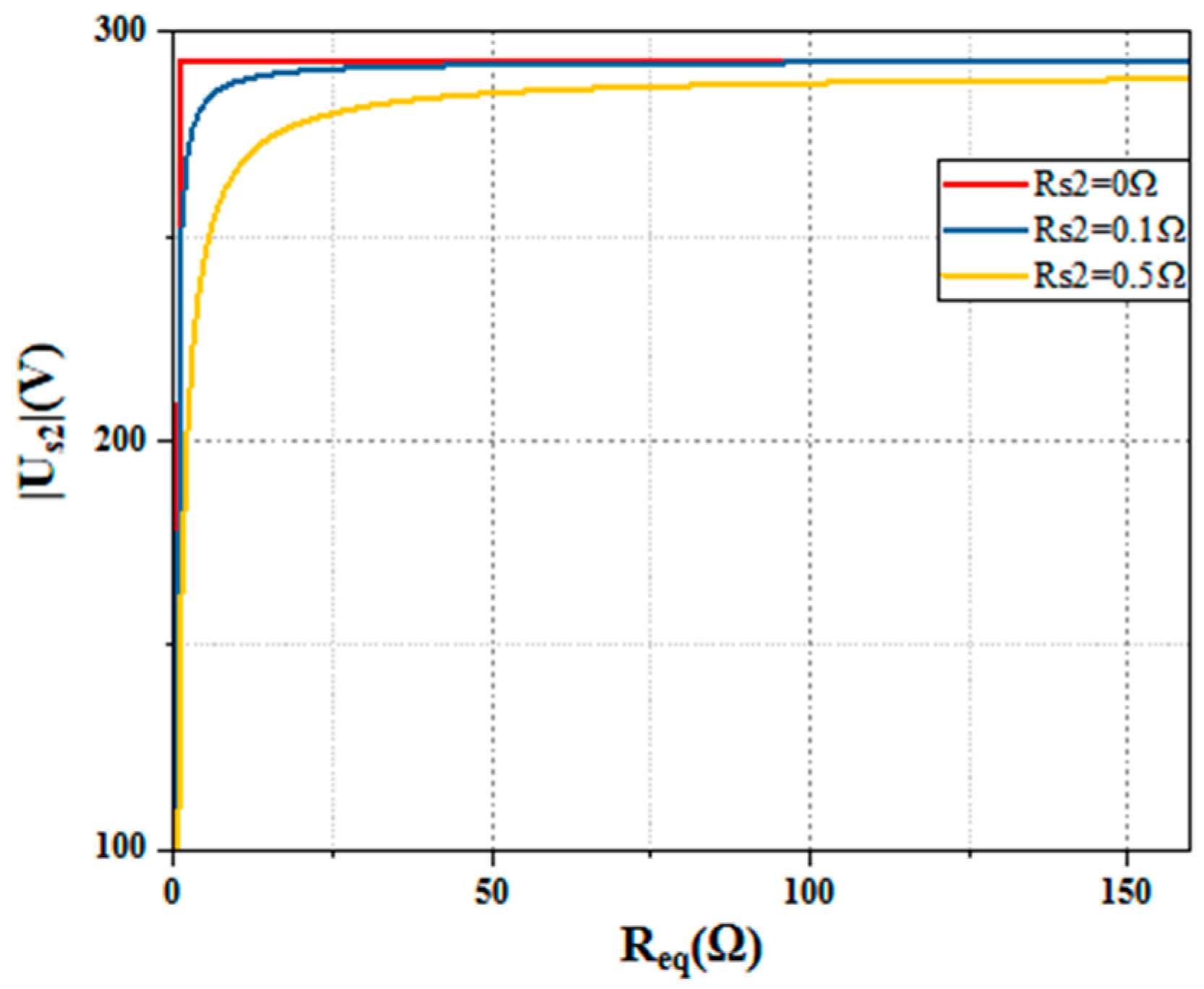

3.1.2. S-LCL Compensation Topology

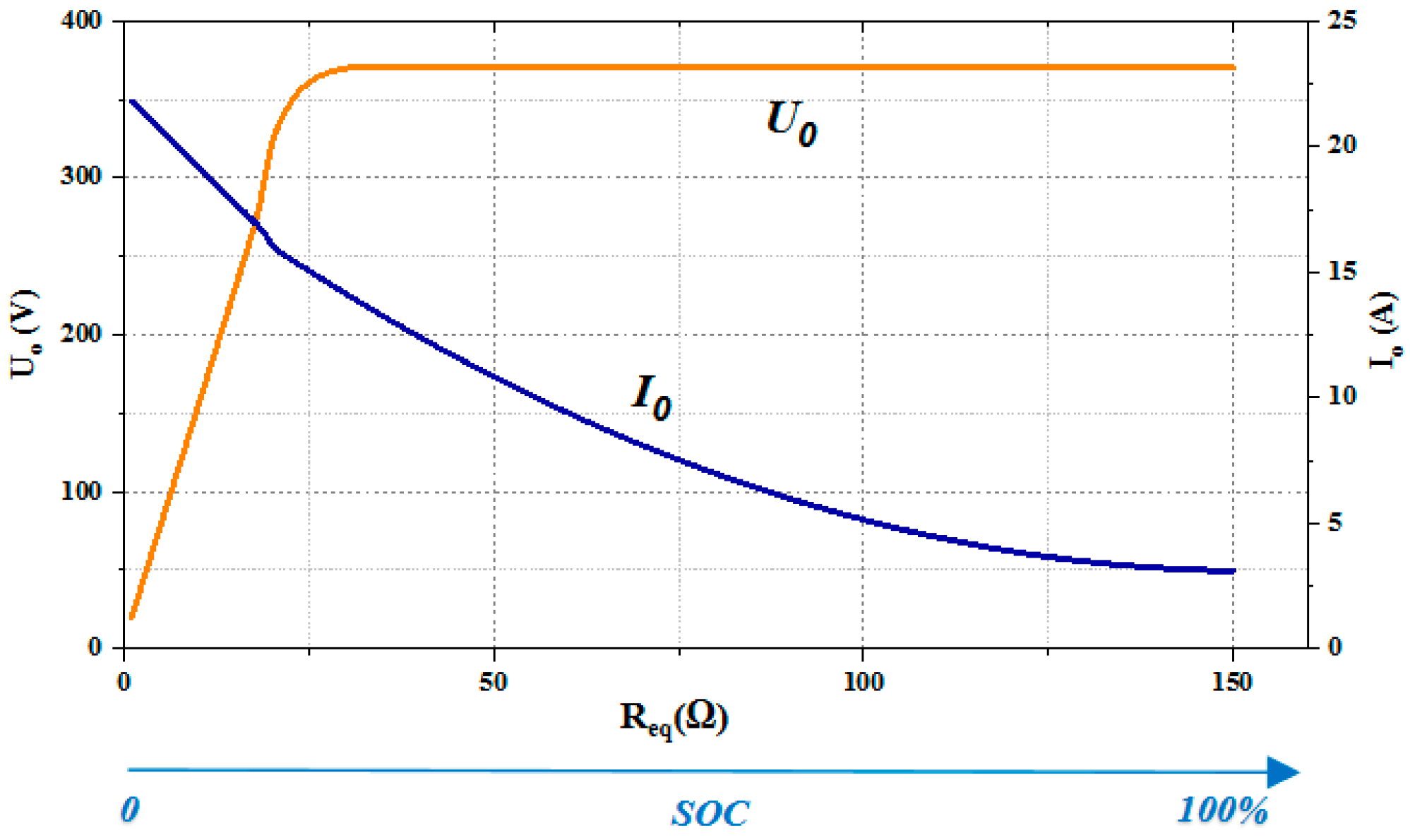

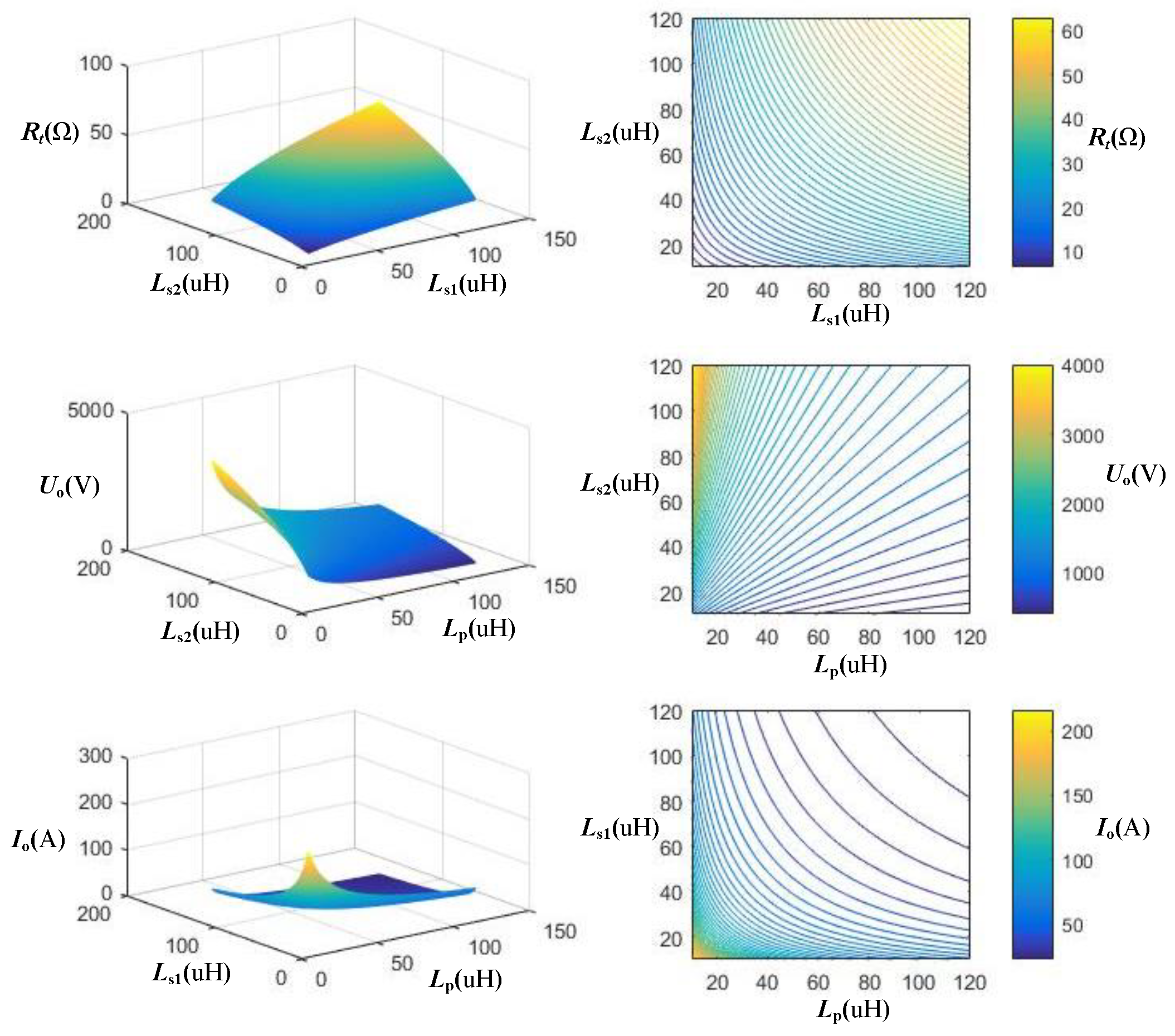

3.2. Transition Point Analysis

3.3. Formatting of Mathematical Components

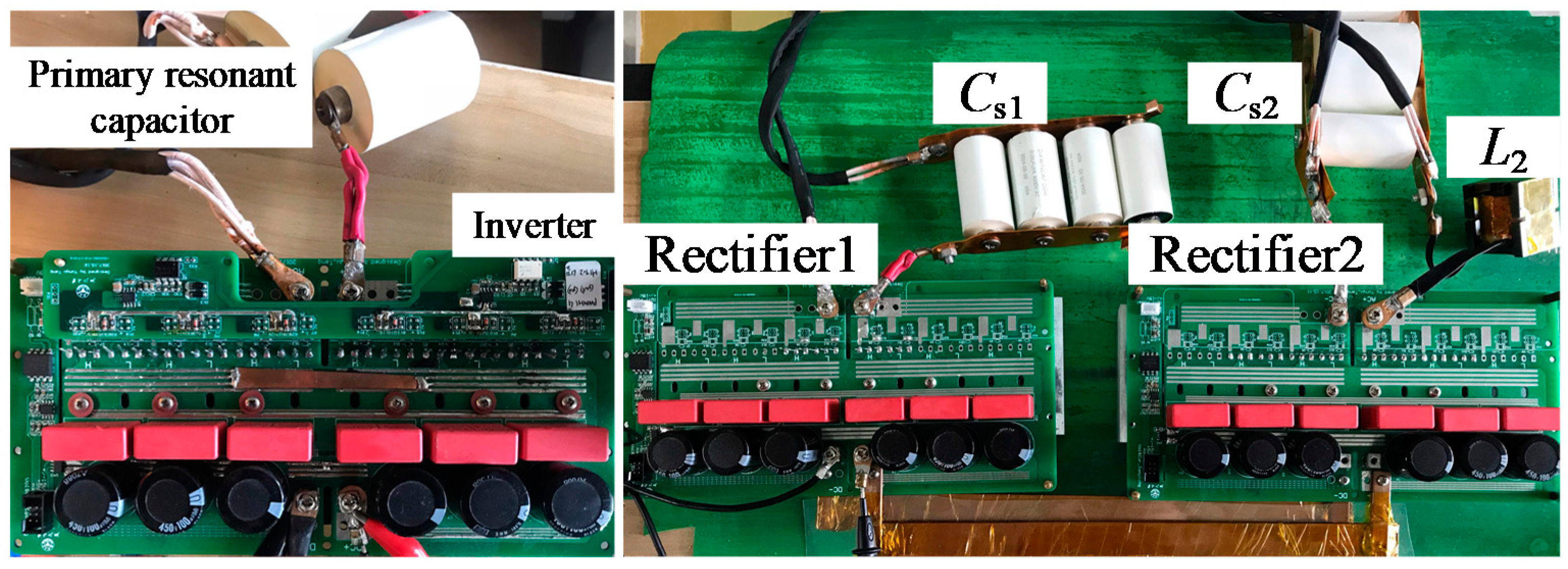

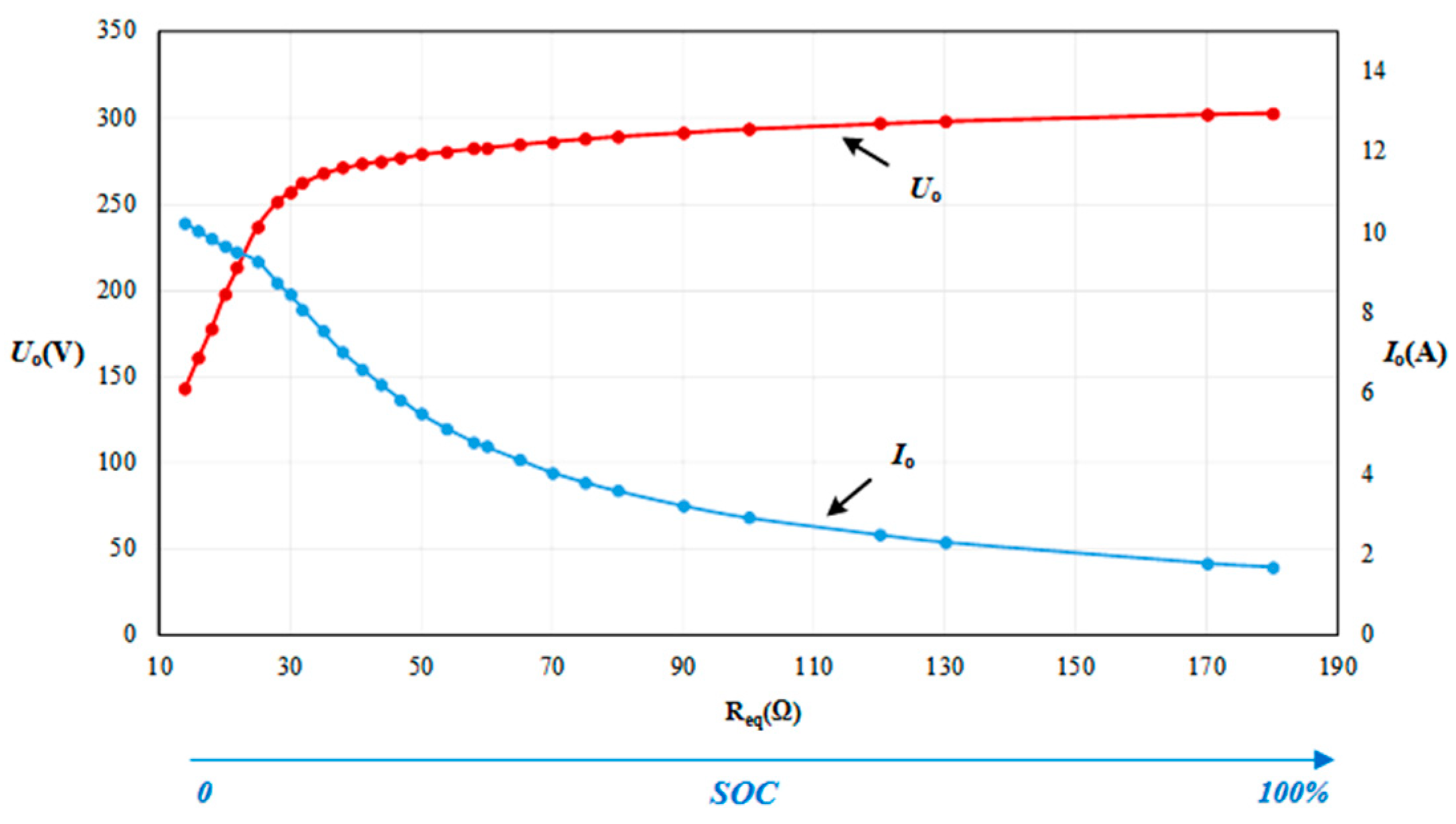

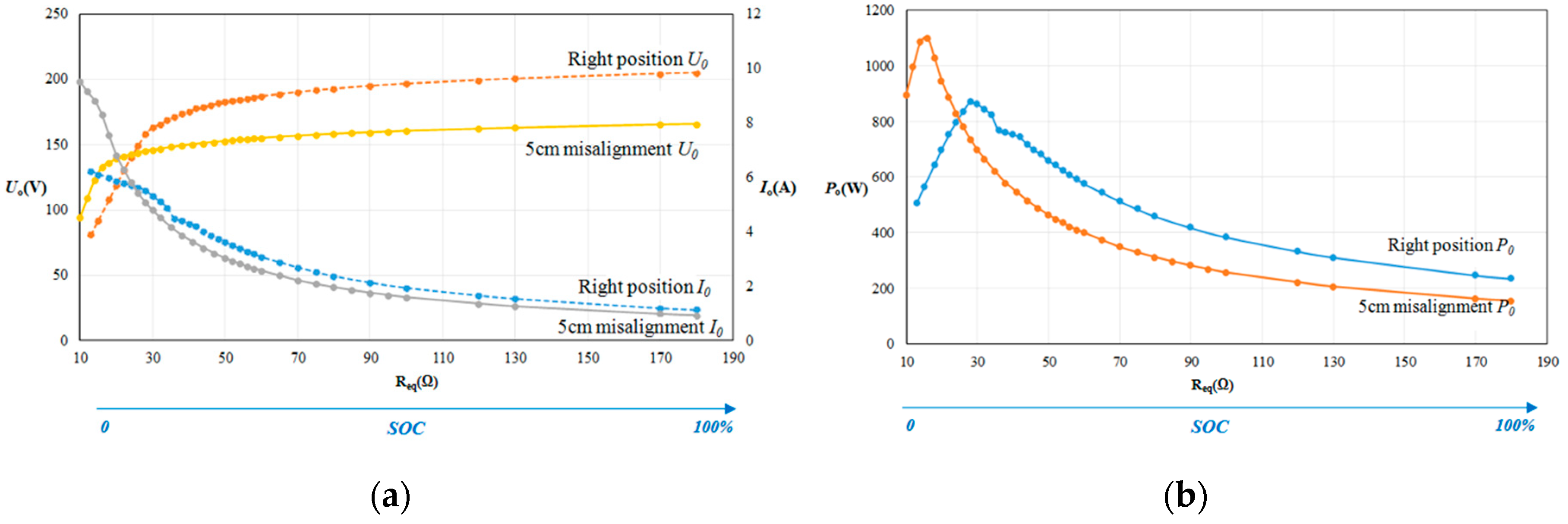

4. Experimental Verification

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hui, S.Y.R.; Zhong, W.; Lee, C.K. A Critical Review of Recent Progress in Mid-Range Wireless Power Transfer. IEEE Trans. Power Electron. 