Abstract

This article presents an innovative methodological approach for the documentation and enhancement of ancient ironworking heritage in the Guéra region of Chad. By combining ethno-historical and archaeological surveys, 3D modeling with Blender, and the generation of images and video sequences through artificial intelligence (AI), we propose an integrated production pipeline enabling the faithful reconstruction of three types of metallurgical furnaces. Our method relies on rigorously collected field data to generate multiple and plausible representations from fragmentary information. A standardized evaluation grid makes it possible to assess the archaeological fidelity, cultural authenticity, and visual quality of the reconstructions, thereby limiting biases inherent to generative models. The results offer strong potential for integration into immersive environments, opening up perspectives in education, digital museology, and the virtual preservation of traditional ironworking knowledge. This work demonstrates the relevance of multimodal approaches in reconciling scientific rigor with engaging visual storytelling.

Keywords:

paleometallurgy; Guéra; archaeology; iron metallurgy; oral traditions; 3D reconstruction; AI 1. Introduction

1.1. Research Context on Ancient Iron Metallurgy in Africa

Archaeological research devoted to ancient iron metallurgy in Africa has, for several decades, occupied a central place in studies on traditional technologies and associated social dynamics. These works have mainly been oriented around two major lines of inquiry. The first concerns the origin and modes of diffusion of iron across the African continent, an issue that has been extensively explored in the scientific literature [1,2,3,4,5,6,7,8,9]. The second line focuses on the diversity of techniques employed and on the evolution of metallurgical know-how across time and space [10,11,12,13,14,15,16,17,18,19,20].

1.2. Variability of Ironworking Techniques

Iron metallurgy represents, in many regions of Africa, an ancient technological activity whose processes display great variability. This diversity is expressed at different scales—between countries, regions, sites, and even within a single archaeological site—and may manifest both simultaneously, within the same space and during the same period, as well as over time. Although the direct production method is widely attested across the continent, ironworking remains reveal marked heterogeneity both in reduction techniques and in the scale of production [21].

1.3. Socio-Economic Role of Iron in Pre-Industrial African Societies

In pre-industrial African societies, iron was an essential material, whose constant use strongly influenced economic, social, and cultural dynamics [22]. Iron metallurgy played a structuring role, with notable developments in resource exploitation, ore processing, and tool manufacturing [23]. The development of this technology contributed to profound transformations of societies, affecting agricultural, artisanal, and military practices alike [15]. This centrality of iron led to an increasing investment of researchers in this field, making the African continent a unique laboratory for comparative studies on ancient technologies [11].

1.4. Persistence of Traditions and Combined Approaches

Traditional iron production persisted in several regions until the 20th century, enabling researchers to combine ethnographic and archaeological approaches. These studies have made it possible to identify an exceptional metallurgical heritage, ranging from small-scale local productions to districts specialized in large-scale production intended for long-distance exchange networks [4,14].

1.5. Research Gaps in Chad and Focus on the Guéra Region

However, certain geographical areas remain largely unexplored, particularly Chad, where archaeometallurgical studies are still fragmentary. While the northern and southern regions of the country present a partially documented archaeological heritage [24,25,26,27,28,29,30,31,32], the central region of Guéra remains understudied, despite the well-attested presence of significant ironworking sites, such as the iron mines of Télé-Nougar mentioned as early as the beginning of the 20th century [33].

In this article, we focus on archaeometallurgy in the Guéra region (central Chad), with the main objective of inventorying ironworking sites and characterizing the technical traditions implemented there. This work is part of a broader approach to valorizing Chadian archaeological heritage and aims to fill a notable gap in research on ancient metallurgy in Central Africa [34].

1.6. Technological Context: AI, AR/VR, and 3D Reconstruction

AI-assisted 3D reconstruction is attracting increasing interest in the fields of augmented reality (AR), computer vision, and cultural heritage [35,36]. These technologies make it possible not only to automate the modeling of objects from textual descriptions or images but also to generate immersive scenes for analysis, dissemination, and cultural mediation [37,38].

In archaeology, feed-forward methods for view synthesis and 3D reconstruction—particularly through deep neural networks, Neural Radiance Fields (NeRF) [39,40], or 3D Gaussian Splatting [41]—offer a promising avenue for rapidly creating usable representations in AR or VR. At the same time, the so-called “AI multiverse” approach proposes generating multiple plausible interpretations from fragmentary data, a valuable strategy for addressing the uncertainty inherent in archaeological sources [42].

The documentation and 3D reconstruction of built heritage in Saharan and Sub-Saharan Africa have already been the subject of several scientific initiatives. In Niger, recent studies have highlighted the relevance of digital approaches for preserving the historical monuments of Agadez [43]. In the same dynamic, the Zamani Project has built an exceptional database by combining laser scanning, photogrammetry, and 3D modeling of emblematic sites such as the Great Mosque of Djenné (Mali), the churches of Lalibela (Ethiopia), and the site of Kilwa Kisiwani (Tanzania) [44,45]. Specific studies on the Great Mosque of Djenné have demonstrated the relevance of 3D reconstruction for virtual accessibility and heritage management [46]. In North Africa, complementary experiences have been carried out, notably on the Roman arch of Musti in Tunisia [47] and the ksar of Timimoun in Algeria, documented by “low-cost” photogrammetry for earthen architecture [48]. Finally, in Ghana, the immersive visualization of Elmina Castle through 3D models optimized for mobile virtual reality illustrates the adaptability of these methods to diverse technical environments [49]. These initiatives show that the digital reconstruction of African heritage, whether Saharan or Sub-Saharan, is now part of an international research dynamic, offering strong perspectives for the conservation, valorization, and transmission of this fragile heritage.

1.7. Objectives and Positioning of the Study

This article lies at the intersection of these technological innovations and experimental archaeology. It proposes a novel methodological framework combining ethno-historical surveys, archaeological data, 3D modeling with Blender, and AI-based video generation via ChatGPT-5 and the Wan 2.1 platform. This approach aims to produce visual reconstructions faithful to documented technical traditions, while exploring the potential of immersive dissemination in AR/VR contexts.

