Development and Application of a Vertical-Agnostic Methodological Assessment Framework for Evaluation of 5G-Based Use Cases

Abstract

1. Introduction and Motivation

2. Methodological Assessment Framework

- (1)

- Start with the value proposition from the user’s perspective: determine the value proposition that is to be achieved through use case implementation (e.g., lower cycle time of a manufacturing process) as well as the product as the outcome of the successful use case application.

- (2)

- (3)

- Determine how the selected User-KPI or User-KVI can be calculated (e.g., through customized equations based on process data) or estimated based on expert estimates.

- (4)

- Define the use case requirements that need to be fulfilled by the employed 5G network so that the use case can be carried out successfully and the User-KPI and User-KVI, which have been selected in Step 3, can be calculated.

- (5)

- Define the evaluation scenario as the step-by-step instructions for the execution of the use case under consideration, including information on what data is to be acquired through measurements.

- (6)

- Evaluate the use case by calculating/estimating User-KPI sand/or User-KVIs and quantify its value proposition.

3. Application of the Methodological Assessment Framework

3.1. Application of the MAF to a Manufacturing Use Case

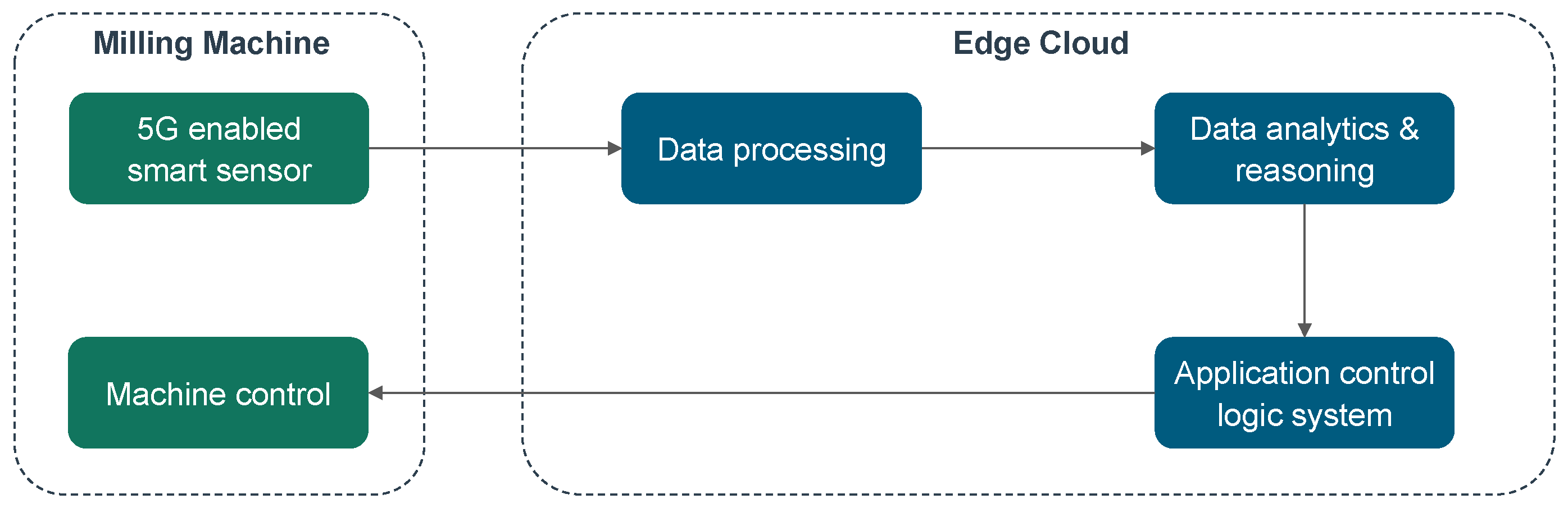

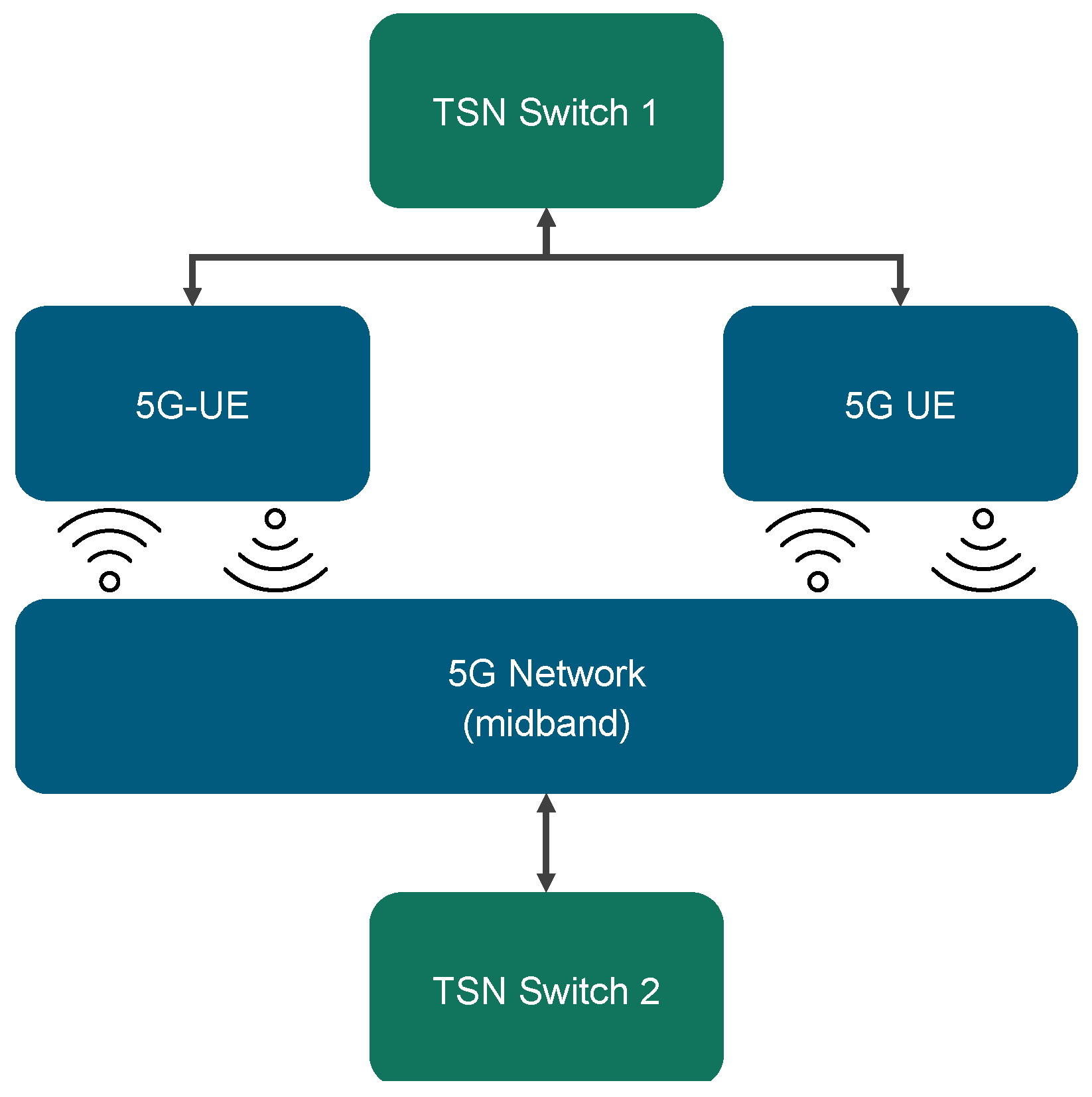

3.1.1. Description of the Use Case

3.1.2. Description of the Selected User-KPI and Evaluation of the Use Case

3.2. Application of the MAF to a Construction Use Case

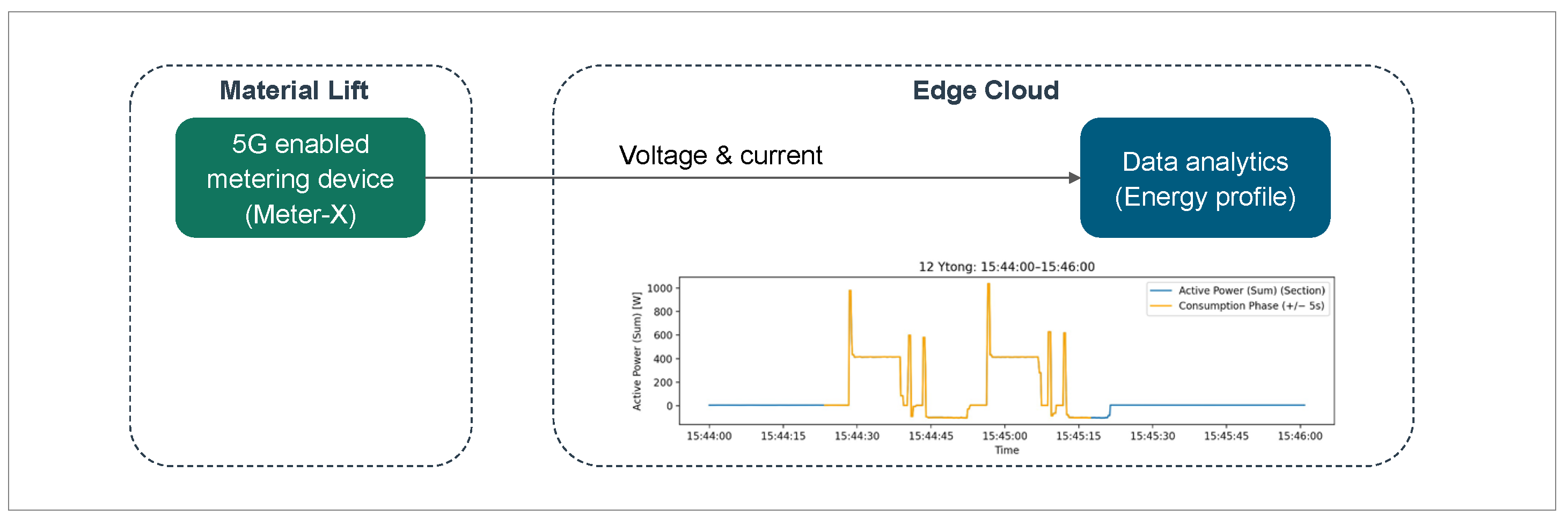

3.2.1. Description of the Use Case

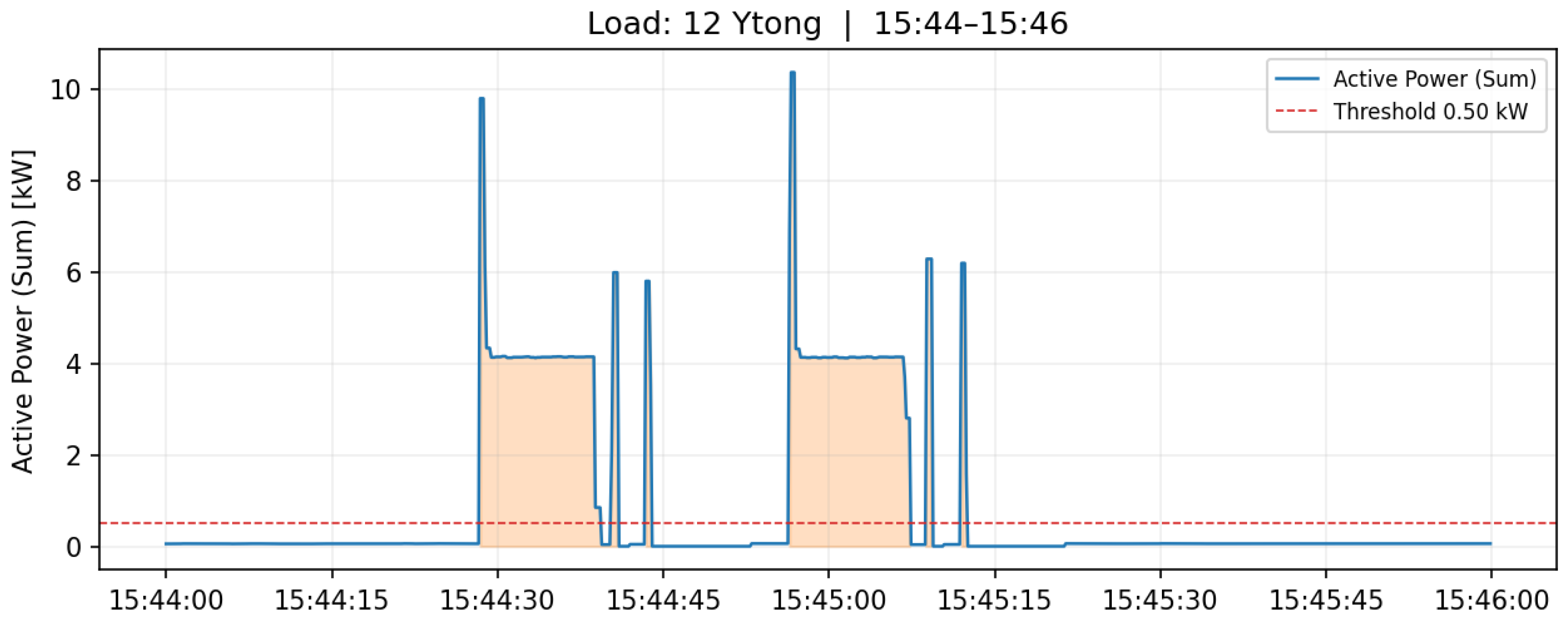

3.2.2. Description of the Selected User-KVI and Evaluation of the Use Case

3.3. Application of the MAF to an Automotive Use Case

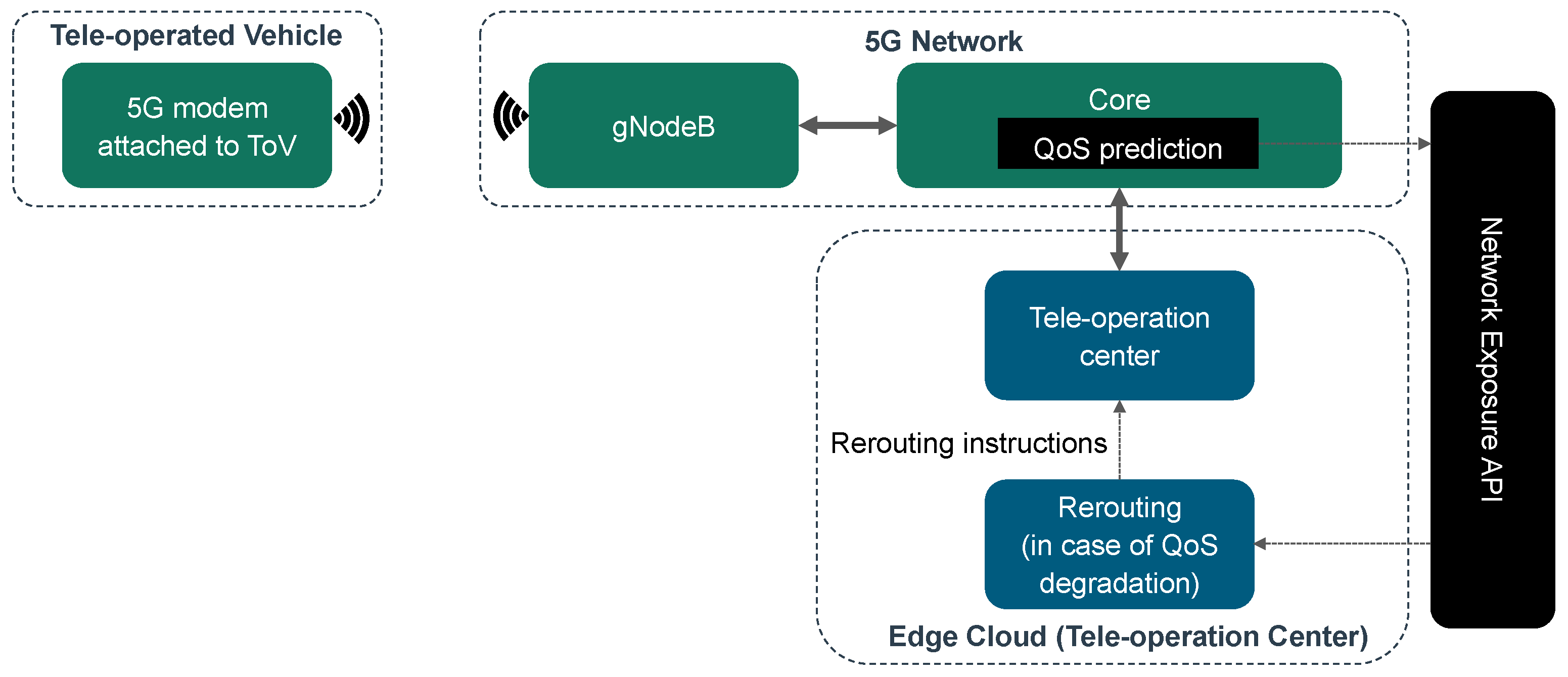

3.3.1. Description of the Use Case

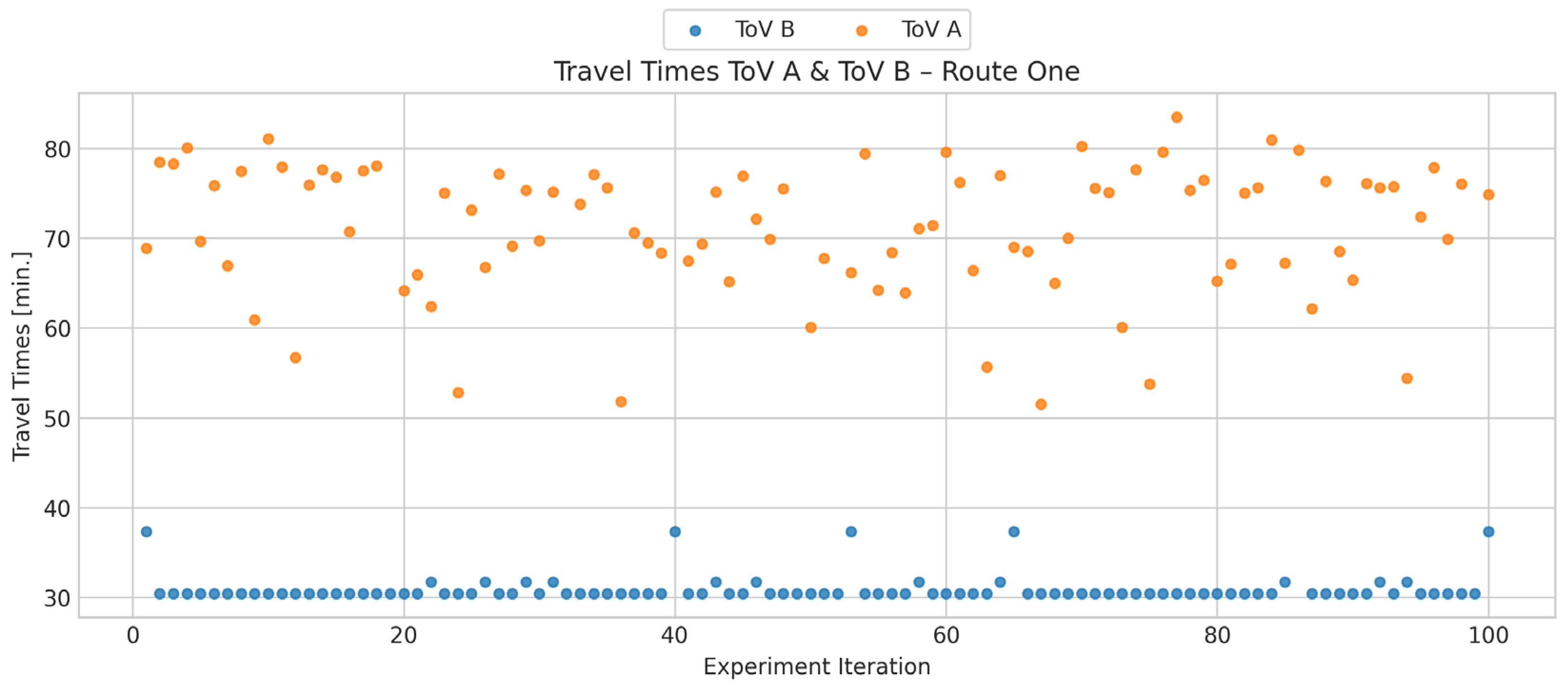

3.3.2. Description of the Selected User-KPI and Evaluation of the Use Case

4. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| 5G | Fifth Generation of Cellular Network Technology |

