Inkjet-Printed Electronics on Paper for RF Identification (RFID) and Sensing

Abstract

1. Introduction

2. Paper Substrates and Electronic Inks for Printing

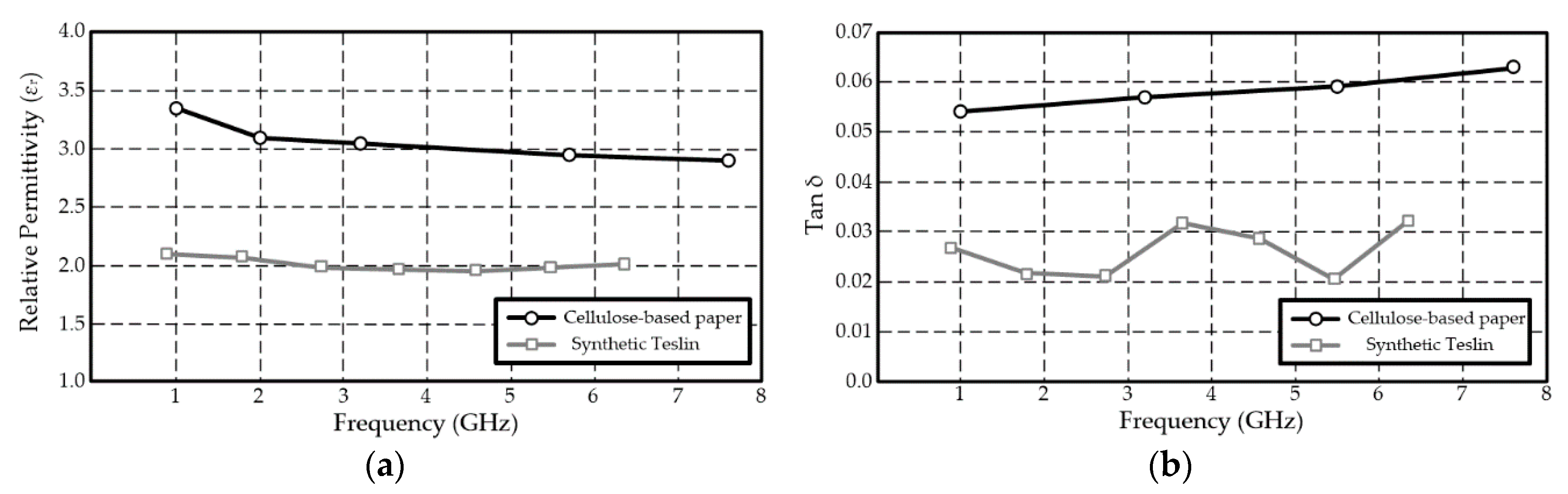

2.1. Paper Substrates

2.1.1. Cellulose-Based Photo-Paper

2.1.2. Synthetic Teslin Paper

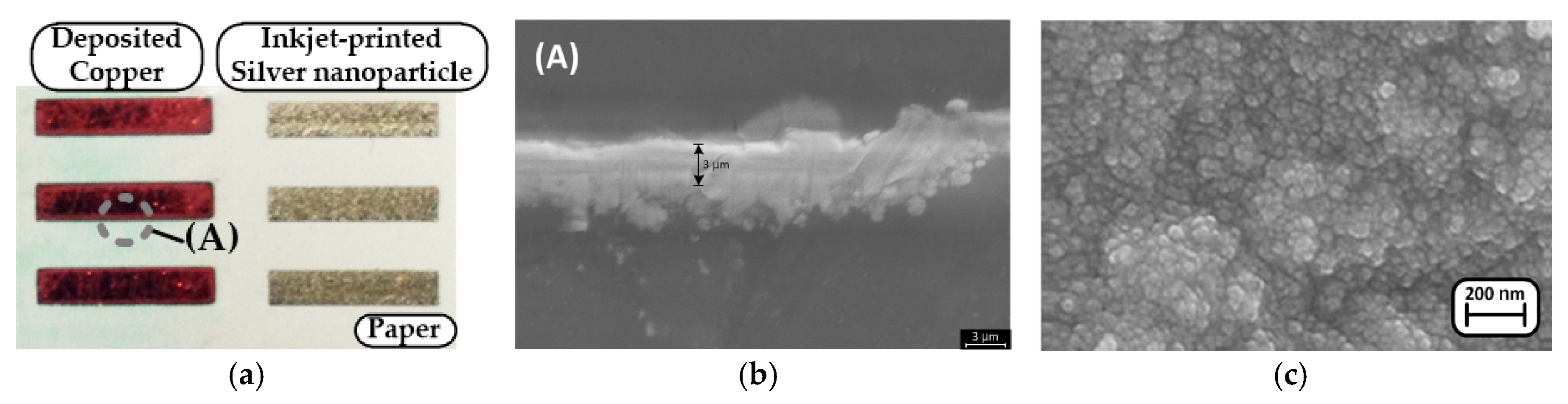

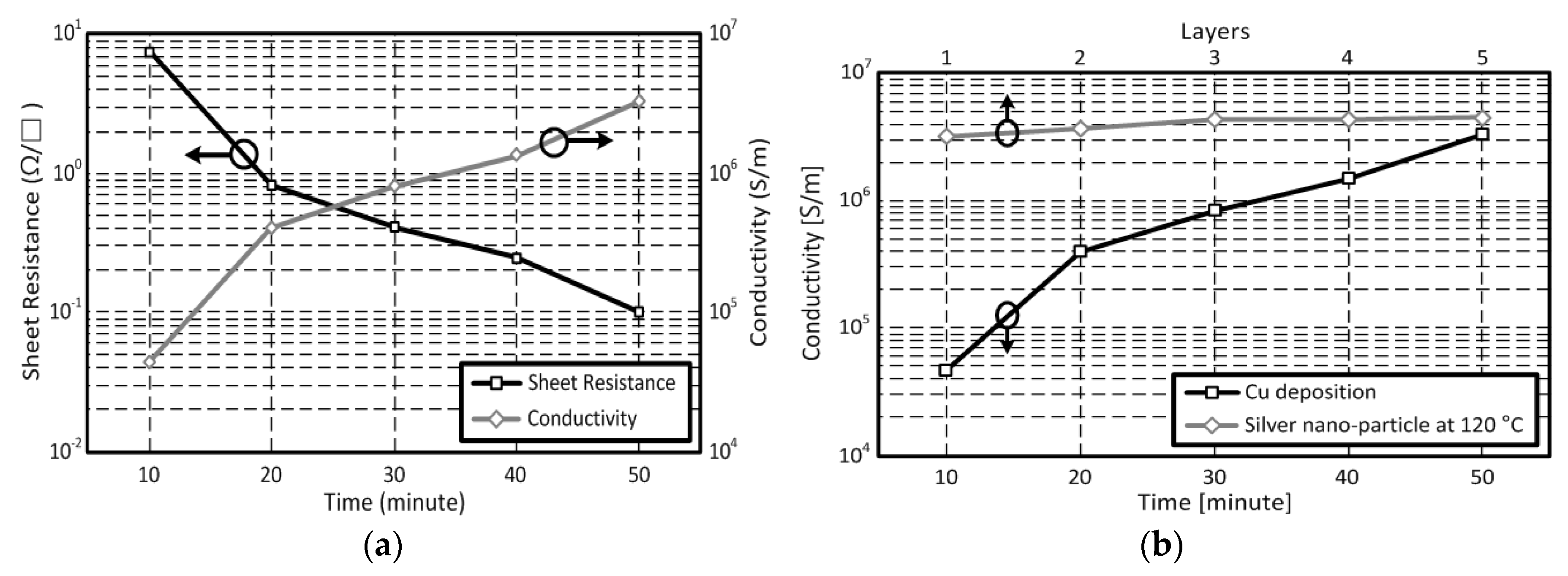

2.2. Metalization: Printed Thin Conductive Film

2.2.1. Inkjet-Printed Silver Nano-Particles

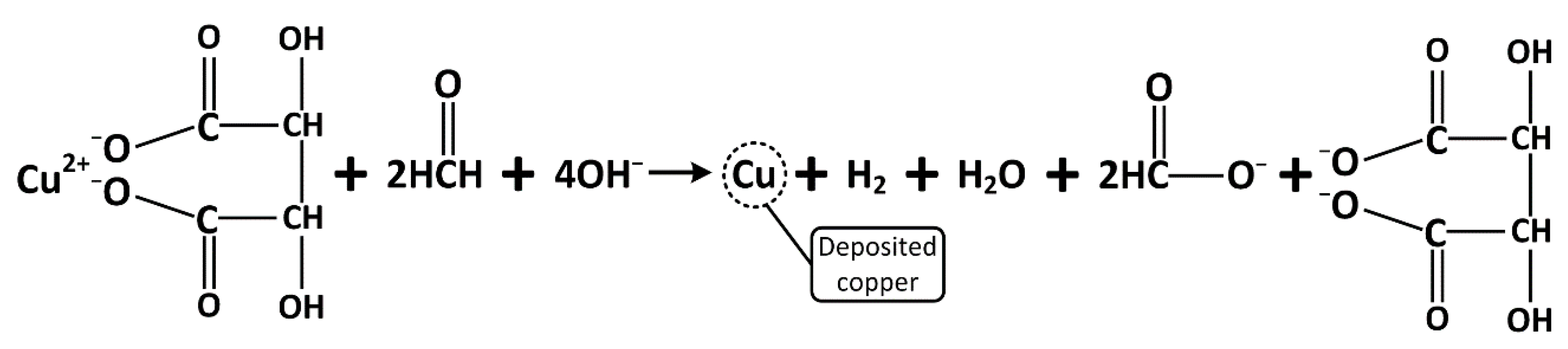

2.2.2. Electroless Copper Deposition

2.3. Deielctric Ink: PVP and SU-8

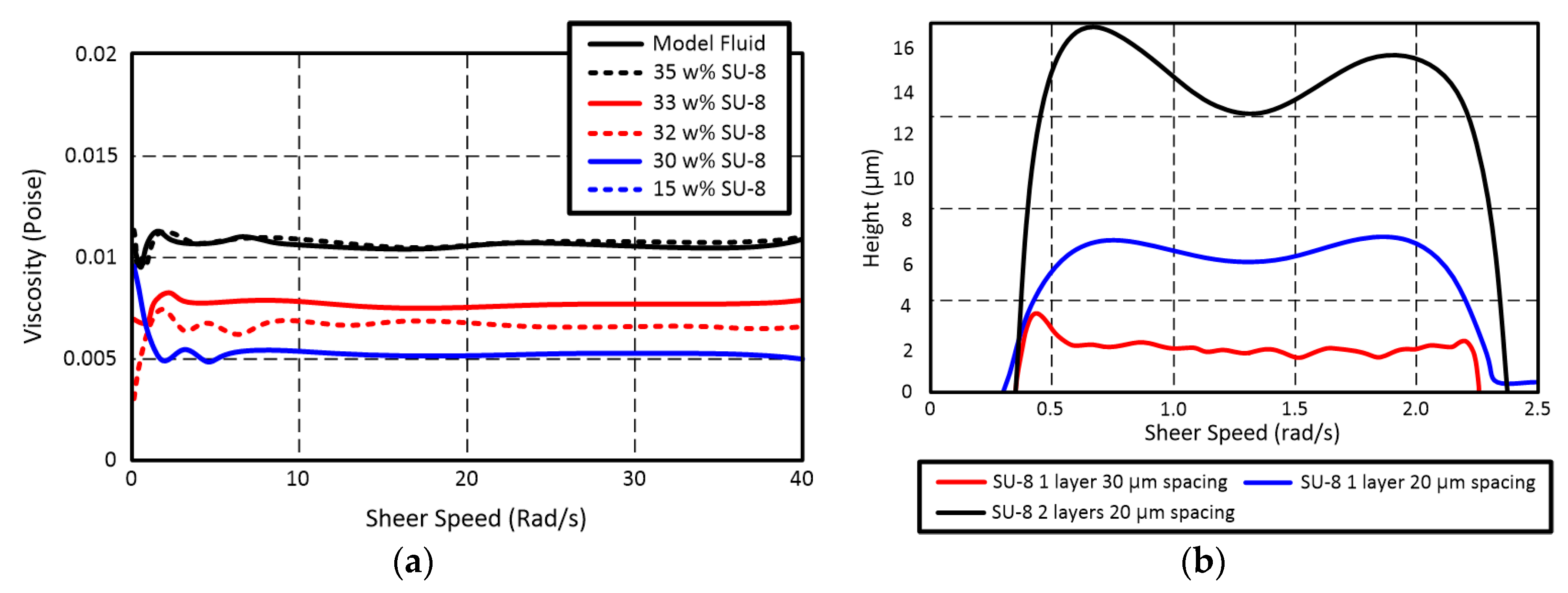

2.3.1. Thick-Layer Dielectric Ink: SU-8

2.3.2. Thin-Layer Dielectric Ink: PVP

3. Inkjet-Printed Microwave Components and Devices

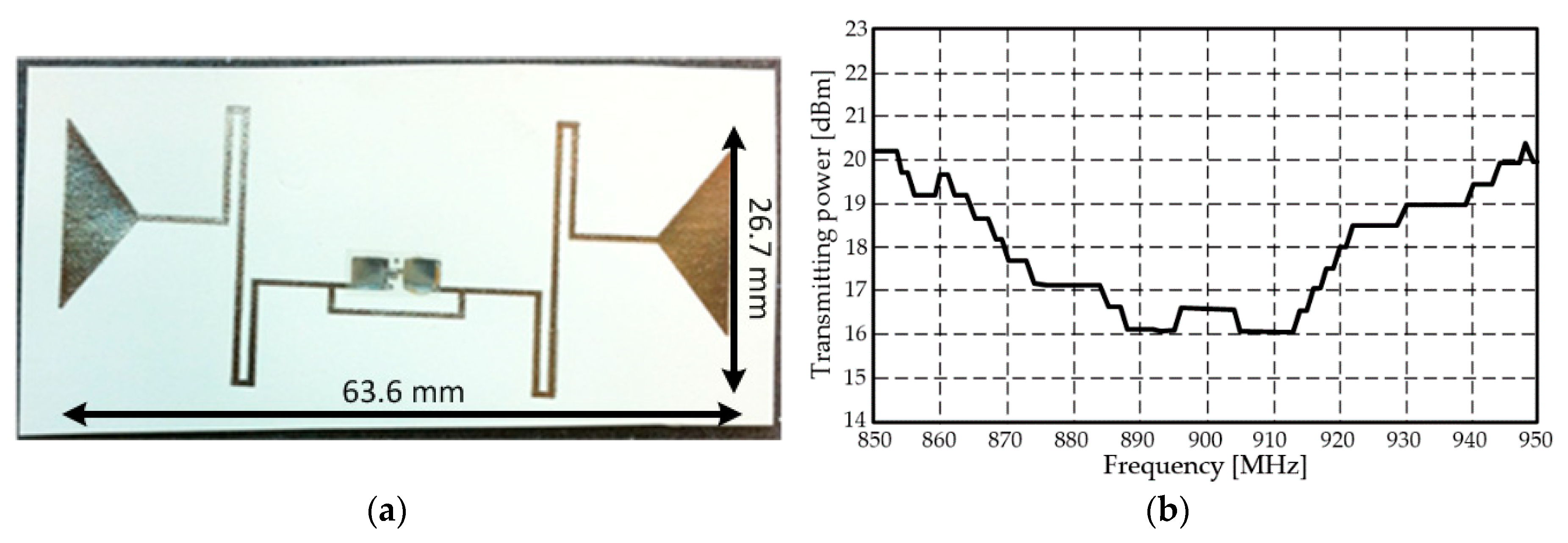

3.1. RFID Tag

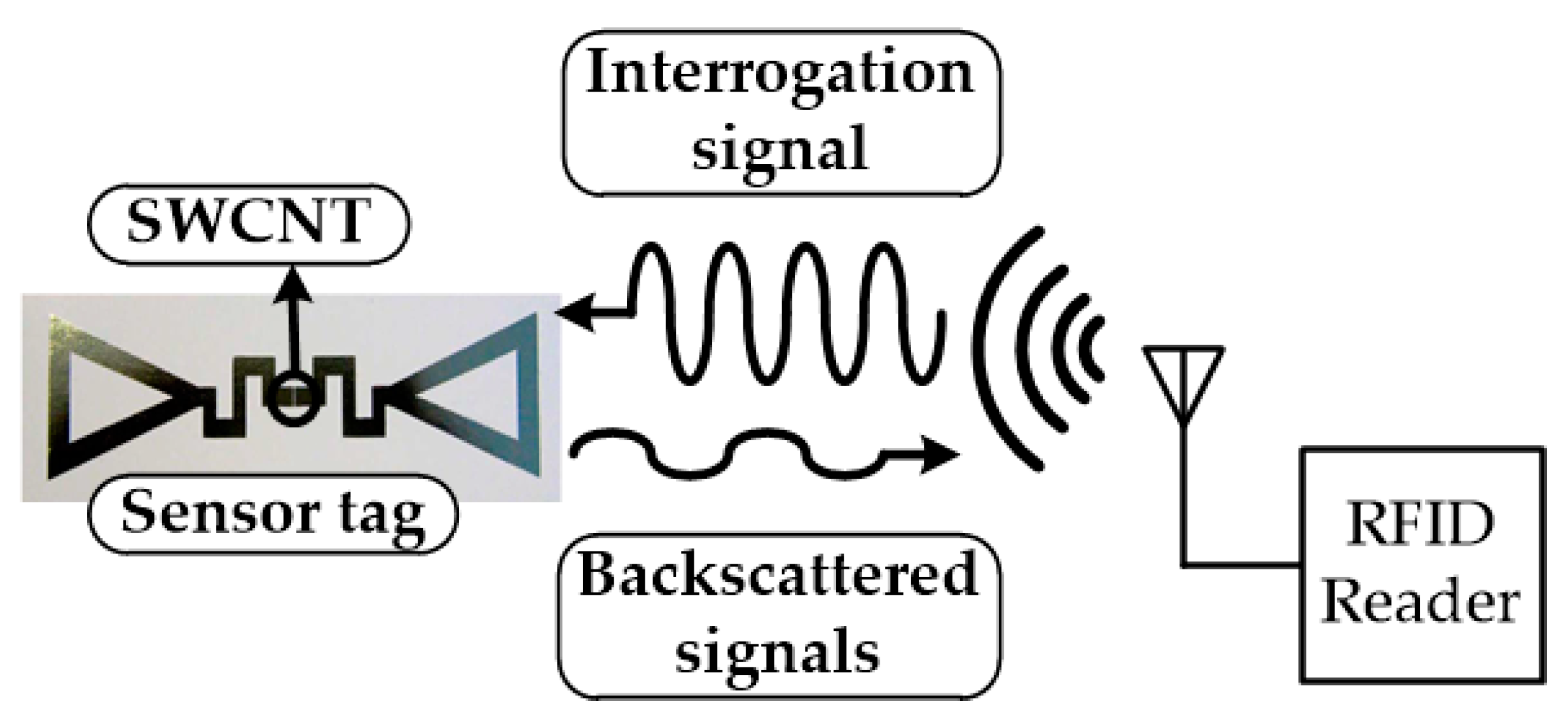

3.2. Inkjet-Printed RFID-Enabled Sensor Utilizing Carbon Nanotubes (CNTs)

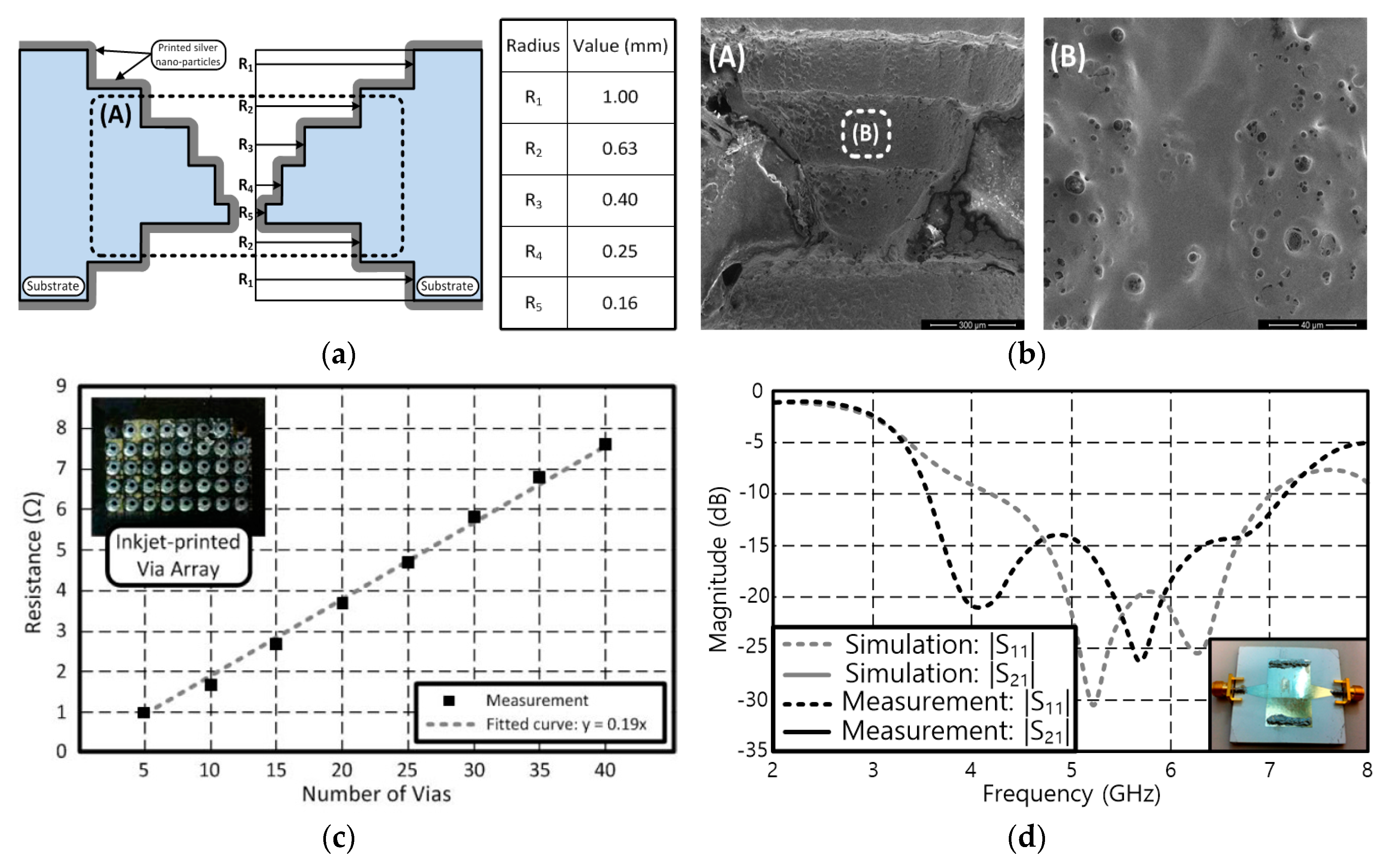

3.3. Substrate-Integrated Waveguide (SIW) Structure and Via Fabrication

3.4. Hybrid Printed Electronics

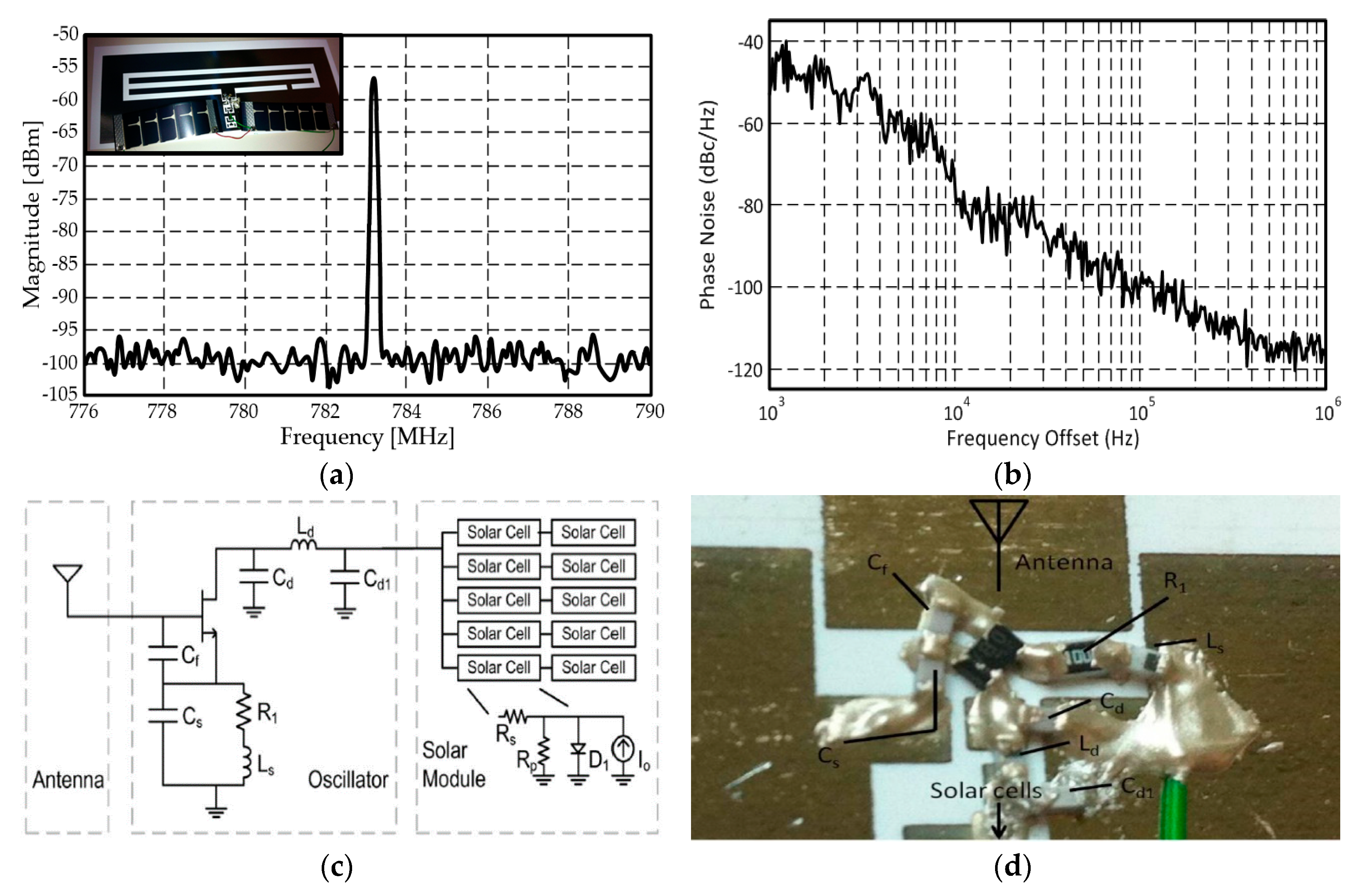

3.4.1. Solar Powered Active Antenna on Paper

3.4.2. Flexible RF Energy Harvester on Printed Copper

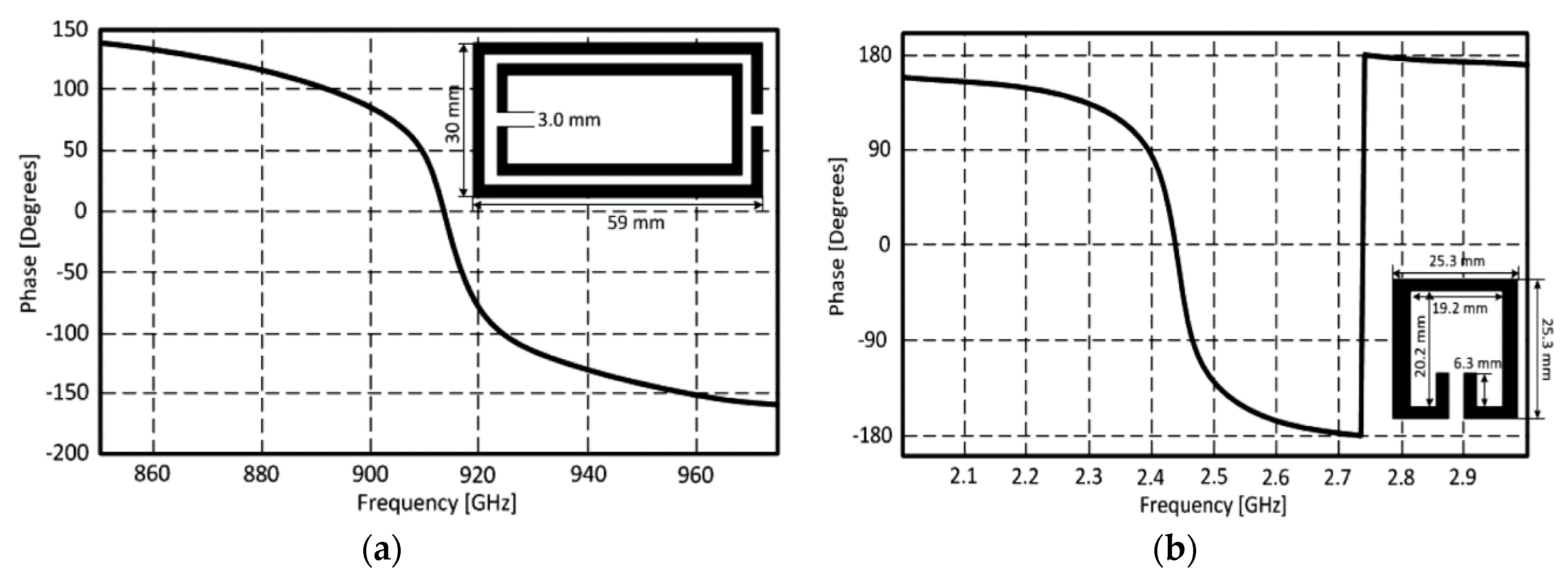

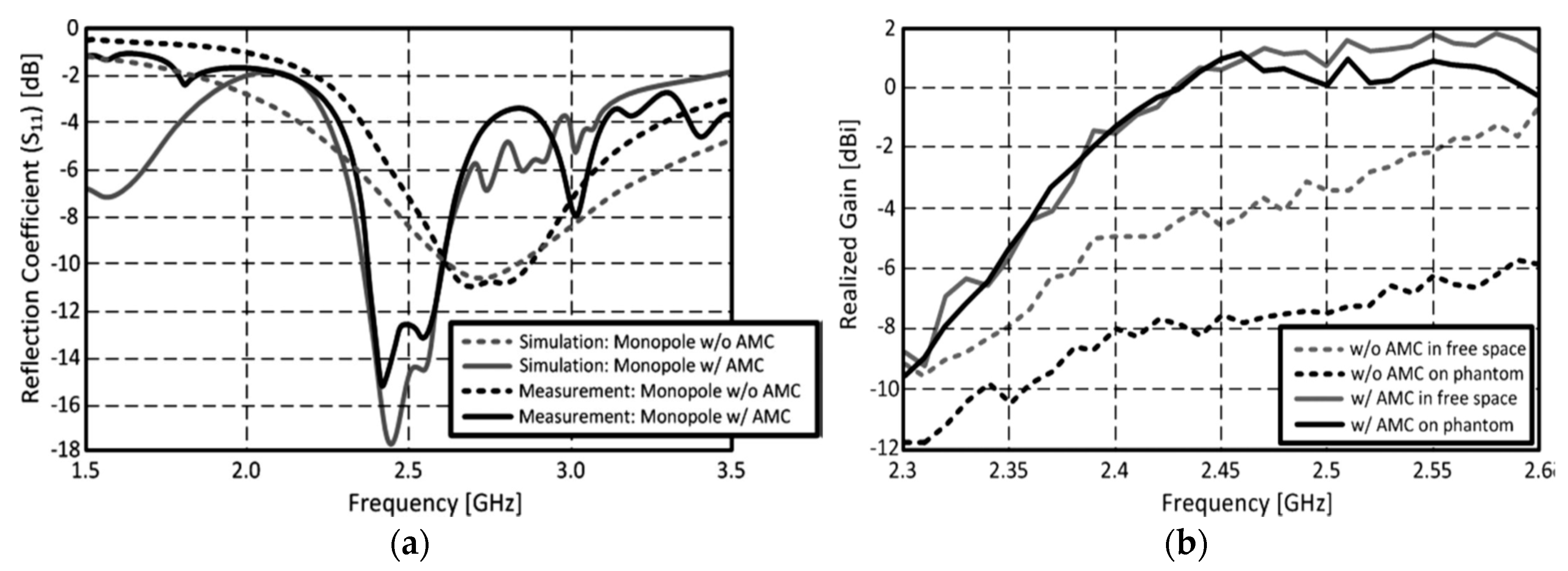

