Development and Implementation of a Low Cost μC- Based Brushless DC Motor Sensorless Controller: A Practical Analysis of Hardware and Software Aspects

Abstract

1. Introduction

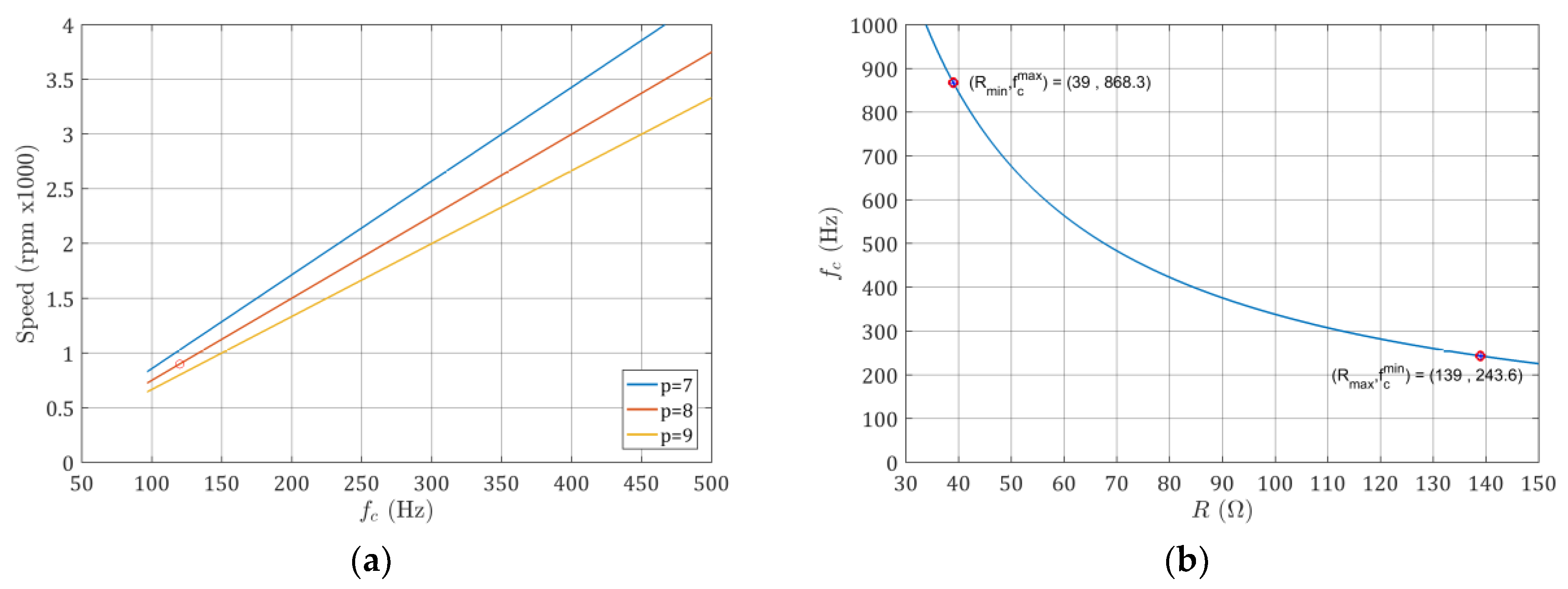

2. Problem Statement and Methods Used

2.1. Brief Theoretical Background of BLDCM Operation

2.2. Zero-Crossing Points (ZCP) Detection Technique

2.3. Sensorless Method with back EMF Difference Calculation

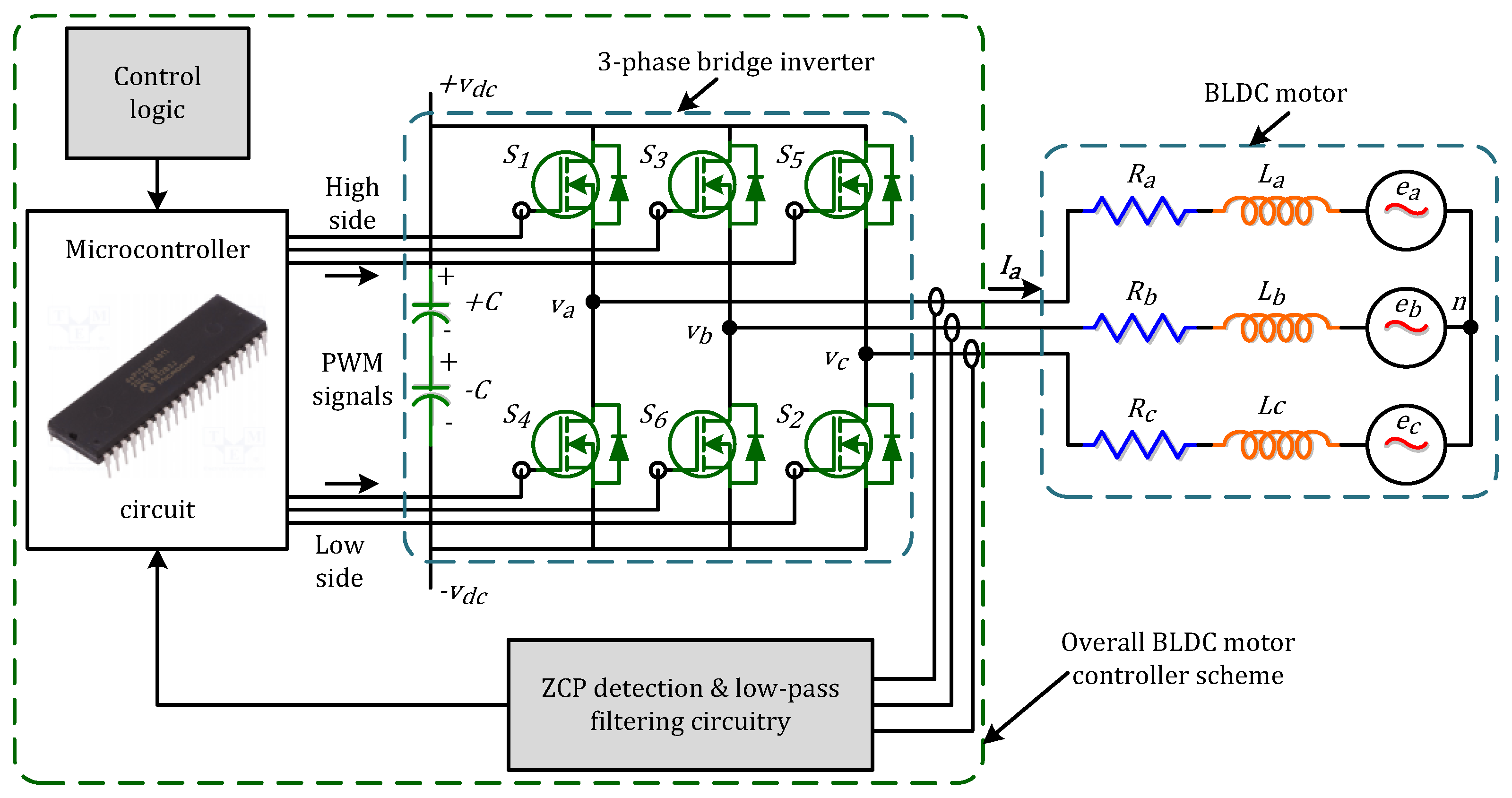

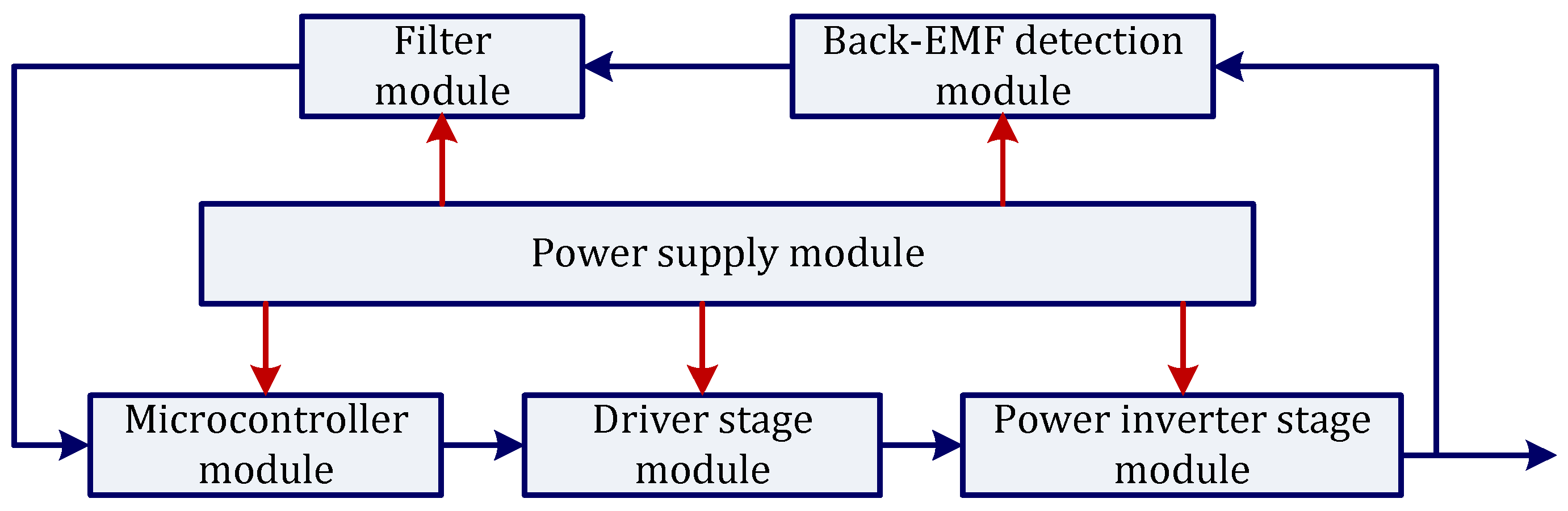

3. BLDC Motor Controller Theoretical Analysis and Design

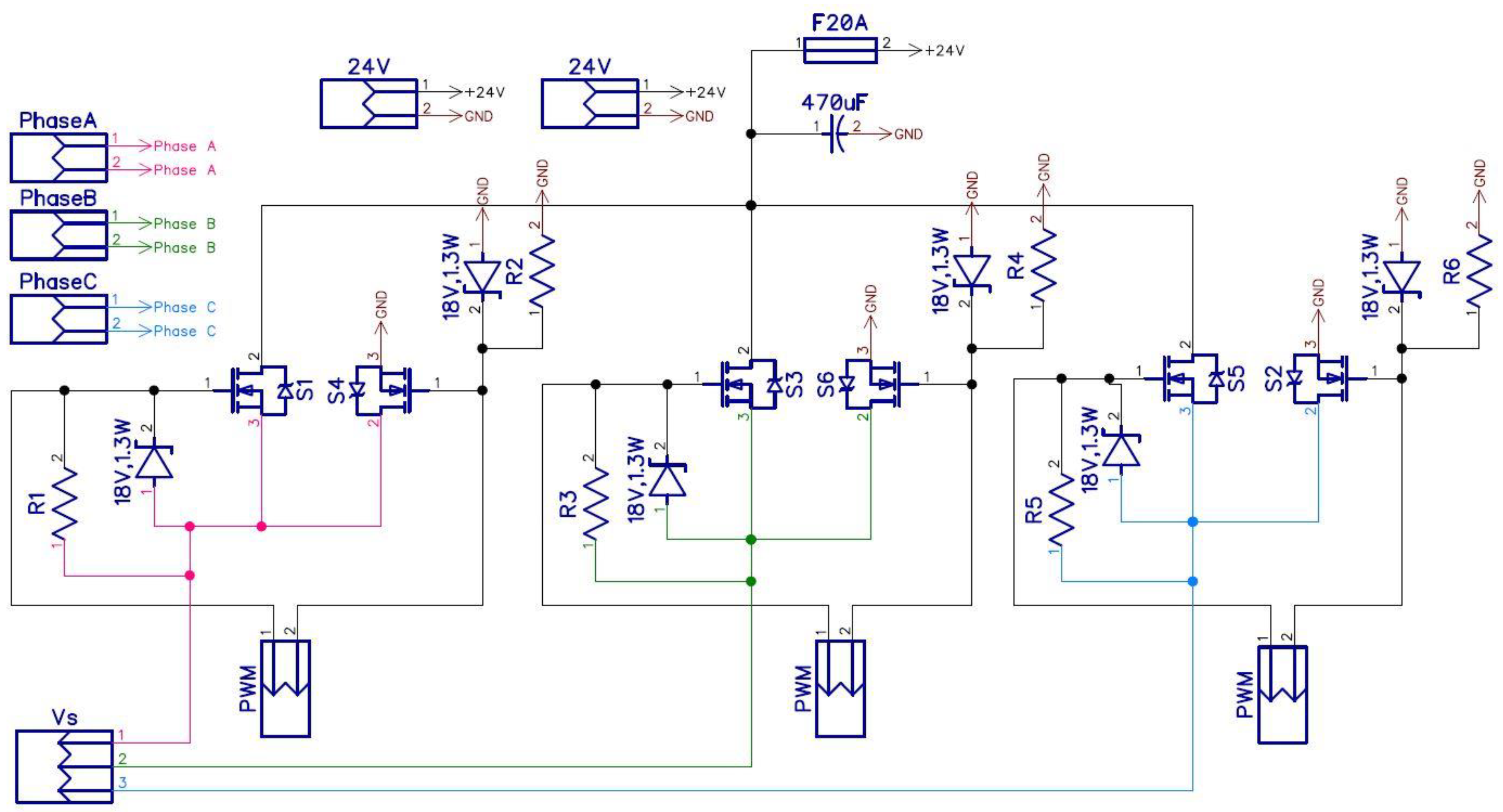

3.1. Power Inverter Stage Module

3.1.1. Selection of MOSFETs

- The voltage drop during the conduction and their conduction resistance determine the conduction losses of the element.

- Switching times (on, off and transition times) determine the switching losses and set the switching frequency limits.

- Current and voltage values determine the power required to be handled by the switching elements.

- The cooling requirements, that is, the temperature coefficient of the conduction resistance of the element.

- Cost is also an important factor when selecting items.

