1. Introduction

As part of a comprehensive industrial policy over the coming years, the EU needs to build resilient supply chains, especially when it comes to raw materials or batteries. Otherwise, EU vehicle manufacturers will be at a disadvantage vis à vis competitors from other regions, compounded by rising energy prices. This includes the impact of the interim review of the CO

2 regulation, which will assess whether sufficient progress has already been made in market development, infrastructure deployment, raw material availability and, consequently, affordability. For the aforementioned reasons, we are making major changes to both the common understanding of what will be needed to meet our climate goals and the technology sector serving the aforementioned needs (new technologies such as sixth generation (6G) networks and generative artificial intelligence (AI)) (

Figure 1 and

Figure 2). These new technologies and the infrastructure and electricity needed for them create new challenges, but also new opportunities to meet commitments to build a more sustainable future across the Industry 4.0/5.0 sector. Significant progress has been made in recent years, but as the pandemic and wars in Ukraine and the Middle East have shown, the area of ensuring supply chain continuity, particularly in lean manufacturing, needs to accelerate progress, to which the concepts of using 6G in combination with AI described in this article will contribute.

The motivation to develop AI and 6G technologies in the supply chain can be based on the fact that cybersecurity attacks are becoming more sophisticated, resulting in famous breach incidents. These technologies offer enhanced capabilities to detect, prevent, and respond to cyber threats, thereby securing supply chain operations. Notable incidents of cybersecurity breaches in supply chains include Target Breach (2013), Not Petya Attack (2017), SolarWinds Hack (2020), and Colonial Pipeline Ransomware Attack (2021). Famous cybersecurity breaches in supply chains highlight the importance of enhancing supply chain security to protect against significant financial, operational, and reputational damage. Integrating AI and 6G technology into supply chain operations can help build more secure, resilient, and adaptive systems that can withstand the changing cyber threat landscape.

The introduction of 6G technology in the industrial sector, and especially in the supply chain, is an inevitable step towards the future. A review of the applications of this technology in a supply chain context is essential for several key reasons: preparation for future challenges and development opportunities, improving delivery efficiency and reducing their costs, increasing treasury transparency, improving data cybersecurity, and sustainable development. An overview of 6G applications in the supply chain is essential for companies to effectively prepare for the future. Thanks to this, they can use the full potential of this technology, improving their efficiency, security, transparency, and sustainable development. Ultimately, this review will help companies not only perform better in the current environment, but also ensure that they are ready for future challenges and opportunities.

Areas have been pre-defined in which action can more quickly translate into the improvement of the current and future situation in the field of the sustainable development of Industry 4.0/5.0, such as the following (from the easiest to implement):

Building public awareness of current and future benefits and costs; Improved measurements;

Reducing the intensity with which we withdraw resources;

The optimization of data centers to support AI workloads;

Increasing the efficiency (including through partnership activities) of the rapid implementation of environmentally friendly innovations;

Ultimately: zero waste policy;

Building markets for such activities/products/services;

Continuously protecting and maintaining achievements in this area for the benefit of the ecosystem.

Maintaining the sustainability of production processes and supply chains is one of the first and most important tasks to be performed.

The pace of technological development, including smart factories as part of Industry 4.0/5.0, means that the vagaries of supply chains seen previously cannot be repeated. The automation and computerization of supply chains, asset tracking, simulation, and the prediction of disruptions through artificial intelligence (AI) are becoming a matter of course. In selected countries, this will be facilitated by sixth-generation mobile networks, which are scheduled for full deployment in 2030. The 6G-based intelligent supply chain management within the Industry 4.0/5.0 paradigm will not only ensure a greater fluidity of supply, but also a faster response to changes in market availability or prices, enabling substitutes to be found and factored into the production process and its logistical sourcing [

1].

This article aims to outline key R&D trends in this area and identify priority developments, taking into account the advantages and opportunities offered by the Industrial Internet of Things (IIoT) and machine learning (ML). The novelty and contribution consist of creating new opportunities to create digital services/supplies, ensuring their continuity, monitoring, responding to threats, and creating alternative scenarios based on smart contracts, as well as developing own solutions and operating scenarios better suited to individual needs, including mass production personalized while minimizing environmental impact.

2. Material and Methods

2.1. Material

In the bibliometric analysis, we focused on examining the research picture reflected in publications in the field of 6G-based strategies and innovations in the area of supply chain management within the Industry 4.0 and Industry 5.0 paradigms, including those based on artificial intelligence. In the review, we used bibliometric methods as analytical tools. To guide the review, we formulated research questions on the key aspects of the above research area. These included the evolution of research topics/issues over time, the geographic distribution of research/publications, the authors and publications with the greatest impact, and topics that may shape future research agendas. It seems crucial to understand as fully as possible the current state of research, industry practices, efforts, and future research directions in the pursuit of sustainable energy solutions. The analysis and interpretation of bibliometric data collected in this way can make a significant contribution to the ongoing discussion on this topic and build a more solid basis for further analyses and research (

Figure 3).

2.2. Methods

As a tool for conducting bibliometric analyses, we used both analytical tools built into the WoS and Scopus databases, as well as the Biblioshiny component from the Bibliometrics Rv.4.1.3 package. The choice of the above tools resulted from their adaptation to bibliometric and scientometric research, offering categorization; insight into authors, documents, and sources; and the possibility of presenting results using charts and information tables with analytical functions.

3. Results

We selected research articles from two major databases: Web of Science (WOS) and Scopus due to the wide range of research findings. In creating queries tailored to our research objectives, we applied filters to ensure the selection of relevant literature. To facilitate bibliometric analysis, we limited our search to articles in English. We then manually screened the articles again, excluding articles to match our research objectives, resulting in a final sample size (

Figure 4). WoS searches were conducted using subject (searches: title, abstract, keyword plus, and author keywords), and Scopus searches were conducted using: article title, abstract, and keywords.

In the WoS database we observed the following:

With the keywords “6G”, “supply chain”, “management”, “Industry 4.0”, and related: two publications

With the keywords “6G”,“supply chain”, “Industry 4.0”, and related: three publications.

In the Scopus database we observed the following:

With the keywords “6G”, “supply chain”, “management”, “Industry 4.0”, and related: two publications

With the keywords “6G”,“supply chain”, “Industry 4.0”, and related: three publications, but only one of these was different from those observed earlier in the WoS database.

