1. Introduction

Work-related musculoskeletal disorders (WMSDs) have become a prevalent issue in the agricultural industry, particularly due to the physically demanding nature of tasks that require repetitive bending and prolonged awkward postures. These biomechanical stressors place workers at a heightened risk of developing low back pain (LBP), one of the most reported WMSDs in this sector [

1]. The physical burden associated with these tasks is exacerbated by prolonged exposure to high-risk postures, repetitive force exertions, and external loads, all of which contribute to musculoskeletal fatigue and injury over time. Kang et al. [

2] investigated WMSD prevalence and risk factors among Korean farmers, finding that over 26% reported back-related WMSDs. Similarly, Shivakumar et al. [

3] found that the 12-month pooled prevalence of LBP among agricultural workers was 61.96% in Africa, 54.16% in Asia, and 28.52% in South/Central America. These findings underscore the global nature of this issue and the need for targeted ergonomic interventions to address the unique demands of agricultural labor, a sector that remains underserved by conventional ergonomic solutions [

4,

5,

6]. Addressing these challenges is particularly critical as agricultural workers often experience longer-than-average work hours with little opportunity for physical recovery, further compounding their risk of injury.

In recent years, the human–robot interaction (HRI) has gained increasing attention as a viable solution to help alleviate physical strain and cognitive workload in labor-intensive industries [

7,

8]. Collaborative robots, or cobots, are designed to work alongside humans, augmenting their capabilities and reducing high-risk postures. Seyyedhasani et al. [

9] developed a simulation model to optimize collaboration between human workers and robots for high-volume harvesting, demonstrating that cobots can increase efficiency and reduce physical demands by minimizing non-productive walking times. In terms of agricultural settings, Adamides et al. [

10] presented a semi-autonomous agricultural robotic sprayer that is designed to work in collaboration with a human teleoperator. Similarly, Yerebakan et al. [

11] investigated the biomechanical and cognitive workload effects of HRIs in agricultural pollination tasks, highlighting the potential of HRIs to mitigate physical and mental fatigue. While these studies establish a foundation for integrating robotic systems in the agricultural sector, further research is needed to explore their impact on the ergonomic challenges faced in specialized, small-scale farming operations.

While fully automated plant-transplanting systems have become increasingly prevalent in large-scale industrial farming, their applicability remains limited in several key scenarios. Small-scale farming operations, especially those with limited financial resources, often lack the infrastructure and capital required to implement and maintain fully automated systems [

12]. In these contexts, human labor remains indispensable, yet the physical demands of manual tasks exacerbate the risk of WMSDs [

5]. Cobots provide a middle-ground solution, combining the adaptability of human labor with the mechanical assistance of automation. While not a replacement for fully manual or fully automated approaches, they offer a flexible alternative that can reduce physical demands in certain agricultural settings with lower investment requirements than large-scale automation [

13,

14]. To rigorously evaluate such alternatives, especially in the early stages of cobot integration, robust sensor-based approaches are essential. Advances in wearable sensor systems, particularly inertial measurement units (IMUs) and surface electromyography (sEMG), now allow for detailed and quantitative analysis of human movement and muscle activation during task execution. These technologies provide precision, portability, and real-time feedback necessary to investigate ergonomic performance in dynamic work environments, including the agriculture sector.

Plant transplanting presents unique ergonomic challenges due to its repetitive nature and the need for workers to maintain sustained postural deviations. These challenges place considerable biomechanical strain on the lower back, particularly in manual transplanting tasks that require prolonged kneeling, squatting, or trunk flexion. Such conditions contribute to the high prevalence of WMSDs among agricultural workers, especially in small-scale and traditional farming settings [

15,

16]. While recent studies have demonstrated the potential of the human–robot interaction (HRI) in reducing physical burden across industrial applications [

17,

18], its application to fine-grained, labor-intensive agricultural tasks like plant transplanting remains largely unexplored.

To address this gap, our research group is actively developing a generalizable, mobile agricultural cobot platform, which has shown early success in controlled-environment pollination tasks [

19,

20,

21]. However, extending this system to support plant transplanting requires a nuanced understanding of the biomechanical demands and physical strategies currently used by human workers. Unlike in prior studies, our approach does not begin with robotic intervention but rather seeks to characterize plant-transplanting-specific motion and posture data that can inform future cobot design. Specifically, through this study, we aim to (1) collect foundational human-centered data on segment velocities, joint accelerations, and muscle activation patterns under normal manual transplanting conditions; and (2) evaluate whether cobot integration can improve human postures and movement profiles that reduce physical load while maintaining task efficiency. The findings will not only guide controller development and adaptive behavior strategies for plant-transplanting cobots but will also contribute empirical insights to the broader HRI-in-agriculture literature. By bridging human biomechanics with collaborative robotics, we lay the groundwork for safer, more efficient cobot-supported farming systems in the future.

