Abstract

The nonvolatile application of La-doped ZrO2 (ZLO) antiferroelectric capacitors is demonstrated in this study, accompanied by systematic investigation of device reliability. A built-in electric field was successfully established through engineered work function modulation. The fabricated nonvolatile (NV) ZLO capacitor exhibits not only avoidance of wake-up and fatigue phenomena typically observed in ferroelectric systems but also demonstration of ultralow coercive voltage (2Vc = 1.2 V) and exceptional endurance exceeding 1012 cycles. The inherent unique polarization reversal mechanism in NV ZLO device was identified as the origin of a unidirectional imprint effect. Accelerated testing at 85 °C for 104 s yielded conclusive evidence of retention characteristic stability. This investigation provides a novel perspective for the engineering utilization of antiferroelectric materials and facilitates their potential incorporation into advanced integrated circuit architectures.

1. Introduction

In 2011, ferroelectric and antiferroelectric characteristics were first reported in Si-doped HfO2 [1]. In 2012, these phenomena were also observed in Zr-doped HfO2 (HZO) through the modification of the composition [2]. The discovery initiated the flourishing research on ferroelectric and antiferroelectric properties of HfO2-based oxides compatible with current semiconductor process. In recent years, significant progress has been made in the study of HfO2-based ferroelectric materials. In order to stabilize and fine-tune the ferroelectric properties of HfO2, a broad spectrum of chemical elements, including Si [1], Al [3], Zr [4], Sc [5], La [6], Gd [7], Y [8], Ge [5], and N [9], have been investigated as potential dopant. In particular, HZO films have emerged as promising candidate for next-generation storage technologies due to the stability and scalability at the nanoscale.

Nevertheless, the subpar endurance and the existence of wake-up and fatigue effects during cycling have significantly impeded the development of HZO ferroelectric devices [10]. Antiferroelectric devices have recently been reported to exhibit high reliability; however, challenges such as imprint effect, retention limitation, and their inherent volatility still hinder their development, necessitating further research [10]. To mitigate these issues in ferroelectric and antiferroelectric, extensive investigations have been conducted on various aspects including electrode optimization [11], film thickness adjustment [12], annealing method [13], and multi-element doping [14]. The incorporation of La into HZO ferroelectric film was reported as an effective strategy for endurance enhancement [14,15,16,17,18]. However, La doping has not been recognized as an optimal solution, as the improvement in endurance performance is accompanied by hysteresis loop pinning and the dominant of antiferroelectric behavior [19,20,21,22,23]. This trade-off originates from La doping-induced elevation in oxygen vacancy formation energy, which drives preferential increase of the tetragonal phase associated with antiferroelectricity [24,25,26]. The antiferroelectric compatibility of La inspired the exploration of La-doped ZrO2 (ZLO) antiferroelectric device. The emergence of ZLO has resolved the wake-up issue in HZO ferroelectric and antiferroelectric systems and exhibited enhanced reliability [27,28,29,30].

In this work, we mainly focused on the nonvolatile (NV) application and the reliability of ZLO antiferroelectric device. To realize nonvolatile application in antiferroelectric, a built-in electric field was induced through the work function tuning method [31,32,33,34]. Typically, TiN is employed as the electrode material due to its excellent thermal stability and compatibility with CMOS processes [35,36,37]. The working function of TiN electrodes can be modulated by varying the film thickness [38,39,40,41,42], which facilitates the introduction of the built-in electric field. The nonvolatile ZLO antiferroelectric capacitors were successfully fabricated through precise optimization of TiN thickness, accompanied by systematic reliability assessment. These capacitors not only overcome the challenges of wake-up and fatigue effects but also exhibit exceptional endurance and retention. This breakthrough broadens the avenue for the practical application of antiferroelectric technology.

2. Experiments

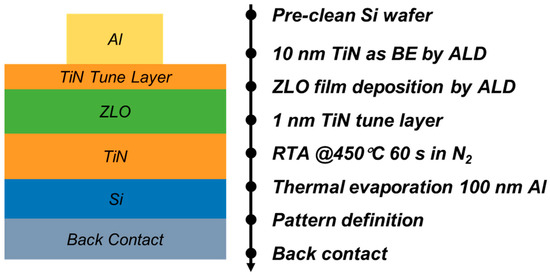

The cross-sectional schematic diagram and the key fabrication procedure of nonvolatile Al/TiN/ZLO/TiN MIM antiferroelectric capacitors are shown in Figure 1. A 10 nm TiN bottom electrode (BE) was deposited on a heavily doped p-type Si substrate by atomic layer deposition (ALD). After that, 8 nm ZLO thin film with a Zr/La ratio up to 20:1 was grown at 290 °C by controlling the number of ALD cycles for ZrO2 and La2O3. The precursors were TEMAZ and La(iPrCp)3, respectively. Then, a 1 nm TiN tuning layer was deposited at 350 °C using TiCl4 and NH3 as reactants. After that, a thermal annealing process of 450 °C for 60 s in an N2 atmosphere was performed. The contact electrode Al was deposited by thermal evaporation. In the end, the patterning process was carried out and the Al back contact was deposited.

Figure 1.

Schematic cross section and fabrication procedure of the fabricated non-volatile ZLO MFM antiferroelectric capacitors.

