Multi-Source Energy Harvesting Systems Integrated in Silicon: A Comprehensive Review

Abstract

1. Introduction

- System architectures, including the number and type of input energy sources.

- Key performance metrics, such as energy conversion efficiency, output power delivered to the load, silicon area footprint, and degree of integration (e.g., reliance on external components).

- Design trade-offs and integration challenges in achieving compact, high-performance EH solutions.

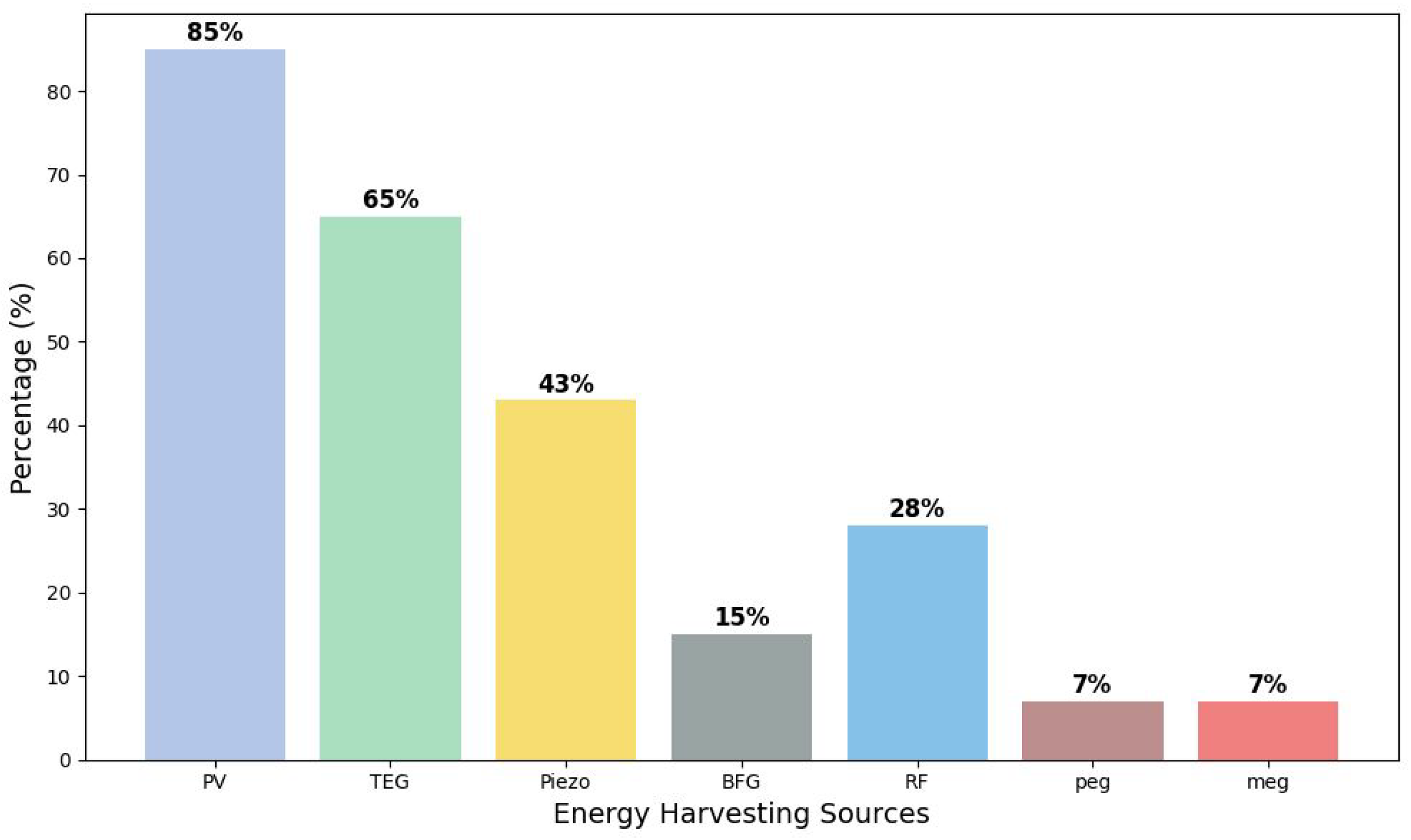

2. Energy Harvesting Technologies Trends

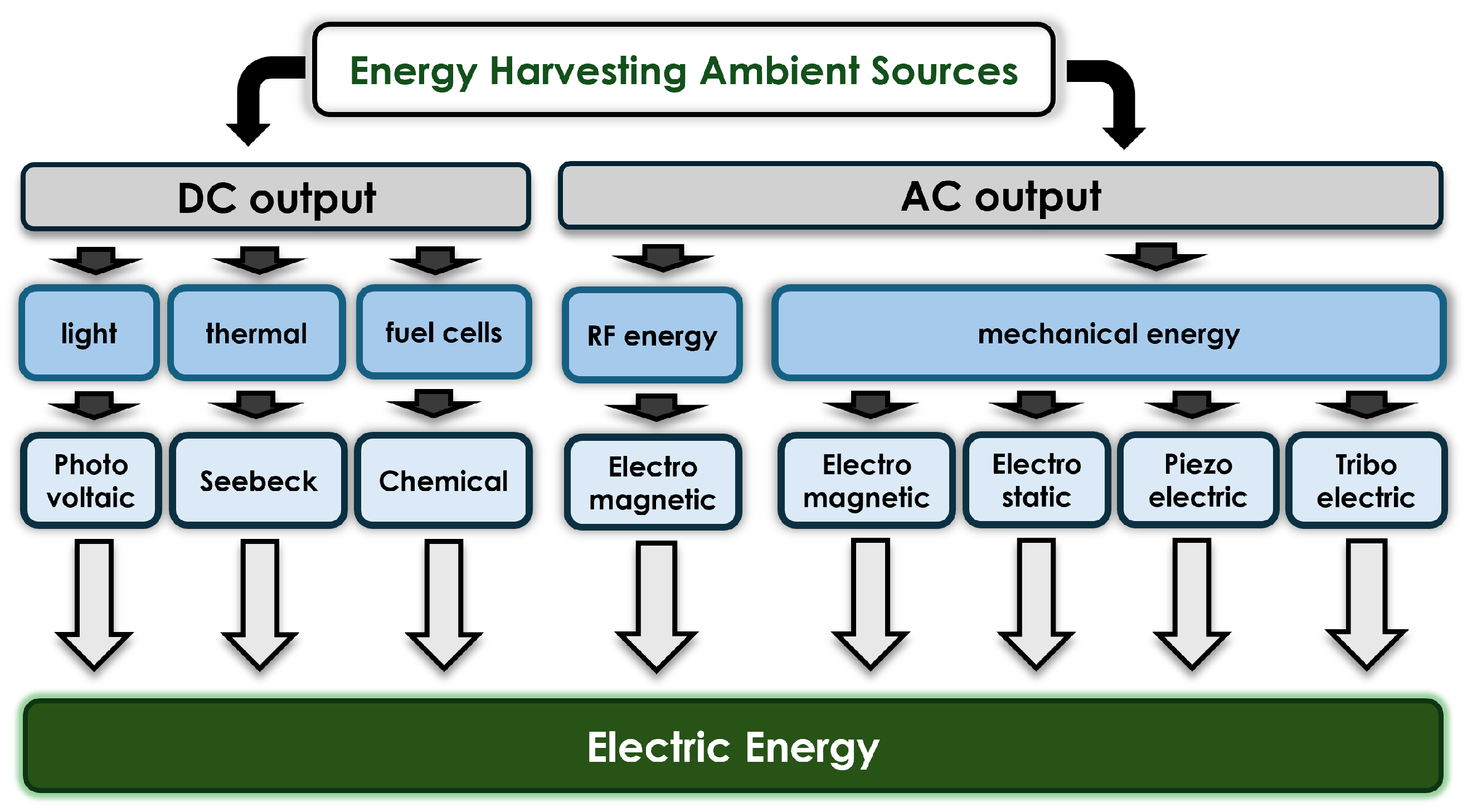

2.1. Ambient Energy Harvesters

2.1.1. Energy Harvesters with DC Output

2.1.2. Energy Harvesters with AC Output

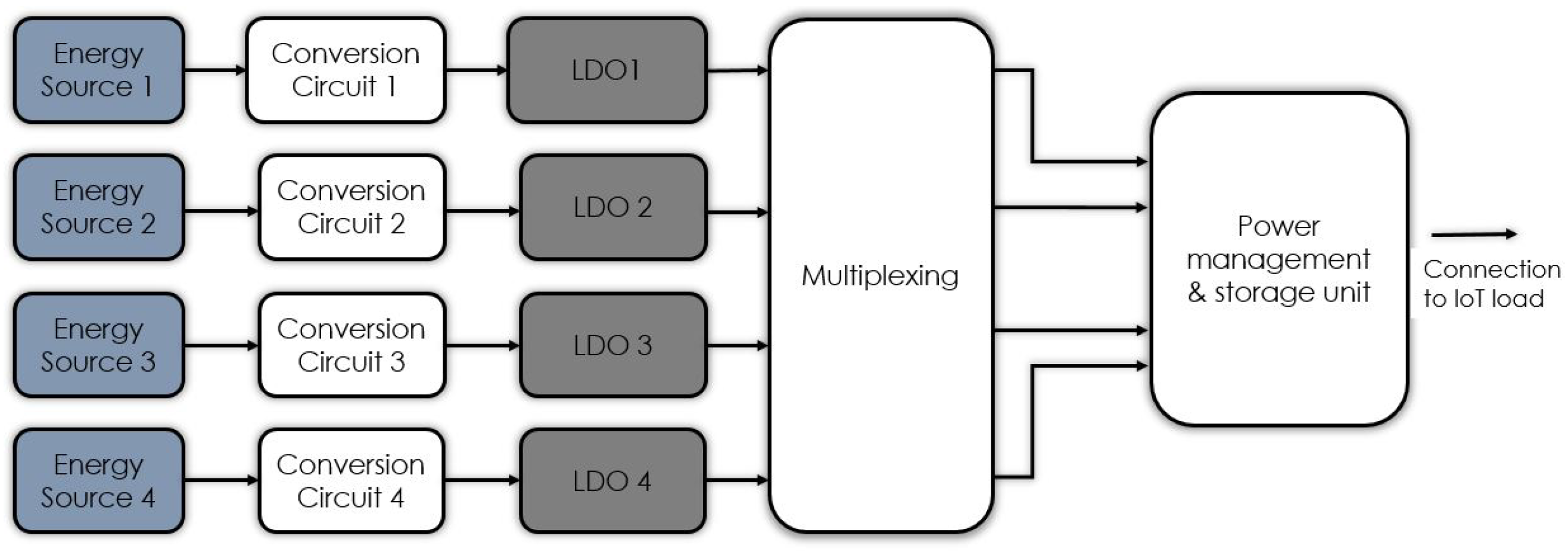

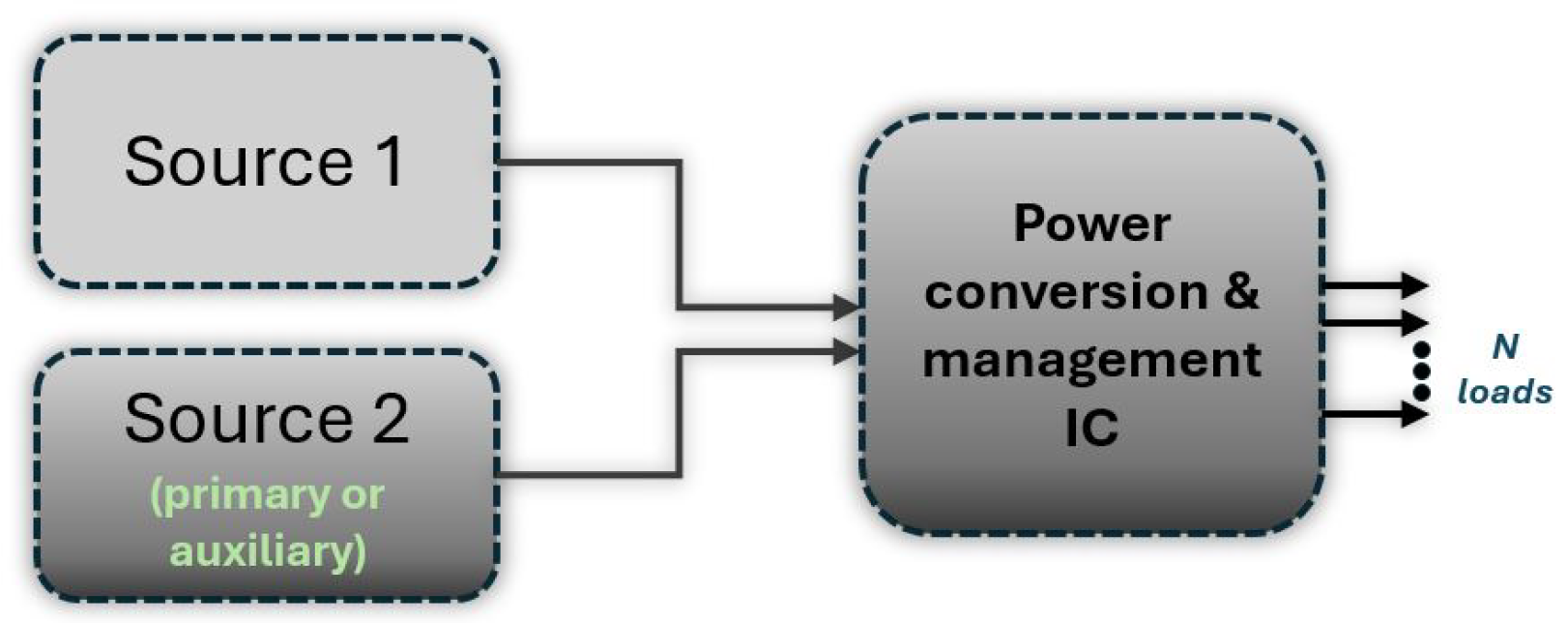

