Quaternion-Based Velocity Scheduling for Robotic Systems

Abstract

1. Introduction

- (1)

- A real-time, complete, near-time-optimal quaternion-based velocity planning approach is proposed, in which the computation time of the proposed approach is much shorter than that of the previous approach.

- (2)

- In the proposed approach, the initial velocity method is implemented before integrating maximum and minimum acceleration. Therefore, the NI-method can be employed directly without searching for switching points.

- (3)

- A mathematical proof for the completeness of the proposed solution search algorithm is given.

- (4)

- The relationship between the position of the task path and the orientation represented by the quaternion is constructed. The proposed approach is suitable for both translation motion planning and orientation motion planning—e.g., [1] or [2,3], or [4,5,6]. See the end of the document for further details on references.

2. Physical Constraints and Motion Type

2.1. Kinematics Constraints

2.2. Dynamics Constraints

2.3. Quaternion

2.4. Types of Motions

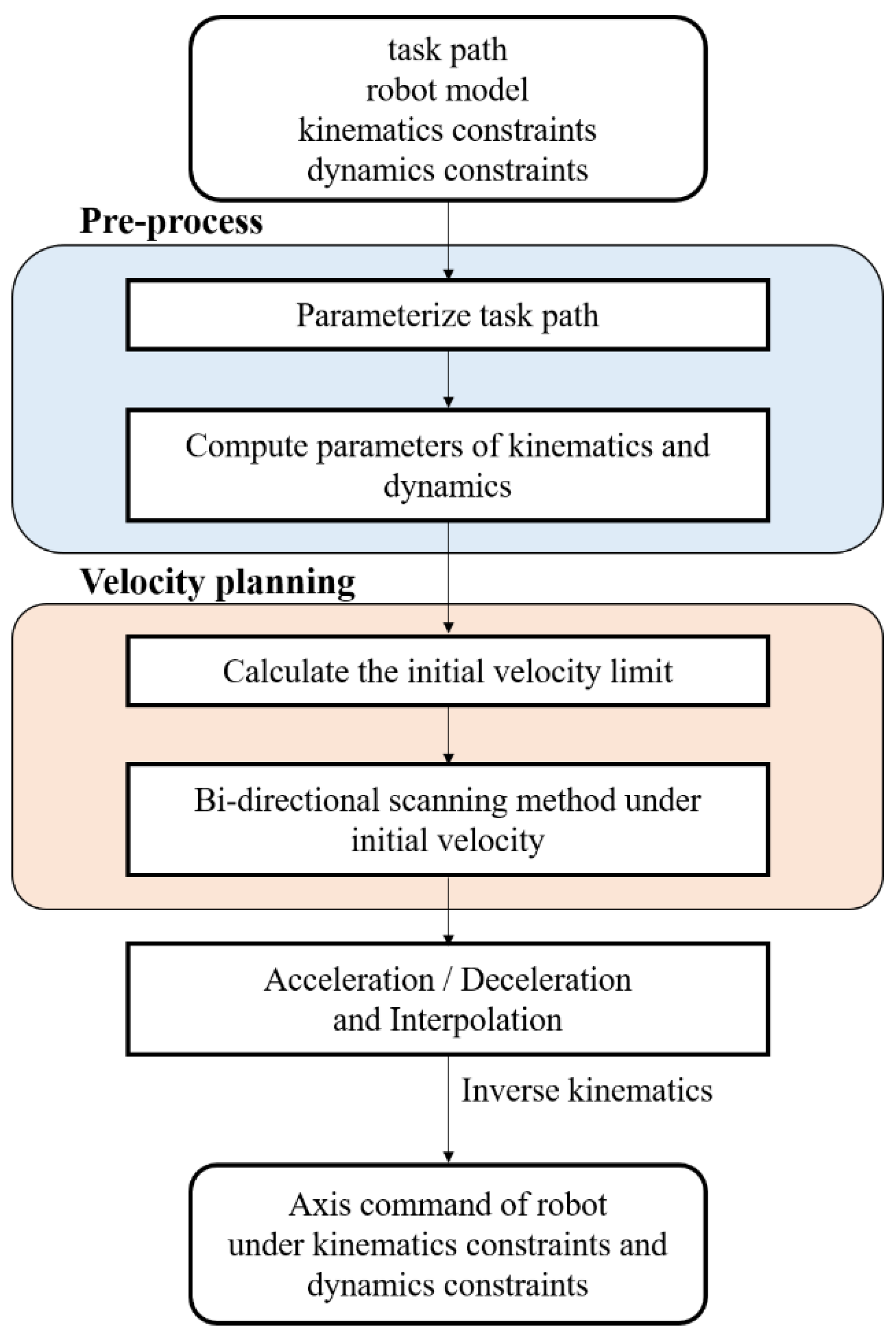

3. Complete and Real-Time Motion Planning

3.1. Initial Velocity Limit

3.2. Bi-Directional Scanning Method

4. Completeness Proof of the Proposed QBVPA

4.1. Numerical Integration Method with Torque and Velocity Constraints

4.2. Mathematical Proof of Existence of Velocity Solution Obtained Using QBVSA

5. Simulation and Experiment Results

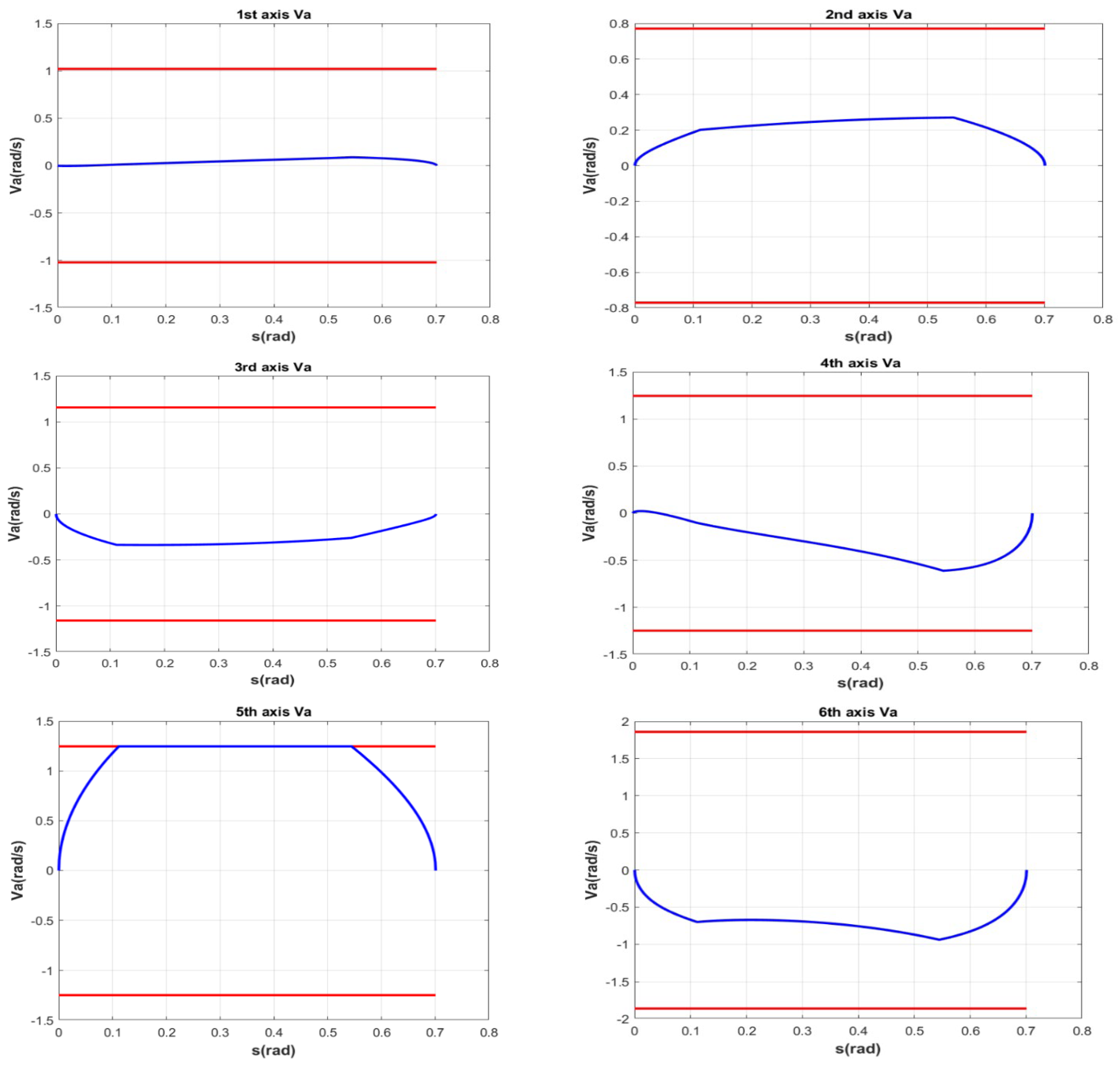

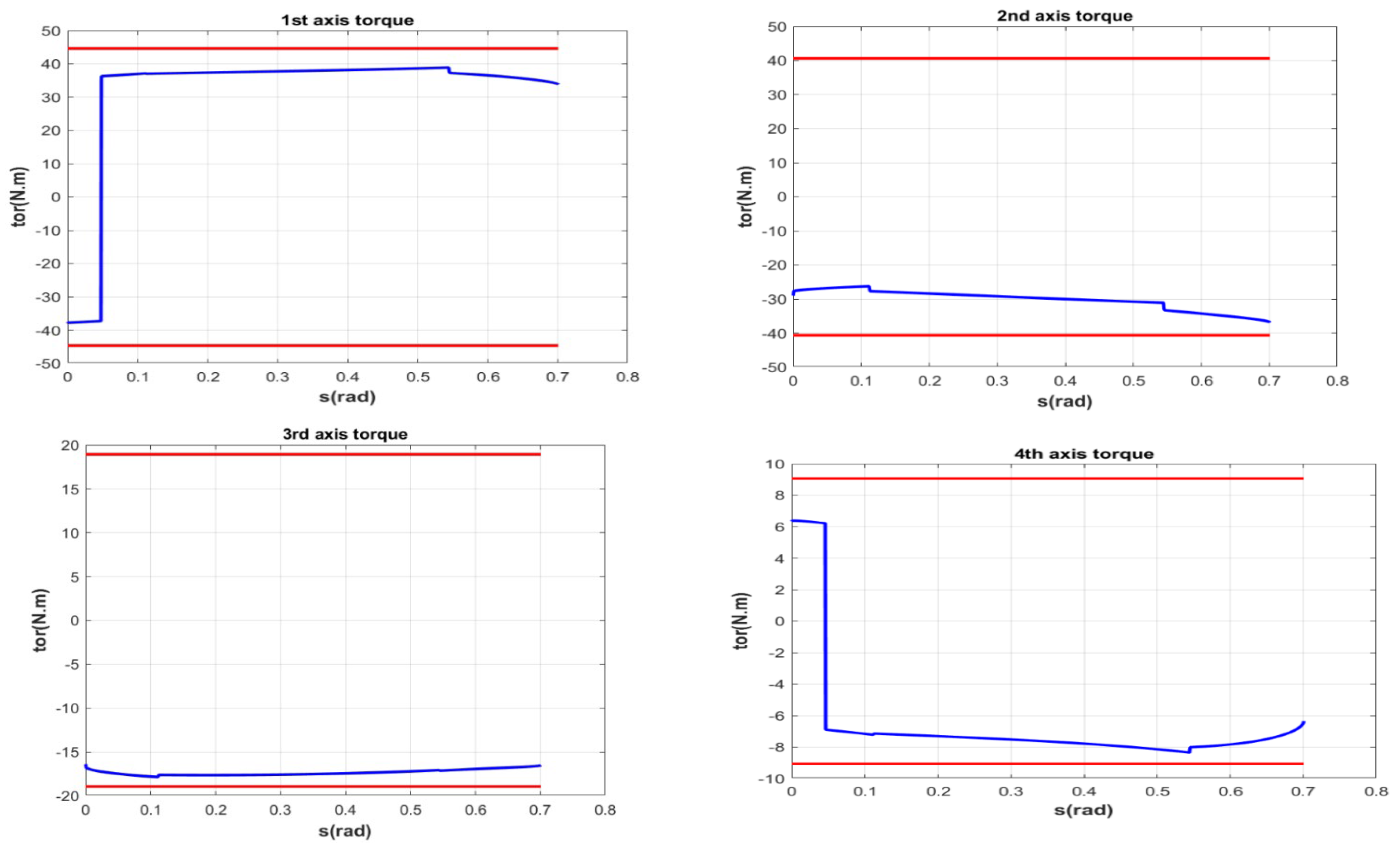

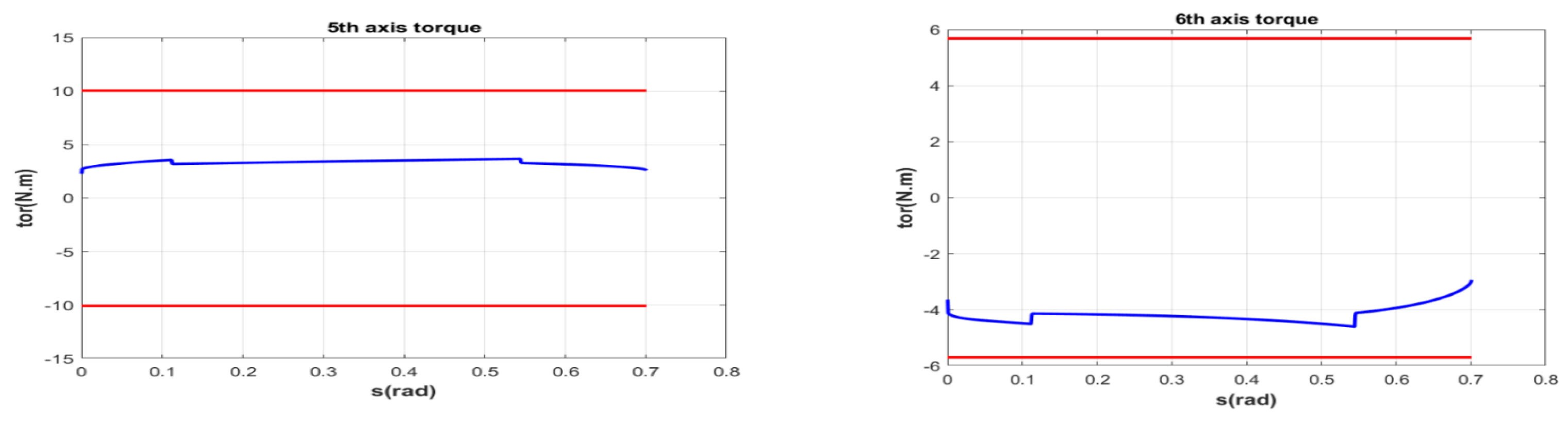

5.1. Simulation Results on Pure Orientation Motion

5.2. Simulation Results on Composite Motion

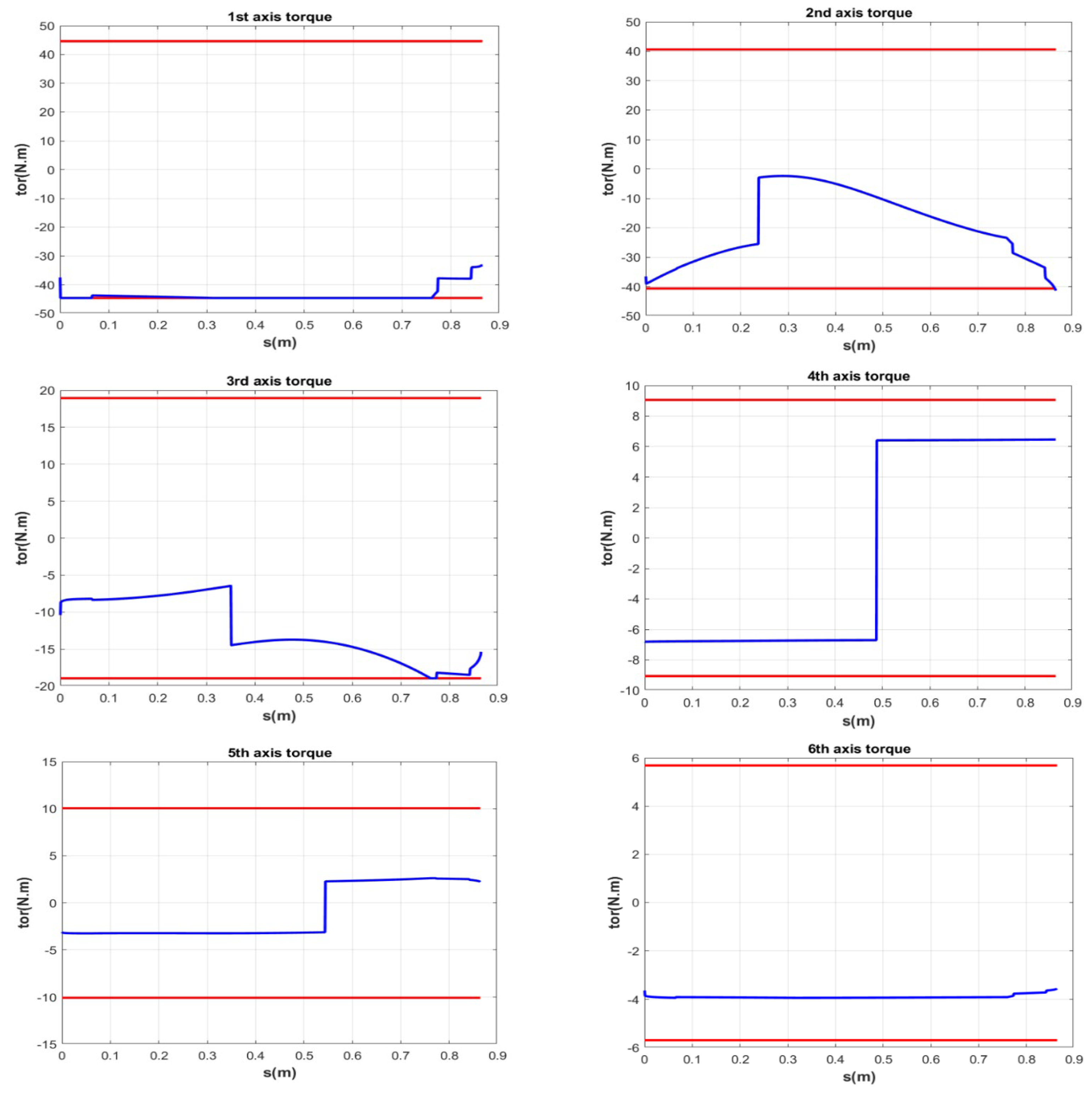

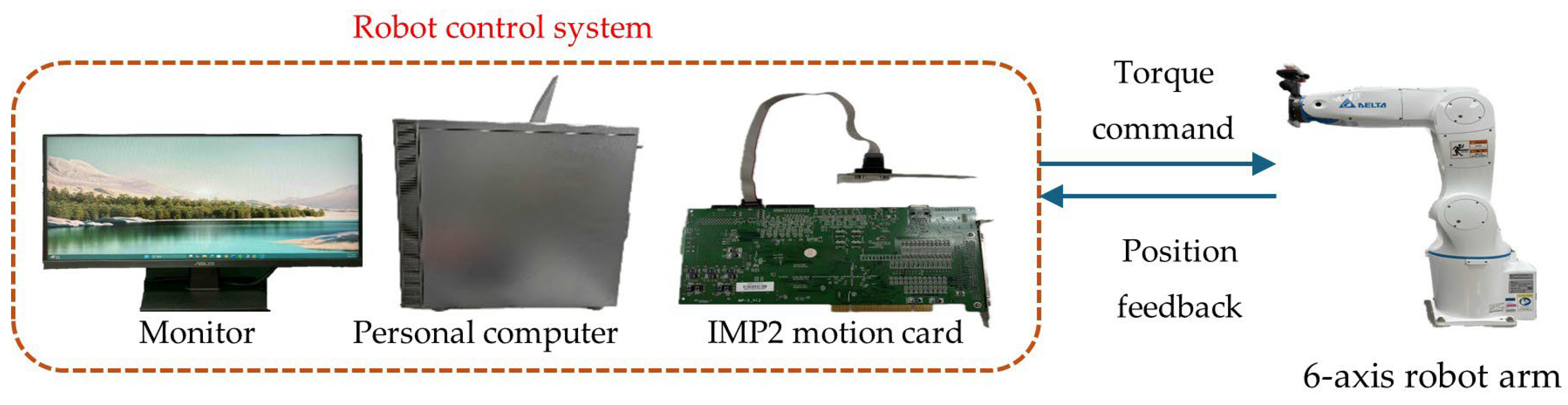

