New “Full-Bridge Buck Inverter–DC Motor” System: Steady-State and Dynamic Analysis and Experimental Validation

Abstract

:1. Introduction

1.1. Related Work

1.2. Discussion of Related Work and Contribution

- The steady-state, stability, controllability, and flatness properties associated with the dynamic behavior of the “full-bridge Buck inverter–DC motor” system are presented.

- The differential flatness property [33] linked to the mathematical model of the system under study is exploited, with the aim of obtaining the reference trajectories of the system offline so that the mathematical model can be validated when time-varying duty cycles are considered.

- Obtaining circuit simulation results when the input and the reference signals are introduced into the system via the SimPowerSystems toolbox of Matlab-Simulink.

- Obtaining experimental results when the input and the reference signals are introduced to a prototype of the system built through Matlab-Simulink along with a DS1104 board.

2. Materials and Methods

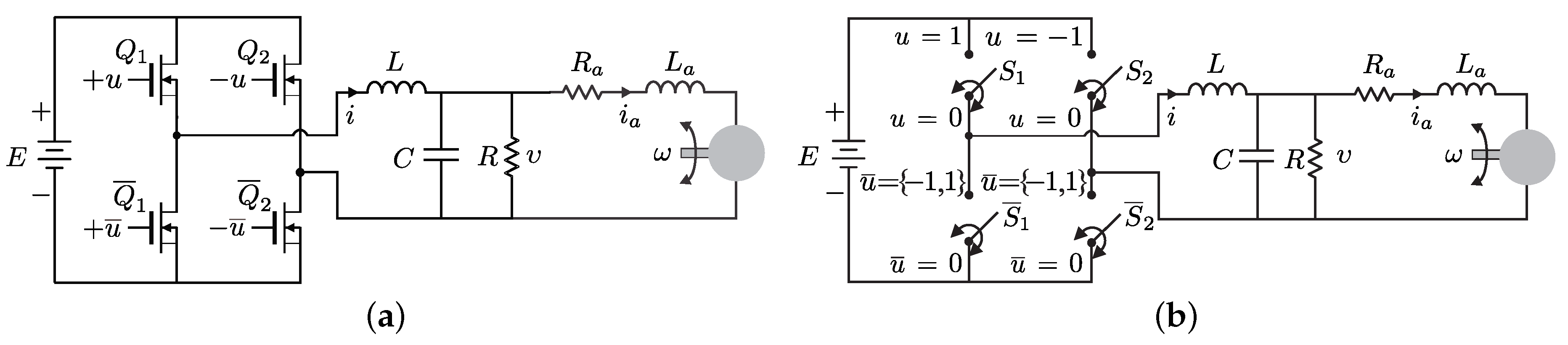

2.1. Model of the “Full-Bridge Buck Inverter–DC Motor” System

2.1.1. Generalities of the Full-Bridge Buck Inverter–DC Motor System

2.1.2. Mathematical Model of the Proposed “Full-Bridge Buck Inverter–DC Motor” Topology

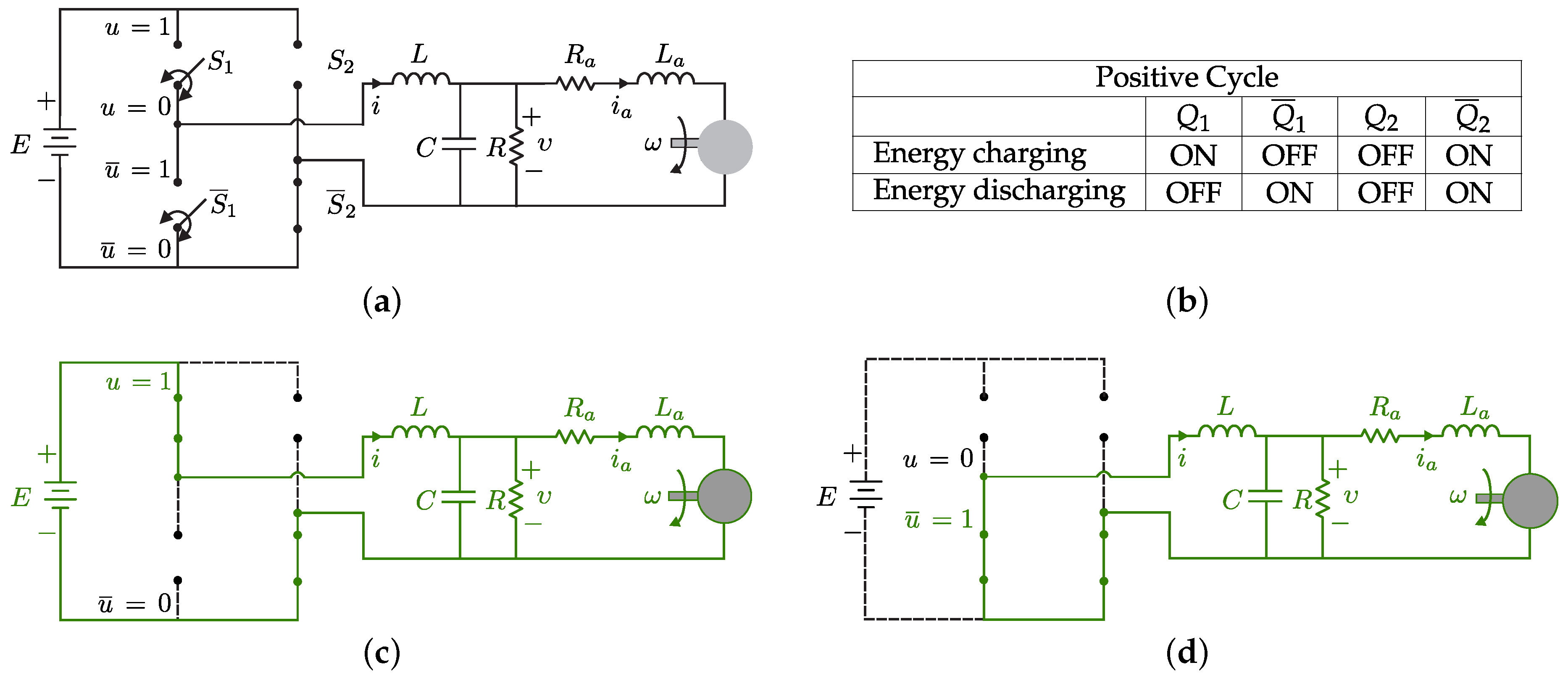

- Positive Cycle

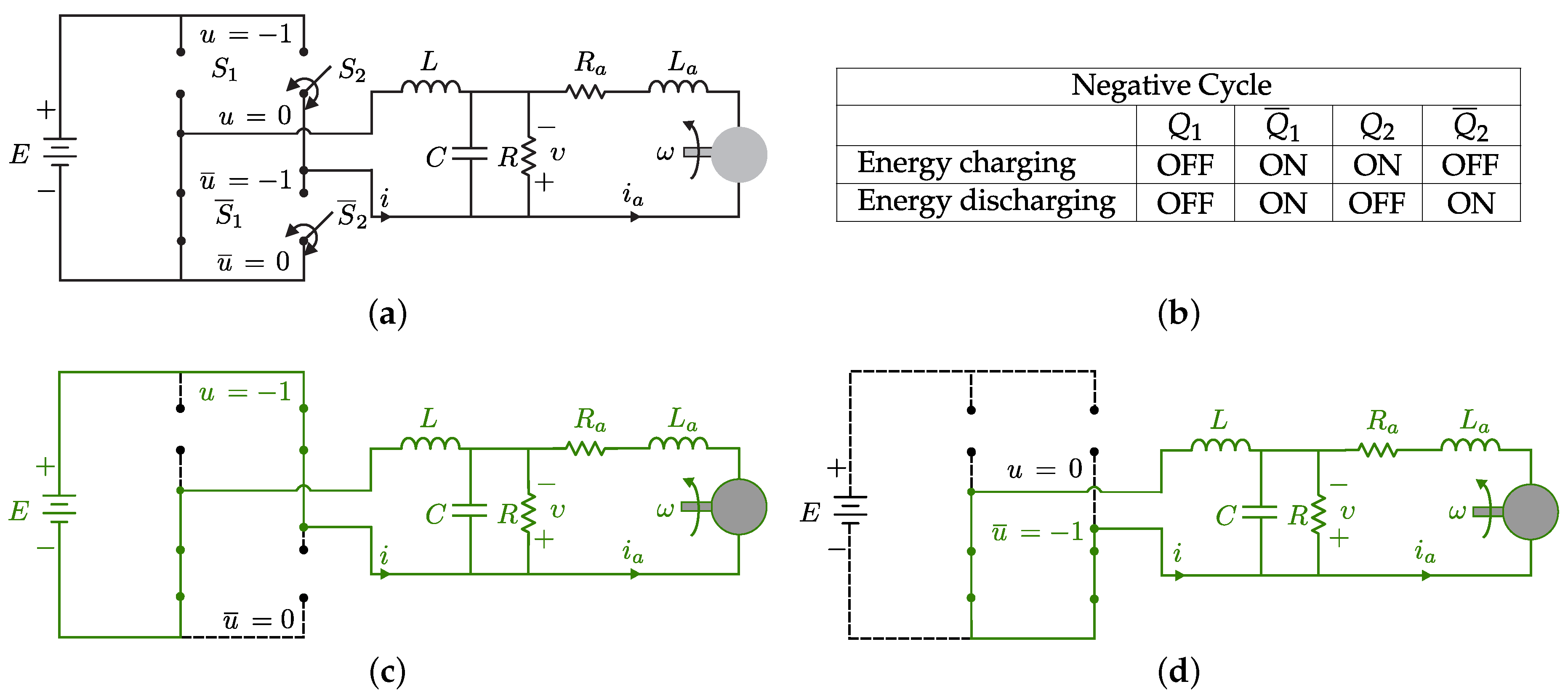

- Negative Cycle

2.2. Properties of the “Full-Bridge Buck Inverter–DC Motor” System

2.2.1. Steady-State

2.2.2. Stability

2.2.3. Controllability

2.3. Generation of Reference Trajectories via Differential Flatness

3. Results

3.1. Circuit Simulation Results

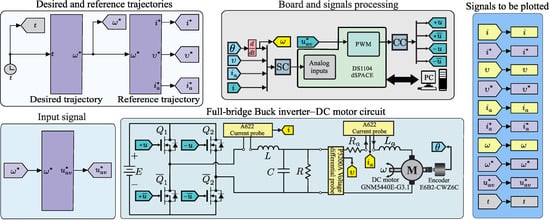

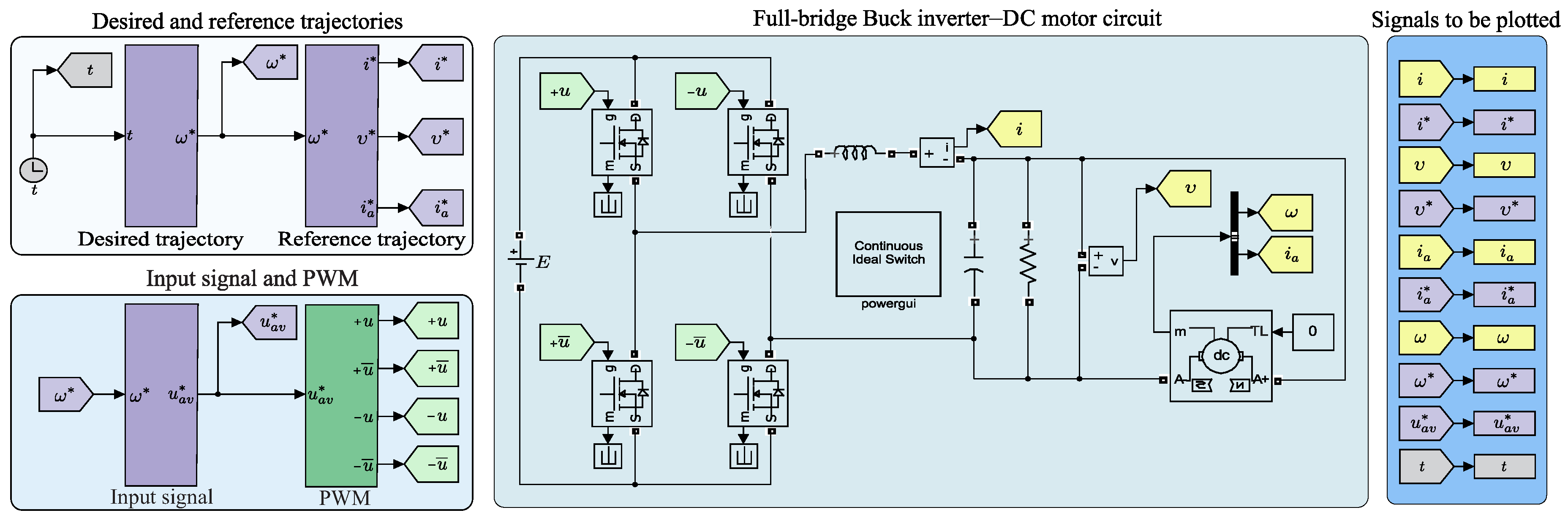

3.1.1. Connection Diagram of the System

- Desired and reference trajectories. In this block, the desired trajectory and the differential parametrization, see Equations (31)–(33), are programmed to obtain the reference trajectories , , and .

- Signals to be plotted. The variables to be plotted are defined in this block. These variables are related to the full-bridge Buck inverter–DC motor system and to the differential parametrization.

- Input signal and PWM. Here, the input , given by Equation (37), is programmed. Also, through this block, the full-bridge transistors are driven when the switched inputs are generated through the PWM signal.

- Full-bridge Buck inverter–DC motor circuit. This block corresponds to the overall system. The parameters of the full-bridge Buck inverter are given by the following values:The sampling frequency of the four transistors, associated with the full-bridge is 50 kHz. The DC motor was manufactured by ENGEL with a 3.1 gearbox with reduction ratio of 14.5:1. Such a motor is a GNM5440E-G3.1 , whose parameters are