3.1.2. Cooling Considerations and Heatsink Calculations

3.1.3. DC Bus Capacitor (Inverter Input)

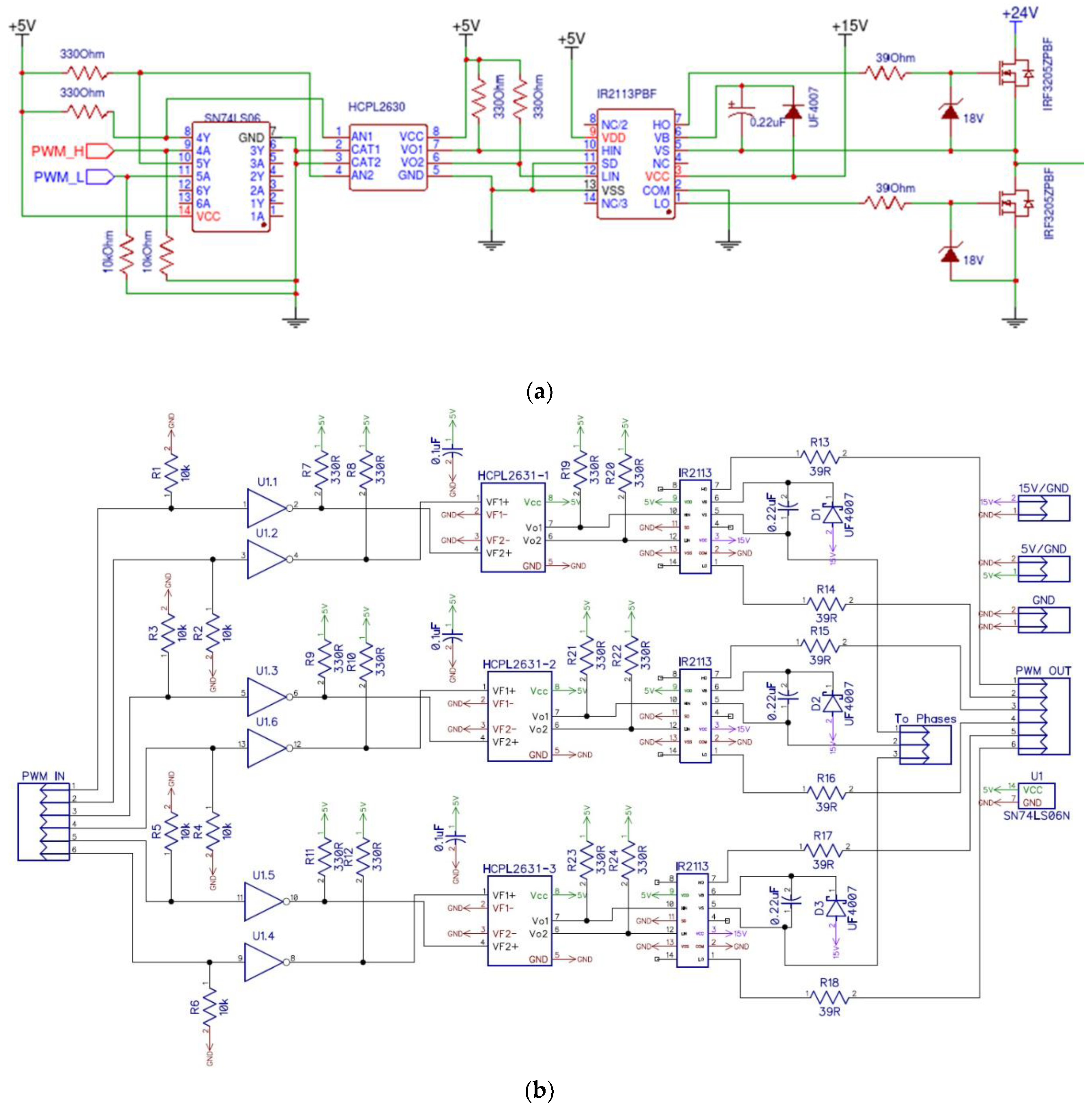

3.2. Driver Stage Module

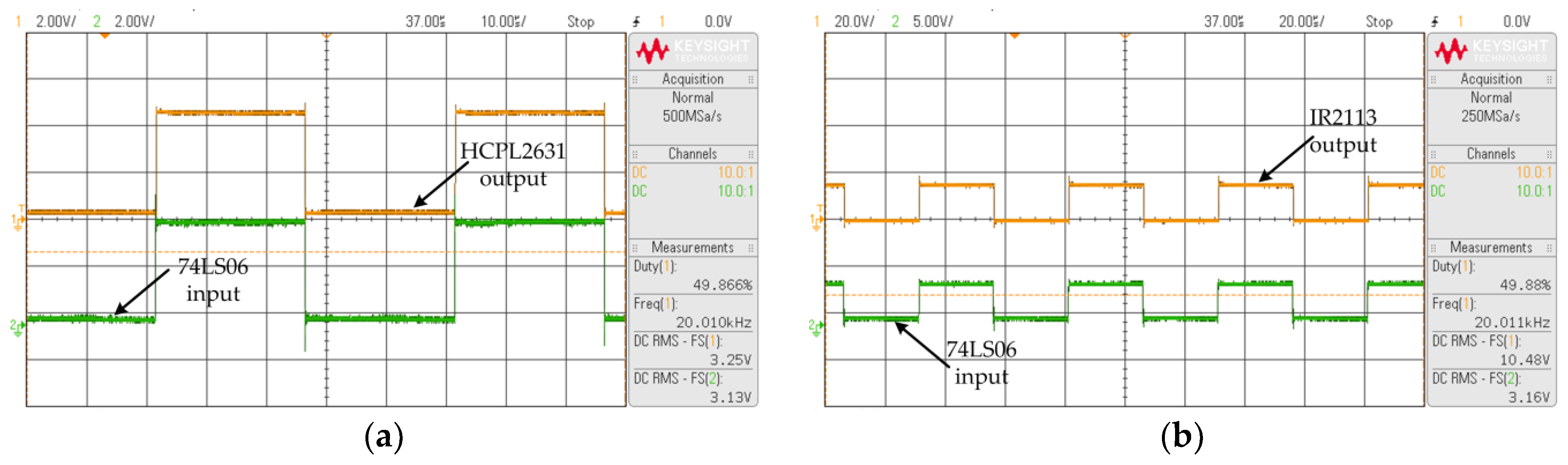

3.2.1. Pulse Amplification and Galvanic Isolation

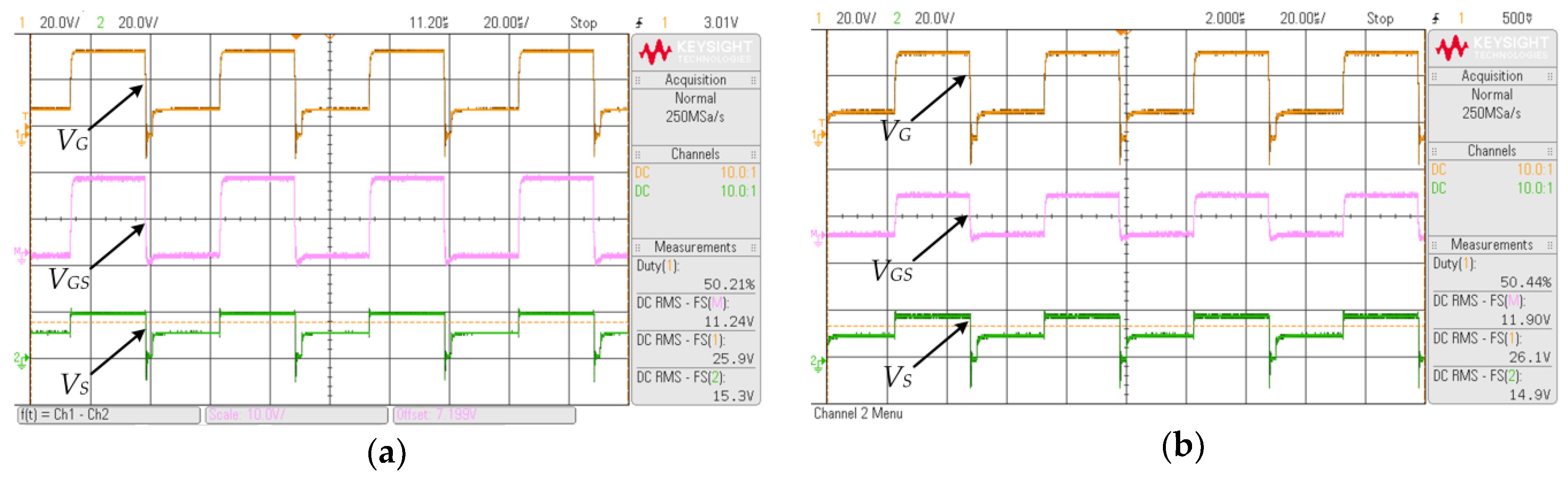

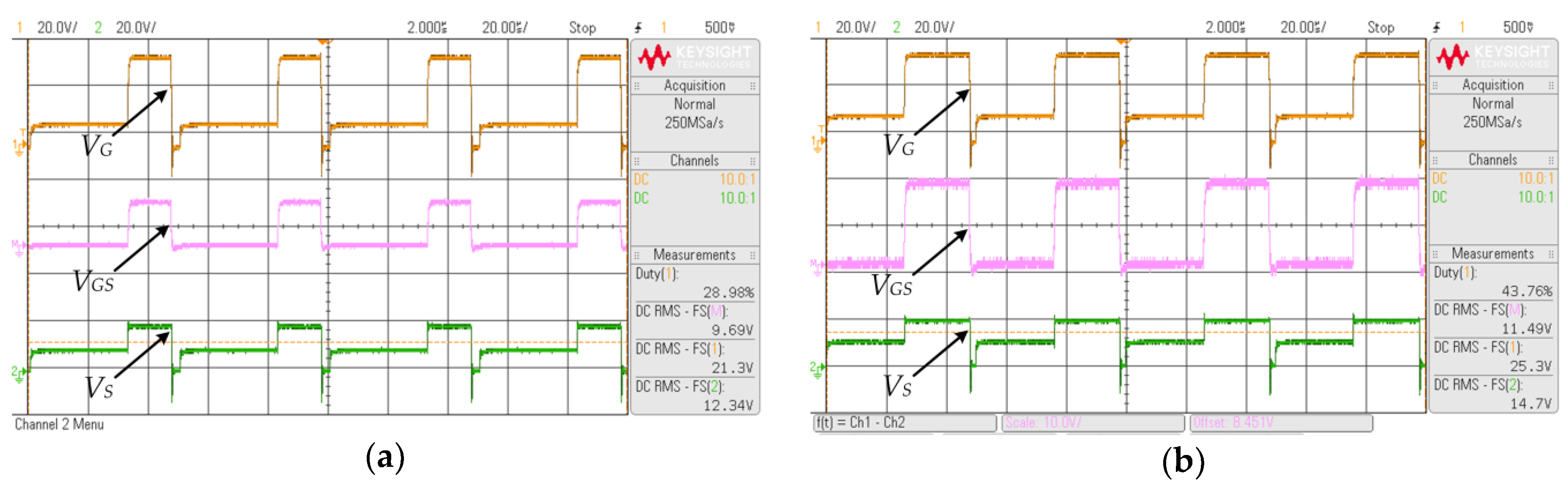

3.2.2. MOSFET Gate Driving and Bootstrap Circuit