2. Materials and Methods

2.1. Methodology of Oral Surveys

Interviews conducted with local populations constituted an essential method for accessing technical history and locating former metallurgical sites. In sub-Saharan societies, oral narratives play a central role in the transmission of technical and social knowledge [50,51]. This work relied on qualitative surveys with holders of technical memory, including blacksmiths, customary chiefs, farmers, notables, and potters, identified as eyewitnesses or heirs of ancient iron practices. These narratives notably made it possible to document the fact that iron production, still active until the early 20th century in certain regions, was only abandoned recently.

The interviews were carried out in parallel with field surveys. A flexible protocol was adopted: a clear presentation of the mission preceded each interview, followed by a semi-structured questionnaire addressing the origin of blacksmiths, their migratory paths, smelting techniques, and the use of iron objects. The exchanges were conducted in local languages or in Arabic to avoid any distortion related to translation.

2.1.1. Individual Interviews

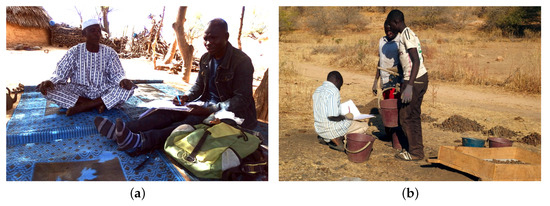

Individual interviews, conducted at the informants’ homes, created a climate of trust conducive to freedom of expression (cf. Figure 1a). This setting encouraged the collection of sensitive or little-known information, particularly regarding the social status of blacksmiths. Depending on the availability of the interlocutors, several sessions were carried out. The responses were transcribed directly, without the use of an interpreter, since one of the researchers on our team is a native of the region and therefore fully understands the local language.

Figure 1.

Individual interview sessions (a) and group sessions (b) with blacksmiths.

2.1.2. Collective Interviews

Collective interviews, organized in the presence of several informants (often at the village or lineage chief’s residence), facilitated inclusion and community consensus (cf. Figure 1b). Although rich in exchanges, these sessions sometimes presented limitations: reluctance to address sensitive issues, and difficulty in contradicting the authority of elders or chiefs.

2.1.3. Summary of the Survey Campaigns

Between 2016 and 2019, 28 villages were covered by the surveys:

- 2016: Three villages in Dangléat territory were the subject of preliminary surveys, which led to the identification of three metallurgical sites.

- 2017: An extensive campaign made it possible to travel by motorcycle through about twenty localities spread over 138 km. Around forty people were interviewed to document the sites, the smelting techniques, and settlement dynamics.

- 2018: The surveys focused on identifying metallurgists, the status of blacksmiths, and the location of new sites. Thirty-seven people were interviewed in ten villages.

- 2019: The investigations aimed to clarify the identity of metallurgists at certain sites and to verify the existence of new sites in the studied area. Four villages were visited and about twenty people were interviewed.

2.2. The History of the Daradik

In the context of this study, we first drew on oral sources concerning the Daradik in the Guéra region. Descended from a group of blacksmiths of Arab origin who came from Sudan, the Daradik are said to have settled in the region as early as the time of the Ouaddaï Kingdom (1611–1635) [52]. Metallurgists, hunters, and herders are today mainly present in the Kenga territory, but also in the Dangléat and Migami areas, particularly in Baro.

Their high mobility is linked to hunting, a complementary activity that requires frequent movements. According to the data collected, two main migratory routes can be identified: one coming from the east via Ouaddaï, the other from the west through Baguirmi.

The oral accounts collected in Ben-Djedid, notably from the chief of the Daradik blacksmiths, interviewed on 31 December 2016, recount that an ancestor reportedly left Narri (Ouaddaï) to settle in Tchikina (Baguirmi), before his descendants migrated to Bolongue, and then further east due to water scarcity. Other testimonies, such as those of the chief of the blacksmiths of Tchalo, interviewed on 9 January 2017, place a settlement in Ambakatché following a departure from Tchikina.

Alternative versions, collected in Abéché from three individuals in 2017, confirm an early presence of the Daradik (or “Daramdé”) in Narri, before their departure under the pressure of attacks or internal conflicts. One man reports a deadly quarrel as the cause of their exile.

Furthermore, Kenga informants, notably a man interviewed on 28 December 2016, in Bitkine, mention a migration from Hadjer Tiguil, between Sarh and Melfi, then towards Bousso and finally Bolongue. According to a person interviewed in 2018, some Daradik would have passed through Baro, via the Abou-Telfane, before dispersing across the Dangléat territory.

The village of Bolongue constitutes a key stage of their settlement in the Guéra, before their dispersion towards Mataya, Golomo, and finally Ben-Djedid, where they founded a village during the Abbasid period. Upon their arrival, they coexisted with two Kenga groups living in the surrounding mountains. According to a survey conducted in Golomo and Abtouyour on 2 January 2018, the Daradik settled there in the precolonial period, before extending their ironworking activities to other localities such as Tchelmé or Djegueré.

The narratives converge towards an earlier arrival of the group coming from the west. They would have founded Ben-Djedid, then migrated to Zopki and Melti, before some returned to Tchalo. Old ties existed between the Daradik of Guéra and those who remained in Tchikina or Ambakatché, now broken.

For the group coming from the east, Forra is mentioned as the first stage in Guéra, followed by Baro (where traces of metallurgy remain), then Bogrom, Barlo, Korbo Golé, Melti, and Toumka. In Bogrom, their departure was caused by a conflict between a blacksmith and a local farmer, according to the testimony of a man interviewed on 14 February 2017, in Solal. At several sites such as Korbo Golé or Toumka, traces of habitation and metallurgical activities remain visible despite agricultural reoccupation.

2.3. Reduction Among the Daradik

The data used in this section come from several localities in the Guéra region, particularly Ben-Djedid, Badibrare, Tchalo, and Melti. The objective was to reconstruct the technical processes and social organization surrounding iron ore reduction, in order to digitally model certain artisan organizational logics.