2. Materials and Methods

2.1. Apparatus

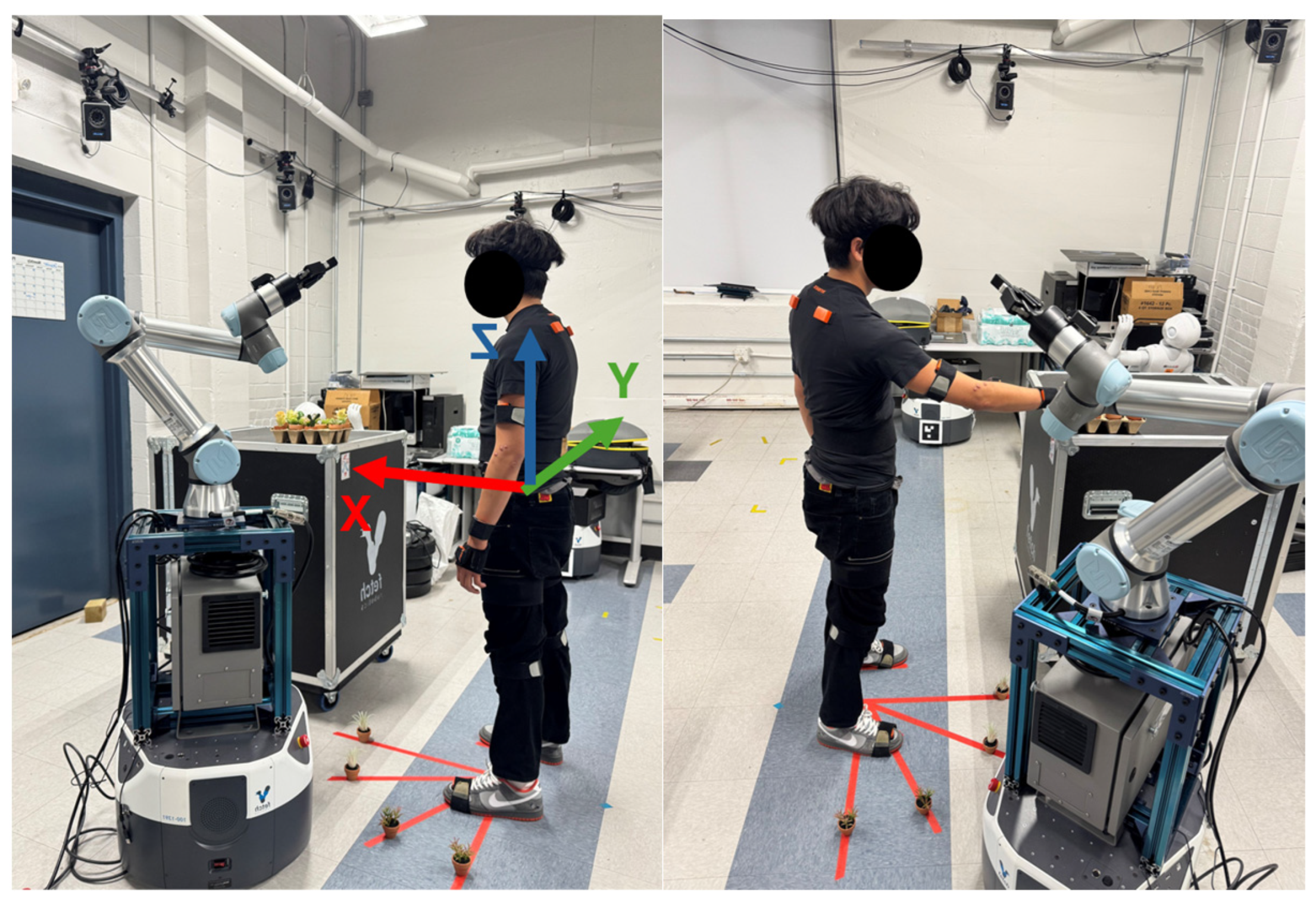

The experimental setup (

Figure 1) was designed to simulate a plant-transplanting task in a controlled laboratory environment. The apparatus included four pots positioned on the ground at angles of 0°, 30°, 60°, and 90° relative to the participant’s body to mimic potential real-world plant-transplanting conditions and postures. Small artificial succulent plants were used as plant substitutes, which participants placed into the pots during the task. Participants were instructed to stand with their feet shoulder-width apart, ensuring a stable base throughout the experiment. Each pot was placed 45 cm away from the participant’s feet, ensuring a consistent reach distance across all angle variations. Kinematics data were collected using the Xsens Awinda system (Xsens, Enschede, The Netherlands), which consisted of 17 inertial measurement unit (IMU) sensors placed on the participant’s body according to the manufacturer’s guidelines. The system recorded segment velocities and accelerations at a sampling rate of 60 Hz. Muscle activation was measured using Trigno EMG sensors (Delsys Inc., Boston, MA, USA), which were placed on the flexor carpi radialis (FCR), brachioradialis (BR), biceps brachii (BB), and upper trapezius (UT) muscles.

This study employed a UR5 robot (Universal Robots, Odense, Denmark) and a Fetch mobile base (Fetch Robotics, San Jose, CA, USA) as the cobot assistant to support plant-transplanting tasks (

Figure 1). The UR5-based setup was used as the proxy of the Stickbug robot [

21], with comparable dimensions and major design features, and was operated as the Wizard of Oz method. In this study, the cobot was operated without autonomous motion planning. While the robot did not execute real-time path planning, its pose and positioning were selected to reflect plausible ergonomic placements. The biomechanical data collected here will inform future control strategies that can adapt robot trajectories to minimize dynamic spinal loading and maximize human comfort.

2.2. Participants

A total of 16 participants (8 males and 8 females) were recruited for this study from the local university and community. All participants reported good health and had no history of musculoskeletal disorders. The inclusion criteria required no dysfunction or recent injuries that could affect their physical capabilities and task completion. The study received approval from the University of Florida Institutional Review Board (IRB), and all participants provided informed consent prior to the experiment. Detailed characteristics of the subjects are summarized in

Table 1.