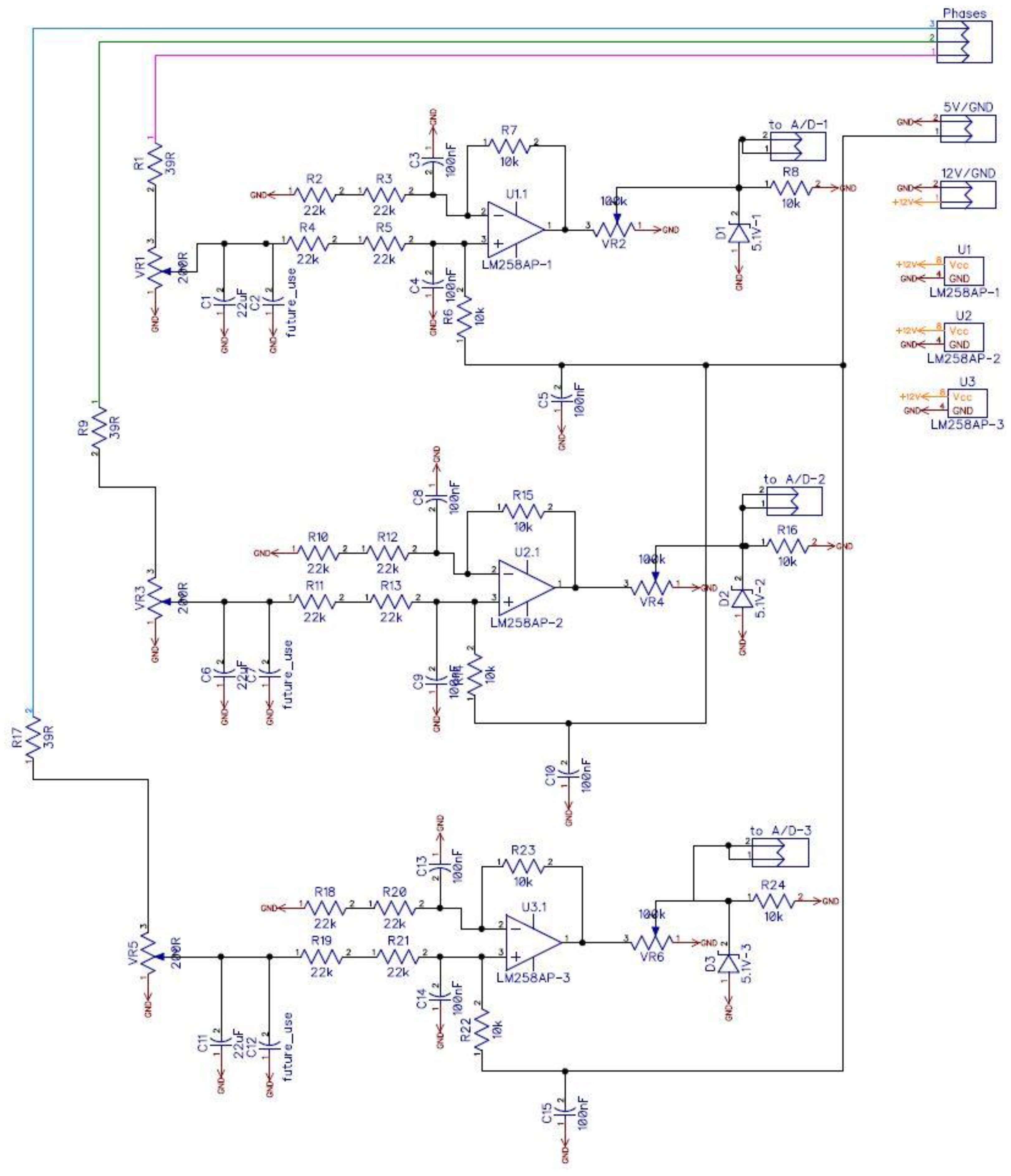

3.3. Back-EMF Measurement & Low Pass Filtering Modules

3.3.1. Back-EMF Measurement

3.3.2. Low Pass Filter

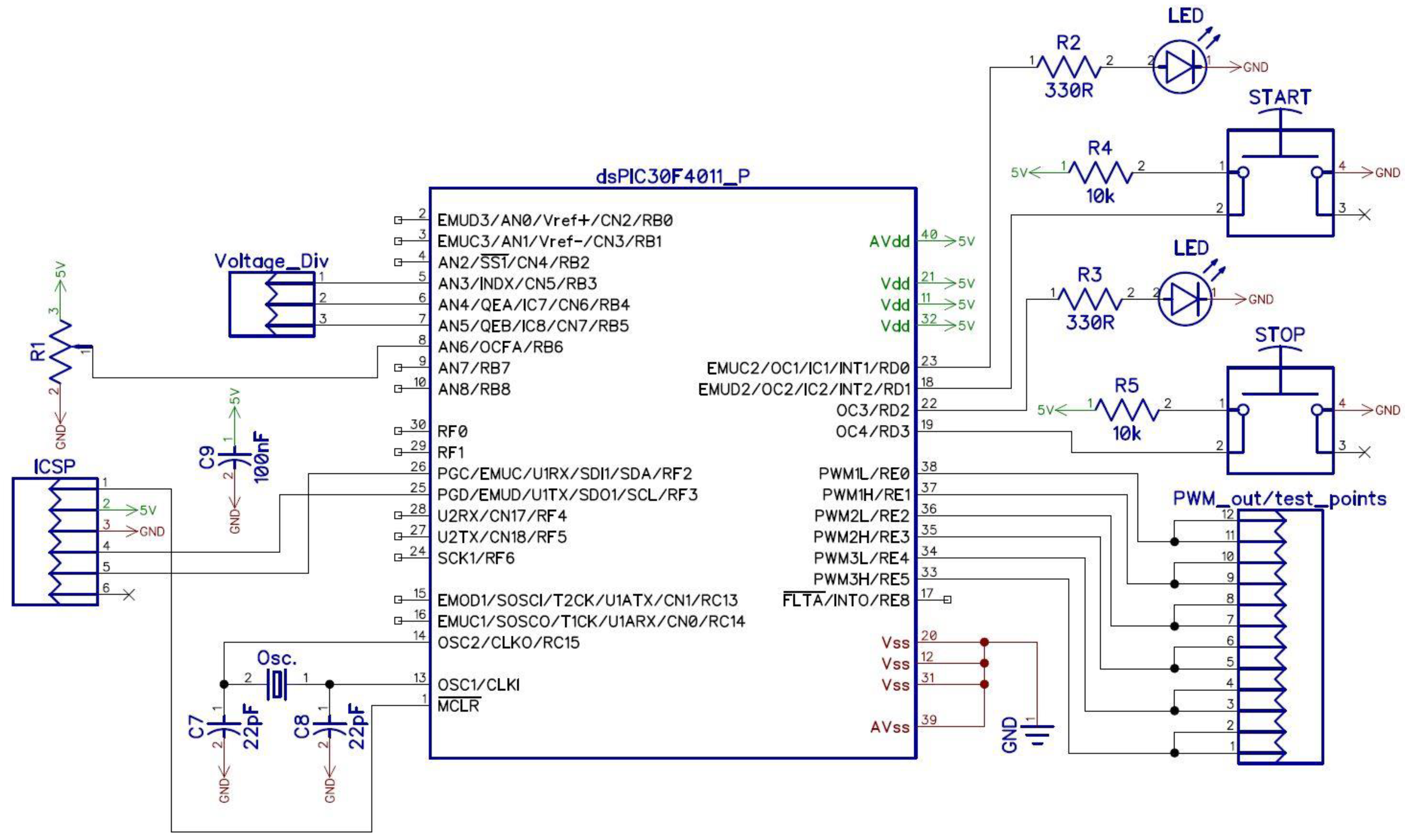

3.4. Microcontroller Module

- It is well suited for control applications of motors since it provides three independent PWM output pairs allowing the control of three-phase and single-phase inverters.