The electrical characteristics were measured using a Keysight B1500A semiconductor analyzer and Liryder F3000 ferroelectric analyzer [43]. Grazing-incidence X-ray diffraction (GIXRD) technology was employed to confirm the change in phase composition within the antiferroelectric ZrO2 films before and after La doping.

3. Results and Discussion

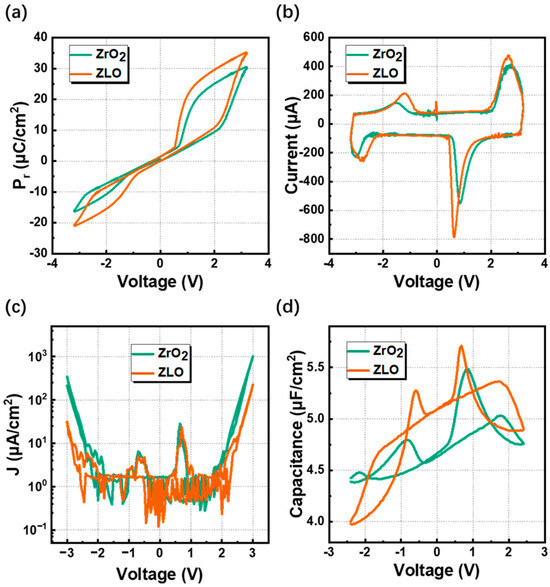

Initially, we conducted a comparison of the electrical characteristics between volatile ZLO and undoped ZrO2 antiferroelectric devices, both featuring a 10 nm-thick top TiN electrode. The resultant P–V curves and the concurrent I–V curves are depicted in Figure 2a and Figure 2b, respectively. The hysteresis loops were measured using pulsed triangular waves with 10 µs rise time, 10 µs fall time, and 10 µs interval time between pulses. It can be clearly observed that the positive segments of the hysteresis loops are more pronounced and saturated than their negative counterparts, a trend evident in both ZLO and undoped ZrO2 devices. This asymmetry likely stems from the asymmetric interface layers, which could be a consequence of the different process undergone by the top and bottom electrodes [44]. Compared to the undoped ZrO2 antiferroelectric capacitor, the ZLO device exhibits superior polarization and a reduced coercive field, which is consistent with the characteristic of La of enhancing the tetragonal phase [19,25,45]. The relationship between leakage current and voltage was then examined for both types of capacitors. As illustrated in Figure 2c, ZLO devices exhibit a lower leakage current compared to undoped ZrO2. The reduction in leakage current is attributed to the La-induced passivation of oxygen vacancies, as well as the modulation of the Fermi level through its role as acceptor defect center [19,24]. Then, the C–V curves were measured at a frequency of 100 kHz. As shown in Figure 2d, both capacitors exhibit the classic double-butterfly characteristic of antiferroelectricity. The C–V curve reveals a significant improvement in permittivity, with ZLO capacitor showing a 10% increase in relative permittivity compared to undoped ZrO2 (from εr = 41.8 to εr = 46). This discrepancy can be attributed to the stabilization of the high-κ tetragonal phase achieved through La doping.

Figure 2.

(a) The P–V curves of ZLO and ZrO2 antiferroelectric capacitors. (b) The I–V curves of these capacitors. (c) The J–V properties and (d) C–V curves.

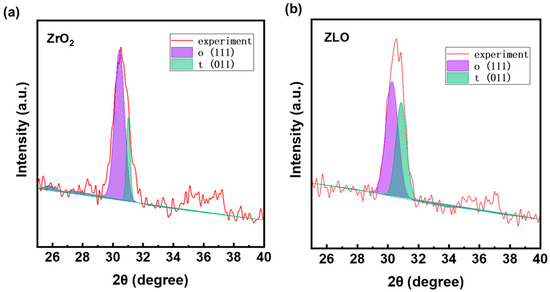

Grazing-incidence X-ray diffraction (GI-XRD) was employed to monitor this evolutionary process. As shown in Figure 3, a pronounced increase in the t-phase content was observed in ZLO, which correlates well with the enhanced antiferroelectric property. Following the methodology reported in prior studies [46], the main diffraction peaks for the o-phase (o 111) and t-phase (t 011) were identified at 30.5° and 30.8°, respectively. The refined calculations revealed that the t-phase content is 19% in pure ZrO2 and 38% in ZLO. This finding reveals a clear structure–property relationship between oxygen vacancy concentration, crystalline phase evolution, and antiferroelectric electrical characteristics.

Figure 3.

The GIXRD patterns of (a) ZrO2 and (b) La-doped ZrO2.

The fundamental electrical properties of conventional volatile ZLO devices have been briefly reviewed in the preceding sections. The following section will provide a detailed discussion of the device characteristics of nonvolatile ZLO antiferroelectric devices, realized through the employing of a designed 1 nm TiN tuning layer.

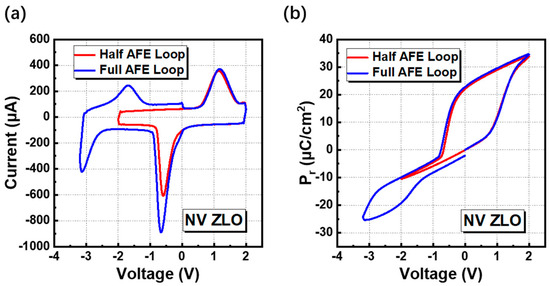

As extensively reported, the work function of TiN exhibits critical dependence on its thickness [38,39,40,41,42]. It decreases by ~1 eV when its thickness is reduced from 6 nm to 1 nm according to a previous report [38]. In this work, the work function difference between the bottom TiN (10 nm) and top TiN (1 nm) electrodes directly manifests as a ~1 V operational voltage shift, which aligns quantitatively with reported thickness-dependent trends. Figure 4a,b depict the I–V and P–V curves, respectively, of ZLO devices, demonstrating the effectiveness of the adopted approach for achieving nonvolatile applications.

