Singularity Analysis and Mode-Switching Planning of a Symmetrical Multi-Arm Robot

Abstract

1. Introduction

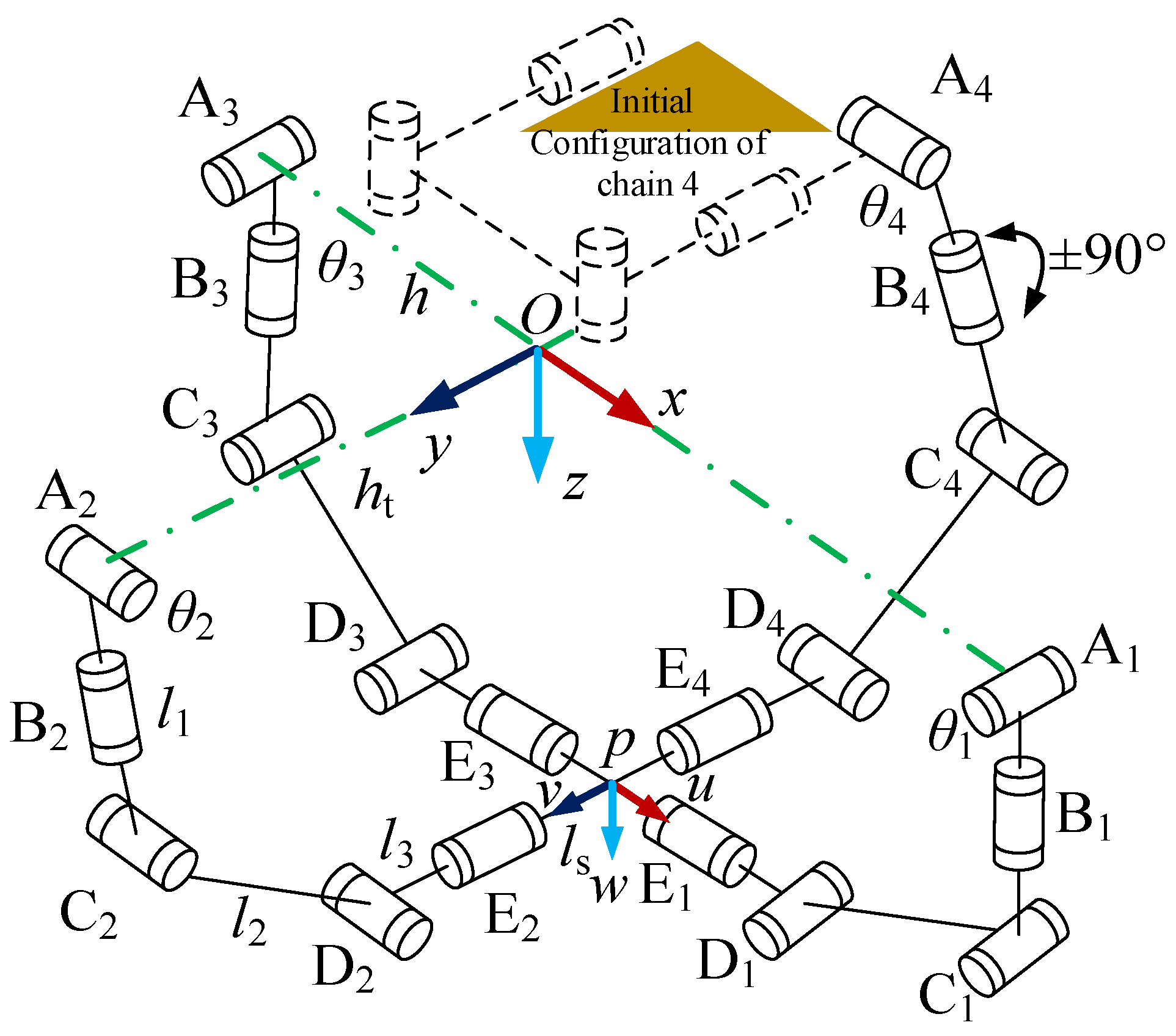

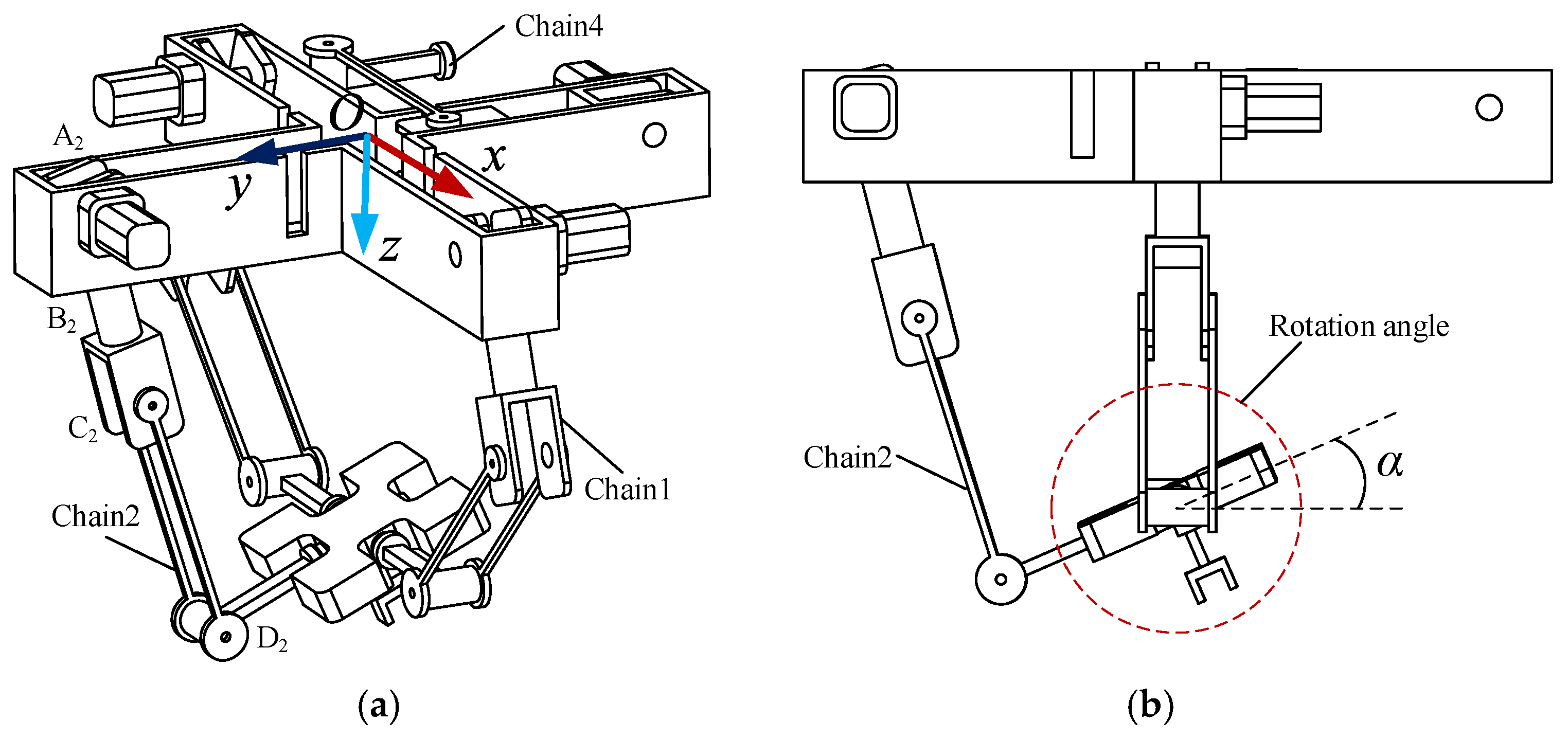

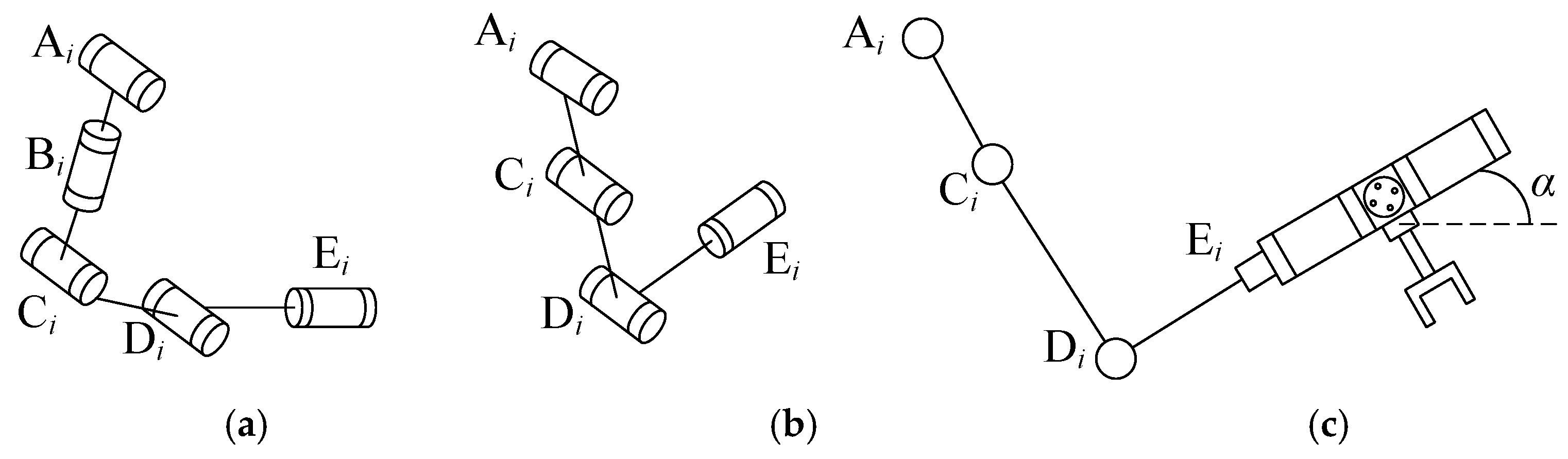

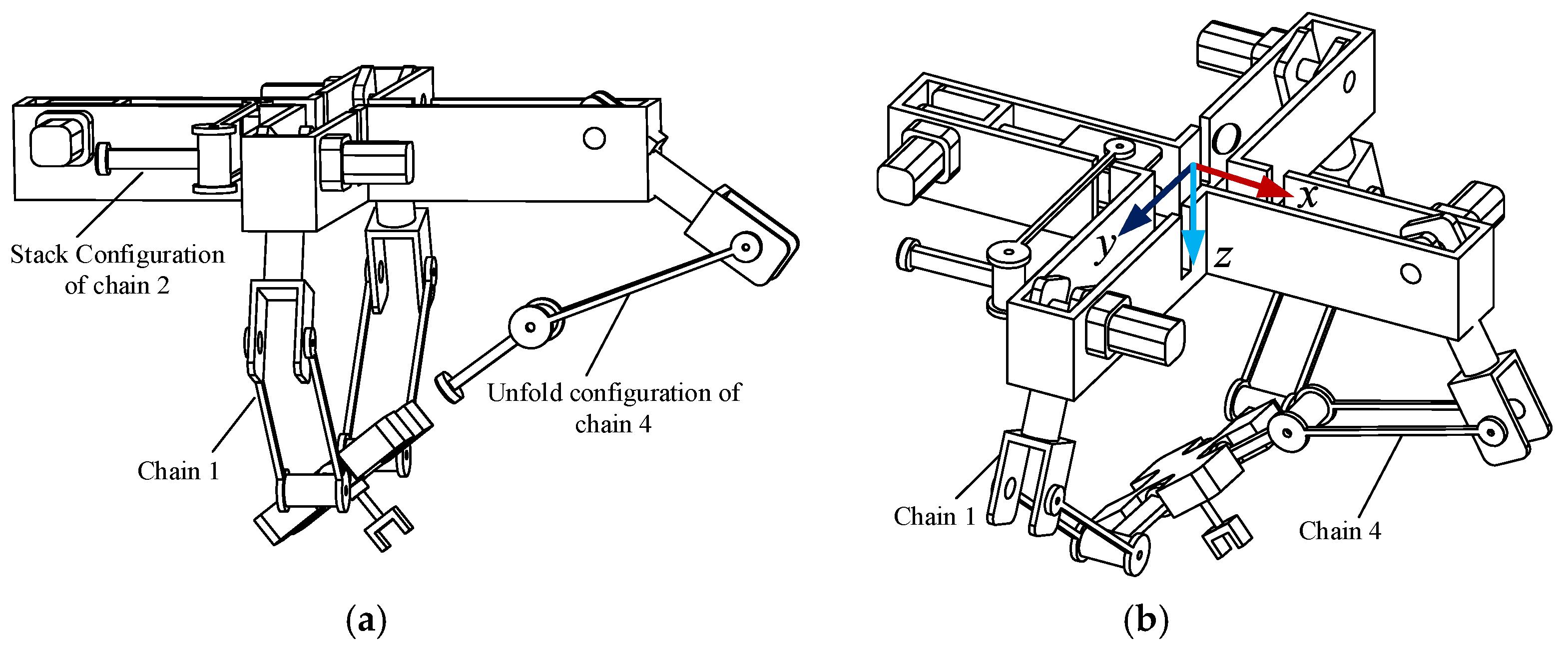

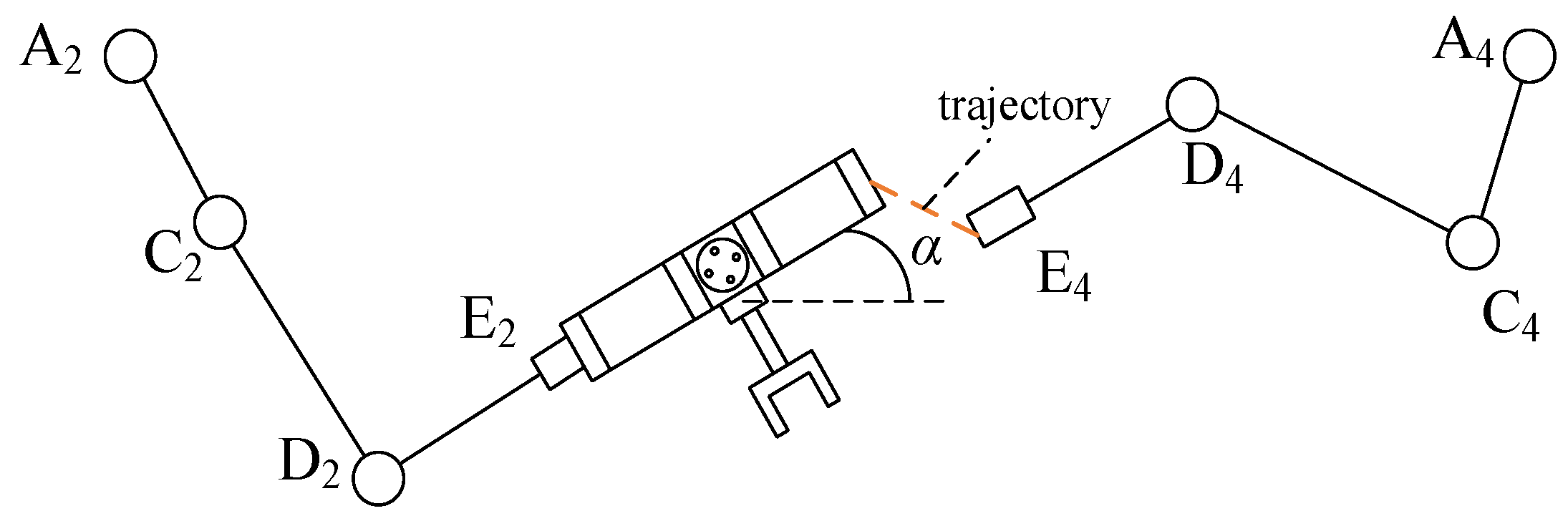

