Life Cycle Assessment of Organic Solar Cells: Structure, Analytical Framework, and Future Product Concepts

Abstract

1. Introduction

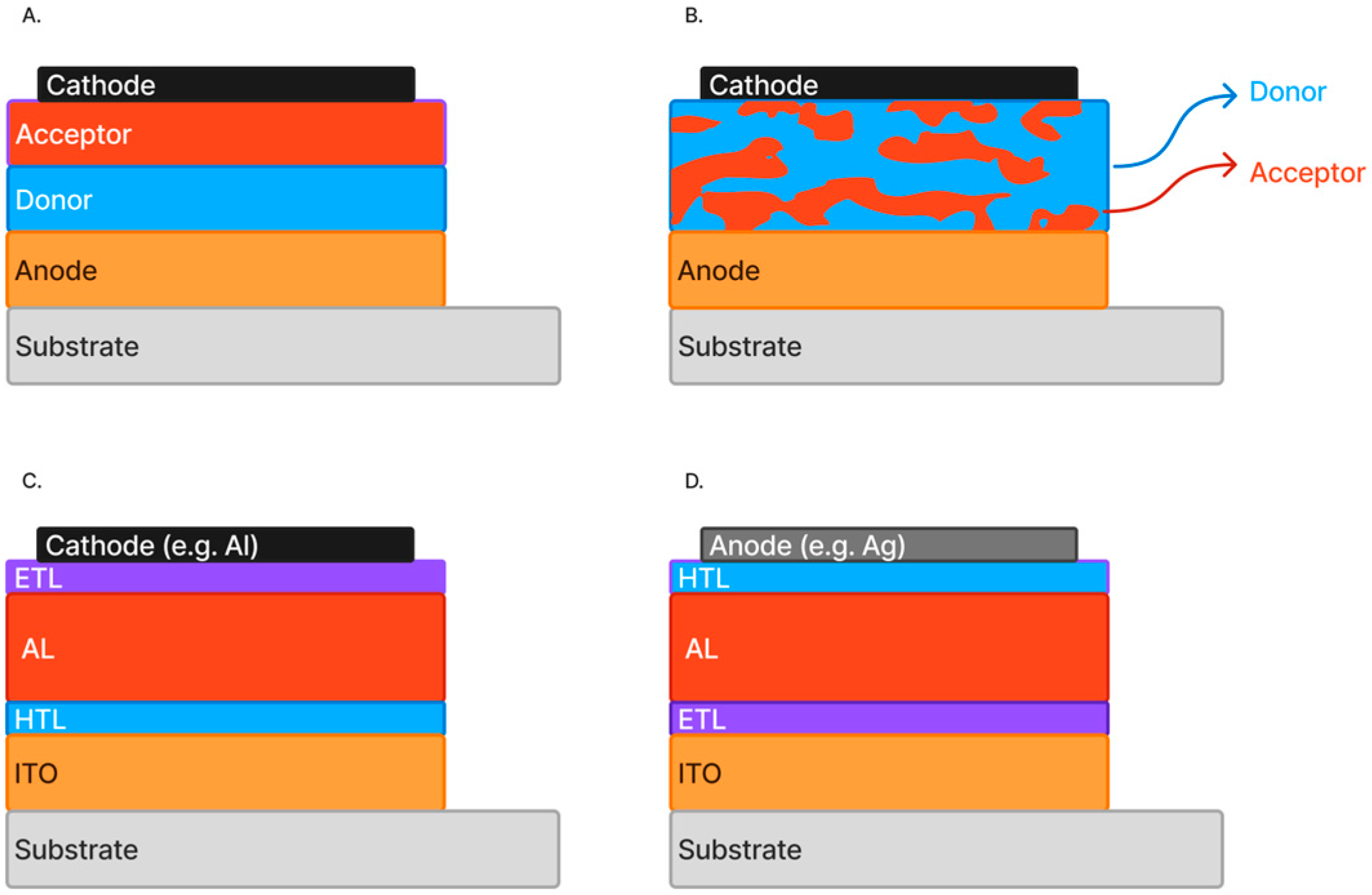

2. Analysis of Organic Solar Cell Structure

3. Life Cycle Analysis Methodology

4. Analysis of the Life Cycle of an OSC

4.1. Raw Material Extraction

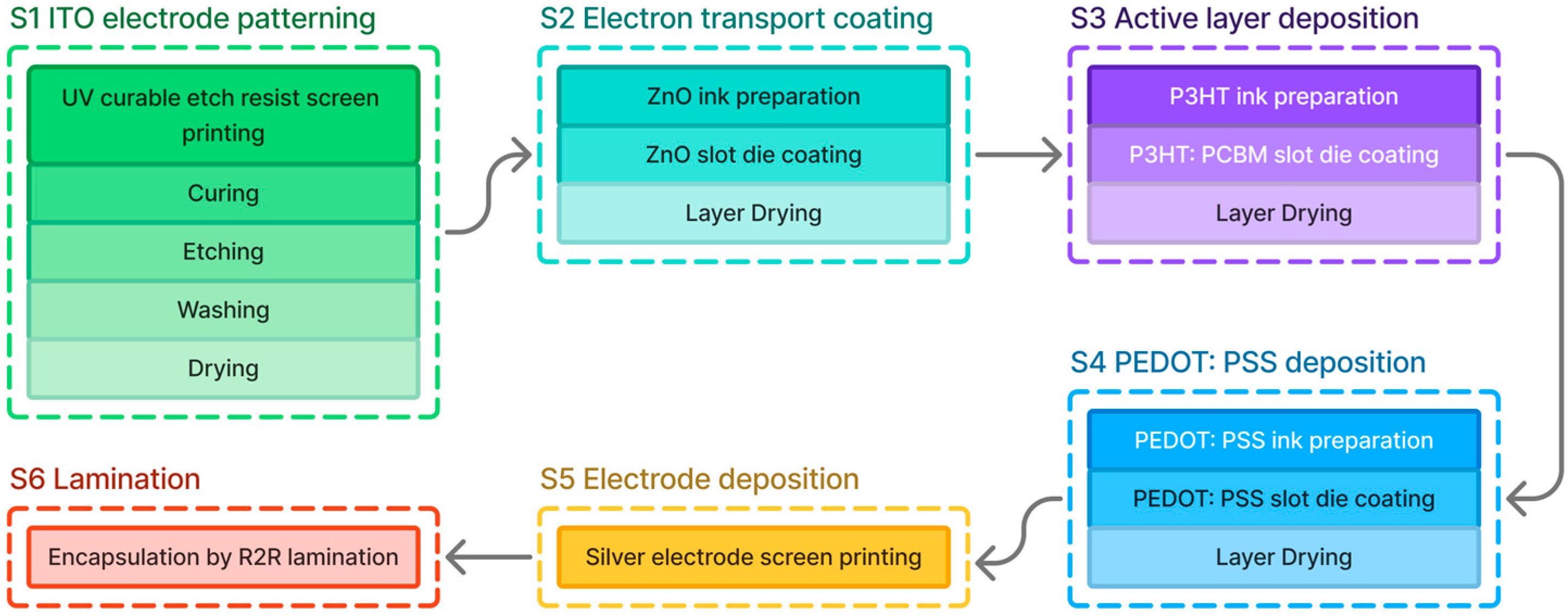

4.2. Manufacturing and Processing

- Wet film formation;

- Processing during or after formation;

- Lamination.