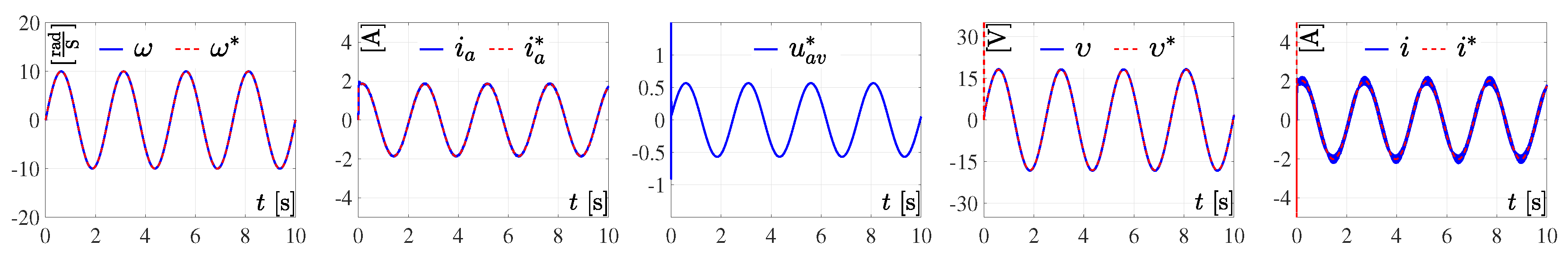

3.1.2. Circuit Simulation Results

- Circuit Simulation 1

- Circuit Simulation 2

- Circuit Simulation 3

- Circuit Simulation 4

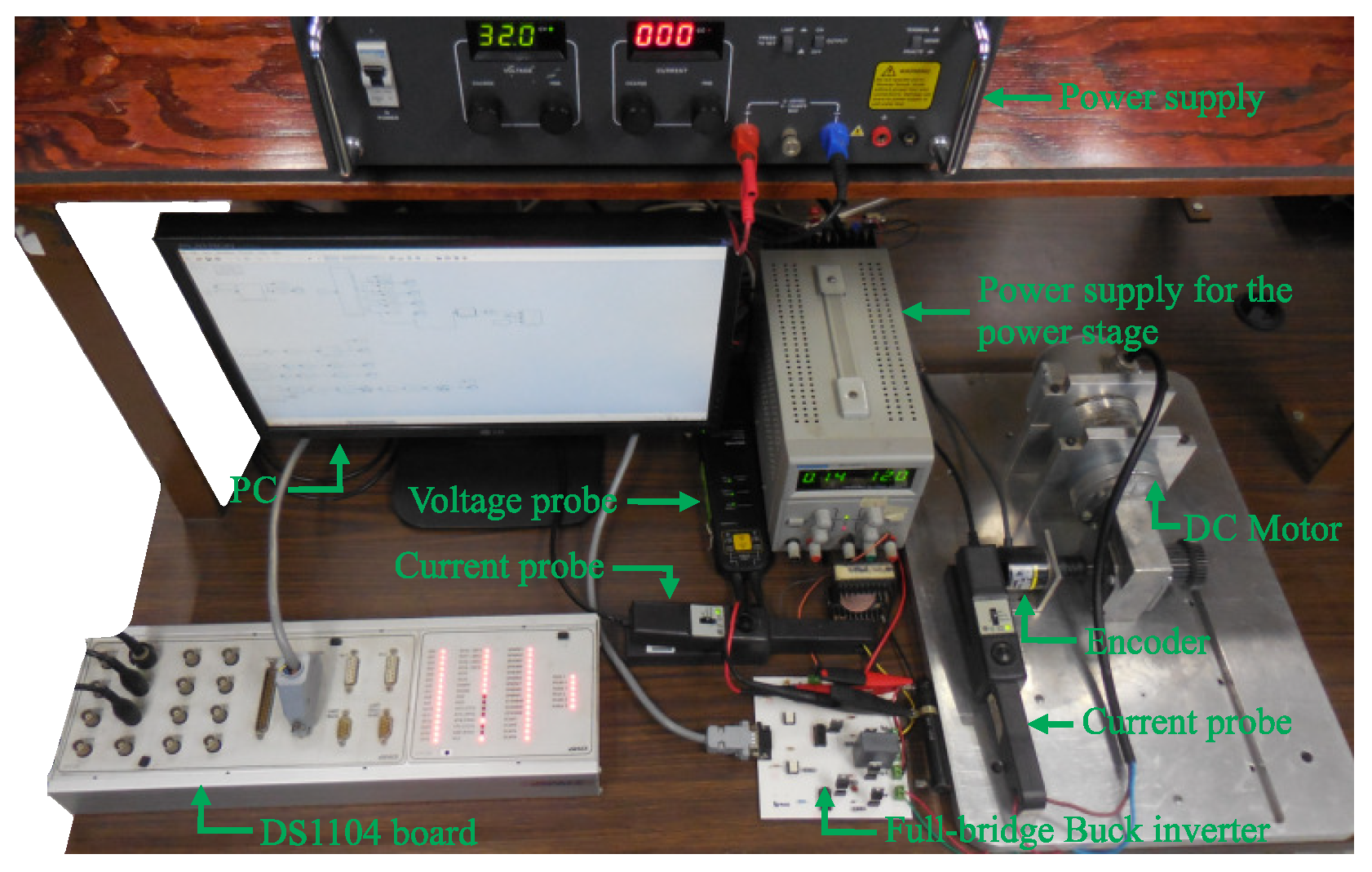

3.2. Results from the Experimental Prototype

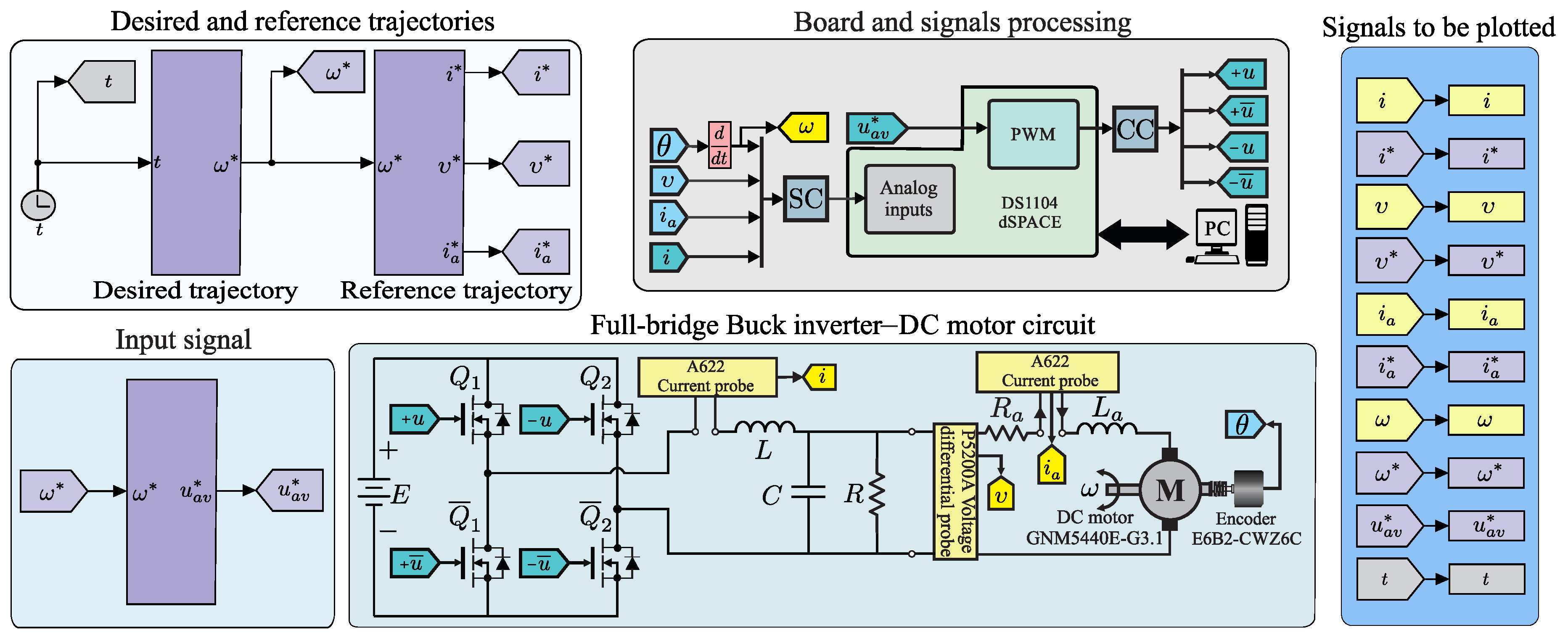

3.2.1. Experimental Diagram of the System

- Desired and reference trajectories. The desired trajectory and the Equations (31)–(33) to obtain the reference trajectories , , and are programmed in this block.

- Input signal. The input , see Equation (37), is programmed here.

- Signals to be plotted. The variables to be plotted are specified in this block.

- Board and signal processing. This block shows the connections between the DS1104 board and the system. As can be seen, signal conditioning (SC) is executed over the angular position , the voltage , and the currents and i. Also, the input signal is introduced into the DS1104 board so that the PWM signal can be generated. This latter is processed through the sub-block conditioning circuit (CC) allowing the correct activation of the transistors.

- Full-bridge Buck inverter–DC motor circuit. This block corresponds to the system under study and the values of its parameters were defined in (47). The sampling frequency of the four IRF640 MOSFET transistors associated with the full-bridge is 50 kHz. Additionally, the parameters of the DC motor are the same of those considered in (48).