All of the above-mentioned papers are included in the results of this review and analyzed later in the article.

3.1. Current Challenges for Supply Chain

The 6G IIoT will be crucial for organizing, maintaining, controlling, and replicating today’s supply chains. As of today, the two main technologies supporting the automation and security of IIoT and supply chains are blockchain and machine learning (ML). The first facilitates efficient communication between all the partners, offering the creation of new business models, business rules, ways to share information, and distributed application classes, e.g., in the form of smart contracts. This gives both data immutability and integrity, data persistence, decentralized consensus, and auditability in distributed transactional networks. ML can be used not only for predictive maintenance, but also for predicting tasks and workloads in the supply chain and, more broadly, in logistics as a whole. A Multi-Head Attention (MHA) Gated Recurrent Unit (GRU) has even been developed for this purpose, providing high matching efficiency and predictive accuracy [

2]. This is because lean production is, and for the foreseeable future will be, widely recognized and accepted in the industrial environment. It fits into Industry 5.0 thanks to the continuous integration of people in the production process and improvement and the focus on value-adding activities by avoiding waste (time, energy, and materials). In addition, Industry 4.0/5.0 allows for the creation of intelligent networks of machines, products, components, properties, people, and ICT systems across the value chain to create smart factories. All these approaches can not only coexist, but also support each other, producing synergies [

3].This eliminates the most commonly identified problems with lean practice in the industry, allowing us to think with hope about the future development of smart factories and a smart supply chain. So far, even though the level of implementation of individual lean tools has been highly rated, the expected effects in terms of eliminating waste have not always been observed. This may mean that the advanced level of the implementation of lean manufacturing alone does not have a significant impact on the elimination of individual types of waste, and needs to be supported by the development of smart supply chains, IIoT, 6G, and AI/ML (

Figure 5) [

4].

The 6G technology is being explored for its potential to support and enhance blockchain applications, despite the inherent speed and power consumption challenges of blockchain. Here is a detailed discussion on how 6G can address these challenges and enable more efficient use of blockchain technology in various applications through increased data transfer rates, ultra-low latency, energy efficiency through advanced antenna technologies, beamforming and network slicing, utilization edge computing (AI leverage to process data closer to the source), high throughput, improved consensus mechanism, and decentralized applications.

Agility is the dynamic capability of an organization which helps it to manage a change and uncertainties in the environment. The purpose of this research is to review the literature from the perspective of agility in Industry 4.0. This paper systematically reviews 381 relevant articles from peer-reviewed academic journals in the period of the last five years. The results show that agility is important for an organization to adopt Industry 4.0 technologies as it helps companies cope with the changes that arise along with the adoption of Industry 4.0 technologies. Further, it also indicates that by adopting Industry 4.0 technologies, companies can significantly enhance their agility capability in various aspects with different technologies. Organizations strive to develop dynamic resilience capabilities. Industry 4.0/5.0 technologies can increase the flexibility of organizations and their resistance to the crises that we are experiencing more and more often. Further research is needed in this area, including on flexibly managed, disruption-resistant supply chains [

5].

Agility is considered a prerequisite for implementing and adopting Industry 4.0/5.0 technologies as it helps organizations transition seamlessly into their ecosystems [

6,

7]. Key technologies for agility in Industry 4.0/5.0 remain smart manufacturing (including supply chain management) [

8,

9,

10,

11], cyber–physical systems [

12,

13], cloud computing [

14,

15], Big Data, and AI-based analytics [

16,

17]. Supplementary roles will fulfill augmented reality, virtual reality [

18,

19], modeling and simulations [

20,

21], sensors [

22,

23], IoT platforms [

24,

25], and machine-to-machine (M2M) communication [

26,

27]. The implementation of a large number of advanced technologies requires preparation and must be performed in stages, and not everywhere will be necessary on such a large scale. The above technologies and their role in the 6G and AI-based supply chain will be discussed in more detail later in this review.

The globalization of products and services, shortening the life cycle of technologically developed products (such as the moral obsolescence of electronic and IT solutions in a maximum of two years), and their mass personalization are putting constant pressure on the manufacturing industry and shortening the cycles of developing new products, delivery times, and production [

28,

29]. In addition, there is an increase in availability and demand, pressure to reduce costs (production and administrative), and availability in trade almost all the time (also via the Internet, often directly from the manufacturer’s warehouses). For these reasons, the leading trend has become outsourcing individual components to external suppliers, which has partially shortened the supply chains of materials, but has often lengthened and complicated the supply chains of semi-finished and finished products. Product development, integration, and marketing must proceed coherently to achieve market success—it is best for the product to be expected on the market, hence the attempts by their producers and distributors to build tension before the premiere of the next generation of products. It is clear that the key elements of the supply chain increasingly include the acquisition and production of components/modules/semi-finished products, assembly of finished products and their transport to retail outlets (in the distribution network, not necessarily traditional stores), and indirectly, product and supplier management [

30]. Such flexible supply chain management is currently an important goal for the development of various enterprises regardless of the industry, but what they have in common is the extensive use of IoT, blockchain, Big Data, and AI/ML technologies aimed at achieving better efficiency, reliability, and security of supply chains, and thus the entire production of the enterprise. However, this requires the following principles to be applied in practice:

Broad flexible approaches to supply chain networks as a set of tasks requiring the management of both traditional supply elements and dynamically emerging areas (e-commerce, logistics, smart cities, and smart territories) will create modern supply chain networks;

Managing the security of supply chains based on IT networks (including 6G and IIoT) requires sufficiently high employee awareness, their appropriate substantive preparation, and the resistance of IT systems to many potential security threats and attacks—enterprise data and transactions should be transmitted, exchanged, and processed in a safe environment;

IIoT sensors and effectors should provide precise, anonymized data as part of edge computing, which will further reduce data transfer, and LoRaWAN solutions will improve the local cost balance;

Big Data analytics and AI/ML algorithms (also within cloud computing) will play an increasingly important role in supply chain network management. It is necessary to develop descriptions of the specific needs of the supply chain network and functional and performance specifications, but also the methods and needs of large-scale data analysis while maintaining data privacy and transaction security, also in distributed processing conditions [

31,

32,

33].