3.5. Antennas on an Inkjet-Printed Artificial Magnetic Conductor (AMC) for Wearable Applications

4. Summary

Funding

Conflicts of Interest

References

- Tobjörk, D.; Österbacka, R. Paper Electronics. Adv. Mater. 2011, 23, 1935–1961. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Rogers, J.A. Inorganic Semiconductors for Flexible Electronics. Adv. Mater. 2007, 19, 1897–1916. [Google Scholar] [CrossRef]

- Siegel, A.C.; Phillips, S.T.; Dickey, M.D.; Lu, N.; Suo, Z.; Whitesides, G.M. Foldable Printed Circuit Boards on Paper Substrates. Adv. Funct. Mater. 2010, 20, 28–35. [Google Scholar] [CrossRef]

- Kim, Y.H.; Moon, D.G.; Han, J.I. Organic TFT Array on a Paper Substrate. IEEE Electron Device Lett. 2004, 25, 702–704. [Google Scholar] [CrossRef]

- Zschieschang, U.; Klauk, H. Organic Transistors on Paper: A Brief Review. J. Mater. Chem. C 2019, 7, 5522–5533. [Google Scholar] [CrossRef]

- Lin, Y.; Gritsenko, D.; Liu, Q.; Lu, X.; Xu, J. Recent Advancements in Functionalized Paper-Based Electronics. ACS Appl. Mater. Interfaces 2016, 8, 20501–20515. [Google Scholar] [CrossRef]

- Raut, N.C.; Al-Shamery, K. Inkjet Printing Metals on Flexible Materials for Plastic and Paper Electronics. J. Mater. Chem. C 2018, 6, 1618–1641. [Google Scholar] [CrossRef]