- It can process and execute complex digital signal calculations very quickly as required for BLDCM control.

- It is manufactured in DIP package and therefore it is suitable for prototyping and breadboard use.

- It can operate in a wide range of power supply (2.5–5.5 V).

- It can withstand wrong voltage levels that by mistake may be applied to its terminals without being damaged.

- It can be found in the market easily and is generally cheap.

- Its development program (MPLAB and compiler) is available free of charge from the manufacturer.

- It is equipped with enough I/O ports for interconnecting peripherals.

- It has nine analogue input channels available, of 10-bit resolution.

3.5. Power Supply Module

3.6. Supplementary Passive Components Used

- Pull-up resistors (330 Ω) were installed between the power supply of the hex-inverter and its outputs, in order to limit the input current to the capacitors below 20 mA and to enable the circuit to supply the input of the next connected element with the output of the hex inverter as long as the transistor of the latter is in cut-off mode. This is because the specific chip’s (SN74LS06) gates are operating through an embedded open-collector transistor.

- Pull-down resistors (10 kΩ) were added between the inputs of the hex inverter and the ground. That is necessary, in case any of the terminals found unconnected for any reason, then its output would be in zero state, otherwise we may face unwanted MOSFET firing or simultaneous firing of MOSFETs of the same leg, which would lead to controller failure.

- Between the outputs of the opto-couplers and the 5 V power supply, 330 Ω (pull-up) resistors were also installed to limit their embedded photo-transistor’s collector current and to enable the circuit to supply properly the next module stage.

- In every module, in order to reduce noise in the power lines, ceramic capacitors of 100 nF were connected so that high frequency currents would flow through them and not the power lines.

- In order to set the desired motor speed i.e., changing the PWM duty cycle, a 5 V/10 kΩ slider potentiometer was used.