In a global economy, a full package of logistics services cannot always be provided by one operator. Terminals and warehouses in different locations may not ensure the simultaneous delivery and distribution of goods on time or the handling of non-standard loads. Supply chain management systems must take this into account by organizing coordinated cooperation between various logistics companies (also of different sizes or specialties) as part of comprehensive services. The concept of a virtual logistics center appeared here as a way to integrate transport and logistics service providers, intermodal terminals, and warehouses within a common entity. This also minimizes the costs of logistics services and the delivery time of goods while maintaining a comprehensive offer of logistics services needed by customers in a given location [

31]. The key areas of supply chain management, especially in the areas of infrastructure, construction, business, technology, manufacturing, blockchain, and agriculture, are also starting to use digital twin technologies. This not only provides a comprehensive perspective, but also identifies new areas, processes, and management methods, taking into account both the micro and macro perspectives. At the same time, it does not neglect the detail of data, making full use of the possibilities provided by AI/ML, robotization, cybersecurity, 6G networks, new production methods (e.g., 3D printing), and production control (e.g., production control in the cloud) [

32]. When analyzing the factors affecting supply chain management, we cannot ignore potential climate changes, which would be a mistake to ignore due to the increased frequency and intensity of weather phenomena (hurricanes, floods, droughts, and increased temperatures).There is no doubt that such phenomena disrupt the flow of goods and services, cause delays and the failures of logistics networks, generating costs, but may also harm human life, cause mass displacements, affecting the location and wealth (financial liquidity) of the producers, cooperators, and recipients of products and services. Already, the preferred approach is climate-resilient sustainable supply chain risk management (CCR-SSCRM), balancing the economy, environment, society, and culture [

33].

3.2. 6G- and IoT-Based Supply Chain Management

From a systemic point of view, supply chain management includes three stages: supply chain design, supply chain planning, and the operation/maintenance of the supply chain. The emergence of 6G technology will revolutionize the industrial paradigm, especially in supply chain design, planning, and operation. These are the anticipated benefits and impacts: improved connectivity and speed, improved supply chain visibility, more efficient design and planning, autonomous logistics, smart factories, sustainability and increased cybersecurity, agility, scalability, and customer experience. It will transform the supply chain with unprecedented speed, connectivity, and efficiency. This technology will improve visibility, automation, and collaboration while supporting sustainable and safe operations. As a result, companies will be able to design, plan, and operate their supply chains with greater precision, flexibility, and responsiveness, ultimately leading to a more robust and agile supply chain ecosystem. The effective management of even a well-designed and operational supply chain requires taking into account many factors contributing to the uncertainty of decisions regarding the flow of products, services, and capital. The above decisions should involve as little risk as possible, but in practice, risk can rarely be avoided. A comprehensive approach to the development and implementation of 6G IoT as a management infrastructure in this area requires meeting the following criteria in subsequent stages:

Supply chain design: Consistent with the strategic long-term development goals of the enterprise, region, and country, usually including not only the strategy of the company’s internal operation, but also the strategy of cooperation with outsourcing companies, wholesale recipients, and individual customers (marketing network, distribution), which constitute the backbone of the network company’s supply chain;

Supply chain planning: Integrating short-term tasks (demand–supply response, inventory strategy, marketing goals, pricing strategies, etc.) within a pre-designed strategic supply chain framework in such a way as to ensure supply chain surplus. It is also a general test of the feasibility of the supply chain strategy and design—if this stage can be reconciled with the previous one, the strategy can be implemented in specific conditions and with specific assumptions (locational, cultural, etc.);

Supply chain performance: Real-time data, visualizations, and models reflect the flow of products through each node of the supply chain network as intended by management. This stage takes into account the required operating parameters of the supply chain, e.g., reaction speed, storage/waiting time, possibilities of accelerating/delaying service progress, the situation in neighboring nodes, and the required advance decision-making process (in minutes, hours, or days).This also includes tracking shipments from the customer placing an order to receiving the product, with variants of further service as the load on individual network nodes changes. In general, each node is to some extent independent; it reacts taking into account its status (the vector/matrix of features in the supply chain management system), received requests, and their priorities (

Figure 6) [

34].