4.2.1. Wet Film Formation

4.2.2. Post-Coating Processing Techniques

4.2.3. Final Lamination and Module Assembly

4.3. Transportation

4.4. Usage and Retail

4.5. Waste Disposal

5. Concept Products of OSCs

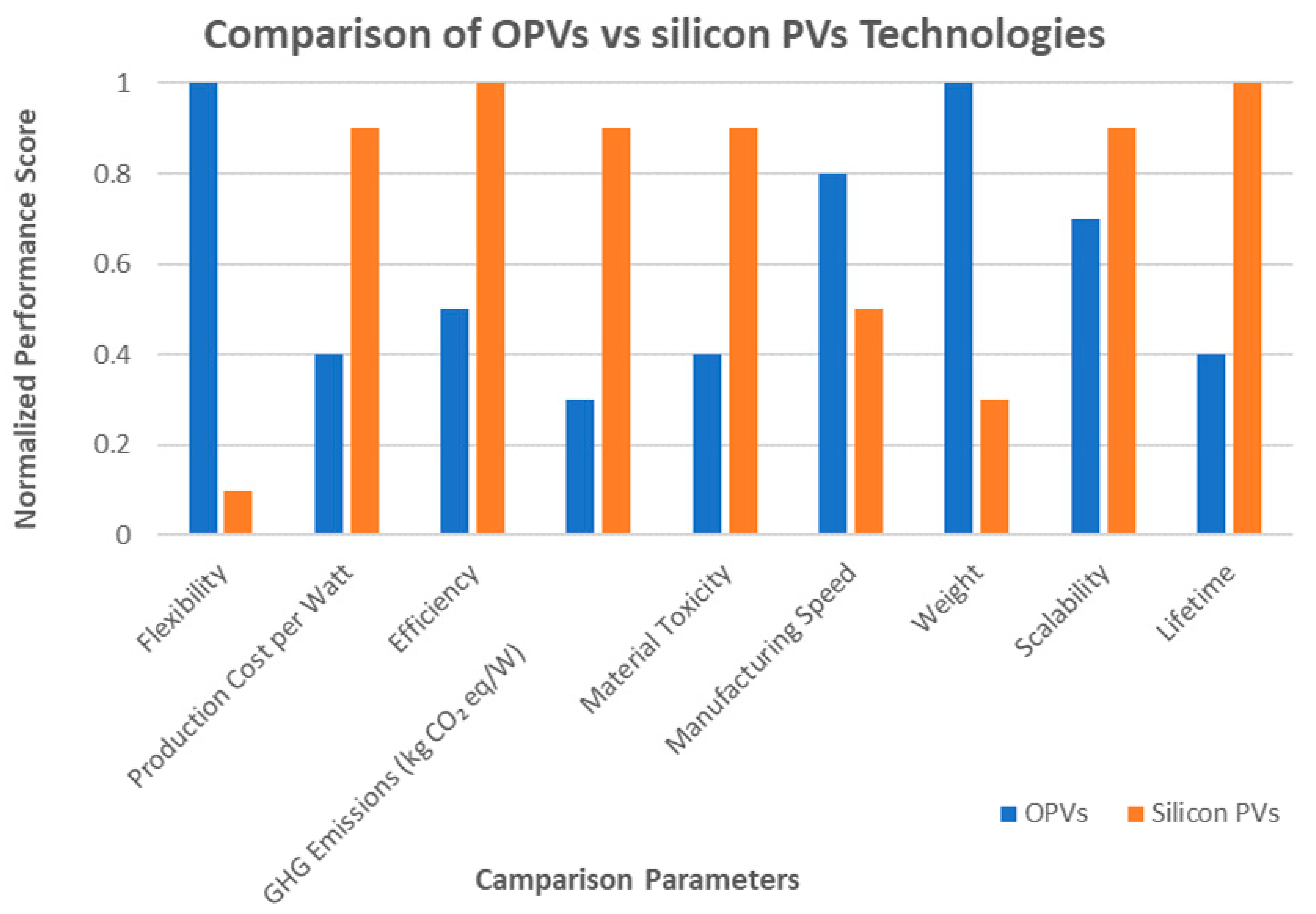

5.1. OSC Sustainability Profile

5.2. Design and Concept Philosophy

- Flexibility;

- Low production cost;

- Non-toxicity;

- Abundant materials;

- Fast and efficient production.

- A compact, foldable portable solar panel designed for ease of transport;

- An automotive solar umbrella, also referred to as an “active sunshade”;

- A solar-energy-generating window film suitable for electric vehicles (EVs).

5.3. The Transportable Solar Panel

5.3.1. Working Principle and Applications of the Transportable Solar Panel

5.3.2. Design Specifics of the Transportable Solar Panel

5.3.3. Cost Analysis of the Transportable Solar Panel

5.3.4. Market Positioning of the Transportable Solar Panel

5.4. The Solar Sunshade/Solar Umbrella

5.4.1. Working Principle and Applications of the Sunshade/Solar Umbrella

5.4.2. Design Specifics of the Sunshade/Solar Umbrella

5.4.3. Cost Analysis of the Sunshade/Solar Umbrella

5.4.4. Market Positioning of the Sunshade/Solar Umbrella

5.5. Window Tint for Electric Vehicles

5.5.1. Working Principle and Applications of Window Tint for Electric Vehicles

5.5.2. Design Specifics of Window Tint for Electric Vehicles

5.5.3. Cost Analysis of Window Tint for Electric Vehicles

5.5.4. Market Positioning of Window Tint for Electric Vehicles

6. Discussion and Future Work

6.1. Stability Under Environmental Stress

6.2. Balancing Efficiency and Cost

6.3. Scalability and Manufacturing Readiness

6.4. Social and Environmental Impact

6.5. Final Thoughts

7. Conclusions

- Raw material extraction and procurement: Materials should be non-toxic, abundant, and preferably bio-derived. The use of heavy metals should be avoided, and substrates should be recyclable or biodegradable.

- Manufacturing and assembly: Processes should follow green chemistry principles, such as low-energy, solution-based fabrication. Design for disassembly should be prioritized to enable recycling of components.

- Transportation and deployment: Due to their light weight and compactness, OSCs have a lower environmental footprint during transportation and are suitable for remote or mobile applications.

- Operational use phase: Real-world performance under various environmental conditions (temperature, light spectrum, etc.) should be studied. Applications include building-integrated PVs, automotive surfaces, and portable electronics.