4. Developed Control Strategy and Relevant Software

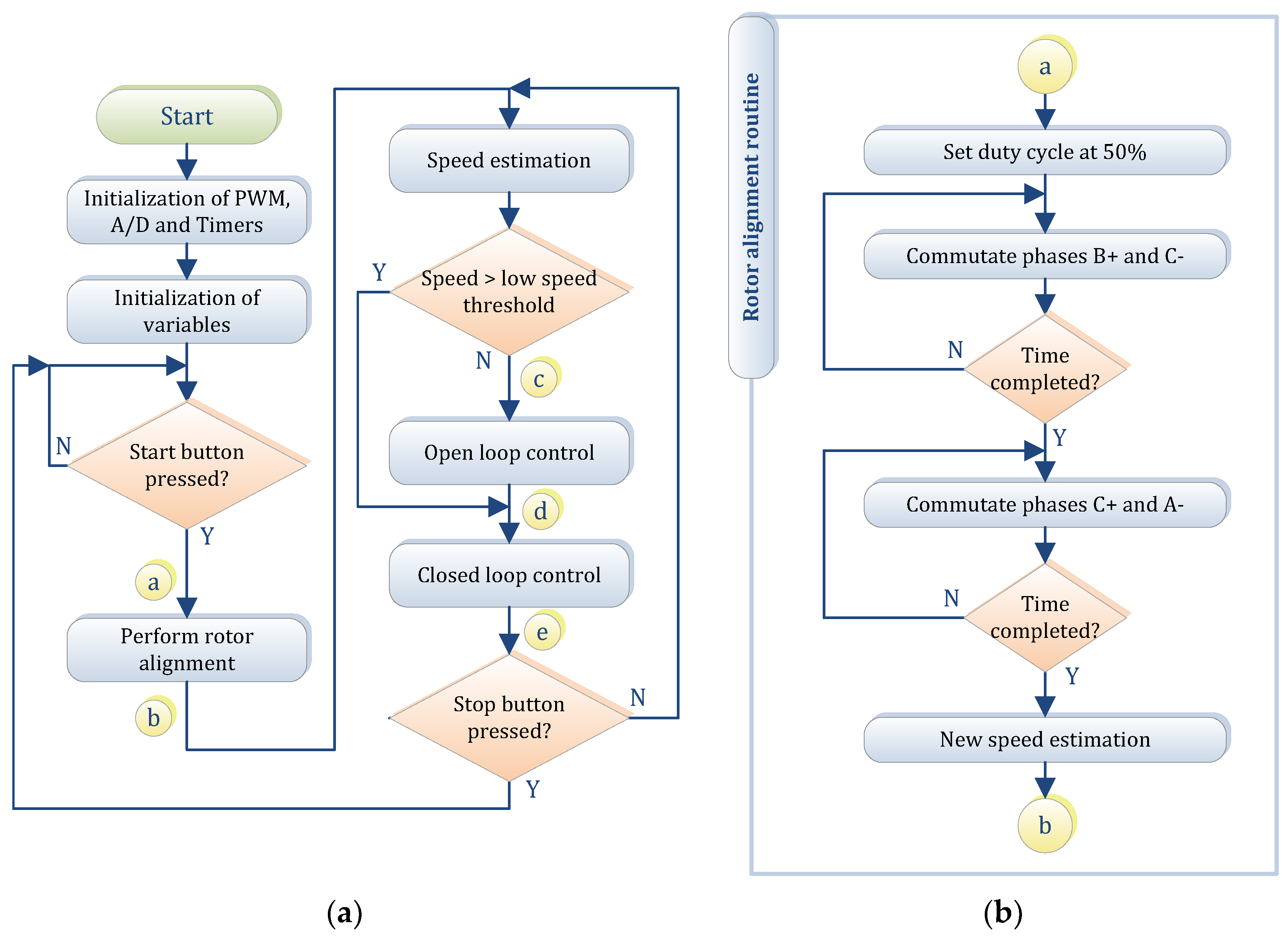

4.1. Control Philosophy

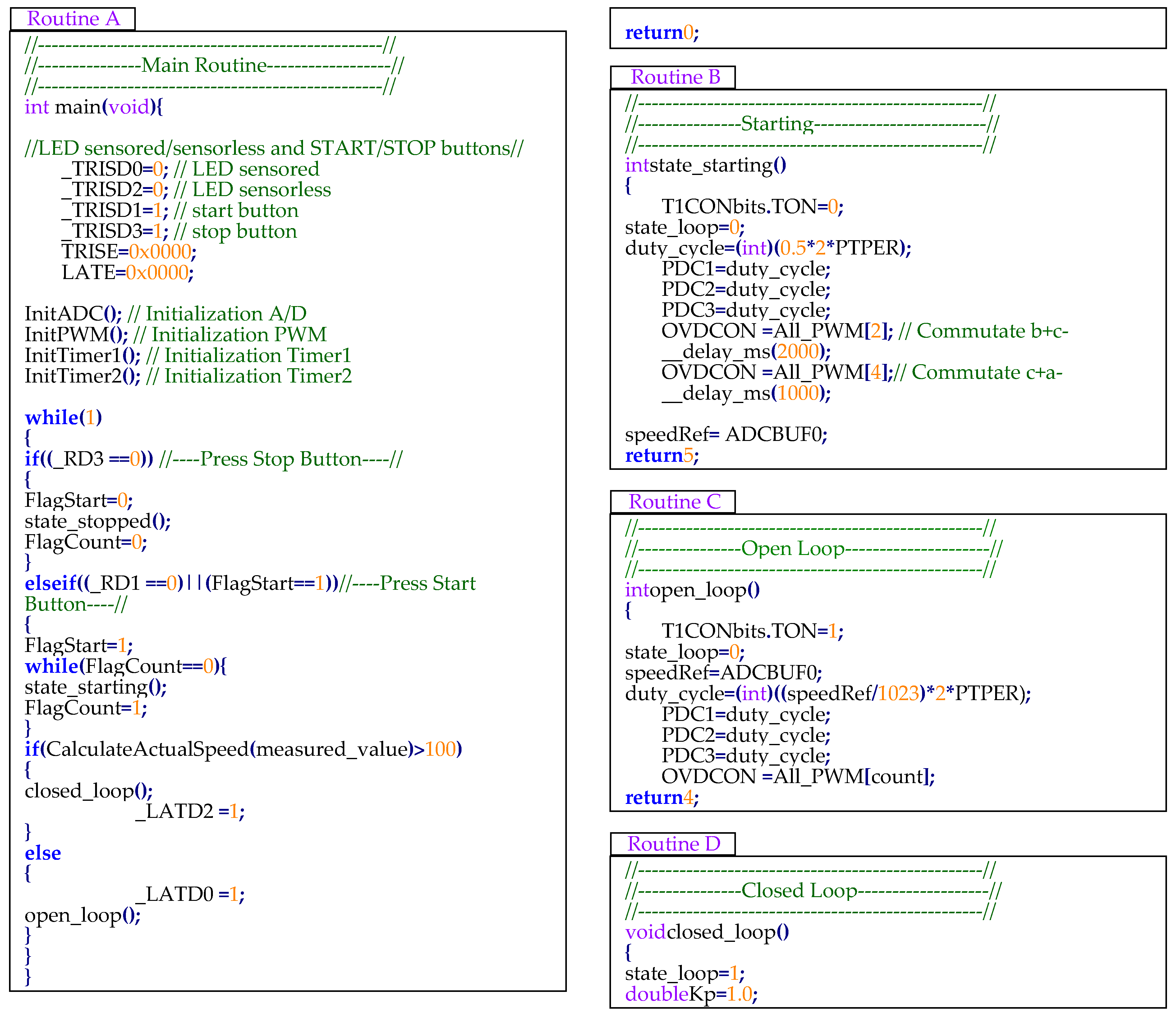

4.2. Main Routine

4.3. Rotor Alignment Routine

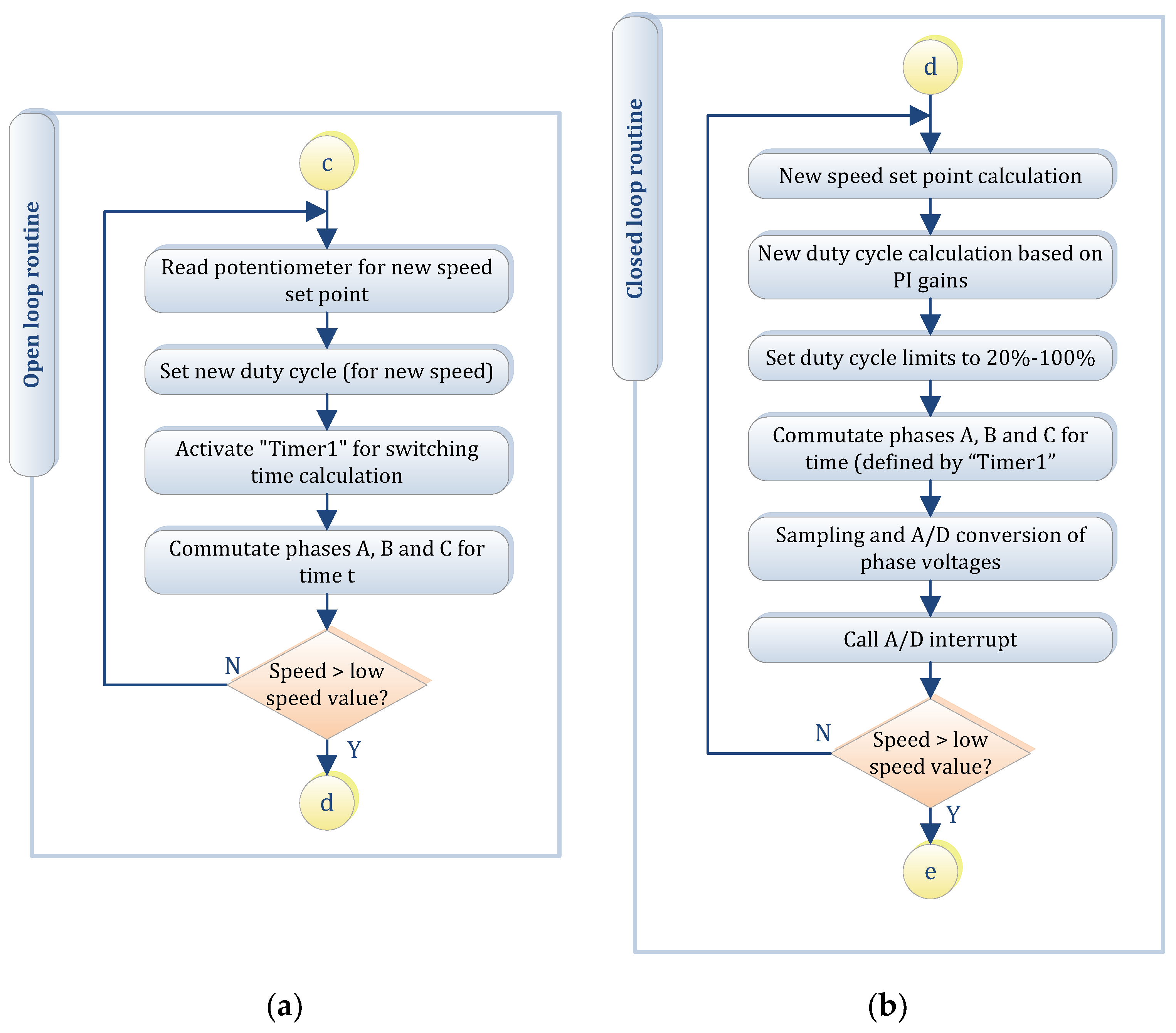

4.4. Control Loops Routines

4.4.1. Open Loop

4.4.2. Closed Loop

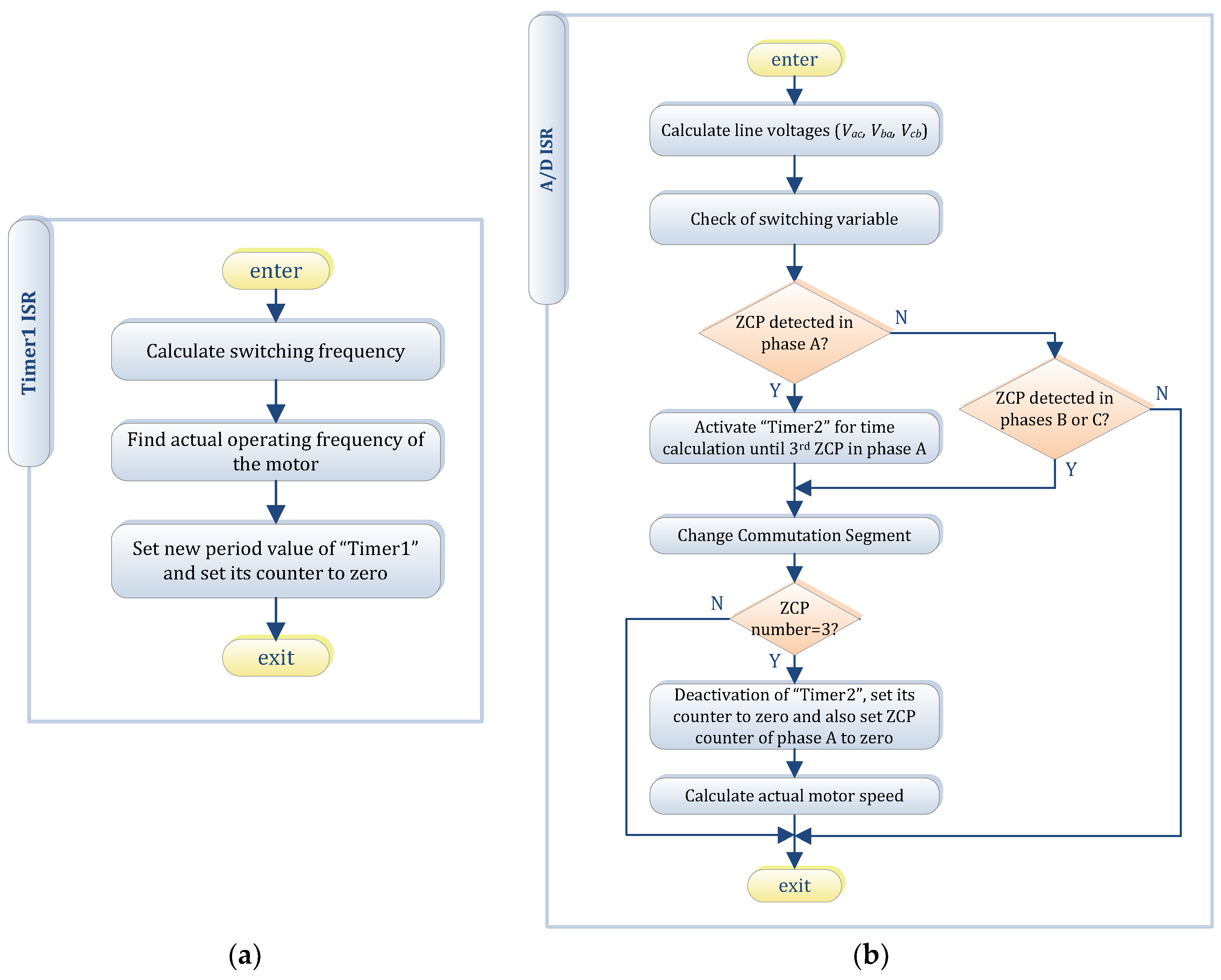

4.5. Interrupt Services Routines

5. Experimental Prototype’s Indicative Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

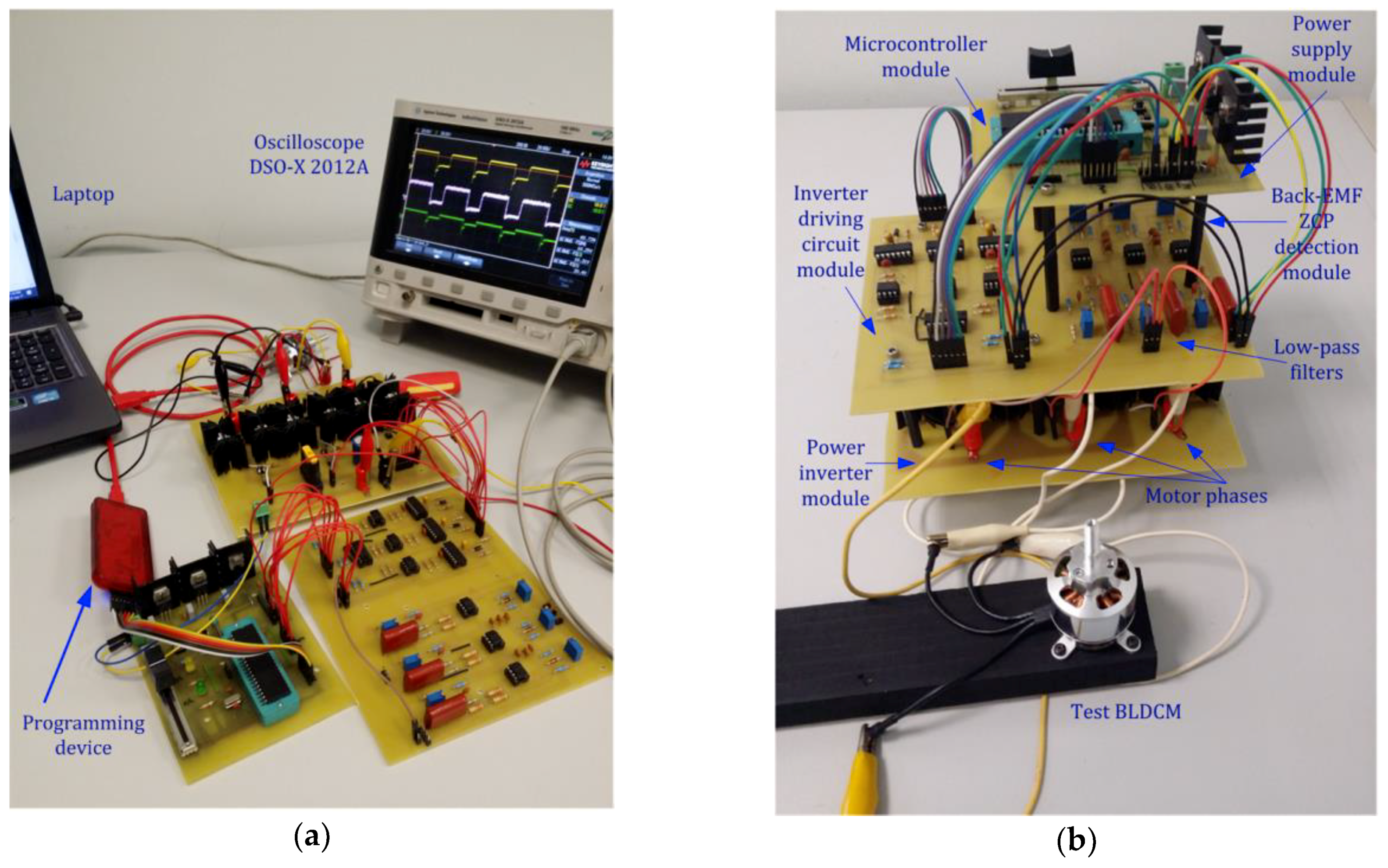

Appendix A. Prototype Modules Photos and Experimental Set-Up Description

Appendix B. C Language Software Code Developed and Loaded to dsPIC30F4011 Microcontroller

References

- Krishnan, A.R. Electric Motor Drives: Modeling, Analysis, and Control, 1st ed.; Prentice Hall Inc.: New Jersey, NJ, USA, 2001. [Google Scholar]

- Hanselman, D.C. Brushless Permanent-Magnet Motor Design, 2nd ed.; Magna Physics Publishing: Ohio, OH, USA, 2003. [Google Scholar]

- Gieras, J.F. Permanent Magnet Motor Technology, Design and Applications, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Gupta, N.; Mohan, M.; Pandey, A.K. A review: Sensorless control of brushless DC motor. Int. J. Eng. Res. Technol. 2012, 1, 1–6. [Google Scholar]