Figure 4.

The (a) I–V curves and (b) P–V curves of ZLO capacitors modulated by 1 nm TiN layer.

The magnitude of Ebuilt-in is governed by the work function difference between the top (WFTE) and bottom (WFBE) electrodes, as expressed by:

where t is the AFE layer thickness and q is the elementary charge. The induced Ebuilt-in shifts the AFE polarization–voltage (P–V) hysteresis loop, centering its right branch toward zero field. At low electric fields, a ferroelectric-like hysteresis loop (the right branch) is observed, whereas the full AFE hysteresis loop emerges under high electric fields. This critical adjustment stabilizes the constricted hysteresis loop, allowing deterministic switching between the polarized (binary “0”) and non-polarized (binary “1”) states without requiring sustained external bias.

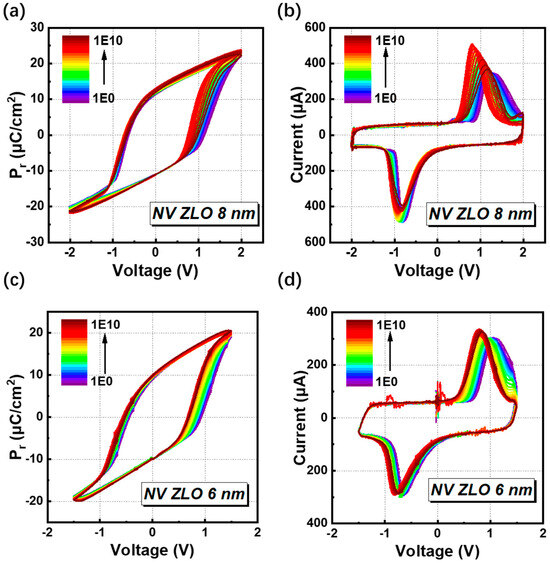

Then, the endurance of the work function-modulated ZLO device was investigated. Given the achievement of a nonvolatile state, the endurance testing protocol aligns with that of ferroelectric devices, involving the application of bipolar stress at 100 kHz. After 1010 cycles, the P–V and I–V curves of the ZLO capacitor incorporating a 1 nm TiN tuning layer are presented in Figure 5a and Figure 5b, respectively. After 1010 cycles, the polarization intensity remains nearly unchanged (2Pr = 22.8 µC/cm2), with only a slight reduction in the positive coercive field. This decrease in the coercive field is advantageous for practical circuit applications.

Figure 5.

The (a) P–V curves and (b) I–V curves of 8 nm NV ZLO capacitors during endurance measurement. The (c) P–V curves and (d) I–V curves of 6 nm NV ZLO capacitors.

To further optimize the ZLO device’s performance, a 6 nm ZLO film was accomplished, targeting a lower operating voltage. The P–V and I–V curves of the 6 nm nonvolatile ZLO capacitor were tested under varying applied voltages. The results reveal that when the measurement voltage is reduced from 2.1 V to 1.5 V, the polarization decreases by only 17%. However, a further reduction to 1.2 V leads to a significant polarization decay (35%), though the 2Pr value remains at a notable 15.6 µC/cm2. In order to balance operate voltage and polarization strength, a bias of 1.5 V was chosen for the endurance process, as depicted in Figure 5c,d. After an extensive 1010 cycles, the NV ZLO device demonstrates exceptional robustness, with the endurance behavior exhibiting virtually no wake-up or fatigue effects.

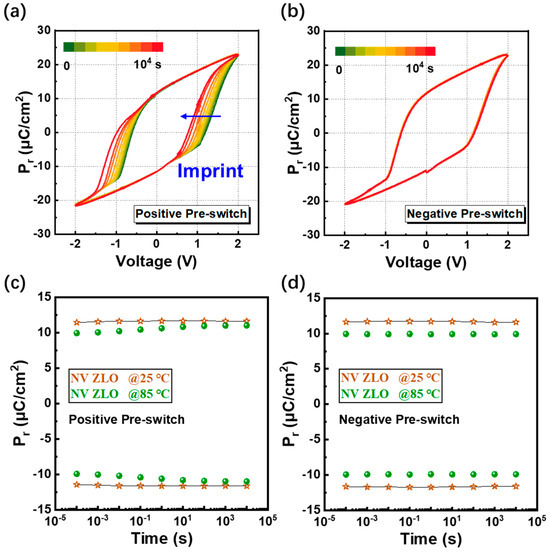

Subsequently, we investigated the imprint effect of the NV ZLO devices. The imprint effect manifests as a persistent shift of the hysteresis loop. This phenomenon, predominantly driven by charge injection and interfacial charge trapping, represents a critical factor in the deterioration in retention performance in ferroelectric and antiferroelectric devices [47]. In Figure 6a, following positive polarization, the leftward shift of the hysteresis loop in the ZLO device, observed over different retention durations, is clearly illustrated. The presence of polarization charge leads to a large internal electric field in the interface layer, thereby causing the charge injection and electric field shift.