2.3. Experimental Design

There was a single independent variable in the current study, which was the HRI mode. HRI modes included manual transplanting, where participants performed tasks independently. In the robot-assisted transplanting mode, a collaborative robot passively held the plants at a consistent, ergonomically favorable height. This condition was not intended to test a finalized robotic control strategy, but rather to allow for the collection of human biomechanical data across different postures. These data serve both to characterize current biomechanical demands in manual transplanting and to inform the development of future cobot motion planning algorithms that optimize ergonomic outcomes based on bending, twisting, and physical strain during transplanting tasks. Details of the mechanical platform and planned control framework will be presented in a separate manuscript. Dependent variables were grouped into two categories: (1) segment velocities and accelerations for L5/S1, T1/C7, and L1/T12, and the pelvis in the x-, y-, and z-axes. The x-axis represents the anteroposterior direction, with positive values indicating forward movement and negative values indicating backward movement. The y-axis corresponds to the mediolateral direction, where positive values represent rightward movement (having the participants facing forward) and negative values represent leftward movement. The z-axis aligns with the vertical direction, with positive values indicating upward movement and negative downward values; (2) muscle activation, measured via EMG from the flexor carpi radialis, brachioradialis, biceps brachii, and upper trapezius. These metrics were selected to assess the biomechanical and physiological impacts on participants. The inclusion of four pot angles (0°, 30°, 60°, and 90°) was intentional to simulate the spatial variability encountered in real-world transplanting environments. Although the angles used in this study do not capture the full irregularity of real-world terrain and plant spacing, they offer a controlled way to simulate variations in the reaching, twisting, and bending required in field transplanting. The chosen configurations reflect common planting layouts and introduce lateral asymmetry that approximates realistic planting conditions while maintaining repeatability. Limiting the study to a single pot angle would have simplified the protocol but failed to represent the asymmetrical and dynamic motions typical of actual agricultural work. Training a controller using biomechanical data derived only from symmetric, forward-reaching postures would hinder its ability to adapt to diverse field configurations. By incorporating multiple angles, this study ensures that both the characterization of human movement and the future cobot behaviors are grounded in realistic and varied transplanting scenarios.

2.4. Protocol

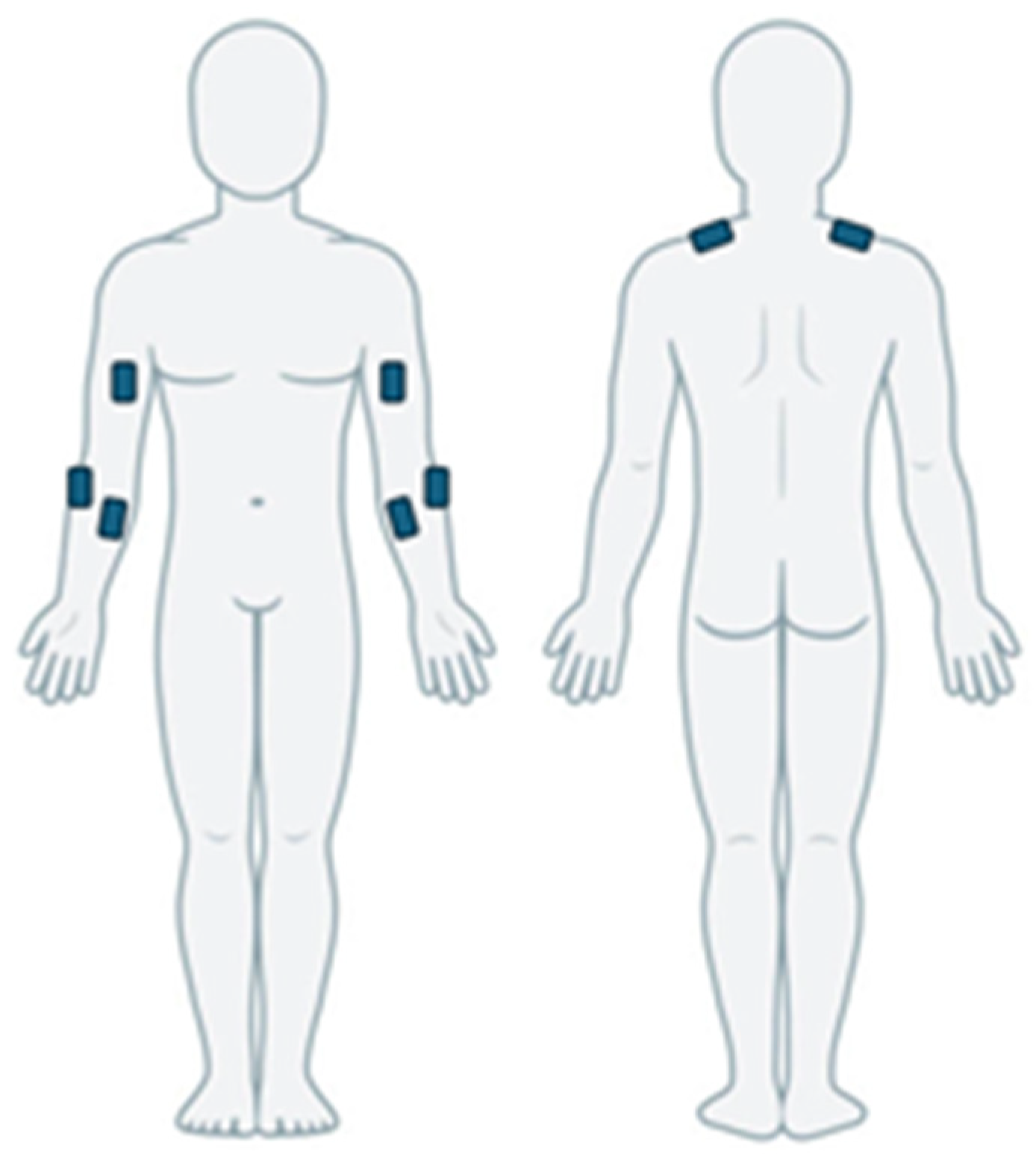

Upon arrival, participants were briefed on the study’s objectives and procedures before providing informed consent. Seventeen inertial measurement unit (IMU) sensors were then positioned on each participant following the manufacturer’s guidelines, as shown in

Figure 2. Anthropometric data were collected, and participants underwent a calibration process using the Xsens MVN Analyze/Animate software (Version 2021.0.1). Calibration consisted of a static pose held for five seconds, followed by a brief walking sequence to ensure precise motion capture alignment. Next, Trigno EMG sensors were attached to the participants, as shown in

Figure 3, to measure muscle activity. The maximum voluntary contraction (MVC) of each muscle was assessed following established guidelines [

22] to normalize muscle activation data across individuals.