- Lee, W.J.; Sul, S.K. A new starting method of BLDC motors without position sensor. IEEE Trans. Ind. Appl. 2006, 42, 1532–1538. [Google Scholar] [CrossRef]

- Vasudevan, K.; Damodharan, P. Sensorless brushless DC motor drive based on the zero-crossing detection of back electromotive force (EMF) from the line voltage difference. IEEE Trans. Energy Convers. 2010, 25, 661–668. [Google Scholar]

- Gao, Y.; Liu, Y. Research of sensorless controller of BLDC motor. In Proceedings of the IEEE 10th International Conference on Industrial Informatics (INDIN), Beijing, China, 25–27 July 2012. [Google Scholar]

- Shao, J.; Nolan, D.; Hopkins, T. Improved direct back EMF detection for sensorless brushless DC (BLDC) motor drives. In Proceedings of the 18th Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Miami, FL, USA, 9–13 February 2003; Volume 1. [Google Scholar]

- Tong, C.; Wang, M.; Zhao, B.; Yin, Z.; Zheng, P. A novel sensorless control strategy for brushless direct current motor based on the estimation of line back electro-motive force. Energies 2017, 10, 1384. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Ede, J.D.; Howe, D. Design criteria for brushless dc motors for high-speed sensorless operation. Int. J. Appl. Electromagn. Mech. 2001, 15, 79–87. [Google Scholar] [CrossRef]