Figure 6.

(a) The imprint effect after positive pre-switch and (b) the imprint effect after negative pre-switch. The retention behavior of (c) P–V curves and (d) I–V curves of 6 nm NV ZLO capacitors.

When a negative voltage is applied, the internal polarization charge undergoes a depolarization process and gradually vanishes, but cannot switch to another polarization state. This means that after the negative reversal, the device is hardly affected by the imprint effect during the retention process, as there is no polarization charge, as shown in Figure 6b. This is significantly different from ferroelectric devices, which tend to exhibit a rightward shift of the hysteresis loop after negative polarization. The difference arises from the distinct polarization reversal mechanisms of ferroelectric and antiferroelectric devices. The unique characteristic being unaffected by the imprint effect may provide inspiration for circuit design. Compared with ferroelectric devices, NV ZLO devices possess unparalleled potential in terms of retention characteristics.

Figure 6c,d depict the retention characteristics of the device under positive and negative polarization conditions, respectively. After 10⁴ seconds of retention testing, the remanent polarization exhibited remarkable stability in both switching states at 25 °C. Notably, at 85 °C, severe degradation in polarization intensity was observed, which is attributed to the temperature-induced enlarging of coercive field, as predicted by Landau theory [48,49]. With prolonged retention time, the device with a positive pre-switch displayed a gradual recovery in coercive field shift toward normal values due to the imprint effect, accompanied by a corresponding increase in 2Pr. In contrast, the negative polarization state maintained complete consistency with its initial configuration owing to its inherent immunity to imprint effect.

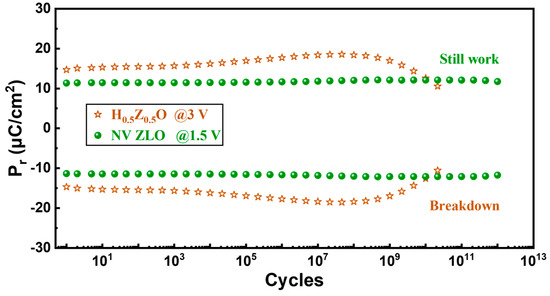

To evaluate the intrinsic endurance limit of the 6 nm-thick antiferroelectric NV-ZLO thin film, we specifically designed a small-scale test structure (2 × 2 μm2) featuring a ground–signal–ground (GSG) crossbar configuration [27]. This architecture, combined with ultrafast commercial testing equipment, enables sub-nanosecond ultrafast cycling while minimizing parasitic effects. The H0.5Z0.5O2 ferroelectric device was also fabricated for comparison. After 108 cycles, the ferroelectric polarization of the H0.5Z0.5O2 devices began to exhibit signs of fatigue and ultimately failed after 1010 cycles, as illustrated in Figure 7. The modest reduction in remanent polarization observed in the NV ZLO antiferroelectric devices can be attributed to the fact that only half of the domains within the thin films were active. Notably, even after 1012 cycles, the polarization of the NV ZLO devices maintained exceptional stability. The endurance performance underscores the immense potential of ZLO antiferroelectric devices.

Figure 7.

Endurance behavior of H0.5Z0.5O2 ferroelectric device and NV ZLO antiferroelectric device.

To highlight the advantages of NV-ZLO systems, we present comparative performance metrics in Table 1, revealing superior characteristics of La-doped ZLO thin films in antiferroelectric applications. Notably, La doping effectively eliminates the wake-up effect, enabling immediate stable switching without preconditioning cycles. The optimized GSG devices demonstrate high endurance (>1012 cycles) with minimal polarization loss, significantly outperforming existing nonvolatile antiferroelectric and ferroelectric devices. Furthermore, the coercive field shows a 50% reduction compared to conventional ferroelectrics, substantially lowering operational power requirements.

Table 1.

Benchmark of Non-Volatile Antiferroelectric and Ferroelectric Devices.

4. Conclusions

This paper provides an in-depth exploration on the nonvolatile applications and reliability of a ZLO antiferroelectric capacitor. The incorporation of La effectively passivates the formation of oxygen vacancies, thereby reducing leakage current and promoting the development of antiferroelectric phases. The nonvolatile application of ZLO antiferroelectric devices was achieved with designed work function engineering. In contrast to conventional ferroelectric devices, nonvolatile ZLO capacitors overcame wake-up and fatigue effects and revealed excellent endurance (>1012 cycles) and retention performance. This study paves the way for new applications of antiferroelectric in integrated circuits, offering innovative perspectives for future technological advancements.

Author Contributions

Conceptualization, J.L. and J.Z.; methodology, J.L.; software, Y.H.; validation, Y.Z., C.L. and Z.W.; formal analysis, W.Y.; investigation, J.L.; resources, Y.Z.; data curation, J.Z.; writing—original draft preparation, J.L.; writing—review and editing, J.L.; visualization, Z.D.; supervision, Y.Z.; project administration, Y.Z.; funding acquisition, Y.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported in part by the National Key Research and Development Program of China under grant 2020AAA0109001, in part by the joint research and development of the Yangtze River Delta Science and Technology Innovation Community under grant 2023CSJGG0300, and in part by the National Natural Science Foundation of China (62204086).