- Agatea, S.; Joyce, M.; Lucia, L.; Pala, L. Cellulose and Nanocellulose-based Flexible-hybrid Printed Electronics and Conductive Composites—A Review. Carbohydr. Polym. 2018, 198, 249–260. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Cui, K.; Ge, S.; Cheng, X.; Yan, M.; Yu, J.; Liu, H. Paper-Based Electronics: Flexible Electronics Based on Micro/Nanostructured Paper. Adv. Mater. 2018, 30, 1870394. [Google Scholar] [CrossRef]

- Barras, R.; Cunha, I.; Gaspar, D.; Fortunato, E.; Martins, R.; Pereira, L. Printable Cellulose-based Electroconductive Composites for Sensing Elements in Paper Electronics. Flex. Print. Electron. 2017, 2, 014006. [Google Scholar] [CrossRef]

- Liu, H.; Qing, H.; Li, Z.; Han, Y.L.; Lin, M.; Yang, H.; Lie, L.; Lu, T.J.; Li, F.; Xu, F. Paper: A Promising Material for Human-friendly Functional Wearable Electronics. Mater. Sci. Eng. R: Rep. 2017, 112, 1–22. [Google Scholar] [CrossRef]

- Nayak, L.; Mohanty, S.; Nayaka, S.K.; Ramadoss, A. A Review on Inkjet Printing of Nanoparticle Inks for Flexible Electronics. J. Mater. Chem. C 2019, 7, 8771–8795. [Google Scholar] [CrossRef]

- Gu, Y.; Zhang, T.; Chen, H.; Wang, F.; Pu, Y.; Gao, C.; Li, S. Mini Review on Flexible and Wearable Electronics for Monitoring Human Health Information. Nanoscale Res. Lett. 2019, 14, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Zhu, C.; Li, L.; Zhang, C.; Liu, J.; Yu, H.-D.; Huang, W. All Paper-Based Flexible and Wearable Piezoresistive Pressure Sensor. ACS Appl. Mater. Interfaces 2019, 11, 25034–25042. [Google Scholar] [CrossRef]

