Transforming Robots into Cobots: A Sustainable Approach to Industrial Automation

Abstract

1. Introduction

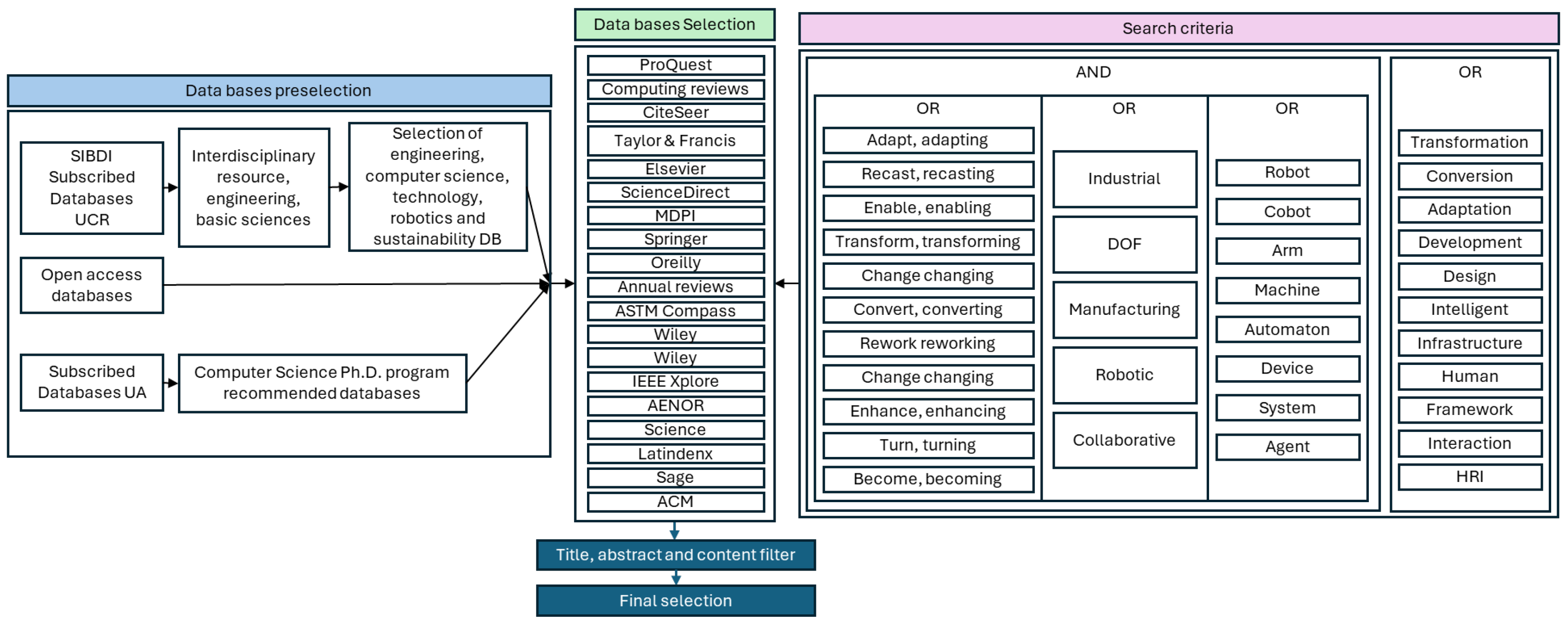

2. Methodology

2.1. Analytical Review of the State of the Art

- Industrial robot typologies: A classification of existing industrial robot models is conducted, focusing on their mechanical robustness, the openness of their control architecture, and their potential for hardware/software upgrades.

- Sustainability and circular economy strategies: A review of concepts such as remanufacturing, lifecycle extension, modular design, and environmental impact to ensure the framework aligns with the principles of sustainable robotics.

2.2. Conceptual Design of a Modular Conversion Framework

- A safe interaction layer: This layer includes the principles behind control strategies enabling safe human–robot interactions, compliant motion, and reactive behavior.

- A sensor integration strategy: Guidelines for integrating multimodal sensing systems (e.g., force, tactile, proximity) into robots for enriched situational awareness.

- A cognitive adaptability layer: A theoretical model for embedding AI-based learning and decision-making capabilities into robots for task adaptation and collaboration.

2.3. Theoretical Impact and Framework Evaluation Criteria

- Safety compliance potential;

- Feasibility of retrofitting across different robot types;

- Alignment with circular economy principles;

- Scalability and modularity;

- Potential for integration into SMEs;

- Expected environmental and economic benefits.

3. An Analytical Review of the State of the Art

3.1. Conversion of Industrial Robots into Cobots

- Security: This category includes publications that address topics related to physical and logical safety in collaborative environments, such as safety standards, collision prevention mechanisms, risk analyses, and compliance with international regulations. Security is a critical component in integrating robots into industrial settings where they interact with humans, ensuring system reliability and incident prevention.

- Control: This includes studies focused on the design, improvement, or implementation of algorithms that govern the dynamic behavior of robots. Topics include motion control, trajectory planning [21], action synchronization, real-time adaptation, and energy management. These algorithms are essential for ensuring the smooth, efficient, and safe operation of robots in environments shared with human operators.

- Interaction: This area refers to research exploring how human–robot interactions take place, both physically and cognitively. It covers user interfaces, multimodal systems (voice, gestures, displays), non-verbal communication, robotic empathy, and user experience design. Well-designed interactions enhance collaboration, reduce user cognitive load, and increase system acceptance.

- Detection: This includes all publications involving the use of sensors as an integral part of the collaborative system. It encompasses proximity sensors, computer vision, force/torque sensors, presence detection, and environmental perception systems. These components enable the robot to perceive its surroundings and respond contextually, enhancing its ability to handle unforeseen events and support safe collaboration.

- Requirements: This category includes works that allow the extraction or definition of desirable features for a collaborative robot (cobot). It may cover technical specifications, user-centered design criteria, industrial environment expectations, performance evaluations, or comparative analyses of different robotic solutions. These publications are useful for identifying functional and non-functional guidelines for the development or enhancement of collaborative systems.

| Ref. | Security | Control | Interaction | Detection | Requirements | Ref. | Security | Control | Interaction | Detection | Requirements |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [22] | X | - | - | X | - | [23] | - | - | - | - | X |

