Energy Harvesting Technologies and Equivalent Electronic Structural Models—Review

Abstract

1. Introduction

- Remove mains supply wires

- Eliminate or reduce dependence on batteries

- Increase the lifetime

- Maintain or/and increase the functionality

- Ease of installation

- Low cost

- Reduce waste

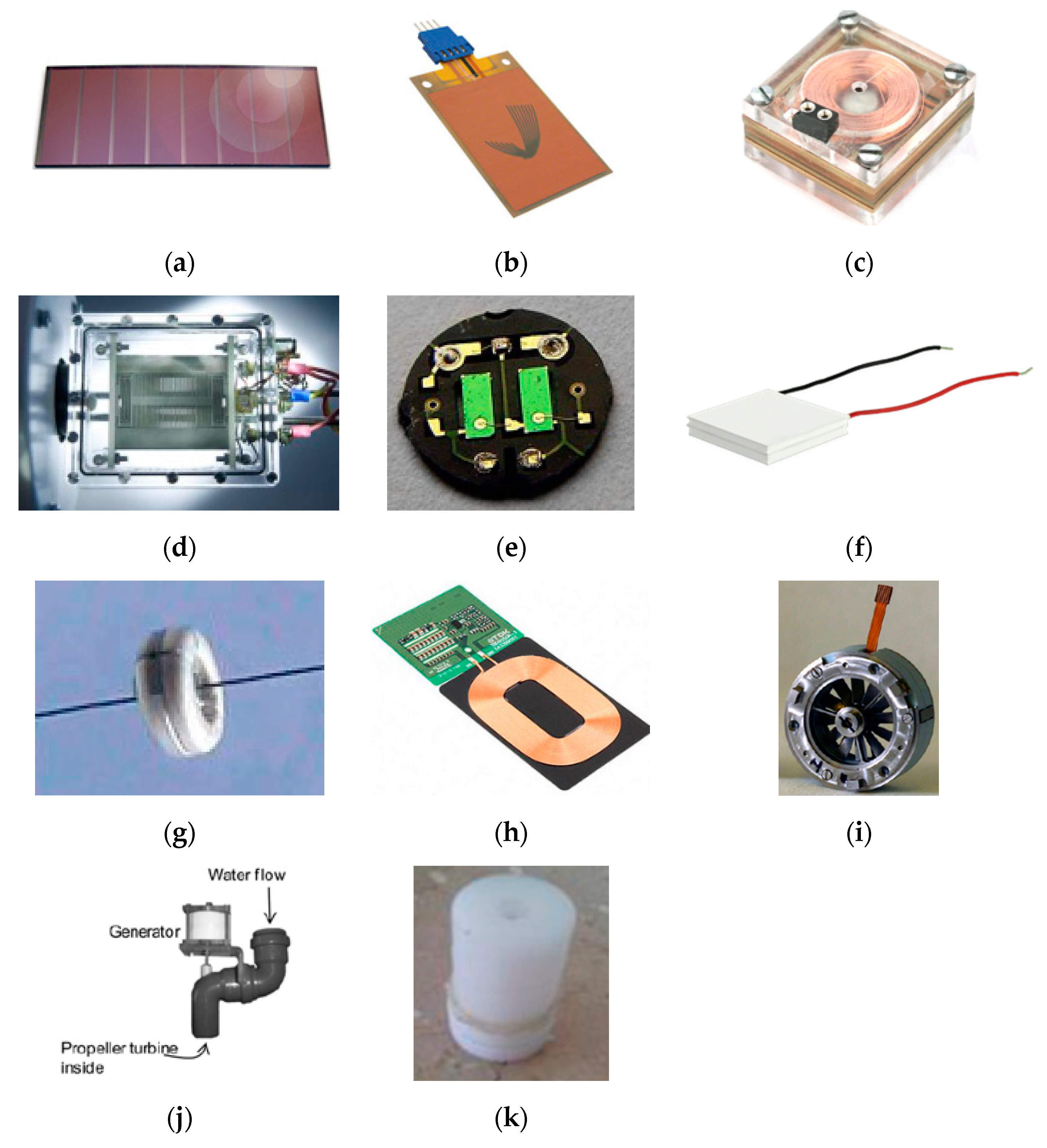

Energy Harvester’s Technologies

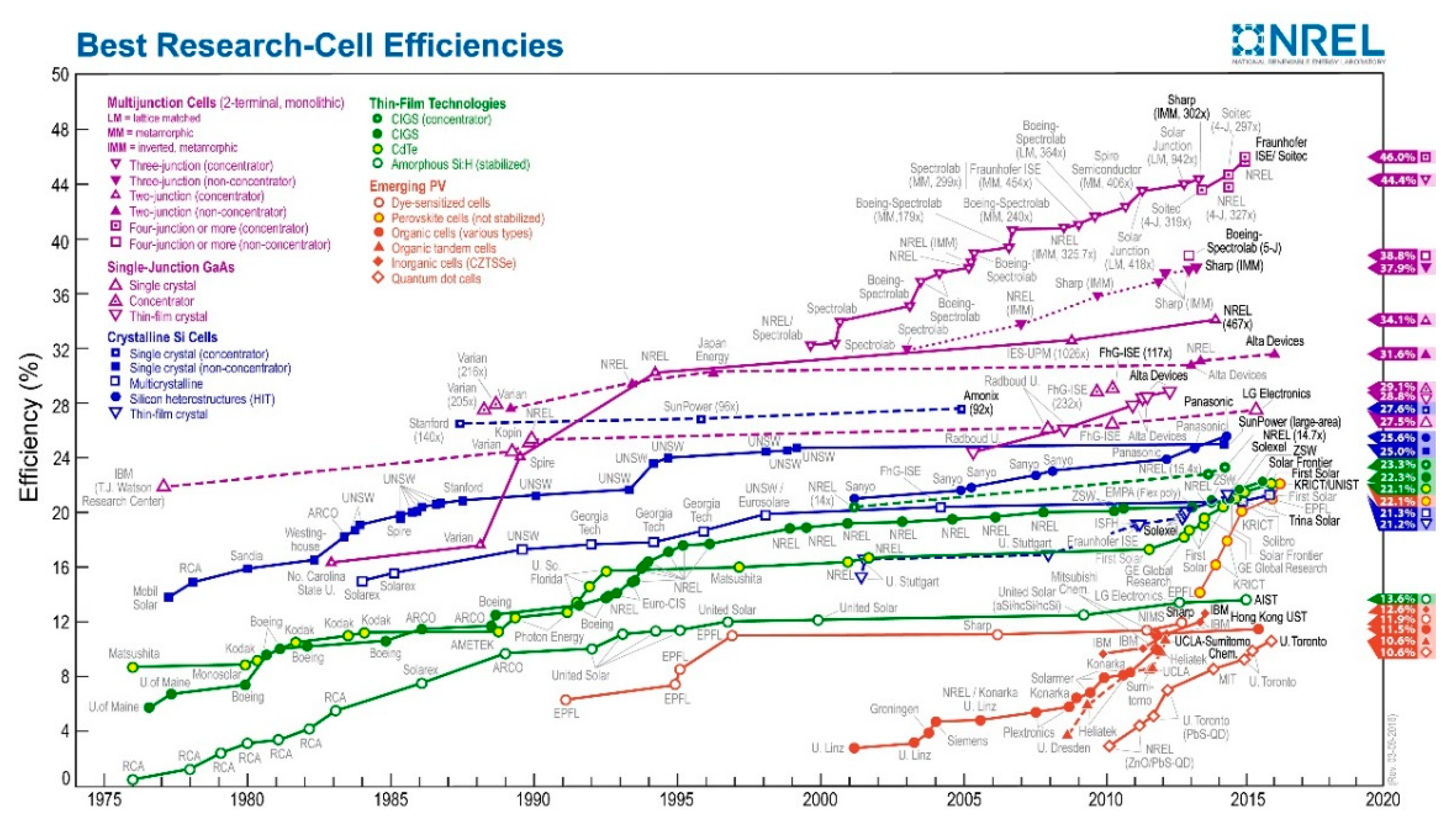

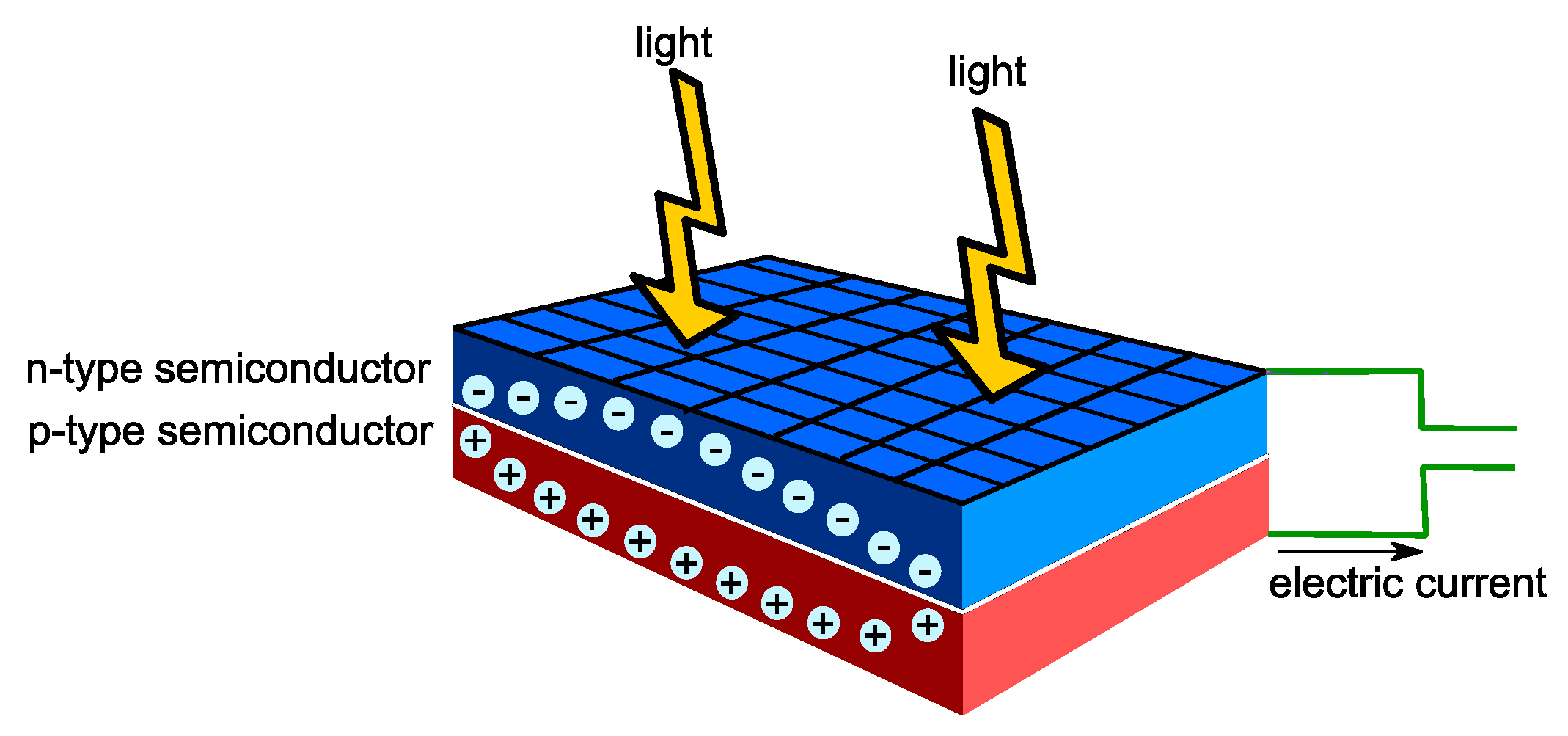

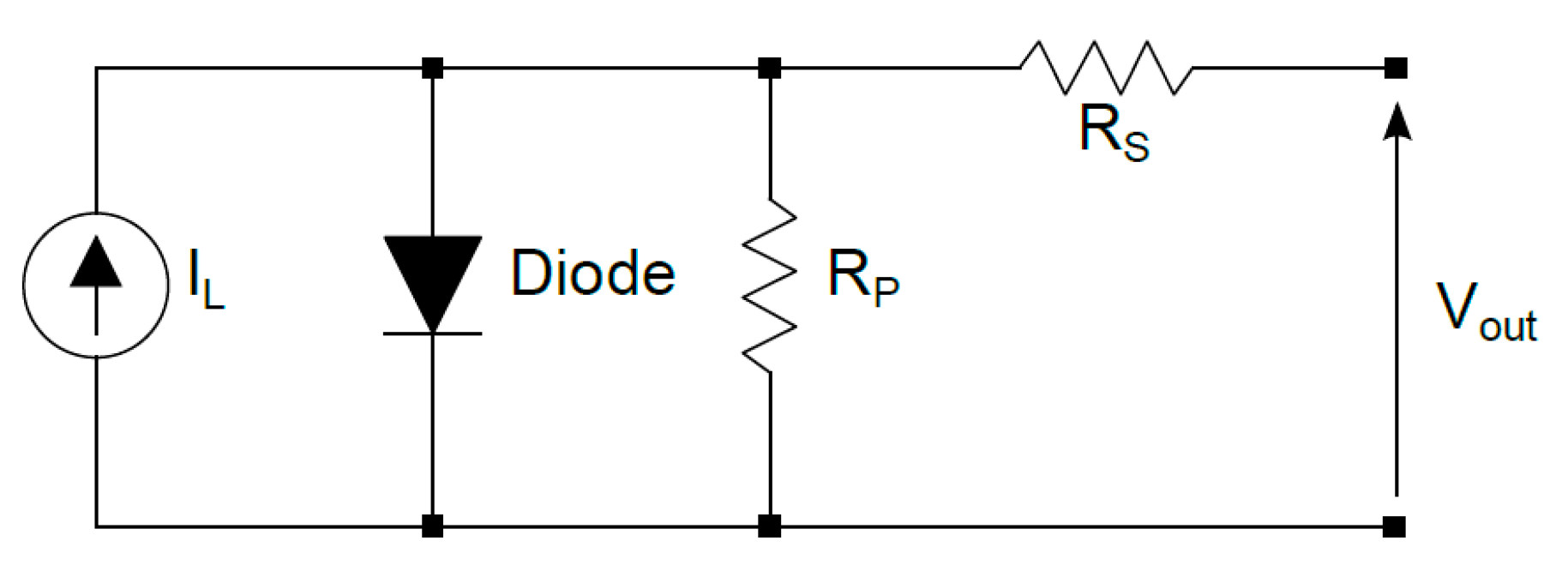

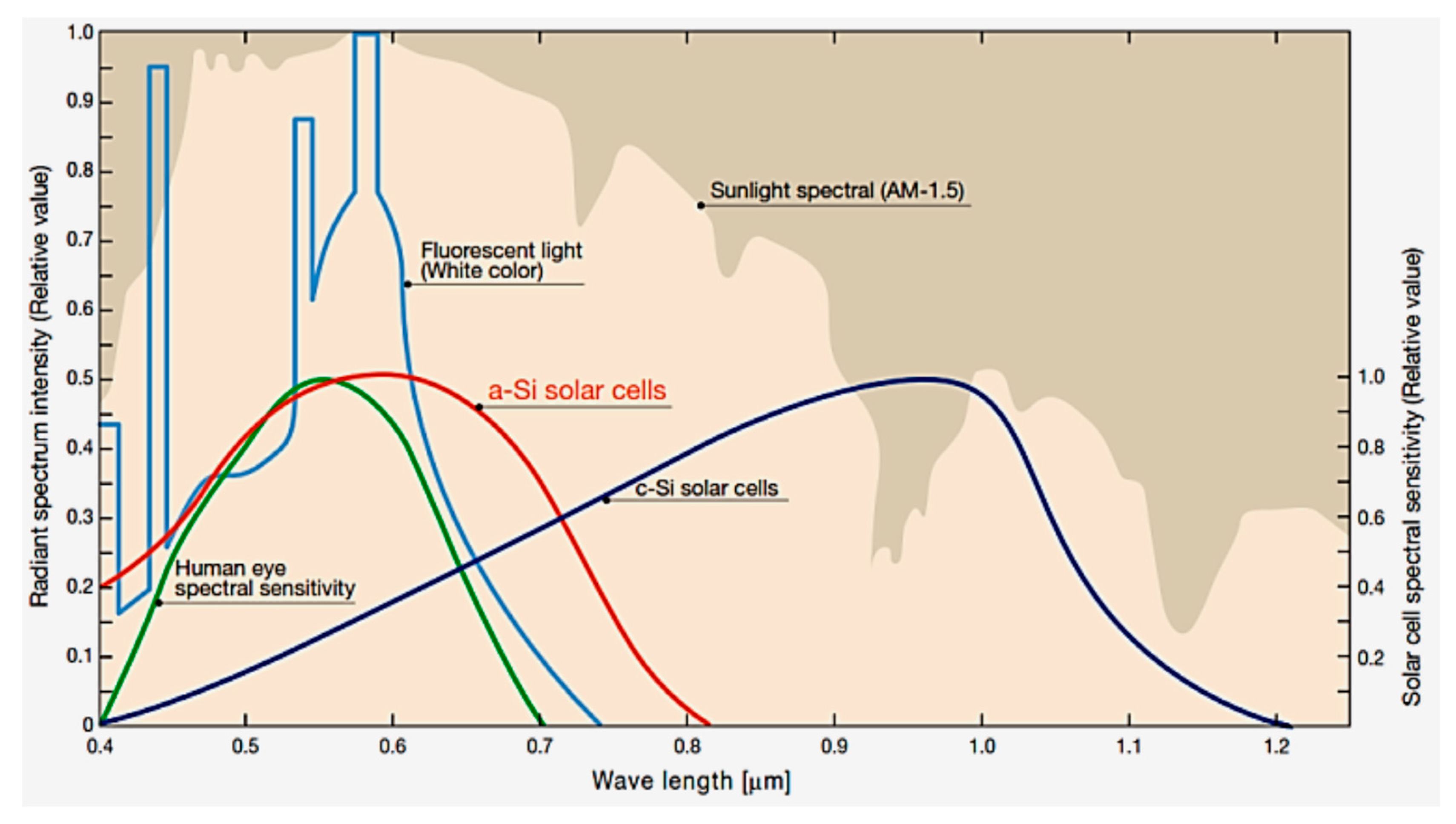

2. Photovoltaic Harvester’s Technology and Devices

3. Kinetic Harvester’s Technology and Devices