- Kim, J.Y.; Park, S.H.; Jeong, T.; Bae, M.J.; Song, S.; Lee, J.; In, T.H.; Jung, D.; Yu, S. Paper as a substrate for inorganic powder electroluminescence device. IEEE Trans. Electron Devices 2010, 57, 1470–1474. [Google Scholar] [CrossRef]

- Ding, M.; Liu, Y.; Wang, Y.; Jia, C.; Chen, P.; Duan, X.; Wang, C.; Song, F.; Li, M.; Wan, C.; et al. Solution-processable 2D semiconductors for high-performance large-area electronics. Nature 2018, 562, 254–258. [Google Scholar]

- Ojo, A.A.; Mudiy, I.M. Electroplating of Semiconductor Materials for Applications in Large Area Electronics: A Review. Electronics 2018, 8, 262. [Google Scholar] [CrossRef]

- Sanz-Robinson, J.; Moy, T.; Huang, L.; Rieutort-Louis, W.; Hu, Y.; Wagner, S.; Sturm, J.C.; Verma, N. Large-Area Electronics: A Platform for Next-Generation Human-Computer Interfaces. IEEE Trans. Emerg. Sel. Top. Circuits Syst. 2017, 7, 38–49. [Google Scholar] [CrossRef]

- Burghartz, J.N.; Alavi, G.; Albrecht, B.; Deuble, T.; Elsobky, M.; Ferwana, S.; Harendt, C.; Mahsereci, Y.; Richter, H.; Yu, Z. Hybrid Systems-in-Foil–Combining the Merits of Thin Chips and of Large-Area Electronics. IEEE J. Electron Devices Soc. 2019, 7, 776–783. [Google Scholar] [CrossRef]