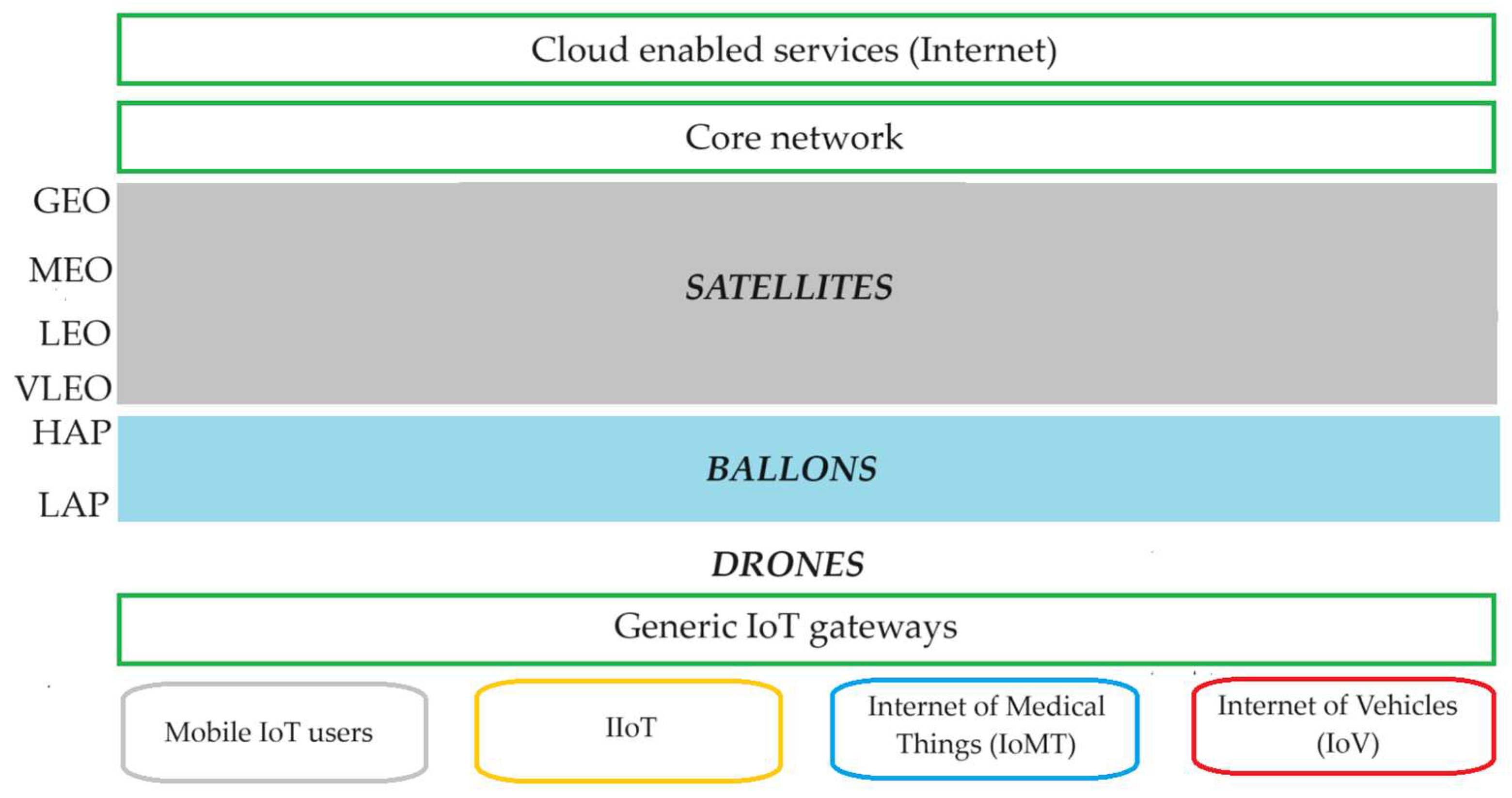

In such conditions, the rapidly developing 6G IIoT paradigm with full terrain coverage, low latency, and high network capacity combined with AI/ML-based analysis will play a key role in managing a flexible and efficient supply chain. The 6G network structure provides for airborne and satellite anchor nodes (ANs) providing relay services and supporting the location of ground IIoT network elements, both currently tracked and searched (

Figure 7) [

34].

The 6G IIoT networks offer high possible device density, network slicing, and low latency resulting in the simultaneous visibility of the entire supply chain, port operations, and improved communication/control. The potential of some technologies (e.g., blockchain) or their potential successors also remains great. To achieve success, great stakeholder involvement and taking into account sustainable development when implementing the abovementioned innovative technologies, which allow them to be accepted more quickly in the demanding logistics market (e.g., smart contracts), is necessary (

Figure 8).

3.3. AI/ML Data Analysis in Supply Chain Supported by 6G

Industry 4.0/5.0 has transformed the existing factories into intelligent cyber–physical production systems (CPPSs). Under CPPS, man, machine, and product are connected throughout the entire supply chain, ensuring flexible and transparent production. However, this introduces more vulnerabilities to attacks that disrupt production, but also the availability of materials, components, and end products as well as related services (e.g., service).ML systems are already used here to detect network anomalies (not necessarily resulting from an attack, but also from human errors or device wear) and construct models based on data. Previous research has shown that supervised algorithms outperform unsupervised and semi-supervised algorithms, achieving an accuracy of up to 0.999 [

35]. The application of AI/ML to supply chain management will be one of the major breakthroughs of 6G IIoT-based supply chain networks. This is due to the fact that the current supply chain management is characterized by a poorer integration of information, its classification, and predictive analysis, and the implementation of solutions based on ML algorithms processing data acquired massively in real-time will contribute to rapid improvement in the visualization of the network and supply status, and in further tuples: for predicting loads, disturbances and failures. AI-based management models constituting second opinion systems will better support the activities of managers and engineers and the business strategy of a specific company, and will increase the accuracy of decisions regarding production needs and delivery schedules. The measurements of the production and delivery process as well as the functioning of the company in the financial dimension with fast and global access to data and their distributed processing will guarantee decision making based on transaction data protected by blockchain. IoT devices will provide reliable and accurate real-world data vectors/matrices based on edge computing (as close to the data source as possible). Currently, the most common use of AI/ML in supply chain management is forecasting demand for products (based on marketing, financial, production, seasonal, weather, and events popularizing them) and forecasting the production of the above-mentioned products (related to inventories and supply chains). But production capacity (and the possibility of its rapid increase) depends not only on the production capacity of a specific production line, but also on the coordination of the capabilities of various suppliers and subcontractors. This not only allows you to smoothly control production, order raw materials, and coordinate production schedules for individual products, but also avoid production line downtime or keeping too large quantities of products in the warehouse. The faster and more accurate these processes are, the faster you can fulfill orders, accelerate the distribution of products on the market, scale inventories to your needs, reduce costs, and increase revenues. In turn, the factors affecting the accuracy of demand forecasting are not always stable, simple, and focused in a way that allows them to be quickly observed—sometimes, only deep market research will allow them to be detected. It is also necessary to ensure that ML algorithms are not susceptible to bias resulting from difficult-to-explain local phenomena reflected in the data. Seemingly, it should be easy to manage accurately and subject to simple audit, but the number of stakeholders and possible obstacles is so large that it is difficult to predict the actual delivery dates. In the case of the above vagaries, it is simply difficult to have a uniform IT system that covers manufacturers, drug distributors, hospitals and outpatient clinics, pharmacies, and government and local government units, allowing them to have simultaneous, quick access to reliable data, their visualization, and analyses/reports. For the above reason, it is worth treating it as a challenge and a lesson, ensuring the coherence of IT systems, and treating campaigning as the exception, not the rule. It is not known how to treat special products and their requirements regarding storage and transport conditions—the supply chain network should promote products in places that meet storage conditions, delivering them using transport companies that meet transport conditions. In some countries, the transport of, e.g., medicines or animals is covered by specific legal provisions and requires separate treatment as special transport. AI/ML algorithms should be subject to human control and the final decision in discussion situations should belong to them. Sometimes you need to take into account the country, region, culture/customs, and other requirements. Moreover, the multitude of ML algorithms requires testing many of them and comparing the results from different solutions [

35,

36].