| [24] | X | - | - | X | - | [25] | - | - | X | X | - |

| [26] | - | X | - | X | - | [27] | - | - | X | - | X |

| [28] | - | X | - | - | X | [29] | - | X | X | - | - |

| [30] | - | - | X | - | X | [31] | - | - | X | - | X |

| [32] | X | X | - | - | - | [33] | - | - | X | - | X |

| [34] | - | - | X | - | X | [35] | - | - | - | - | X |

| [36] | - | X | - | X | - | [37] | - | - | - | - | X |

| [6] | X | - | - | - | X | [38] | X | - | - | - | - |

| [39] | X | - | - | - | X | [40] | - | X | - | - | X |

| [41] | X | X | - | - | X | [42] | - | - | X | - | - |

| [43] | - | X | - | - | - | [44] | - | - | - | - | X |

| [45] | X | - | - | - | X | [46] | - | - | - | - | X |

| [47] | - | - | X | - | - | [48] | - | - | - | - | X |

| [49] | X | X | - | X | - | [50] | - | X | - | - | - |

| [51] | - | - | - | - | X | [52] | - | - | - | - | X |

| [53] | - | - | X | - | X | [54] | - | X | - | - | - |

| [55] | - | - | - | - | X | [56] | - | X | X | - | - |

| [57] | X | - | - | X | - | [58] | - | - | X | X | - |

| [59] | X | - | - | - | - | [60] | - | - | - | - | X |

| [61] | - | - | - | - | X | [62] | - | - | X | X | - |

| [63] | - | - | - | - | X | [64] | X | - | - | - | X |

| [65] | - | - | X | - | X | [66] | - | X | - | - | - |

| [67] | - | X | X | - | - | [68] | - | - | X | - | - |

| [69] | - | X | - | - | - | [70] | - | - | X | - | X |

| [71] | - | - | X | - | X | [72] | - | - | - | - | X |

| [73] | - | X | X | - | - | [74] | - | - | - | - | X |

| [75] | - | - | - | - | X | [76] | - | - | - | - | X |

| [77] | X | - | - | - | X | [78] | - | X | - | - | X |

| [79] | - | - | X | - | - | [80] | - | - | X | - | - |

| [81] | - | X | X | - | - | [82] | - | - | X | - | - |

3.2. Safety Standards and Regulatory Frameworks

3.3. Enabling Technologies: Sensors, Control, and Monitoring

- Redundant control systems that ensure that a failure in one subsystem does not compromise the overall safety of the system [28].

- Human–machine interfaces (HMIs) adapted for safe operation, allowing for intuitive supervision, diagnostics, and collaborative mode configuration.

3.3.1. Retrofitting and Compliance Challenges

3.3.2. Emerging Trends and Future Requirements

3.4. Industrial Robot Typologies and Their Reusability Potential

3.4.1. Robot Typologies and Their Key Characteristics

Articulated Robots

- Mechanical Structure: These robots feature a series of linked arms, often modeled after a human arm, providing high dexterity and reach. The flexibility of their design allows for the execution of a wide range of tasks, from welding to assembly and packaging.

- Payload Capacity: Articulated robots are typically designed to handle heavy payloads, which makes them suitable for demanding industrial tasks. However, this can also limit their applicability in collaborative settings, as their high payloads may pose risks in environments where humans are in close proximity.

- Control Architecture: These robots are usually controlled by sophisticated systems that provide high precision and fine control over motion. However, many traditional articulated robots operate on proprietary control systems, which can limit their ease of integration with open-source platforms like the ROS (Robot Operating System).

- Upgrade Potential: Articulated robots with modular joints and open control architectures (or the ability to retrofit such systems) are ideal candidates for retrofitting into cobots. Their strong mechanical base, combined with their compatibility with additional sensors and safety systems, facilitates their transformation into robots that can safely interact with humans in shared workspaces.

SCARA Robots

- Mechanical Structure: SCARA robots’ design allows for high-speed operations with a focus on lateral precision, which makes them ideal for tasks like pick-and-place, assembly, and packaging. SCARA robots are more compact than articulated robots, making them suitable for applications where space is limited.

- Payload Capacity: SCARA robots usually have a moderate payload capacity compared to articulated robots. This makes them suitable for light- to medium-duty tasks, which often aligns with collaborative work environments, where the robot needs to handle smaller items or tools.

- Control Architecture: SCARA robots typically feature more standardized control systems compared to articulated robots. This makes them easier to integrate with open software architectures like the ROS 1 or version 2, which is crucial for retrofitting these robots for collaborative operations.

- Upgrade Potential: Due to their relatively simple design and control systems, SCARA robots present a strong opportunity for collaborative conversion, particularly when equipped with additional safety-rated sensors and adaptable software systems. Their ease of programming and integration make them an appealing choice for applications where human–robot interaction is necessary.

Delta Robots

- Mechanical Structure: Delta robots are characterized by their unique parallel kinematic design, which allows them to achieve high-speed, high-precision movements within limited space. Their structure offers a low payload capacity but excels in speed and agility [100].

- Payload Capacity: Due to their lightweight design, delta robots typically handle smaller payloads, making them suitable for collaborative environments where robots need to interact with delicate or lightweight objects.

- Control Architecture: Delta robots tend to be controlled by highly specialized software, and many are integrated into closed-loop control systems that optimize speed and accuracy. While the closed nature of their systems can pose challenges, there is potential for retrofitting these robots with open-source controllers and adding collaborative capabilities.

- Upgrade Potential: The small payload and speed advantages of delta robots make them ideal for environments where speed and precision are critical, and where human–robot interactions do not involve heavy lifting. Their modular control systems and ability to incorporate safety sensors and cameras make them promising candidates for reuse in collaborative settings.

3.4.2. Key Attributes for Collaborative Transformation

- Modular Joints and Flexible Architecture: Robots with modular joints and adaptable designs are ideal for retrofitting. These systems allow for the easier integration of the additional sensors, safety mechanisms, and end effectors needed for safe and efficient human–robot collaboration. Articulated robots with modular arm joints, for instance, can be outfitted with force sensors, proximity sensors, and cameras to enhance their interaction with humans [99].

- Accessible Programming Interfaces: Robots that offer accessible programming interfaces, such as compatibility with the Robot Operating System (ROS) version 1 or 2, allow for easier integration with third-party software, increasing their adaptability in collaborative settings. Open-source programming environments enable more flexibility in developing customized control algorithms for safe human-robot interactions [101].

- Scalable Sensor Inputs: The integration of scalable sensor inputs plays a crucial role in making robots more adaptable to varying environments [102]. By equipping robots with a range of safety-rated sensors (e.g., vision systems, force/torque sensors, LIDAR), their system can dynamically adjust their behavior based on their proximity to humans or objects in the workspace.

3.4.3. Reusability and Retrofitting Strategies

3.4.4. Supporting Scalable Deployment

3.5. Sustainable Engineering and Circular Economy Principles

3.5.1. Sustainable Engineering in Robotics

Energy Efficiency in Robotic Systems

- Low-power actuators and motors: Using energy-efficient actuators that consume less power while maintaining performance is essential for reducing energy consumption in robotic systems. For example, hybrid electric actuators and energy-harvesting technologies, such as piezoelectric devices, could be explored.

- Energy-efficient control algorithms: The design of control algorithms that allow robots to perform tasks efficiently, without excess energy usage, is a fundamental aspect of sustainable engineering. This includes optimizing robot movements to minimize unnecessary motion, using machine learning to predict energy demands, and adjusting robot speeds [106] and workloads based on real-time feedback.

- Regenerative energy systems: In certain robotic systems, such as those used for pick-and-place tasks, regenerative braking systems can capture energy during deceleration and store it for future use, improving the system’s overall energy efficiency.

Material Efficiency and Sustainable Manufacturing

- Material selection: The choice of materials for manufacturing robots is crucial. Lightweight materials, such as advanced composites and aluminum alloys, not only improve the robot’s performance by reducing its energy consumption but also minimize material usage. Moreover, recyclable materials can help reduce the ecological impact of robots once they reach the end of their lifecycle.

- Additive manufacturing (3D printing): Three-dimensional printing technologies are becoming a key enabler of sustainable manufacturing in robotics. By using additive manufacturing, it is possible to create complex, lightweight structures that require less material than traditional manufacturing methods [107]. This can significantly reduce waste and energy consumption during the production process.

- Modular design: Designing robots with modular components allows for the easy replacement of damaged or outdated parts without the need to discard the entire robot. This reduces waste and supports sustainability by enabling the reuse of parts and materials, contributing to a more circular approach.