- Vilan, A.; Aswal, D.; Cahen, D. Large-Area Ensemble Molecular Electronics: Motivation and Challenges. Chem. Rev. 2017, 117, 4248–4286. [Google Scholar] [CrossRef]

- Gluhak, A.; Krco, S.; Nati, M.; Pfisterer, D.; Mitton, N.; Razafindralambo, T. A Survey on Facilities for Experimental Internet of Things Research. IEEE Commun. Mag. 2011, 49, 58–67. [Google Scholar] [CrossRef]

- Sirringhaus, H.; Kawase, T.; Friend, R.H.; Shimoda, T.; Inbasekaran, M.; Wu, W.; Woo, E.P. High-Resolution Inkjet Printing of All-polymer Transistor Circuits. Science 2000, 290, 2123–2126. [Google Scholar] [CrossRef] [PubMed]

- Calvert, P. Inkjet Printing for Materials and Devices. Chem. Mater. 2001, 13, 3299–3305. [Google Scholar] [CrossRef]

- Perelaer, J.; Gans, B.J.; Schubert, U.S. Ink-jet Printing and Microwave Sintering of Conductive Silver Tracks. Adv. Mater. 2006, 18, 2101–2104. [Google Scholar] [CrossRef]

- Wijshoff, H. Drop Dynamics in the Inkjet Printing Process. Curr. Opin. Colloid Interface Sci. 2018, 36, 20–27. [Google Scholar] [CrossRef]

- Gans, B.J.; Duineveld, P.C.; Schubert, U.S. Inkjet printing of polymers: State of the art and future developments. Adv. Mater. 2004, 16, 203–213. [Google Scholar] [CrossRef]

- Fuller, S.B.; Wilhelm, E.J.; Jacobson, J.M. Ink-jet Printed Nanoparticle Microelectromechanical Systems. J. Microelectromech. Syst. 2002, 11, 54–60. [Google Scholar] [CrossRef]