| 5G-ACIA | 5G Alliance for Connected Industries and Automation |

| 6G | Sixth Generation of Cellular Network Technology |

| EU | European Union |

| FRER | Frame Replication and Elimination for Reliability |

| ISO | International Organization for Standardization |

| KPI | Key Performance Indicator |

| KVI | Key Value Indicator |

| NEF | Network Exposure Function |

| NWDAF | Network Data Analytics Function |

| LCA | Life Cycle Assessment |

| LT | Lower Tolerance |

| MAF | Methodological Assessment Framework |

| NPV | Net Present Value |

| OEE | Overall Equipment Efficiency |

| QoS | Quality of Service |

| RoI | Return on Investment |

| SDG | Sustainable Development Goals |

| ToV | Tele-operated Vehicle |

| TSN | Time-Sensitive Networking |

| UT | Upper Tolerance |

References

- Attaran, M. The impact of 5G on the evolution of intelligent automation and industry digitization. J. Ambient. Intell. Humaniz. Comput. 2023, 14, 5977–5993. [Google Scholar] [CrossRef] [PubMed]

- Apruzzese, M.; Bruni, M.E.; Musso, S.; Perboli, G. 5G and Companion Technologies as a Boost in New Business Models for Logistics and Supply Chain. Sustainability 2023, 15, 11846. [Google Scholar] [CrossRef]

- Cheng, J.; Yang, Y.; Zou, X.; Zuo, Y. 5G in manufacturing: A literature review and future research. Int. J. Adv. Manuf. Technol. 2024, 131, 5637–5659. [Google Scholar] [CrossRef]

- Mertes, J.; Glatt, M.; Schellenberger, C.; Simon, P.M.; Yi, L.; Schotten, H.D.; Aurich, J.C. Implementation and Evaluation of 5G-enabled sensors for Machine Tools. Procedia CIRP 2023, 120, 45–50. [Google Scholar] [CrossRef]

- Lundgren, C.; Turanoglu Bekar, E.; Bärring, M.; Stahre, J.; Skoogh, A.; Johansson, B.; Hedman, R. Determining the impact of 5G-technology on manufacturing performance using a modified TOPSIS method. Int. J. Comput. Integr. Manuf. 2022, 35, 69–90. [Google Scholar] [CrossRef]

- Walia, J.S.; Hammainen, H.; Flinck, H. Future scenarios and value network configurations for industrial 5G. In Proceedings of the 2017 8th International Conference on the Network of the Future (NOF), London, UK, 22–24 November 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 79–84, ISBN 978-1-5386-0554-7. [Google Scholar]