3.5.2. Circular Economy Principles in Robotics

Designing for Longevity and Reusability

- Durable and modular construction: A focus on building robots that can withstand long-term use while minimizing the need for repairs or replacements is crucial. This may involve using high-quality materials, such as durable metals or advanced polymers, that extend the lifespan of robotic systems.

- Upgradability and refurbishment: Instead of designing robots with a fixed lifecycle, manufacturers are beginning to consider how robots can be upgraded or refurbished. By enabling the reuse of core components such as sensors, processors, and actuators, robots can evolve with changing technologies, extending their functional life and reducing the need for new, resource-intensive manufacturing.

Recycling and Recovery of Robot Components

- Recycling robot parts: When robots reach the end of their lifecycle, it is important to ensure that valuable materials, such as metals, plastics, and rare earth elements, are recovered and reused. For example, motors, sensors, and circuit boards can often be recycled or refurbished for use in new robots.

- Automated disassembly: Using disassembly-friendly design principles can make it easier to recover and recycle robot components. Automated disassembly processes, potentially utilizing collaborative robots, could facilitate the sorting of materials and components for recycling, which is in line with the principles of the circular economy.

3.5.3. Environmental Impact Reduction Through Robotics

- Precision manufacturing: Cobots can improve the precision of tasks such as assembly, packaging, and material handling, reducing the amount of waste generated during production processes. By using cobots for tasks like waste sorting or waste reduction, manufacturers can optimize resource usage and reduce their environmental impact.

- Sustainability in production: Cobots can help monitor energy use, optimize workflows, and even adjust production speeds to reduce energy consumption. By working alongside human operators, cobots can assist in identifying inefficiencies in production systems, ultimately contributing to greener manufacturing practices.

3.5.4. Embracing Sustainability in Robotics

3.6. Technological Enablers: AI, Vision, and Control

4. Conceptual Design of a Modular Conversion Framework

4.1. Comparative Analysis of Traditional Industrial Robots and Commercial Cobots

4.2. Layered Modular Architecture and Design Paradigm

- Interoperability: The framework must accommodate robots from different manufacturers, with heterogeneous hardware interfaces and proprietary control architectures.

- Safety-Centric Engineering: All modules must inherently support safety-by-design, incorporating features for risk mitigation [111] and real-time monitoring.

- Rapid Deployment: Plug-and-play capabilities, auto-configuration routines, and minimal downtime are essential to reduce operational disruptions.

- Lifecycle-Oriented Modularity: The framework is designed to adapt not only existing robots but also future upgrades, supporting circular economy principles.

4.2.1. Perceptual and Context-Aware Layer

4.2.2. Safety Control and the Middleware Abstraction Layer

4.2.3. Human–Machine Interaction Layer

4.2.4. Cognitive and Adaptive Behavior Layer

4.2.5. Mechanical and Structural Adaptability

4.2.6. Deployment Toolkit and Configuration Management

4.2.7. Integration with Industrial Ecosystems

5. Evaluation Steps and Benchmarking Criteria

- Step 1: Apply a checklist based on applicable redesign requirements. Review and analyze the necessary requirements [116,117,118] to convert the industrial robot into a collaborative one. The checklist should cover economic, environmental, cost-effectiveness, technical, safety, and operational aspects to ensure the robot’s feasibility to be upgraded to the performance expectations of the collaborative system.

- Step 2: Define the robot’s usage requirements, including production process modifications. Determine how the collaborative robot should be integrated into the production process. It is essential to identify the tasks it will perform, the required changes in the process, and the resulting impact on the production line.

- Step 3: Assess criteria for implementing modifications. Verify the availability of the necessary modules to perform the required changes and evaluate the technical capabilities of operators to implement them. It is important to determine whether adequate resources are available or if additional investments will be needed.

- Step 4: Estimate the development costs of the required components. Calculate the costs associated with the components and adaptations needed to convert the industrial robot into a collaborative system. This includes hardware, software, and any modifications to the workspace’s infrastructure.

- Step 5: Quote the hypothetical purchase and installation of an equivalent collaborative robot. Obtain a reference quotation for a collaborative robot with similar specifications, including the cost of the equipment, its installation, and any necessary workspace adjustments. This will serve as a baseline for comparing both alternatives.

- Step 6: Perform a comparative analysis between modifying the existing industrial robot and purchasing a new collaborative one. Key factors such as reliability, implementation time, costs, and risks must be considered [111]. This evaluation will support informed decision-making that is aligned with the project’s objectives and the available resources.

6. Discussion

- The gap between conceptual design and operational reality: While simulations and conceptual frameworks offer clarity and control, real-world production environments introduce variability, regulatory constraints, and human factors that may challenge the model’s assumptions.

- The technical limitations of legacy hardware: Older robotic platforms differ significantly in their architecture, wear level, and integration capacity, which may affect both the feasibility and cost-effectiveness of retrofitting as discussed.

- The complexities of human–robot interaction: Safety, perception, and real-time adaptability in unstructured environments require rigorous empirical testing, especially under international safety standards (e.g., ISO/TS 15066), which are beyond the scope of this initial theoretical phase.

7. Conclusions

8. Future Research Directions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lowe, B.D.; Hayden, M.; Albers, J.; Naber, S. Case studies of robots and automation as health/safety interventions in small manufacturing enterprises. Hum. Factors Ergon. Manuf. Serv. Ind. 2023, 33, 69–103. [Google Scholar] [CrossRef] [PubMed]

- Fletcher, S.; Webb, P. Industrial Robot Ethics: The Challenges of Closer Human Collaboration in Future Manufacturing Systems. In A World with Robots; Springer: Cham, Switzerland, 2025; pp. 179–189. [Google Scholar] [CrossRef]

- Li, Q.; Liu, Y.; Li, W.; Zheng, L. Will Industrial Robots Terminate Enterprise Innovation?—An Empirical Evidence from China’s Enterprise Robot Penetration. J. Knowl. Econ. 2024. [CrossRef]

- Sadiku, M.; Ajayi-Majebi, A.; Adebo, P. Robotic Automation in Manufacturing. In Emerging Technologies in Manufacturing; Springer: Cham, Switzerland, 2025; pp. 33–47. [Google Scholar] [CrossRef]

- Montini, E.; Daniele, F.; Agbomemewa, L.; Confalonieri, M.; Cutrona, V.; Rocco, P. Collaborative Robotics: A Survey from Literature and Practitioners’ Perspectives. J. Intell. Robot. Syst. 2024, 110, 117. [Google Scholar] [CrossRef]

- Patil, S.; Vasu, V.; Srinadh, K. Advances and Perspectives in Collaborative Robotics: A Review of Key Technologies and Emerging Trends. Discov. Mech. Eng. 2023, 1, 21. [Google Scholar] [CrossRef]

- Lafeuillade, A.C.; Barcellini, F.; Buchmann, W.; Benchekroun, T.H. Integrating Collaborative Robotics into Work Situations: The Intentions of SME Managers in the Digital Transformation of their Companies. In Digital Transformations in the Challenge of Activity and Work; Chaumon, M.E.B., Ed.; Wiley: Hoboken, NJ, USA, 2021. [Google Scholar] [CrossRef]

- Leal Filho, W.; Sigahi, T.; Anholon, R.; Rampasso, I.S.; Platje, J.; Velazquez, L.; Salvia, A.L. Sustainable Innovation: Case Studies from Product Development. Sustain. Dev. 2025, 33, 3086–3098. [Google Scholar] [CrossRef]

- Asfahani, Z.; Sopha, B.M.; Wibisono, M.A. Barriers to Circular Economy Transition in Small and Medium-sized Businesses: A Systematic Review. In Proceedings of the 2023 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 18–21 December 2023; pp. 0470–0474. [Google Scholar] [CrossRef]

- ISO/TS 15066:2016; Robots and Robotic Sevices—Collaborative Robots. International Organization for Standardization: Geneva, Switzerland, 2016.