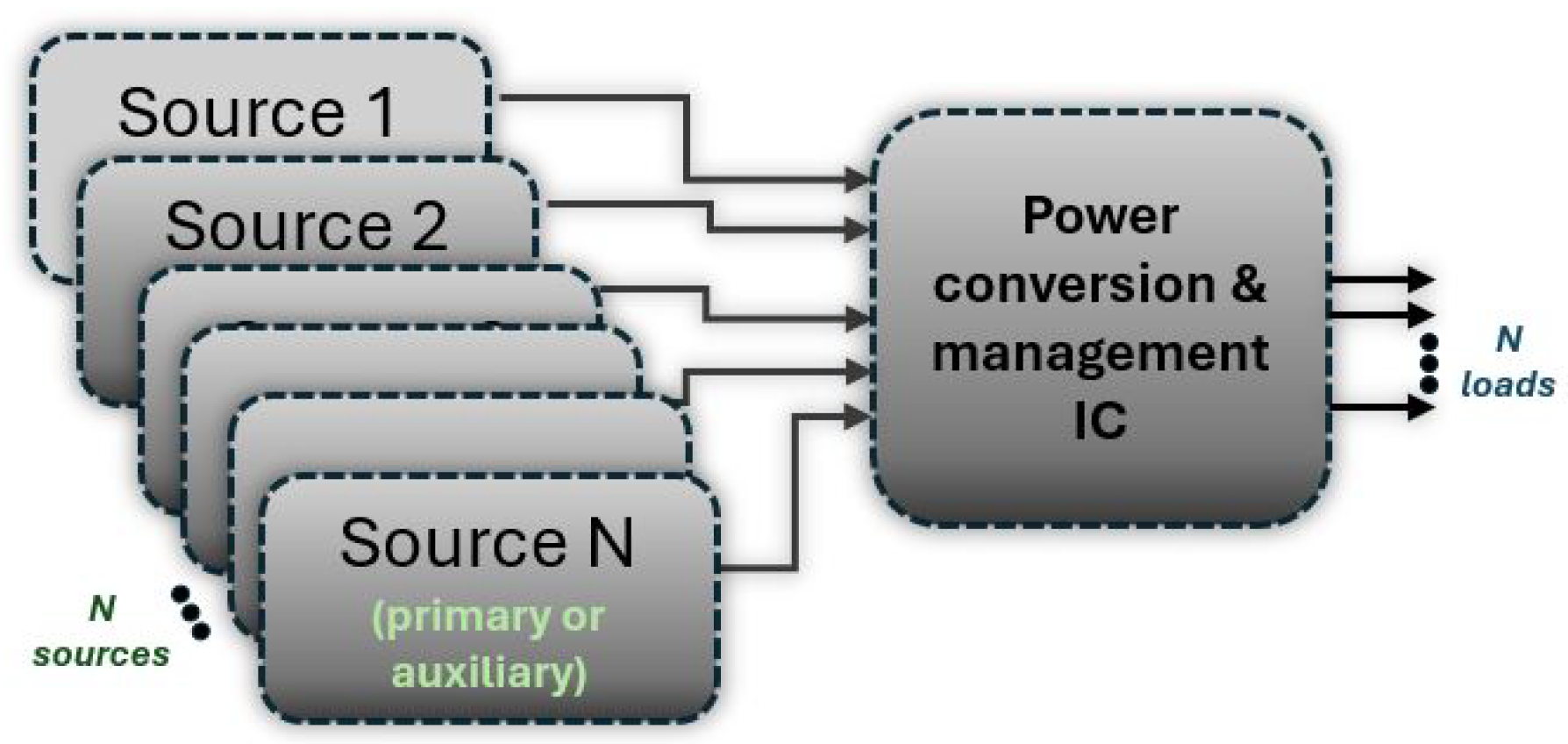

2.2. Main Types of Energy Harvesting System Architectures

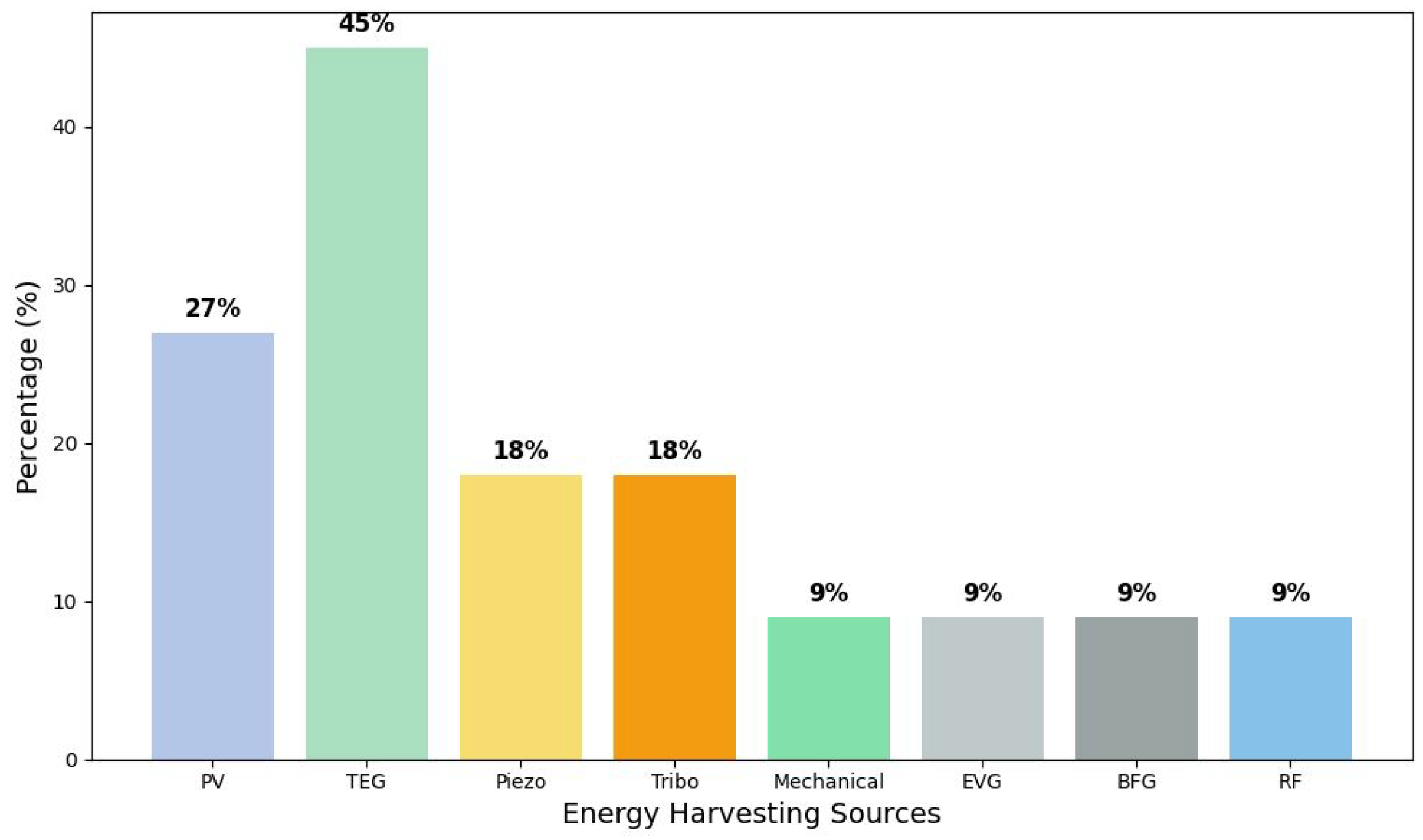

2.3. Overview of State-of-the-Art Multi-Source Energy Harvesting Systems

- : The maximum output power of the system delivered to the load.

- eff: Maximum efficiency of the system.

- Silicon Area: The silicon footprint of the system.

- : Number of external components used for the system.