2014, 29, 4500–4511. [Google Scholar]

- Mi, C.C.; Buja, G.; Choi, S.Y.; Rim, C.T. Modern Advances in Wireless Power Transfer Systems for Roadway Powered Electric Vehicles. IEEE Trans. Ind. Electron. 2016, 63, 6533–6545. [Google Scholar]

- Zhang, C.; Lin, D.; Hui, S.Y. Ball-Joint Wireless Power Transfer Systems. IEEE Trans. Power Electron. 2018, 33, 65–72. [Google Scholar]

- Zhang, C.; Lin, D.; Tang, N.; Hui, S.Y.R. A Novel Electric Insulation String Structure with High-Voltage Insulation and Wireless Power Transfer Capabilities. IEEE Trans. Power Electron. 2018, 33, 87–96. [Google Scholar]

- Tang, Y.; Zhu, F.; Wang, Y.; Ma, H. Design and optimizations of solenoid magnetic structure for inductive power transfer in EV applications. In Proceedings of the 41st Annual Conference of the IEEE Industrial Electronics Society (IECON 2015), Yokohama, Japan, 9–12 November 2015. [Google Scholar]

- Hu, S.; Liang, Z.; He, X. Ultracapacitor-battery hybrid energy storage system based on the asymmetric bidirectional Z-source topology for EV. IEEE Trans. Power Electron. 2016, 31, 7489–7498. [Google Scholar]

- Hu, S.; Liang, Z.; Fan, D.; He, X. Hybrid Ultracapacitor–Battery Energy Storage System Based on Quasi-Z-source Topology and Enhanced Frequency Dividing Coordinated Control for EV. IEEE Trans. Power Electron. 2016, 31, 7598–7610. [Google Scholar]

- Budhia, M.; Covic, G.A.; Boys, J.T. Design and Optimization of Circular Magnetic Structures for Lumped Inductive Power Transfer Systems. IEEE Trans. Power Electron. 2011, 26, 30963108. [Google Scholar]

- Kim, J.; Kim, J.J.; Kong, S.; Kim, H.; Suh, I.-S.; Suh, N.P.; Cho, D.-H.; Kim, J.; Ahn, S. Coil Design and Shielding Methods for a Magnetic Resonant Wireless Power Transfer System. Proc. IEEE. 2013, 101, 1332–1342. [Google Scholar]

- Budhia, M.; Boys, J.T.; Coyic, G.A.; Huang, C.Y. Development of a single-sided flux vehicle IPT charging systems. IEEE Trans. Ind. Electron. 2013, 60, 318–328. [Google Scholar]

- Budhia, M.; Covic, G.; Boys, J. A new IPT magnetic coupler for electric vehicle charging systems. In Proceedings of the 36th Annual Conference of IEEE Industrial Electronics Society (IECON 2010), Glendale, AZ, USA, 7–10 November 2010. [Google Scholar]

- Nagatsuka, Y.; Ehara, N.; Kaneko, Y.; Abe, S.; Yasuda, T. Compact contactless power transfer system for electric vehicles. In Proceedings of the 2010 International Power Electronics Conference—ECCE ASIA, Sapporo, Japan, 21–24 June 2010. [Google Scholar]