- Kim, D.; Moon, J. Highly Conductive Ink Jet Printed Films of Nanosilver Particles for Printable Electronics. Electrochem. Solid-State Lett. 2005, 8, 30–33. [Google Scholar] [CrossRef]

- Vyas, R.; Lakafosis, V.; Lee, H.; Shaker, G.; Yang, L.; Orecchini, G.; Traille, A.; Tentzeris, M.M.; Roselli, L. Inkjet Printed, Self Powered, Wireless Sensors for Environmental, Gas and Authentication-based Sensing. IEEE Sens. J. 2011, 11, 3139–3152. [Google Scholar] [CrossRef]

- Park, J.U.; Hardy, M.; Kang, S.J.; Barton, K.; Adair, K.; Mukhopadhyay, D.K.; Lee, C.Y.; Strano, M.S.; Alleyne, A.G.; Georgiadis, A.G.; et al. High-resolution Electrohydrodynamic Jet Printing. Nat. Mater. 2007, 6, 782–789. [Google Scholar] [CrossRef]

- Lee, Y.; Choi, J.R.; Lee, K.J.; Stott, N.E.; Kim, D. Large-scale Synthesis of Copper Nanoparticles by Chemically Controlled Reduction for Applications of Inkjet-printed Electronics. Nanotechnology 2008, 19, 415604. [Google Scholar] [CrossRef] [PubMed]

- Chow, E.; Herrmann, J.; Barton, C.S.; Raguse, B.; Wieczorek, L. Inkjet-printed Gold Nanoparticle Chemiresistors: Influence of Film Morphology and Ionic Strength on the Detection of Organics Dissolved in Aqueous Solution. Anal. Chim. Acta 2009, 632, 135–142. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Rida, A.; Vyas, R.; Tentzeris, M.M. RFID Tag and RF Structures on a Paper Substrate using Inkjet-printing Technology. IEEE Trans. Microw. Theory Tech. 2007, 55, 2894–2901. [Google Scholar] [CrossRef]

- Available online: https://www.teslin.com/en-US/Home.aspx/ (accessed on 2 October 2020).

- Available online: http://www.kodak.com/ (accessed on 2 October 2020).

- Latti, K.P.; Kettunen, M.; Stoem, J.P.; Silventoinen, P. A Review of Microstrip T-Resonator Method in Determining the Dielectric Properties of Printed Circuit Board Materials. IEEE Trans. Instrum. Meas. 2007, 56, 1845–1850. [Google Scholar] [CrossRef]

- Thompson, D.; Tantot, O.; Jallageas, H.; Phonchak, G.E.; Tentzeris, M.M.; Papapolymerou, J. Characterization of Liquid Crystal Polymer (LCP) Material and Transmission Lines on LCP Substrates from 30 to 110 GHz. IEEE Trans. Microw. Theory Tech. 2004, 53, 1343–1352. [Google Scholar] [CrossRef]

- Maza, A.R.; Cook, B.; Jabbour, G.; Shamim, A. Paper-based Inkjet-printed Ultra-wideband Fractal Antennas. IET Microw. Antennas Propag. 2012, 6, 1366–1373. [Google Scholar] [CrossRef]

- Manteghi, M.; Rahmat-Samii, Y. A Novel UWB Feeding Mechanism for the TEM Horn Antenna, Reflector IRA, and the Vivaldi Antenna. IEEE Antennas Propag. Mag. 2004, 46, 81–87. [Google Scholar] [CrossRef]

- Shaker, G.; Safavi-Naeini, S.; Sangary, N.; Tentzeris, M.M. Inkjet Printing of Ultrawideband (UWB) Antennas on Paper-based Substrates. IEEE Antennas Wireless Propag. Lett. 2011, 10, 111–114. [Google Scholar] [CrossRef]

- Saghlatoon, H.; Björninen, T.; Sydänheimo, L.; Tentzeris, M.M.; Ukkonen, L. Inkjet-Printed Wideband Planar Monopole Antenna on Cardboard for RF Energy-Harvesting Applications. IEEE Antennas Wirel. Propag. Lett. 2015, 14, 325–328. [Google Scholar] [CrossRef]

- Maekawa, K.; Yamasaki, K.; Niizeki, T.; Mita, M.; Matsuba, Y.; Terada, N.; Saito, H. Drop-on-demand Laser Sintering with Silver Nanoparticles for Electronics Packaging. IEEE Trans. Compon. Pack. Manuf. Technol. 2012, 2, 868–877. [Google Scholar] [CrossRef]

- Polzinger, B.; Schoen, F.; Matic, V.; Keck, J.; Willeckm, H.; Eberhardt, W.; Kueck, H. UV-sintering of Inkjet-Printed Conductive Silver Tracks. In Proceedings of the 11th IEEE International Conference on Nanotechnology, Portland, OR, USA, 15–18 August 2011. [Google Scholar]

- Allen, M.; Alastalo, A.; Suhonen, M.; Mattila, T.; Leppäniemi, J.; Seppa, H. Contactless Electrical Sintering of Silver Nanoparticles on Flexible Substrates. IEEE Trans. Microw. Theory Tech. 2011, 59, 1419–1429. [Google Scholar] [CrossRef]

- Kim, S.; Mariotti, C.; Alimenti, F.; Mezzanotte, P.; Georgiadis, A.; Collado, A.; Roselli, L.; Tentzeris, M.M. No Battery Required. IEEE Microw. Mag. 2013, 14, 66–77. [Google Scholar] [CrossRef]

- Soltmanm, D.; Subramanian, V. Inkjet-printed Line Morphologies and Temperature Control of the Coffee Ring Effect. Langmuir 2008, 24, 2224–2231. [Google Scholar] [CrossRef] [PubMed]

- Singh, M.; Haverinen, H.M.; Dhagat, P.; Jabbour, G.E. Inkjet Printing-process and its Applications. Adv. Mater. 2009, 22, 673–685. [Google Scholar] [CrossRef]

- Cook, B.S.; Fang, Y.; Kim, S.; Le, T.; Goodwin, W.B.; Sandhage, K.H.; Tentzeris, M.M. Inkjet Catalyst Printing and Electroless Copper Deposition for Low-cost Patterned Microwave Passive Devices on paper. Electron. Mater. Lett. 2013, 9, 669–676. [Google Scholar] [CrossRef][Green Version]

- Mallory, G.O.; Hajdu, J.B. Electroless Plating-Fundamentals and Applications; William Andrew Publishing/Noyes: New York, NY, USA, 1990. [Google Scholar]

- Xu, L.; Liao, J.; Huang, L.; Ou, D.; Guo, Z.; Zhang, H.; Ge, C.; Gu, N.; Liu, J. Surface-bound Nanoparticles for Initiating Metal Deposition. Thin Solid Films 2003, 434, 121–125. [Google Scholar] [CrossRef]

- Ohno, I. Electrochemistry of Electroless Plating. Mater. Sci. Eng. A-Struct. 1991, 146, 33–49. [Google Scholar] [CrossRef]

- Fang, Y.N.; Berrigan, J.D.; Cai, Y.; Marder, S.R.; Sandhage, K.H. Syntheses of Nanostructured Cu- and Ni-based Micro-assemblies with Selectable 3-D Hierarchical Biogenic Morphologies. J. Mater. Chem. 2012, 22, 1305–1312. [Google Scholar] [CrossRef]

- Schift, H.; Spreu, C.; Schleunitz, A.; Lee, J. Shape Control of Polymer Reflow Structures Fabricated by Nanoimprint Lithography. Microelectron. Eng. 2011, 88, 87–92. [Google Scholar] [CrossRef]

- Cook, B.S.; Cooper, J.R.; Tentzeris, M.M. Multi-layer RF Capacitors on Flexible Substrates Utilizing Inkjet Printed Dielectric Polymers. IEEE Microw. Wirel. Compon. Lett. 2013, 23, 353–355. [Google Scholar] [CrossRef]

- Sharif, A.; Ouyang, J.; Yan, Y.; Raza, A.; Imran, M.A.; Abbasi, Q.H. Low-Cost Inkjet-Printed RFID Tag Antenna Design for Remote Healthcare Applications. IEEE J. Electromagn. RF Microw. Med. Biol. 2019, 3, 261–268. [Google Scholar] [CrossRef]