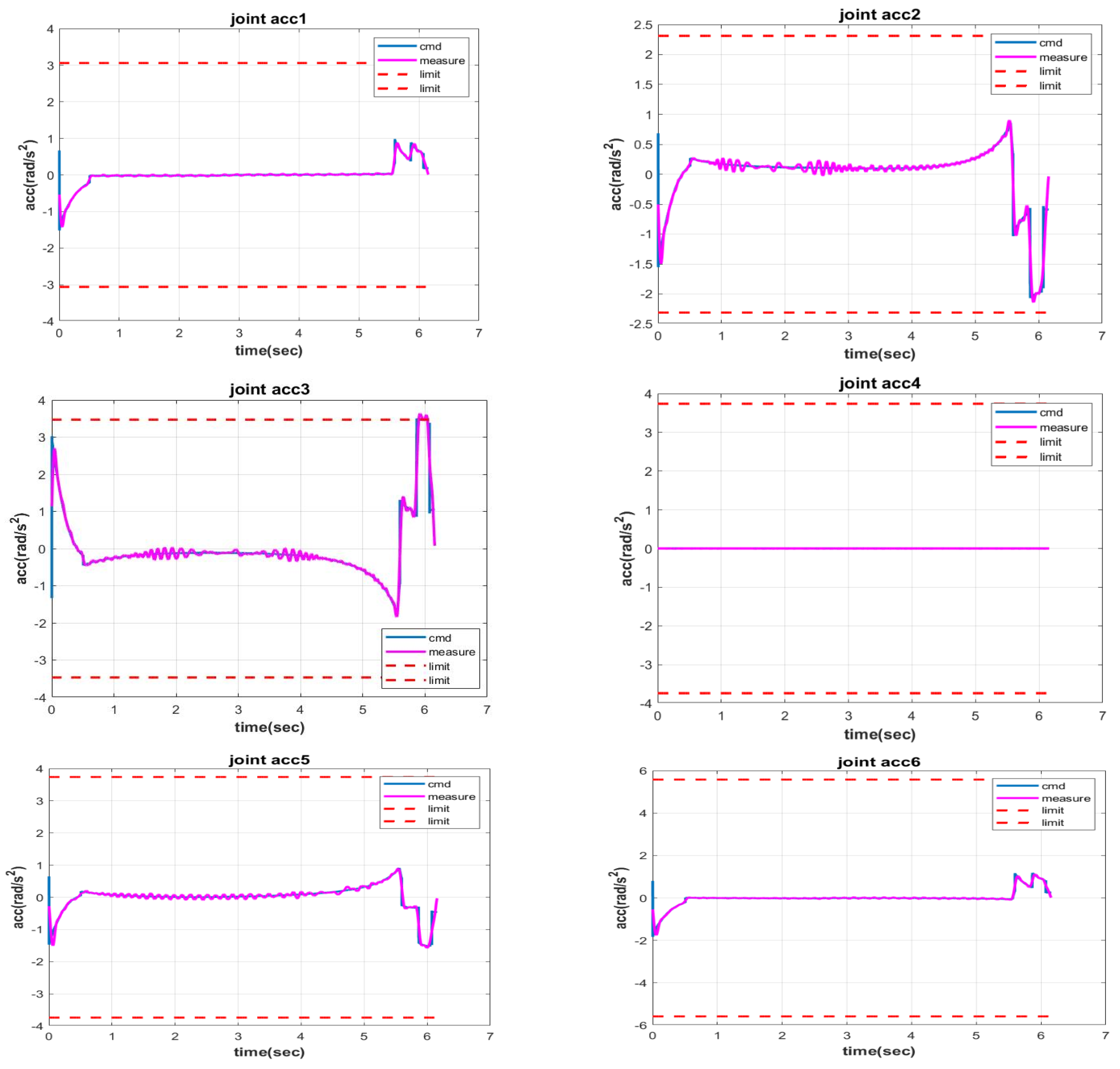

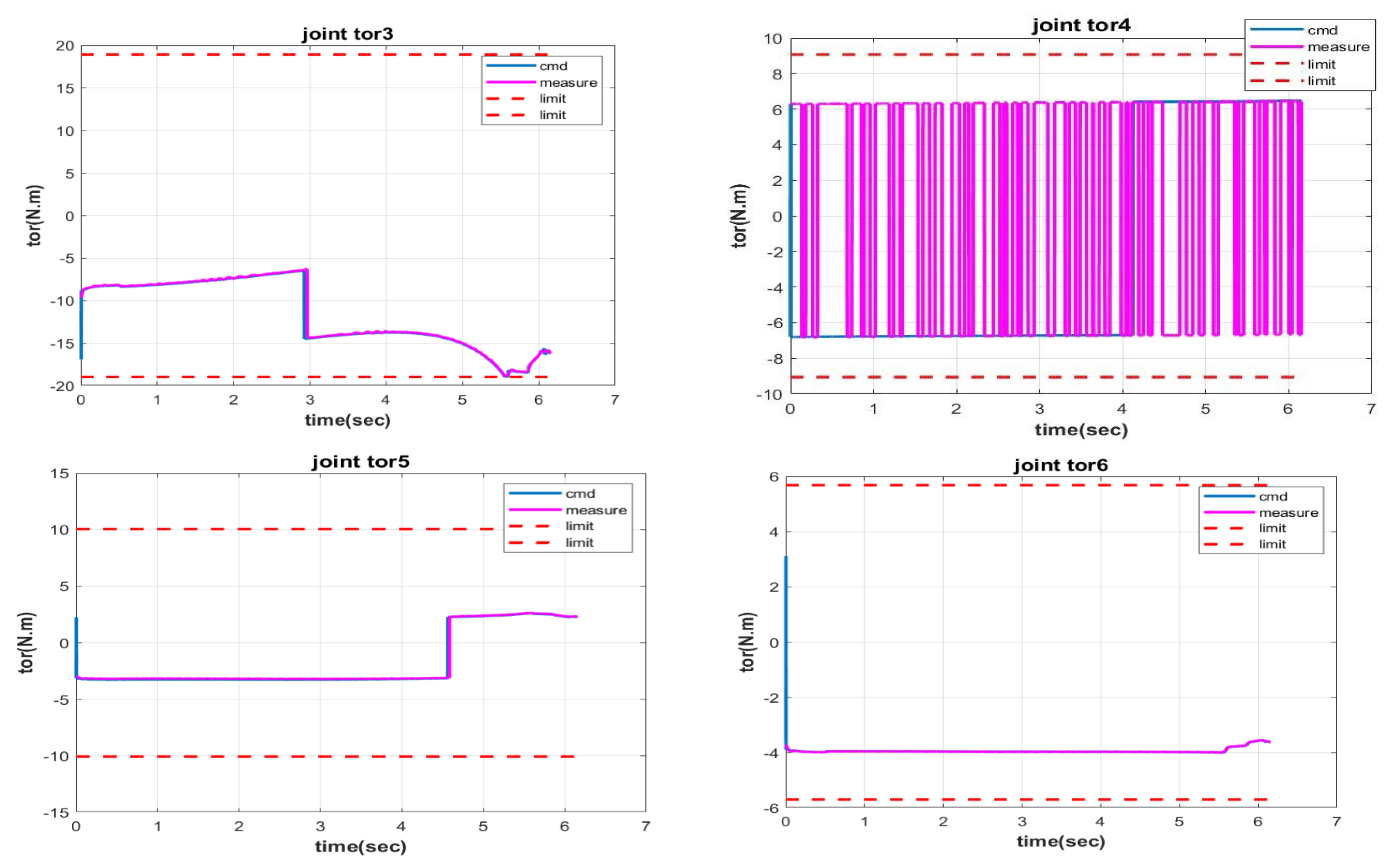

5.3. Experimental Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Quaternion-Based Velocity Scheduling Algorithm (QBVSA) | |

| Input: kinematics constraints, dynamics constraints, parameterized task path, parameters of kinematics and dynamics | |

| Output: a velocity solution | |

| 1: | Calculate initial velocity limit of each task point, |

| Forward scanning start | |

| 2: | Velocity of the starting task point |

| 3: | Move to the next task point (k = k + 1) |

| 4: | Record as the velocity of the last task point |

| 5: | if |

| 6: | go to 3 |

| 7: | else |

| 8: | go to 10 |

| 9: | end if |

| 10: | Calculate coefficients of the velocity quadratic polynomial (19) |

| 11: | Get the minimum upper bound of the velocity quadratic polynomial |

| 12: | Solve the forward velocity of the task point |