In the manual plant-transplanting task, participants were required to stoop to place a small plant into each of the four pots positioned on the ground at angles of 0°, 30°, 60°, and 90° relative to their body. After placing a plant in each pot, participants returned to a neutral standing posture before stooping again to reach the next pot. This required participants to repeatedly stoop, return to neutral, and stoop again until all four pots were planted, simulating the repetitive bending motions commonly involved in manual plant-transplanting tasks. In contrast, in the robot-assisted mode, participants were asked to stoop once to plant all four pots without returning to a neutral posture. The robot held the plant container in an ergonomically friendly position, allowing participants to reach each pot sequentially without the need for repetitive stooping and standing, thereby reducing the physical demands of the task.

Each plant-transplanting task was repeated twice to ensure data reliability, resulting in 4 trials per participant (2 HRI modes × 2 repetitions). Each trial lasted for around 20 s, during which motion and muscle data were recorded. The total duration of the experiment lasted around 1 h.

2.5. Data Processing and Statistical Analysis

Kinematic data were collected using the Xsens Awinda system and processed through its built-in software. Participant movements were recorded at a frame rate of 60 Hz, and the processed data were exported for further analysis. The final kinematic values for each condition were obtained by computing the mean across the two repeated trials. The normality of the datasets was assessed prior to statistical testing. EMG signals were pre-processed using MATLAB R2018b. The DC offset was removed, and the signals were filtered using a 60 Hz notch filter and a fourth-order Butterworth band-pass filter (15–450 Hz) to eliminate environmental noise and retain the relevant frequency content. Full-wave rectification was applied to the signals, followed by smoothing with a fourth-order Butterworth low-pass filter at a cutoff frequency of 6 Hz to extract the linear envelope. The signals were then normalized to the maximum value of the maximum voluntary contraction (MVC) for each participant. Out of the 16 participants, EMG data were recorded and analyzed for 10 participants due to an unexpected hardware issue. A one-way ANOVA was then conducted to compare the mean values between conditions, yielding F-statistics and p-values to determine the significance of differences. A significance threshold of p < 0.05 was chosen to determine statistical significance.

4. Discussion

The integration of cobots into agricultural tasks has the potential to mitigate some of the ergonomic risks associated with repetitive bending, side bending, or twisting, though their effectiveness depends on task complexity and user adaptability. Our prior research has demonstrated the potential of cobots to reduce awkward postures and excessive joint angles during pollination operations, thereby enhancing ergonomics and improving worker safety and comfort in HRI systems [

11]. Building on this foundation, the present study examines the biomechanical effects of cobot-assisted plant transplanting, with a specific focus on joint kinematics as well as EMG activity. By reframing the analysis from merely evaluating cobot utility to exploring movement strategies in repetitive transplanting tasks, the findings contribute baseline data for developing ergonomically adaptive cobots. This study uniquely demonstrates how wearable IMU and EMG sensors can capture high-resolution human biomechanics in agricultural tasks, providing a replicable approach for evaluating cobot-assisted interventions beyond traditional lab setups.