2. Mechanism Design and Analysis of a Multi-Arm Robot with a Symmetrical Structure

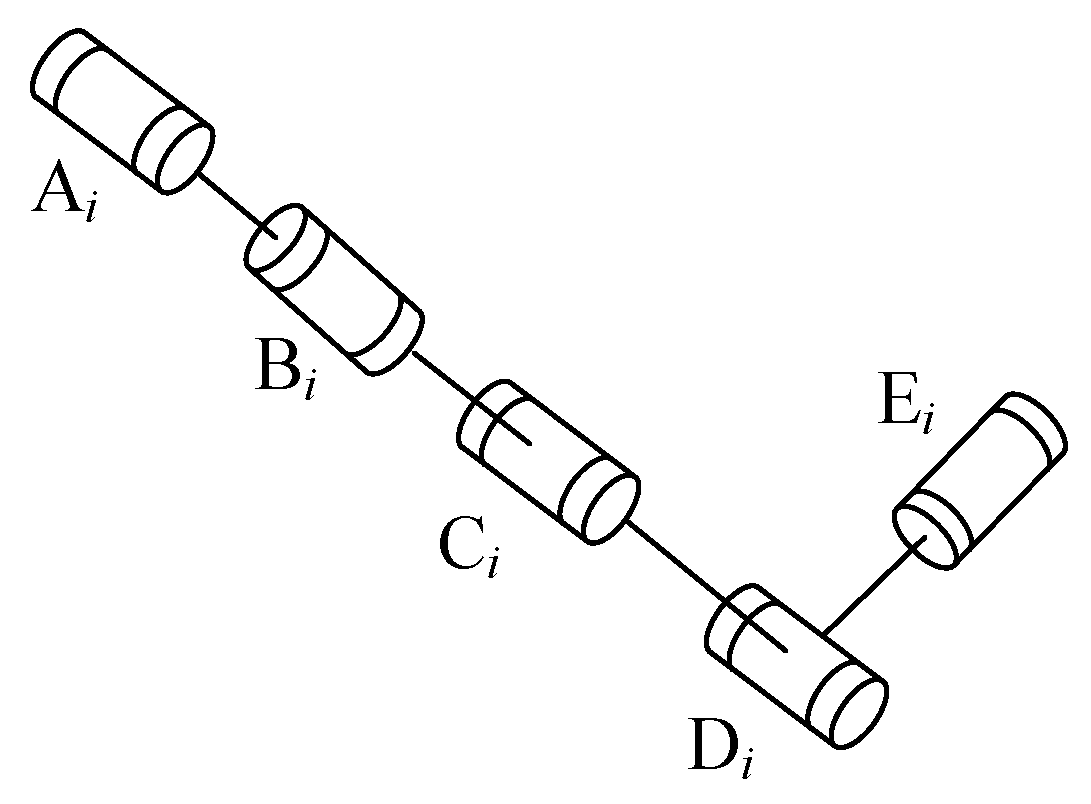

2.1. Mechanism Design

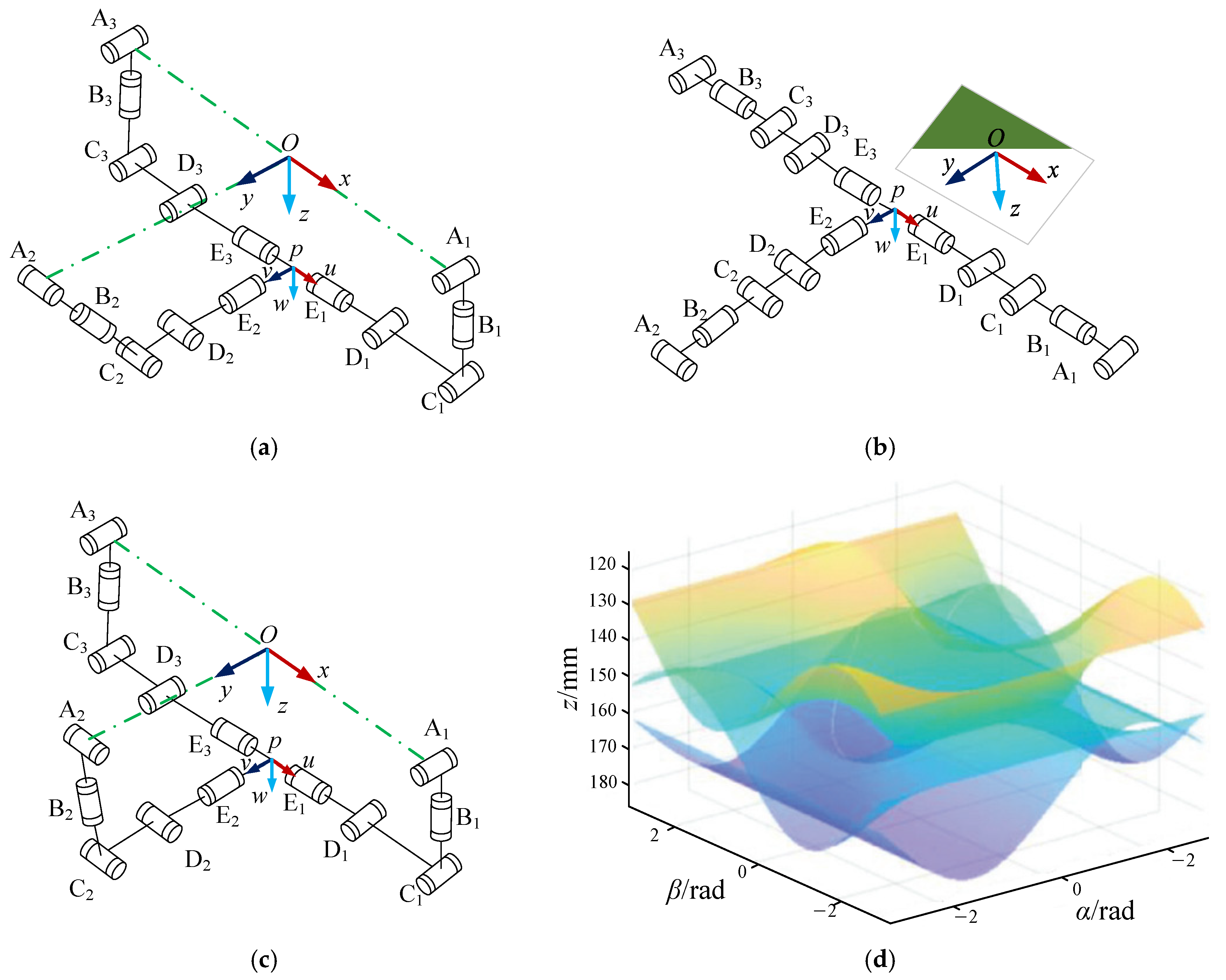

2.2. Kinematics Analysis

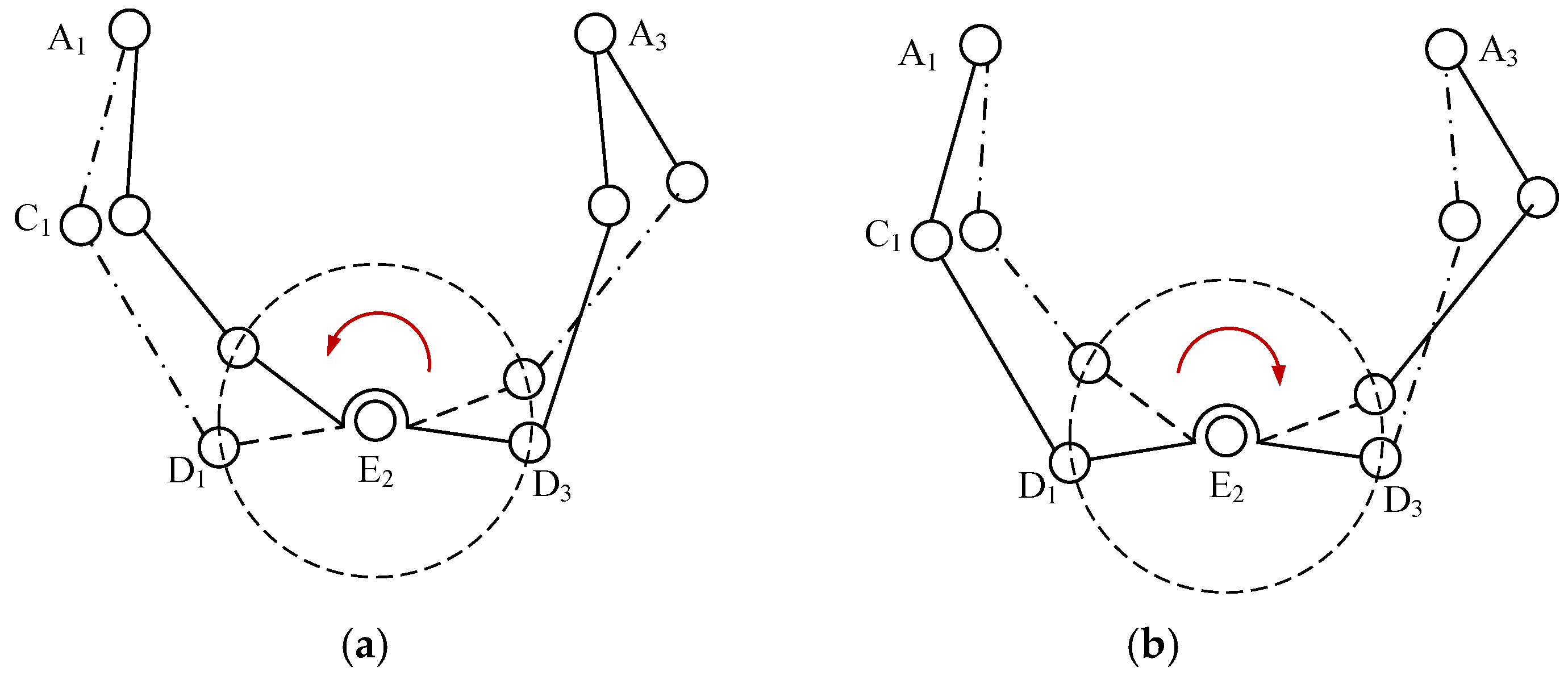

2.3. Singularity Analysis of Mechanism

2.3.1. Forward Kinematics Singularity

2.3.2. Inverse Kinematic Singularity