To sum up, thanks to 6G and IoT technology, it will be possible to obtain very detailed data on the location and condition of goods transport in real-time.AI (including ML) can analyze the above-mentioned bulk data to more quickly detect and respond to potential issues such as delays or damaged goods. AI can predict demand, optimize transportation routes, and manage inventory more efficiently. By analyzing the historical and current data, these technologies can suggest the most effective delivery methods, minimizing costs and delivery times. In warehouses and distribution centers, AI can control robots and automated systems that process and pack goods. Utilizing 6G technologies will enable almost instantaneous communication between devices, which will speed up warehouse operations. AI can predict risks in the supply chain, such as production interruptions, changes in weather conditions, and fluctuations in raw material prices. Thanks to this, companies can prepare for various scenarios and adapt their strategies accordingly. AI can help minimize energy and other resource consumption by optimizing logistics processes. It can also reduce emissions: through better route planning and more effective fleet management, it is possible to significantly reduce CO2 emissions.

4. Discussion

World-class global companies are increasingly integrating 6G technologies and artificial intelligence into their supply chains to increase efficiency, transparency, and responsiveness across industries. These technologies are used in demand forecasting, just-in-time delivery, real-time tracking, connected autonomous vehicles and drones, delivery center management, personalized customer service, and intelligent energy management. Stakeholders have access to up-to-date information, which increases trust and cooperation. Predictive maintenance, optimized routing, and efficient inventory management reduce operational costs. Faster and more reliable deliveries, personalized services, and product authenticity increase customer satisfaction. By leveraging 6G technology and artificial intelligence, global companies can build more resilient, responsive, and efficient supply chains, ultimately gaining a competitive advantage in their industries. Globally, the integration of 6G IoT into supply chains means more interconnected and resilient systems. It enables better coordination between international partners, faster response to disruptions, and a more efficient supply chain able to adapt to market changes and unexpected events. The integration of 6G with IIoT in supply chains is expected to revolutionize global logistics and operations. The use of 6G will provide data transfer rates of up to 1 terabit per second, which is much faster than 5G. This speed will enable real-time data processing and communication between IoT devices throughout the supply chain. Improved connectivity will ensure every part of the supply chain is seamlessly connected, from production to delivery and end customer service. Thanks to the 6G network, it is possible to analyze the huge amount of data generated by IoT devices more effectively. This enables better decision making through predictive analytics, identifying potential problems before they occur, and optimizing various aspects of the supply chain such as inventory management, demand forecasting, and route optimization. The high speed and low latency of 6G will support more advanced automation technologies. Autonomous vehicles, drones, and robotics can operate more efficiently, increasing efficiency and reducing human error. This is especially beneficial in warehouses and last-mile deliveries. The 6G IoT enables the comprehensive tracking of goods throughout the entire supply chain. Sensors and devices can provide real-time updates on the location, condition, and status of products. This increases traceability and transparency, which is crucial for compliance, quality control, and consumer confidence. By optimizing routes and reducing latency, the 6G IoT can contribute to more sustainable supply chain operations. Reducing energy consumption and waste is possible through the more precise monitoring and control of resources. While the benefits are significant, the adoption of the 6G IoT in supply chains also comes with challenges, particularly in terms of security and privacy. The huge number of connected devices increases the risk of cyber threats. Therefore, robust security measures and protocols are essential to protect sensitive data and maintain supply chain integrity. Taken together, the convergence of 6G and IoT will transform global supply chains by improving connectivity, enabling advanced data analytics, supporting increased automation, improving traceability, and promoting sustainability. This transformation will lead to more efficient, transparent, and resilient supply chains that can meet the demands of a rapidly evolving global market.

Priority directions for the development of IIoT 6G-based supply chains include their scalability, efficiency, the reduced cost of ownership, improved transaction systems, data management, asset tracking, system integration, and system portability. Priority application areas include not only the industry, but also the public sector, commerce, finance, insurance, or services (including healthcare). This list will grow longer with the growth of more industries based on 6G, blockchain, and AI/ML technologies. In accordance with the analysis so far, the road map for achieving new solutions has been formulated as follows:

The identification of business needs (e.g., services that cause the most problems in supply chain management today);

Determining needs (cost and optimization) and describing them with objective parameters/indicators;

Learning the characteristics of solutions, testing, and selecting the best ones;

Developing standards for the interoperability and integration of services and data;

The implementation and evaluation of pilot implementations, assessment of effectiveness compared to existing solutions, costs and return on investment, and risk analysis;

Acquiring technological and business partners, and the demonstration of advantages.

4.1. Limitations of Current Studies

There are still many technological, organizational, and legal limitations and challenges that need to be addressed in the study area, as shown in

Table 1.

In summary, implementing 6G networks in supply chain management poses significant challenges, including high upfront investments required in infrastructure and an increased risk of cyberattacks due to improved connectivity. Interoperability with existing systems and different regulatory standards in different regions further complicate the integration process. Advanced technological complexity requires specialized skills that may not be readily available, which can lead to skills gaps. Additionally, the higher energy consumption of 6G networks raises sustainability concerns and may conflict with environmental goals. All these challenges affect the profitability and pace of the implementation of this group of systems, making progress in this area an even more urgent task for scientists and engineers.

4.2. Directions for Further Research

Further research developing 6G-based supply chain management within the Industry 4.0/5.0 paradigm should be led in an improving manner. The integration of AI/ML with 6G networks to optimize supply chain processes should be implemented through predictive analytics and automated decision making to make full use of large amounts of collected data, access it with minimal delays, and anticipate many scenarios: from the most probable to the risky, but more profitable. Improving interoperability standards between 6G networks and the existing systems will ensure a smooth transition and integration in supply chains (databases, communication protocols, etc.).The development of edge computing in 6G applications can reduce latency and improve real-time data processing efficiency in supply chain operations. This also requires improving the effectiveness of cybersecurity protocols in protecting 6G supply chains against advanced cyber threats, often still unknown, that need to be anticipated and countered. Blockchain integration with 6G technology can increase transparency, traceability, and security in supply chain management, including transactions. Developing energy-efficient hardware and network designs is key to profitability and reducing the environmental impact of 6G networks in supply chains. This includes the use of environmentally friendly materials and processes in the construction and maintenance of 6G infrastructure. This can help adapt supply chain management to environmental goals, which are increasingly a criterion for selecting individual solutions. The potential of quantum computing in combination with 6G networks is being explored, which could lead to breakthroughs in solving complex supply problems, especially in improving the speed of the execution of complex algorithms. Improving human–machine cooperation is becoming increasingly important, especially in the area of AI/ML-based solutions and research on interactions between people and machines in the 6G-enabled supply chain. This can help in designing systems that increase human productivity and improve the efficiency and speed of decision making, in particular in making decisions of critical importance or based on incomplete/uncertain data (here: fuzzy logic, including Ordered Fuzzy Numbers (OFNs). The basis to consolidate solutions will be the development of a comprehensive regulatory framework that will guide the development and deployment of 6G technology in supply chains, ensuring seamlessness, efficiency, compliance, and public trust [

46,

47,

48,

49,

50].