In Ben-Djedid, the iron reduction operational sequence involved a gender-based division of labor. Women, selected for their strength, extracted ore from riverbanks and sieved it on site before transporting it to the workshops. Men, on the other hand, were responsible for constructing the furnaces and carrying out the reduction itself. The furnaces (cf. Figure 2) consisted of a circular pit (Soukoutou) 30 to 40 cm deep, equipped with three bellows devices (afaroya), each fitted with two tuyères (nouffaka). The chimney (chiheba), approximately one meter high, was built from clay mixed with plant or organic materials. Reduction began a few days after the structure had dried, first involving elders to light the fire, then young people to operate the bellows, in an atmosphere punctuated by songs and high-pitched cries. Once the mass of iron had formed inside the furnace, metallurgists pierced a channel (nougra) to evacuate the slag. The recovered iron was used to manufacture tools and weapons, which were then locally exchanged through barter.

Figure 2.

Oven of the tradition present only in Bankakotch, photographed during the excavation (a) and furnace base (b).

In Badibrare, according to the accounts collected in Tchalo, smelting took place collectively at the end of the rainy season. Women extracted the sandy ore within the Kenga territory and transported it on livestock. The furnaces built by men were circular, with two to four openings, each equipped with two tuyères. Reduction began at dawn and lasted all day.

In Melti, although the practice has disappeared, the stories passed down by elders allow us to reconstruct the techniques used. Ore extraction varied according to the season: men would go to Djogolo during the dry season to collect a dense rock called kadjam, while women gathered a shiny black powder (makou) along the riverbeds during the rainy season. The furnaces had removable chimneys, a drainage channel, and a circular pit with a central depression (kalol) to collect molten iron. Bellows were arranged around this pit in varying numbers, up to six. The entire setup was carefully sealed with clay. Reduction began at dawn and ended in the evening. After cooling, the iron bloom was extracted to be transformed into various tools, exchanged for local goods such as millet or peanuts.

2.4. The History of the Filémat

The data used here are based on surveys concerning the Filémat, a group of Arab origin now assimilated into the population of Mongo. These surveys allowed for the documentation of their journey across the Guéra region, their settlement at various ironworking sites, and the evolution of their social status.

Testimonies collected from the last active blacksmith in Matagué and two other individuals make it possible to distinguish two major migratory phases. Originally from Kamitcho (Ati region), the Filémat first migrated to the Abou-Telfane massif, where they coexisted with the Migami in Gourbatcho Oulaya. There, they practiced ore reduction before settling in Bankakotch, identified as their second metallurgical site. Part of the group then continued its migration southward into the Salamat region, while another segment settled in Mongo, abandoning metallurgy in favor of agriculture, trade, or welding. This development explains their current assimilation into the local population.

Another fragment of the group is said to have migrated to Sisi. Although the marginal status of blacksmiths there led to a form of taboo, information collected from local notables and the village chief confirms the settlement of blacksmiths from Kamitcho. According to transmitted accounts, an ancestor named Aboungassi introduced iron reduction techniques to Sisi, where the activity continued until a relatively recent period before being abandoned. Today, these blacksmiths are fully integrated into the Migami community, sharing language, culture, and agricultural activities. The presence of eyewitnesses of ironworking in Sisi suggests a more recent settlement than at the other sites associated with the Filémat.

2.5. Reduction Among the Filémat

The study in this section relies on eyewitness accounts and local residents, particularly in Sisi and N’Djamena, to document the collective practices of Filémat blacksmiths in iron reduction, an exclusively male activity. The ore was collected from a hill rich in iron ore in the Ouaddaï region, for a symbolic payment to the chief of the neighboring village. The ore, a dense surface rock, was transported in sacks or baskets over a journey of about ten days. On site, it was broken into small fragments using hammers and anvils, with simple devices to limit the scattering of shards.

The collected data allowed for an accurate reconstruction of the furnace architecture and the loading protocol, although some descriptions may reflect a certain idealization of the craftsmanship.

The production of charcoal, essential for combustion, favored Prosopis africana [53] due to its thermal properties, although Acacia nilotica [54] was sometimes used. The abundance of this species is now reduced, likely in connection with this activity.

The construction of the cylindrical furnace (chihéba) required collective labor. It was built from clay soil, with a chimney about 2 m high and 40–60 cm in diameter, placed on an arranged pit and equipped with tuyeres adapted to the number of bellows operators (usually three to four). The bottom of the furnace was insulated with a mixture of millet husks and cow dung, promoting ignition and preventing the formation of residual embers.

The alternating loading of ore and charcoal was performed according to a ratio of three measures of charcoal to one measure of ore, under the supervision of a blacksmith standing on a platform. A sacrificial ritual, including the immolation of a goat, marked the start of the reduction, seeking a blessing for the production of a high-quality iron bloom.

The reduction involved several blacksmiths equipped with manual bellows (noufaka), blowing in a coordinated and intense manner around the furnace. The combustion produced a flame several meters high, audible for several kilometers. After several hours, a distinct sound signaled the formation and fall of the iron bloom into the pit, which the team extracted after cooling.

The iron bloom, often comparable in size to a medium-sized container, was then cut into pieces for the production of agricultural and domestic tools. The chimney, preserved throughout the dry season, was destroyed before the rainy season for cultural reasons linked to local beliefs.

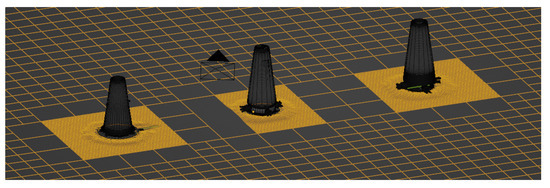

2.6. Three-Dimensional Reconstruction

The 3D models of the furnaces were built based on 2D reconstructions obtained from oral surveys and archaeological excavations—(a) in Ben-Djedid, (b) in Melti, and (c) among the Filémat—as published in [34]. These reconstructions served as vertical reference plans in Blender 4.4.3, following a reproducible modeling protocol [55].

Although Figure 3 presents only the finalized models for clarity, their design relies directly on the original archaeological surveys and drawings. These hand-drawn sketches, which are not to scale, provide a faithful representation of the general forms of the structures. They were used as reference profiles to trace NURBS curves in Blender, forming the basis of the 3D modeling. Careful comparison between the sketches and the 3D models was carried out throughout the modeling process to ensure morphological accuracy: wall proportions, inclinations, and tuyère placements were respected, visually translating in volume what the sketches represented in plan.

Figure 3.

The 3D reconstruction process.