2.3.3. Combinatorial Singularity

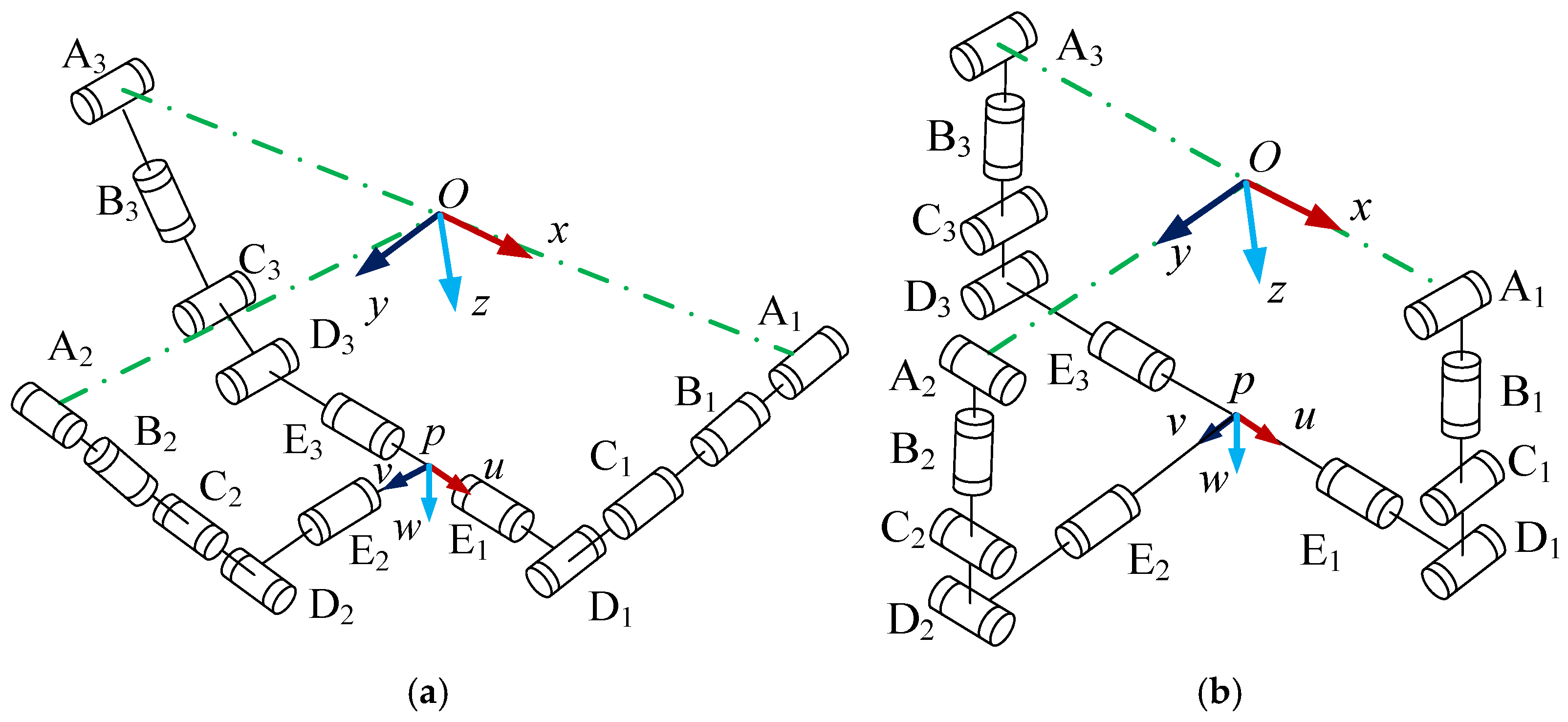

2.4. Motion Planning Based on a Type-I Singular Branch Chain

3. Simulation Control of the Planning of Branch-Chain Switching

3.1. Position and Pose Model of Branch-Chain Motion

3.2. Path Planning Algorithm for Branch Chains

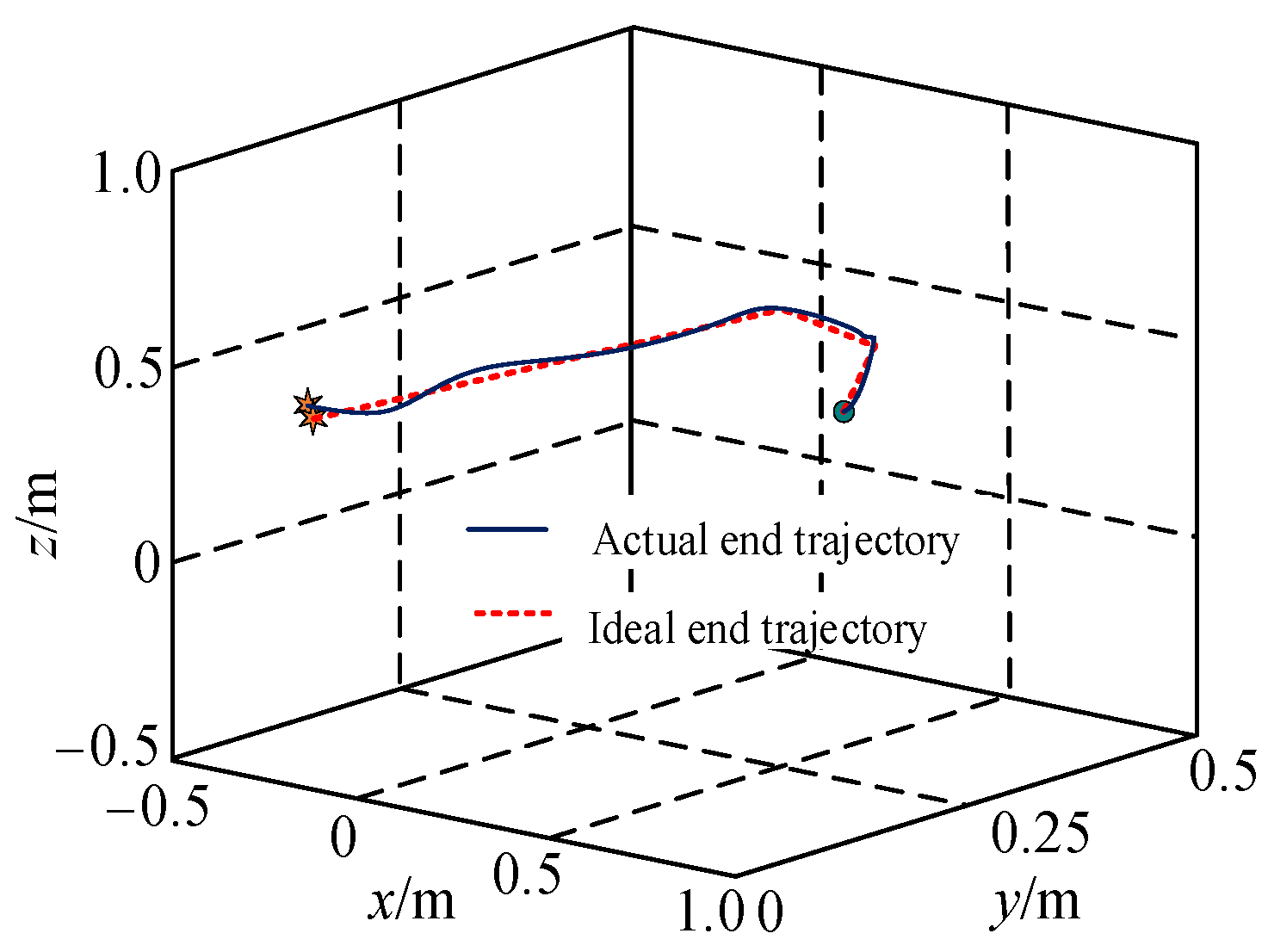