- Jassim, M.M.; Mosa, M.M.; Okbi, Z.A.I.; Abdullah, S.B.; Taha, S.W.; Migo, P.; Kondakova, S. Cost-Effectiveness Analysis of IoT Deployment in 5G Networks. In Proceedings of the 2024 36th Conference of Open Innovations Association (FRUCT), Lappeenranta, Finland, 30 October–1 November 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 493–502, ISBN 978-952-65246-2-7. [Google Scholar]

- Nancarrow, S.A.; Booth, A.; Ariss, S.; Smith, T.; Enderby, P.; Roots, A. Ten principles of good interdisciplinary team work. Hum. Resour. Health 2013, 11, 19. [Google Scholar] [CrossRef] [PubMed]

- Parmenter, D. Key Performance Indicators: Developing, Implementing, and Using Winning KPIs, 4th ed.; Wiley: Hoboken, NJ, USA, 2020; ISBN 978-1-119-62077-8. [Google Scholar]

- Kehl, P.E.; Ansari, J.; Lovrin, M.; Mohanram, P.; Liu, C.-C.; Yeh, J.-L.; Schmitt, R.H. 5G-TSN Integrated Prototype for Reliable Industrial Communication Using Frame Replication and Elimination for Reliability. Electronics 2025, 14, 758. [Google Scholar] [CrossRef]