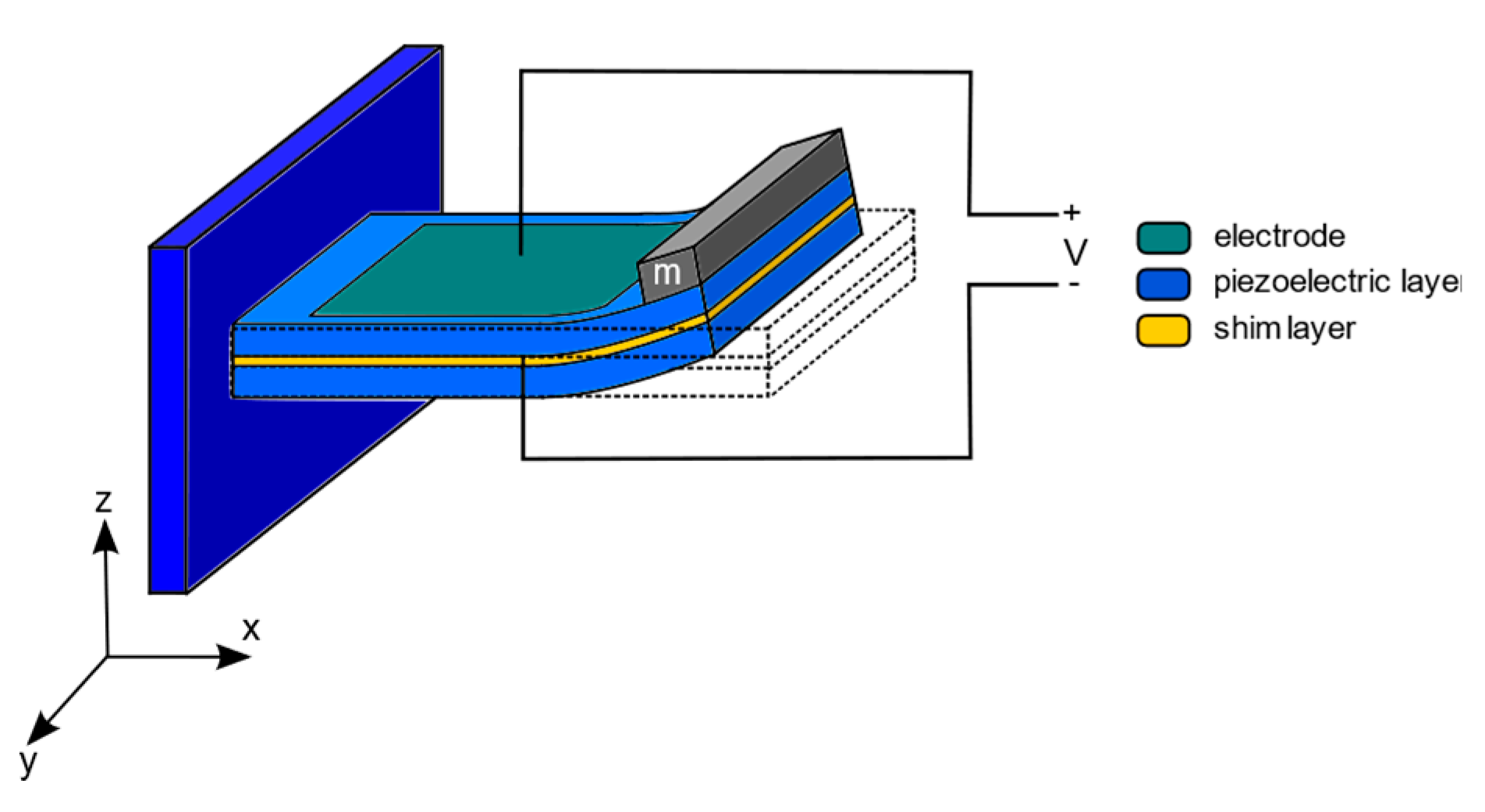

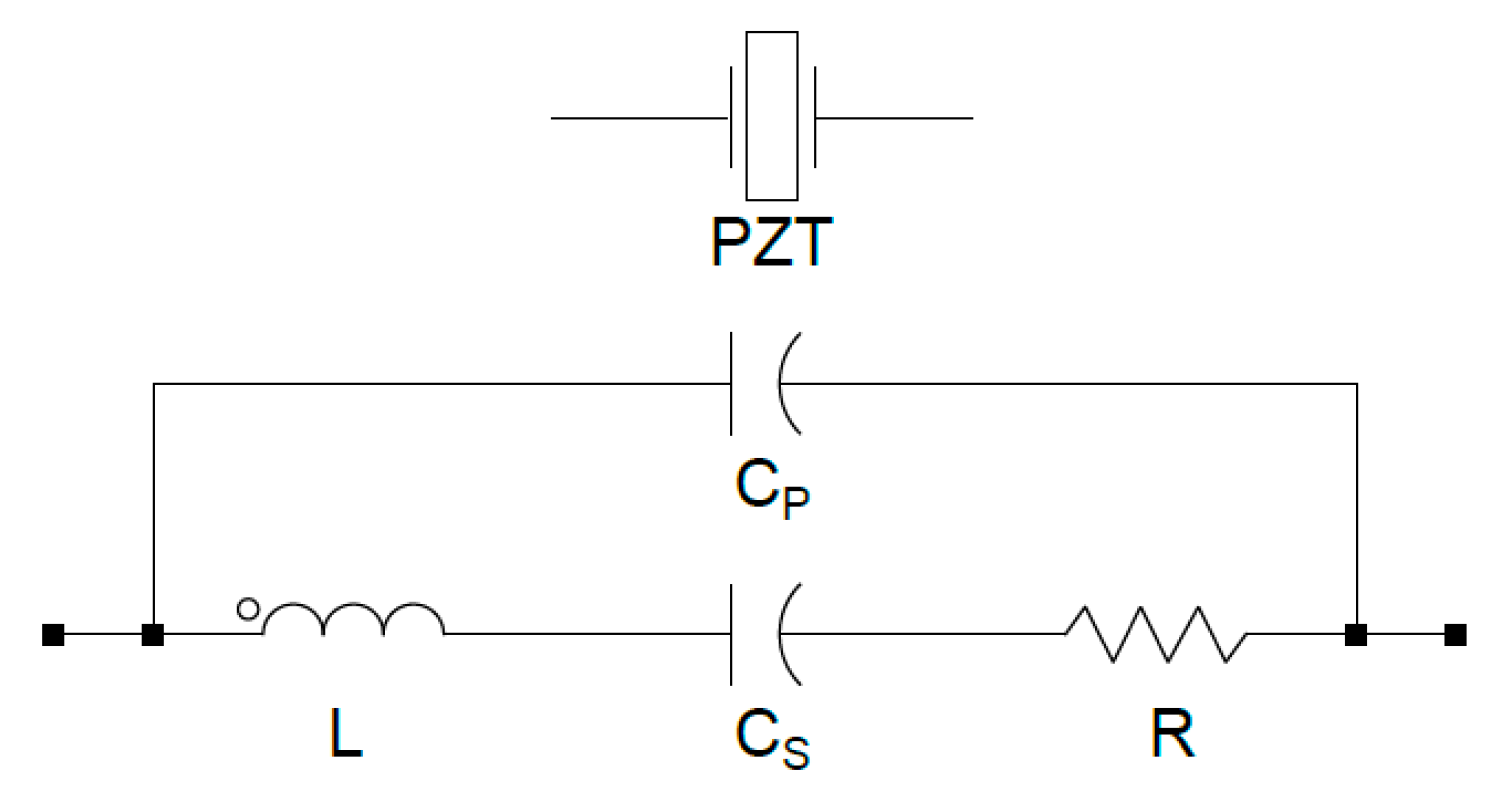

3.1. Piezoelectric Transduction

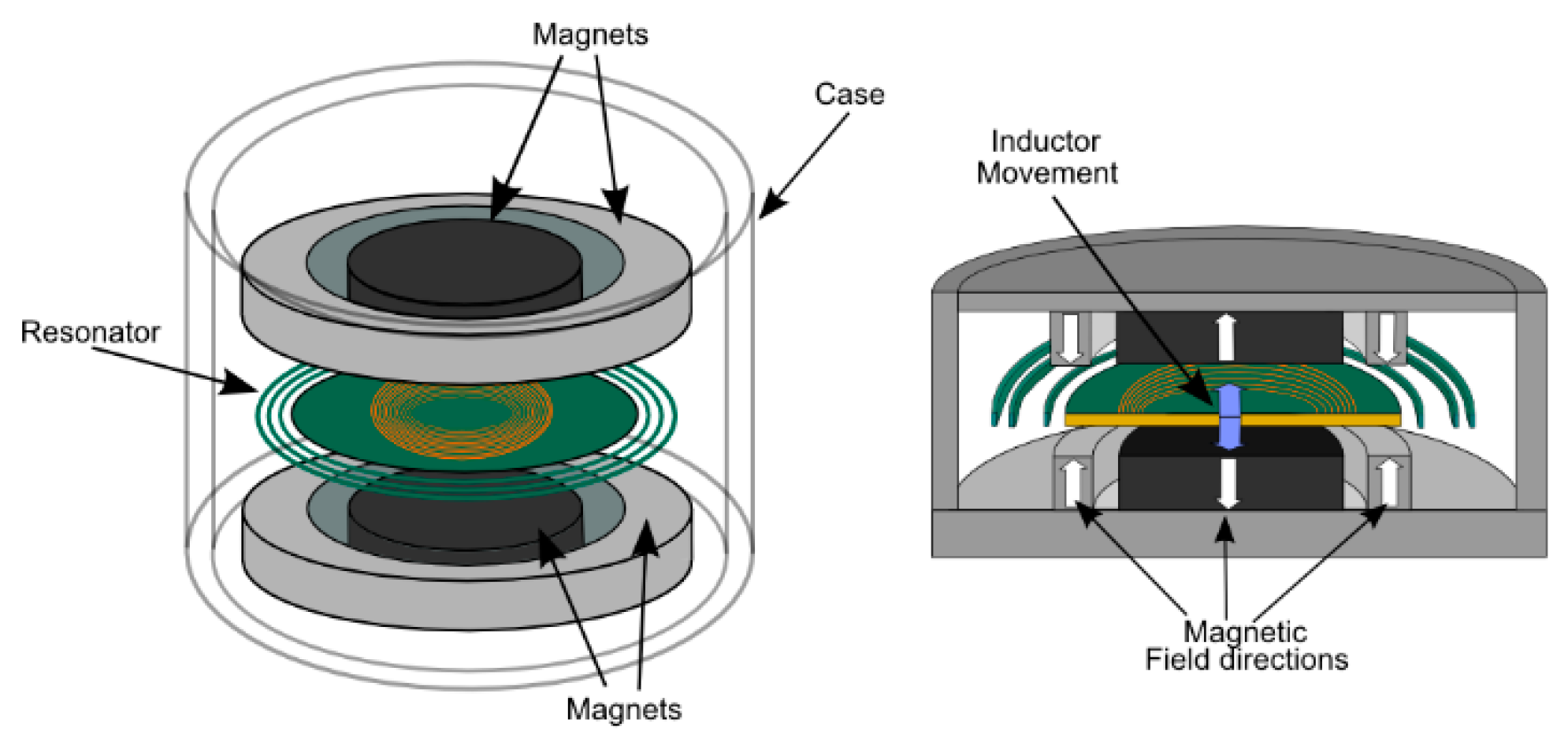

3.2. Electromagnetic Transduction

- Linear vibration

- Time-varying magnetic field, B.

3.3. Electrostatic Transduction

- Out of plane, gap varying, voltage constrained.

- In a plane, overlap varying, charge constrained.

- In a plane, the gap is varying.

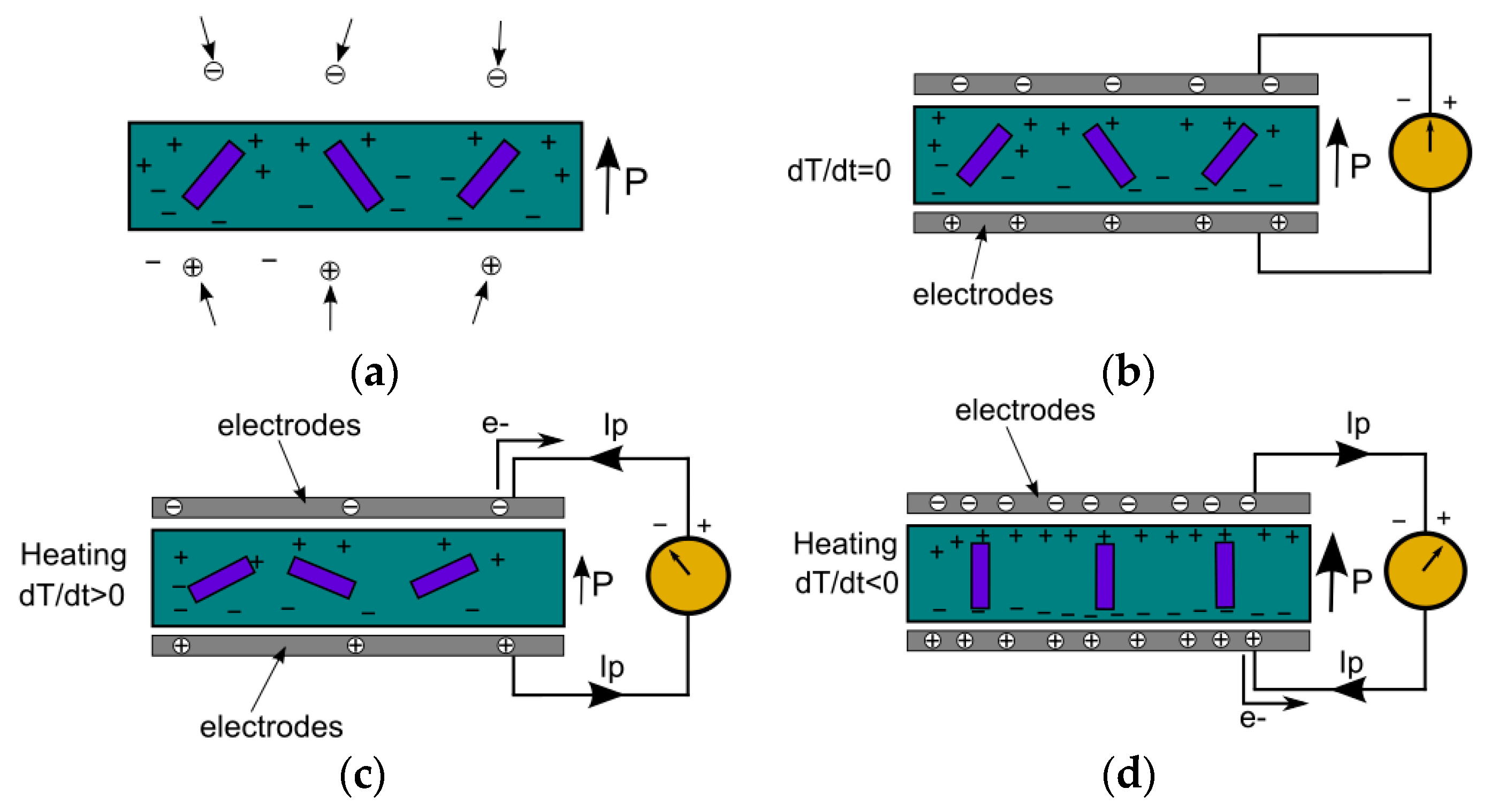

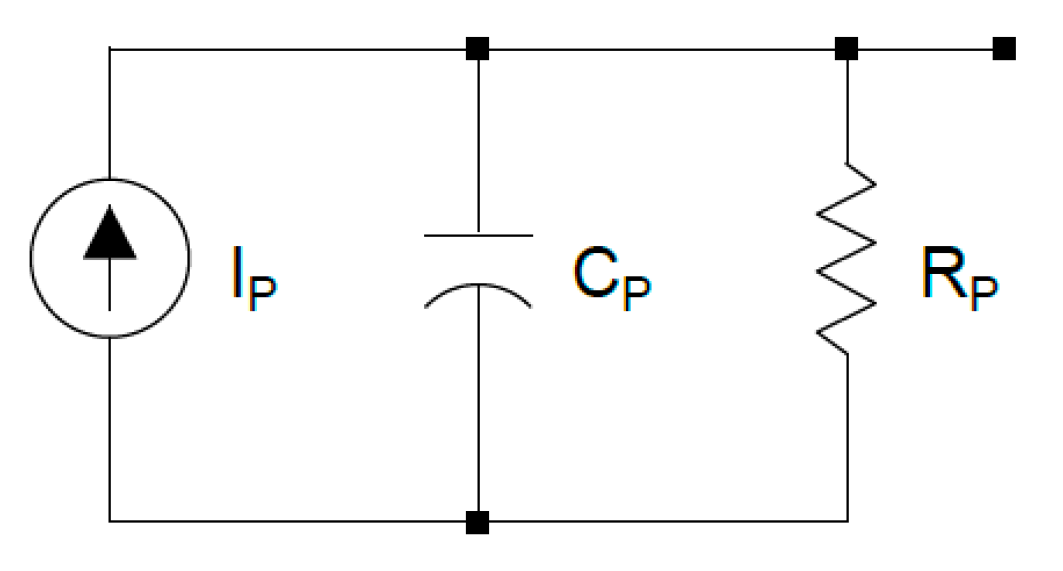

3.4. Pyroelectric Transduction

- Pyroelectric free charges (represented as positive and minus circles) are attracted to the material due to its spontaneous polarization (Figure 12a).

- If a capacitor is formed with two electrodes plates and the assembly is set at constant temperature, the spontaneous polarization remains constant, consequently is no current flow through the ammeter (Figure 12b).

- As the harvester is being heated, the dipole moment diminishes and the spontaneous polarization slows down. As a result, the number of bound charges at the electrodes decreases, causing a redistribution of charges that produce a current flow through the external circuit (Figure 12c).

- As the harvester is being cooled, the spontaneous polarization increases, and the current sign is (Figure 12d).