Data Availability Statement

The data presented in this study are available in this article.

Conflicts of Interest

The author Wenchao Yan was employed by the company Zhejiang Liryder Technologies Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Böscke, T.S.; Müller, J.; Bräuhaus, D.; Schröder, U.; Böttger, U. Ferroelectricity in hafnium oxide thin films. Appl. Phys. Lett. 2011, 99, 102903. [Google Scholar] [CrossRef]

- Müller, J.; Böscke, T.S.; Schröder, U.; Mueller, S.; Bräuhaus, D.; Böttger, U.; Frey, L.; Mikolajick, T. Ferroelectricity in Simple Binary ZrO2 and HfO2. Nano Lett. 2012, 12, 4318–4323. [Google Scholar] [CrossRef] [PubMed]

- Mueller, S.; Mueller, J.; Singh, A.; Riedel, S.; Sundqvist, J.; Schroeder, U.; Mikolajick, T. Incipient Ferroelectricity in Al-Doped HfO2 Thin Films. Adv. Funct. Mater. 2012, 22, 2412–2417. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, H.J.; Kim, Y.J.; Moon, T.; Kim, K.D.; Hwang, C.S. Toward a multifunctional monolithic device based on pyroelectricity and the electrocaloric effect of thin antiferroelectric HfxZr1−xO2 films. Nano Energy 2015, 12, 131–140. [Google Scholar] [CrossRef]

- Xu, L.; Nishimura, T.; Shibayama, S.; Yajima, T.; Migita, S.; Toriumi, A. Kinetic pathway of the ferroelectric phase formation in doped HfO2 films. J. Appl. Phys. 2017, 122, 124104. [Google Scholar] [CrossRef]

- Schroeder, U.; Richter, C.; Park, M.H.; Schenk, T.; Pešić, M.; Hoffmann, M.; Fengler, F.P.G.; Pohl, D.; Rellinghaus, B.; Zhou, C.; et al. Lanthanum-Doped Hafnium Oxide: A Robust Ferroelectric Material. Inorg. Chem. 2018, 57, 2752–2765. [Google Scholar] [CrossRef]

- Hoffmann, M.; Schroeder, U.; Schenk, T.; Shimizu, T.; Funakubo, H.; Sakata, O.; Pohl, D.; Drescher, M.; Adelmann, C.; Materlik, R.; et al. Stabilizing the ferroelectric phase in doped hafnium oxide. J. Appl. Phys. 2015, 118, 072006. [Google Scholar] [CrossRef]

- Müller, J.; Schröder, U.; Böscke, T.S.; Müller, I.; Böttger, U.; Wilde, L.; Sundqvist, J.; Lemberger, M.; Kücher, P.; Mikolajick, T.; et al. Ferroelectricity in yttrium-doped hafnium oxide. J. Appl. Phys. 2011, 110, 114113. [Google Scholar] [CrossRef]

- Xu, L.; Nishimura, T.; Shibayama, S.; Yajima, T.; Migita, S.; Toriumi, A. Ferroelectric phase stabilization of HfO2 by nitrogen doping. Appl. Phys. Express 2016, 9, 091501. [Google Scholar] [CrossRef]

- Pesic, M.; Schroeder, U.; Slesazeck, S.; Mikolajick, T. Comparative Study of Reliability of Ferroelectric and Anti-Ferroelectric Memories. IEEE Trans. Device Mater. Reliab. 2018, 18, 154–162. [Google Scholar] [CrossRef]

- Goh, Y.; Hwang, J.; Lee, Y.; Kim, M.; Jeon, S. Ultra-thin Hf0.5Zr0.5O2 thin-film-based ferroelectric tunnel junction via stress induced crystallization. Appl. Phys. Lett. 2020, 117, 242901. [Google Scholar] [CrossRef]

- Saha, A.K.; Si, M.; Ni, K.; Datta, S.; Ye, P.D.; Gupta, S.K. Ferroelectric Thickness Dependent Domain Interactions in FEFETs for Memory and Logic: A Phase-field Model based Analysis. In Proceedings of the 2020 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 12–18 December 2020; pp. 4.3.1–4.3.4. [Google Scholar] [CrossRef]

- Park, M.H.; Chung, C.; Schenk, T.; Richter, C.; Opsomer, K.; Detavernier, C.; Adelmann, C.; Jones, J.L.; Mikolajick, T.; Schroeder, U. Effect of Annealing Ferroelectric HfO2 Thin Films: In Situ, High Temperature X-Ray Diffraction. Adv. Electron. Mater. 2018, 4, 1800091. [Google Scholar] [CrossRef]

- Walke, A.M.; Popovici, M.I.; Banerjee, K.; Clima, S.; Kumbhare, P.; Desmet, J.; Meersschaut, J.; Bosch, G.V.D.; Delhougne, R.; Kar, G.S.; et al. Electrical Investigation of Wake-Up in High Endurance Fatigue-Free La and Y Doped HZO Metal–Ferroelectric–Metal Capacitors. IEEE Trans. Electron Devices 2022, 69, 4744–4749. [Google Scholar] [CrossRef]

- Weng, Z.; Qu, Y.; Lan, Z.; Liu, J.; Su, M.; Li, J.; Ding, Y.; Lee, C.; Zhao, L.; Zhao, Y. Wake-Up Free La-Doped HfO2-ZrO2 Ferroelectrics Achieved with an Atomic Layer-Specific Doping Technique. IEEE Electron Device Lett. 2022, 43, 1665–1668. [Google Scholar] [CrossRef]