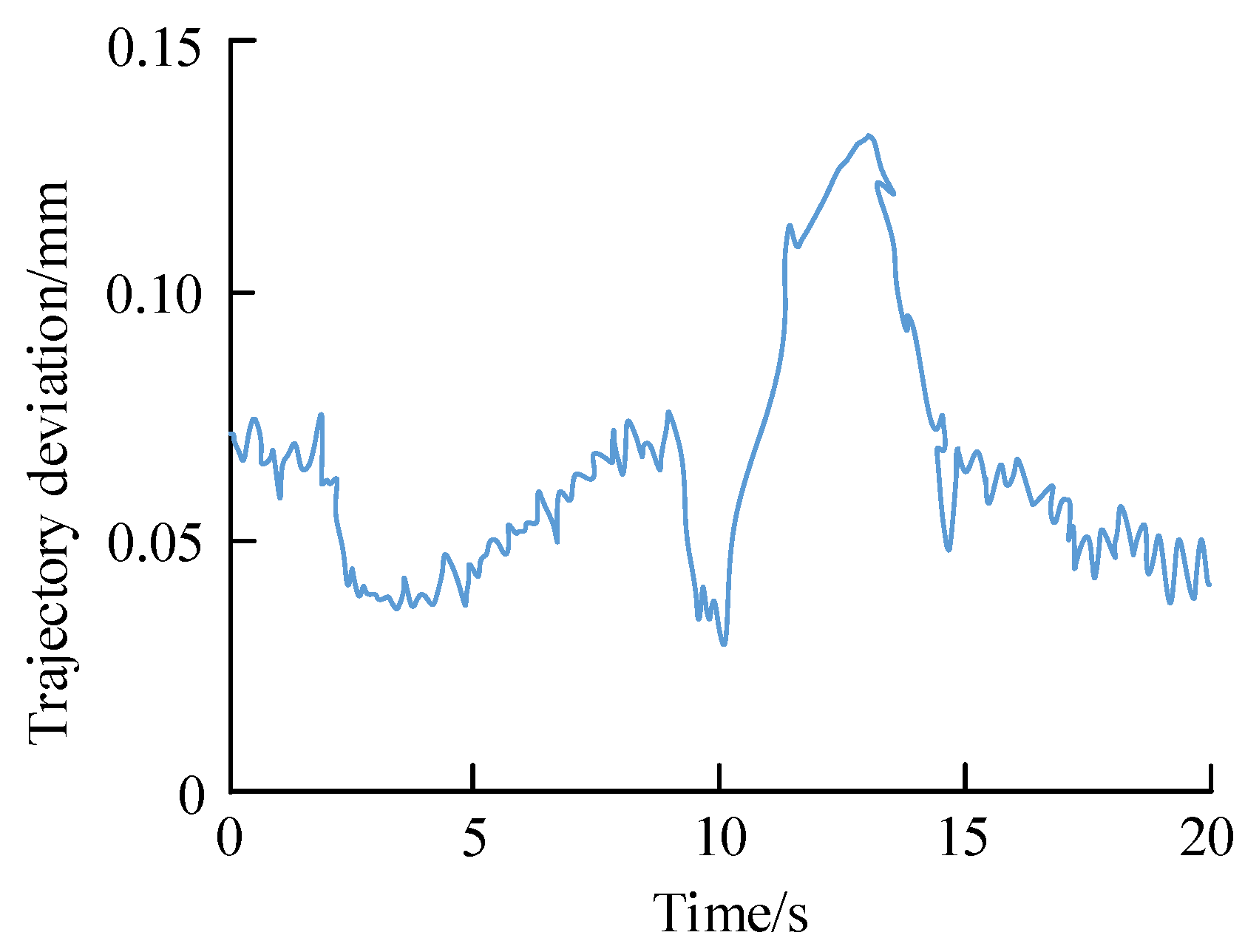

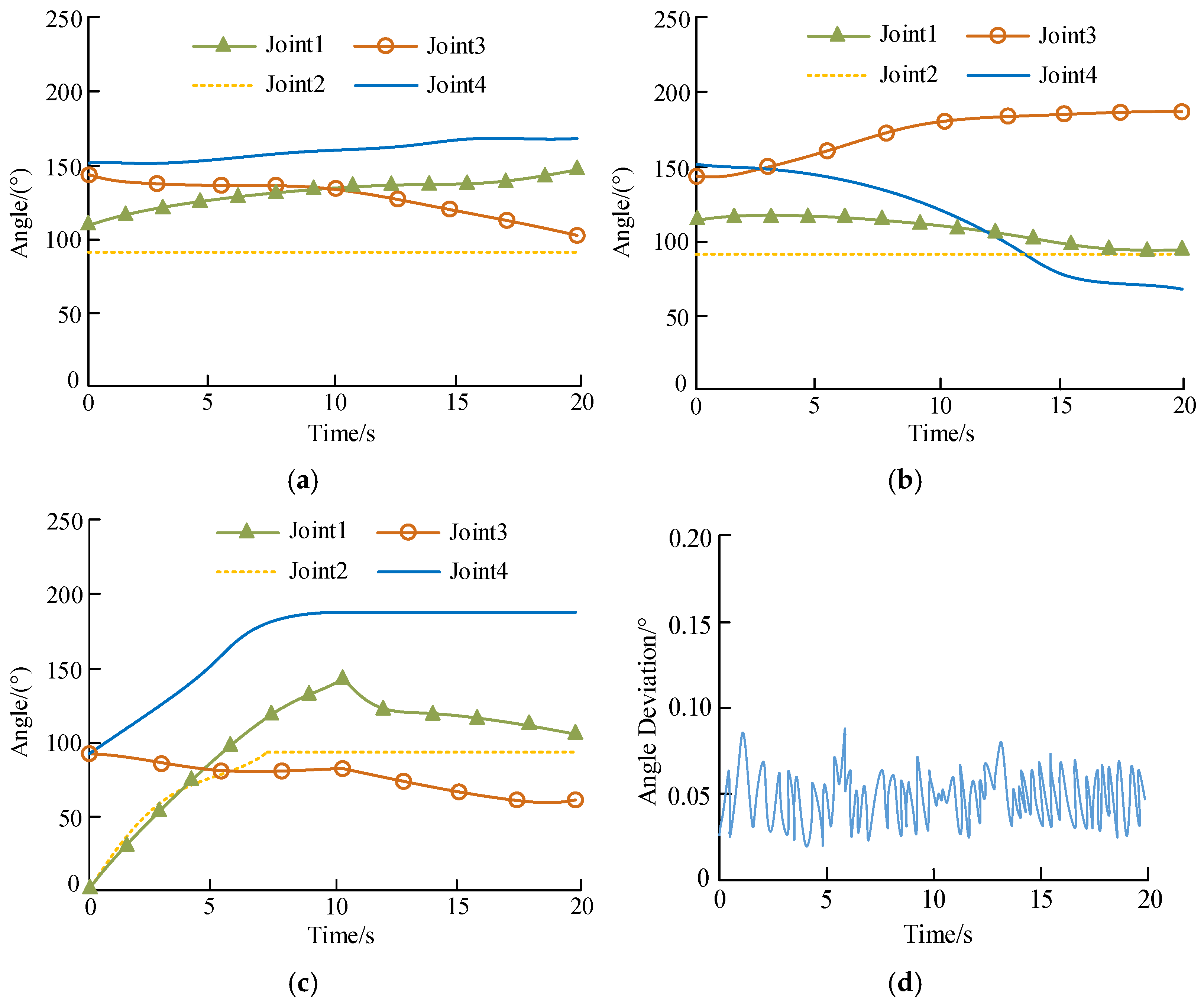

3.3. Simulation Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dai, Y.C.; Li, Z.; Chen, X.J. A Novel Space Robot with Triple Cable-Driven Continuum Arms for Space Grasping. Micromachines 2023, 14, 416. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Jin, H.; Ge, M. Real-Time Kinematically Synchronous Planning for Cooperative Manipulation of Multi-Arms Robot Using the Self-Organizing Competitive Neural Network. Sensors 2023, 23, 5120. [Google Scholar] [CrossRef]

- Liu, J.J.; Chen, Y.T.; Dong, Z.P. Robot cooking with stir-fry: Bimanual non-prehensile manipulation of semi-fluid objects. IEEE Robot. Autom. Lett. 2022, 7, 5159–5166. [Google Scholar] [CrossRef]

- Avigal, Y.; Berscheid, L.; Asfour, T. Speedfolding: Learning efficient bimanual folding of garments. In Proceedings of the 2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), IEEE, Kyoto, Japan, 23–27 October 2022; pp. 1–8. [Google Scholar]

- McGhan, C.L.R.; Atkins, E.M. Human productivity in a workspace shared with a safe robotic manipulator. J. Aerosp. Inf. Syst. 2014, 11, 42753. [Google Scholar] [CrossRef]

- Myron, A.; Joshua, M.; Muhammad, E. Robonaut 2-the first humanoid robot in space. In Proceedings of the IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 2178–2183. [Google Scholar]