- End-of-life management: OSCs are favorable due to the absence of toxic metals like lead or cadmium. Components can potentially be recovered through mechanical or solvent-based recycling. Where recycling is unfeasible, safe incineration or biodegradable alternatives may be implemented.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CAGR | Compound annual growth rate |

| CED | Cumulative energy demand |

| EPBT | Energy payback time |

| ERF | Energy return factor |

| EPE | Equivalent primary energy |

| EROI | Energy return on investment |

| EV | Electric vehicles |

| LCA | Life cycle assessment |

| LCI | Life cycle inventory |

| OSC | Organic solar cells |

| PCE | Power conversion efficiency |

| PV | Photovoltaic technology |

References

- Wu, M.; Ma, B.; Li, S.; Han, J.; Zhao, W. Powering the future: A critical review of research progress in enhancing stability of high-efficiency organic solar cells. Adv. Funct. Mater. 2023, 33, 2305445. [Google Scholar] [CrossRef]

- Yelshibay, A.; Bukari, S.D.; Baptayev, B.; Balanay, M.P. Conducting Polymers in Solar Cells: Insights, Innovations, and Challenges. Organics 2024, 5, 640–669. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Rahim, N.A.; Rahim, N.A.; Jeyraj, A.; Selvaraj, L. Progress in solar PV technology: Research and achievement. Renew. Sustain. Energy Rev. 2013, 20, 443–461. [Google Scholar] [CrossRef]

- Jiang, Y.; Bai, Y.; Wang, S. Organic Solar Cells: From Fundamental to Application. Energies 2023, 16, 2262. [Google Scholar] [CrossRef]

- Kalyani, N.; Bhanvase, B.A.; Pawade, V.B.; Dhoble, S.J.; Sonawane, S.H.; Ashokkumar, M. Empowering the Future With Organic Solar Cell Devices. In Nanomaterials for Green Energy, 1st ed.; Bhanvase, B.A., Pawade, V.B., Dhoble, S.J., Sonawane, S.H., Ashokkumar, M., Eds.; Micro and Nano Technologies series; Elsevier: Amsterdam, The Netherlands, 2018; pp. 325–350. [Google Scholar] [CrossRef]

- Li, Y.; Sha, M.; Huang, S. A Review on Transparent Electrodes for Flexible Organic Solar Cells. Coatings 2024, 14, 1031. [Google Scholar] [CrossRef]

- Topuz, E. Integration of ecotoxicity assessment with product design for circularity management. Integr. Environ. Assess. Manag. 2022, 18, 305–307. [Google Scholar] [CrossRef]

- Lizin, S.; Van Passel, S.; De Schepper, E.; Maes, W.; Lutsen, L.; Manca, J.; Vanderzande, D. Life cycle analyses of organic photovoltaics: A review. Energy Environ. Sci. 2013, 6, 3136–3149. [Google Scholar] [CrossRef]

- Bourtsalas, A.C.; Papadatos, P.E.; Kiskira, K.; Kalkanis, K.; Psomopoulos, C.S. Ecodesign for industrial furnaces and ovens: A review of the current environmental legislation. Sustainability 2023, 15, 9436. [Google Scholar] [CrossRef]

- Plakantonaki, S.; Stergiou, M.; Panagiotatos, G.; Kiskira, K.; Priniotakis, G. Regenerated cellulosic fibers from agricultural waste. In Proceedings of the AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2022; Volume 2430. [Google Scholar]

- Kalkanis, K.; Vokas, G.; Kiskira, K.; Psomopoulos, C.S. Investigating the Sustainability of Wind Turbine Recycling: A Case Study—Greece. Mater. Circ. Econ. 2024, 6, 52. [Google Scholar] [CrossRef]

- Psomopoulos, C.S.; Kalkanis, K.; Chatzistamou, E.D.; Kiskira, K.; Ioannidis, G.C.; Kaminaris, S.D. End of life treatment of photovoltaic panels: Expected volumes up to 2045 in EU. In Proceedings of the AIP Conference Proceedings, Athens, Greece, 28–30 May 2021; AIP Publishing: Melville, NY, USA, 2022; Volume 2437. [Google Scholar]

- Gumpert, F.; Janßen, A.; Basu, R.; Brabec, C.J.; Egelhaaf, H.-J.; Lohbreier, J.; Distler, A. On the theoretical framework for meniscus-guided manufacturing of large-area OPV modules. Prog. Org. Coat. 2024, 192, 108505. [Google Scholar] [CrossRef]

- Mikucioniene, D.; Mínguez-García, D.; Repon, M.R.; Milašius, R.; Priniotakis, G.; Chronis, I.; Kiskira, K.; Hogeboom, R.; Belda-Anaya, R.; Díaz-García, P. Understanding and addressing the water footprint in the textile sector: A review. AUTEX Res. J. 2024, 24, 20240004. [Google Scholar] [CrossRef]

- Kalkanis, K.; Kiskira, K.; Papageorgas, P.; Kaminaris, S.D.; Piromalis, D.; Banis, G.; Mpelesis, D.; Batagiannis, A. Advanced manufacturing design of an emergency mechanical ventilator via 3D printing—Effective crisis response. Sustainability 2023, 15, 2857. [Google Scholar] [CrossRef]

- Kiskira, K.; Lymperopoulou, T.; Lourentzatos, I.; Tsakanika, L.A.; Pavlopoulos, C.; Papadopoulou, K.; Ochsenkühn, K.M.; Tsopelas, F.; Chatzitheodoridis, E.; Lyberatos, G.; et al. Bioleaching of scandium from bauxite residue using fungus Aspergillus niger. Waste Biomass Valorization 2023, 14, 3377–3390. [Google Scholar] [CrossRef]

- Panidi, J.; Georgiadou, D.G.; Schoetz, T.; Prodromakis, T. Advances in organic and perovskite photovoltaics enabling a greener Internet of Things. Adv. Funct. Mater. 2022, 32, 2200694. [Google Scholar] [CrossRef]

- Walsh, K.K.; Murphy, C.; Russo, S.; Craciun, M.F. Improved stability of organic photovoltaic devices with FeCl3 intercalated graphene electrodes. Front. Electron. 2021, 2, 643687. [Google Scholar] [CrossRef]

- Jakobs, A.; Schulte, S.; Pauliuk, S. Price variance in hybrid-LCA leads to significant uncertainty in carbon footprints. Front. Sustain. 2021, 2, 666209. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Stadler, K.; Wood, R.; Bulavskaya, T.; Södersten, C.J.; Simas, M.; Schmidt, S.; Usubiaga, A.; Acosta-Fernández, J.; Kuenen, J.; Bruckner, M.; et al. EXIOBASE 3: Developing a time series of detailed environmentally extended multi-regional input-output tables. J. Ind. Ecol. 2018, 22, 502–515. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Al-Othman, A.; Kafiah, F.; Abdelsalam, E.; Almomani, F.; Alkasrawi, M. Environmental impacts of solar photovoltaic systems: A critical review of recent progress and future outlook. Sci. Total Environ. 2021, 759, 143528. [Google Scholar] [CrossRef]