- Merin, J.; Vinu, T. Position sensorless control of BLDC motor based on back EMF difference estimation method. In Proceedings of the International Conference on Power and Energy Systems Conference: Towards Sustainable Energy (PESTSE), Bangalore, India, 13–15 March 2014. [Google Scholar]

- Chen, C.H.; Cheng, M.Y. A new cost effective sensorless commutation method for brushless DC motors without phase shift circuit and neutral voltage. IEEE Trans. Power Electron. 2007, 22, 644–653. [Google Scholar] [CrossRef]

- Niasar, A.H.; Moghbeli, H.; Kashani, E.B. A low-cost sensorless BLDC motor drive using one-cycle current control strategy. In Proceedings of the 22nd Iranian Conference on Electrical Engineering (ICEE), Tehran, Iran, 20–22 May 2014. [Google Scholar]

- Park, J.S.; Lee, K.-D.; Lee, S.G.; Kim, W.-H. Unbalanced ZCP compensation method for position sensorless BLDC Motor. IEEE Trans. Power Electron. 2018, 34, 3020–3024. [Google Scholar] [CrossRef]

- Chang, P.I.-T.; Lin, X.-Y.; Yu, I.-J. Sensorless BLDC motor sliding mode controller design for interference recovery. In Proceedings of the 6th International Conference on Control, Decision and Information Technologies (CoDIT), Paris, France, 23–26 April 2019. [Google Scholar]