- Manuel Pitz, M.P.; Marit Zöcklein, M.Z.; Manassés Pinheiro de Souza, L.; Kedar Rajpathak, K.R.; Amon Göppert, A.G.; Sigrid Brell-Cokcan, S.B.-C.; Robert, H.; Schmitt, R.H.S.; Antonello Monti, A.M. Enhancing Energy Monitoring in Construction and Robotics with Plug-and-Play Solution Meter-X. In Proceedings of the 2025 European Conference on Computing in Construction, Porto, Portugal, 14 July 2025; European Council for Computing in Construction: Sint-Niklaas, Belgium, 2025. [Google Scholar]

- Paul Salvati. Automotive Toolset and Service Implementation: TARGET-X Deliverable 4.2. 2024. Available online: https://target-x.eu/wp-content/uploads/2025/01/TARGET-X_D4.2_Final-Version.pdf (accessed on 7 October 2025).

- Pablo Tomasi, K.G. Special Report—5G in Manufacturing. Available online: https://omdia.tech.informa.com/om128397/special-report--5g-in-manufacturing (accessed on 7 October 2025).

- Fortier, P.; Gupta, M.; Karonis, F.; Mishra, S.; Merli, S.; Petit, J.-P.; Buvat, J.; Subrahmanyam, K.V.J.; Nambiar, R.; Khemka, Y. Accelerating the 5G Industrial Revolution: State of 5G and Edge in Industrial Operations. 2021. Available online: https://www.capgemini.com/wp-content/uploads/2021/06/Final-Web-Report-5G.pdf (accessed on 19 November 2025).

- Frank, H.; Colman-Meixner, C.; Assis, K.D.R.; Yan, S.; Simeonidou, D. Techno-Economic Analysis of 5G Non-Public Network Architectures. IEEE Access 2022, 10, 70204–70218. [Google Scholar] [CrossRef]

- Kokkinis, D.; Ioannou, N.; Katsianis, D.; Varoutas, D. A Techno-Economic Modeling Approach to 6G Network Deployment: Exploring Costs and Use Case Feasibility. IEEE Access 2025, 13, 35597–35608. [Google Scholar] [CrossRef]

- Chiha, A.; Denis, B.; Verbrugge, S.; Colle, D. Techno-Economic Analysis of MEC Clustering Models for Seamless CCAM Service Provision. IEEE Commun. Mag. 2023, 61, 32–37. [Google Scholar] [CrossRef]

- Nakimuli, W.; Garcia-Reinoso, J.; Sierra-Garcia, J.E.; Serrano, P.; Fernandez, I.Q. Deployment and Evaluation of an Industry 4.0 Use Case over 5G. IEEE Commun. Mag. 2021, 59, 14–20. [Google Scholar] [CrossRef]

- Bouali, F.; Pinola, J.; Karyotis, V.; Wissingh, B.; Mitrou, M.; Krishnan, P.; Moessner, K. 5G for Vehicular Use Cases: Analysis of Technical Requirements, Value Propositions and Outlook. IEEE Open J. Intell. Transp. Syst. 2021, 2, 73–96. [Google Scholar] [CrossRef]

- Brochhaus, M. Forward Looking Use Cases, Their Requirements and KPIs/KVIs: TARGET-X Deliverable 1.2. 2024. Available online: https://target-x.eu/wp-content/uploads/2025/01/241231_TARGET-X_Deliverable-1.2_vF.pdf (accessed on 7 October 2025).

- Brochhaus, M.; König, N.; Ortmann, M. Business Value and Return-on-Invest Calculation for Industrial 5G Use Cases: A 5G-ACIA White Paper, Frankfurt. 2025. Available online: https://5g-acia.org/whitepapers/business-value-and-return-on-invest-calculation-for-industrial-5g-use-cases/ (accessed on 1 October 2025).

- Patsouras, I.; Charemis, A.; Wedikkara Gedara, I.; Ghoraishi, M.; Basaras, P.; Mesogiti, I.; Theodoropoulou, E.; Lazaro, J.A.; Petersen, K. 6G KVIs—SNS Projects Initial Survey Results 2025. 2025. Available online: https://smart-networks.europa.eu/wp-content/uploads/2025/05/sns-ju-white-paper-6g-kvis-survey-2025_final-1.pdf (accessed on 25 November 2025).

- Wikström, G.; Bledow, N.; Matinmikko-Blue, M.; Breuer, H.; Costa, C.; Darzanos, G.; Gavras, A.; Hossfeld, T.; Mesogiti, I.; Petersen, K.; et al. Key value indicators: A framework for values-driven next-generation ICT solutions. Telecommun. Policy 2024, 48, 102778. [Google Scholar] [CrossRef]

- Stapenhurst, T. Mastering Statistical Process Control: A Handbook for Performance Improvement Using Cases; Elsevier Butterworth-Heinemann: Amsterdam, The Netherlands, 2005; ISBN 978 0 7506 6529 2. [Google Scholar]

- Lin, T.-H.; Huang, L.-C.; Chen, Y.-Y.; Lee, L.-C.; Lin, D.-Y.M. Implementing Process Capability Index (Cpk) for Effective Product Quality Stabilization: The Case of a Lock Manufacturing Company. Sens. Mater. 2025, 37, 1211. [Google Scholar] [CrossRef]

- DIN ISO 22514-2:2019-07; Statistische Verfahren im Prozessmanagement_-Fähigkeit und Leistung_-Teil_2: Prozessleistungs-und Prozessfähigkeitskenngrößen von zeitabhängigen Prozessmodellen (ISO_22514-2:2017). DIN Media GmbH: Berlin, Germany, 2019; (In Deutsch and English).