The profile of each furnace was traced as a NURBS curve corresponding to the archaeological cross-section and then converted into a 3D volume using the Screw modifier (axis = Y, angle = 360°, steps = 36, render steps = 36). The resulting surface was then thickened using the Solidify modifier (thickness = 0.05 m, offset = 1) to simulate the clay walls [56]. Openings and tuyères were modeled independently from cylinders, inclined outward at 25° and slightly downward, according to ethnographic descriptions. Three tuyères were arranged for the Ben-Djedid-type furnace, four for the Filémat-type, and six for the Melti-type furnace.

Peripheral mounds around the furnaces were reproduced through simple mesh deformations, representing either construction debris or the gradual accumulation of ash and slag (see Figure 3). Textures were applied using PBR materials from Polyhaven (gravelly sand for the ground and clay plaster for the furnace walls). UV mapping was adjusted to achieve a realistic grain size, and material integration was performed using the Node Wrangler add-on [57], ensuring consistent mapping across objects.

Final rendering was carried out with the Cycles engine (4096 samples, denoiser enabled) [58], using an HDRI environment for ambient illumination and a directional Sun lamp. This workflow ensures both archaeological fidelity, through strict adherence to dimensions and proportions, and reproducibility of the 3D modeling process, allowing other researchers to replicate or adapt this methodology for comparable case studies.

2.7. AI Reconstruction

The AI reconstruction experiment was conducted in two stages. Prompt design was a central step: descriptors were chosen to balance archaeological fidelity (precise furnace dimensions, tuyère orientation, conical shape), cultural authenticity (number of operators, gestures, traditional attire), and environmental realism (savannah landscape, daylight conditions). First, an image was generated in ChatGPT [59] (GPT-4o, July 2025 release) with DALL-E 3 [60] using the following prompt:

A realistic photograph of a traditional iron-smelting furnace in full operation, reconstructed exactly according to this description. The furnace is 1 m tall, conical in shape, with a base diameter of 40 cm, built from reddish-brown mud. At its base, three small rounded tuyères (nozzle-like vents) emerge, oriented outward and slightly downward. Small, dense smoke rises from the top and some of the tuyères, while a red-orange glow is visible inside, showing active iron smelting. Three Chadian men from rural villages in the Guéra region work around the furnace: one is feeding wood or charcoal into a tuyère, while the other two supervise and tend the area. The setting is a dry savannah landscape with cracked soil, sparse vegetation, scattered rocks, and distant hills under bright daylight. Realistic lighting, dust, and subtle heat distortion should be visible.

The resulting image (Ben-Djedid type) was imported into the Wan platform [61], enabling the generation of a 6 s MP4 sequence (1168 × 1760 px, 30 fps) after approximately one hour of processing.

In the second stage, a 3D rendering of the Ben-Djedid-type furnace was produced in Blender, in a low-angle view. This rendering was imported into Wan along with the following prompt:

Generate a short video showing three Black Chadian men in traditional attire around a 1-meter-high traditional Chadian charcoal furnace used for ironmaking, set in a dry, arid landscape. Two men are actively working at the furnace: one crouches and adjusts a piece of wood in a tuyère to keep the fire burning, while thick smoke rises from the conical clay or earth top. The third man stands nearby, observing. In the background, sparse vegetation and a few dry trees are visible under a clear, hot, desert-like sky. Capture the sense of traditional craftsmanship, teamwork, and rural life.

This resulted in a 6 s MP4 sequence (1216 × 1696 px, 30 fps) after approximately one hour of processing.

3. Results

3.1. Three-Dimensional Reconstruction of Traditional Furnaces

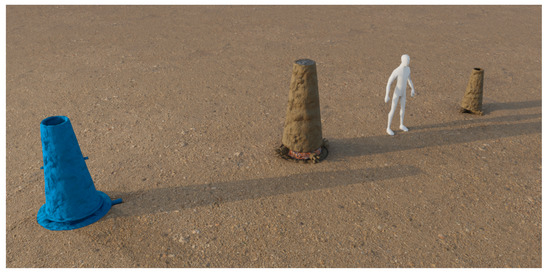

The 3D reconstruction process allowed for the virtual modeling of three distinct types of traditional iron-smelting furnaces identified during ethnographic and archaeological surveys in the Guéra region of Chad. Each furnace type—Melti, Filémat, and Ben-Djedid—was modeled in Blender using dimensional data collected in the field and detailed archaeological plans. The reconstructions preserve the characteristic morphology of each structure, including furnace height, wall inclination, and tuyère placement, ensuring archaeological fidelity. Figure 4 illustrates the final textured models, arranged side-by-side to facilitate comparison of their structural and stylistic differences. The height of the Melti furnace type remains uncertain; it is therefore represented in blue in the image to indicate this uncertainty. A virtual mannequin is included to provide a clear visual reference for scale. The 3D model is available online [62].

Figure 4.

Three-dimensional reconstruction of the three types of traditional furnaces documented during field surveys, with a human figure added for scale: Melti (left, in blue to indicate an uncertain height), Filémat (center), and Ben-Djedid (right).

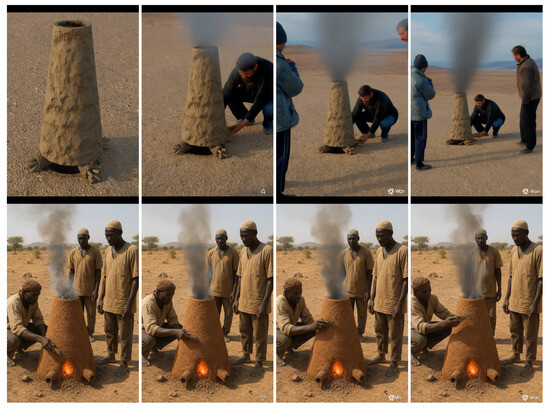

3.2. AI-Based Video Reconstructions

The two generated sequences (Figure 5) [63] were evaluated using a standardized grid including six criteria:

Figure 5.

Comparison of AI-generated video reconstructions using Wan [63] top row: sequence generated from a 3D Blender rendering of the Ben-Djedid furnace; bottom row: sequence generated directly from a ChatGPT-produced image using a textual prompt.

- (a)

- Archaeological fidelity: correspondence with field survey data and 2D plans (furnace shape, tuyère type and orientation, and actors’ positions).