- Frischknecht, R.; Wyss, F.; Büsser Knöpfel, S.; Lützkendorf, T.; Balouktsi, M. Cumulative energy demand in LCA: The energy harvested approach. Int. J. Life Cycle Assess. 2015, 20, 957–969. [Google Scholar] [CrossRef]

- Yue, P.; Khatav, F.; You, F.; Darling, S.B. Deciphering the uncertainties in life cycle energy and environmental analysis of organic photovoltaics. Energy Environ. Sci. 2012, 5, 9163–9172. [Google Scholar] [CrossRef]

- Anrango-Camacho, C.; Martínez-Díaz, M.V.; Romero-Nieto, C. Recent advances in hole-transporting layers for organic solar cells. Nanomaterials 2022, 12, 443. [Google Scholar] [CrossRef] [PubMed]

- Sampaio, P.G.V.; González, M.O.A. A review on organic photovoltaic cell. Int. J. Energy Res. 2022, 46, 17813–17828. [Google Scholar] [CrossRef]

- Tong, J.; Yang, X.; Xu, Y.; Li, W.; Tang, J.; Song, H.; Zhou, Y. Efficient top-illuminated organic-quantum dots hybrid tandem solar cells with complementary absorption. ACS Photonics 2017, 4, 1172–1177. [Google Scholar] [CrossRef]

- Tao, C.; Ruan, S.; Xie, G.; Kong, X.; Shen, L.; Meng, F.; Liu, C.; Zhang, X.; Dong, W.; Chen, W. Role of tungsten oxide in inverted polymer solar cells. Appl. Phys. Lett. 2009, 94, 042112. [Google Scholar] [CrossRef]

- Tong, Y.; Xu, B.; Ye, F. Recent advance in solution-processed hole transporting materials for organic solar cells. Adv. Funct. Mater. 2024, 34, 2310865. [Google Scholar] [CrossRef]

- Marinova, N.; Valero, S.; Delgado, J.L. Organic and perovskite solar cells: Working principles, materials and interfaces. J. Colloid Interface Sci. 2017, 488, 373–389. [Google Scholar] [CrossRef]

- Li, K.; Li, F.; Chen, C.; Jiang, P.; Lu, S.; Wang, S.; Lu, Y.; Tu, G.; Guo, J.; Shui, L.; et al. One-dimensional Sb2Se3 enabling ultra-flexible solar cells and mini-modules for IoT applications. Nano Energy 2021, 86, 106101. [Google Scholar] [CrossRef]

- Hou, J.; Inganäs, O.; Friend, R.; Gao, F. Organic solar cells based on non-fullerene acceptors. Nat. Mater. 2018, 17, 119–128. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Mahmud, M.P.; Farjana, S.H. Comparative life cycle environmental impact assessment of renewable electricity generation systems: A practical approach towards Europe, North America and Oceania. Renew. Energy 2022, 193, 1106–1120. [Google Scholar] [CrossRef]

- Fthenakis, V.; Frischknecht, R.; Raugei, M.; Kim, H.C.; Alsema, E.; Held, M.; de Wild-Scholten, M. Methodology Guidelines on Life Cycle Assessment of Photovoltaic Electricity; International Energy Agency Photovoltaic Power Systems Programme: Paris, France, 2011. [Google Scholar]

- Frischknecht, R.; Stolz, P.; Heath, G.; Raugei, M.; Sinha, P.; de Wild-Scholten, M. Methodology Guidelines on Life Cycle Assessment of Photovoltaic Electricity, 4th ed.; IEA-PVPS Task 12; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2020. [Google Scholar]

- Valiente, D.; Rodríguez-Mas, F.; González, J.J.; Tro, R.; Corral, P.; Alonso, J.L.; Ferrer, J.C.; de Ávila, S.F. Time degradation analysis of organic solar cells based on ITO/PEDOT:PSS/P3HT:PCBM/Al structure. Eng. Proc. 2022, 21, 41. [Google Scholar] [CrossRef]

- Al-Ahmad, A.; Vaughan, B.; Holdsworth, J.; Belcher, W.; Zhou, X.; Dastoor, P. The role of the electron transport layer in the degradation of organic photovoltaic cells. Coatings 2022, 12, 1071. [Google Scholar] [CrossRef]

- Anctil, A.; Babbitt, C.W.; Raffaelle, R.P.; Landi, B.J. Cumulative energy demand for small molecule and polymer photovoltaics. Prog. Photovolt. Res. Appl. 2013, 21, 1541–1554. [Google Scholar] [CrossRef]

- Espinosa, N.; Hösel, M.; Jørgensen, M.; Krebs, F.C. Large scale deployment of polymer solar cells on land, on sea and in the air. Energy Environ. Sci. 2014, 7, 855–866. [Google Scholar] [CrossRef]

- Tsang, M.P.; Sonnemann, G.W.; Bassani, D.M. Life-cycle assessment of cradle-to-grave opportunities and environmental impacts of organic photovoltaic solar panels compared to conventional technologies. Sol. Energy Mater. Sol. Cells 2016, 156, 37–48. [Google Scholar] [CrossRef]

- Glogic, E.; Weyand, S.; Tsang, M.P.; Young, S.B.; Schebek, L.; Sonnemann, G. Life cycle assessment of organic photovoltaic charger use in Europe: The role of product use intensity and irradiation. J. Clean. Prod. 2019, 233, 1088–1096. [Google Scholar] [CrossRef]

- García-Valverde, R.; Cherni, J.A.; Urbina, A. Life cycle analysis of organic photovoltaic technologies. Prog. Photovolt. Res. Appl. 2010, 18, 535–558. [Google Scholar] [CrossRef]

- Espinosa, N.; García-Valverde, R.; Urbina, A.; Lenzmann, F.; Manceau, M.; Angmo, D.; Krebs, F.C. Life cycle assessment of ITO-free flexible polymer solar cells prepared by roll-to-roll coating and printing. Sol. Energy Mater. Sol. Cells 2012, 97, 3–13. [Google Scholar] [CrossRef]

- Li, Q.; Monticelli, C.; Zanelli, A. Life cycle assessment of organic solar cells and perovskite solar cells with graphene transparent electrodes. Renew. Energy 2022, 195, 906–917. [Google Scholar] [CrossRef]

- D’Onofrio, C. Analysis, Design and Study of Flexible Solar Systems. Bachelor’s Thesis, University of West Attica, Athens, Greece, 2023. [Google Scholar]

- Hatzilyberis, K.; Tsakanika, L.A.; Lymperopoulou, T.; Georgiou, P.; Kiskira, K.; Tsopelas, F.; Ochsenkühn, K.M.; Ochsenkühn-Petropoulou, M. Design of an advanced hydrometallurgy process for the intensified and optimized industrial recovery of scandium from bauxite residue. Chem. Eng. Process. 2020, 155, 108015. [Google Scholar] [CrossRef]