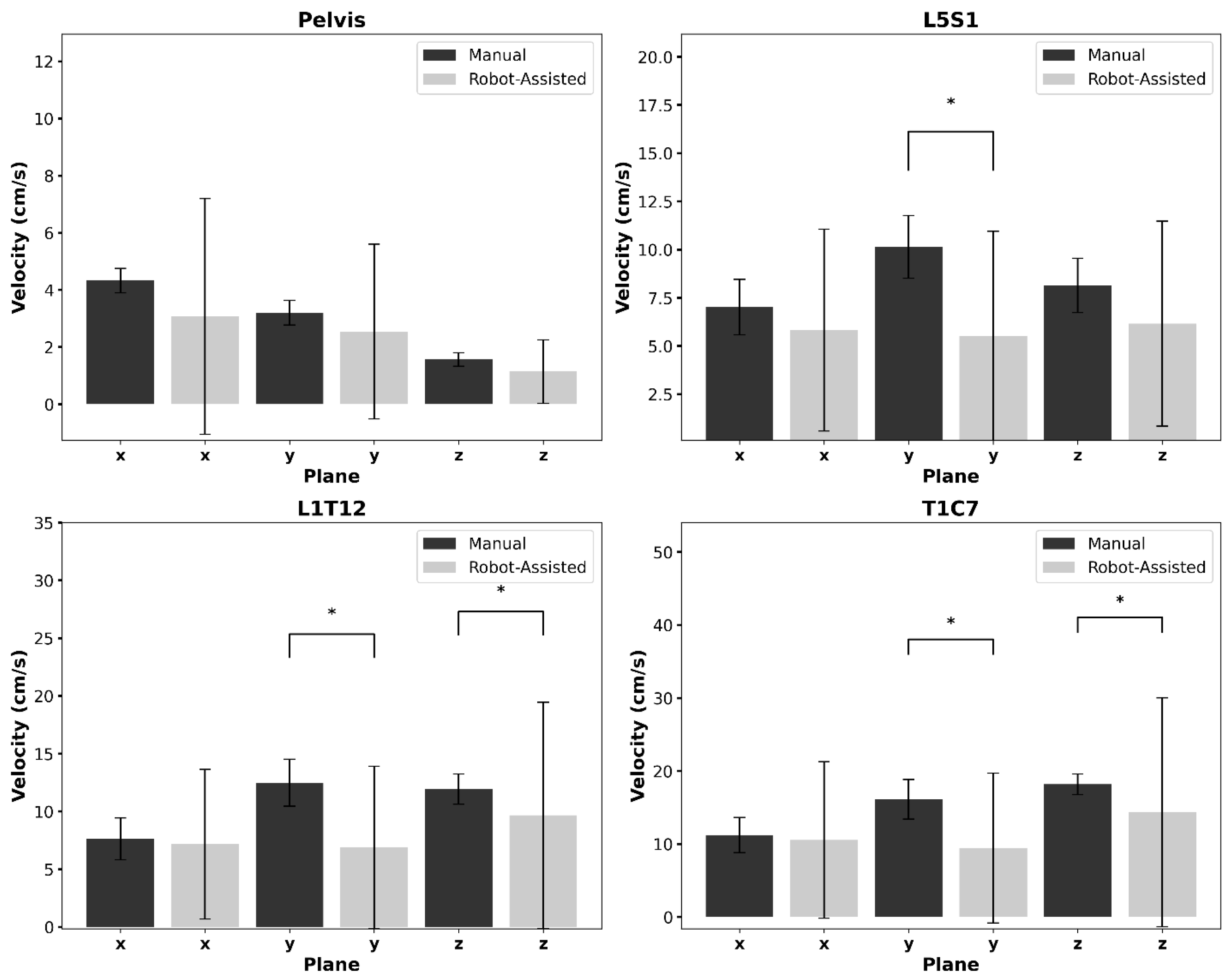

For segment velocities across the pelvis, and L5/S1, L1/T12, and T1/C7 joints, all showed decreases across the x, y, and z planes (

Table 2), with a portion being statistically significant. This reduction is particularly relevant from a biomechanical perspective, as lower segment velocities can potentially minimize dynamic spinal loading, thereby reducing excessive shear and compression forces that contribute to musculoskeletal strain and injury. Davis and Marras [

25] conducted a comprehensive review of the effects of trunk motion on musculoskeletal loading and injury risk, demonstrating that increased movement velocity leads to greater muscle coactivation, higher spinal loads, and reduced trunk strength—factors known to elevate the risk of LBP. Their findings identified three-dimensional trunk velocity as a significant risk factor, as higher velocities were directly associated with increased spinal compression and shear forces. Similarly, Marras et al. [

26] reported that elevated trunk velocities amplify trunk muscle coactivation and lateral shear forces, further exacerbating musculoskeletal strain. More recent studies have reinforced these findings. Allread and Vossenas [

27] examined trunk motions and LBP risk among hotel-room cleaners, demonstrating that an increased speed of work was associated with higher spinal loading and an increased likelihood of developing LBDs. These findings reinforce the significance of the present study, where the observed reductions in segment velocity across spinal regions suggest a potential ergonomic advantage of cobot assistance. By lowering segment velocity, cobot-assisted interventions may contribute to reduced spinal loading and mitigate cumulative strain, particularly in highly repetitive agricultural tasks.