- (b)

- Visual realism: texture quality, lighting, proportions, and material rendering.

- (c)

- Cultural authenticity: accuracy of clothing, skin tone, and actors’ postures.

- (d)

- Camera dynamics: stability or movement consistent with intended style (documentary or cinematic).

- (e)

- Environmental representation: credibility of background landscape and integration in the geographical context.

- (f)

- Atmospheric effects: smoke, flames, dust, and thermal distortion rendering.

- Sequence from ChatGPT-generated image (bottom row).

The framing is highly precise, reminiscent of a cinematic scene. The camera remains static and much of the action is already summarized in the first frame. The four actors have dark skin tones and plausible clothing. However, the tuyères appear rectangular instead of rounded, contradicting archaeological observations. The smoke is technically well rendered but overly dense, and the flames, although clearly visible, lack realism.

- Sequence from 3D Blender rendering (top row).

The output has a more documentary style, with a consistent low-angle camera view and relative stability. The three actors have skin tones that are too light and clothing that does not match ethnographic references. Nevertheless, their gestures and postures appear more natural and less spectacular, enhancing overall credibility.

4. Discussion

4.1. Archaeological and Reconstruction Challenges

The documentation of metallurgical furnaces presents several intrinsic challenges. On the one hand, the uncertainty regarding the height of the Melti furnace is heuristic: it highlights the importance of scale in the perception and relevance of reconstructions. The assigned size directly influences the coherence of reconstructed interactions, particularly the posture of characters and their gestures toward the device.

On the other hand, the fragility of clay structures complicates their preservation. Once abandoned, furnaces rapidly disappear due to natural erosion, animal activity, or human reuse of sites. This vulnerability underscores the urgency of documenting and modeling these structures to safeguard their scientific and heritage memory.

4.2. Technological and Scientific Contributions

Our methodological pipeline—combining ethno-archaeological surveys, field data, 3D modeling in Blender, and AI-based image/video generation—demonstrates the potential of emerging technologies for digitally documenting archaeological heritage [64].

It is characterized by the following:

- The direct linkage between in situ ethnographic data and digital reconstructions, ensuring a strong scientific grounding;

- The innovative use of natural language prompts to generate both images and videos, opening the way to dynamic and contextualized visual storytelling [65];

- The implementation of a standardized evaluation framework to assess archaeological fidelity, cultural authenticity, and visual quality, thus limiting the risk of interpretive drift or excessive “embellishment”.

A major contribution lies in the speed and flexibility of this approach compared to traditional 3D animations. It enables the generation of multiple plausible versions of the same structure, integrating archaeological uncertainties and technical variations, while multimodal AI allows the rapid inclusion of human actors, gestures, and postures within reconstructed environments.

4.3. Methodological Limitations

Despite these advances, several limitations remain. AI-generated reconstructions sometimes display noticeable discrepancies, such as lighter skin tones, inconsistent clothing, or overly generic landscapes (see Table 1). These divergences are most likely due to the underrepresentation of African physiognomies and Sahelian environments in training datasets, as well as to limitations in prompt interpretation.

Table 1.

Comparative evaluation of AI-generated video sequences (scores from 1 = low to 5 = excellent) based on six standardized criteria.

Modeling in Blender ensures a faithful archaeological morphology of the structures. However, the post-production integration of human figures, while behaviorally convincing, can lack typological representativeness. In this sense, the complementarity between approaches is particularly relevant: generative AI contributes expressivity and dynamism, while 3D modeling provides rigor and control as a structural support for AI.

4.4. Ethical and Cultural Implications

The use of generative AI for heritage reconstruction also raises important ethical issues:

- Cultural biases embedded in training datasets may reproduce stereotypical representations, distorting the image of the societies under study.

- The visual realism of AI-generated images may create an illusion of authenticity, potentially misleading both researchers and the public if uncertainties are not explicitly communicated.

- The involvement of local communities in validating reconstructions is essential to ensure respect, legitimacy, and scientific reliability.

Methodological transparency and the integration of local stakeholders therefore appear as necessary conditions for the responsible dissemination of reconstructions.

4.5. Immersive Applications and Future Perspectives

The reconstructions produced can be integrated into immersive augmented reality (AR) or virtual reality (VR) environments, offering significant potential for scientific mediation and heritage promotion [66].

In the longer term, multimodal enrichment—including realistic textures, ambient sounds, and real-time interactions—could lead to the following:

- Immersive training for researchers, students, and artisans;

- Participatory digital museology initiatives;

- The virtual preservation of technical know-how at risk of disappearing.

Thus, our method goes beyond mere visual reconstruction: it constitutes a tool for safeguarding, transmitting, and valorizing both the tangible and intangible heritage associated with traditional metallurgy.

5. Conclusions

This research has demonstrated that a close integration of ethnographic data, archaeology, and immersive AI technologies can produce 3D and video reconstructions that are simultaneously accurate, immersive, and scientifically exploitable. The developed pipeline—spanning from the collection of oral testimonies to 3D modeling and video generation—represents a major methodological advance for the documentation and dissemination of African technical heritage. By combining it with a systematic evaluation framework, we ensure rigorous control over archaeological fidelity and cultural authenticity, thereby reinforcing the scientific credibility of the reconstructions. Beyond academic research, this approach opens new avenues for digital museology, immersive training, and the safeguarding of endangered know-how. It could be deployed in other heritage contexts, thus contributing to the preservation and transmission of ancient technologies in the digital era.