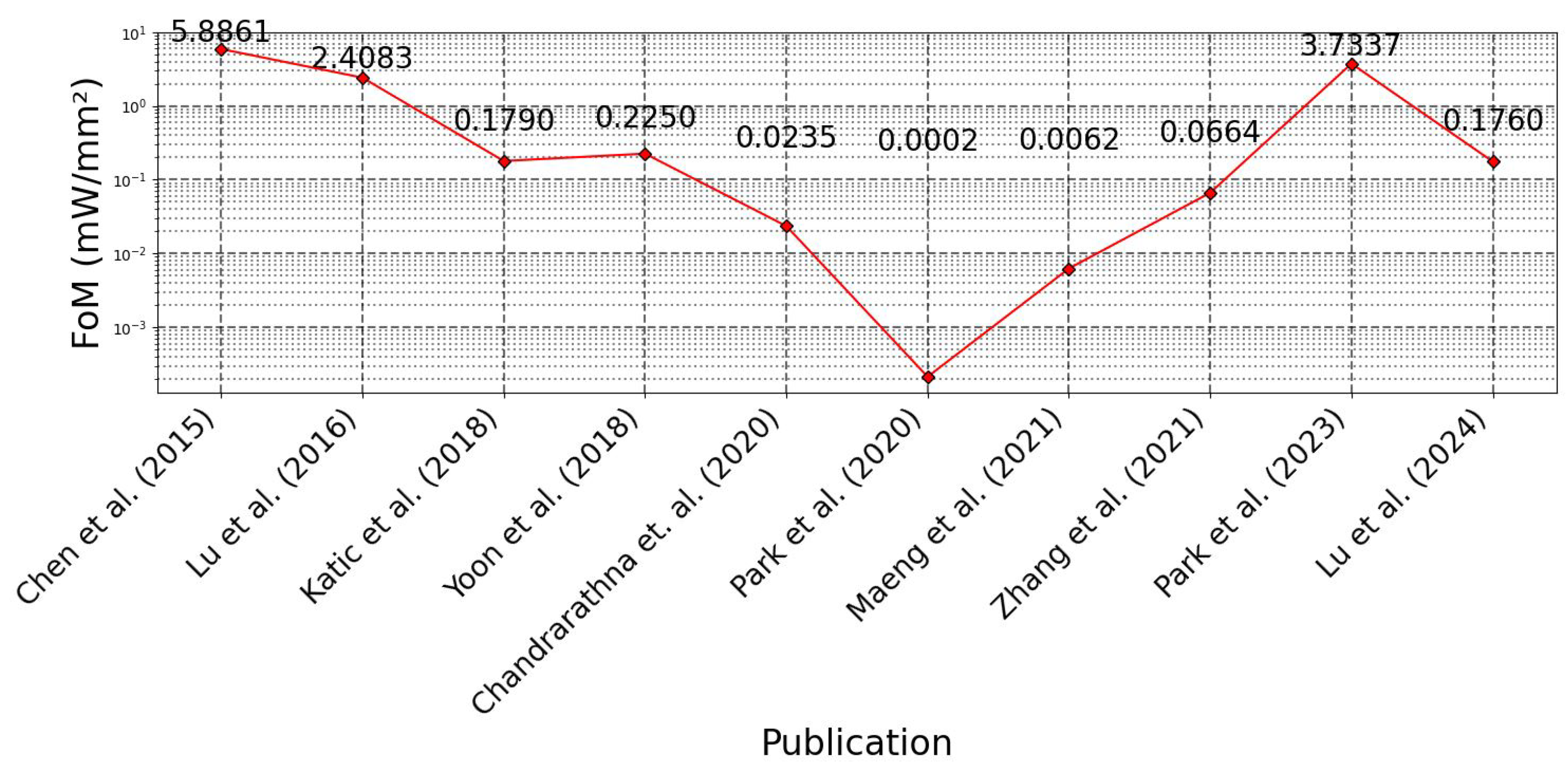

2.3.1. Dual Input Energy Harvesting Systems

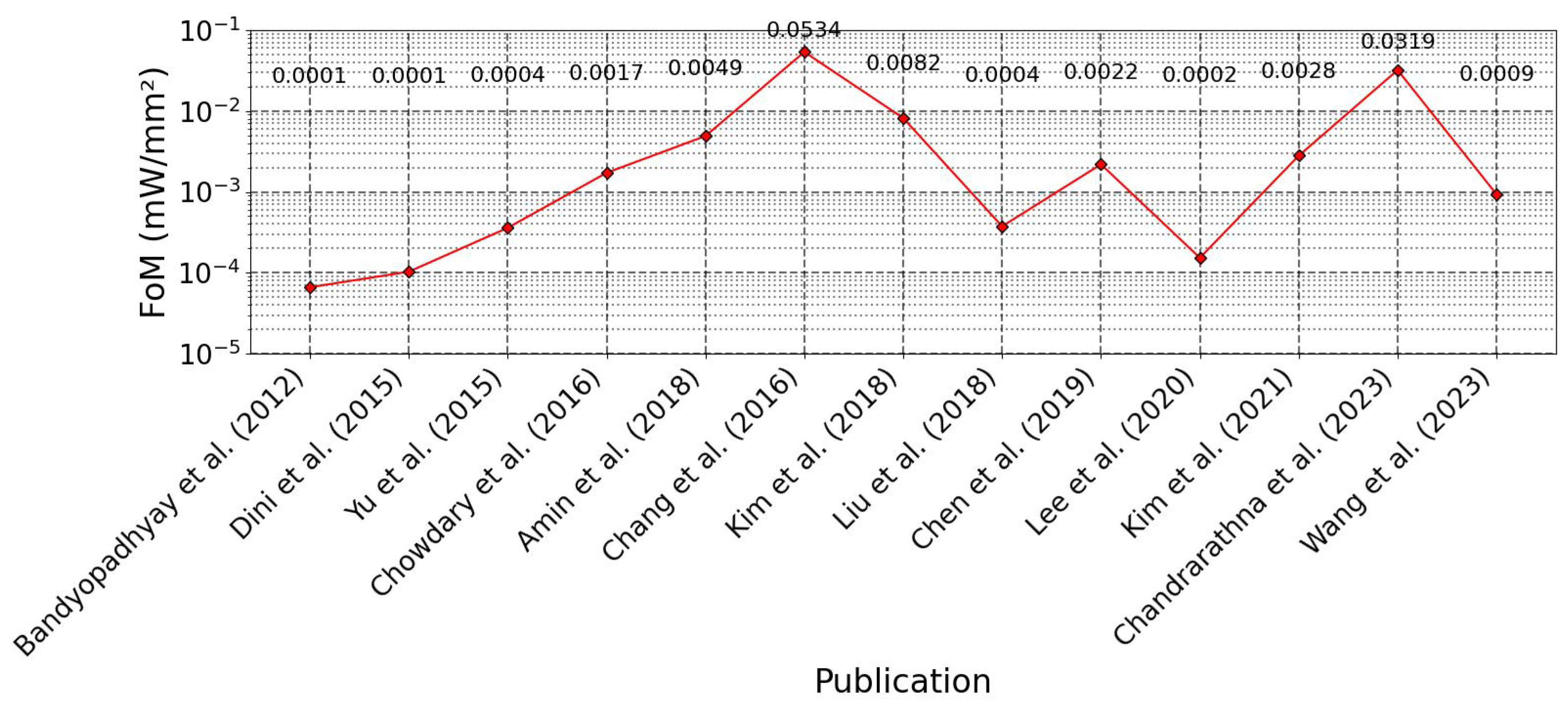

2.3.2. Multi-Input Energy Harvesting Systems

2.3.3. Challenges and Strategies for State-of-the-Art Multi-Source Energy Harvesting Systems

2.3.4. Advancing Toward True Simultaneous Energy Harvesting

3. Discussion and Future Directions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Qaim, W.B.; Ometov, A.; Molinaro, A.; Lener, I.; Campolo, C.; Lohan, E.S.; Nurmi, J. Towards energy efficiency in the internet of wearable things: A systematic review. IEEE Access 2020, 8, 175412–175435. [Google Scholar] [CrossRef]

- Niu, S.; Zhang, C.; Shi, Y.; Niu, S.; Jian, L. Foreign object detection considering misalignment effect for wireless EV charging system. ISA Trans. 2022, 130, 655–666. [Google Scholar] [CrossRef] [PubMed]