- Guine, J.B.; Huppes, G.; Heijungs, R. Life Cycle Assessment. In An Operational Guide to ISO Standards; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002; Volume 1–3. [Google Scholar]

- Montzka, S.A.; Dlugokencky, E.; Butler, J.H.; Hall, B.D.; Mondeel, D.; Siso, C.; Elkins, J.W. A decline in global CFC-11 emissions during 2018–2019. Nature 2021, 590, 428–432. [Google Scholar] [CrossRef]

- Krebs, F.C.; Norrman, K. Degradation of organic photovoltaics: Mechanisms and countermeasures. ACS Appl. Mater. Interfaces 2010, 2, 877–883. [Google Scholar] [CrossRef]

- Shen, L.; Nieuwlaar, E.; Worrell, E.; Patel, M.K. Life cycle energy and GHG emissions of PET recycling: Change-oriented effects. Int. J. Life Cycle Assess. 2011, 16, 522–536. [Google Scholar] [CrossRef]

- Babeli, I.; Ruano, G.; Casanovas, J.; Ginebra, M.P.; García-Torres, J.; Alemán, C. Conductive, self-healable and reusable poly (3,4-ethylenedioxythiophene)-based hydrogels for highly sensitive pressure arrays. J. Mater. Chem. C 2020, 8, 8654–8667. [Google Scholar] [CrossRef]

- Schlesinger, M.E. Recycling of aluminum. In Aluminum Science and Technology; ASM International: Materials Park, OH, USA, 2018; pp. 96–107. [Google Scholar]

- Espinosa, N.; Garcia-Valverde, R.; Urbina, A.; Krebs, F.C. A life cycle analysis of polymer solar cell modules prepared using roll-to-roll methods under ambient conditions. Sol. Energy Mater. Sol. Cells 2011, 95, 1293–1302. [Google Scholar] [CrossRef]

- Aziz, F.; Ismail, A.F. Spray coating methods for polymer solar cells fabrication: A review. Mater. Sci. Semicond. Process. 2015, 39, 416–425. [Google Scholar] [CrossRef]

- Roth, B.; Søndergaard, R.; Krebs, F.C. Roll-to-roll printing and coating techniques for manufacturing large-area flexible organic. In Handbook of Flexible Organic Electronics: Materials, Manufacturing and Applications; Elsevier: Amsterdam, The Netherlands, 2014; pp. 171–192. [Google Scholar]

- Søndergaard, R.; Hösel, M.; Angmo, D.; Larsen-Olsen, T.T.; Krebs, F.C. Roll-to-roll fabrication of polymer solar cells. Mater. Today 2012, 15, 36–49. [Google Scholar] [CrossRef]

- Wengeler, L.; Schmidt-Hansberg, B.; Peters, K.; Scharfer, P.; Schabel, W. Investigations on knife and slot die coating and processing of polymer nanoparticle films for hybrid polymer solar cells. Chem. Eng. Process. 2011, 50, 478–482. [Google Scholar] [CrossRef]

- Sumaiya, S.; Kardel, K.; El-Shahat, A. Organic solar cell by inkjet printing—An overview. Technologies 2017, 5, 53. [Google Scholar] [CrossRef]

- Alstrup, J.; Andersen, T.R.; Bundgaard, E.; Larsen-Olsen, T.T.; Jørgensen, M.; Krebs, F.C. Ultra fast and parsimonious materials screening for polymer solar cells using differentially pumped slot-die coating. Sol. Energy Mater. Sol. Cells 2010, 94, 214–221. [Google Scholar] [CrossRef]

- Krebs, F.C.; Søndergaard, R.; Jørgensen, M. Printed metal back electrodes for R2R fabricated polymer solar cells studied using the LBIC technique. Sol. Energy Mater. Sol. Cells 2011, 95, 1348–1353. [Google Scholar] [CrossRef]

- Credgington, D. Organic photovoltaics. In Clean Electricity from Photovoltaics; Green, M.A., Ed.; World Scientific: Singapore, 2015; pp. 339–412. [Google Scholar]

- Kuntze, T.; Wollmann, P.; Klotzbach, U.; Fledderus, H. Roll-to-roll suitable short-pulsed laser scribing of organic photovoltaics and close-to-process characterization. In Proceedings of the Laser-Based Micro- and Nanoprocessing XI, San Francisco, CA, USA, 7 March 2017; Volume 10092, pp. 93–98. [Google Scholar]

- Kim, B.; Nam, H.K.; Watanabe, S.; Park, S.; Kim, Y.; Kim, Y.J.; Fushinobu, K.; Kim, S.W. Selective laser ablation of metal thin films using ultrashort pulses. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 771–782. [Google Scholar] [CrossRef]

- Xiao, S.; Gröger, B.; Fernandes, S.A.; Ostendorf, A. Laser selective patterning of ITO on flexible PET for organic photovoltaics. In Proceedings of the Laser-Based Micro- and Nanopackaging and Assembly V, San Francisco, CA, USA, 21 February 2011; Volume 7921, pp. 127–134. [Google Scholar]

- Shin Thant, K.K.; Seriwattanachai, C.; Jittham, T.; Thamangraksat, N.; Sakata, P.; Kanjanaboos, P. Comprehensive review on slot-die-based perovskite photovoltaics: Mechanisms, materials, methods, and marketability. Adv. Energy Mater. 2025, 15, 2403088. [Google Scholar] [CrossRef]

- Riede, M.; Spoltore, D.; Leo, K. Organic solar cells—The path to commercial success. Adv. Energy Mater. 2021, 11, 2002653. [Google Scholar] [CrossRef]

- American Bureau of Transportation Statistics (ABTS). Available online: https://www.bts.gov/ (accessed on 19 January 2025).

- National Motor Freight Traffic Association (NMFTA). Available online: https://nmfta.org/ (accessed on 10 December 2024).

- FCCR. Available online: https://fccr.co/ (accessed on 20 April 2025).

- Prentice, B.E.; Prokop, D. Concepts of Transportation Economics; World Scientific Publishing Company: Singapore, 2015. [Google Scholar]

- Xu, T.; Yu, L. How to design low bandgap polymers for highly efficient organic solar cells. Mater. Today 2014, 17, 11–15. [Google Scholar] [CrossRef]

- Eco-Business. Available online: https://www.ecobusiness.com/news/the-elephant-in-the-room-can-the-solar-industry-go-circular/ (accessed on 10 January 2025).