Author Contributions

In this study, D.G. carried out the archaeological excavations and oral history investigations, while J.-B.B. managed the digital reconstruction and data processing. C.R.-B. oversaw the archaeological research and revised the article’s archaeological content. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Ethical review and approval were waived for this study because all participants provided written informed consent prior to participation.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The ethnographic interview transcripts contain sensitive personal information and are therefore not openly accessible; they can be obtained from the authors upon reasonable request. The 3D models [62] and AI-generated images/videos [63] produced in this study are deposited in a public repository (currently without DOI, which will be assigned later). The evaluation grid is provided only as a proposed model and is not currently based on raw data, although such use may be possible in future work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Quéchon, G. Les datations de la métallurgie du fer à Termit (Niger): Leur fiabilité, leur signification. Mediterr. Archaeol. 2001, 14, 247–253. [Google Scholar]

- Bocoum, H. Aux origines de la métallurgie du fer en Afrique de l’Ouest. Mediterr. Archaeol. 2001, 14, 235–245. [Google Scholar]

- Essomba, J.M. Bilan de l’archéologie de l’âge de fer au Cameroun Méridional; UNESCO Headquarters: Paris, France, 2002. [Google Scholar]

- Killick, D. What do we know about African iron working? J. Afr. Archaeol. 2004, 2, 97–112. [Google Scholar] [CrossRef]

- Alpern, S.B. Did they or didn’t they invent it? Iron in sub-Saharan Africa. Hist. Afr. 2005, 32, 41–94. [Google Scholar] [CrossRef]

- Chirikure, S.; Rehren, T. Ores, furnaces, slags, and prehistoric societies: Aspects of iron working in the Nyanga Agricultural Complex, AD 1300–1900. Afr. Archaeol. Rev. 2004, 21, 135–152. [Google Scholar] [CrossRef]

- Chirikure, S.; Burrett, R.; Heimann, R.B. Beyond furnaces and slags: A review study of bellows and their role in indigenous African metallurgical processes. Azania Archaeol. Res. Afr. 2009, 44, 195–215. [Google Scholar] [CrossRef]

- Chirikure, S. Metals in society: Iron production and its position in Iron Age communities of southern Africa. J. Soc. Archaeol. 2007, 7, 72–100. [Google Scholar] [CrossRef]

- Robion-Brunner, C. L’Afrique des métaux. In L’Afrique Ancienne. De l’Acacus au Zimbabwe, 20000 Avant Notre ère–XVIIe Siècle; Fauvelle, F.X., Ed.; Belin: Paris, France, 2018; pp. 518–543. [Google Scholar]

- Célis, G. Les Fonderies Africaines du fer, un Grand Métier Disparu; Frankfurt, Museum für Völkerkunde: Frankfurt am Main, Germany, 1991. [Google Scholar]

- Martinelli, B. Au seuil de la métallurgie intensive–Le choix de la combustion lente dans la boucle du Niger (Burkina Faso et Mali). In Aux Origines de la Métallurgie du fer en Afrique—Une Ancienneté Méconnue; Bocoum, H., Ed.; Éditions de l’UNESCO: Paris, France, 2002; pp. 165–188. [Google Scholar]

- Robion-Brunner, C.; Serneels, V.; Perret, S. Variability in iron smelting practices: Assessment of technical, cultural and economic criteria to explain the metallurgical diversity in the Dogon area (Mali). In The World of Iron; Archetype Publications London: London, UK, 2013; pp. 257–265. [Google Scholar]

- Serneels, V.; Kiénon-Kaboré, H.T.; Koté, L.; Kouassi, S.K.; Ramseyer, D.; Simporé, L. Origine et développement de la métallurgie du fer au Burkina Faso et en Côte d’Ivoire. Premiers résultats sur le site sidérurgique de Korsimoro (Sanmatenga, Burkina Faso). In Jahresberichtder Schweizerisch-Liechtensteinische Stiftung für Archäologische Forschungen im Ausland (SLSA); Thorbecke Verlag: Zürich, Switzerland, 2012; pp. 23–54. [Google Scholar]

- Serneels, V.; Donadini, F.; Kiénon-Kaboré, H.T.; Koté, L.; Kouassi, S.K.; Ramseyer, D.; Simporé, L. Origine et développement de la métallurgie du fer au Burkina Faso et en Côte d’Ivoire. Avancement des recherches en 2013 et quantification des vestiges de Korsimoro (Burkina Faso). In Jahresbericht der Schweizerisch-Liechtensteinische Stiftung für Archäologische Forschungen im Ausland SLSA; Thorbecke Verlag: Zürich, Switzerland, 2014; pp. 65–112. [Google Scholar]

- Robion-Brunner, C. Peuplements des Forgerons et Traditions Sidérurgiques: Vers une Histoire de la Production du fer sur le Plateau de Bandiagara (Pays Dogon, Mali) Durant les Empires Précoloniaux; Journal of African Archaeology Monograph Series; Africa Magna Verlag: Frankfurt, Germany, 2010; Volume 3, Série Monographique 1. [Google Scholar]

- Kiéthéga, J.B. La Métallurgie Lourde du fer au Burkina Faso: Une Technologie à L’époque Précoloniale; Karthala Éditions: Paris, France, 2009. [Google Scholar]

- Fabre, J.M. La métallurgie du fer au Sahel burkinabé à la fin du 1 millénaire AD. In Crossroads/Carrefour Sahel: Cultural and Technological Developments in First Millennium BC/AD West Africa; Africa Magna Verlag: Main, Germany, 2009; p. 167. [Google Scholar]

- Guillon, R.; Petit, C.; Rajot, J.L.; Bichet, V.; Idé, O.A.; Garba, Z.; Sebag, D.; Touré, A.A. Analyse de la répartition spatiale de bas fourneaux d’un territoire sidérurgique au sud-ouest du Niger (4e-14e siècle ap. J.-C.). In Métallurgie du fer et Sociétés Africaines: Bilans et Nouveaux Paradigmes dans la Recherche Anthropologique et Archéologique; HAL: Lyon, France, 2012; pp. 153–163. [Google Scholar]

- Robion-Brunner, C. «Pourquoi ton four n’est pas comme le mien?» Diversité technique dans la sidérurgie ancienne: Le cas du Dendi (Bénin). J. Afr. 2018, 88, 16–39. [Google Scholar] [CrossRef]

- Robion-Brunner, C. What Is the Meaning of the Extreme Variability of Ancient Ironworking in West Africa? A Comparison between Four Case Studies; Cambridge University Press: Cambridge, UK, 2020; pp. 290–314. [Google Scholar] [CrossRef]

- Serneels, V. Des montagnes de fer en pays dogon. In Le Magazine de l’Université de Fribourg; Université de Fribourg: Fribourg, Switzerland, 2009; pp. 44–45. [Google Scholar]

- Martinelli, B. Le choix de la combustion lente. Mutation technique et mutation sociale au Yatenga, Burkina Faso. In Arts du feu et Productions Artisanales; HAL: Lyon, France, 2000; pp. 123–142. [Google Scholar]