- Niu, S.; Zhao, Q.; Chen, H.; Niu, S.; Jian, L. Noncooperative Metal Object Detection Using Pole-to-Pole EM Distribution Characteristics for Wireless EV Charger Employing DD Coils. IEEE Trans. Ind. Electron. 2024, 71, 6335–6344. [Google Scholar] [CrossRef]

- Niu, S.; Niu, S.; Zhang, C.; Jian, L. Blind-Zone-Free Metal Object Detection for Wireless EV Chargers Employing DD Coils by Passive Electromagnetic Sensing. IEEE Trans. Ind. Electron. 2023, 70, 965–974. [Google Scholar] [CrossRef]

- Sun, Y.; Li, Y.Z.; Yuan, M. Requirements, challenges, and novel ideas for wearables on power supply and energy harvesting. Nano Energy 2023, 115, 108715. [Google Scholar] [CrossRef]

- Mitcheson, P.D.; Yeatman, E.M.; Rao, G.K.; Holmes, A.S.; Green, T.C. Energy Harvesting from Human and Machine Motion for Wireless Electronic Devices. Proc. IEEE 2008, 96, 1457–1486. [Google Scholar] [CrossRef]

- Sanislav, T.; Mois, G.D.; Zeadally, S.; Folea, S.C. Energy Harvesting Techniques for Internet of Things (IoT). IEEE Access 2021, 9, 39530–39549. [Google Scholar] [CrossRef]

- Liu, H.; Fu, H.; Sun, L.; Lee, C.; Yeatman, E.M. Hybrid energy harvesting technology: From materials, structural design, system integration to applications. Renew. Sustain. Energy Rev. 2020, 137, 110473. [Google Scholar] [CrossRef]

- International Roadmap for Devices and Systems (IRDS™) 2023 Update: More Moore. Available online: https://irds.ieee.org/images/files/pdf/2023/2023IRDS_MM.pdf (accessed on 26 February 2025).

- Mandourarakis, I.; Gogolou, V.; Koutroulis, E.; Siskos, S. Integrated Maximum Power Point Tracking System for Photovoltaic Energy Harvesting Applications. IEEE Trans. Power Electron. 2022, 37, 9865–9875. [Google Scholar] [CrossRef]

- Gogolou, V.; Karipidis, S.; Noulis, T.; Siskos, S. A frequency boosting technique for cold-start charge pump units. Integration 2024, 94, 102076. [Google Scholar] [CrossRef]

- Gogolou, V.; Voulkidou, A.; Karipidis, S.; Noulis, T.; Siskos, S. Design of crosstalk aware energy harvesting system-on-chip. AEU-Int. J. Electron. Commun. 2023, 170, 154850. [Google Scholar] [CrossRef]

- Li, B.; Hou, B.; Amaratunga, G.A.J. Indoor photovoltaics, The Next Big Trend in solution-processed solar cells. InfoMat 2021, 3, 445–459. [Google Scholar] [CrossRef]

- Jaziri, N.; Boughamoura, A.; Müller, J.; Mezghani, B.; Tounsi, F.; Ismail, M. A comprehensive review of Thermoelectric Generators: Technologies and common applications. Energy Rep. 2020, 6, 264–287. [Google Scholar] [CrossRef]

- Liu, S.; Hu, B.; Liu, D.; Li, F.; Li, J.F.; Li, B.; Li, L.; Lin, Y.H.; Nan, C.W. Micro-thermoelectric generators based on through glass pillars with high output voltage enabled by large temperature difference. Appl. Energy 2018, 225, 600–610. [Google Scholar] [CrossRef]

- Talkhooncheh, A.H.; Yu, Y.; Agarwal, A.; Kuo, W.W.T.; Chen, K.C.; Wang, M.; Hoskuldsdottir, G.; Gao, W.; Emami, A. A biofuel-cell-based energy harvester with 86% peak efficiency and 0.25-V minimum input voltage using source-adaptive MPPT. IEEE J.-Solid-State Circuits 2021, 56, 715–728. [Google Scholar] [CrossRef]

- Bairagi, S.; Shahid-ul-Islam; Shahadat, M.; Mulvihill, D.M.; Ali, W. Mechanical energy harvesting and self-powered electronic applications of textile-based piezoelectric nanogenerators: A systematic review. Nano Energy 2023, 111, 108414. [Google Scholar] [CrossRef]

- Walden, R.; Kumar, C.; Mulvihill, D.M.; Pillai, S.C. Opportunities and Challenges in Triboelectric Nanogenerator (TENG) based Sustainable Energy Generation Technologies: A Mini-Review. Chem. Eng. J. Adv. 2022, 9, 100237. [Google Scholar] [CrossRef]

- Ramalingam, L.; Mariappan, S.; Parameswaran, P.; Rajendran, J.; Nitesh, R.S.; Kumar, N.; Nathan, A.; Yarman, B.S. The Advancement of Radio Frequency Energy Harvesters (RFEHs) as a Revolutionary Approach for Solving Energy Crisis in Wireless Communication Devices: A Review. IEEE Access 2021, 9, 106107–106139. [Google Scholar] [CrossRef]

- Xie, L.; Song, W.; Ge, J.; Tang, B.; Zhang, X.; Wu, T.; Ge, Z. Recent progress of organic photovoltaics for indoor energy harvesting. Nano Energy 2021, 82, 105770. [Google Scholar] [CrossRef]

- Yan, J.; Liao, X.; Yan, D.; Chen, Y. Review of Micro Thermoelectric Generator. J. Microelectromechanical Syst. 2018, 27, 1–18. [Google Scholar] [CrossRef]

- Slate, A.J.; Whitehead, K.A.; Brownson, D.A.C.; Banks, C.E. Microbial fuel cells: An overview of current technology. Renew. Sustain. Energy Rev. 2019, 101, 60–81. [Google Scholar] [CrossRef]

- Song, J.; Gao, L.; Tao, X.; Li, L. Ultra-Flexible and Large-Area Textile-Based Triboelectric Nanogenerators with a Sandpaper-Induced Surface Microstructure. Materials 2018, 11, 2120. [Google Scholar] [CrossRef] [PubMed]

- De Mil, P.; Jooris, B.; Tytgat, L.; Catteeuw, R.; Moerman, I.; Demeester, P.; Kamerman, A. Design and Implementation of a Generic Energy-Harvesting Framework Applied to the Evaluation of a Large-Scale Electronic Shelf-Labeling Wireless Sensor Network. EURASIP J. Wirel. Commun. Netw. 2010, 2010, 343690. [Google Scholar] [CrossRef]

- Cabello, D.; Ferro, E.; Pereira-Rial, Ó; Martínez-Vázquez, B.; Brea, V.M.; Carrillo, J.M.; López, P. On-Chip Solar Energy Harvester and PMU with Cold Start-Up and Regulated Output Voltage for Biomedical Applications. IEEE Trans. Circuits Syst. I Regul. Pap. 2020, 67, 1103–1114. [Google Scholar] [CrossRef]

- Rozgić, D.; Marković, D. A Miniaturized 0.78-mW/cm2 Autonomous Thermoelectric Energy-Harvesting Platform for Biomedical Sensors. IEEE Trans. Biomed. Circuits Syst. 2017, 11, 773–783. [Google Scholar] [CrossRef]

- Kwon, D.; Rincón-Mora, G.A. A Single-Inductor 0.35 µm CMOS Energy-Investing Piezoelectric Harvester. IEEE J.-Solid-State Circuits 2014, 49, 2277–2291. [Google Scholar] [CrossRef]

- Katic, J.; Rodriguez, S.; Rusu, A. A Dual-Output Thermoelectric Energy Harvesting Interface with 86.6% Peak Efficiency at 30 uW and Total Control Power of 160 nW. IEEE J.-Solid-State Circuits 2016, 51, 1928–1937. [Google Scholar] [CrossRef]