The proper selection of priority directions for further research is crucial. This is critical to success in today’s competitive, rapidly changing global business landscape. The risk of black swans (unpredictable market changes and breakdowns) requires a rethink and the 6G-based digitalization of complex demand and supply systems. Creating dynamic, collaborative, interdependent processes and proactive, data-driven decisions can only be achieved with a fully integrated intelligent supply network. The limitations of traditional supply chains and the potential of digital supply flows result not from the current, but from the future needs of individual industries. In the coming years, the transformation to 6G will streamline operations and build supply networks, and thus increase revenues, shape new business models, and deliver added value to customers, stakeholders, and society through the new stages of development and opportunities. This primarily concerns Big Data analytics, synchronized planning, the wider implementation of AI/ML for inference, blockchain, smart delivery, digital product and service development, and order fulfillment as part of the transformation towards digitally connected supply networks. The resilience of 6G-based supply chain networks when risk propagates across supply chain networks can be optimized by adapting the network structure, which has important implications for practice [

51,

52,

53].

5. Conclusions

The emergence of 6G technology, especially when powered by AI, will transform supply chains by providing unprecedented visibility, automation, and collaboration, while supporting sustainable and safe operations. By leveraging these capabilities, companies will be able to design, plan, and operate their supply chains with greater precision, flexibility, and responsiveness, ultimately leading to a more robust and agile supply chain ecosystem. Resource management will improve and response time to market changes will be shortened, while providing customers with better personalized services with minimal impact on the environment. Agility and technology implementation must go hand in hand, so achieving the target state of Industry 5.0 infrastructure must include 6G interoperability and AI technologies. It will also allow for better and more even use of limited resources, including recycled ones, in the area of materials, semi-finished products, and entire components/modules that are currently not produced or available uniformly around the world. It will also enable more efficient use of increasingly expensive energy by effectively planning transportation and other logistics processes and responding to disruptions in supply cycles by selecting from available alternatives developed by AI systems based on real data delivered via the 6G network with minimal latency.

Author Contributions

Conceptualization, I.R., M.J.-K., A.P., K.G. and D.M.; methodology, I.R., M.J.-K., A.P., K.G. and D.M.; software, I.R., M.J.-K., A.P., K.G. and D.M.; validation, I.R., M.J.-K., A.P., K.G. and D.M.; formal analysis, I.R., M.J.-K., A.P., K.G. and D.M.; investigation, I.R., M.J.-K., A.P., K.G. and D.M.; resources, II.R., M.J.-K., A.P., K.G. and D.M.; data curation, I.R., M.J.-K., A.P., K.G. and D.M.; writing—original draft preparation, I.R., M.J.-K., A.P., K.G. and D.M.; writing—review and editing, I.R., M.J.-K., A.P., K.G. and D.M.; visualization, I.R., M.J.-K., A.P., K.G. and D.M.; supervision, I.R., M.J.-K. and D.M.; project administration, I.R. funding acquisition, I.R. All authors have read and agreed to the published version of the manuscript.

Funding

The work presented in the paper has been financed under a grant to maintain the research potential of Kazimierz Wielki University.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author. The data are not publicly available due to cybersecurity issues.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rojek, I.; Kotlarz, P.; Dorożyński, J.; Mikołajewski, D. Sixth-Generation (6G) Networks for Improved Machine-to-Machine (M2M) Communication in Industry 4.0. Electronics 2024, 13, 1832. [Google Scholar] [CrossRef]

- Liang, W.; Zhang, L.; Kadoch, M. 6G IoT Tracking- and Machine Learning-Enhanced Blockchained Supply Chain Management. Electronics 2023, 12, 40. [Google Scholar] [CrossRef]

- Mrugalska, B.; Wyrwicka, M.K. Towards lean production in industry 4.0. Procedia Eng. 2017, 182, 466–473. [Google Scholar] [CrossRef]

- Wyrwicka, M.K.; Mrugalska, B. Mirages of lean manufacturing in practice. Procedia Eng. 2017, 182, 780–785. [Google Scholar] [CrossRef]

- Mrugalska, B.; Ahmed, J. Organizational agility in industry 4.0: A systematic literature review. Sustainability 2023, 13, 8272. [Google Scholar] [CrossRef]

- Genest, M.C.; Gamache, S. Prerequisites for the Implementation of Industry 4.0 in Manufacturing SMEs. Procedia Manuf. 2020, 51, 1215–1220. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Pradhan, N.; Macias de Anda, E.; Trevino Martinez, S.; Sawhney, R.; Kumar, M. Designing lean value streams in the fourth industrial revolution era: Proposition of technology-integrated guidelines. Int. J. Prod. Res. 2020, 58, 5020–5033. [Google Scholar] [CrossRef]

- Witczak, M.; Majdzik, P.; Stetter, R.; Lipiec, B. Multiple agv fault-tolerant within an agile manufacturing warehouse. IFAC-PapersOnLine 2019, 52, 1914–1919. [Google Scholar] [CrossRef]

- Rojek, I.; Dostatni, E.; Hamrol, A. Ecodesign of Technological Processes with the Use of Decision Trees Method. In Proceedings of the International Joint Conference SOCO’17-CISIS’17-ICEUTE’17, León, Spain, 6–8 September 2017; Advances in Intelligent Systems and Computing. Pérez García, H., Alfonso-Cendón, J., Sánchez González, L., Quintián, H., Corchado, E., Eds.; Springer: Cham, Switzerland, 2018; Volume 649, pp. 318–327. [Google Scholar] [CrossRef]