- Muramira, F. Mutation de la Technologie du fer en Centre Afrique: Étude Comparée de la Forge en Bangui-Bambari. Master’s Thesis, Faculté des Lettres, Arts et Sciences Humaines, Université de Bangui, Bangui, Central African Republic, 2006. [Google Scholar]

- Courtin, J. Découverte de harpons en os au Borkou, République du Tchad. In Bulletin de la Société Préhistorique Française. Comptes Rendus des Séances Mensuelles; Société Préhistorique Française: Paris, France, 1965; pp. LXX–LXXV. [Google Scholar] [CrossRef]

- Courtin, J. Poterie à décor zoomorphe du Nord-Tchad, environs de Largeau, Borkou. In Bulletin de la Société Préhistorique Française. Comptes Rendus des Séances Mensuelles; Société Préhistorique Française: Paris, France, 1965; pp. CXXXV–CXXXVIII. [Google Scholar] [CrossRef]

- Courtin, J. Labrets préhistoriques en quartz au Borkou, Nord-Tchad. In Bulletin de la Société Préhistorique Française. Comptes Rendus des Séances Mensuelles; Société Préhistorique Française: Paris, France, 1965; pp. CXLVIII–CLI. [Google Scholar] [CrossRef]

- Treinen-Claustre, F. Sahara et Sahel à l’âge du fer: Borkou, Tchad; Société des Africanistes: Paris, France, 1982; Volume 7. [Google Scholar]

- Lavachery, P.; MacEachern, S.; Bouimon, T.; Gouem Gouem, B.; Kinyock, P.; Mbairo, J.; Mbida, C.; Nkokonda, O. Cultural heritage management in Central Africa: Regional survey on the Chad-Cameroon oil pipeline. Antiquity 2005, 79, 56–60. [Google Scholar]

- Lavachery, P. De Komé à Kribi: Archéologie Préventive le Long de l’oléoduc Tchad-Cameroun, 1999–2004; Africa Magna: Frankfurt am Main, Germany, 2010. [Google Scholar]

- Mbairo, J. Sites Métallurgiques de Maikery dans le Canton Miandoum: Archéologie et Traditions Orales. Master’s Thesis, Université de Paris I Panthéon-Sorbonne, Paris, France, 2007. [Google Scholar]

- Mbairo, J. Répertoire des Sites Culturels du Bassin Pétrolier, Rapport Annuel (Doba, Logone Oriental); Rapport Annuel; HAL Open Science: Lyon, France, 2011. [Google Scholar]

- Clison, N. Paléométallurgie du fer à Kana et à Deli et Mouvements de Populations Dans la Haute Vallée du Logone au Sud du Tchad. Ph.D. Thesis, Département d’Histoire et d’Archéologie, Université de Ouagadougou, Ouagadougou, Burkina Faso, 2015. [Google Scholar]

- Dérendinger, G. Les curieuses mines de fer de Télé-Nugar (Tchad). J. Soc. Afr. 1936, 6, 197–204. [Google Scholar] [CrossRef]

- Guemona, D. La Paléo-Métallurgie dans la région du Guéra (Centre du Tchad): Inventaire des Sites et Essai de Caractérisation des Traditions Sidérurgiques. Ph.D. Thesis, Université Toulouse le Mirail-Toulouse II, Toulouse, France, 2020. [Google Scholar]

- Kersten, T.; Tschirschwitz, F.; Deggim, S. Virtual and Augmented Reality Applications in Cultural Heritage. Remote Sens. 2023, 15, 542. [Google Scholar] [CrossRef]

- Piccirillo, A.; Buscaglia, P.; Caliri, C.; Romano, F.P.; Pavone, D.P.; Ravan, E.L.; Botticelli, M.; Conti, C.; Catrambone, M.; Miliani, C.; et al. Unraveling the mummy’s shroud: A multi-analytical study of a rare painted textile from Roman Egypt. J. Cult. Herit. 2024, 68, 107–121. [Google Scholar] [CrossRef]

- Bekele, M.; Pierdicca, R.; Frontoni, E.; Malinverni, E.S.; Gain, J. A Survey of Augmented, Virtual, and Mixed Reality for Cultural Heritage. J. Comput. Cult. Herit. 2018, 11, 1–36. [Google Scholar] [CrossRef]

- Bruno, F.; Bruno, S.; De Napoli, L. Immersive Virtual Museums: State of the Art and Future Trends. Appl. Sci. 2023, 13, 8134. [Google Scholar] [CrossRef]

- Mildenhall, B.; Srinivasan, P.P.; Tancik, M.; Barron, J.T.; Ramamoorthi, R.; Ng, R. NeRF: Representing Scenes as Neural Radiance Fields for View Synthesis. Commun. ACM 2021, 65, 99–106. [Google Scholar] [CrossRef]

- Zarzo, M. Clarifying Key Concerns about the Dating of Holy Relics: The Holy Chalice of the Last Supper at the Cathedral of Valencia. Heritage 2024, 7, 139–161. [Google Scholar] [CrossRef]

- Kerbl, B.; Kopanas, G.; Leimkühler, T.; Drettakis, G. 3D Gaussian Splatting for Real-Time Radiance Field Rendering. In Proceedings of the ACM SIGGRAPH 2023 Conference Proceedings, Los Angeles, CA, USA, 6–10 August 2023. [Google Scholar] [CrossRef]

- Forte, M. Exploring Multiverses: Generative AI and Neuroaesthetic Perspectives. Heritage 2025, 8, 102. [Google Scholar] [CrossRef]

- Alhassane, M.; Barreau, J.B.; Varoutsikos, B.; Cissée, A.; Coulin, M.; Ubelmann, Y.; Salifou, A.; Giligny, F. Digital Preservation and Restoration of Historic Buildings in Agadez, Niger. In 3D Research Challenges in Cultural Heritage IV; Springer Nature: Cham, Switzerland, 2025; pp. 97–109. [Google Scholar] [CrossRef]

- Boswell, R. Review: Zamani Project. Rev. Digit. Humanit. 2024, V. [Google Scholar] [CrossRef]