| 13: | if k is the last task point of the parameterized task path |

| 14: | go to 17 |

| 15: | else |

| 16: | go to 3 |

| 17: | end if |

| Backward scanning start | |

| 18: | Velocity of the end task point |

| 19: | Move to the next task point (k = k − 1) |

| 20: | Record as the velocity of the last task point |

| 21: | if |

| 22: | go to 19 |

| 23: | else |

| 24: | go to 25 |

| 25: | end if |

| 26: | Calculate coefficients of the velocity quadratic polynomial (19) |

| 27: | Get minimum upper bound of the velocity quadratic polynomial |

| 28: | Solve the backward velocity of the task point |

| 29: | if k is the starting task point of the parameterized task path |

| 30: | go to 34 |

| 31: | else |

| 32: | go to 19 |

| 33: | endif |

| 34: | Get final velocity |

References

- Lynch, K.M.; Park, F.C. Modern Robotics; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

- Wu, G.; Zhang, N. Kinematically Constrained Jerk–Continuous S-Curve Trajectory Planning in Joint Space for Industrial Robots. Electronics 2023, 12, 1135. [Google Scholar] [CrossRef]

- Chen, Y.C. Solving robot trajectory Planning problems with uniform cubic B-splines. Optim. Control Appl. Methods 1991, 12, 247–262. [Google Scholar] [CrossRef]

- Macfarlane, S.; Croft, E. Jerk-bounded manipulator trajectory planning Design for real-time applications. IEEE Trans. Robot. Autom. 2003, 19, 42–52. [Google Scholar] [CrossRef]

- Kant, K.; Zucker, S. Toward efficient trajectory planning: The velocity decomposition. Int. J. Robot. Res. 1986, 5, 72–89. [Google Scholar] [CrossRef]

- Jiang, L.; Liu, S.; Cui, Y.; Jiang, H. Path Planning for Robotic Manipulator in Complex Multi-Obstacle Environment Based on Improved RRT. IEEE/ASME Trans. Mechatron. 2022, 27, 4774–4785. [Google Scholar] [CrossRef]

- Chen, Y.; Dong, F. Robot machining: Recent development and future research issues. Int. J. Adv. Manuf. Technol. Technol. 2013, 66, 1489–1497. [Google Scholar] [CrossRef]

- Constantinescu, D.; Croft, E. Smooth and time-optimal trajectory planning for industrial manipulators along specified paths. J. Robot. Syst. 2000, 17, 233–249. [Google Scholar] [CrossRef]

- Verscheure, D.; Demulenaere, B.; Swevers, J.; Schutter, J.; Diehl, M. Time-optimal path tracking for robots: A convex optimization approach. IEEE Trans. Autom. Control 2009, 54, 2318–2327. [Google Scholar] [CrossRef]

- Debrouwere, F.; Van Loock, W.; Pipeleers, G.; Dinh, Q.T.; Diehl, M.; De Schutter, J.; Swevers, J. Time-optimal path following for robots with convex-concave constraints using sequential convex programming. IEEE Trans. Robot. 2013, 29, 1485–1495. [Google Scholar] [CrossRef]