- Chaikovska, I.; Hryhoruk, P.; Khrushch, N.; Grygoruk, S.; Tkach, T.; Chaikovskyi, M. Integration of Digital Economy, Knowledge Economy and Circular Economy in the Conditions of Industry 5.0. In Proceedings of the 2024 14th International Conference on Advanced Computer Information Technologies (ACIT), Ceske Budejovice, Czech Republic, 19–21 September 2024; pp. 250–253. [Google Scholar] [CrossRef]

- ISO 10218-1:2025; Robots and Robotic Devices—Safety Requirements for Industrial Robots—Part 1: Robots. International Organization for Standardization: Geneva, Switzerland, 2025.

- ISO 10218-2:2025; Robots and Robotic Devices—Safety Requirements for Industrial Robots—Part 2: Robot Systems and Integration. International Organization for Standardization: Geneva, Switzerland, 2025.

- Orts, S.; Garcia-Rodriguez, J.; Viejo, D.; Cazorla, M.; Morell, V. GPGPU implementation of growing neural gas: Application to 3D scene reconstruction. J. Parallel Distrib. Comput. 2012, 72, 1361–1372. [Google Scholar] [CrossRef]

- Thalhammer, S.; Bauer, D.; Hönig, P.; Weibel, J.B.; García-Rodríguez, J.; Vincze, M. Challenges for Monocular 6-D Object Pose Estimation in Robotics. IEEE Trans. Robot. 2024, 40, 4065–4084. [Google Scholar] [CrossRef]

- Viejo, D.; Garcia-Rodriguez, J.; Cazorla, M. Combining Visual Features and Growing Neural Gas Networks for Robotic 3D SLAM. Inf. Sci. 2014, 276, 174–185. [Google Scholar] [CrossRef]

- Garcia-Garcia, A.; Garcia-Rodriguez, J.; Orts-Escolano, S.; Oprea, S.; Gomez-Donoso, F.; Cazorla, M. A Study of the Effect of Noise and Occlusion on the Accuracy of Convolutional Neural Networks Applied to 3D Object Recognition. Comput. Vis. Image Underst. 2017, 164, 124–134. [Google Scholar] [CrossRef]

- Martinez-Gonzalez, P.; Oprea, S.; Castro-Vargas, J.A.; Garcia-Garcia, A.; Orts-Escolano, S.; Garcia-Rodriguez, J.; Vincze, M. UnrealROX+: An Improved Tool for Acquiring Synthetic Data from Virtual 3D Environments. In Proceedings of the 2021 International Joint Conference on Neural Networks (IJCNN), Shenzhen, China, 18–22 July 2021; pp. 1–8. [Google Scholar] [CrossRef]

- Garcia-Garcia, A.; Orts-Escolano, S.; Garcia-Rodriguez, J.; Cazorla, M. Interactive 3D object recognition pipeline on mobile GPGPU computing platforms using low-cost RGB-D sensors. J. Real-Time Image Process. 2018, 14, 585–604. [Google Scholar] [CrossRef]

- Garcia-Garcia, A.; Orts-Escolano, S.; Oprea, S.; Garcia-Rodriguez, J.; Azorin-Lopez, J.; Saval-Calvo, M.; Cazorla, M. Multi-sensor 3D object dataset for object recognition with full pose estimation. Neural Comput. Appl. 2017, 28, 941–952. [Google Scholar] [CrossRef]

- You, Y.; Thomas, V.; Colas, F.; Skilton, R.; Buffet, O. Online Robust Robot Planning for Human-Robot Collaboration. In Towards Autonomous Robotic Systems. TAROS 2024; Springer: Cham, Switzerland, 2025. [Google Scholar] [CrossRef]

- Ge, C.; Wang, Z.; Liu, Z.; Wu, T.; Wang, S.; Ren, X.; Chen, D.; Zhao, J.; Hu, P.; Zhang, J. A Capacitive and Piezoresistive Hybrid Sensor for Long-Distance Proximity and Wide-Range Force Detection in Human–Robot Collaboration. Adv. Intell. Syst. 2022, 4, 2100213. [Google Scholar] [CrossRef]

- Lee, J.D.; Seppelt, B. Handbook of Human Factors and Ergonomics; Salvendy, G., Ed.; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar] [CrossRef]

- Tsuji, S.; Kohama, T. A General-Purpose Safety Light Curtain Using ToF Sensor for End Effector on Human Collaborative Robot. IEEJ Trans. Electr. Electron. Eng. 2020, 15, 1868–1874. [Google Scholar] [CrossRef]

- Zhou, C.; Ren, D.; Zhang, X.; Yu, C.; Ju, L. Human Position Detection Based on Depth Camera Image Information in Mechanical Safety. Adv. Math. Phys. 2022, 2022, 9170642. [Google Scholar] [CrossRef]

- Wang, Z.; Hai, M.; Liu, X.; Zhang, Q.; Li, Y.; Chen, J. A Human–Robot Interaction Control Strategy for Teleoperation Robot System under Multi-Scenario Applications. Int. J. Intell. Robot. Appl. 2025, 9, 125–145. [Google Scholar] [CrossRef]

- Ibarguren, A.; Aivaliotis, S.; González Huarte, J.; Urquiza, A.; Baris, P.; Papavasileiou, A.; Michalos, G.; Makris, S. Human-Centric Robotic Solution for Motor and Gearbox Assembly: An Industry 5.0 Pilot Study. Robotics 2025, 14, 56. [Google Scholar] [CrossRef]

- Miljanovic, D.; Croft, E. A taxonomy for robot control. In Proceedings of the 1999 IEEE International Conference on Robotics and Automation (Cat. No.99CH36288C), Detroit, MI, USA, 10–15 May 1999; Volume 1, pp. 176–181. [Google Scholar] [CrossRef]

- Asuzu, K.; Singh, H.; Idrissi, M. Human–robot interaction through joint robot planning with large language models. Intell. Serv. Robot. 2025, 2025, 261–277. [Google Scholar] [CrossRef]

- Di Pasquale, V.; Fanti, M.P.; Pedrocchi, N.; Ranzieri, S.; Rea, F.; Sgarbossa, F.; Teti, R. A Taxonomy of Factors Influencing Worker’s Performance in Human–Robot Collaboration. IET Collab. Intell. Manuf. 2023, 5, 12069. [Google Scholar] [CrossRef]

- Hindemith, L.; Wiebel-Herboth, C.; Wersing, H.; Ritter, H. Improving HRI Through Robot Architecture Transparency. Int. J. Soc. Robot. 2025, in press. [Google Scholar] [CrossRef]

- Gril, L.; Wedenig, P.; Torkar, C.; Kleb, U. A Tensor-based Regression Approach for Human Motion Prediction. Qual. Reliab. Eng. Int. 2023, 39, 481–499. [Google Scholar] [CrossRef]