- Pereira, P.; Seghatchian, J.; Caldeira, B.; Xavier, S.; de Sousa, G. Statistical control of the production of blood components by control charts of attribute to improve quality characteristics and to comply with current specifications. Transfus. Apher. Sci. 2018, 57, 285–290. [Google Scholar] [CrossRef] [PubMed]

- Ishak, A.; Mohamad, E.; Hambali, A.; Johari, N.L. The reliability and process capability assessment of suspended growth sewage treatment plant in Melaka, Malaysia. Water Sci. Technol. 2022, 86, 2233–2247. [Google Scholar] [CrossRef] [PubMed]

- United Nations, Department of Economic and Social Affairs. Transforming our World: The 2030 Agenda for Sustainable Development. Available online: https://sdgs.un.org/sites/default/files/publications/21252030%20Agenda%20for%20Sustainable%20Development%20web.pdf (accessed on 7 October 2025).

- John, J.; Noor-A-Rahim, M.; Vijayan, A.; Poor, H.V.; Pesch, D. Industry 4.0 and Beyond: The Role of 5G, WiFi 7, and Time-Sensitive Networking (TSN) in Enabling Smart Manufacturing. Future Internet 2024, 16, 345. [Google Scholar] [CrossRef]

- Cheng, J.; Chen, W.; Tao, F.; Lin, C.-L. Industrial IoT in 5G environment towards smart manufacturing. J. Ind. Inf. Integr. 2018, 10, 10–19. [Google Scholar] [CrossRef]

- Kehl, P.; Mohanram, P.; Manassés, L. Report on Working Demonstrators and Validation Implemented for 5G/6G Technologies in Manufacturing: TARGET-X Deliverable 2.5. 2025. Available online: https://target-x.eu/wp-content/uploads/2025/09/TARGET-X_D2.5_V1.0_Report_on_working_demonstrators_and_validation_implemented_for_5G_6G_technologies_in_manufacturing.pdf (accessed on 7 October 2025).

- 802.1CB-2017; IEEE Standard for Local and Metropolitan Area Networks—Frame Replication and Elimination for Reliability. IEEE: Piscataway, NJ, USA, 2017.

- Khan, A.M.; Alrasheed, K.A.; Waqar, A.; Almujibah, H.; Benjeddou, O. Internet of things (IoT) for safety and efficiency in construction building site operations. Sci. Rep. 2024, 14, 28914. [Google Scholar] [CrossRef] [PubMed]

- Chnaidini, S.; Khan, M.J.; Ullah, F.; Khan, A.A.; Prashar, D. 5G The Missing Piece in Digital Transformation of The Construction Sector. In Proceedings of the 2024 28th International Computer Science and Engineering Conference (ICSEC), Khon Kaen, Thailand, 6–8 November 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6, ISBN 979-8-3503-6686-0. [Google Scholar]

- Mendoza, J.; de-la-Bandera, I.; Álvarez-Merino, C.S.; Khatib, E.J.; Alonso, J.; Casalderrey-Díaz, S.; Barco, R. 5G for Construction: Use Cases and Solutions. Electronics 2021, 10, 1713. [Google Scholar] [CrossRef]

- Pitz, M. Pilot Sites Energy: TARGET-X Deliverable 3.5. 2024. Available online: https://target-x.eu/wp-content/uploads/2025/01/TARGET-X-D3.5-V1.0-Pilot-sites-energy.pdf (accessed on 7 October 2025).

- DIN EN ISO 14040:2009-11; Umweltmanagement_-Ökobilanz_-Grundsätze und Rahmenbedingungen (ISO_14040:2006). Deutsche und Englische Fassung EN_ISO_14040:2006. Beuth Verlag GmbH: Berlin, Germany, 2009.

- DIN EN ISO 14044:2021-02; Umweltmanagement_-Ökobilanz_-Anforderungen und Anleitungen (ISO_14044:2006_+Amd_1:2017_+Amd_2:2020); Deutsche Fassung EN_ISO_14044:2006_+A1:2018_+A2:2020. DIN Media GmbH: Berlin, Germany, 2021.