- Jung, B.; Park, J.; Seo, D.; Park, N. Sustainable system for raw-metal recovery from crystalline silicon solar panels: From noble-metal extraction to lead removal. ACS Sustain. Chem. Eng. 2016, 4, 4079–4083. [Google Scholar] [CrossRef]

- Ren, T.; Zhan, H.; Xu, H.; Chen, L.; Shen, W.; Xu, Y.; Zhao, D.; Shao, Y.; Wang, Y. Recycling and high-value utilization of polyethylene terephthalate wastes: A review. Environ. Res. 2024, 249, 118428. [Google Scholar] [CrossRef]

- Zhang, S.; Qin, Y.; Zhu, J.; Hou, J. Green-solvent-processable organic solar cells. Mater. Today 2016, 19, 533–543. [Google Scholar] [CrossRef]

- Kavlak, G.; McNerney, J.; Trancik, J.E. Evaluating the causes of cost reduction in photovoltaic modules. Energy Policy 2018, 123, 700–710. [Google Scholar] [CrossRef]

- Plakantonaki, S.; Kiskira, K.; Zacharopoulos, N.; Belessi, V.; Sfyroera, E.; Priniotakis, G.; Athanasekou, C. Investigating the routes to produce cellulose fibers from agro-waste: An upcycling process. ChemEngineering 2024, 8, 112. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, S.; Garg, D.; Haleem, A. Barriers to renewable/sustainable energy technologies adoption: Indian perspective. Renew. Sustain. Energy Rev. 2015, 41, 762–776. [Google Scholar] [CrossRef]

- Sun, C.; Pan, F.; Bin, H.; Zhang, J.; Xue, L.; Qiu, B.; Wei, Z.; Zhang, Z.G.; Li, Y. A low cost and high performance polymer donor material for polymer solar cells. Nat. Commun. 2018, 9, 743. [Google Scholar] [CrossRef]

- European Commission (EC, 2020). Lightweight, Bendy, Cheaper—The Promise of Organic Solar Panels. Available online: https://projects.research-and-innovation.ec.europa.eu/en/horizon-magazine/lightweight-bendy-cheaper-promise-organic-solar-panels?utm.com (accessed on 20 March 2025).

- Acumen, Research and Consulting. Flexible Solar Panels Market Size—Global Industry, Share, Analysis, Trends and Forecast 2024–2032. Available online: https://www.acumenresearchandconsulting.com/flexible-solar-panels-market?utm (accessed on 23 February 2025).

- ARC. IndustryARC. Report “Portable Solar Panel Industry Outlook—Forecast (2022–2027)”. Available online: https://www.industryarc.com/Report/19366/portable-solar-panel-market.html (accessed on 12 February 2025).

- Chander, S.; Purohit, A.; Sharma, A.; Nehra, S.P.; Dhaka, M.S. A study on photovoltaic parameters of mono-crystalline silicon solar cell with cell temperature. Energy Rep. 2015, 1, 104–109. [Google Scholar] [CrossRef]

- Liu, C.; Xiao, C.; Xie, C.; Li, W. Flexible organic solar cells: Materials, large-area fabrication techniques and potential applications. Nano Energy 2021, 89, 106399. [Google Scholar] [CrossRef]

- Kaduwal, A.; Søndergaard, R.; Krebs, F.C. ITO-free laminated concept for flexible organic solar cells. Sol. Energy Mater. Sol. Cells 2014, 120, 449–453. [Google Scholar] [CrossRef]

- Angmo, D.; Espinosa, N.; Hösel, M.; Krebs, F.C. Roll-to-roll inkjet printing and photonic sintering of electrodes for ITO-free polymer solar cell modules and facile product integration. Adv. Energy Mater. 2013, 3, 172–175. [Google Scholar] [CrossRef]

- Augusto, A.; Tyler, K.; Herasimenka, S.Y.; Bowden, S.G. Flexible modules using <70 μm thick silicon solar cells. Energy Procedia 2016, 92, 493–499. [Google Scholar]

- ThinkEpic. Top 8 Most Cost-Effective Portable Solar Panels for 2020. Available online: https://www.thinkepic.com/solar/top-8-most-cost-effective-portable-solar-panels-for-2020/?utm (accessed on 15 April 2025).

- Zheng, Z.; Wang, J.; Bi, P.; Ren, J.; Wang, Y.; Yang, Y.; Liu, X.; Zhang, S.; Hou, J. Tandem organic solar cell with 20.2% efficiency. Joule 2022, 6, 171–184. [Google Scholar] [CrossRef]

- Madsen, D.N.; Hansen, J.P. Outlook of solar energy in Europe based on economic growth characteristics. Renew. Sustain. Energy Rev. 2019, 114, 109306. [Google Scholar] [CrossRef]

- ASCA. Printed OPV Solar Umbrellas: Shade and Power. Available online: https://www.asca.com/applications/projects/printed-opv-solar-umbrellas/ (accessed on 10 April 2025).

- Kickstarter. Solar Powered Electric Retractable Car Umbrella. Available online: https://www.kickstarter.com/projects/884044457/solar-powered-electric-retractable-car-umbrella (accessed on 1 April 2025).

- Phipps, K. Shelf Solar Sunshade Concept Generates Power and Shields Your Car. New Atlas. Available online: https://newatlas.com/shelf-car-sunshade-generates-solar-power/13370/ (accessed on 15 March 2025).

- Wu, L.; Silverman, A.; Fell, H.; Glynn, J.; Wu, L.Z.; Silverman, A. A Quantitative Analysis of Variables Affecting Power Transmission Infrastructure Projects in the US. Center on Global Energy Policy, Columbia University. Available online: https://www.energypolicy.columbia.edu/wp-content/uploads/2024/04/USTransmissionInfrastructureDevelopment-CGEP_Report_032924-1.pdf?utm (accessed on 1 March 2025).

- Cook, M.; Davidson, F.T.; Fell, H.; Glynn, J.; Lott, M.; Rhodes, J.D. Electrification on the Path to Net Zero: A Comparison of Studies Examining Opportunities and Barriers in the United States. Center on Global Energy Policy, Columbia University. 2022. Available online: https://www.energypolicy.columbia.edu/publications/electrification-path-net-zero-comparison-studies-examining-opportunities-and-barriers-united-states/ (accessed on 23 February 2025).

- Qi, Q.; Xian, K.; Ke, H.; Wu, J.; Zhou, K.; Gao, M.; Liu, J.; Li, S.; Zhao, W.; Chen, Z.; et al. Improving the thermal stability of organic solar cells via crystallinity control. ACS Appl. Energy Mater. 2022, 5, 15656–15665. [Google Scholar] [CrossRef]

- Dauzon, E.; Sallenave, X.; Plesse, C.; Goubard, F.; Amassian, A.; Anthopoulos, T.D. Pushing the limits of flexibility and stretchability of solar cells: A review. Adv. Mater. 2021, 33, 2101469. [Google Scholar] [CrossRef]

- Kalowekamo, J.; Baker, E. Estimating the manufacturing cost of purely organic solar cells. Sol. Energy 2009, 83, 1224–1231. [Google Scholar] [CrossRef]

- Green, M.A. How did solar cells get so cheap? Joule 2019, 3, 631–633. [Google Scholar] [CrossRef]

- Fu, J.; Fong, P.W.K.; Liu, H.; Zhang, Y.; Lu, X.; Li, G. 19.31% binary organic solar cell and low non-radiative recombination enabled by non-monotonic intermediate state transition. Nat. Commun. 2023, 14, 1760. [Google Scholar] [CrossRef]

- Australian Space Weather Forecasting Service (ASWFS). Available online: https://www.sws.bom.gov.au/Educational/2/1/12 (accessed on 8 April 2025).