- Ozaki, T.; Hirose, T.; Asano, H.; Kuroki, N.; Numa, M. Fully-Integrated High-Conversion-Ratio Dual-Output Voltage Boost Converter with MPPT for Low-Voltage Energy Harvesting. IEEE J.-Solid-State Circuits 2016, 51, 2398–2407. [Google Scholar] [CrossRef]

- Abdelmagid, B.A.; Hmada, M.H.K.; Mohieldin, A.N. An Adaptive Fully Integrated Dual-Output Energy Harvesting System with MPPT and Storage Capability. IEEE Trans. Circuits Syst. Regul. Pap. 2023, 70, 593–606. [Google Scholar] [CrossRef]

- Song, S.; Wang, D.; Li, M.; Cao, S.; Zheng, F.; Huang, K.; Tan, Z.; Du, S.; Zhao, M. Low-Power On-Chip Energy Harvesting: From Interface Circuits Perspective. IEEE Open J. Circuits Syst. 2024, 5, 267–290. [Google Scholar] [CrossRef]

- Gomathy, S.; Senthilnathan, N.; Swathi, S.; Poorviga, R.; Dinakaran, P. Review on multi-input multi output dc-dc converter. Int. J. Sci. Technol. Res. 2020, 9, 428–440. [Google Scholar]

- Maghami, I.; Victor, V.A.; Morsy, M.M.; Lach, J.C.; Goodall, J.L. Exploring the complementary relationship between solar and hydro energy harvesting for self-powered water monitoring in low-light conditions. Environ. Model. Softw. 2021, 140, 105032. [Google Scholar] [CrossRef]

- Tan, Y.K.; Panda, S.K. Energy Harvesting From Hybrid Indoor Ambient Light and Thermal Energy Sources for Enhanced Performance of Wireless Sensor Nodes. IEEE Trans. Ind. Electron. 2011, 58, 4424–4435. [Google Scholar] [CrossRef]

- Kang, T.; Kim, S.; Hyoung, C.; Kang, S.; Park, K. An Energy Combiner for a Multi-Input Energy-Harvesting System. IEEE Trans. Circuits Syst. II Express Briefs 2015, 62, 911–915. [Google Scholar] [CrossRef]

- Colomer-Farrarons, J.; Miribel-Catala, P.; Saiz-Vela, A.; Samitier, J. A Multiharvested Self-Powered System in a Low-Voltage Low-Power Technology. IEEE Trans. Ind. Electron. 2011, 58, 4250–4263. [Google Scholar] [CrossRef]

- Amin, S.S.; Mercier, P.P. MISIMO: A multi-input single-inductor multi-output energy harvesting platform in 28-nm fdsoi for powering net-zero-energy systems. IEEE J. Solid-State Circuits 2018, 53, 3407–3419. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Chandrakasan, A.P. Platform Architecture for Solar, Thermal, and Vibration Energy Combining with MPPT and Single Inductor. IEEE J. Solid-State Circuits 2012, 47, 2199–2215. [Google Scholar] [CrossRef]

- Chou, Y.Y.; Wu, C.C.; Chen, Y.H.; Huang, Y.C.; Chiu, Y.C.; Tsai, L.J.; Hsieh, W.C.; Li, W.C.; Huang, Y.J.; Lu, S.S. Multi-input energy harvesting interface for low-power biomedical sensing system. In Proceedings of the 2014 International Symposium on Next-Generation Electronics (ISNE), Kwei-Shan Tao-Yuan, Taiwan, 7–10 May 2014; pp. 2–3. [Google Scholar] [CrossRef]

- Chen, H.J.; Wang, Y.H.; Huang, P.C.; Kuo, T.H. An energy-recycling three-switch single-inductor dual-input buck/boost DC-DC converter with 93% peak conversion efficiency and 0.5 mm2 active area for light energy harvesting. Dig. Tech. Pap.-IEEE Int. Solid-State Circuits Conf. 2015, 58, 374–375. [Google Scholar] [CrossRef]

- Lu, Y.; Yao, S.; Shao, B.; Brokaw, P. A 200 nA single-inductor dual-input-triple-output (DITO) converter with two-stage charging and process-limit cold-start voltage for photovoltaic and thermoelectric energy harvesting. Dig. Tech. Pap.-IEEE Int. Solid-State Circuits Conf. 2016, 59, 368–369. [Google Scholar] [CrossRef]

- Katic, J.; Rodriguez, S.; Rusu, A. A high-efficiency energy harvesting interface for implanted biofuel cell and thermal harvesters. IEEE Trans. Power Electron. 2018, 33, 4125–4134. [Google Scholar] [CrossRef]

- Yoon, K.S.; Hong, S.W.; Cho, G.H. Double Pile-Up Resonance Energy Harvesting Circuit for Piezoelectric and Thermoelectric Materials. IEEE J. Solid-State Circuits 2018, 53, 1049–1060. [Google Scholar] [CrossRef]

- Chandrarathna, S.C.; Lee, J.W. A 580 nW Dual-Input Energy Harvester IC Using Multi-Task MPPT and a Current Boost Converter for Heterogeneous Source Combining. IEEE Trans. Circuits Syst. I Regul. Pap. 2020, 67, 5650–5663. [Google Scholar] [CrossRef]

- Park, I.; Maeng, J.; Shim, M.; Jeong, J.; Kim, C. A High-Voltage Dual-Input Buck Converter Achieving 52.9% Maximum End-to-End Efficiency for Triboelectric Energy-Harvesting Applications. IEEE J. Solid-State Circuits 2020, 55, 1324–1336. [Google Scholar] [CrossRef]

- Maeng, J.; Park, I.; Shim, M.; Jeong, J.; Kim, C. A High-Voltage Dual-Input Buck Converter with Bidirectional Inductor Current for Triboelectric Energy-Harvesting Applications. IEEE J. Solid-State Circuits 2021, 56, 541–553. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhan, C.; Law, M.K.; Jiang, Y.; Mak, P.I.; Martins, R.P. A High-Efficiency Dual-Antenna RF Energy Harvesting System Using Full-Energy Extraction with Improved Input Power Response. IEEE Open J. Circuits Syst. 2021, 2, 436–444. [Google Scholar] [CrossRef]

- Park, I.; Jeon, J.; Kim, H.; Park, T.; Jeong, J.; Kim, C. A Thermoelectric Energy-Harvesting Interface with Dual-Conversion Reconfigurable DC-DC Converter and Instantaneous Linear Extrapolation MPPT Method. IEEE J. Solid-State Circuits 2023, 58, 1706–1718. [Google Scholar] [CrossRef]

- Lu, T.; Wang, R.; Tang, Z.; Zou, Y.; Yue, X.; Liang, Y.; Gong, H.; Liu, S.; Chen, Z.; Liu, X.; et al. A Thermoelectric Energy Harvesting System Assisted by a Piezoelectric Transducer Achieving 10-MV Cold-Startup and 82.7% Peak Efficiency. IEEE Trans. Power Electron. 2024, 39, 6352–6363. [Google Scholar] [CrossRef]

- Dini, M.; Romani, A.; Filippi, M.; Bottarel, V.; Ricotti, G.; Tartagni, M. A nanocurrent power management IC for multiple heterogeneous energy harvesting sources. IEEE Trans. Power Electron. 2015, 30, 5665–5680. [Google Scholar] [CrossRef]

- Yu, G.; Chew, K.W.R.; Sun, Z.C.; Tang, H.; Siek, L. A 400 nW Single-Inductor Dual-Input-Tri-Output DC-DC Buck-Boost Converter with Maximum Power Point Tracking for Indoor Photovoltaic Energy Harvesting. IEEE J. Solid-State Circuits 2015, 50, 2758–2772. [Google Scholar] [CrossRef]