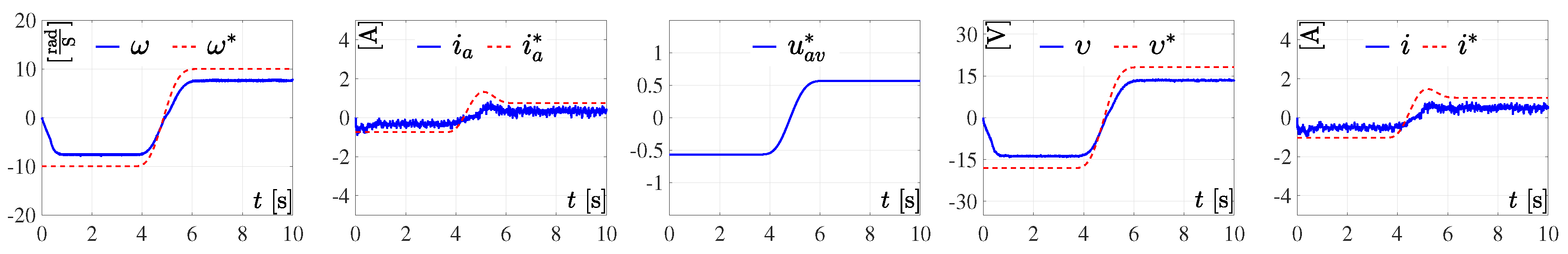

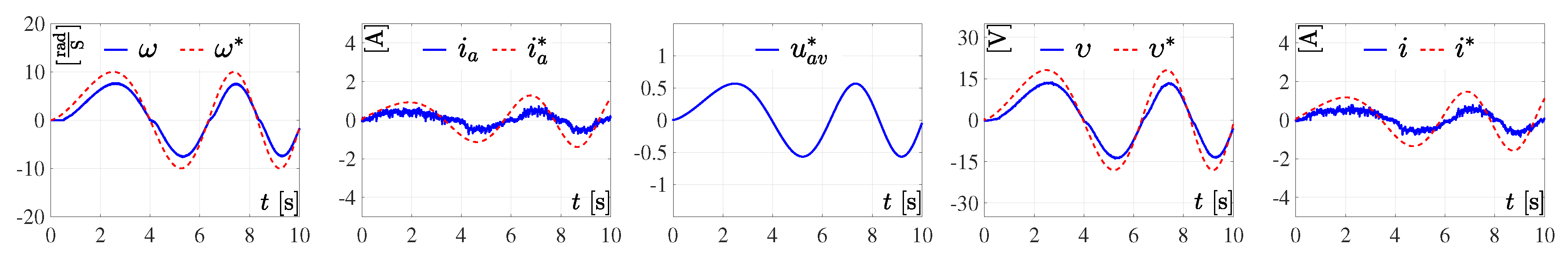

3.2.2. Experimental Results

- Experiment 1

- Experiment 2

- Experiment 3

- Experiment 4

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| DC | Direct current |

| PI | Proportional-integral |

| PID | Proportional-integral-derivative |

| LQR | Linear quadratic regulator |

| ZAD | Zero average dynamics |

| FPIC | Fixed point inducting control |

| dPSO | Dynamic particle swarm optimization |

| GPI | Generalized proportional-integral |

| MOSFET | Metal-oxide-semiconductor field-effect transistor |

| BIBO | Bounded-input bounded-output |

| PWM | Pulse width modulation |

| SC | Signal conditioning |

| CC | Conditioning circuit |

| Notation | |

| i | Converter inductor current |

| Converter capacitor voltage | |

| DC motor armature circuit current | |

| DC motor angular velocity | |

| DC motor angular position | |

| u | Switch position function |

| Complementary switch position function | |

| Duty cycle or Average input signal | |

| E | Power supply |

| R | Converter output resistance |

| C | Converter capacitance |

| L | Converter inductance |

| DC motor armature circuit resistance | |

| DC motor armature inductance | |

| J | Moment of inertia of the rotor |

| b | DC motor viscous friction coefficient |

| Counterelectromotive force constant | |

| DC motor torque constant | |

| , | MOSFET transistors |

| , | Complementary MOSFET transistors |

| , | Ideal switches |

| , | Complementary ideal switches |

| Analog filter conformed by L and C | |

| x | State vector |

| , , , , | Nominal variables and nominal input |

| , | Constant angular velocities for interpolating the Bézier polynomial |

| , , | Constant matrices |

| y | System output |

| Controllability matrix | |

| Flat output | |

| Flat output reference trajectory | |

| , , , , | System reference trajectories and reference input |

References

- Lyshevski, S.E. Electromechanical Systems, Electric Machines, and Applied Mechatronics; CRC Press: Boca Raton, FL, USA, 2000; ISBN 0-8493-2275-8. [Google Scholar]

- Ahmad, M.A.; Ismail, R.M.T.R.; Ramli, M.S. Control strategy of Buck converter driven DC motor: A comparative assessment. Austral. J. Basic Appl. Sci. 2010, 4, 4893–4903. [Google Scholar]

- Bingöl, O.; Paçaci, S. A virtual laboratory for neural network controlled DC motors based on a DC-DC Buck converter. Int. J. Eng. Educ. 2012, 28, 713–723. [Google Scholar]

- Sira-Ramírez, H.; Oliver-Salazar, M.A. On the robust control of Buck-converter DC-motor combinations. IEEE Trans. Power Electron. 2013, 28, 3912–3922. [Google Scholar] [CrossRef]

- Silva-Ortigoza, R.; García-Sánchez, J.R.; Alba-Martínez, J.M.; Hernández-Guzmán, V.M.; Marcelino-Aranda, M.; Taud, H.; Bautista-Quintero, R. Two-stage control design of a Buck converter/DC motor system without velocity measurements via a Σ-Δ-modulator. Math. Probl. Eng. 2013, 2013, 929316. [Google Scholar] [CrossRef]

- Hoyos, F.E.; Rincón, A.; Taborda, J.A.; Toro, N.; Angulo, F. Adaptive quasi-sliding mode control for permanent magnet DC motor. Math. Probl. Eng. 2013, 2013, 693685. [Google Scholar] [CrossRef]

- Silva-Ortigoza, R.; Márquez-Sánchez, C.; Carrizosa-Corral, F.; Antonio-Cruz, M.; Alba-Martínez, J.M.; Saldaña-González, G. Hierarchical velocity control based on differential flatness for a DC/DC Buck converter-DC motor system. Math. Probl. Eng. 2014, 2014, 912815. [Google Scholar] [CrossRef]

- Wei, F.; Yang, P.; Li, W. Robust adaptive control of DC motor system fed by Buck converter. Int. J. Control Autom. 2014, 7, 179–190. [Google Scholar] [CrossRef]