- Roderick, S.; Roberts, B.; Atkins, E. The ranger robotic satellite servicer and its autonomous software-based safety system. IEEE Intell. Syst. 2004, 19, 12–19. [Google Scholar] [CrossRef]

- David, J.C.; Ulrik, P.S.; Kasper, S. A distributed and morphology-independent strategy for adaptive locomotion in self-reconfigurable modular robots. Robot. Auton. Syst. 2013, 61, 1021–1035. [Google Scholar]

- Saburo, M. Advanced space robot for in-orbit servicing mission. Jpn. Soc. Mech. Eng. 2003, 46, A6–A8. [Google Scholar]

- Aghili, F.; Parsa, K. A reconfigurable robot with lockable cylindrical joints. IEEE Trans. Robot. 2009, 25, 785–797. [Google Scholar] [CrossRef]

- Ibarkreche, J.I.; Hernández, A.; Petuya, V. A methodology to achieve the set of operation modes of reconfigurable parallel manipulators. Meccanica 2019, 54, 2507–2520. [Google Scholar] [CrossRef]

- Corves, B.; Mannheim, T.; Riedel, M. Re-grasping: Improving capability for multi-arm robot system by dynamic reconfiguration. In Proceedings of the International Conference on Intelligent Robotics and Applications, Aachen, Germany, 6–8 December 2011; pp. 132–141. [Google Scholar]

- Tian, C.; Zhang, D. Design and analysis of novel kinematically redundant reconfigurable generalized parallel manipulators. Mech. Mach. Theory 2021, 166, 104481. [Google Scholar] [CrossRef]

- Tian, C.X.; Fang, Y.F.; Guo, S. Structure synthesis of reconfigurable parallel mechanisms with closed-loop metamorphic linkages. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 1303–1316. [Google Scholar] [CrossRef]

- Tian, C.X.; Xia, Z.H.; Li, L.Q. The novel synthesis of reconfigurable generalized parallel manipulators with kinematic redundancy. Mech. Mach. Theory 2024, 201, 105748. [Google Scholar] [CrossRef]

- Tian, C.X.; Zhang, D.; Tang, H.Y. Structure synthesis of reconfigurable generalized parallel mechanisms with configurable platforms. Mech. Mach. Theory 2021, 160, 104281. [Google Scholar] [CrossRef]

- Riedel, M.; Corves, B.; Nefzi, M. An adjustable gripper as a reconfigurable robot with a parallel structure. In Proceedings of the Second International Workshop on Fundamental Issues and Future Research Directions for Parallel Mechanisms and Manipulators, Montpellier, France, 21–22 September 2008; pp. 1–8. [Google Scholar]

- Jin, X.D.; Fang, Y.F.; Zhang, D. Synthesis of 3-[P][S] Parallel Mechanism-Inspired Multimode Dexterous Hands With Parallel Finger Structure. J. Mech. Des. 2020, 142, 083301. [Google Scholar] [CrossRef]

- Jin, X.D.; Fang, Y.F.; Zhang, D. Design of a class of generalized parallel mechanisms with large rotational angles and integrated end-effectors. Mech. Mach. Theory 2019, 134, 117–134. [Google Scholar] [CrossRef]

- Zhao, F.Q.; Guo, S.; Su, H.J. Design of self-reconfigurable multiarm robot mechanism based on deployable kinematic chains. Chin. J. Mech. Eng. 2020, 33, 70. [Google Scholar] [CrossRef]

- Xu, D.L.; Guo, S.; Zhao, F.Q. Design and Analysis of a Bimanual Parallel Dexterous Hand with Cooperative Manipulation Capability. J. Mech. Robot. 2025, 17, 061014. [Google Scholar] [CrossRef]

- Xue, Z.H.; Liu, J.G.; Li, Y.M. Configuration Optimization of a Dual-Arm Reconfigurable Space Robot Based on Closed-Chain Inertia Matching. IEEE Trans. Autom. Sci. Eng. 2024, 1–18. [Google Scholar] [CrossRef]

- Moosavian, A.; Xi, F.J. Design and analysis of reconfigurable parallel robots with enhanced stiffness. Mech. Mach. Theory 2014, 77, 92–110. [Google Scholar] [CrossRef]

- Gao, F.; Li, W.M.; Zhao, X.C. New kinematic structures for 2-, 3-, 4-, and 5-dof parallel manipulator designs. Mech. Mach. Theory 2002, 11, 37. [Google Scholar] [CrossRef]

- Gao, F.; Yang, J.; Ge, Q.J. Type synthesis of parallel mechanisms having the second class GF sets and two dimensional rotations. J. Mech. Robot. 2011, 3, 011003. [Google Scholar] [CrossRef]

- Gosselin, C.M.; Angeles, J. Singularity analysis of closed-loop kinematic chains. IEEE Trans. Robot. Autom. 1990, 6, 281–290. [Google Scholar] [CrossRef]

- Xu, W.; Li, C.; Liang, B. The Cartesian path planning of free-floating space robot using particle swarm optimization. Int. J. Adv. Robot. Syst. 2008, 5, 301–331. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, M.; Wang, M.; Jiang, D.; Li, E.; Xu, D.; Zhao, F.; Jin, X. Singularity Analysis and Mode-Switching Planning of a Symmetrical Multi-Arm Robot. Electronics 2025, 14, 1131. https://doi.org/10.3390/electronics14061131

Gao M, Wang M, Jiang D, Li E, Xu D, Zhao F, Jin X. Singularity Analysis and Mode-Switching Planning of a Symmetrical Multi-Arm Robot. Electronics. 2025; 14(6):1131. https://doi.org/10.3390/electronics14061131

Chicago/Turabian StyleGao, Meng, Meijing Wang, Da Jiang, Erkang Li, Donglai Xu, Fuqun Zhao, and Xiaodong Jin. 2025. "Singularity Analysis and Mode-Switching Planning of a Symmetrical Multi-Arm Robot" Electronics 14, no. 6: 1131. https://doi.org/10.3390/electronics14061131

APA StyleGao, M., Wang, M., Jiang, D., Li, E., Xu, D., Zhao, F., & Jin, X. (2025). Singularity Analysis and Mode-Switching Planning of a Symmetrical Multi-Arm Robot. Electronics, 14(6), 1131. https://doi.org/10.3390/electronics14061131