- Nadir, B.; Mohammed, O.; Minh-Tuan, N.; Abderrezak, S. Optimal trajectory generation method to find a smooth robot joint trajectory based on multiquadric radial basis functions. Int. J. Adv. Manuf. Technol. 2022, 120, 297–312. [Google Scholar] [CrossRef]

- Gasparetto, A.; Zanotto, V. A technique for time-jerk optimal planning of robot trajectories. Robot. Comput. Manuf. 2008, 97, 415–426. [Google Scholar] [CrossRef]

- Lin, J.; Somani, N.; Hu, B.; Rickert, M.; Knoll, A. An efficient and time-optimal trajectory generation approach for waypoints under kinematic constraints and error bounds. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 5869–5876. [Google Scholar]

- Huang, J.; Hu, P.; Wu, K.; Zeng, M. Optimal time-jerk trajectory planning for industrial robots. Mech. Mach. Theory 2018, 121, 530–544. [Google Scholar] [CrossRef]

- Kim, J.; Croft, E.A. Online near time-optimal trajectory planning for industrial robots. Robot. Comput. Manuf. 2019, 58, 158–171. [Google Scholar] [CrossRef]

- Tang, L.; Huang, J.; Zhu, L.M.; Zhu, X.; Gu, G. Path tracking of a cable-driven snake robot with a two-level motion planning method. IEEE/ASME Trans. Mechatron. 2019, 24, 935–946. [Google Scholar] [CrossRef]

- Bianco, C.G.L.; Faroni, M.; Beschi, M.; Visioli, A. A Predictive technique for the real-time trajectory scaling under high-order constraints. IEEE/ASME Trans. Mechatron. 2022, 27, 315–326. [Google Scholar] [CrossRef]

- Katzschmann, R.; Kröger, T.; Asfour, T.; Khatib, O. Toward online trajectory generation considering robot dynamics and torque limits. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2013), Tokyo, Japan, 3–7 November 2013; pp. 5644–5651. [Google Scholar]

- Sun, Y.W.; Zhao, Y.; Bao, Y.R.; Guo, D.M. A smooth curve evolution approach to the feedrate planning on five-axis toolpath with geometric and kinematic constraints. Int. J. Mach. Tools Manuf. 2017, 97, 86–97. [Google Scholar] [CrossRef]

- Tajima, S.; Sencer, B. Online interpolation of 5-axis machining toolpaths with global blending. Int. J. Mach. Tools Manuf. 2022, 175, 103862. [Google Scholar] [CrossRef]

- Stuelpnagel, J. On the parameterization of the three-dimensional rotation group. Soc. Ind. Appl. Math. Rev. 1962, 6, 422–430. [Google Scholar]

- Talebi, S.P.; Kanna, S.; Xia, Y.; Mandic, D.P. A distributed quaternion Kalman filter with applications to fly-by-wire systems. In Proceedings of the 2016 IEEE International Conference on Digital Signal Processing (DSP), Beijing, China, 16–18 October 2016; pp. 30–34. [Google Scholar]

- Talebi, S.P.; Werner, S.; Mandic, D.P. Quaternion-valued distributed filtering and control. IEEE Trans. Autom. Control 2020, 65, 4246–4257. [Google Scholar] [CrossRef]

- Wang, D.; Cao, W.; Takanishi, A. Dual-Quaternion-Based SLERP MPC Local Controller for Safe Self-Driving of Robotic Wheelchairs. Robotics 2023, 12, 153. [Google Scholar] [CrossRef]

- Weitschat, R.; Dietrich, A.; Vogel, J. Online motion generation for mirroring human arm motion. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 4245–4250. [Google Scholar]

- Grassmann, R.M.; Kahrs, J.B. Quaternion-based smooth trajectory generator for via poses in SE (3) considering kinematic limits in Cartesian space. IEEE Robot. Autom. Lett. 2019, 4, 4192–4199. [Google Scholar] [CrossRef]

- Lu, L.; Han, J.; Dong, F.; Ding, Z.; Fan, C.; Chen, S.; Liu, H.; Wang, H. Joint-smooth toolpath planning by optimized differential vector for robot surface machining considering the tool orientation constraints. IEEE/ASME Trans. Mechatron. 2021, 27, 2301–2311. [Google Scholar] [CrossRef]

- Li, Z.; Peng, F.; Yan, R.; Tang, X.; Xin, S.; Wu, J. A virtual repulsive potential field algorithm of posture trajectory planning for precision improvement in robotic multi-axis milling. Robot. Comput. Manuf. 2022, 74, 102288. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, Y.; Liu, X.; Xu, X. Analysis of obstacle avoidance strategy for dual-arm robot based on speed field with improved artificial potential field algorithm. Electronics 2021, 10, 1850. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, L.; Dong, W.; Li, C. Optimizing Redundant Robot Kinematics and Motion Planning via Advanced DH Analysis and Enhanced Artificial Potential Fields. Electronics 2024, 13, 3304. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, X.; Zong, J.A.; Leng, Z.; Hou, Z. Real-Time Trajectory Planning and Effectiveness Analysis of Intercepting Large-Scale Invading UAV Swarms Based on Motion Primitives. Drones 2024, 8, 588. [Google Scholar] [CrossRef]

- Shin, K.; McKay, N. Minimum-time control of robotic manipulators with geometric path constraints. IEEE Trans. Autom. Control 1985, 30, 531–541. [Google Scholar] [CrossRef]

- Bobrow, J.; Dubowsky, S.; Gibson, J. Time-optimal control of robotic manipulators along specified paths. Int. J. Robot. Res. 1985, 4, 3–17. [Google Scholar] [CrossRef]