- Chowdary, G.; Singh, A.; Chatterjee, S. An 18 nA, 87% Efficient Solar, Vibration and RF Energy-Harvesting Power Management System with a Single Shared Inductor. IEEE J. Solid-State Circuits 2016, 51, 2501–2513. [Google Scholar] [CrossRef]

- Chang, C.L.; Lee, T.C. An thermoelectric and RF multi-source energy harvesting system. In Proceedings of the 2016 2nd International Conference on Intelligent Green Building and Smart Grid (IGBSG), Prague, Czech Republic, 27–29 June 2016. [Google Scholar] [CrossRef]

- Kim, S.; Vaidya, V.; Schaef, C.; Lines, A.; Krishnamurthy, H.; Weng, S.; Liu, X.; Kurian, D.; Karnik, T. A Single-Stage, Single-Inductor, 6-Input 9-Output Multi-Modal Energy Harvesting Power Management IC for 100 uW–120 MW Battery-Powered IoT Edge Nodes. In Proceedings of the 2018 IEEE Symposium on VLSI Circuits, Honolulu, HI, USA, 18–22 June 2018; pp. 195–196. [Google Scholar] [CrossRef]

- Liu, C.W.; Lee, H.H.; Liao, P.C.; Chen, Y.L.; Chung, M.J.; Chen, P.H. Dual-Source Energy-Harvesting Interface with Cycle-by-Cycle Source Tracking and Adaptive Peak-Inductor-Current Control. IEEE J. Solid-State Circuits 2018, 53, 2741–2750. [Google Scholar] [CrossRef]

- Chen, P.H.; Cheng, H.C.; Lo, C.L. A Single-Inductor Triple-Source Quad-Mode Energy-Harvesting Interface with Automatic Source Selection and Reversely Polarized Energy Recycling. IEEE J. Solid-State Circuits 2019, 54, 2671–2679. [Google Scholar] [CrossRef]

- Lee, H.H.; Liu, C.W.; Takamiya, M.; Chen, P.H. Single-Inductor Dual-Input Dual-Output Battery-PV Hybrid System with 2-D Adaptive On-Time Control for Internet of Things. IEEE Trans. Circuits Syst. I Regul. Pap. 2020, 67, 1069–1078. [Google Scholar] [CrossRef]

- Liang, Z.; Yuan, J. An event-driven multi-input multi-output buck-boost converter with adaptive MPPT for wide power range RF energy harvesting. In Proceedings of the 2021 IEEE International Symposium on Circuits and Systems (ISCAS), Daegu, Republic of Korea, 22–28 May 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Kim, H.; Maeng, J.; Park, I.; Jeon, J.; Lim, D.; Kim, C. A 90.2% peak efficiency multi-input single-inductor multi-output energy harvesting interface with double-conversion rejection technique and buck-based dual-conversion mode. IEEE J. Solid-State Circuits 2021, 56, 961–971. [Google Scholar] [CrossRef]

- Chandrarathna, S.C.; Moon, S.Y.; Lee, J.W. A Power Management System for Hybrid Energy Harvesting From Multiple Multitype Sources and Ultrawide Range Source Tracking. IEEE Trans. Power Electron. 2023, 38, 4859–4875. [Google Scholar] [CrossRef]

- Wang, X.; Xia, Y.; Zhu, Z.; Shi, G.; Xia, H.; Ye, Y.; Chen, Z.; Qian, L.; Liu, L. Configurable Hybrid Energy Synchronous Extraction Interface with Serial Stack Resonance for Multi-Source Energy Harvesting. IEEE J. Solid-State Circuits 2023, 58, 451–461. [Google Scholar] [CrossRef]

- Helaly, A.A.; Abu-Elyazeed, M.F.; Mohieldin, A.N. An Integrated Simultaneous Thermal/RF Energy Harvesting System for Wireless Sensor Networks. In Proceedings of the 2022 IEEE 31st International Symposium on Industrial Electronics (ISIE), Anchorage, AK, USA, 1–3 June 2022; pp. 78–83. [Google Scholar] [CrossRef]

- Helaly, A.A.; Mohieldin, A.N. An integrated thermal and RF energy harvesting system with rectifying combination and storage controller for IoT devices. Microelectron. J. 2023, 142, 106020. [Google Scholar] [CrossRef]

| Energy Harvesting Technology | Type/Material | Power Density (μW/cm−2) | Indicative Application |

|---|---|---|---|

| Organic Solar Cells [20] | P3HT: ICBA | 22.57 (@ 500 lux) | Fluorescent light indoor energy harvesting (e.g., office) |

| PTB7:PC71BM (0.15 cm2) | 15.487 (@ 500 lux) | LED lamp indoor energy harvesting | |

| PM6:PC71BM (1 cm2) | 54.69 (@ 300 lux) | dim indoor light harvesting | |

| Micro-TEGs 1 [21] | Bi0.5Sb1.5Te3/Be2Te2.4Se0.6 thin-film | 0.0016 | Sensor power up (IR sensors, flow sensors, power sensors) |

| Bi2Te3-based flexible | 0.0026 | Human body applications | |

| Silicon-based monolithic planar | 0.000032 | wearables | |

| Microbial Fuel Cells [22] | Deltaproteobacterium | 1.4 | Low-power marine sensors power up |

| Gammaproteobacteria, Shewanella affinis | 3.6 | Biocatalytic fuel cells for medical or environmental biosensing | |

| Betaproteobacteria | 4.0 ± 0.2 | Bio-batteries or lab-on-a-chip systems for microelectronic or wearable devices | |

| Piezoelectric Transducers [17] | PVDF-Ce-G | 0.56 | Pressure based energy harvesting |

| PVDF-Er3+/Fe3+ | 76.8 | Capacitor charging | |

| PVDF-TrFE-BT NPs | 5.05 | Biomechanical energy harvesting | |

| Triboelectric Nanogenerators [23] | Fiber-based | 8.5 | Wearable energy harvesting |

| All-fiber | 70 | Smart textiles and self-powered sensors | |

| Textile-based | 0.1 | Wearable devices, motion sensors | |

| Radio Frequency [24] | Radio GSM | 0.1 | Low-power sensors, wearable trackers, asset tags in urban environments |

| WiFi | 0.001 | Passive RFID-like sensors, smart home buttons, ultra-low-power IoT devices |

| Ref. | Year | Process (nm) | Input Type | No. Load | Vin Range | Pout Max (mW) | Peak Efficiency | Area (mm2) | External Components | Battery |

|---|---|---|---|---|---|---|---|---|---|---|

| [39] | 2014 | 350 | PV, mechanical | 1 | 0.2–1.7 V | n/a | 73% | 4 | Cload, L (values n/a) | yes |

| [40] | 2015 | 500 V CMOS | Battery, PV | 1 | PV: 40 μW | 15 | 93% | 0.79 | L = 10 H, CPV = 4.7 F, Co = 4.7 F | yes |

| [41] | 2016 | 350 | PV, Battery | 3 | 1 V Voc | 34 | 85% | 4 | L = 22 H, Cin = 4.7 F, Cout = 4.7 F | yes |

| [42] | 2017 | 180 | BFC, TEG | 2 | TEG: 10–90 mV, BFC: 26–250 mV | 2.3 | 85.2% TEG, 90.4% GBFC, 89.5% Combined | 2.3 | L = 100 H, CIN1 = 4.7 F, CIN2 = 10 F, CST = 100 nF, CCTRL = 30 nF, switch | no |