- Kim, S.; Kawahara, Y.; Georgiadis, A.; Collado, A.; Tentzeris, M.M. Low-cost Inkjet-printed Fully Passive RFID Tags for calibration-free Capacitive/haptic sensor Applications. IEEE Sens. J. 2015, 15, 3135–3145. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, R.; Staiculescu, D.; Wong, C.P.; Tentzeris, M.M. A Novel Conformal RFID-enabled Module Utilizing Inkjet-printed Antennas and Carbon Nanotubes for Gas-detection Applications. IEEE Antennas Wirel. Propag. Lett. 2009, 8, 653–656. [Google Scholar] [CrossRef]

- Girbau, D.; Ramos, A.; Lazaro, A.; Rima, S.; Villarino, R. Passive Wireless Temperature Sensor Based on Time-coded UWB Chipless RFID Tags. IEEE Trans. Microw. Theory Tech. 2012, 60, 3623–3632. [Google Scholar] [CrossRef]

- Potyrailo, R.A.; Surman, C.; Go, S.; Lee, Y.; Sivavec, T.; Morris, W.G. Development of Radio-frequency Identification Sensors Based on Organic Electronic Sensing Materials for Selective Detection of Toxic Vapors. J. Appl. Phys. 2009, 106, 124092. [Google Scholar] [CrossRef]

- Occhiuzzi, C.; Paggi, C.; Marrocco, G. Passive RFID Strain-sensor Based on Meander-line Antennas. IEEE Trans. Antennas Propag. 2011, 59, 4836–4840. [Google Scholar] [CrossRef]

- Virtanen, J.; Ukkonen, L.; Bjorninen, T.; Elsherbeni, A.Z.; Sydänheimo, L. Inkjet-printed Humidity Sensor for Passive UHF RFID Systems. IEEE Trans. Instrum. Meas. 2011, 60, 2768–2777. [Google Scholar] [CrossRef]

- Gao, J.; Sidén, J.; Nilsson, H.E.; Gulliksson, M. Printed Humidity Sensor with Memory Functionality for Passive RFID tags. IEEE Sens. J. 2013, 13, 1824–1834. [Google Scholar] [CrossRef]

- Wang, D.W.; Li, F.; Zhao, J.; Ren, W.; Chen, Z.G.; Tan, J.; Wu, Z.S.; Gentle, I.; Lu, G.Q.; Cheng, H.M. Fabrication of Graphene/polyaniline Composite Paper via in situ Anodic Electropolymerization for High-performance Flexible Electrode. ACS Nano 2009, 3, 1745–1752. [Google Scholar] [CrossRef]

- Ali, A.A.S.; Farhat, A.; Mohamad, S.; Amira, A.; Bensaali, F.; Benammar, M.; Bermak, A. Embedded Platform for Gas Applications Using Hardware/Software Co-Design and RFID. IEEE Sens. J. 2018, 18, 4633–4642. [Google Scholar]

- Ramos, A.; Clement, P.; Lazaro, A.; Llobet, E.; Girbau, D. Nitrogen Dioxide Wireless Sensor Based on Carbon Nanotubes and UWB RFID Technology. IEEE Antennas Wirel. Propag. Lett. 2015, 14, 1145–1148. [Google Scholar] [CrossRef]

- Kim, S.; Cook, B.; Le, T.; Cooper, J.; Lee, H.; Lakafosis, V.; Vyas, R.; Moro, R.; Bozzi, M.; Georgiadis, A.; et al. Inkjet-printed Antennas, Sensors and Circuits on Paper Substrate. IET Microw. Antenna Propag. 2013, 7, 858–868. [Google Scholar] [CrossRef]

- Rida, A.; Yang, L.; Vyas, R.; Tentzeris, M.M. Conductive Inkjet-printed Antennas on Flexible Low-cost Paper-based Substrates for RFID and WSN Applications. IEEE Antennas Propag. Mag. 2009, 51, 13–23. [Google Scholar] [CrossRef]

- Bozzi, M.; Georgiadis, A.; Wu, K. Review of Substrate-integrated Waveguide Circuits and Antennas. IET Microw. Antennas Propag. 2011, 5, 909–920. [Google Scholar] [CrossRef]

- Massoni, E.; Silvestri, L.; Alaimo, G.; Marconi, S.; Bozzi, M.; Perregrini, L.; Auricchio, F. 3-D Printed Substrate Integrated Slab Waveguide for Single-Mode Bandwidth Enhancement. IEEE Microw. Wirel. Compon. Lett. 2017, 27, 536–538. [Google Scholar] [CrossRef]

- Rocco, G.M.; Bozzi, M.; Schreurs, D.; Perregrini, L.; Marconi, S.; Alaimo, G.; Auricchio, F. 3-D Printed Microfluidic Sensor in SIW Technology for Liquids’ Characterization. IEEE Trans. Microw. Theory Tech. 2020, 68, 1175–1184. [Google Scholar] [CrossRef]

- Moro, R.; Kim, S.; Bozzi, M.; Tentzeris, M.M. Inkjet-printed Paper-based Substrate-integrated Waveguide (SIW) Components and Antennas. Int. J. Microw. Wirel. Tech. 2013, 5, 197–204. [Google Scholar] [CrossRef]

- Reinhold, I.; Thielen, M.; Voit, W.; Zapka, W.; Gotzen, R.; Bohlmann, H. Inkjet Printing of Electrical Vias. In Proceedings of the 18th European Microelectronics & Packaging Conference, Brighton, UK, 2–15 September 2011. [Google Scholar]

- Kawase, T.; Sirringhaus, H.; Friend, R.H.; Shimoda, T. Inkjet Printed Via-hole Interconnections and Resistors for All-polymer Transistor Circuits. Adv. Mater. 2001, 13, 1601–1605. [Google Scholar] [CrossRef]

- Falat, T.; Felba, J.; Moscicki, A.; Borecki, J. Nano-silver Inkjet Printed Interconnections through the Microvias for Flexible Electronics. In Proceedings of the 11th IEEE International Conference on Nanotechnology, Portland, OR, USA, 15–18 August 2011. [Google Scholar]

- Kim, S.; Shamim, A.; Georgiadis, A.; Aubert, H.; Tentzeris, M.M. Fabrication of Fully Inkjet-printed Vias and SIW Structures on Thick Polymer Substrates. IEEE Trans. Compon. Packag. Manuf. Technol. 2016, 6, 486–496. [Google Scholar] [CrossRef]

- Available online: https://www.rogerscorp.cn/documents/606/acs/RT-duroid-5870-5880-Data-Sheet.pdf (accessed on 2 October 2020).

- Khan, Y.; Thielens, A.; Muin, S.; Ting, J.; Baumbauer, C.; Arias, A.C. A New Frontier of Printed Electronics: Flexible Hybrid Electronics. Adv. Mater. 2019, 32, 1905279. [Google Scholar] [CrossRef]

- Bhattacharjee, M.; Bandyopadhyay, D. Mechanisms of Humidity Sensing on a CdS Nanoparticle Coated Paper Sensor. Sens. Actuator A Phys. 2019, 285, 241–247. [Google Scholar] [CrossRef]

- Li, Q.; Liu, H.; Zhang, S.; Zhang, D.; Liu, X.; He, Y.; Mi, L.; Zhang, J.; Liu, C.; Shen, C.; et al. Superhydrophobic Electrically Conductive Paper for Ultrasensitive Strain Sensor with Excellent Anticorrosion and Self-Cleaning Property. ACS Appl. Mater. Interfaces 2019, 11, 21904–21914. [Google Scholar] [CrossRef] [PubMed]

- Maity, A.; Raychaudhuri, A.K.; Ghosh, B. High Sensitivity NH3 Gas Sensor with Electrical Readout Made on Paper with Perovskite Halide as Sensor Material. Sci. Rep. 2019, 9, 7777. [Google Scholar] [CrossRef] [PubMed]

- Valentine, A.D.; Busbee, T.A.; Boley, J.W.; Raney, J.R.; Chortos, A.; Kotikian, A.; Berrigan, J.D.; Durstock, M.F.; Lewis, J.A. Hybrid 3D Printing of Soft Electronics. Adv. Mater. 2017, 29, 1703817. [Google Scholar] [CrossRef]