- Kozodaev, M.G.; Chernikova, A.G.; Korostylev, E.V.; Park, M.H.; Khakimov, R.R.; Hwang, C.S.; Markeev, A.M. Mitigating wakeup effect and improving endurance of ferroelectric HfO2-ZrO2 thin films by careful La-doping. J. Appl. Phys. 2019, 125, 034101. [Google Scholar] [CrossRef]

- Popovici, M.; Walke, A.M.; Banerjee, K.; Ronchi, N.; Meersschaut, J.; Celano, U.; McMitchell, S.; Spampinato, V.; Franquet, A.; Favia, P.; et al. Ferroelectric La-Doped ZrO2/HfZrO2 Bilayer Stacks with Enhanced Endurance. Phys. Status Solidi (RRL)-Rapid Res. Lett. 2021, 15, 2100033. [Google Scholar] [CrossRef]

- Zeng, M.; Hu, Q.; Li, Q.; Liu, H.; Yan, S.; Gu, C.; Zhao, W.; Huang, R.; Wu, Y. First Demonstration of Annealing-Free Top Gate La:HZO-IGZO FeFET with Record Memory Window and Endurance. In Proceedings of the 2023 International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 9–13 December 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Chernikova, A.G.; Kozodaev, M.G.; Negrov, D.V.; Korostylev, E.V.; Park, M.H.; Schroeder, U.; Hwang, C.S.; Markeev, A.M. Improved Ferroelectric Switching Endurance of La-Doped Hf0.5Zr0.5O2 Thin Films. ACS Appl. Mater. Interfaces 2018, 10, 2701–2708. [Google Scholar] [CrossRef]

- Walke, A.M.; Popovici, M.I.; Sharifi, S.H.; Demir, E.C.; Puliyalil, H.; Bizindavyi, J.; Yasin, F.; Clima, S.; Fantini, A.; Belmonte, A.; et al. La Doped HZO-Based 3D-Trench Metal-Ferroelectric-Metal Capacitors with High-Endurance (>10¹²) for FeRAM Applications. IEEE Electron Device Lett. 2024, 45, 578–581. [Google Scholar] [CrossRef]

- Xu, K.; Wang, T.; Liu, Y.; Yu, J.; Liu, Y.; Li, Z.; Meng, J.; Zhu, H.; Sun, Q.; Zhang, D.W.; et al. La-Doped HZO (La:HZO) Ferroelectric Devices Toward High-Temperature Application. IEEE Trans. Electron Devices 2024, 71, 5375–5379. [Google Scholar] [CrossRef]

- Walke, A.M.; Clima, S.; I Popovici, M.; Van Houdt, J. Understanding Anti-ferroelectric Behavior and Wake-up in La Doped HZO Metal-FerroelectricMetal Capacitors Using Nucleation Limited Switching Model. In Proceedings of the 2024 IEEE European Solid-State Electronics Research Conference (ESSERC), Bruges, Belgium, 9–12 September 2024; pp. 565–568. [Google Scholar] [CrossRef]

- Mehmood, F.; Mikolajick, T.; Schroeder, U. Wake-Up Mechanisms in Ferroelectric Lanthanum-Doped Hf0.5Zr0.5O2 Thin Films. Phys. Status Solidi (A) 2020, 217, 2000281. [Google Scholar] [CrossRef]

- Umezawa, N.; Shiraishi, K.; Sugino, S.; Tachibana, A.; Ohmori, K.; Kakushima, K.; Iwai, H.; Chikyow, T.; Ohno, T.; Nara, Y.; et al. Suppression of oxygen vacancy formation in Hf-based high-k dielectrics by lanthanum incorporation. Appl. Phys. Lett. 2007, 91, 132904. [Google Scholar] [CrossRef]

- Jeong, J.; Han, Y.; Sohn, H. Effect of La doping on dielectric constant and tetragonality of ZrO2 thin films deposited by atomic layer deposition. J. Alloys Compd. 2022, 927, 166961. [Google Scholar] [CrossRef]

- Mehmood, F.; Hoffmann, M.; Lomenzo, P.D.; Richter, C.; Materano, M.; Mikolajick, T.; Schroeder, U. Bulk Depolarization Fields as a Major Contributor to the Ferroelectric Reliability Performance in Lanthanum Doped Hf0.5Zr0.5O2 Capacitors. Adv. Mater. Interfaces 2019, 6, 1901180. [Google Scholar] [CrossRef]

- Weng, Z.; Lan, Z.; Ding, Y.; Qu, Y.; Zhao, Y. Orthorhombic-I Phase and Related Phase Transitions: Mechanism of Superior Endurance (>1014) of HfZrO Anti-ferroelectrics for DRAM Applications. In Proceedings of the 2024 IEEE International Reliability Physics Symposium (IRPS), 14–18 April 2024; pp. P11.EM-1–P11.EM-6. [Google Scholar] [CrossRef]