- Scholz, C.; Cao, H.; El Makrini, I.; van der Smagt, P.; Vanderborght, B. Improving Robot-to-Human Communication Using Flexible Display Technology as a Robotic-Skin-Interface: A Co-Design Study. Int. J. Intell. Robot. Appl. 2025, 9, 146–163. [Google Scholar] [CrossRef]

- Tchane Djogdom, G.V.; Otis, M.J.D.; Meziane, R. A Theoretical Foundation for Erroneous Behavior in Human–Robot Interaction. J. Intell. Robot. Syst. 2025, 105, 22. [Google Scholar] [CrossRef]

- Faccio, M.; Cohen, Y. Intelligent cobot systems: Human-cobot collaboration in manufacturing. J. Intell. Manuf. 2024, 35, 1905–1907. [Google Scholar] [CrossRef]

- Gracia, L.; Perez-Vidal, C.; Valls-Miro, J. Advanced Mathematical Methods for Collaborative Robotics. Math. Probl. Eng. 2018, 2018, 1605817. [Google Scholar] [CrossRef]

- Manonmani, A.; Akash, S.; Aswinraj, A.; Manikandan, A. Literature Review on Advanced Cloud Robotics for Enhanced Industrial Automation. In Proceedings of the 2025 International Conference on Electronics and Renewable Systems (ICEARS), Tuticorin, India, 11–13 February 2025; pp. 46–51. [Google Scholar] [CrossRef]

- Zhang, D.; Wei, B.; Rosen, M. Overview of an Engineering Teaching Module on Robotics Safety. In Mechatronics and Robotics Engineering for Advanced and Intelligent Manufacturing; Springer: Nice, France, 2016; pp. 29–43. [Google Scholar] [CrossRef]

- Ciccarelli, M.; Forlini, M.; Papetti, A.; Cavallo, P.; Fiorentino, M.; Uva, A.E. Advancing Human–Robot Collaboration in Handcrafted Manufacturing: Cobot-Assisted Polishing Design Boosted by Virtual Reality and Human-in-the-Loop. Int. J. Adv. Manuf. Technol. 2024, 135, 4489–4504. [Google Scholar] [CrossRef]

- Fang, C.; Wang, J.; Yuan, F.; Chen, S.; Zhou, H. Path Planning for Dragon-Fruit-Harvesting Robotic Arm Based on XN-RRT* Algorithm. Sensors 2025, 25, 2773. [Google Scholar] [CrossRef]

- Hjorth, S.; Lachner, J.; Stramigioli, S.; Madsen, O.; Chrysostomou, D. An Energy-based Approach for the Integration of Collaborative Redundant Robots in Restricted Work Environments. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 25–29 October 2020; pp. 7152–7158. [Google Scholar] [CrossRef]

- Mukherjee, D.; Hong, J.; Vats, H.; Bae, S.; Najjaran, H. Personalization of Industrial Human–Robot Communication Through Domain Adaptation Based on User Feedback. User Model. User-Adapt. Interact. 2024, 34, 1327–1367. [Google Scholar] [CrossRef]

- Angelidis, A.; Plevritakis, E.; Vosniakos, G.; Papakostas, N.; Chryssolouris, G. An Open Extended Reality Platform Supporting Dynamic Robot Paths for Studying Human–Robot Collaboration in Manufacturing. Int. J. Adv. Manuf. Technol. 2025, 137, 3–15. [Google Scholar] [CrossRef]

- Fletcher, S.; Johnson, T.; Larreina, J. Putting People and Robots Together in Manufacturing: Are We Ready? In Robotics and Well-Being; Springer: Cham, Switzerland, 2019; pp. 163–178. [Google Scholar] [CrossRef]

- Heo, I.; Putri, A.S.; Kim, K.H.; Kim, B.S.; Kwon, M.S.; Kim, S.H. Analysis of Quality Standards for Industrial Collaborative Robots Based on User-Centered Design Framework. Hum. Factors Ergon. Manuf. Serv. Ind. 2024, 34, 100–117. [Google Scholar] [CrossRef]

- Gosnall, T.; Mansouri, M. Robot Ethnography for Culturally Responsive Human–Robot Interactions. AI Soc. 2025, 40, 367–380. [Google Scholar] [CrossRef]

- Tan, Q.; Tong, Y.; Wu, S.; Li, D. Anthropocentric Approach for Smart Assembly: Integration and Collaboration. J. Robot. 2019, 2019, 3146782. [Google Scholar] [CrossRef]

- Haidegger, T.; Galambos, P.; Rudas, I.J. Robotics 4.0—Are we there yet? In Proceedings of the 2019 IEEE 23rd International Conference on Intelligent Engineering Systems (INES), Godollo, Hungary, 25–27 April 2019; pp. 000117–000124. [Google Scholar] [CrossRef]

- Ma, Z.; Jiao, W.; Li, L.; Yang, S.; Xu, X. Application of Keypoint Recognition for Industrial Human-Robot Safe Collaboration Scenarios. In Proceedings of the 2024 7th International Symposium on Autonomous Systems (ISAS), Chongqing, China, 7–9 May 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Chohan, J.S.; Bawa, G.; Hussain, A.; Al-Nafei, A.A.M.; Uday Pal Reddy, M.; Gehlot, A. Robotics and its Control Systems: Innovation Overview and Future Challenges. In Proceedings of the 2024 11th International Conference on Computing for Sustainable Global Development (INDIACom), New Delhi, India, 28 February–1 March 2024; pp. 524–528. [Google Scholar] [CrossRef]

- Islam, M.M.M.; Emon, J.I.; Ng, K.Y.; Asadpour, A.; Aziz, M.M.R.A.; Baptista, M.L.; Kim, J.M. Artificial Intelligence in Smart Manufacturing: Emerging Opportunities and Prospects. In Artificial Intelligence for Smart Manufacturing and Industry X.0; Islam, M.M.M., Baptista, M.L., Tariq, F., Eds.; Springer Nature: Cham, Switzerland, 2025; pp. 9–36. [Google Scholar] [CrossRef]

- Almuaythir, S.; Singh, A.K.; Alhusban, M.; Alzubi, M.M.; Alzubi, O.A.; Alshammari, N.S.; Alzubi, J.A.; Alshammari, A.S.; Alzubi, M.A. Robotics Technology: Catalyst for Sustainable Development—Impact on Innovation, Healthcare, Inequality, and Economic Growth. Discov. Sustain. 2024, 5, 44. [Google Scholar] [CrossRef]

- Bavelos, A.C.; Anastasiou, E.; Dimitropoulos, N.; Oikonomou, G.; Makris, S. Augmented reality-based method for road maintenance operators in human–robot collaborative interventions. Comput.-Aided Civ. Infrastruct. Eng. 2024, 39, 1077–1095. [Google Scholar] [CrossRef]

- Brecher, C.; Weck, M. Robots and Robot Controllers. In Machine Tools Production Systems 3: Mechatronic Systems, Control and Automation; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2022; pp. 533–603. [Google Scholar] [CrossRef]

- Vassev, E.; Hinchey, M. Autonomy requirements engineering. In Proceedings of the 2013 IEEE 14th International Conference on Information Reuse & Integration (IRI), San Francisco, CA, USA, 14–16 August 2013; pp. 175–184. [Google Scholar] [CrossRef]

- Vorndamme, J.; Melone, A.; Kirschner, R.; Figueredo, L.; Haddadin, S. Safe Robot Reflexes: A Taxonomy-Based Decision and Modulation Framework. IEEE Trans. Robot. 2025, 41, 982–1001. [Google Scholar] [CrossRef]