- Rüther, H.; Held, C.; Bhurtha, R.; Schröder, R.; Wessels, S. Challenges in heritage documentation with terrestrial laser scanning. In Proceedings of the 1st AfricaGEO Conference, Capetown, South Africa, 31 May–1 June 2011; Volume 30. [Google Scholar]

- Yaseen, F.R.; Mustafa, F.A.; Rashid, S.J. Study of the Minaret Location in the Context of Main Styles of Mosques: A Geometric-Thematic Analysis. Eurasian J. Sci. Eng. 2023, 9, 180–200. [Google Scholar] [CrossRef]

- Franczuk, J. Information processes in Virtual 3D reconstruction of Roman Three-Bay Double Arch of Musti (Tunisia). Virtual Archaeol. Rev. 2025, 16, 1–16. [Google Scholar] [CrossRef]

- Ben Charif, H.; Zerlenga, O.; Iaderosa, R. Low-Cost Photogrammetry for Detailed Documentation and Condition Assessment of Earthen Architectural Heritage: The Ex-Hotel Oasis Rouge in Timimoun as a Case Study. Buildings 2024, 14, 3292. [Google Scholar] [CrossRef]

- Ye, S.; Wu, T.; Jarvis, M.; Zhu, Y. Digital reconstruction of Elmina Castle for mobile virtual reality via point-based detail transfer. Electron. Imaging 2022, 34, 409-1–409-8. [Google Scholar] [CrossRef]

- Robion-Brunner, C.; Serneels, V. Protéger et fouiller un site archéologique: Le cas des sites métallurgiques. In Manuel de Terrain en Archéologie Africaine; Musée Royal de l’Afrique Centrale: Tervuren, Belgium, 2017; pp. 129–133. [Google Scholar]

- Diop, P.S. Introduction à l’oeuvre littéraire de Boubacar Boris Diop: Du français au wolof. Études Littéraires Afr. 2018, 19–29. [Google Scholar] [CrossRef]

- Saxon, D.E. Wadai (Ouaddai) Empire. In The Encyclopedia of Empire; Wiley: Hoboken, NJ, USA, 2016; pp. 1–2. [Google Scholar] [CrossRef]

- Akaaimo, D.; Raji, A. Some physical and engineering properties of Prosopis africana seed. Biosyst. Eng. 2006, 95, 197–205. [Google Scholar] [CrossRef]

- Bargali, K.; Bargali, S. Acacia nilotica: A multipurpose leguminous plant. Nat. Sci. 2009, 7, 11–19. [Google Scholar]

- Barreau, J.B.; Nouviale, F.; Gaugne, R.; Bernard, Y.; Llinares, S.; Gouranton, V. An Immersive Virtual Sailing on the 18th-Century Ship Le Boullongne. Presence Teleoperators Virtual Environ. 2015, 24, 201–219. [Google Scholar] [CrossRef]

- Blain, J.M. The Complete Guide to Blender Graphics: Computer Modeling & Animation; AK Peters/CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Hamdani, A. 3D Environment Design with Blender: Enhance Your Modeling, Texturing, and Lighting Skills to Create Realistic 3D Scenes; Packt Publishing Ltd.: Birmingham, UK, 2023. [Google Scholar]

- Rao, G.R.K.; Sgar, P.V.; Bikku, T.; Prasad, C.; Cherukuri, N. Comparing 3D rendering engines in blender. In Proceedings of the 2021 2nd International Conference on Smart Electronics and Communication (ICOSEC), Trichy, India, 7–9 October 2021; pp. 489–495. [Google Scholar] [CrossRef]

- Cobb, P.J. Large language models and generative ai, oh my!: Archaeology in the time of chatgpt, midjourney, and beyond. Adv. Archaeol. Pract. 2023, 11, 363–369. [Google Scholar] [CrossRef]

- Gheorghiu, D.; Ştefan, L.; Moţăianu, M.; Olteanu, V. Augmented Creativity: Augmenting the Archaeological Imagination with Generative AI Tools. In Human-Computer Creativity; Springer Nature: Cham, Switzerland, 2025; pp. 217–240. [Google Scholar] [CrossRef]

- Wan, T.; Wang, A.; Ai, B.; Wen, B.; Mao, C.; Xie, C.W.; Chen, D.; Yu, F.; Zhao, H.; Yang, J.; et al. Wan: Open and Advanced Large-Scale Video Generative Models. arXiv 2025, arXiv:2503.20314. [Google Scholar] [CrossRef]

- Barreau, J.B. Reconstructing Ancient Iron Smelting Furnaces of Guéra (Chad) Through 3D Modeling and AI-Assisted Video Generation [3D Model]. 2025. Available online: https://github.com/jean-baptiste-barreau/jean-baptiste-barreau.github.io/raw/refs/heads/main/publications/Reconstructing_Ancient_Iron_Smelting_Furnaces_of_Guera_(Chad)_through_3D_Modeling_and_AI_Assisted_Video_Generation/3D_model/Furnaces_of_Guera_(Chad).fbx (accessed on 20 September 2025).

- Barreau, J.B. Reconstructing Ancient Iron Smelting Furnaces of Guéra (Chad) Through 3D Modeling and AI-Assisted Video Generation [Video]. 2025. Available online: https://github.com/jean-baptiste-barreau/jean-baptiste-barreau.github.io/raw/refs/heads/main/publications/Reconstructing_Ancient_Iron_Smelting_Furnaces_of_Guera_(Chad)_through_3D_Modeling_and_AI_Assisted_Video_Generation/video_result.mp4 (accessed on 20 September 2025).

- Remondino, F. Heritage recording and 3D modeling with photogrammetry and 3D scanning. Remote Sens. 2011, 3, 1104–1138. [Google Scholar] [CrossRef]

- Guerreiro, J. Text-to-video generation for cultural heritage applications. In Proceedings of the 2023 IEEE International Symposium on Mixed and Augmented Reality (ISMAR), Sydney, Australia, 16–20 October 2023; pp. 784–793. [Google Scholar]

- Anwar, M.S.; Yang, J.; Frnda, J.; Choi, A.; Baghaei, N.; Ali, M. Metaverse and XR for cultural heritage education: Applications, standards, architecture, and technological insights for enhanced immersive experience. Virtual Real. 2025, 29, 51. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).