- Kakkavas, G.; Nyarko, K.N.; Lahoud, C.; Kuhnert, D.; Kuffner, P.; Gabriel, M.; Ehsanfar, S.; Diamanti, M.; Karyotis, V.; MoBner, K.; et al. Teleoperated Support for Remote Driving over 5G Mobile Communications. In Proceedings of the 2022 IEEE International Mediterranean Conference on Communications and Networking (MeditCom), Athens, Greece, 5–8 September 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 280–285, ISBN 978-1-6654-9825-8. [Google Scholar]

- Marquez-Barja, J.; Hadiwardoyo, S.A.; Maglogiannis, V.; Naudts, D.; Moerman, I.; Hellinckx, P.; Verbrugge, S.; Delaere, S.; Vandenberghe, W.; Kenis, E.; et al. Enabling cross-border tele-operated transport in the 5G Era: The 5G Blueprint approach. In Proceedings of the 2021 IEEE 18th Annual Consumer Communications & Networking Conference (CCNC), Las Vegas, NV, USA, 9–12 January 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–4, ISBN 978-1-7281-9794-4. [Google Scholar]

- Oliver, R.R.; Nasreddine, J.; Camps-Mur, D.; Salvati, P. Reducing travel times of Tele-Operated vehicles through Connected Road Maps. In Proceedings of the MSWiM’25, the 27th International ACM Conference on Modeling Analysis and Simulation of Wireless and Mobile Systems, Barcelona, Spain, 27–31 October 2025. [Google Scholar]

| Techno-Economic Goals | User-KPI |

|---|---|

| Expanding Process Insights | Accuracy of Process and Product Data |

| Completeness of Process and Product Data | |

| Consistency of Process and Product Data | |

| Reliability of Process and Product Data | |

| Timeliness of Process and Product Data | |

| Uniqueness of Process and Product Data | |

| Validity of Process and Product Data | |

| Increasing Operational Capability | Process Performance Index (Ppk) |

| Process Capability (cp & cpk) | |

| Process Variability | |

| Increasing Process Efficiency | Cycle Time |

| Throughput | |

| First-pass Yield | |

| Overall Equipment Efficiency (OEE) | |

| Error Rate | |

| Quality Rate | |

| Worker Efficiency | |

| Increased Profitability | Net Present Value (NPV) |

| Return on Investment (RoI) |

| Societal Goals | User-KVI |

|---|---|

| Improvement of Safety-Related Aspects | Work Accident Rate Manufacturing |

| Work Accident Rate Construction | |

| Absolute Number of Prevented Traffic Accidents | |

| Transparency About Ecological Impacts | Global Warming Potential |

| Water Consumption | |

| Ozone Depletion | |

| Photochemical Ozone Formation | |

| Depletion of Abiotic Resources (Minerals and Metals) | |

| Depletion of Abiotic Resources (Fossil Fuels) | |

| Digital Inclusion | Digital Literacy |

| User-KVI | Calculated Values | Unit |

|---|---|---|

| Global Warming Potential | 7.22 × 10−3 | kg CO2-eq. |

| Water Consumption | 2.89 × 10−3 | m3 |

| Ozone Depletion | 1.43 × 10−10 | kg CFC 11-eq. |

| Photochemical Ozone Formation | 2.20 × 10−5 | kg NMVOC-eq. |

| Consumed Electricity Per Kilogram of Transported Mass | 1.19 × 10−4 | kWh/kg |

| Calculated cp and cpk Values | Route One | Route Two |

|---|---|---|

| ToV A, cp | 0.228 | 0.153 |

| ToV A, cpk | 0.228 | 0.153 |

| ToV B, cp | 1.082 | 2.838 |

| ToV B, cpk | 1.082 | 2.838 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brochhaus, M.; Kehl, P.; Grunert, D.; König, N.; Schmitt, R.H.; Zöcklein, M.; Brell-Cokcan, S.; Nasreddine, J. Development and Application of a Vertical-Agnostic Methodological Assessment Framework for Evaluation of 5G-Based Use Cases. Electronics 2025, 14, 4771. https://doi.org/10.3390/electronics14234771

Brochhaus M, Kehl P, Grunert D, König N, Schmitt RH, Zöcklein M, Brell-Cokcan S, Nasreddine J. Development and Application of a Vertical-Agnostic Methodological Assessment Framework for Evaluation of 5G-Based Use Cases. Electronics. 2025; 14(23):4771. https://doi.org/10.3390/electronics14234771

Chicago/Turabian StyleBrochhaus, Maximilian, Pierre Kehl, Dennis Grunert, Niels König, Robert H. Schmitt, Marit Zöcklein, Sigrid Brell-Cokcan, and Jad Nasreddine. 2025. "Development and Application of a Vertical-Agnostic Methodological Assessment Framework for Evaluation of 5G-Based Use Cases" Electronics 14, no. 23: 4771. https://doi.org/10.3390/electronics14234771

APA StyleBrochhaus, M., Kehl, P., Grunert, D., König, N., Schmitt, R. H., Zöcklein, M., Brell-Cokcan, S., & Nasreddine, J. (2025). Development and Application of a Vertical-Agnostic Methodological Assessment Framework for Evaluation of 5G-Based Use Cases. Electronics, 14(23), 4771. https://doi.org/10.3390/electronics14234771