- Dostatni, E.; Rojek, I.; Hamrol, A. The Use of Machine Learning Method in Concurrent Ecodesign of Products and Technological Processes. In Advances in Manufacturing; Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2018; pp. 321–330. [Google Scholar] [CrossRef]

- Rojek, I.; Jasiulewicz-Kaczmarek, M.; Piechowski, M.; Mikołajewski, D. An Artificial Intelligence Approach for Improving Maintenance to Supervise Machine Failures and Support Their Repair. Appl. Sci. 2023, 13, 4971. [Google Scholar] [CrossRef]

- Ding, K.; Jiang, P. Incorporating social sensors, cyber-physical system nodes, and smart products for personalized production in a social manufacturing environment. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 2323–2338. [Google Scholar] [CrossRef]

- Barenji, R.V.; Akdag, Y.; Yet, B.; Oner, L. Cyber-physical-based PAT (CPbPAT) framework for Pharma 4.0. Int. J. Pharm. 2019, 567, 118445. [Google Scholar] [CrossRef] [PubMed]

- Ooi, K.B.; Lee, V.H.; Tan, G.W.H.; Hew, T.S.; Hew, J.J. Cloud computing in manufacturing: The next industrial revolution in Malaysia? Expert. Syst. Appl. 2018, 93, 376–394. [Google Scholar] [CrossRef]

- Li, D.; Tang, H.; Wang, S.; Liu, C. A big data enabled load-balancing control for smart manufacturing of Industry 4.0. Clust. Comput. 2017, 20, 1855–1864. [Google Scholar] [CrossRef]

- Barlette, Y.; Baillette, P. Big data analytics in turbulent contexts: Towards organizational change for enhanced agility. Prod. Plan. Control 2020, 33, 105–122. [Google Scholar] [CrossRef]

- Al-Qaralleh, R.E.; Atan, T. Impact of knowledge-based HRM, business analytics and agility on innovative performance: Linear and FsQCA findings from the hotel industry. Kybernetes 2021, 51, 423–441. [Google Scholar] [CrossRef]

- Lee, J.; Um, C.; Shin, J.; Jeong, J. Design and Applications of Agile Factory AaaS Architecture Based on Container-based Virtualized Automation Control Unit. Procedia Comput. Sci. 2019, 151, 622–629. [Google Scholar] [CrossRef]

- Houngbé, M.; Barthe-Delanoë, A.M.; Négny, S. Towards virtual biorefineries. In Working Conference on Virtual Enterprises; Springer: Berlin/Heidelberg, Germany, 2018; pp. 571–580. [Google Scholar]

- Micheler, S.; Goh, Y.M.; Lohse, N. Innovation landscape and challenges of smart technologies and systems—A European perspective. Prod. Manuf. Res. 2019, 7, 503–528. [Google Scholar] [CrossRef]

- Kaar, C.; Frysak, J.; Stary, C.; Kannengiesser, U.; Müller, H. Resilient ontology support facilitating multi-perspective process integration in industry 4.0. In Proceedings of the 10th International Conference on Subject-Oriented Business Process Management, Linz, Austria, 5–6 April 2018; pp. 1–10. [Google Scholar]

- Rathee, G.; Balasaraswathi, M.; Chandran, K.P.; Gupta, S.D.; Boopathi, C. A secure IoT sensors communication in industry 4.0 using blockchain technology. J. Ambient. Intell. Humaniz. Comput. 2021, 12, 533–545. [Google Scholar] [CrossRef]

- Schmidt, D.; Villalba Diez, J.; Ordieres-Meré, J.; Gevers, R.; Schwiep, J.; Molina, M. Industry 4.0 Lean Shopfloor Management Characterization Using EEG Sensors and Deep Learning. Sensors 2020, 20, 2860. [Google Scholar] [CrossRef]

- Yao, F.; Alkan, B.; Ahmad, B.; Harrison, R. Improving Just-in-Time Delivery Performance of IoT-Enabled Flexible Manufacturing Systems with AGV Based Material Transportation. Sensors 2020, 20, 6333. [Google Scholar] [CrossRef]

- Lyu, M.; Biennier, F.; Ghodous, P. Integration of ontologies to support Control as a Service in an Industry 4.0 context. Serv. Oriented Comput. Appl. 2021, 15, 127–140. [Google Scholar] [CrossRef]

- Chelloug, S.A.; El-Zawawy, M.A. Middleware for internet of things: Survey and challenges. Intell. Autom. Soft Comput. 2017, 3, 1–9. [Google Scholar] [CrossRef]

- Ammar, M.; Russello, G.; Crispo, B. Internet of things: A survey on the security of IoT frameworks. J. Inform. Secur. Appl. 2018, 38, 8–27. [Google Scholar] [CrossRef]

- Liberman-Pincu, E.; Oron-Gilad, T. Exploring the Effect of Mass Customization on User Acceptance of Socially Assistive Robots (SARs). In Proceedings of the 2022 17th ACM/IEEE International Conference on Human-Robot Interaction (HRI), Sapporo Hokkaido, Japan, 7–10 March 2022; pp. 880–884. [Google Scholar]

- Wang, Y.; Zhao, W.; Wan, W.X. Needs-Based Product Configurator Design for Mass Customization Using Hierarchical Attention Network. IEEE Trans. Autom. Sci. Eng. 2021, 18, 195–204. [Google Scholar] [CrossRef]

- Esfandiari, S. The effect of blockchain technology on supply chain management: Its potential to prevent fraud and reduce risks to food safety and its effects on the relationships between supply chain actors in the Mexican food processing industry. In Proceedings of the 2022 IEEE Technology and Engineering Management Conference (TEMSCON EUROPE), Izmir, Turkey, 25–29 April 2022; pp. 179–183. [Google Scholar]

- Paulauskas, V.; Filina-Dawidowicz, L.; Senčila, V.; Paulauskas, D.; Plačienė, B. Theoretical Framework for Virtual Logistics Centers Creation. Sustainability 2024, 16, 3680. [Google Scholar] [CrossRef]

- Hirata, E.; Watanabe, D.; Chalmoukis, A.; Lambrou, M. A Topic Modeling Approach to Determine Supply Chain Management Priorities Enabled by Digital Twin Technology. Sustainability 2024, 16, 3552. [Google Scholar] [CrossRef]