- Silva-Ortigoza, R.; Hernández-Guzmán, V.M.; Antonio-Cruz, M.; Muñoz-Carrillo, D. DC/DC Buck power converter as a smooth starter for a DC motor based on a hierarchical control. IEEE Trans. Power Electron. 2015, 30, 1076–1084. [Google Scholar] [CrossRef]

- Hernández-Guzmán, V.M.; Silva-Ortigoza, R.; Muñoz-Carrillo, D. Velocity control of a brushed DC-motor driven by a DC to DC Buck power converter. Int. J. Innov. Comp. Inf. Control 2015, 11, 509–521. [Google Scholar]

- Kumar, S.G.; Thilagar, S.H. Sensorless load torque estimation and passivity based control of Buck converter fed DC motor. Sci. World J. 2015, 2015, 132843. [Google Scholar] [CrossRef]

- Khubalkar, S.; Chopade, A.; Junghare, A.; Aware, M.; Das, S. Design and realization of stand-alone digital fractional order PID controller for Buck converter fed DC motor. Circuits Syst. Signal Process. 2016, 35, 2189–2211. [Google Scholar] [CrossRef]

- Rigatos, G.; Siano, P.; Wira, P.; Sayed-Mouchaweh, M. Control of DC–DC converter and DC motor dynamics using differential flatness theory. Intell. Ind. Syst. 2016, 2, 371–380. [Google Scholar] [CrossRef]

- Nizami, T.K.; Chakravarty, A.; Mahanta, C. Design and implementation of a neuro-adaptive backstepping controller for Buck converter fed PMDC-motor. Control Eng. Pract. 2017, 58, 78–87. [Google Scholar] [CrossRef]

- Hoyos Velasco, F.E.; Candelo-Becerra, J.E.; Rincón Santamaria, A. Dynamic analysis of a permanent magnet DC motor using a Buck converter controlled by ZAD-FPIC. Energies 2018, 11, 3388. [Google Scholar] [CrossRef]

- Khubalkar, S.W.; Junghare, A.S.; Aware, M.V.; Chopade, A.S.; Das, S. Demonstrative fractional order-PID controller based DC motor drive on digital platform. ISA Trans. 2018, 82, 79–93. [Google Scholar] [CrossRef]

- Rigatos, G.; Siano, P.; Ademi, S.; Wira, P. Flatness-based control of DC-DC converters implemented in successive loops. Electr. Power Compon. Syst. 2018, 46, 673–687. [Google Scholar] [CrossRef]

- Yang, J.; Wu, H.; Hu, L.; Li, S. Robust predictive speed regulation of converter-driven DC motors via a discrete-time reduced-order GPIO. IEEE Trans. Ind. Electron. 2019, 66, 7893–7903. [Google Scholar] [CrossRef]

- Rigatos, G.; Siano, P.; Sayed-Mouchaweh, M. Adaptive neurofuzzy H-infinity control of DC-DC voltage converters. Neural Comput. Appl. 2019, 1–14. [Google Scholar] [CrossRef]

- Ismail, A.A.A.; Elnady, A. Advanced drive system for DC motor using multilevel DC/DC Buck converter circuit. IEEE Access 2019, 7, 54167–54178. [Google Scholar] [CrossRef]

- Silva-Ortigoza, R.; Alba-Juárez, J.N.; García-Sánchez, J.R.; Antonio-Cruz, M.; Hernández-Guzmán, V.M.; Taud, H. Modeling and experimental validation of a bidirectional DC/DC Buck power electronic converter–DC motor system. IEEE Latin Am. Trans. 2017, 15, 1043–1051. [Google Scholar] [CrossRef]

- Silva-Ortigoza, R.; Alba-Juárez, J.N.; García-Sánchez, J.R.; Hernández-Guzmán, V.M.; Sosa-Cervantes, C.Y.; Taud, H. A sensorless passivity-based control for the DC/DC Buck converter–inverter–DC motor system. IEEE Latin Am. Trans. 2016, 14, 4227–4234. [Google Scholar] [CrossRef]

- Hernández-Márquez, E.; García-Sánchez, J.R.; Silva-Ortigoza, R.; Antonio-Cruz, M.; Hernández-Guzmán, V.M.; Taud, H.; Marcelino-Aranda, M. Bidirectional tracking robust controls for a DC/DC Buck converter-DC motor system. Complexity 2018, 2018, 1260743. [Google Scholar] [CrossRef]

- Linares-Flores, J.; Reger, J.; Sira-Ramírez, H. Load torque estimation and passivity-based control of a Boost-converter/DC-motor combination. IEEE Trans. Control Syst. Technol. 2010, 18, 1398–1405. [Google Scholar] [CrossRef]

- García-Rodríguez, V.H.; Silva-Ortigoza, R.; Hernández-Márquez, E.; García-Sánchez, J.R.; Taud, H. DC/DC Boost converter–inverter as driver for a DC motor: Modeling and experimental verification. Energies 2018, 11, 2044. [Google Scholar] [CrossRef]