- Hsiang, K.-Y.; Liao, C.-Y.; Liu, J.-H.; Wang, J.-F.; Chiang, S.-H.; Hsieh, F.-C.; Liang, H.; Lin, C.-Y.; Lou, Z.-F.; Hou, T.-H.; et al. Bilayer-Based Antiferroelectric HfZrO2 Tunneling Junction with High Tunneling Electroresistance and Multilevel Nonvolatile Memory. IEEE Electron Device Lett. 2021, 42, 1464–1467. [Google Scholar] [CrossRef]

- Li, J.; Zhou, J.; Wu, F.; Lee, C.; Zhao, Y. BEOL Compatible High-reliability La-doped ZrO2 Antiferroelectric Capacitor. In Proceedings of the Extended Abstracts of the 2024 International Conference on Solid State Devices and Materials, 1–4 September 2024. [Google Scholar] [CrossRef]

- Li, J.; Zhou, J.; Wu, F.; Weng, Z.; Huo, Y.; Chen, Z.; Chen, L.; Qu, Y.; Lee, C.H.; Zhao, Y. Wake-up free La-doped ZrO2 antiferroelectric capacitors. Jpn. J. Appl. Phys. 2024, 63, 12SP13. [Google Scholar] [CrossRef]

- Goh, Y.; Hwang, J.; Jeon, S. Excellent Reliability and High-Speed Antiferroelectric HfZrO2 Tunnel Junction by a High-Pressure Annealing Process and Built-In Bias Engineering. ACS Appl. Mater. Interfaces 2020, 12, 57539–57546. [Google Scholar] [CrossRef]

- Pesic, M.; Larcher, L.; Mikolajick, T.; Li, T.; Di Lecce, V.; Hoffmann, M.; Materano, M.; Richter, C.; Max, B.; Slesazeck, S.; et al. Built-In Bias Generation in Anti-Ferroelectric Stacks: Methods and Device Applications. IEEE J. Electron Devices Soc. 2018, 6, 1019–1025. [Google Scholar] [CrossRef]

- Pesic, M.; Hoffmann, M.; Richter, C.; Slesazeck, S.; Schroeder, U.; Mikolajick, T. Anti-ferroelectric-like ZrO2 non-volatile memory: Inducing non-volatility within state-of-the-art DRAM. In Proceedings of the 2017 17th Nonvolatile Memory Technology Symposium (NVMTS), Aachen, Germany, 30 August–1 September 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Pesic, M.; Knebel, S.; Hoffmann, M.; Richter, C.; Mikolajick, T.; Schroeder, U. How to make DRAM non-volatile? Anti-ferroelectrics: A new paradigm for universal memories. In Proceedings of the 2016 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 3–7 December 2016; pp. 11.6.1–11.6.4. [Google Scholar] [CrossRef]

- Wang, X.-R.; Jiang, Y.-L.; Xie, Q.; Detavernier, C.; Ru, G.-P.; Qu, X.-P.; Li, B.-Z. Annealing effect on the metal gate effective work function modulation for the Al/TiN/SiO2/p-Si structure. Microelectron. Eng. 2011, 88, 573–577. [Google Scholar] [CrossRef]

- Pandey, R.K.; Sathiyanarayanan, R.; Kwon, U.; Narayanan, V.; Murali, K.V.R.M. Role of point defects and HfO2/TiN interface stoichiometry on effective work function modulation in ultra-scaled complementary metal–oxide–semiconductor devices. J. Appl. Phys. 2013, 114, 034505. [Google Scholar] [CrossRef]

- Li, Y.; Tang, X.; Xu, G.; Li, H.; He, S.; Hu, X.; Su, X.; Bai, W.; Lu, D.; Long, S. The Effects of Postdeposition Anneal and Postmetallization Anneal on Electrical Properties of TiN/ZrO2/TiN Capacitors. IEEE Trans. Electron Devices 2022, 70, 59–64. [Google Scholar] [CrossRef]

- Sathiyanarayanan, R.; Vaidya, D. Effective Work Function Computation of HfO2/TiN/W Bi-metal System: Role of Barrier-TiN. In Proceedings of the 2020 5th IEEE International Conference on Emerging Electronics (ICEE), New Delhi, India, 26–28 November 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Calzolari, A.; Catellani, A. Controlling the TiN Electrode Work Function at the Atomistic Level: A First Principles Investigation. IEEE Access 2020, 8, 156308–156313. [Google Scholar] [CrossRef]

- Kadoshima, M.; Matsuki, T.; Miyazaki, S.; Shiraishi, K.; Chikyo, T.; Yamada, K.; Aoyama, T.; Nara, Y.; Ohji, Y. Effective-Work-Function Control by Varying the TiN Thickness in Poly-Si/TiN Gate Electrodes for Scaled High-k CMOSFETs. IEEE Electron Device Lett. 2009, 30, 466–468. [Google Scholar] [CrossRef]

- Choi, K.; Lysaght, P.; Alsbareef, H.; Wen, H.-C.; Huffman, C.; Harris, R.; Luan, H.; Matthews, K.; Majhi, P.; Lee, B. Growth mechanism of ALD-TiN and the thickness dependence of work function. In Proceedings of the IEEE VLSI-TSA International Symposium on VLSI Technology, Hsinchu, Taiwan, 25–27 April 2005; pp. 103–104. [Google Scholar] [CrossRef]

- Choi, K.; Wen, H.-C.; Alshareef, H.; Harris, R.; Lysaght, P.; Luan, H.; Majhi, P.; Lee, B. The effect of metal thickness, overlayer and high-k surface treatment on the effective work function of metal electrode. In Proceedings of the 35th European Solid-State Device Research Conference, Grenoble, France, 12–16 September 2005; pp. 101–104. [Google Scholar] [CrossRef]

- Zhejiang Liryder Technologies Co., Ltd. Available online: https://www.liryder.com/en/ (accessed on 6 April 2025).