- Kim, K.; Kim, B.; Lee, C.H. Printing Flexible and Hybrid Electronics for Human Skin and Eye-Interfaced Health Monitoring Systems. Adv. Mater. 2020, 32, 1902051. [Google Scholar] [CrossRef]

- Araki, T.; Uemura, T.; Yoshimoto, S.; Takemoto, A.; Noda, Y.; Izumi, S.; Sekitani, T. Wireless Monitoring Using a Stretchable and Transparent Sensor Sheet Containing Metal Nanowires. Adv. Mater. 2020, 32, 1902684. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, Y.; Cai, S.; Han, Z.; Liu, X.; Wang, F.; Cao, Y.; Wang, Z.; Li, H.; Chen, Y.; et al. Flexible Hybrid Electronics for Digital Healthcare. Adv. Mater. 2020, 32, 1902062. [Google Scholar] [CrossRef]

- Kim, S.; Georgiadis, A.; Collado, A.; Tentzeris, M.M. An Inkjet-printed Solar-powered Wireless Beacon on Paper for Identification and Wireless Power Transmission Applications. IEEE Trans. Microw. Theory Tech. 2012, 60, 4178–4186. [Google Scholar] [CrossRef]

- Liu, W.; Huang, K.; Zhou, X.; Durrani, S. Next Generation Backscatter Communication: Systems, Techniques, and Applications. EURASIP J. Wirel. Commun. 2019, 69. [Google Scholar] [CrossRef]

- Tao, Y.; Li, B.; Zhao, C.; Liang, Y.-C. Hardware-Efficient Signal Detection for Ambient Backscattering Communications. IEEE Commun. Lett. 2019, 23, 2196–2199. [Google Scholar] [CrossRef]

- Deng, F.; He, Y.; Li, B.; Song, Y.; Wu, X. Design of a Slotted Chipless RFID Humidity Sensor Tag. Sens. Actuators B Chem. 2018, 264, 255–262. [Google Scholar] [CrossRef]

- Correia, R.; Boaventura, A.; Carvalho, N.B. Quadrature Amplitude Backscatter Modulator for Passive Wireless Sensors in IoT Applications. IEEE Trans. Microw. Theory Tech. 2017, 65, 1103–1110. [Google Scholar] [CrossRef]

- Daskalakis, S.N.; Goussetis, G.; Assimonis, S.D.; Tentzeris, M.M.; Georgiadis, A. A uW Backscatter-Morse-Leaf Sensor for Low-Power Agricultural Wireless Sensor Networks. IEEE Sens. J. 2018, 18, 7889–7898. [Google Scholar] [CrossRef]

- Kang, J.S.; Kim, H.S.; Ryu, J.; Hahn, H.T.; Jang, S.; Joung, J.W. Inkjet Printed Electronics using Copper Nanoparticle Ink. J. Mater. Sci. Mater. Electron. 2010, 21, 1213–1220. [Google Scholar] [CrossRef]

- Park, S.-H.; Chung, W.-H.; Kim, H.-S. Temperature Changes of Copper Nanoparticle Ink During Flash Light Sintering. J. Mater. Process. Technol. 2014, 214, 2730–2738. [Google Scholar] [CrossRef]

- Kim, S.; Jeong, S.; Bito, J.; Georgiadis, A.; Tentzeris, M.M. A Flexible RF Energy Harvester using a Hybrid Printing Technology for ‘Stand-alone’ Wireless Sensor Platforms. Flex. Print. Electron. 2018, 3, 015004. [Google Scholar] [CrossRef]

- Sievenpiper, D.; Zhang, L.; Broas, R.F.J.; Alexopolous, N.G.; Yablonovitch, E. High-Impedance Electromagnetic Surfaces with a Forbidden Frequency Band. IEEE Trans. Microw. Theory Tech. 1999, 47, 2059–2074. [Google Scholar] [CrossRef]

- Cook, B.S.; Shamim, A. Utilizing wideband AMC Structures for High Gain Inkjet-printed Antennas on Lossy Paper Substrate. IEEE Antennas Wirel. Propag. Lett. 2013, 12, 76–79. [Google Scholar] [CrossRef]

- Zhu, S.; Langley, R. Dual-band Wearable Textile Antenna on an EBG Substrate. IEEE Trans. Antennas Propag. 2009, 57, 926–934. [Google Scholar] [CrossRef]

- Cooper, J.R.; Kim, S.; Tentzeris, M.M. A Novel Polarization-independent, Free-space, Microwave Beam Splitter utilizing an Inkjet-printed, 2-D Array Frequency Selective Surface. IEEE Antennas Wirel. Propag. Lett. 2012, 11, 686–688. [Google Scholar] [CrossRef]

- Assimonis, S.D.; Fusco, V. Polarization Insensitive, Wide-Angle, Ultra-wideband, Flexible, Resistively Loaded, Electromagnetic Metamaterial Absorber using Conventional InkjetPrinting Technology. Sci. Rep. 2019, 9, 12334. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Yan, L.; Ma, H.; Fan, Y.; Wang, J.; Feng, M.; Qu, S. Electromagnetic Wave Absorption and Compressive Behavior of a Three-dimensional Metamaterial Absorber Based on 3D Printed Honeycomb. Sci. Rep. 2018, 8, 4817. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Ren, Y.-J.; Lee, H.; Rida, A.; Nikolaou, S.; Tentzeris, M.M. Monopole antenna with inkjet-printed EBG array on paper substrate for wearable applications. IEEE Antennas Wirel. Propag. Lett. 2012, 11, 663–666. [Google Scholar] [CrossRef]

- Basar, E.; Renzo, M.D.; Rosny, J.D.; Debbah, M.; Alouini, M.-S.; Zhang, R. Wireless Communications Through Reconfigurable Intelligent Surfaces. IEEE Access 2019, 7, 116753–116773. [Google Scholar] [CrossRef]

- Palma, L.D.; Clemente, A.; Dussopt, L.; Sauleau, R.; Potier, P.; Pouliguen, P. Circularly-Polarized Reconfigurable Transmitarray in Ka-Band with Beam Scanning and Polarization Switching Capabilities. IEEE Trans. Antennas Propag. 2017, 65, 529–540. [Google Scholar] [CrossRef]

- Dai, L.; Wang, B.; Wang, M.; Yang, X.; Tan, J.; Bi, S.; Xu, S.; Yang, F.; Chen, Z.; Renzo, M.D.; et al. Reconfigurable Intelligent Surface-Based Wireless Communications: Antenna Design, Prototyping, and Experimental Results. IEEE Access 2020, 8, 45913–45923. [Google Scholar] [CrossRef]

- Özdogan, Ö.; Björnson, E.; Larsson, E.G. Intelligent Reflecting Surfaces: Physics, Propagation, and Pathloss Modeling. IEEE Wirel. Commun. Lett. 2020, 9, 581–585. [Google Scholar] [CrossRef]

- Available online: https://kb.ettus.com/N200/N210 (accessed on 2 October 2020).

- Lee, H.; Kim, S.; Donno, D.D.; Tentzeris, M.M. A Novel “Universal” Inkjet-printed EBG-backed Flexible RFID for Rugged on-body and Metal Mounted Applications. In Proceedings of the IEEE/MTT-S International Microwave Symposium Digest, Montreal, QC, Canada, 17–22 June 2012. [Google Scholar]

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S. Inkjet-Printed Electronics on Paper for RF Identification (RFID) and Sensing. Electronics 2020, 9, 1636. https://doi.org/10.3390/electronics9101636

Kim S. Inkjet-Printed Electronics on Paper for RF Identification (RFID) and Sensing. Electronics. 2020; 9(10):1636. https://doi.org/10.3390/electronics9101636

Chicago/Turabian StyleKim, Sangkil. 2020. "Inkjet-Printed Electronics on Paper for RF Identification (RFID) and Sensing" Electronics 9, no. 10: 1636. https://doi.org/10.3390/electronics9101636

APA StyleKim, S. (2020). Inkjet-Printed Electronics on Paper for RF Identification (RFID) and Sensing. Electronics, 9(10), 1636. https://doi.org/10.3390/electronics9101636