- García-Sánchez, J.R.; Hernández-Márquez, E.; Ramírez-Morales, J.; Marciano-Melchor, M.; Marcelino-Aranda, M.; Taud, H.; Silva-Ortigoza, R. A robust differential flatness-based tracking control for the “MIMO DC/DC Boost converter–inverter–DC motor” system: Experimental results. IEEE Access 2019, 7, 84497–84505. [Google Scholar] [CrossRef]

- Linares-Flores, J.; Barahona-Avalos, J.L.; Sira-Ramírez, H.; Contreras-Ordaz, M.A. Robust passivity-based control of a Buck–Boost-converter/DC-motor system: An active disturbance rejection approach. IEEE Trans. Ind. Appl. 2012, 48, 2362–2371. [Google Scholar] [CrossRef]

- Hernández-Márquez, E.; Silva-Ortigoza, R.; García-Sánchez, J.R.; Marcelino-Aranda, M.; Saldaña-González, G. A DC/DC Buck-Boost converter–inverter–DC motor system: Sensorless passivity-based control. IEEE Access 2018, 6, 31486–31492. [Google Scholar] [CrossRef]

- Hernández-Márquez, E.; Avila-Rea, C.A.; García-Sánchez, J.R.; Silva-Ortigoza, R.; Silva-Ortigoza, G.; Taud, H.; Marcelino-Aranda, M. Robust tracking controller for a DC/DC Buck-Boost converter–inverter–DC motor system. Energies 2018, 11, 2500. [Google Scholar] [CrossRef]

- Ghazali, M.R.; Ahmad, M.A.; Ismail, R.M.T.R. Adaptive safe experimentation dynamics for data-driven neuroendocrine-PID control of MIMO systems. IETE J. Res. 2019, 1–14. [Google Scholar] [CrossRef]

- Sira-Ramírez, H.; Pérez-Moreno, R.A.; Ortega, R.; García-Esteban, M. Passivity-based controllers for the stabilization of DC-to-DC power converters. Automatica 1997, 33, 499–513. [Google Scholar] [CrossRef]

- Hernández-Márquez, E.; Avila-Rea, C.A.; Silva-Ortigoza, R.; García-Sánchez, J.R.; Antonio-Cruz, M.; Taud, H.; Marcelino-Aranda, M. Modeling and simulation of a DC motor fed by a full-bridge Buck inverter. In Proceedings of the 2017 International Conference on Mechatronics, Electronics and Automotive Engineering, ICMEAE 2017, Cuernavaca, Mexico, 21–24 November 2017; pp. 77–81. [Google Scholar]

- Sira-Ramírez, H.; Agrawal, S.K. Differentially Flat Systems; Marcel Dekker: New York, NY, USA, 2004; ISBN 0-8247-5470-0. [Google Scholar]

- Hernández-Guzmán, V.M.; Silva-Ortigoza, R. Velocity Control of a Permanent Magnet Brushed Direct Current Motor. In Automatic Control with Experiments. Advanced Textbooks in Control and Signal Processing; Springer: Cham, Switzerland, 2019; pp. 605–644. ISBN 978-3-319-75804-6. [Google Scholar] [CrossRef]

- Usman, H.M.; Mukhopadhyay, S.; Rehman, H. Permanent magnet DC motor parameters estimation via universal adaptive stabilization. Control Eng. Pract. 2019, 90, 50–62. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández-Márquez, E.; Avila-Rea, C.A.; García-Sánchez, J.R.; Silva-Ortigoza, R.; Marciano-Melchor, M.; Marcelino-Aranda, M.; Roldán-Caballero, A.; Márquez-Sánchez, C. New “Full-Bridge Buck Inverter–DC Motor” System: Steady-State and Dynamic Analysis and Experimental Validation. Electronics 2019, 8, 1216. https://doi.org/10.3390/electronics8111216

Hernández-Márquez E, Avila-Rea CA, García-Sánchez JR, Silva-Ortigoza R, Marciano-Melchor M, Marcelino-Aranda M, Roldán-Caballero A, Márquez-Sánchez C. New “Full-Bridge Buck Inverter–DC Motor” System: Steady-State and Dynamic Analysis and Experimental Validation. Electronics. 2019; 8(11):1216. https://doi.org/10.3390/electronics8111216

Chicago/Turabian StyleHernández-Márquez, Eduardo, Carlos Alejandro Avila-Rea, José Rafael García-Sánchez, Ramón Silva-Ortigoza, Magdalena Marciano-Melchor, Mariana Marcelino-Aranda, Alfredo Roldán-Caballero, and Celso Márquez-Sánchez. 2019. "New “Full-Bridge Buck Inverter–DC Motor” System: Steady-State and Dynamic Analysis and Experimental Validation" Electronics 8, no. 11: 1216. https://doi.org/10.3390/electronics8111216

APA StyleHernández-Márquez, E., Avila-Rea, C. A., García-Sánchez, J. R., Silva-Ortigoza, R., Marciano-Melchor, M., Marcelino-Aranda, M., Roldán-Caballero, A., & Márquez-Sánchez, C. (2019). New “Full-Bridge Buck Inverter–DC Motor” System: Steady-State and Dynamic Analysis and Experimental Validation. Electronics, 8(11), 1216. https://doi.org/10.3390/electronics8111216