- Huang, X.; Ying, Y.; Dong, W. CEASE: Collision-Evaluation-Based Active Sense System for Collaborative Robotic Arms. IEEE Trans. Instrum. Meas. 2024, 73, 1–11. [Google Scholar] [CrossRef]

- Tsuji, S. String-Like Time of Flight Sensor Module for a Collaborative Robot. IEEJ Trans. Electr. Electron. Eng. 2023, 18, 1576–1582. [Google Scholar] [CrossRef]

- Gleirscher, M.; Johnson, N.; Karachristou, P.; Calinescu, R.; Law, J.; Clark, J. Challenges in the Safety-Security Co-Assurance of Collaborative Industrial Robots. In The 21st Century Industrial Robot: When Tools Become Collaborators; Aldinhas Ferreira, M.I., Fletcher, S.R., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 191–214. [Google Scholar] [CrossRef]

- Boesl, D.B.O.; Bode, M.; Greisel, S. Successful Consumer Robotics beyond Science Fiction—Use Case based Requirements Engineering for Product Development of a Consumer Robot. In Proceedings of the 2019 IEEE 23rd International Conference on Intelligent Engineering Systems (INES), Godollo, Hungary, 25–27 April 2019; pp. 000159–000164. [Google Scholar] [CrossRef]

- Rahman, M.M.; Khatun, F.; Jahan, I.; Devnath, R.; Bhuiyan, M.A.A. Cobotics: The Evolving Roles and Prospects of Next-Generation Collaborative Robots in Industry 5.0. J. Robot. 2024, 2024, 2918089. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, J.; Lu, P.; Wang, Z.; He, B. TacSuit: A Wearable Large-Area, Bioinspired Multimodal Tactile Skin for Collaborative Robots. IEEE Trans. Ind. Electron. 2024, 2024, 1708–1717. [Google Scholar] [CrossRef]

- Álvarez, D.D.; Væhrens, L. Collaborative Robots for Smart Production in SMEs. In The Future of Smart Production for SMEs; Madsen, O., Berger, U., Møller, C., Heidemann Lassen, A., Vejrum Waehrens, B., Schou, C., Eds.; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Adriaensen, A.; Costantino, F.; Di Gravio, G.; Patriarca, R. Teaming with industrial cobots: A socio-technical perspective on safety analysis. Hum. Factors Man. 2022, 2022, 173–198. [Google Scholar] [CrossRef]

- Hatanaka, T.; Yamauchi, J.; Fujita, M.; Handa, H. Contemporary Issues and Advances in Human–Robot Collaborations. In Cyber–Physical–Human Systems; Annaswamy, A.M., Ed.; Wiley: Hoboken, NJ, USA, 2025. [Google Scholar] [CrossRef]

- Xu, W.; Yang, H.; Ji, Z.; Liu, Z.; Liu, J. The Bees Algorithm for Robotics-Enabled Collaborative Manufacturing. In Intelligent Engineering Optimisation with the Bees Algorithm; Pham, D.T., Hartono, N., Eds.; Springer: Cham, Switzerland, 2025. [Google Scholar] [CrossRef]

- Ayub, A.; De Francesco, Z.; Holthaus, P.; Nehaniv, C.L.; Dautenhahn, K. Continual Learning Through Human-Robot Interaction: Human Perceptions of a Continual Learning Robot in Repeated Interactions. Int. J. Soc. Robot. 2025, 2025, 277–296. [Google Scholar] [CrossRef]

- Chen, N.; Cao, J.; Hu, X. The Effects of Robot Managers’ Reward-Punishment Behaviours on Human–Robot Trust and Job Performance. Int. J. Soc. Robot. 2024, 2024, 529–545. [Google Scholar] [CrossRef]

- Aeini, A.; Droudian, E.; Ghanbarzadeh, A.; Najafi, E. Design of an Intelligent Control System for Safe Collaboration between Human and a Robotic Manipulator. In Proceedings of the 2021 9th RSI International Conference on Robotics and Mechatronics (ICRoM), Tehran, Iran, 17–19 November 2021; pp. 335–340. [Google Scholar] [CrossRef]

- Vianello, L.; Ivaldi, S.; Aubry, A.; Peternel, L. The effects of role transitions and adaptation in human–cobot collaboration. J. Intell. Manuf. 2024, 2024, 2005–2019. [Google Scholar] [CrossRef]

- Gervasi, R.; Capponi, M.; Mastrogiacomo, L.; Franceschini, F. Does size matter? Exploring the effect of cobot size on user experience in human–robot collaboration. Int. J. Adv. Manuf. Technol. 2024, 2024, 5777–5791. [Google Scholar] [CrossRef]

- Liang, L.; Lu, L.; Su, L. The impact of industrial robot adoption on corporate green innovation in China. Sci. Rep. 2023, 13, 18695. [Google Scholar] [CrossRef]

- Yan, S.; Zhu, Y.; Chen, W.; Zhang, J.; Zhu, C.; Chen, Q. Dynamic Obstacle Avoidance for Robotic Arms Using Deep Reinforcement Learning with Adaptive Reward Mechanisms. Appl. Sci. 2025, 15, 4496. [Google Scholar] [CrossRef]

- Guo, J.; Chang, S.; Guo, M. The impact of peer effect of industrial robot application on enterprise carbon emission reduction. Sci. Rep. 2024, 14, 12070. [Google Scholar] [CrossRef]

- Patel, R.; Hedelind, M.; Lozan-Villegas, P. Enabling robots in small-part assembly lines: The “ROSETTA Approach”—An industrial perspective. In Proceedings of the ROBOTIK 2012, Munich, Germany, 21–22 May 2012. [Google Scholar]

- Remington, R.; Boehm-Davis, D.; Folk, C. The Role of Automation in Human-System Performance. In Introduction to Humans in Engineered Systems; Wiley: Hoboken, NJ, USA, 2025. [Google Scholar] [CrossRef]

- Delang, K.; Todtermuschke, M.; Schmidt, P.A.; Bdiwi, M.; Putz, M. Enhanced service modelling for flexible demand-driven implementation of human–robot interaction in manufacturing. IET Collab. Intell. Manuf. 2019, 2019, 20–27. [Google Scholar] [CrossRef]

- Romero, S.; Valero, J.; García, A.V.; Rodríguez, C.F.; Montes, A.M.; Marín, C.; Bolaños, R.; Álvarez-Martínez, D. Trajectory Planning for Robotic Manipulators in Automated Palletizing: A Comprehensive Review. Robotics 2025, 14, 55. [Google Scholar] [CrossRef]

- Cárdenas, P.; García, J.; Begazo, R.; Aguilera, A.; Dongo, I.; Cardinale, Y. Evaluation of Robot Emotion Expressions for Human–Robot Interaction. Int. J. Soc. Robot. 2024, 2024, 2019–2041. [Google Scholar] [CrossRef]

- D’Attanasio, S.; Studzinska, A. Understanding Human Responses to Robot Errors to Enhance Human-Robot Interaction Design in a Non-industrial Context. In Computer-Human Interaction Research and Applications; Springer: Cham, Switzerland, 2025. [Google Scholar] [CrossRef]

- Inoue, T. Future tasks of research in robotics. In Proceedings of the 1995 IEEE International Conference on Robotics and Automation, Nagoya, Japan, 21–27 May 1995; p. 24. [Google Scholar] [CrossRef]