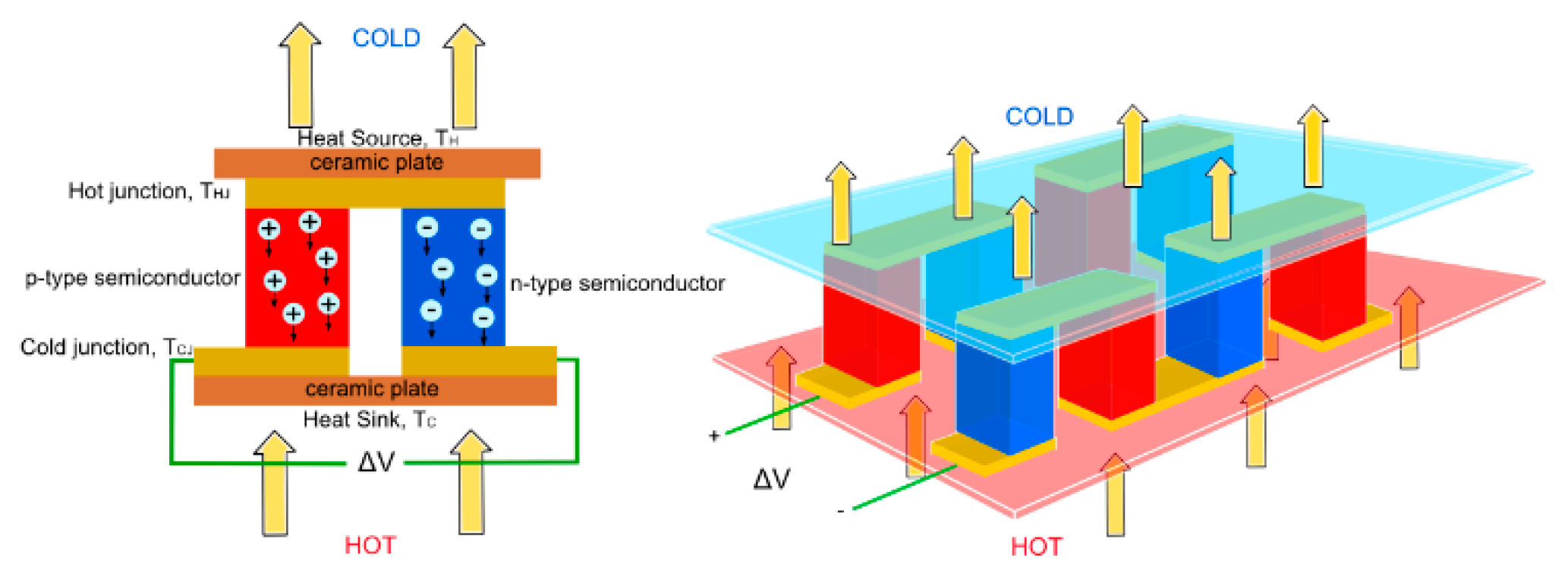

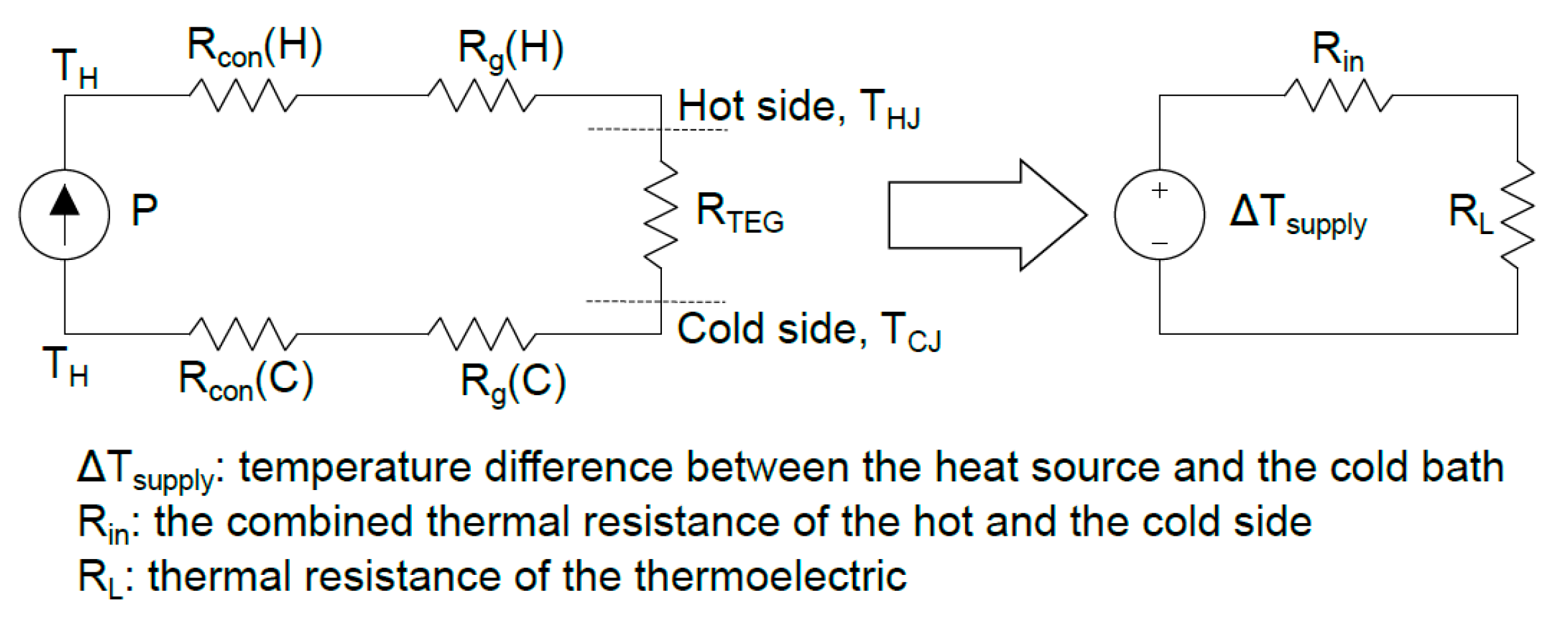

4. Thermoelectric Harvester’s Technology and Devices

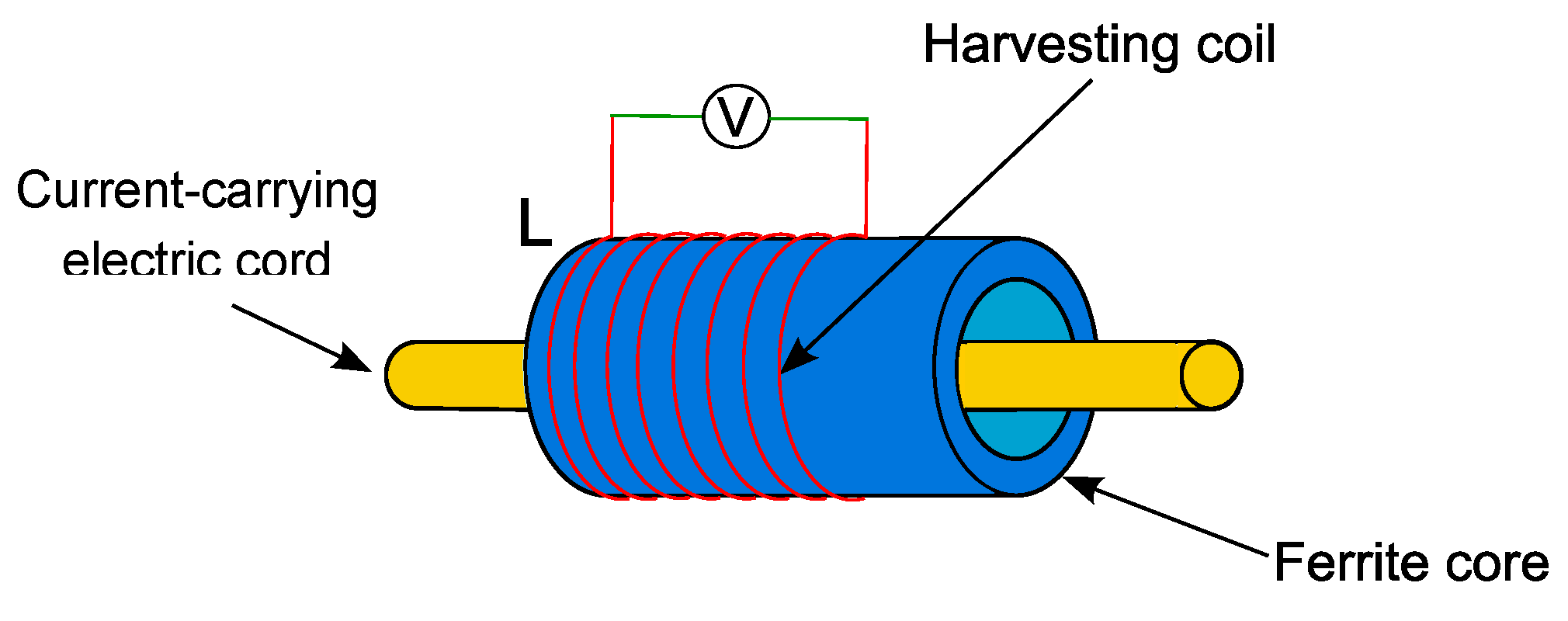

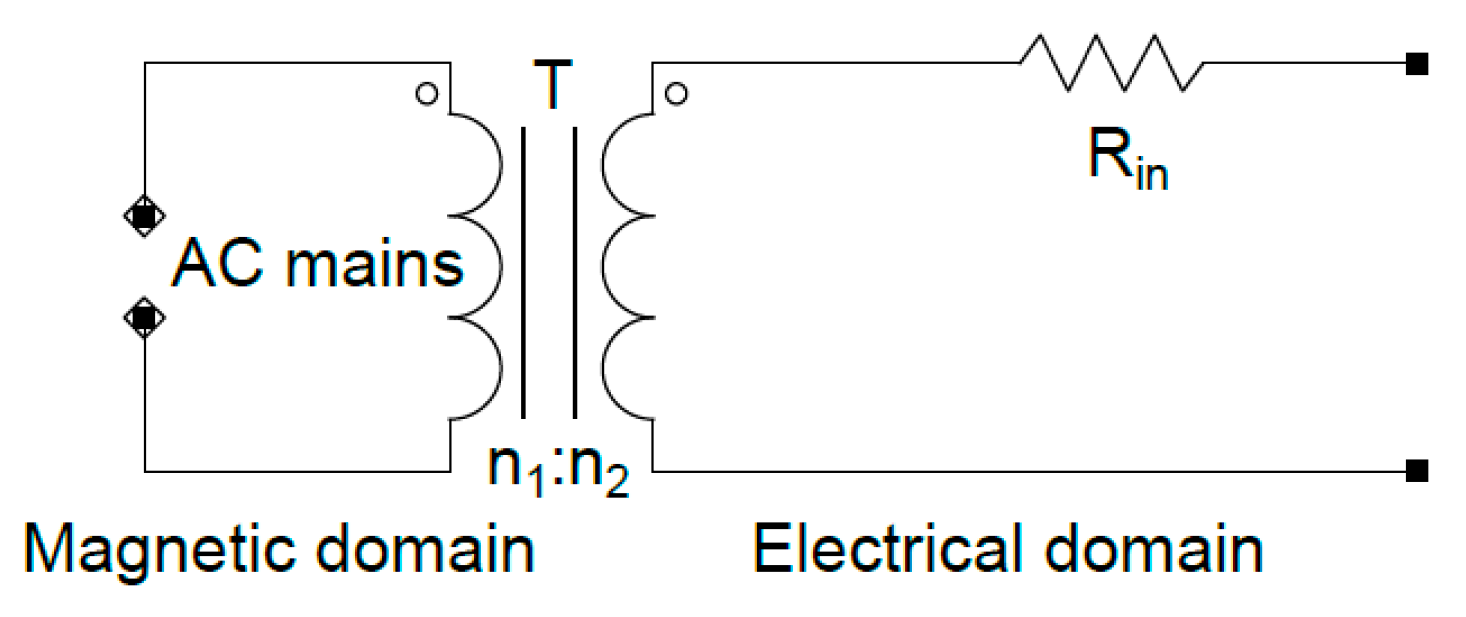

5. Magnetic Harvester’s Technology and Devices

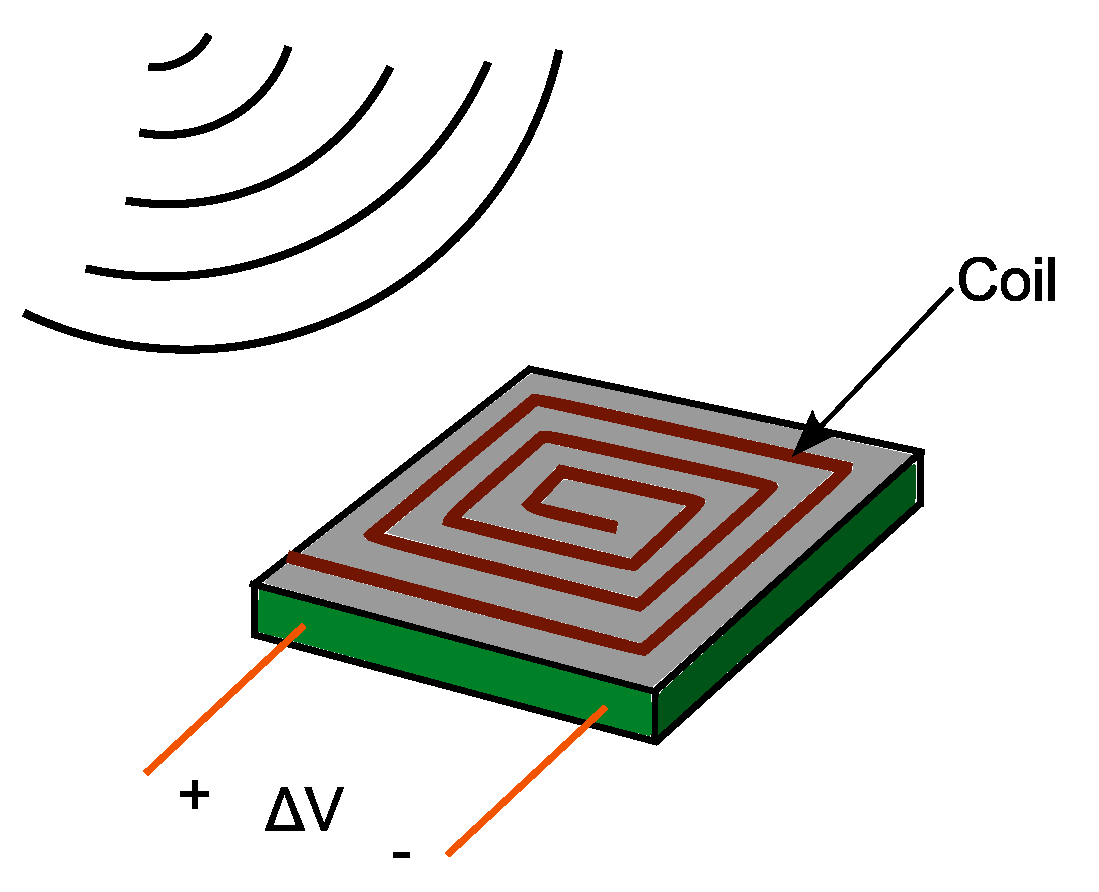

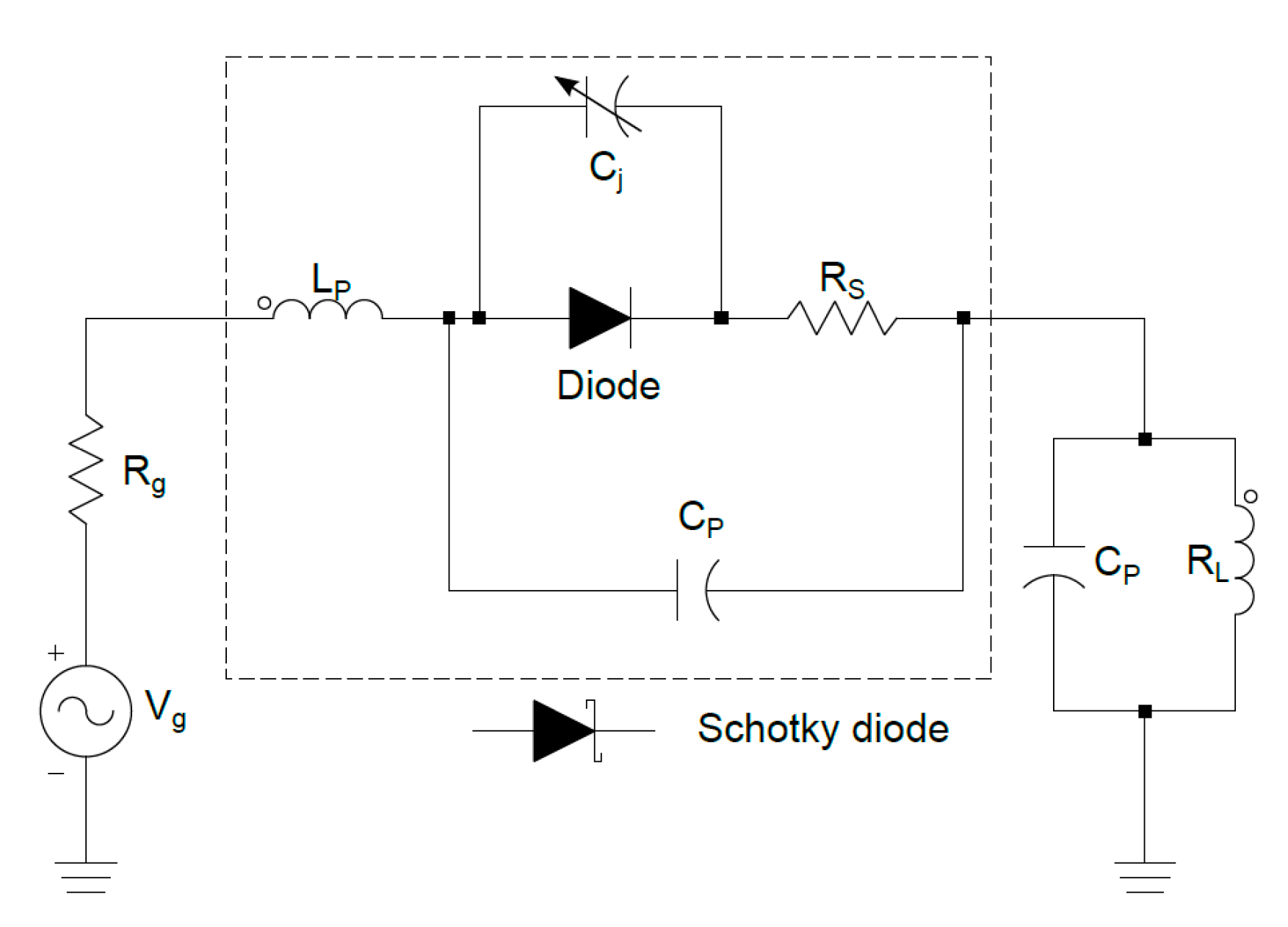

6. RF Harvester’s Technology and Devices

7. Dynamic Fluid Energy Harvesting

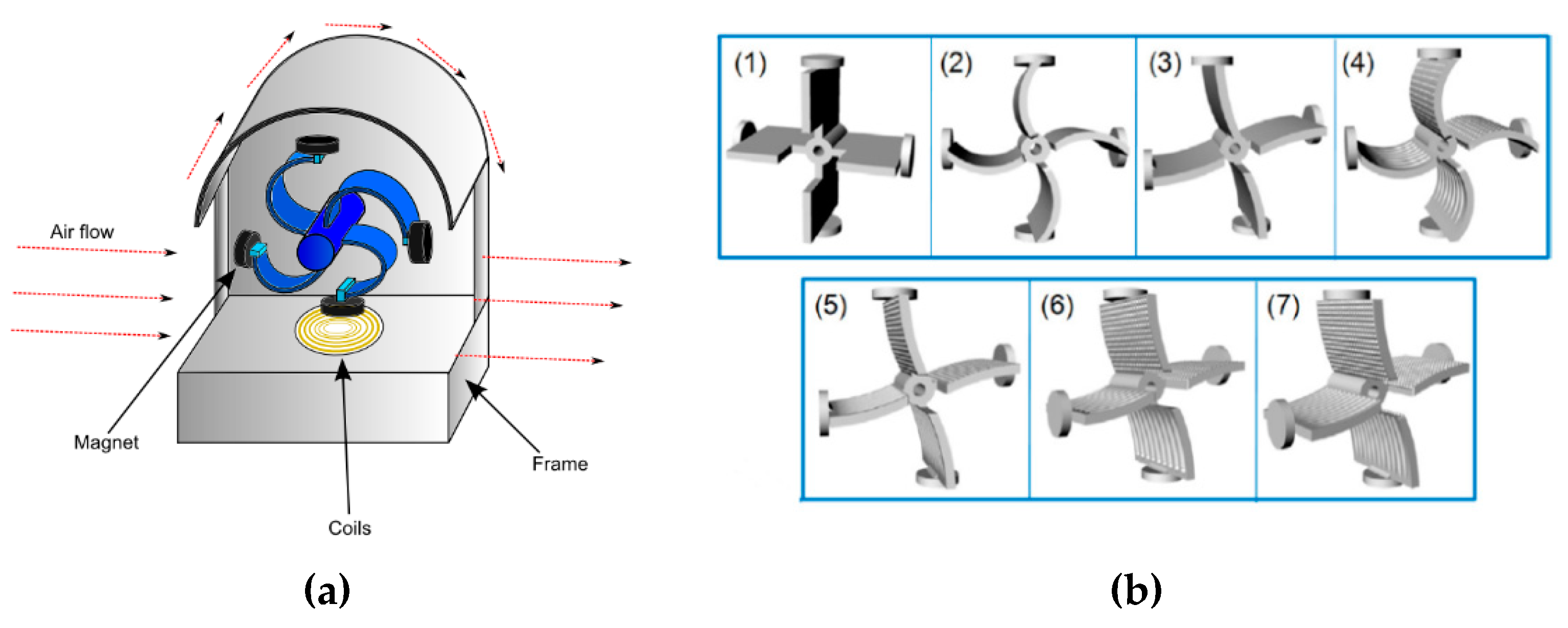

7.1. Wind Harvester’s Technology and Devices

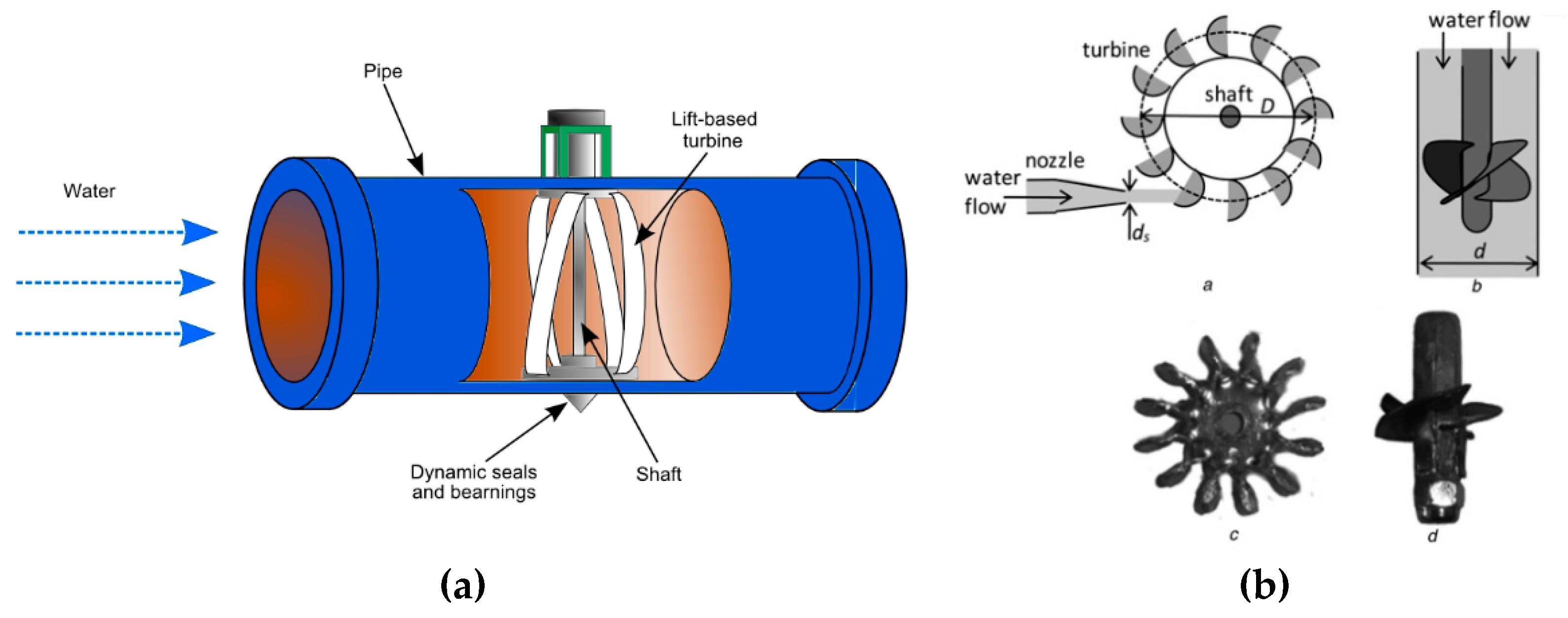

7.2. Water Flow Harvester’s Technology and Devices

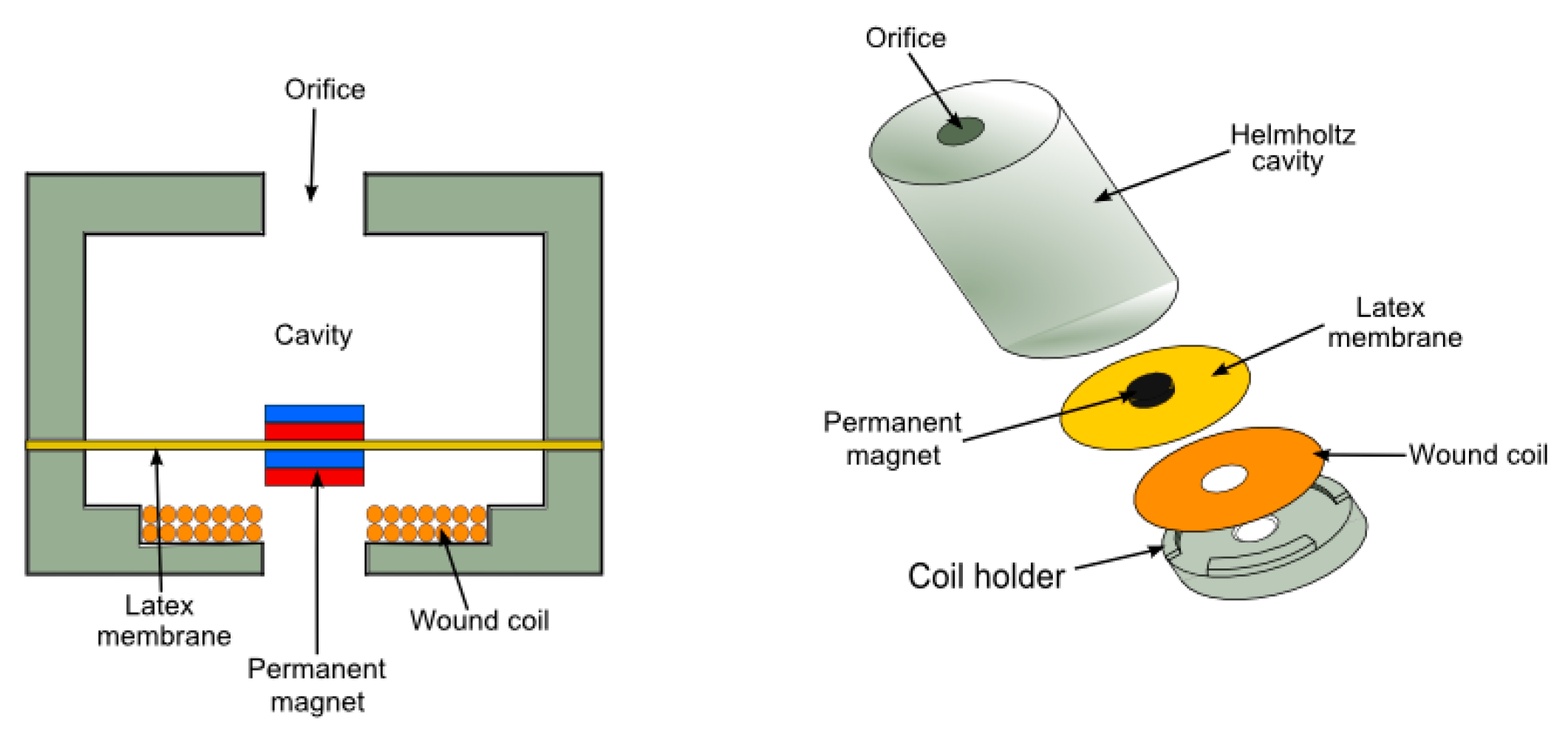

8. Acoustic Noise Harvester’s Technology and Devices

9. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Walker, C. Surpassing The Limits of Battery Technology. 2016. Available online: https://chemical-materials.elsevier.com/chemical-manufacturing-excellence/surpassing-limits-battery-technology/ (accessed on 20 March 2019).

- Guardian, T. The Rise of Electric Cars Could Leave Us with a Big Battery Waste Problem. 10 August 2017. Available online: http://www.theguardian.com/sustainable-business/2017/aug/10/electric-cars-big-battery-waste-problem-lithium-recycling (accessed on 20 March 2019).

- Tollefson, J.; Reese, L. Understanding & Managing the Plethora of MCU Low-Power Modes. 2017. Available online: http://www.mouser.es/applications/low-power-ewc-low-power/. (accessed on 20 March 2019).