- Zlajpah, L. On time optimal path control of manipulators with bounded joint velocities and torques. In Proceedings of the IEEE International Conference on Robotics and Automation, Minneapolis, MN, USA, 22–28 April 1996; pp. 1572–1577. [Google Scholar]

- Pham, Q. A general, fast, and robust implementation of the time-optimal path parameterization algorithm. IEEE Trans. Robot. 2014, 30, 1533–1540. [Google Scholar] [CrossRef]

- Dong, J.; Stori, J. A generalized time-optimal bidirectional scan algorithm for constrained feed-rate optimization. J. Dyn. Syst. Meas. Control 2006, 128, 379–390. [Google Scholar] [CrossRef]

- Beudaert, X.; Lavernhe, S.; Tournier, C. Feedrate interpolation with axis jerk constraints on 5-axis nurbs and g1 tool path. Int. J. Mach. Tools Manuf. 2012, 57, 73–82. [Google Scholar] [CrossRef]

- Pham, Q.; Stasse, O. Time-Optimal path parameterization for redundantly actuated robots: A numerical integration approach. IEEE/ASME Trans. Mechatron. 2015, 20, 3257–3263. [Google Scholar] [CrossRef]

- Goldberg, K. Completeness in Robot Motion Planning; Algorithmic Found; Robot Workshop: San Francisco, CA, USA, 1994; pp. 419–429. [Google Scholar]

- Shen, P.; Zhang, X.; Fang, Y. Complete and time-optimal path-constrained trajectory planning with torque and velocity constraints: Theory and applications. IEEE/ASME Trans. Mechatron. 2018, 23, 735–746. [Google Scholar] [CrossRef]

- Shen, P.; Zhang, X.; Fang, Y.; Yuan, M. Real-time acceleration-continuous path-constrained trajectory planning with built-in tradeoff between cruise and time-optimal motions. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1911–1924. [Google Scholar] [CrossRef]

- Orthey, A.; Chamzas, C.; Kavraki, L.E. Sampling-based motion planning: A comparative review. Annu. Rev. Control Robot. Auton. Syst. 2024, 7, 285–310. [Google Scholar] [CrossRef]

- Zhao, Z.; Cheng, S.; Ding, Y.; Zhou, Z.; Zhang, S.; Xu, D.; Zhao, Y. A survey of optimization-based task and motion planning: From classical to learning approaches. IEEE/ASME Trans. Mechatron. 2024, 30, 2799–2825. [Google Scholar] [CrossRef]

- Dam, E.B.; Koch, M.; Lillholm, M. Quaternion, Interpolation and Animation; Technical Report DIKU-TR-98/5; Department of Computer Science, University of Copenhagen: Copenhagen, Denmark, 1998. [Google Scholar]

- Pascal, D.G.; Gosselin, C. Beyond-the-static-workspace point-to-point trajectory planning of a 6-DoF cable-suspended mechanism using oscillating SLERP. Mech Mach Theory 2022, 174, 104894. [Google Scholar]

- Shen, P.; Zhang, X.; Fang, Y. Essential properties of numerical integration for time-optimal trajectory planning along a specified path. IEEE Robot. Autom. Lett. 2017, 2, 888–895. [Google Scholar] [CrossRef]

- Hirsch, M.W.; Smale, S. Differential Equations, Dynamical Systems, and Linear Algebra; Pure and Applied Mathematics; Academic Press: New York, NY, USA, 1974; Volume 60. [Google Scholar]

| Axis | Joint Velocity (rad/s) | Joint Torque (N·m) | |

|---|---|---|---|

| 1 | 1.02 | 3.06 | 44.65 |

| 2 | 0.77 | 2.31 | 40.66 |

| 3 | 1.16 | 3.47 | 18.95 |

| 4 | 1.25 | 3.74 | 9.06 |

| 5 | 1.25 | 3.74 | 10.05 |

| 6 | 1.86 | 5.5 | 5.69 |

| Parameter of Trajectory | Start Point | End Point |

|---|---|---|

| 0.30 | 0.30 | |

| 0.40 | 0.40 | |

| 0.30 | 0.30 | |

| 3.14 | 2.44 | |

| 0.00 | 0.96 | |

| 0.00 | 0.52 |

| Parameter | Start Point | End Point |

|---|---|---|

| 0.10 | 0.45 | |

| 0.40 | −0.35 | |

| 0.45 | 0.20 | |

| 3.14 | 3.14 | |

| 0.00 | 0.00 | |

| 0.17 | 0.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, T.-Y.; Wong, J.L.; Cheng, M.-Y. Quaternion-Based Velocity Scheduling for Robotic Systems. Electronics 2025, 14, 3869. https://doi.org/10.3390/electronics14193869

Huang T-Y, Wong JL, Cheng M-Y. Quaternion-Based Velocity Scheduling for Robotic Systems. Electronics. 2025; 14(19):3869. https://doi.org/10.3390/electronics14193869

Chicago/Turabian StyleHuang, Tzu-Yuan, Jun Loong Wong, and Ming-Yang Cheng. 2025. "Quaternion-Based Velocity Scheduling for Robotic Systems" Electronics 14, no. 19: 3869. https://doi.org/10.3390/electronics14193869

APA StyleHuang, T.-Y., Wong, J. L., & Cheng, M.-Y. (2025). Quaternion-Based Velocity Scheduling for Robotic Systems. Electronics, 14(19), 3869. https://doi.org/10.3390/electronics14193869