- Cao, P.; Tang, Y.; Zhu, F.; Zhang, Z.; Zhou, J.; Bai, Z.; Ma, H. An IPT System with Constant Current and Constant Voltage Output Features for EV Charging. In Proceedings of the 44th Annual Conference of the IEEE Industrial Electronics Society (IECON 2018), Washington, DC, USA, 21–23 October 2018. [Google Scholar]

- Li, Z.; Zhu, C.; Jiang, J.; Song, K.; Wei, G. A 3-kW Wireless Power Transfer System for Sightseeing Car Supercapacitor Charge. IEEE Trans. Power Electron. 2016, 32, 3301–3316. [Google Scholar]

- Qu, X.; Han, H.; Wong, S.-C.; Tse, C.K.; Chen, W. Hybrid IPT Topologies With Constant Current or Constant Voltage Output for Battery Charging Applications. IEEE Trans. Power Electron. 2015, 30, 6329–6337. [Google Scholar]

- Mai, R.; Chen, Y.; Li, Y.; Zhang, Y.; Cao, G.; He, Z. Inductive Power Transfer for Massive Electric Bicycles Charging Based on Hybrid Topology Switching With a Single Inverter. IEEE Trans. Power Electron. 2017, 32, 5897–5906. [Google Scholar]

- Li, Y.; Xu, Q.; Lin, T.; Hu, J.; He, Z.; Mai, R. Analysis and Design of Load-Independent Output Current or Output Voltage of a Three-Coil Wireless Power Transfer System. IEEE Trans. Transp. Electrif. 2018, 4, 364–375. [Google Scholar]

- Chen, Y.; Yang, B.; Kou, Z.; He, Z.; Cao, G.; Mai, R. Hybrid and Reconfigurable IPT Systems With High-Misalignment Tolerance for Constant-Current and Constant-Voltage Battery Charging. IEEE Trans. Power Electron. 2018, 33, 8259–8269. [Google Scholar]

- Kim, M.; Joo, D.-M.; Lee, B.K.; Woo, D.-G. Design and control of inductive power transfer system for electric vehicles considering wide variation of output voltage and coupling coefficient. In Proceedings of the 2017 IEEE Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017. [Google Scholar]

- Berger, A.; Agostinelli, M.; Vesti, S.; Oliver, J.A.; Cobos, J.A.; Huemer, M. A Wireless Charging System Applying Phase-Shift and Amplitude Control to Maximize Efficiency and Extractable Power. IEEE Trans. Power Electron. 2015, 30, 6338–6348. [Google Scholar]

- Matysik, J.T. The Current and Voltage Phase Shift Regulation in Resonant Converters with Integration Control. IEEE Trans. Ind. Electron. 2007, 54, 1240–1242. [Google Scholar]

- Wang, C.-S.; Covic, G.A.; Stielau, O.H. Power Transfer Capability and Bifurcation Phenomena of Loosely Coupled Inductive Power Transfer Systems. IEEE Trans. Ind. Electron. 2004, 51, 148–157. [Google Scholar]

- Zhong, W.; Hui, S.Y. Reconfigurable Wireless Power Transfer Systems with High Energy Efficiency Over Wide Load Range. IEEE Trans. Power Electron. 2018, 33, 6379–6390. [Google Scholar]

- Yang, Y.; Zhong, W.; Kiratipongvoot, S.; Tan, S.-C.; Hui, S.Y.R. Dynamic Improvement of Series–Series Compensated Wireless Power Transfer Systems Using Discrete Sliding Mode Control. IEEE Trans. Power Electron. 2018, 33, 6351–6360. [Google Scholar]

- Qu, X.; Jing, Y.; Han, H.; Wong, S.-C.; Tse, C.K. Higher Order Compensation for Inductive-Power-Transfer Converters With Constant-Voltage or Constant-Current Output Combating Transformer Parameter Constraints. IEEE Trans. Power Electron. 2017, 32, 394–405. [Google Scholar]

- Zaheer, A.; Hao, H.; Covic, G.A.; Kacprzak, D. Investigation of Multiple Decoupled Coil Primary Pad Topologies in Lumped IPT Systems for Interoperable Electric Vehicle Charging. IEEE Trans. Power Electron. 2015, 30, 1937–1955. [Google Scholar]