- Woias, P. Energy Harvesting, Courses in Microtec and Nanotec; FSRM – Swiss Foundation for Research in Microtechnology: Zurich, Switcherland, February 2016. [Google Scholar]

- Zorzi, M.; Gluhak, A.; Lange, S.; Bassi, A. From today’s INTRAnet of things to a future INTERnet of things: A wireless- and mobility-related view. IEEE Wirel. Commun. 2010, 17, 44–51. [Google Scholar] [CrossRef]

- Clifford, G. Energy Harvesting: How We’ll Build the Internet of Perpetual Things, Jabil, [Online]. Available online: https://www.jabil.com/content/dam/insights/white-papers/en/energy-harvesting-how-we-will-build-the-internet-of-perpetual-things (accessed on 20 March 2019).

- Webster, J.G.; Eren, H. Measurement, Instrumentation, and Sensors Handbook: Spatial, Mechanical, Thermal, and Radiation Measurement, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Tan, Y.K.; Panda, S.K. Review of Energy Harvesting Technologies for Sustainable Wireless Sensor Network (WSN). December 2010. Available online: https://www.intechopen.com/books/sustainable-wireless-sensor-networks/review-of-energy-harvesting-technologies-for-sustainable-wsn (accessed on 20 March 2019).

- Priya, S.; Inman, D.J. Energy Harvesting Technologies; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Kazmierski, T.J.B.S. Energy Harvesting Systems: Principles, Modeling and Applications; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Elvin, N.; Ertuk, A. Advances in Energy Harvesting Methods; Springer: New York, NY, USA, 2013. [Google Scholar]

- Spies, P.; Pollak, M.; Mateu, L. Handbook of Energy Harvesting Power Supplies and Applications; Pan Stanford Publishing: Singapore, 2015. [Google Scholar]

- Selvan, K.V.; Ali, M.S.M. Micro-scale energy harvesting devices: Review of methodological performances in the last decade. Renew. Sustain. Energy Rev. 2016, 54, 1035–1047. [Google Scholar] [CrossRef]

- Zhou, M.; Al-Furjan, M.S.H.; Zou, J.; Liu, W. Review on heat and mechanical energy harvesting from human—Principles, prototypes and perspectives. Renew. Sustain. Energy Rev. 2018, 82, 3582–3609. [Google Scholar] [CrossRef]

- Akbari, S. Energy Harvesting for Wireless Sensor Networks Review. In Proceedings of the 2014 Federated Conference on Computer Science and Information Systems, Warsaw, Poland, 7–10 September 2014; Volume 2, pp. 987–992. [Google Scholar]

- Seah, W.K.; Eu, Z.A.; Tan, H.-P. Wireless sensor networks powered by ambient energy harvesting (WSN-HEAP)—Survey and challenges. In Proceedings of the 1st International Conference on Wireless Communication, Vehicular Technology, Information Theory and Aerospace & Electronic Systems Technology, Aalborg, Denmark, 17–20 May 2009; pp. 1–5. [Google Scholar]

- Zhou, G.; Huang, L.; Li, W.; Zhu, Z. Harvesting ambient environmental energy for wireless sensor networks: A survey. J. Sens. 2014, 2014, 815467. [Google Scholar] [CrossRef]

- Moghe, R.; Yang, Y.; Lambert, F.C.; Divan, D. A Scoping Study of Electric and Magnetic Field Energy Harvesting for Wireless Sensor Networks in Power System Applications Deepak Divan. In Proceedings of the 2009 IEEE Energy Conversion Congress and Exposition, San Jose, CA, USA, 20–24 September 2009; pp. 3550–3557. [Google Scholar]

- Gilbert, J.M.; Balouchi, F. Comparison of energy harvesting systems for wireless sensor networks. Int. J. Autom. Comput. 2008, 5, 334–347. [Google Scholar] [CrossRef]

- Mitcheson, P.D.; Yeatman, E.M.; Rao, G.K.; Holmes, A.S.; Green, T.C. Energy harvesting from human and machine motion for wireless electronic devices. Proc. IEEE 2008, 96, 1457–1486. [Google Scholar] [CrossRef]

- HY-Line and Enocean, Solar Cells ECS 300/310. Available online: https://www.hy-line.de/en/product/detail/cat334/energy-harvesting-1/ecs-300-310/ (accessed on 20 March 2019).

- Digikey, Piezoelectric Energy harvester V25W, Midé Technology Corporation. Available online: https://www.digikey.com/product-detail/en/V25W/V25W-ND/2402862 (accessed on 20 March 2019).

- Bouendeu, E.; Greiner, A.; Smith, P.; Korvink, J. An efficient low cost electromagnetic vibration harvester. In Proceedings of the PowerMEMS 2009 Porceedings, Washington, DC, USA, 1–4 December 2009. [Google Scholar]

- Boisseau, S.; Despesse, G.; Seddik, B.A. Electrostatic Conversion for Vibration Energy Harvesting. In Small-Scale Energy Harvesting; Intech: London, UK, 2012; pp. 1–39. [Google Scholar]

- Kruse, N. Pyroelectricity, Wikipedia. 2002. Available online: https://en.wikipedia.org/wiki/Pyroelectricity (accessed on 20 March 2019).

- Cui_inc, Peltier Module CP85-2 Series. 2016. Available online: https://www.cui.com/product/thermal-management/peltier-devices/multi-stage-peltier-modules/cp85-2-series (accessed on 20 March 2019).

- Sordiashie, E. Electromagnetic Harvesting to Power Energy Management Sensors in the Built Environment. 2012. Available online: https://digitalcommons.unl.edu/cgi/viewcontent.cgi?article=1018&context=archengdiss (accessed on 20 March 2019).

- Digikey, WRM483245-15F5-5V-G. TDK Corporation. Available online: https://www.digikey.com/product-detail/es/tdk-corporation/WRM483245-15F5-5V-G/445-16097-ND/4702663 (accessed on 20 March 2019).

- Howey, D.A.; Bansal, A.; Holmes, A. Design and performance of a centimetre-scale shrouded wind turbine for energy harvesting. Smart Mater. Struct. 2011, 20, 1–12. [Google Scholar] [CrossRef]

- Azevedo, J.A.R.; Santos, F.E.S. Energy harvesting from wind and water for autonomous wireless sensor nodes. IET Circuits Devices Syst. 2012, 6, 413–420. [Google Scholar] [CrossRef]

- Khan, F.U.; Izhar, E. Acoustic-Based Electrodynamic Energy Harvester for Wireless Sensor Nodes Application. Int. J. Mater. Sci. Eng. 2013, 1, 72–78. [Google Scholar] [CrossRef]

- Matiko, J.W.; Grabham, N.J.; Beeby, S.P.; Tudor, M.J. Review of the application of energy harvesting in buildings. Meas. Sci. Technol. 2014, 25, 1–25. [Google Scholar] [CrossRef]

- Tan, Y.K.; Panda, S.K. Energy Harvesting From Hybrid Indoor Ambient Light and Thermal Energy Sources for Enhanced Performance of Wireless Sensor Nodes. IEEE Trans. Ind. Electron. 2011, 58, 4424–4435. [Google Scholar] [CrossRef]

- Visconti, P.; Primiceri, P.; Ferri, R.; Pucciarelli, M.; Venere, E. An Overview on State-of-art Energy Harvesting Techniques and Choice Criteria: A WSN Node for Goods Transport and Storage Powered by a Smart Solar- based EH System. Int. J. Renew. Energy Res. 2017, 7, 1281–1295. [Google Scholar]

- Beeby, S.; White, N. Energy Harvesting for Autonomous Systems; Artech House: Norwood, MA, USA, 2010. [Google Scholar]

- Randall, J.; Bharatula, N.B.; Perera, N.; von Büren, T.; Ossevoort, S.; Tröster, G. Indoor Tracking using Solar Cell Powered System: Interpolation of Irradiance. In Proceedings of the Sixth International Conference on Ubiquitous Computing (Ubicomp 2004), Nottinghan, UK, 7–10 September 2004. [Google Scholar]

- Mathews, I.; Kelly, G.; King, P.J.; Frizzell, R. GaAs solar cells for Indoor Light Harvesting. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 510–513. [Google Scholar]

- Nasiri, A.; Zabalawi, S.A.; Mandic, G. Indoor Power Harvesting Using Photovoltaic Cells for Low-Power Applications. IEEE Trans. Ind. Electron. 2009, 56, 4502–4509. [Google Scholar] [CrossRef]

- Harrison, K.H.L.; Wu, J.; Jérémy, B.; Jain, S.M.; Wood, S.; Speller, E.M.; Li, Z.; Castro, F.A.; Durrantab, J.R.; Tso, W.C. Organic photovoltaic cells—Promising indoor light harvesters for self-sustainable electronics. J. Mater. Chem. A 2018, 14, 5618–5626. [Google Scholar]

- Mathews, I.; King, P.J.; Stafford, F.; Frizzell, R. Performance of III–V Solar Cells as Indoor. IEEE J. Photovolt. 2016, 6, 230–235. [Google Scholar] [CrossRef]

- Hsu, T.-W.M.; Wu, H.-H.; Tsai, D.-L.; Wei, C.-L. Photovoltaic Energy Harvester With Fractional Open-Circuit Voltage Based Maximum Power Point Tracking Circuit. IEEE Trans. Circuits Syst. II Express Briefs 2019, 22, 257–261. [Google Scholar] [CrossRef]

- Aoki, Y. Photovoltaic performance of Organic Photovoltaics for indoor energy harvester. Org. Electron. 2017, 48, 194–197. [Google Scholar] [CrossRef]

- Richter, C.; Lincot, D.; Gueymard, C.A. Solar Energy; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Research Cell Efficiency Records. Solar Energy Technolgies Office, September 2015. Available online: www.energy.gov/eere/solar/downloads/research-cell-efficiency-records (accessed on 20 March 2019).

- Chirap, A.; Popa, V.; Coca, E.; Potorac, D.A. A study on light energy harvesting from indoor environment: The autonomous sensor nodes. In Proceedings of the 12th International Conference on Development and Application Systems, Suceava, Romania, 15–17 May 2014; pp. 127–131. [Google Scholar]

- Priya, S.; Son, H.-C.; Zhou, Y.; Varghese, R.; Chopra, A.; Kim, S.-G.; Kanno, I.; Wu, L.; Ha, D.S.; Ryu, J.; Polcawich, R.G. A Review on Piezoelectric Energy Harvesting: Materials, Methods, and Circuits. Energy Harvest. Syst. 2017, 4, 3–39. [Google Scholar] [CrossRef]

- Shu, Y.C.; Lien, I.C. Analysis of power output for piezoelectric energy harvesting systems. Smart Mater. Struct. 2006, 15, 1499–1512. [Google Scholar] [CrossRef]

- Harne, R.L.; Wang, K.W. A review of the recent research on vibration energy harvesting via bistable systems. Smart Mater. Struct. 2013, 22, 1–12. [Google Scholar] [CrossRef]

- Khaligh, A.; Zeng, P.; Zheng, C. Kinetic Energy Harvesting Using Piezoelectric and Electromagnetic Technologies—State of the Art. IEEE Trans. Ind. Electron. 2010, 57, 850–860. [Google Scholar] [CrossRef]

- Briscoe, J.; Dunn, S. Piezoelectric nanogenerators—A review of nanostructured piezoelectric energy harvesters. Nano Energy 2015, 14, 15–29. [Google Scholar] [CrossRef]

- Hwang, G.-T.; Byun, M.; Jeong, C.K.; Lee, K.J. Flexible Piezoelectric Thin-Film Energy Harvesters and Nanosensors for Biomedical Applications. Adv. Healthc. Mater. 2015, 4, 646–658. [Google Scholar] [CrossRef]

- Madinei, H.; Khodaparast, H.H.; Adhikari, S.; Friswell, M. Design of MEMS piezoelectric harvesters with electrostatically adjustable resonance frequency. Mech. Syst. Signal Process. 2016, 81, 360–374. [Google Scholar] [CrossRef]

- Rincón-Mora, G.A.; Yang, S. Tiny Piezoelectric Harvesters: Principles, Constraints, and Power Conversion. IEEE Trans. Circuits Syst. I Regul. Pap. 2016, 63, 639–649. [Google Scholar] [CrossRef]

- Cadei, A.; Dionisi, A.; Sardini, E.; Serpelloni, M. Kinetic and thermal energy harvesters for implantable medical devices and biomedical autonomous sensors. Meas. Sci. Technol. 2013, 25, 1–14. [Google Scholar] [CrossRef]

- Marioli, D.; Sardini, E.; Serpelloni, M. Electromagnetic Generators Employing Planar Inductors for Autonomous Sensor Applications. Procedia Chem. 2009, 1, 469–472. [Google Scholar] [CrossRef][Green Version]

- Beeby, S.; Torah, R.N.; Tudor, M.J.; Glynne-Jones, P.; O’Donnell, T.; Saha, C.; Roy, S. A micro electromagnetic generator for vibration energy harvesting. J. Micromech. Microeng. 2007, 17, 1257–1265. [Google Scholar] [CrossRef]

- Leung, C.M.; Li, J.; Viehland, D.Z. A review on applications of magnetoelectric composites: From heterostructural uncooled magnetic sensors, energy harvesters to highly efficient power converters. J. Phys. D Appl. Phys. 2018, 51, 1–20. [Google Scholar] [CrossRef]

- Song, H.-C.; Kumar, P.; Sriramdas, R.; Lee, H.; Sharpes, N.; Kang, M.-G.; Maurya, D.; Sanghadasa, M.; Kang, H.-W.; Ryu, J.; et al. Broadband dual phase energy harvester: Vibration and magnetic field. Appl. Energy 2018, 225, 1132–1142. [Google Scholar] [CrossRef]

- Wang, W.; Cao, J.; Zhang, N.; Lin, J.; Liao, W.-H. Magnetic-spring based energy harvesting from human motions: Design, modeling and experiments. Energy Convers. Manag. 2017, 132, 189–197. [Google Scholar] [CrossRef]

- Electrical Resistivity and Conductivity, Wikipedia. Available online: https://en.wikipedia.org/wiki/Electrical_resistivity_and_conductivity (accessed on 20 March 2019).