- Krishnan, R.; Ghosh, R. Starting algorithm and performance of a PM DC brushless motor drive system with no position sensor. In Proceedings of the 20th IEEE Power Electronics Specialists Conference (PESC), Milwaukee, WI, USA, 26–29 June 1989; pp. 815–821. [Google Scholar]

- Zhou, X.; Chen, X.; Peng, C.; Zhou, Y. High performance non-salient sensorless BLDC motor control strategy from standstill to high speed. IEEE Trans. Ind.Inf. 2018, 14, 4365–4375. [Google Scholar] [CrossRef]

- Ziaeinejad, S.; Sangsefidi, Y.; Shoulaie, A. Analysis of commutation torque ripple of BLDC motors and a simple method for its reduction. In Proceedings of the 2011 International Conference on Electrical Engineering and Informatics (ICEEI), Bandung, Indonesia, 17–19 July 2011. [Google Scholar]

- Devendra, P.; Kalyan, P.; Mary, K.A.; Ch, S.B. Simulation approach for torque ripple minimization of BLDC motor using direct torque control. Int. J. Adv. Res. Electr. Electron. Instrum. Eng. 2013, 7, 3703–3710. [Google Scholar]

- Lu, H.; Zhang, L.; Qu, W. A new torque control method for torque ripple minimization of BLDC motors with un-ideal back EMF. IEEE Trans. Power Electr. 2008, 23, 750–758. [Google Scholar] [CrossRef]

- Chowdhury, D.; Chattopadhyay, M.; Roy, P. Modelling and simulation of cost effective sensorless drive for brushless DC motor. In Proceedings of the International Conference on Computational Intelligence: Modelling, Techniques and Applications (CIMTA), Kalyani, India, 27–28 September 2013; pp. 279–287. [Google Scholar]

- Kamalapathi, K.; Priyadarshi, N.; Padmanaban, S.; Holm-Nielsen, J.B.; Azam, F.; Umayal, C.; Ramachandaramurthy, V.K. A Hybrid Moth-Flame Fuzzy Logic Controller Based Integrated Cuk Converter Fed Brushless DC Motor for Power Factor Correction. Electronics 2018, 7, 288. [Google Scholar] [CrossRef]

- Jamshidi, J.; Tohidi, H. Sensorless control strategy for brushless DC motor drives based on sliding mode observer. Int. J. Comput. Sci. Netw. Secur. 2016, 16, 43–48. [Google Scholar]

- Sathyan, A.; Milivojevic, N.; Lee, Y.J.; Krishnamurthy, M.; Emadi, A. An FPGA-based novel digital PWM control scheme for BLDC motor drives. IEEE Trans. Ind. Electr. 2007, 56, 3040–3047. [Google Scholar] [CrossRef]

- Karnavas, Y.L.; Topalidis, A.S.; Drakaki, M. Development of a low cost brushless DC motor sensorless controller using dsPIC30F4011. In Proceedings of the 7th International Conference on Modern Circuits and Systems Technologies (MOCAST), Thessaloniki, Greece, 7–9 May 2018; pp. 1–4. [Google Scholar]

- Lee, B.K.; Kim, T.H.; Ehsani, M. On the feasibility of four-switch three-phase BLDC motor drives for low cost commercial applications: Topology and control. IEEE Trans. Power Electr. 2003, 18, 164–172. [Google Scholar]

- Gamazo-Real, J.C.; Vázquez-Sánchez, E.; Gómez-Gil, J. Position and speed control of brushless DC motors using sensorless techniques and application trends. Sensors 2010, 10, 6901–6947. [Google Scholar] [CrossRef]

- Damodharan, P.; Sandeep, R.; Vasudevan, K. Simple position sensorless starting method for brushless DC motor. IET Electr. Power Appl. 2008, 2, 49–55. [Google Scholar] [CrossRef]

- Astik, M.B.; Bhatt, P.; Bhalja, B.R. Analysis of sensorless control of brushless DC motor using unknown input observer with different gains. J. Electr. Eng. 2017, 68, 99–108. [Google Scholar] [CrossRef]

- Graovac, D.; Purschel, M.; Kiep, A. MOSFET power losses calculation using the datasheet parameters. Application Note, Infineon Technologies AG, ver 1.1, July 2006. Available online: http://application-notes.digchip.com/070/70-41484.pdf (accessed on 25 May 2019).

- Kahrimanovic, E. Power Loss and Optimized MOSFET Selection in BLDC Motor Inverter Designs; White paper; Infineon Technologies AG: Neubiberg, Germany, 2016; pp. 1–31. [Google Scholar]

- Fairchild Semiconductor Corporation. Design and application guide of bootstrap circuit for high-voltage gate-drive IC. Application Note, no. AN-6076, revision date 18 December 2014. Available online: https://www.onsemi.com/pub/Collateral/AN-6076.pdf (accessed on 25 May 2019).

- Salcone, Μ.; Bond, J. Selecting film bus link capacitors for high performance inverter applications. In Proceedings of the IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 3–6 May 2009. [Google Scholar]

- Furst, F. Design of a 48 V three-phase inverter for automotive applications. Master’s Thesis, Department of Energy and Environment, Chalmers University of Technology, Gothenburg, Sweden, 2015. [Google Scholar]

- Zheng, S. TPA31xxDx Bootstrap Circuit. Application Report No. SLOA259, Texas Instruments, Dallas, Texas, November 2017. Available online: https://www.ti.com/ (accessed on 25 May 2019).

- Diallo, M. Bootstrap Circuitry Selection for Half-bridge Configurations. Application Report No. SLUA887. High Power Drivers Group, Texas Instruments: Dallas, TX, USA, August 2018. Available online: https://www.ti.com/lit/an/slua887/slua887.pdf (accessed on 25 May 2019).

| Characteristic | Symbol | Value |

|---|---|---|

| Max. Drain-to-Source voltage | VDS | 55 V |

| Continuous Drain current (@25 °C) | ID | 110 A |

| Continuous Drain current (@100 °C) | ID | 75 A |

| Static Drain-to-Source on-resistance | RDS(on) | 6.5 mΩ |

| Turn-on delay time | Td(on) | 18 ns |

| Turn-off delay time | Td(off) | 45 ns |

| Max. temperature for safe operation | Tj | 175 °C |

| Sector | Duration | Switching Sequence | Phase Voltage Level (vaN) | Line Voltage Level (vab) |

|---|---|---|---|---|

| I | [0, π/3] | S1, S6 | +Vin/2 | +Vin |

| II | [π/3, 2π/3] | S1, S2 | +Vin/2 | +Vin/2 |

| III | [2π/3, π] | S2, S3 | 0 | −Vin/2 |

| IV | [π, 4π/3] | S3, S4 | −Vin/2 | −Vin |

| V | [4π/3, 5π/3] | S4, S5 | −Vin/2 | −Vin/2 |

| VI | [5π/3, 2π] | S5, S6 | 0 | +Vin/2 |

| Company | Model Name | Cost | Max. Power Range |

|---|---|---|---|

| NXP | MTRCKTSBNZVM128 | 670 € | 120 W |

| Silicon Labs | C8051F850-BLDC-RD | 220 € | 240 W |

| ST Micro | STEVAL-IHM017V1 | 172 € | 100 W |

| - | Controller presented here | 69 €1 | 500 W |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karnavas, Y.L.; Topalidis, A.S.; Drakaki, M. Development and Implementation of a Low Cost μC- Based Brushless DC Motor Sensorless Controller: A Practical Analysis of Hardware and Software Aspects. Electronics 2019, 8, 1456. https://doi.org/10.3390/electronics8121456

Karnavas YL, Topalidis AS, Drakaki M. Development and Implementation of a Low Cost μC- Based Brushless DC Motor Sensorless Controller: A Practical Analysis of Hardware and Software Aspects. Electronics. 2019; 8(12):1456. https://doi.org/10.3390/electronics8121456

Chicago/Turabian StyleKarnavas, Yannis L., Anestis S. Topalidis, and Maria Drakaki. 2019. "Development and Implementation of a Low Cost μC- Based Brushless DC Motor Sensorless Controller: A Practical Analysis of Hardware and Software Aspects" Electronics 8, no. 12: 1456. https://doi.org/10.3390/electronics8121456

APA StyleKarnavas, Y. L., Topalidis, A. S., & Drakaki, M. (2019). Development and Implementation of a Low Cost μC- Based Brushless DC Motor Sensorless Controller: A Practical Analysis of Hardware and Software Aspects. Electronics, 8(12), 1456. https://doi.org/10.3390/electronics8121456