- Yun, N.Y.; Ülkü, M.A. Sustainable Supply Chain Risk Management in a Climate-Changed World: Review of Extant Literature, Trend Analysis, and Guiding Framework for Future Research. Sustainability 2023, 15, 13199. [Google Scholar] [CrossRef]

- Apruzzese, M.; Bruni, M.E.; Musso, S.; Perboli, G. 5G and Companion Technologies as a Boost in New Business Models for Logistics and Supply Chain. Sustainability 2023, 15, 11846. [Google Scholar] [CrossRef]

- Saghezchi, F.B.; Mantas, G.; Violas, M.A.; de Oliveira Duarte, A.M.; Rodriguez, J. Machine Learning for DDoS Attack Detection in Industry 4.0 CPPSs. Electronics 2022, 11, 602. [Google Scholar] [CrossRef]

- Rinaldi, S.; Bellagente, P.; Ciribini, A.L.C.; Tagliabue, L.C.; Poli, T.; Mainini, A.G.; Speroni, A.; Blanco Cadena, J.D.; Lupica Spagnolo, S. A Cognitive-Driven Building Renovation for Improving Energy Efficiency: The Experience of the ELISIR Project. Electronics 2020, 9, 666. [Google Scholar] [CrossRef]

- Zylka, L.; Burek, J.; Mazur, D. Diagnostic of peripheral longitudinal grinding by using acoustic emission signal. Adv. Prod. Eng. Manag. 2017, 12, 221–232. [Google Scholar]

- Prokopowicz, P.; Mikolajewski, D.; Mikołajewska, E.; Kotlarz, P. Fuzzy System as an Assessment Tool for Analysis of the Health-Related Quality of Life for the People After Stroke. In Artificial Intelligence and Soft Computing: 16th International Conference, ICAISC 2017, Zakopane, Poland, 11–15 June 2017; Springer: Cham, Switzerland, 2017; Volume 10245, pp. 710–721. [Google Scholar] [CrossRef]

- Mazur, D.; Wachta, H.; Lesko, K. Research of Cohesion Principle in Illuminations of Monumental Objects. In Analysis And Simulation of Electrical and Computer Systems; Springer: Cham, Switzerland, 2018; Volume 452, pp. 395–406. [Google Scholar] [CrossRef]

- Martinek, R.; Ladrova, M.; Sidikova, M.; Jaros, R.; Behbehani, K.; Kahankova, R.; Kawala-Sterniuk, A. Advanced Bioelectrical Signal Processing Methods: Past, Present, and Future Approach-Part III: Other Biosignals. Sensors 2021, 21, 6064. [Google Scholar] [CrossRef] [PubMed]

- Martinek, R.; Ladrova, M.; Sidikova, M.; Jaros, R.; Behbehani, K.; Kahankova, R.; Kawala-Sterniuk, A. Advanced Bioelectrical Signal Processing Methods: Past, Present and Future Approach-Part I: Cardiac Signals. Sensors 2021, 21, 5186. [Google Scholar] [CrossRef]

- Bauer, W.; Kawala-Janik, A. Implementation of bi-fractional filtering on the Arduino Uno hardware platform. Lect. Notes Electr. Eng. 2017, 407, 419–428. [Google Scholar]

- Grzesiak, K.; Piotrowski, Z.; Kelner, J.M. A wireless covert channel based on dirty constellation with phase drift. Electronics 2021, 10, 647. [Google Scholar] [CrossRef]

- Sieczkowski, K.; Sondej, T.; Dobrowolski, A.; Olszewski, R. Autocorrelation algorithm for determining a pulse wave delay. In Proceedings of the Signal Processing—Algorithms, Architectures, Arrangements, and Applications Conference Proceedings, SPA, Poznan, Poland, 21–23 September 2016; pp. 321–326. [Google Scholar]

- Sondej, T.; Piotrowski, Z.; Sawicki, K. Architecture of car measurement system for driver monitoring. In Lecture Notes in Computer Science; Lecture Notes in Artificial Intelligence; Lecture Notes in Bioinformatics; Springer: Berlin/Heidelberg, Germany, 2012; pp. 68–79. [Google Scholar]

- Zhang, G.; Liu, B. Research on time series classification using CNN and Bidirectional GRU. J. Front. Comput. Sci. Technol. 2019, 13, 916–927. [Google Scholar]

- Hocheriter, S.; Schmidhuber, J.; Cummins, F. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Ouyang, L.; Yuan, Y.; Ni, X.; Han, X.; Wang, F. Blockchain-enabled smart contracts: Architecture, applications, and future trends. IEEE Trans. Syst. Man. Cybern. Syst. 2019, 49, 2266–2277. [Google Scholar] [CrossRef]

- Paik, H.; Xu, X.; Bandara, H.M.N.D.; Lee, S.U.; Lo, S.K. Analysis of data management in blockchain-based systems: From architecture to governance. IEEE Access 2019, 7, 186091–186107. [Google Scholar] [CrossRef]

- Ahl, A.; Yarime, M.; Tanaka, K.; Sagawa, D. Review of blockchain-based distributed energy: Implications for institutional development. Renew. Sustain. Energy Rev. 2019, 107, 200–211. [Google Scholar] [CrossRef]

- Sinha, A.; Bernardes, E.; Calderon, R.; Wuest, T. Digital Supply Networks: Transform Your Supply Chain and Gain Compettive Advantage with Disruptive Technology and Reimagined Processes; McGraw-Hill Education: New York, NY, USA, 2020. [Google Scholar]

- Xue, S.; Li, J.; Yu, J.; Li, M.; Shi, X. Research on Supply Chain Network Resilience: Considering Risk Propagation and Node Type. Appl. Sci. 2024, 14, 2675. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, S.; Lawson, S.B.; Doddapaneni, V.V.K.; Albert, M.; Sutton, B.; Chang, C.-H.; Pasebani, S.; Xu, D. Atomic Diffusivities of Yttrium, Titanium and Oxygen Calculated by Ab Initio Molecular Dynamics in Molten 316L Oxide-Dispersion-Strengthened Steel Fabricated via Additive Manufacturing. Materials 2024, 17, 1543. [Google Scholar] [CrossRef] [PubMed]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).