- Le, C.P.; Halvorsen, E.; Søråsen, O.; Yeatman, E.M. Wideband excitation of an electrostatic vibration energy harvester with power-extracting end-stops. Smart Mater. Struct. 2013, 22, 1–9. [Google Scholar] [CrossRef]

- Deterre, M.; Risquez, S.; Bouthaud, B.; Molin, R.D.; Woytasik, M.; Lefeuvre, E. Multilayer out-of-plane overlap electrostatic energy harvesting structure actuated by blood pressure for powering intra-cardiac implants. J. Phys. Conf. Ser. 2013, 476, 1–5. [Google Scholar] [CrossRef]

- Naruse, Y.; Matsubara, N.; Mabuchi, K.; Izumi, M.; Suzuki, S. Electrostatic micro power generation from low-frequency vibration such as human motion. J. Micromech. Microeng. 2009, 19, 1–5. [Google Scholar] [CrossRef]

- Ahmed, S.; Kakkar, V. An Electret-Based Angular Electrostatic Energy Harvester for Battery-Less Cardiac and Neural Implants. IEEE Access 2017, 5, 19631–19643. [Google Scholar] [CrossRef]

- Khan, F.U.; Qadir, M.U. State-of-the-art in vibration-based electrostatic energy harvesting. J. Micromech. Microeng. 2016, 26, 1–28. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, T.; Luo, A.; Hu, Y.; Li, X.; Wang, F. Micro electrostatic energy harvester with both broad bandwidth and high normalized power density. Appl. Energy 2018, 212, 362–371. [Google Scholar] [CrossRef]

- Cuadras, A.; Gasulla, M.; Ferrari, V. Thermal energy harvesting through pyroelectricity. Sens. Actuators A Phys. 2010, 158, 132–139. [Google Scholar] [CrossRef]

- Lee, F.Y.; Navid, A.; Pilon, L. Pyroelectric waste heat energy harvesting using heat conduction. Appl. Therm. Eng. 2012, 37, 30–37. [Google Scholar] [CrossRef]

- Ravindran, S.; Kroener, M.; Woias, P. A standalone pyroelectric harvester for thermal energy harvesting. In Proceedings of the Power MEMS, Atlanta, GA, USA, 2–5 December 2012; pp. 80–83. [Google Scholar]

- Xie, M.; Zabek, D.; Bowen, C.; Abdelmageed, M.; Arafa, M. Wind-driven pyroelectric energy harvesting device. Smart Mater. Struct. 2016, 25, 1–8. [Google Scholar] [CrossRef]

- Siao, A.-S.; Chao, C.-K.; Hsiao, C.-C. Study on Pyroelectric Harvesters with Various Geometry. Sensors 2015, 15, 19633–19648. [Google Scholar] [CrossRef]

- Hsiao, C.-C.; Jhang, J.-W. Pyroelectric Harvesters for Generating Cyclic Energy. Energies 2015, 8, 3489–3502. [Google Scholar] [CrossRef]

- Leonov, V. Thermoelectric energy harvester on the heated human machine. J. Micromech. Microeng. 2011, 21, 1–8. [Google Scholar] [CrossRef]

- Li, S.; Yao, X.; Fu, J. Research on a power management system for thermoelectric generators to drive wireless sensors on a spindle unit. Sensors 2014, 14, 12701–12714. [Google Scholar] [CrossRef]

- Kiziroglou, M.E.; Wright, S.W.; Toh, T.T.; Mitcheson, P.D.; Becker, T.; Yeatman, E.M. Design and Fabrication of Heat Storage Thermoelectric Harvesting Devices. IEEE Trans. Ind. Electron. 2014, 61, 302–309. [Google Scholar] [CrossRef]

- Champier, D. Thermoelectric generators: A review of applications. Energy Convers. Manag. 2017, 140, 167–181. [Google Scholar] [CrossRef]

- Ito, M.; Koizumi, T.; Kojima, H.; Saito, T. From materials to device design of a thermoelectric fabric for wearable energy harvesters. J. Mater. Chem. A 2017, 5, 12068–12072. [Google Scholar] [CrossRef]

- Kiziroglou, M.E.; Becker, T.; Wright, S.W.; Yeatman, E.M.; Evans, J.W.; Wright, P.K. Three-Dimensional Printed Insulation For Dynamic Thermoelectric Harvesters With Encapsulated Phase Change Materials. IEEE Sens. Lett. 2017, 1, 1–4. [Google Scholar] [CrossRef]

- Koukharenko, E.; Boden, S.A.; Sessions, N.P.; Frety, N.; Nandhakumar, I.; White, N.M. Towards thermoelectric nanostructured energy harvester for wearable applications. J. Mater. Sci. Mater. Electron. 2018, 29, 3423–3436. [Google Scholar] [CrossRef]

- Moghe, R.; Divan, D.; Lambert, F. Powering Low-Cost Utility Sensors using Energy Harvesting. In Proceedings of the 2011 14th European Conference on Power Electronics and Applications, Birmingham, UK, 30 August–1 September 2011; pp. 1–10. [Google Scholar]

- Roscoe, N.M.; Judd, M.D. Harvesting Energy from Magnetic Fields to Power Condition Monitoring Sensors. IEEE Sens. J. 2013, 13, 2263–2270. [Google Scholar] [CrossRef]

- Taithongchai, T.; Leelarasmee, E. Adaptive electromagnetic energy harvesting circuit for wireless sensor application. In Proceedings of the 6th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology, Pattaya, Thailand, 6–9 May 2009; pp. 278–281. [Google Scholar]

- Moon, J.; Leeb, S.B. Analysis Model for Magnetic Energy Harvesters. IEEE Trans. Power Electron. 2015, 30, 4302–4311. [Google Scholar] [CrossRef]

- Hosseinimehr, T.; Tabesh, A. Magnetic Field Energy Harvesting from AC Lines for Powering Wireless Sensor Nodes in Smart Grids. IEEE Trans. Ind. Electron. 2016, 63, 4947–4954. [Google Scholar] [CrossRef]

- Moon, J.; Leeb, S.B. Power Electronic Circuits for Magnetic Energy Harvesters. IEEE Trans. Power Electron. 2016, 31, 270–279. [Google Scholar] [CrossRef]

- Tashiro, K.; Wakiwaka, H.; Inoue, S.-I.; Uchiyama, Y. Energy Harvesting of Magnetic Power-Line Noise. IEEE Trans. Magn. 2011, 47, 4441–4444. [Google Scholar] [CrossRef]

- Lu, X.; Wang, P.; Niyato, D.; Kim, D.I.; Han, Z. Wireless Networks with RF Energy Harvesting: A Contemporary Survey. IEEE Commun. Surv. Tutor. 2014, 17, 757–789. [Google Scholar] [CrossRef]

- Talla, V.; Pellerano, S.; Xu, H.; Ravi, A.; Palaskas, Y. Wi-Fi RF energy harvesting for battery-free wearable radio platforms. In Proceedings of the 2015 IEEE International Conference on RFID (RFID), San Diego, CA, USA, 15–17 April 2015; pp. 47–54. [Google Scholar]

- Sim, Z.W. Radio Frequency Energy Harvesting for Embedded Sensor Networks in the Natural Environment. Master’s Thesis, Electrical and Electronic Engineering, The University of Manchester, Manchester, UK, 2012. [Google Scholar]

- Fadel, L.; Oyhenart, L.; Bergès, R.; Vigneras, V.; Taris, T. A concurrent 915/2440 MHz RF energy harvester. Int. J. Microw. Wirel. Technol. 2016, 8, 405–413. [Google Scholar] [CrossRef]

- Sun, M.; Abbott, D.; Al-Sarawi, S.F. A Fully Integrable RF Energy Harvester with Dynamic Efficiency Tuning. In Proceedings of the 2017 International SoC Design Conference (ISOCC 2017), Seoul, Korea, 5–8 November 2017. [Google Scholar]

- Clerckx, B.; Zhang, R.; Schober, R.; Ng, D.W.K.; Kim, D.I.; Poor, H.V. Fundamentals of Wireless Information and Power Transfer: From RF Energy Harvester Models to Signal and System Designs. IEEE J. Sel. Areas Commun. 2019, 37, 4–33. [Google Scholar] [CrossRef]

- Kuhn, V.; Lahuec, C.; Seguin, F.; Person, C. A Multi-Band Stacked RF Energy Harvester With RF-to-DC Efficiency Up to 84%. IEEE Trans. Microw. Theory Tech. 2015, 63, 1768–1778. [Google Scholar] [CrossRef]

- Wu, X.; Lee, D.-W. An electromagnetic energy harvesting device based on high efficiency windmill structure for wireless forest fire monitoring application. Sens. Actuators A Phys. 2014, 219, 73–79. [Google Scholar] [CrossRef]

- Ramasur, D.; Hancke, G.P. A wind energy harvester for low power wireless sensor networks. In Proceedings of the 2012 IEEE International Instrumentation and Measurement Technology Conference Proceedings, Graz, Austria, 13–16 May 2012; pp. 2623–2627. [Google Scholar]

- Ahmad, T.J.; Arsalan, M.; Black, M.J.; Noui-Mehidi, M.N. Harvesting Energy From Fluid Flow. U.S. Patent 2018/0351480 A1, 6 December 2018. [Google Scholar]

- Hu, G.; Tse, K.; Wei, M.; Naseer, R.; Abdelkefi, A.; Kwok, K. Experimental investigation on the efficiency of circular cylinder-based wind energy harvester with different rod-shaped attachments. Appl. Energy 2018, 226, 682–689. [Google Scholar] [CrossRef]

- Du, L.; Fang, Z.; Yan, J.; Zhao, Z. Enabling a wind energy harvester based on ZnO thin film as the building skin. Sens. Actuators A Phys. 2017, 260, 35–44. [Google Scholar] [CrossRef]

- Hoffmann, D.; Willmann, A.; Göpfert, R.; Becker, P.; Folkmer, B.; Manoli, Y. Energy Harvesting from Fluid Flow in Water Pipelines for Smart Metering Applications. J. Phys. Conf. Ser. 2013, 476, 1–5. [Google Scholar] [CrossRef]

- Hardik, P.; Sanat, D. Performance Prediction of Horizontal Axis Wind Turbine Blade. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 1401–1406. [Google Scholar]

- Shan, X.; Song, R.; Fan, M.; Xie, T. Energy-Harvesting Performances of Two Tandem Piezoelectric Energy Harvesters with Cylinders in Water. Appl. Sci. 2016, 6, 230. [Google Scholar] [CrossRef]

- Xu, F.; Yuan, F.-G.; Liu, L.; Hu, J.; Qiu, Y. Performance Prediction and Demonstration of a Miniature Horizontal Axis Wind Turbine. J. Energy Eng. 2013, 139, 143–152. [Google Scholar] [CrossRef]

- Ibrahim, B.K. Utilization of wind energy in space heating and cooling with hybrid HVAC systems and heat pumps. Energy Build. 1999, 30, 147–153. [Google Scholar]

- Heier, S. Grid Integration of Wind Energy Conversion Systems; Wiley: Hoboken, NJ, USA, 1998. [Google Scholar]

- Calderaro, V.; Galdi, V.; Piccolo, A.; Siano, P. A fuzzy controller for maximum energy extraction from variable speed wind power generation systems. Electr. Power Syst. Res. 2008, 78, 1109–1118. [Google Scholar] [CrossRef]

- Sengupta, A.; Verma, M.P. An Analytical expression for the power coefficient of an ideal horizontal-axis wind turbine. Int. J. Energy Res. 1992, 16, 453–455. [Google Scholar] [CrossRef]

- Slootweg, J.G.; Polinder, H.; Kling, W.L. Representing wind turbine electrical generating systems in fundamental frequency simulations. IEEE Trans. Energy Convers. 2003, 18, 516–524. [Google Scholar] [CrossRef]

- Borowy, B.; Salameh, Z. Optimum photovoltaic array size for a hybrid wind/PV system. IEEE Trans. Energy Convers. 1994, 9, 482–488. [Google Scholar] [CrossRef]

- Borowy, B.S.; Salameh, Z.M. Methodology for Optimally Sizing the Combination of a Battery Bank and PV Array in a Wind/PV Hybrid System. IEEE Trans. Energy Convers. 1996, 11, 367–375. [Google Scholar] [CrossRef]

- Abdulmunam, R.T.; Taha, L.; Ivey, P.C. Modeling of Low Power Electrostatic Wind Energy Harvester for Macro-Scale Applications. Int. J. Inf. Electron. Eng. 2012, 2, 912–917. [Google Scholar]

- Bhat, R. Acoustic Energy Harvesting. Int. J. Sci. Res. 2014, 3, 1354–1359. [Google Scholar]