- European Environmental Agency (EEA). New Registrations of Electric Vehicles in Europe. 2024. Available online: https://www.eea.europa.eu/en/analysis/indicators/new-registrations-of-electric-vehicles (accessed on 12 March 2025).

- Technavio. Automotive Window Power Sunshade Market Analysis—US, Germany, China, UK, Japan—Size and Forecast 2024–2028. Available online: https://www.technavio.com/report/automotive-window-power-sunshade-market-industry-analysis (accessed on 10 April 2025).

- Allied Market Research (AMR). 2025. Available online: https://www.alliedmarketresearch.com/ (accessed on 10 January 2025).

- Shukla, A.K.; Sudhakar, K.; Baredar, P. Recent advancement in BIPV product technologies: A review. Energy Build. 2017, 140, 188–195. [Google Scholar] [CrossRef]

- Saleh, A.; Pellet, N.; Zakeeruddin, S.M.; Dar, M.I.; Grätzel, M. A Fully Printable Hole-Transporter-Free Semi-Transparent Perovskite Solar Cell. Eur. J. Inorg. Chem. 2021, 2021, 3752–3760. [Google Scholar] [CrossRef]

- Li, Y.; Huang, B.; Zhang, X.; Ding, J.; Zhang, Y.; Xiao, L.; Wang, B.; Cheng, Q.; Huang, G.; Zhang, H.; et al. Lifetime over 10,000 hours for organic solar cells with Ir/IrOx electron-transporting layer. Nat. Commun. 2023, 14, 1241. [Google Scholar] [CrossRef]

- VEHQ. 2025. Available online: https://vehq.com/ (accessed on 2 February 2025).

- Van der Roest, E.; Voeten, J.G.; Cirkel, D.G. Increasing solar panel output with blue-green roofs in water-circular and nature inclusive urban development. Build. Environ. 2023, 244, 110704. [Google Scholar] [CrossRef]

- Gambhir, A.; Sandwell, P.; Nelson, J. The future costs of OPV–A bottom-up model of material and manufacturing costs with uncertainty analysis. Sol. Energy Mater. Sol. Cells 2016, 156, 49–58. [Google Scholar] [CrossRef]

- Duan, L.; Uddin, A. Progress in Stability of Organic Solar Cells. Adv. Sci. 2020, 7, 1903259. [Google Scholar] [CrossRef]

- Plakantonaki, S.; Zacharopoulos, N.; Christopoulos, M.; Kiskira, K.; Markou, G.; Tsakanika, L.A.; Priniotakis, G. Upcycling industrial peach waste to produce dissolving pulp. Environ. Sci. Pollut. Res. 2025, 32, 4636–4655. [Google Scholar] [CrossRef]

- Savagatrup, S.; Printz, A.D.; O’Connor, T.F.; Zaretski, A.V.; Rodriquez, D.; Sawyer, E.J.; Rajan, K.M.; Acosta, R.I.; Root, S.E.; Lipomi, D.J. Mechanical degradation and stability of organic solar cells: Molecular and microstructural determinants. Energy Environ. Sci. 2015, 8, 55–80. [Google Scholar] [CrossRef]

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K.-H. Solar energy: Potential and future prospects. Renew. Sustain. Energy Rev. 2018, 82, 894–900. [Google Scholar] [CrossRef]

- Tong, Y.; Xiao, Z.; Du, X.; Zuo, C.; Li, Y.; Lv, M.; Yuan, Y.; Yi, C.; Hao, F.; Hua, Y.; et al. Progress of the key materials for organic solar cells. Sci. China Chem. 2020, 63, 758–765. [Google Scholar] [CrossRef]

- Ding, Y.; Memon, W.A.; Xiong, S.; Gong, S.; Li, M.; Deng, Z.; Liu, H.; Liu, Y.; Chen, X.; Zheng, N.; et al. Molecular Design of Dimeric Acceptor Enables Binary Organic Solar Cells with 19.78% Efficiency and Enhanced Stability. Adv. Mater. 2025, 37, 2501671. [Google Scholar] [CrossRef]

- Saitov, E.B.; Toshov, J.B.; Fayzullayev, B.H.; Abdullabekov, I.A.; Nasriddinov, B.A. Optimization of Solar Power Systems in Different Regions. J. Crit. Rev. 2020, 7, 1777–1783. [Google Scholar]

- Kannan, N.; Vakeesan, D. Solar energy for future world: A review. Renew. Sustain. Energy Rev. 2016, 62, 1092–1105. [Google Scholar] [CrossRef]

| Study | Topic | PV System | Module Size | Module Efficiency | Functional Unit (FU) 1 | System Boundaries | LCIA Methodology | Environmental Indices |

|---|---|---|---|---|---|---|---|---|

| [43] | LCA of lab production of a BHJ OSC and compares with those obtained for the industrial production of other PV technologies. | OPVs based on polymer–fullerene blends fabricated in a lab setting; extrapolated to module and system level (solar home system). | 1 m2 (used as the base for functional unit and energy calculations). | Two scenarios: -5% (current lab-scale performance), -10% (anticipated industrial module performance by 2020). | 1 m2 | -Cradle-to-gate for lab-scale device fabrication. -Gate-to-grave estimated by extrapolating module/frame processes from conventional PV. | -Midpoint approach using CED. -CO2 emissions calculated via energy mix conversion factor (gCO2/kWh) using UCPTE database. -Custom calculations based on embedded energy. | -EPBT: ranges based on efficiency and manufacturing assumptions. -CO2 emissions: reported in kg CO2/m2 of PV module. -CO2 payback time (CO2PBT): time to offset the embedded emissions based on avoided emissions from local grid mix. |

| [40] | LCA of large-area organic solar modules fabricated by R2R printing techniques under ambient conditions. | Polymer solar cells (P3HT:PCBM active layer) manufactured via six-step R2R process. | Based on 1 m2 of processed surface; functional unit corresponds to either 1 m2 or 1 linear meter of 305 mm wide foil (0.305 m2). | Typical range for P3HT:PCBM: ~2–3%. | 1 m2 of solar module over its lifetime | Cradle-to-gate. | -Impacts calculated as embedded energy and CO2-equivalent emissions. -No software used (custom calc). | -EPBT not explicitly calculated. -CO2 emissions from production calculated using Danish grid emission factor. |