- Wang, Q.; Zhang, Y.; Yang, P.; Cao, R.; Liu, H.; Xu, H.; Liu, S.; Li, Q. Improved Symmetry of Ferroelectric Switching in HZO Based MFM Capacitors Enabled by High Pressure Annealing. IEEE J. Electron Devices Soc. 2022, 10, 1009–1014. [Google Scholar] [CrossRef]

- Wiemer, C.; Debernardi, A.; Lamperti, A.; Molle, A.; Salicio, O.; Lamagna, L.; Fanciulli, M. Influence of lattice parameters on the dielectric constant of tetragonal ZrO2 and La-doped ZrO2 crystals in thin films deposited by atomic layer deposition on Ge(001). Appl. Phys. Lett. 2011, 99, 232907. [Google Scholar] [CrossRef]

- Gaddam, V.; Das, D.; Jeon, S. Insertion of HfO2 Seed/Dielectric Layer to the Ferroelectric HZO Films for Heightened Remanent Polarization in MFM Capacitors. IEEE Trans. Electron Devices 2020, 67, 745–750. [Google Scholar] [CrossRef]

- Yuan, P.; Mao, G.-Q.; Cheng, Y.; Xue, K.-H.; Zheng, Y.; Yang, Y.; Jiang, P.; Xu, Y.; Wang, Y.; Wang, Y.; et al. Microscopic mechanism of imprint in hafnium oxide-based ferroelectrics. Nano Res. 2022, 15, 3667–3674. [Google Scholar] [CrossRef]

- Rabe, K.M.; Ahn, C.H.; Triscone, J.-M. Physics of ferroelectrics: A modern perspective. In Topics in Applied Physics; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar] [CrossRef]

- Chen, D.; Zhong, S.; Dong, Y.; Cui, T.; Liu, J.; Si, M.; Li, X. Antiferroelectric Phase Evolution in HfxZr1-xO2 Thin Film Toward High Endurance of Non-Volatile Memory Devices. IEEE Electron Device Lett. 2022, 43, 2065–2068. [Google Scholar] [CrossRef]

- Liu, C.-H.; Hsiang, K.-Y.; Li, Z.-X.; Chang, F.-S.; Lou, Z.-F.; Lee, J.-Y.; Liu, C.W.; Su, P.; Hou, T.-H.; Lee, M.-H. Nonvolatile and Volatile Memory Fusion of Antiferroelectric-like Hafnium–Zirconium Oxide for Multi-Bit Access and Endurance >1012 Cycles by Alternating Polarity Cycling Recovery and Spatially Resolved Evolution. ACS Appl. Mater. Interfaces 2025, 17, 14342–14349. [Google Scholar] [CrossRef]

- Pesic, M.; Hoffmann, M.; Richter, C.; Slesazeck, S.; Kampfe, T.; Eng, L.M.; Mikolajick, T.; Schroeder, U. Anti-ferroelectric ZrO2, an enabler for low power non-volatile 1T-1C and 1T random access memories. In Proceedings of the 2017 47th European Solid-state Device Research Conference (ESSDERC), Leuven, Belgium, 11–14 September 2017; pp. 160–163. [Google Scholar] [CrossRef]

- Toprasertpong, K.; Tahara, K.; Hikosaka, Y.; Nakamura, K.; Saito, H.; Takenaka, M.; Takagi, S. Low Operating Voltage, Improved Breakdown Tolerance, and High Endurance in Hf0.5Zr0.5O2 Ferroelectric Capacitors Achieved by Thickness Scaling Down to 4 nm for Embedded Ferroelectric Memory. ACS Appl. Mater. Interfaces 2022, 14, 51137–51148. [Google Scholar] [CrossRef]

- Kim, S.J.; Mohan, J.; Kim, H.S.; Lee, J.; Young, C.D.; Colombo, L.; Summerfelt, S.R.; San, T.; Kim, J. Low-voltage operation and high endurance of 5-nm ferroelectric Hf0.5Zr0.5O2 capacitors. Appl. Phys. Lett. 2018, 113, 182903. [Google Scholar] [CrossRef]

- Li, J.; Wang, H.; Du, X.; Luo, Z.; Wang, Y.; Bai, W.; Su, X.; Shen, S.; Yin, Y.; Li, X. High endurance (>1012) via optimized polarization switching ratio for Hf0.5Zr0.5O2-based FeRAM. Appl. Phys. Lett. 2023, 122, 082901. [Google Scholar] [CrossRef]

- Yu, Z.; Saini, B.; Liao, P.J.; Chang, Y.K.; Hou, V.; Nien, C.H.; Shih, Y.C.; Yeong, S.H.; Afanas’Ev, V.; Huang, F.; et al. CeO2-Doped Hf0.5Zr0.5O2 Ferroelectrics for High Endurance Embedded Memory Applications. In Proceedings of the 2022 International Symposium on VLSI Technology, Systems and Applications (VLSI-TSA), Hsinchu, Taiwan, 18–21 April 2022; pp. 1–2. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).