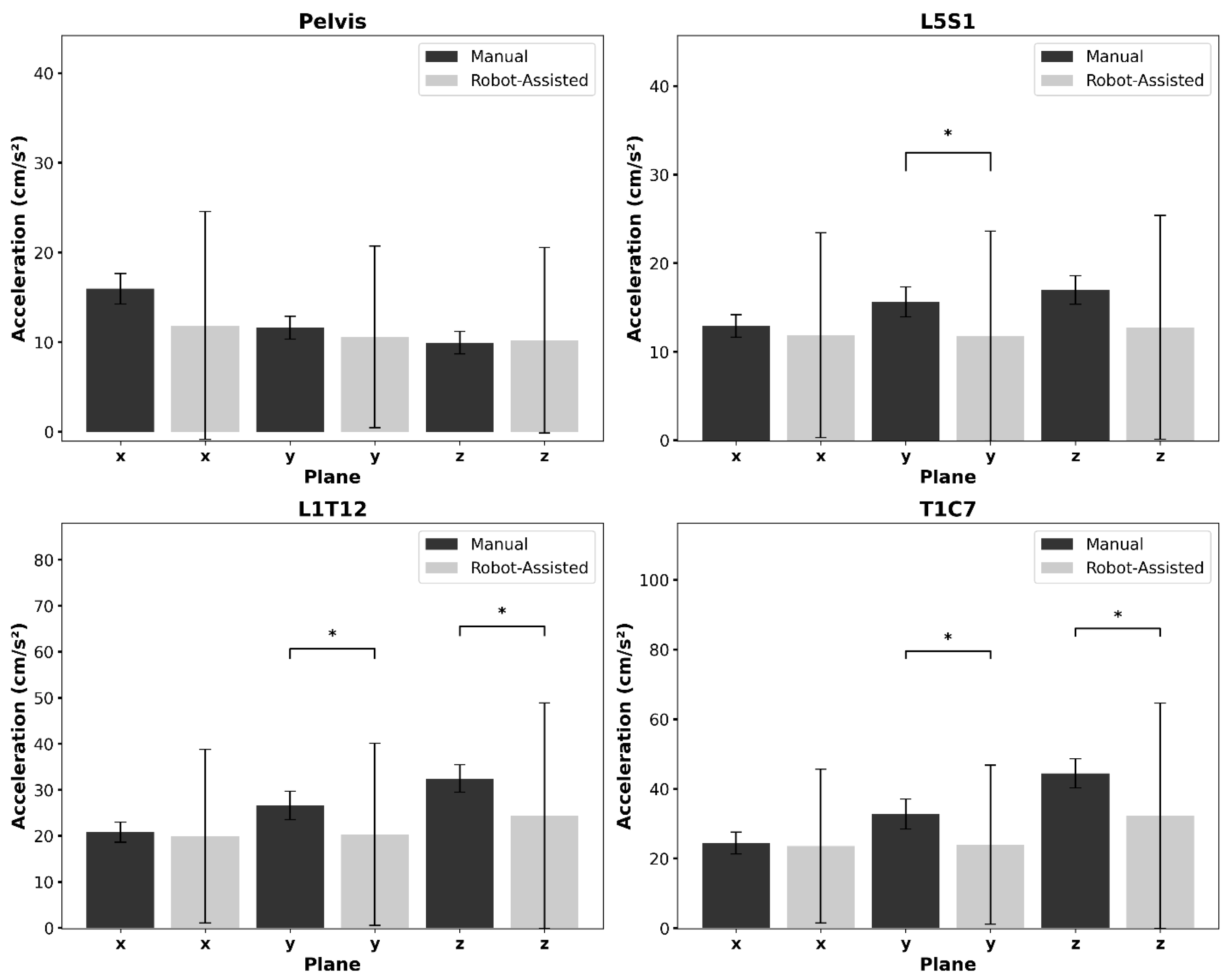

Compared to segment velocity, segment acceleration also exhibited variation across most planes and joints following the introduction of the cobot (

Table 3). This suggests that cobot assistance may help regulate movement, reducing the likelihood of abrupt changes in acceleration that could contribute to increased mechanical loading on the spine. Tsang et al. [

28] investigated the effects of different bending speeds on lumbo-pelvic kinematics and found that individuals with LBP exhibited compromised control over segment acceleration, particularly at slower speeds, leading to less efficient movement coordination. Their study demonstrated that uncontrolled acceleration changes increased mechanical demand on the lumbar spine, reinforcing the importance of regulating segment accelerations to reduce spinal stress. Similarly, in the present study, the reduction in segment acceleration suggests that cobot assistance maintained controlled and stable movement patterns, potentially mitigating sudden mechanical stress on the spine and reducing the risk of cumulative strain during repetitive tasks. The findings align with prior research emphasizing that higher movement accelerations contribute to increased spinal loading, leading to potential long-term musculoskeletal strain. By moderating movement acceleration, cobot assistance may provide an ergonomic advantage in reducing the risk of low back disorders (LBDs), particularly in physically demanding tasks that require repetitive trunk flexion.

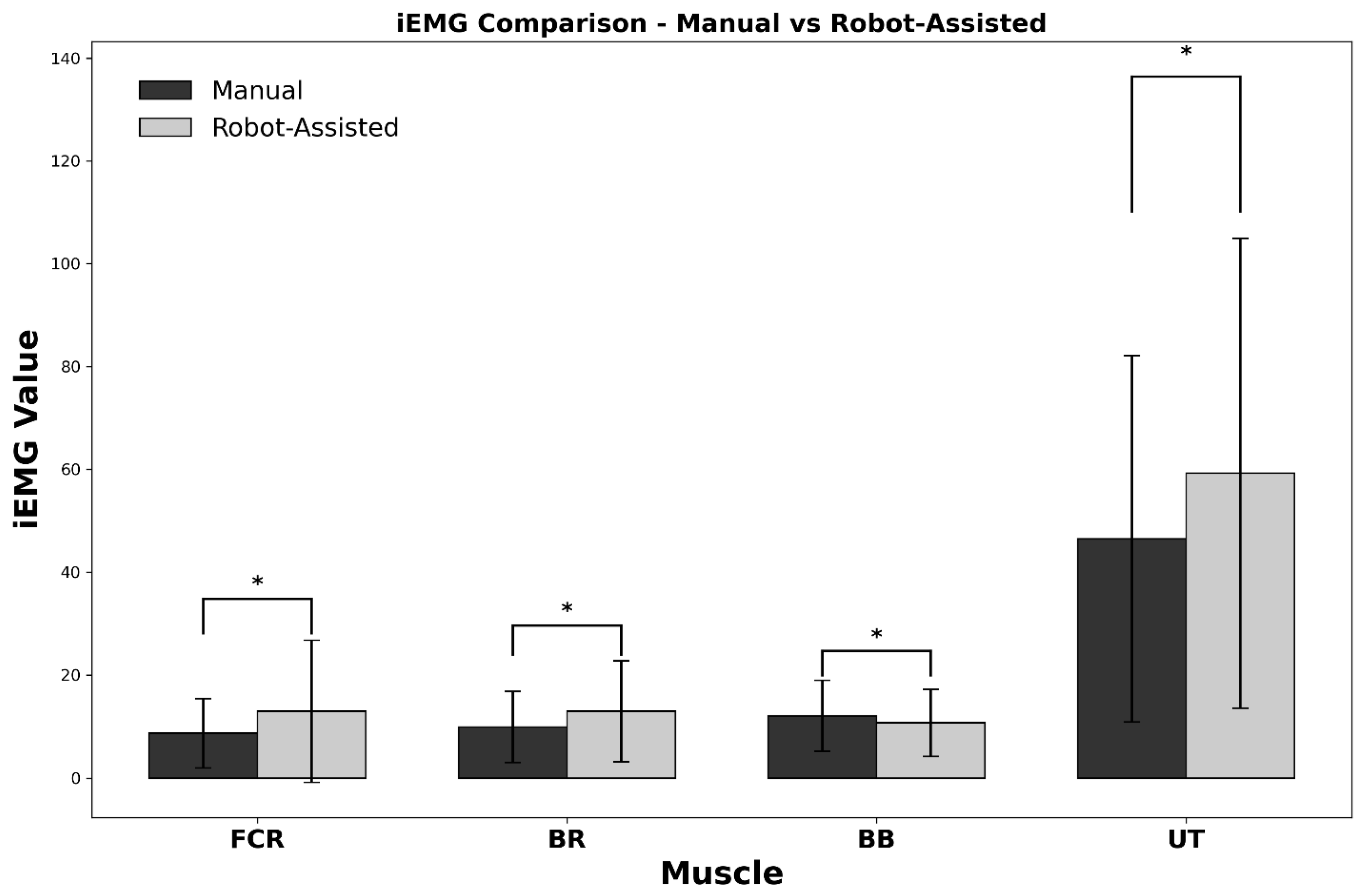

While reductions in segment velocity and acceleration indicate that cobot assistance may reduce dynamic spinal loading, EMG analysis revealed increased activation in the flexor carpi radialis (FCR), brachioradialis (BR), and upper trapezius (UT) muscles, suggesting a redistribution rather than a universal reduction in muscular demands (