| [44] | LCA of ITO-free flexible polymer solar cells, focusing on R2R-coated OPV modules. The study compares the environmental impact of replacing ITO with alternative low-cost electrodes. | OPV modules using ITO-free electrodes. | -Processed area per FU: 1 m2 (290 mm × 3483 mm). -Only 54% of the processed area is covered by OPV modules. -Of that, 68.1% is considered active area. | Range: 1–5%. | 1 m2 of processed foil | -Production stage, included only: (a) Direct energy to process (electricity/heat for printing, coating, etc.); (b) Energy to produce materials (e.g., patterned substrates, active materials). | -Focuses on EPBT and ERF. -Also considers CO2-equivalent emissions based on Denmark’s 2008 electricity mix (420.88 g CO2-eq/kWh_el). -All energy flows converted to EPE. | -EPBT: time required to generate the same amount of energy used during production. -Energy Return Factor (ERF): total energy generated over lifetime/total embodied energy. -CO2 Emission Factor: expressed in kg CO2-eq per kWh produced. |

| [39] | LCA of OPV, specifically CED analysis of 26 different OPV device architectures (polymer and small-molecule-based). | -Polymer-based OPVs (bulk heterojunctions). -Small-molecule-based OPVs (planar and planar-mixed heterojunctions). -Both single- and multi-junction configurations. | -Devices are typically <0.2 cm2 (lab-scale). -CED values normalized to an FU of 1 Wp module size. | -P3HT:PCBM ~5%. -PTB7-based ~7.4%. -Multi-junction small-molecule devices up to ~5.2%. | 0.00049 m2 | Cradle-to-gate. | -CED method. -Implemented using SimaPro® 7.2. -Based on Ecoinvent and literature-derived data. -Includes sensitivity. | -CED (MJ/Wp) is the main environmental metric. -Correlated with other environmental impact indicators as a proxy. |

| [40] | LCA of OPV on land, sea, and air. Focuses on the environmental impact, installation, and energy return of OPV. | Polymer solar cells developed and printed at DTU, deployed in terrestrial, marine, and airborne applications. | Not explicitly stated, implied to be large-scale. | Not numerically stated, efficiency is incorporated in calculations of energy generation and discussed in EPBT and EROI. Also tied to the PCE used in modeling. | 0.588 m2 | Cradle-to-grave. | -CML 2000—midpoint approach (problem-oriented). -ReCiPe 2008—eEndpoint approach (damage-oriented, used here with normalized and weighted scores). -GHG Protocol—for carbon footprint analysis (including fossil, biogenic, land transformation, and carbon uptake). -Software used: SimaPro | ReCiPe 2008 midpoint (H) impact categories (18). |

| [41] | Examination of the environmental impacts of OPV solar modules. | (a) A default OPV technology with polymer-based BHJ with a fullerene derivative and a polymer in its layer, and (b) all-polymer technology, polymer acceptor–polymer donor. | 75 cm2/Wp. | 5%. | 0.00059 m2 | Cradle-to-grave | openLCA v1.4.2 with ReCiPe 2008 (Midpoint H) and CED. | EPBT, CPBT (in terms of CO2-eq emissions), CED CCE, ReCiPe 2008 midpoint (H) impact categories (18). |

| [42] | Environmental impacts of using an OPV solar charger to charge a mobile phone instead of the electricity grid in Europe. | Standalone 10 Wp OPV solar charger (without power bank). | 0.2 m2 of OPV panel area. | 5%. | 0.00059 m2 | Cradle-to-grave | ReCiPe 2008 Midpoint (H) v1.11, using OpenLCA 1.6.3 and Ecoinvent v3.3 consequential database. | 18 categories used (from ReCiPe Midpoint H). |

| [45] | LCA of organic and perovskite solar cells with glass substrate (OSC-G and PSC-G), focusing on their environmental performance from a cradle-to-gate perspective. | Lab-scale PV systems: OSC-G OSC with glass substrate) PSC-G (perovskite solar cell with glass substrate). | 1 m2 of PV module. | Not directly specified but inferred through use of PCE and performance ratio in calculations of EPBT and GHG emission factor. | 1 m2 of PV module | Cradle-to-gate | -CED. -IPCC GWP 100a (global warming potential over 100 years). -CML-IA baseline (midpoint, 10 indicators). -ReCiPe 2016 Endpoint (H) (human health, ecosystem, and resource damage). Indicators used: -EPBT. -GHG rmission factor. -Monte Carlo simulation with 1,000,000 trials. -Sensitivity analysis using Oracle Crystal Ball. | -CED. -GHG emissions (CO2-equivalent). -EPBT. -GHG emission factor (CO2-eq. per kWh). -10 CML-IA Midpoint Indicators. -ReCiPe 2016 endpoint indicators (human health, ecosystems, resources). |

| Density 1 | Estimated Freight Class |

|---|---|

| Less than 1 | 400 |

| More than 1 but less than 2 | 300 |

| More than 6 but less than 8 | 125 |

| More than 15 but less than 22.5 | 70 |

| 30 or greater | 60 |

| Windshield | Door Windows | |

|---|---|---|

| Smaller cars | 150 cm × 80 cm = 1.2 m2 | 36 cm × 61 cm = 0.2 m2 |

| Bigger cars | 206 cm × 166 cm = 3.4 m2 | 40 cm × 66 cm = 0.26 m2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiskira, K.; Kalkanis, K.; Coelho, F.; Plakantonaki, S.; D’onofrio, C.; Psomopoulos, C.S.; Priniotakis, G.; Ioannidis, G.C. Life Cycle Assessment of Organic Solar Cells: Structure, Analytical Framework, and Future Product Concepts. Electronics 2025, 14, 2426. https://doi.org/10.3390/electronics14122426

Kiskira K, Kalkanis K, Coelho F, Plakantonaki S, D’onofrio C, Psomopoulos CS, Priniotakis G, Ioannidis GC. Life Cycle Assessment of Organic Solar Cells: Structure, Analytical Framework, and Future Product Concepts. Electronics. 2025; 14(12):2426. https://doi.org/10.3390/electronics14122426

Chicago/Turabian StyleKiskira, Kyriaki, Konstantinos Kalkanis, Fernando Coelho, Sofia Plakantonaki, Christian D’onofrio, Constantinos S. Psomopoulos, Georgios Priniotakis, and George C. Ioannidis. 2025. "Life Cycle Assessment of Organic Solar Cells: Structure, Analytical Framework, and Future Product Concepts" Electronics 14, no. 12: 2426. https://doi.org/10.3390/electronics14122426

APA StyleKiskira, K., Kalkanis, K., Coelho, F., Plakantonaki, S., D’onofrio, C., Psomopoulos, C. S., Priniotakis, G., & Ioannidis, G. C. (2025). Life Cycle Assessment of Organic Solar Cells: Structure, Analytical Framework, and Future Product Concepts. Electronics, 14(12), 2426. https://doi.org/10.3390/electronics14122426