- Liao, S.; Lin, L.; Chen, Q.; Pei, H. Why not work with anthropomorphic collaborative robots? The mediation effect of perceived intelligence and the moderation effect of self-efficacy. Hum. Factors Ergon. Manuf. Serv. Ind. 2024, 2024, 241–260. [Google Scholar] [CrossRef]

- Aichaoui, Y.; Kovács, T.A. Enhancing Safety and Efficiency: Human-Cobot Interaction in Critical Infrastructure. In The Impact of the Energy Dependency on Critical Infrastructure Protection; Kovács, T.A., Stadler, R.G., Daruka, N., Eds.; Springer: Budapest, Hungary, 2024; pp. 1–25. [Google Scholar] [CrossRef]

- Liu, Y.; Jebelli, H. Intention-aware robot motion planning for safe worker–robot collaboration. Comput. Aided Civil Infrastruct. Eng. 2024, 39, 2242–2269. [Google Scholar] [CrossRef]

- Liau, Y.; Ryu, K. Integrating Ontology with Cobot Execution for Human-Robot Collaborative Assembly Using Heterogeneous Cobots. In Advances in Production Management Systems. Production Management Systems for Volatile, Uncertain, Complex, and Ambiguous Environments. APMS; Thürer, M., Riedel, R., von Cieminski, G., Romero, D., Eds.; Springer: Cham, Switzerland, 2024; pp. 1–25. [Google Scholar] [CrossRef]

- Pinto, A.; Duarte, I.; Carvalho, C.; Rocha, L.; Santos, J. Enhancing Cobot Design Through User Experience Goals: An Investigation of Human–Robot Collaboration in Picking Tasks. Hum. Behav. Emerg. Technol. 2024, 2024, 7058933. [Google Scholar] [CrossRef]

- Hernandez, C.; Fernandez-Sanchez, J. Model-based systems engineering to design collaborative robotics applications. In Proceedings of the 2017 IEEE International Systems Engineering Symposium (ISSE), Vienna, Austria, 11–13 October 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Buxbaum, H.; Sen, S.; Häusler, R. Theses on the Future Design of Human-Robot Collaboration. In Human-Computer Interaction. Multimodal and Natural Interaction. HCII; Kurosu, M., Ed.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- DGH Ingeniería; ONTECH; I3TE; ITERA; COPO, G.; IZMAR; Tecnológico, A.C. Nota de prensa: ROBERTO desarrollará un sistema robotizado industrial que permitirá el uso seguro de robots industriales (ITC-20161153). Nota de prensa, digitalizacionindustrial.org, 2016. Proyecto financiado por el Programa Innterconecta 2016, con la colaboración del CDTI, Ministerio de Economίa y Competitividad y fondos FEDER. Available online: http://digitalizacionindustrial.org/NP_ROBERTO.PDF (accessed on 28 May 2025).

- Digitalización Industrial. Proyectos de innovación en Digitalización Industrial: ROBERTO, RECUPERA y FISIOROB. Sitio web de Digitalización Industrial, 2025. Descripción de proyectos de innovación en robótica industrial y rehabilitación, incluyendo ROBERTO (ITC-20161153), RECUPERA (IN852A 2016/160) y FISIOROB (ITC 20133011). Available online: https://www.digitalizacionindustrial.com/innovacion-eu (accessed on 27 May 2025).

- Grupo Copo. Projects and Partnerships: GreenAuto, ADVANSEAT, ROBERTO, DIGI4AUT y otros. Sitio web de Grupo Copo, 2025. Descripción de proyectos de innovación y colaboraciones industriales, incluyendo GreenAuto, ADVANSEAT, ROBERTO (ITC-20161153) y DIGI4AUT. Available online: https://www.grupocopo.com/en/projects-and-partnerships/ (accessed on 27 May 2025).

- AIRSKIN GmbH. AIRSKIN: Safety solutions for industrial robots and collaborative automation. Sitio web de AIRSKIN, 2025. Soluciones de seguridad certificadas (PL e, Cat. 3 / SIL 3, ISO 13849) para robots industriales y colaborativos. Available online: https://www.airskin.io/ (accessed on 27 May 2025).

- ISO 13849-1:2023; Safety of Machinery—Safety-Related Parts of Control Systems—Part 1: General Principles for Design. International Organization for Standardization: Geneva, Switzerland, 2023.

- UNE-EN IEC 62061:2021; Safety of Machinery—Functional Safety of Safety-Related Control Systems. Spanish Standardization Association: Madrid, Spain, 2021.

- Ghanbarzadeh, A.; Najafi, E. Safe Physical Human–Robot Interaction through Variable Impedance Control Based on ISO/TS 15066. Int. J. Interact. Des. Manuf. 2024, 18, 2077–2088. [Google Scholar] [CrossRef]

- Arents, J.; Abolins, V.; Judvaitis, J.; Vismanis, O.; Oraby, A.; Ozols, K. Human–Robot Collaboration Trends and Safety Aspects: A Systematic Review. J. Sens. Actuator Netw. 2021, 10, 48. [Google Scholar] [CrossRef]

- IEC 61508-1:2010; Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems—Part 1: General Requirements. International Electrotechnical Commission: Geneva, Switzerland, 2010.

- So, J.; Lee, I.B.; Kim, S. Federated Learning-Based Framework to Improve the Operational Efficiency of an Articulated Robot Manufacturing Environment. Appl. Sci. 2025, 15, 4108. [Google Scholar] [CrossRef]

- Fernández Vega, M.; Alfaro Víquez, D.; Zamora-Hernandez, M.A.; Garcia-Rodriguez, J.; Azorín-López, J. Towards a Comprehensive Taxonomy of Cobots: A Tool for Multi-criteria Classification. In Proceedings of the The 19th International Conference on Soft Computing Models in Industrial and Environmental Applications SOCO, Salamanca, Spain, 9–11 October 2024; Springer: Berlin/Heidelberg, Germany, 2025; Volume 889. [Google Scholar] [CrossRef]

- Ceroni, J.; Huang, C.Y.; Lara, M.; Williams, N.; Vincent, D. Robotics Around the World. In Handbook of Industrial Robotics; Nof, S.Y., Ed.; Wiley: Hoboken, NJ, USA, 1999; pp. 1–20. [Google Scholar] [CrossRef]

- Bruyninckx, H. Robotics Software: The Future Should Be Open [Position]. IEEE Robot. Autom. Mag. 2008, 15, 9–11. [Google Scholar] [CrossRef]

- Khalid, A.; Kirisci, P.; Ghrairi, Z. A Methodology to Develop Collaborative Robotic Cyber Physical Systems for Production Environments. Logist. Res. 2016, 9, 23. [Google Scholar] [CrossRef]

- Rahman, M.H.; Yaqot, M.; Menezes, B.C. Towards Circular Economy in Manufacturing Industries Based on Industry 4.0 Technologies. In Proceedings of the 2023 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 18–21 December 2023; pp. 1502–1506. [Google Scholar] [CrossRef]

- Grari, M.; Di Mascolo, M.; Simeu-Abazi, Z. Management of obsolescence during the maintenance phase in a circular economy context: State-of-the-art. In Proceedings of the 2024 International Conference on Control, Automation and Diagnosis (ICCAD), Paris, France, 15–17 May 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Voulgaridis, K.; Lagkas, T.; Sarigiannidis, P. Towards Industry 5.0 and Digital Circular Economy: Current Research and Application Trends. In Proceedings of the 2022 18th International Conference on Distributed Computing in Sensor Systems (DCOSS), Los Angeles, CA, USA, 30 May–1 June 2022; pp. 153–158. [Google Scholar] [CrossRef]