Table 4). In contrast, activation of the biceps brachii (BB) decreased significantly from 12.09 (±6.9) to 10.72 (±6.5) (F = 6.29,

p = 0.018), suggesting that cobot support may reduce the reliance on primary movers while shifting muscular demand to the stabilizing and fine-motor-control muscles. A similar redistribution of muscle activity has been reported in exoskeleton-assisted tasks, where external support alleviates the load on primary muscles but leads to increased activation in the stabilizing muscles due to postural adjustments and task-specific demands [

29]. It was demonstrated that exoskeletons reduced trunk muscle activation in prolonged surgical postures but did not alleviate shoulder and neck muscle strain, highlighting the complex neuromuscular adaptations that occur with assistive devices. This shift may explain why FCR, BR, and UT activation increased despite the reduction in segment velocity. Notably, the flexion–relaxation phenomenon (FRP), which typically allows for muscle relaxation during certain movement phases, has been shown to be disrupted by assistive devices, leading to sustained muscle activation [

30]. This redistribution pattern suggests that while the cobot reduced gross movement demands (e.g., for biceps brachii), it simultaneously increased the need for fine motor and stabilizer muscle activity to manage reach coordination and postural control during sequential pot placements. While this redistribution may alleviate overuse in primary movers, prolonged activation of stabilizers like the UT and BR may lead to localized fatigue. Chronic overuse of these muscles could contribute to discomfort or even overuse injury if not managed with appropriate rest cycles or cobot control adjustments. Longitudinal studies are needed to determine the cumulative effects of these activation patterns.

4.1. Impact of Cobot Assistance on Task Dynamics and Efficiency

The robot-assisted approach fundamentally alters task dynamics by allowing participants to depend on the robot for assistance, leading to greater variability in segment velocity and accelerations as they adapt to the robot’s presence. This variability indicates less-consistent movement patterns, as the robot reduces some of the biomechanical demands. In contrast, manual tasks enforce more uniform motion patterns due to their repetitive nature and the direct control exerted by participants. Research has shown that adaptive robotic systems not only modify physical behaviors but also enhance task efficiency by decreasing task completion time and improving team fluency [

31]. In our study, the cobot reduced the total task time by an average of 59.46%, a reduction that significantly outweighed the observed increases in iEMG values. Similarly, Liu et al. [

32] found that while cobots enhance efficiency, they may redistribute physical demands rather than uniformly reduce them. These findings highlight the potential of cobot assistance to not only balance physical demands but also improve overall task performance in repetitive, collaborative environments [

33,

34].

Although the cobot-assisted condition resulted in a higher percentage of movements classified as high-risk postures, this increase should be interpreted in the context of overall task efficiency and exposure duration. While participants spent a larger proportion of time in high-risk postures during the cobot-assisted tasks (78.97% ± 6.08%) compared to the manual tasks (36.23% ± 10.71%), the shorter task duration plays a crucial role in mitigating prolonged exposure to these postures. When examining the absolute time spent in each risk category, participants in the manual condition spent an average of 39.44 ± 8.70 s in low-risk postures, 7.00 ± 3.25 s in moderate-risk postures, and 27.88 ± 12.37 s in high-risk postures. In contrast, the cobot-assisted condition significantly reduced time spent in low- and moderate-risk categories to 4.79 ± 1.04 s (F = 140.61, p < 0.001) and 1.30 ± 0.20 s (F = 27.62, p < 0.001), respectively. Although the percentage of high-risk postures increased, the absolute time spent in high-risk postures still decreased to 23.76 ± 5.05 s in the cobot-assisted condition, albeit not significantly (F = 0.86, p = 0.367). Our results demonstrate that, while cobot integration alters posture dynamics, it significantly reduces the overall task duration and moderates segmental motion. These findings support the second objective of this study, showing that cobot assistance can improve movement efficiency and potentially reduce long-term physical strain. Taken together with the detailed segmental and muscular analyses, this study offers foundational biomechanical data on human movement strategies in plant transplanting, fulfilling our first objective and paving the way for informed cobot control design and future HRI optimization.

4.2. Limitations

This study provides evidence supporting the potential benefits of cobot assistance in reducing biomechanical strain during plant-transplanting tasks. However, it is important to acknowledge that manual labor remains valuable in certain agricultural contexts. The controlled laboratory environment, while ideal for precise data collection, does not fully capture the variability of real-world farming conditions. Additionally, participants were not professional agricultural workers, which may limit the generalizability of our findings. Experienced workers may demonstrate optimized movement strategies developed over time. Although recruitment focused on healthy individuals with no musculoskeletal impairments, the lack of farming experience may underrepresent biomechanical adaptations acquired through real-world exposure. Future studies should include professional agricultural laborers to better understand how expertise influences biomechanics and to validate cobot assistance under more ecologically valid conditions. These real-world complexities may influence the effectiveness of cobot assistance and underscore situations where manual tasks remain practical or even preferable, particularly in small-scale or highly variable farming operations.