| [43] | 2018 | 180 | Piezo, TEG | 1 | PZT: 0.6 V, @ 140 Hz TEG: 0.1–0.5 V | 0.45 | 75% | 1.5 | L = 680 H | yes |

| [44] | 2020 | 180 | EVG, TEG | 1 | EVG: 0.5–1 Vp, TEG: 25–100 mV | 0.119 | 82% | 0.83 | CIN = 1 F, CTEG = 0.1 F, C12 = 7.6 F, COUT = 10 F, L = 1 mH | yes |

| [45] | 2020 | 180 BCD | Tribo × 2 | 1 | 70 V | 0.01 | 52.90% | 2.482 | R = 30 GOhm × 4, L = 1 mH × 1, C = 5 F × 5 | no |

| [46] | 2020 | 180 BCD | Tribo × 2 | 1 | <70 V | 0.042 | 75.60% | 1.694 | L = 10 mH, C = 1 F × 2 | yes |

| [47] | 2021 | 180 | RF × 2 | 1 | 915 MHz | 0.03 | 75.20% | 0.085 | Cb = 1 nF × 2, Cs = 1 F, L = 10 H | yes |

| [48] | 2023 | 180 | TEG, Battery | 1 | TEG: 0.1–0.6 V, Battery: 1.5 V | 31.5 | 90.48% | 2.531 | R = 0.3 Ohm, R_LDO = 84 MOhm, R = 40 MOhm | yes |

| [49] | 2024 | 180 BCD | TEG, Piezo (aux) | 1 | PZT: 1.8 Vp @ 280 Hz, TEG (DC emulation) 10–100 mV | 0.44 | 63.90% | 0.4 | L = 220 H, Rldo1 = 84 MOHm, Rldo2 = 40 MOhm, Cbuf = n/a | no |

| Ref. | Year | Process (nm) | Input Type | No. Load | Vin Range | Pout Max (mW) | Peak Efficiency | Area (mm2) | External Components | Battery |

|---|---|---|---|---|---|---|---|---|---|---|

| [38] | 2012 | 350 | PV, TEG, Piezo | 2 | TEG: 20 mV–0.16 V, PV: 0.15–0.75 V, Piezo: 1.5–5 V | 10 | 58% TEG, 83% PV, 79% Piezo | 25 | L = 22 H, C = 15 F, CPV = 47 F, CTEG = 94 F, CPz = 1 F | yes |

| [50] | 2015 | 320 BCD | Piezo, TEG, PV, RF | 1 | PZ: 0.7–5 V, LV: 0.1–1 V, HV: 1–5 V | 2.12 | 89.60% | 4.6 | CST = 66 F, L = 10 mH, CbHV1 = 2.7 F, CbLV = 22 F | no |

| [51] | 2015 | 180 | PV, Battery | 3 | PV: 1.5 V, Vbat: 2.5 V | 10 | 83% | 4.62 | L = 10 H, 4 × C = 10 F | yes |

| [52] | 2016 | 180 | PV, Piezo, RF | 1 | PV: 0.2–1.2 V, RF, Piezo n/a | 9 | 84% | 1.1 | L = 44 H, CB = 10 F, CD = 10 F, Cstore = 100 F | no |

| [53] | 2016 | 40 | TEG, RF | 1 | RF 100 μW–5 mW, TEG: 50–300 mV | 36 | 85.5% TEG, 93.8% RF | 1.38 | CIN1 = 4.7 F, CIN2 = 22 mF, CSTO = 2.6 mF, CL = 47 F, LLTO = 8.2 H | no |

| [37] | 2018 | 28 FDSOI | PV, TEG, BFC, Battery | 4 | PV: 0.2–1 V, TEG: 0.1–0.4 V, BFC: 0.2–0.5 V, Battery: 1.8 V | 60 | 89% | 0.5 | 10 H, Cout = 1 F | yes |

| [54] | 2018 | 180 | PV, Piezo | 9 | n/a | 120 | 71.90% | 5.29 | L, Cout (values n/a) | yes |

| [55] | 2018 | 180 | PV, TEG, Storage | 3 | PV: 0.4–0.8 V, TEG: 0.05–0.3 V | 4 | 84.40% | 1.8 | 4 L = 4.7 H, CPV/CTEG = 10 F, COUT1 = 1 F, COUT2 = 1 F, COUT3 = 100 F | no |

| [56] | 2019 | 180 | PV × 2, TEG | 1 | 0.1–0.8 V | 10 | 82% | 0.75 | L = 4.7 H, CPV1/CPV2 = 0.1 F, CTEG = 1 F, COUT = 10 F, CSTO = 100 F | no |

| [57] | 2019 | 180 | PV, Battery | 2 | PV: 0.55–0.7 V, Vbat: 1.4 V | 1.2 | 92.50% | 2.415 | 4.7 H, Caps × 2 (value n/a) | yes |

| [58] | 2021 | 180 | RF × 2 | 2 | 240–440 mV | n/a | 85% | n/a | L = 47 H, CH1 = 2 F, CH2 = 1 F, CL1 = 10 F, CL2 = 100 F, CSTO = 100 F | no |

| [59] | 2021 | 180 | PV, TEG, BFC | 3 | PV: 1.45–1.8 V, BFC: 0.2–0.7 V, TEG: 0.03–0.09 V | 24 | 90.20% | 2.58 | L = 4.7 H, Cin = 10 F, Cout = 2.2 F | yes |

| [60] | 2023 | 180 | PV, TEG, Piezo, PEG, MEG, RF | 3 | PV1: 2–5 V, PV2: 20–120 mV, TEG/BFC: 0.03–0.5 V, PEG/MEG: 1.8–5 V, RF: 2–5 V | 132.6 | 92.50% | 1.92 | L = 80 H, SCs = 22 mF | yes |

| [61] | 2023 | 180 | Piezo × 2, TEG, PV | 1 | PZT × 2: 0.5–2 V, TEG: 0.05–0.4 V, PV: 0.2–1.5 V | 5 | 84% PV, 76% TEG, 76.5% PZT | 0.9 | L = 470 H, CPV = 4.7 F, CTEG = 22 F, CSTO = 22 F, Csamp = 1 nF | no |

| Ref. | Year | Process (nm) | Input Type | No. Load | Vin Range | Pout Max (mW) | Peak Efficiency | Area (mm2) | External Components | Battery |

|---|---|---|---|---|---|---|---|---|---|---|

| [62] | 2019 | 180 | DC-like emulation | 1 | 25 W to 600 W | 0.5 | 55% | n/a | none | no |

| [63] | 2023 | 180 | TEG, RF | 2 | DC: 300 mV, RF: −2 dBm | 1.275 | 60.30% | 3.33 | none | no |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gogolou, V.; Noulis, T.; Pavlidis, V.F. Multi-Source Energy Harvesting Systems Integrated in Silicon: A Comprehensive Review. Electronics 2025, 14, 1951. https://doi.org/10.3390/electronics14101951

Gogolou V, Noulis T, Pavlidis VF. Multi-Source Energy Harvesting Systems Integrated in Silicon: A Comprehensive Review. Electronics. 2025; 14(10):1951. https://doi.org/10.3390/electronics14101951

Chicago/Turabian StyleGogolou, Vasiliki, Thomas Noulis, and Vasilis F. Pavlidis. 2025. "Multi-Source Energy Harvesting Systems Integrated in Silicon: A Comprehensive Review" Electronics 14, no. 10: 1951. https://doi.org/10.3390/electronics14101951

APA StyleGogolou, V., Noulis, T., & Pavlidis, V. F. (2025). Multi-Source Energy Harvesting Systems Integrated in Silicon: A Comprehensive Review. Electronics, 14(10), 1951. https://doi.org/10.3390/electronics14101951