- Park, C.M.; Lee, S.H. Propagation of acoustic waves in a metamaterial with a refractive index of near zero. Appl. Phys. Lett. 2013, 102, 1–4. [Google Scholar] [CrossRef]

- Peng, X.; Wen, Y.; Li, P.; Yang, A.; Bai, X. Enhanced Acoustoelectric Coupling in Acoustic Energy Harvester Using Dual Helmholtz Resonators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 2121–2128. [Google Scholar] [CrossRef] [PubMed]

- Phipps, A.; Liu, F.; Cattafesta, L.; Sheplak, M.; Nishida, T. Demonstration of a wireless, self-powered, electroacoustic liner system. J. Acoust. Soc. Am. 2009, 125, 873–881. [Google Scholar] [CrossRef] [PubMed]

- Khan, F.U.; Izhar. State of the art in acoustic energy harvesting. J. Micromech. Microeng. 2015, 25, 1–13. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, X.; Zhang, T.; Bano, S.; Pan, H.; Qi, L.; Zhang, Z.; Yuan, Y. A renewable low-frequency acoustic energy harvesting noise barrier for high-speed railways using a Helmholtz resonator and a PVDF film. Appl. Energy 2018, 230, 52–61. [Google Scholar] [CrossRef]

- Yuan, M.; Cao, Z.; Luo, J.; Zhang, J.; Chang, C. An efficient low-frequency acoustic energy harvester. Sens. Actuators A Phys. 2017, 264, 84–89. [Google Scholar] [CrossRef]

- Zhou, Z.; Qin, W.; Zhu, P. Harvesting acoustic energy by coherence resonance of a bi-stable piezoelectric harvester. Energy 2017, 126, 527–534. [Google Scholar] [CrossRef]

- Pozo, B. Double Smart energy Harvesting System for Self-Powered Industrial IOT. Ph.D. Thesis, University of the Basque Country, Lejona, Spain, 2018. Available online: https://www.educacion.gob.es/teseo/mostrarRef.do?ref=444036 (accessed on 20 March 2019).

| Harvester | Physical/Chemical Operation Mode | Power Density | Efficiency (%) | Mature/Emerging | References |

|---|---|---|---|---|---|

| Photovoltaic | Photovoltaic effect | Outdoors: 15 mW/cm2 Indoors: 10–100 µW/cm2 | Until 40 | Mature | [17,32,33] |

| Piezoelectric | Piezoelectric effect | 330 µW/cm3 shoes insert | Until 30 | Mature | [17,18,32] |

| Electromagnetic | Faraday’s law | Human: 4 µW/cm3 @ kHz Industrial: 306 µW/cm3 @ kHz | Until 67 | Mature | [18,33] |

| Electrostatic | Vibration-dependent capacitors | 50 µW/cm3 to 100 µW/cm3 | 9.5–23.6 | Emerging | [17] |

| Pyroelectric | Olsen cycle | 3.5 µW/cm3 at the temperature rate of 85 °C/s @ 0.11 Hz | 1–3.5 | Emerging | [32,34] |

| Thermoelectric | Seebeck effect | Human: 100 µW/cm3 Industrial: 100 mW/cm3 | 10–15 | Mature | [15,17,32] |

| Magnetic | Ampere, Maxwell, and Faraday laws | 1.8 mW/cm3 with 400 A at 4 cm from conductor | 0.1325 | Emerging | [18] |

| RF | Ubiquitous radio transmitters | GSM: 0.1 µW/cm2 WiFi: 0.01 µW/cm2 | 50–70 | Mature | [15,34] |

| Wind and water | Faraday’s law | 1.16 mW/cm3 at the speed of 5 m/s 4.91 µW/cm3 at the speed of 3 L/s | 0.61–17.6 1.7–29.5 | Emerging in small scale | [30,32,33] |

| Acoustic | Helmotz effect | 1.436 mW/cm2 at 123 dB | 0.012 | Emerging | [31] |

| Classification | Efficiency | Advantage | Disadvantage |

|---|---|---|---|

| Silicon solar cells | |||

| Mono-crystalline | 15–24% | High conversion efficiency and reliability | Expensive |

| Large silicon demand | |||

| Complexity of the production processes | |||

| Polysilicon, poly-Si | 15–20.4% | Recession cannot be manufactured on substrates | Large silicon demand |

| Its cost is lower than monocrystalline ones | Expensive and complex production process | ||

| Multi-junction solar cells | |||

| Cadmium sulphide (CdS) | Up to 16% | Low cost | Recycling of toxic admium |

| Suitable for mass production | |||

| Cadmiun telluride (CdTe) | 28% | Absorption rate under strong light | Uses tellurium a scarce natural resource |

| High conversion efficiency | Expensive process | ||

| Stable performance | Recycling of toxic cadmium | ||

| Gallium arsenide (GaAs) | Up to 30% | Absorption coefficient under strong light | Expensive process |

| High conversion efficiency | |||

| Endurance to high temperature | |||

| Copper indium gallium selenide (CIGS) | Up to 20% | Low cost | Require rare earths |

| Good performance under dimmed light | |||

| Able to be deposit on a wide range of substrates | |||

| Adjustable optical band gap | |||

| Piezoelectric Devices | Electromagnetic Devices | Electrostatic Devices | |

|---|---|---|---|

| Advantages |

|

|

|

| Disadvantages |

|

|

|

| Property | Quartz | PZT-5H | PZT-5A | BaTiO3 | PVDF |

|---|---|---|---|---|---|

| Material type | Single crystal | Piezoceramic | Piezoceramic | Piezoceramic | Polymer |

| d33 (1012 C/N) | −2.3 (d11) | 593 | 374 | 149 | −33 |

| d31 (1012 C/N) | −0.93 (d12) | −274 | −171 | 78 | 23 |

| g33 (103 Vm/N) | −58 | 19.7 | 24.8 | 14.1 | 330 |

| g31 (103 Vm/N) | - | −9.1 | −11.4 | 5 | 216 |

| k33 | 0.07 | 0.75 | 0.71 | 0.48 | 0.15 |

| k31 | - | 0.39 | 0.31 | 0.21 | 0.12 |

| Relative permittivity(ε/ε0) | 4.4 | 3400 | 1700 | 1700 | 12 |

| Curie temperature (°C) | 573 | 195 | 365 | 120 | ~150 |

| Material | (BH)MAX (kJ/m3) | Flux Density (mT) | Max. Work. Temp. (°C) | Curie Temp. (°C) | Density (kg/m3) |

|---|---|---|---|---|---|

| Ceramic | 26 | 100 | 250 | 460 | 4980 |

| Alnico | 42 | 130 | 550 | 860 | 7200 |

| SmCo (2:17) | 208 | 350 | 300 | 750 | 8400 |

| NdFeB(N38H) | 306 | 450 | 120 | 320 | 7470 |

| Material | ρ (Ω·m) at 20 °C | σ (S/m) at 20 °C | Material | ρ (Ω·m) at 20 °C | σ (S/m) at 20 °C |

|---|---|---|---|---|---|

| Silver | 1.59 × 10−8 | 6.30 × 107 | Tungsten | 5.60 × 10−8 | 1.79 × 107 |

| Copper | 1.68 × 10−8 | 5.96 × 107 | Zinc | 5.90 × 10−8 | 1.69 × 107 |

| Annealed copper | 1.72 × 10−8 | 5.80 × 107 | Nickel | 6.99 × 10−8 | 1.43 × 107 |

| Gold | 2.44 × 10−8 | 4.10 × 107 | Lithium | 9.28 × 10−8 | 1.08 × 107 |

| Aluminium | 2.65 × 10−8 | 3.77 × 107 | Iron | 9.71 × 10−8 | 1.00 × 107 |

| Calcium | 3.36 × 10−8 | 2.98 × 107 | Tungsten | 5.60 × 10−8 | 1.79 × 107 |

| Structure | Charge Constrained | Voltage Constrained |

|---|---|---|

| Out of plane gap varying | Fe constant | Fe ~1/x |

| In-plane overlap varying | Fe ~1/x2 | Fe constant |

| In-plane gap varying | Fe ~x | Fe ~1/x2 |

| Material | Relative Permeability (µr) | Material | Relative Permeability (µr) |

|---|---|---|---|

| Cobalt | 250 | Permalloy | 100,000 |

| Nickel | 600 | Fe3O4 (Magnetite) | 100 |

| Iron | 6000 | Ferrites | 5000 |

| Supermalloy | 107 | Mumetal | 100,000 |

| Steel | 100 | Permendur | 5000 |

| Silicon iron | 7000 | - | - |

| Harvester | Power Density (µW/cm3) | Harvester | Power Density (µW/cm3) | ||

|---|---|---|---|---|---|

| 21.2 µT | 200 µT | 21.2 µT | 200 µT | ||

| Coil 1 | 0.81 | 71 | Coil 3 | 0.08 | 7.6 |

| Coil 2 | 1.47 | 130 | Coil 4 | 0.21 | 18 |

| Source | Source Power (W) | Frequency (MHz) | Distance (m) | Power Harvested Rate (μW) |

|---|---|---|---|---|

| Isotropic RF trans. | 4 | 902–928 | 15 | 5.5 |

| Isotropic RF trans. | 1.78 | 868 | 25 | 2.3 |

| Isotropic RF trans. | 1.78 | 868 | 27 | 2 |

| TX91501 power trans. | 3 | 915 | 5 | 189 |

| TX91501 power trans. | 3 | 915 | 11 | 1 |

| KING-TV tower | 960,000 | 674–680 | 4100 | 60 |

| Ref. | Type | Wind Velocity (m/s) | Generated Power (mW) |

|---|---|---|---|

| [110] | Electrostatic | 10 | 4.761 |

| [29] | Turbine-Electromagnetic | 10 | 4.3 |

| [94] | Electromagnetic | 5 | 13.5 |

| [95] | Electromagnetic | 7 | 70 |

| Turbine | P (mW) | V (m/s) | A (cm3) | η (%) | P/V (mV/cm3) |

|---|---|---|---|---|---|

| Pelton 2.2 mm | 42 | 1 | 76 | 22.6 | 0.55 |

| 287 | 3 | 26.5 | 3.78 | ||

| 663 | 5 | 29.5 | 8.72 | ||

| Pelton 3.2 mm | 92 | 1 | 76 | 24.5 | 1.21 |

| 500 | 3 | 26.5 | 6.58 | ||

| 1125 | 5 | 28.4 | 14.80 | ||

| Small Pelton | 4.4 | 1 | 7 | 1.7 | 0.63 |

| 194 | 3 | 14.1 | 27.71 | ||

| 491 | 5 | 17.0 | 70.14 | ||

| Three-bladed propeller | 118 | 0.5 | 135 | 5.0 | 0.87 |

| 340 | 1 | 5.5 | 2.52 | ||

| 592 | 1.5 | 5.5 | 4.39 | ||

| Four-bladed propeller | 105 | 0.5 | 135 | 4.4 | 0.78 |

| 265 | 1 | 4.3 | 1.96 | ||

| 462 | 2 | 4.3 | 3.42 |

| Sound Source | Sound Intensity (dB) | P (µW) |

|---|---|---|

| Mess Kitchen | 60 | 1.476 |

| Child Shouting | 76 | 4.600 |

| Mechanical | 88 | 7.280 |

| Group of people | 90 | 10.540 |

| Motorbike | 92 | 14.040 |

| Tractor | 102 | 23.000 |

| Car horn | 109 | 35.960 |

| Truck horn | 128 | 98.700 |

| Type | Device Dimensions (mm) | Sound Pressure Level (SPL) (dB) | F (kHz) | R (Ω) | P (µW) | |||

|---|---|---|---|---|---|---|---|---|

| Neck | Cavity | |||||||

| Diameter | Height | Diameter | Height | |||||

| Piezoelectric | 2.39 | 3.18 | 6.35 | 16.1 | 149 | 13.57 | 1000 | 6 × 10−6 |

| Piezoelectric | 2.39 | 3.18 | 6.35 | 16.1 | 100 | 24 | 550 | 11 × 10−6 |

| Piezoelectric | 2.42 | 3.16 | 6.34 | 16.4 | 161 | 2.64 | 20,000 | 30 × 103 |

| Piezoelectric | 0.1 | 0.18 | 1.2 | 1.02 | 100 | 3.5 | 1000 | 1.69 × 10−3 |

| Electrodynamic | 2.5 | 4 | 6.5 | 16 | 125 | 0.143 | 66 | 1503.4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pozo, B.; Garate, J.I.; Araujo, J.Á.; Ferreiro, S. Energy Harvesting Technologies and Equivalent Electronic Structural Models—Review. Electronics 2019, 8, 486. https://doi.org/10.3390/electronics8050486

Pozo B, Garate JI, Araujo JÁ, Ferreiro S. Energy Harvesting Technologies and Equivalent Electronic Structural Models—Review. Electronics. 2019; 8(5):486. https://doi.org/10.3390/electronics8050486

Chicago/Turabian StylePozo, Borja, José Ignacio Garate, José Ángel Araujo, and Susana Ferreiro. 2019. "Energy Harvesting Technologies and Equivalent Electronic Structural Models—Review" Electronics 8, no. 5: 486. https://doi.org/10.3390/electronics8050486

APA StylePozo, B., Garate, J. I., Araujo, J. Á., & Ferreiro, S. (2019). Energy Harvesting Technologies and Equivalent Electronic Structural Models—Review. Electronics, 8(5), 486. https://doi.org/10.3390/electronics8050486