While the present study focused on controlled simulations to replicate real-world environments, it is important to recognize the inherent limitations of this approach. Simulated tasks, although valuable for isolating specific biomechanical and neuromuscular parameters, cannot fully capture the dynamic and unpredictable nature of agricultural work. However, the biomechanical components examined here remain relevant to field applications. For instance, Lüling et al. [

35] demonstrated that a robotic planting unit with AI-based adjustment still required human oversight, underscoring that manual movements remain integral in real-world settings. This supports the relevance of our simulation for informing ergonomic design. Moreover, the cobot used in this study was operated under a Wizard-of-Oz protocol to simulate assistance in a controlled manner. While effective for initial feasibility evaluation, this method does not reflect adaptive or autonomous cobot behavior and may introduce experimenter bias. Future studies should integrate real-time human-aware control strategies to better reflect the intended system performance.

To further address the ecological validity gap, future studies should include parallel data collection under both simulated and real agricultural conditions using the same wearable sensor configuration. Comparative analyses of biomechanical variability could quantify how uneven terrain and spatial irregularity influence human motion during transplanting tasks. Additionally, sensor performance metrics such as EMG signal noise, IMU drift, and data dropout rates could serve as indirect indicators of field-related disruptions. These comparisons would provide a quantitative framework for calibrating lab-based results and guiding cobot development that is robust to environmental variability. While this study does not directly quantify the difference between laboratory and real-world biomechanical responses, its simulated design was intentionally chosen to isolate key neuromuscular and postural features without the interference of environmental confounds. This level of control allows for the high-resolution analysis of cobot–human interaction dynamics and strain-reduction mechanisms that may otherwise be masked in complex field settings. Importantly, while this study was conducted in a controlled laboratory setting, the biomechanical patterns observed still reflect meaningful human responses to the physical demands of transplanting tasks. Prior research has shown that controlled environments are necessary to isolate key movement features and reduce confounding variables, allowing for the high-resolution assessment of postural strategies, muscle activation patterns, and joint dynamics. As is supported by Moore and Clifton [

36], laboratory- and field-based studies should be seen as complementary: findings from simulated conditions provide essential mechanistic insight that informs and enhances the translational value of future field-based validations. Therefore, the current findings offer foundational insights into physical strain and human–robot interactions that can inform future field-validated cobot designs.

Building on these considerations, future research should also explore adjustable robotic configurations tailored to user-specific ergonomic needs, enhancing the adaptability of cobots across diverse agricultural settings. Although both IMU and EMG systems used have been validated in prior studies, variability due to soft tissue movement, sensor placement, and electrode impedance may affect data consistency. Future studies will incorporate reliability testing to quantify these potential sources of error and consider multi-sensor fusion to improve robustness. In addition to traditional motion and muscle activity tracking, emerging wearable sensor technologies such as photonic smart wristbands, which enable real-time cardiorespiratory monitoring and biometric identification, could be integrated to provide a more comprehensive understanding of user physiology and task demands. These technologies may offer new insights into human–cobot interactions by capturing both physical and physiological stressors in field applications. For example, physiological indicators such as heart rate variability, respiration rate, and electrodermal activity [

37] could help to identify systemic stress responses associated with cobot use, particularly under prolonged or repetitive tasks. Incorporating these metrics alongside biomechanical data would enable a holistic assessment of user strain and support the development of cobot systems that optimize both physical load distribution and physiological recovery. Additionally, due to hardware instability, EMG data from six participants were excluded from the final analysis. While this did not affect the kinematic dataset, it reduced the EMG sample size to 10 participants. Future studies should employ improved sensor calibration protocols and real-time signal monitoring to mitigate data loss. Expanding the sample size to include experienced agricultural workers could further improve the generalizability of the results, as their expertise may reveal subtle yet significant differences in how manual and cobot-assisted techniques are executed. Furthermore, integrating real-world task simulations could provide deeper insights into the practical applications of cobot technology in agriculture. Factors such as uneven terrain, soil softness, and spatial irregularities, along with fluctuating weather and varying plant heights, were not accounted for, which may limit the ecological validity of the findings. These environmental factors can alter user posture, compromise sensor stability, and affect robot navigation, highlighting the need for future field-based trials to evaluate cobot performance under realistic agricultural conditions. These efforts will also help to identify scenarios where manual labor may offer advantages in terms of flexibility, cost-effectiveness, or task adaptability.

5. Conclusions

This study provides foundational biomechanical evidence on human movement strategies during plant transplanting, fulfilling the first objective of characterizing manual task demands prior to cobot integration. Using wearable sensor systems, including inertial measurement units (IMUs) and surface electromyography (sEMG), we analyzed segment velocities, joint accelerations, and muscle activation patterns to identify key contributors to biomechanical strain in repetitive transplanting tasks. The second objective, assessing the impact of cobot assistance, was supported by findings that demonstrated significant reductions in movement velocity and acceleration across spinal segments, along with improved task efficiency. However, these benefits were accompanied by a redistribution of muscular demand, particularly in the stabilizing muscle groups. These results underscore the need to design cobot systems that are biomechanically informed, not simply optimized for speed or automation, so that they can better support human physical needs. Overall, this study contributes both empirical insights and practical sensor-derived data to guide the ergonomic design of collaborative robots, particularly in small-scale, labor-intensive agricultural environments where manual strategies still prevail. These findings can directly inform cobot design by identifying optimal arm-reach limits, segment velocity thresholds, and ergonomic delivery positions. Such sensor-informed design principles can guide motion planning algorithms that adapt in real time to user kinematics, ensuring that collaborative assistance enhances rather than hinders biomechanical efficiency. In doing so, it establishes a sensor-integrated framework for real-time human monitoring and cobot adaptation in dynamic field applications.