- Bosshard, R.; Kolar, J.W. All-SiC 9.5 kW/dm3On-Board Power Electronics for 50 kW/85 kHz Automotive IPT System. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 5, 419–431. [Google Scholar]

- Deng, J.; Li, W.; Nguyen, T.D.; Li, S.; Mi, C.C. Compact and Efficient Bipolar Coupler for Wireless Power Chargers: Design and Analysis. IEEE Trans. Power Electron. 2015, 30, 6130–6140. [Google Scholar]

| Structure | Coupling | Cost | Misalignment Tolerance | System Complexity | Electro-Magnetic Radiation |

|---|---|---|---|---|---|

| Circular | Low | Low | Low | Low | High |

| Rectangular | Low | Low | Middle | Low | High |

| DD | Middle | Middle | Middle | Middle | Low |

| DDQ 1 | High | High | High | High | Low |

| Bipolar | High | High | High | High | Low |

| Solenoid | High | Middle | Middle | Low | High |

| Proposed | High | Middle | High | Middle | Low(shielded) |

| Start | Rated Point | End | |

|---|---|---|---|

| Battery Voltage (V) | 200 | 380 | ~400 |

| Charging Current (A) | 15 | 9 | Small current |

| Symbol | Variable | Value |

|---|---|---|

| f | System resonant frequency | 85 kHz |

| Lp | Self-inductance of primary coil | 234 μH |

| Ls1 | Self-inductance of secondary coil1 | 106 μH |

| Ls2 | Self-inductance of secondary coil2 | 12 μH |

| L2 | LCL network resonant inductance | 12 μH |

| k12 | Coupling coefficient between primary coil and secondary coil1 | 0.17 |

| k13 | Coupling coefficient between primary coil and secondary coil2 | 0.17 |

| Cp | Resonant capacitance on primary side | 0.014 μF |

| Cs1 | Resonant capacitance on secondary side 1 | 0.03 μF |

| Cs2 | Resonant capacitance on secondary side 2 | 0.276 μF |

| Dimensions (mm) × gap (mm) | Misalignment (mm) | Coupling Coefficient | Efficiency (Aligned) | Efficiency (300 mm Misalignment) | |

|---|---|---|---|---|---|

| Proposed | 600 × 600 × 200 | +/−300 | 0.35–0.2 | 95.2% (~94.2%) | 92.2% (~90.7%) |

| The University of Auckland [26] | 775 × 485 × 200 | +/−200 | 0.3–0.15 | 90% | 86% |

| ETH (Swiss Federal Institute of Technology Zurich) [27] | 760 × 410 × 160 | +/−150 | 0.23–0.15 | 96% | 92% |

| San Diego State University [28] | 600 × 600 × 150 | +/−200 | 0.3–0.14 | 95% | 92% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Yao, P.; Guo, K.; Cao, P.; Zhang, Y.; Ma, H. A Heterogeneous Inductive Power Transfer System for Electric Vehicles with Spontaneous Constant Current and Constant Voltage Output Features. Electronics 2020, 9, 1978. https://doi.org/10.3390/electronics9111978

Zhou J, Yao P, Guo K, Cao P, Zhang Y, Ma H. A Heterogeneous Inductive Power Transfer System for Electric Vehicles with Spontaneous Constant Current and Constant Voltage Output Features. Electronics. 2020; 9(11):1978. https://doi.org/10.3390/electronics9111978

Chicago/Turabian StyleZhou, Jing, Pengzhi Yao, Kan Guo, Pengju Cao, Yao Zhang, and Hao Ma. 2020. "A Heterogeneous Inductive Power Transfer System for Electric Vehicles with Spontaneous Constant Current and Constant Voltage Output Features" Electronics 9, no. 11: 1978. https://doi.org/10.3390/electronics9111978

APA StyleZhou, J., Yao, P., Guo, K., Cao, P., Zhang, Y., & Ma, H. (2020). A Heterogeneous Inductive Power Transfer System for Electric Vehicles with Spontaneous Constant Current and Constant Voltage Output Features. Electronics, 9(11), 1978. https://doi.org/10.3390/electronics9111978