- Koppenborg, M.; Nickel, P.; Naber, B.; Lungfiel, A.; Huelke, M. Effects of Movement Speed and Predictability in Human–Robot Collaboration. Hum. Factors Man. 2017, 27, 197–209. [Google Scholar] [CrossRef]

- Wendt, T.M.; Weeber, T. Redefining Robotic Engineering: Harnessing Generative Design, Additive Manufacturing, Printable Conductive Materials, and Wireless Technologies to Develop Novel Articulated Robot Arms. In Proceedings of the 2024 IEEE International Symposium on Robotic and Sensors Environments (ROSE), Chemnitz, Germany, 20–21 June 2024; pp. 01–08. [Google Scholar] [CrossRef]

- Dai, W.; Leitão, P.; Tsang, K.F.; Shi, Y.; Hancke, G.; Shu, L.; Behnam, M.; Haase, J.; Vyatkin, V. Synergies of Operation, Information, and Communication Technology for Solving New Societal and Industrial Challenges: Future Directions. IEEE Ind. Electron. Mag. 2024, 2024, 6–16. [Google Scholar] [CrossRef]

- ISO/IEC/IEEE 29148:2018(E); Software Engineering Life Cycle Processes Requirements Engineering. IEEE: Piscataway, NJ, USA, 2018; pp. 1–104. [CrossRef]

- Meredith, J.; Hyer, N.; Gerwin, D.; Rosenthal, S.; Wemmerlöv, U. Research needs in managing factory automation. J. Oper. Manag. 1986, 1986, 203–218. [Google Scholar] [CrossRef]

- Glendon, A. Risk Management. In The Wiley Blackwell Handbook of the Psychology of Occupational Safety and Workplace Health; Clarke, S., Probst, T.M., Guldenmund, F., Passmore, J., Eds.; Wiley: Hoboken, NJ, USA, 2015; pp. 1–20. [Google Scholar] [CrossRef]

- Shang, X.; Xu, T.; Karamouzas, I.; Kallmann, M. Constraint-based multi-agent reinforcement learning for collaborative Tasks. Comput. Animat. Virtual World 2023, 34, e2182. [Google Scholar] [CrossRef]

- Mazeas, D.; Namoano, B. Study of Visualization Modalities on Industrial Robot Teleoperation for Inspection in a Virtual Co-Existence Space. Virtual Worlds 2025, 4, 17. [Google Scholar] [CrossRef]

- Karjalainen, J.; Heinonen, S.; Shaw, M. Peer-to-peer and circular economy principles in the fourth industrial revolution (4IR)—New risks and opportunities. In Proceedings of the 2019 International Conference on the Domestic Use of Energy (DUE), Wellington, South Africa, 25–27 March 2019; pp. 220–230. [Google Scholar]

- Bushuyev, S.; Bushuyeva, N.; Ivko, A.; Bushuiev, D.; Bushuieva, V.; Iazykov, D. Principles of Circular Economy as a Driver of Development Projects. In Proceedings of the 2023 IEEE International Conference on Smart Information Systems and Technologies (SIST), Astana, Kazakhstan, 4–6 May 2023; pp. 37–41. [Google Scholar] [CrossRef]

- Fahmi, S.; Choi, H.J. Software Reverse Engineering to Requirements. In Proceedings of the 2007 International Conference on Convergence Information Technology (ICCIT 2007), Gyeongju, Republic of Korea, 21–23 November 2007; pp. 2199–2204. [Google Scholar] [CrossRef]

- Daun, M.; Grubb, A.; Stenkova, V.; Tenbergen, B. The Field of Requirements Engineering Education. In Proceedings of the 2023 IEEE 35th International Conference on Software Engineering Education and Training (CSEE&T), Tokyo, Japan, 7–9 August 2023; p. 119. [Google Scholar] [CrossRef]

- Mavin, A.; Mavin, S.; Penzenstadler, B.; Venters, C. Towards an Ontology of Requirements Engineering Approaches. In Proceedings of the 2019 IEEE 27th International Requirements Engineering Conference (RE), Jeju, Republic of Korea, 23–27 September 2019; pp. 514–515. [Google Scholar] [CrossRef]

| Criterion | Traditional Industrial Robot (e.g., ABB IRB 120) | Commercial Cobot (UR5e/LBR iiwa/YuMi) |

|---|---|---|

| Payload capacity | 3–10 kg | 3–10 kg |

| Repeatability | High (±0.01 mm) | High (±0.03–0.05 mm) |

| Collaboration without fencing | No (requires fencing or external scanners) | Yes (designed and certified under ISO/TS 15066) |

| Integrated torque sensors | No | Yes (in each joint) |

| Speed and acceleration | High (up to 6 m/s, no human contact) | Limited by contact regulation (≈1.5 m/s) |

| Safe physical design | No (sharp edges, no soft covers) | Yes (ergonomic design, rounded surfaces) |

| Environmental perception | None or limited (requires external vision) | Partial or integrated, depending on model |

| Collaborative programming | Not native (requires external PLCs/ROS) | Yes, via intuitive APIs and HMI panels |

| Integration curve | High complexity | Low, plug-and-play interface |

| Estimated total cost | Low (if robot is already owned) | High (USD 30,000–60,000) |

| Aftermarket flexibility/scalability | Limited | High, compatible with AI, vision, cloud modules |

| Category | Metric | Description |

|---|---|---|

| Safety | Risk of accident | Combination of likelihood and severity used to estimate potential harm. |

| Quality Attributes | Reliability and performance | Consistency and efficiency in task execution. |

| Flexibility | Reconfiguration time | Time required to switch between different operational modes. |

| Usability | Operator learning curve | Time needed for a non-expert to operate the robot safely. |

| ROI | Cost–benefit ratio | Comparison between retrofit cost and new cobot acquisition. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernandez-Vega, M.; Alfaro-Viquez, D.; Zamora-Hernandez, M.; Garcia-Rodriguez, J.; Azorin-Lopez, J. Transforming Robots into Cobots: A Sustainable Approach to Industrial Automation. Electronics 2025, 14, 2275. https://doi.org/10.3390/electronics14112275

Fernandez-Vega M, Alfaro-Viquez D, Zamora-Hernandez M, Garcia-Rodriguez J, Azorin-Lopez J. Transforming Robots into Cobots: A Sustainable Approach to Industrial Automation. Electronics. 2025; 14(11):2275. https://doi.org/10.3390/electronics14112275

Chicago/Turabian StyleFernandez-Vega, Michael, David Alfaro-Viquez, Mauricio Zamora-Hernandez, Jose Garcia-Rodriguez, and Jorge Azorin-Lopez. 2025. "Transforming Robots into Cobots: A Sustainable Approach to Industrial Automation" Electronics 14, no. 11: 2275. https://doi.org/10.3390/electronics14112275

APA StyleFernandez-Vega, M., Alfaro-Viquez, D., Zamora-Hernandez, M., Garcia-Rodriguez, J., & Azorin-Lopez, J. (2025). Transforming Robots into Cobots: A Sustainable Approach to Industrial Automation. Electronics, 14(11), 2275. https://doi.org/10.3390/electronics14112275