1. Introduction

The rise in global electrical energy demand and the depletion of fossil energy sources has led to an urgent need for renewable energy sources. The development and optimization of renewable energy technologies, such as solar, wind and hydropower, has emerged as a viable solution. In particular, several studies have focused on using remote sensing data to assess land cover changes and their impact on ecosystem services [

1,

2,

3]. Geospatial analysis has also been utilized to enhance precision agriculture and optimize animal husbandry practices [

4,

5]. Additionally, climate change impacts on various sectors, including agriculture and animal production, have been investigated through the integration of remote-sensing, geospatial and modeling approaches [

6,

7]. These efforts have led to improved understanding of environmental processes and informed decision-making for sustainable resource management. Hence, integrating the power grid of renewable energy sources such as Photovoltaic (PV) and wind energy has become a relevant solution [

8]. To solve the issues of global warming as well as greenhouse gas emissions, the energetic transition should pass through the multiplication of installations of PV and wind generators [

9]. Today, the electricity flow produced by renewable energy sources, such as PV and wind sources, is considered an important alternative solution to compensate the increase in electricity demand [

10].

For the last few years, wind turbine technologies have generally featured novel construction, performance and operation aspects. Currently, the variable-speed Wind Energy Conversion System (WECS) is the most used. It has been given significant consideration, and its extent of cross-country energy has risen more quickly in the last few decades. Indeed, compared to fixed-speed WECSs, the variable-speed WECS features some advantages such as reduced mechanical stress, good quality of the produced electrical energy and the existence of a maximum power point with a variable position that depends on wind speed [

11]. Despite the benefits of variable-speed WECSs that are based on a Permanent Magnet Synchronous Generator (PMSG), the main problem of this wind system consists of wind speed fluctuations. Power generated from the WECS is directly proportional to the wind profile. As a result, a small variation in the wind speed has a big impact on the extracted power. In fact, the latter is inconsistent with the power grid for the reason that the grid voltage should have an acceptably stable amplitude and frequency. A wind turbine is an intermittent power source that can cause fluctuations such as communication delays and cyber-attacks in the power demand and frequency of the power system. Any change in the power requirements of the grid can cause deviations from the nominal frequency, leading to potential damage to the devices connected in the grid. However, in order to improve the stability and reliability of power systems, much effort has been devoted to studying them [

12,

13,

14].

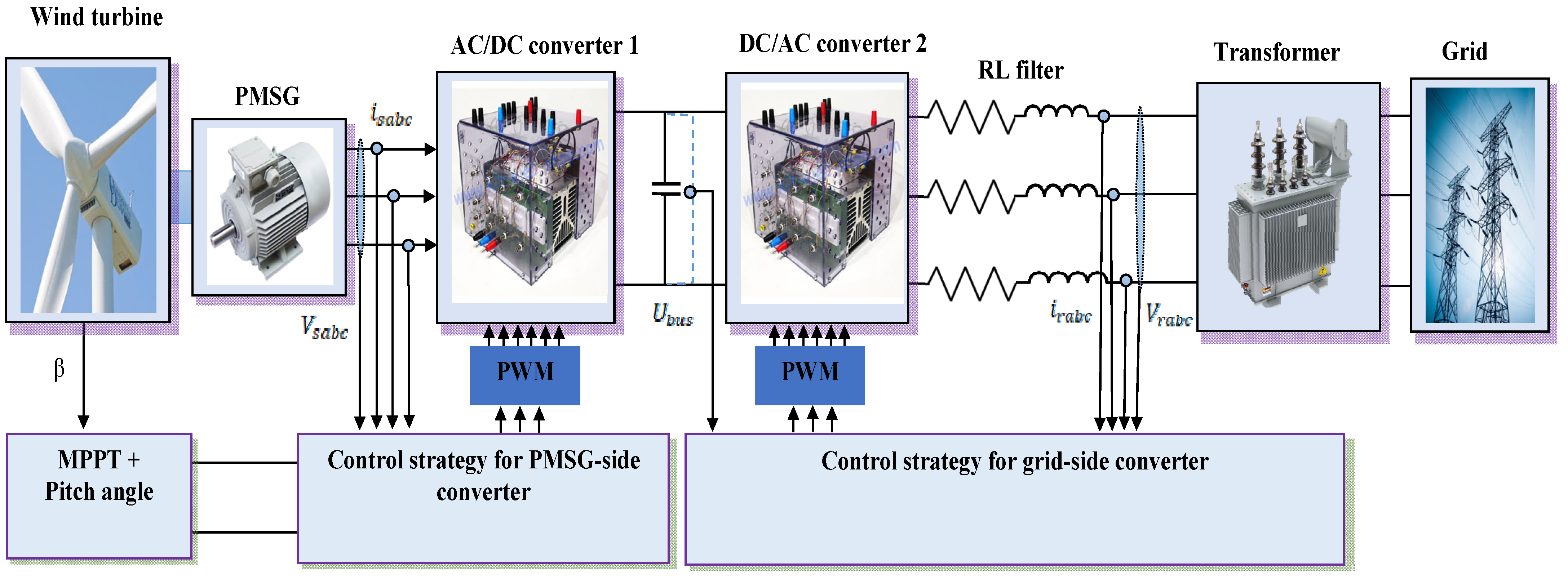

Recently, PMSGs have been progressively used for variable-speed wind turbines given their good performance, high efficiency, high-power density, low heat generation and small size. The wind turbine is connected to the power grid by the use of one power electronic interface and one Resistor-Inductor (RL) filter. The power electronic interface is made up of an Alternative Current (AC)/Direct Current (DC) rectifier, a DC/AC inverter and a common DC bus, which are controlled by two vector control strategies. Thus, determining adequate control strategies is a very important aspect of this system. Generally, the most known control technique is the conventional Vector Control Strategy integrating a control loop based on Proportional Integral (VCS-PI) controllers or Proportional Integral Derivate (PID) controllers [

15]. A PID controller can be used to control some aspects of a nonlinear system, especially if the nonlinearity is small or can be approximated by a linear model over a certain operating range [

16,

17]. In this case, a PID controller can be used to control the system within that range, and the control performance will be acceptable. Indeed, PI and PID controllers are more suitable for linear systems, but these controllers can be utilized for controlling nonlinear systems such as electrical machines, wind turbines, etc. [

18,

19,

20,

21]. However, WECSs based on PI or PID controllers provide poor performance in terms of tracking, accuracy and robustness since they are exposed to various internal and external disturbances, such as fluctuations in the wind speed, changes in the turbine blade angle, variations in the generator speed and changes in the stator resistance due to temperature variations or other factors [

22,

23]. Consequently, the linearity of VCS-PI controllers is not designed to withstand the complex nonlinear behavior of WECSs, since the inadequate choice of the controller gains can lead to the instability of the system [

24].

Therefore, the VCS of the WECS is usually based on a Proportional Integral (PI) controller for controlling the generator currents, the grid currents and the DC voltage [

25]. Furthermore, the linear PI controller cannot be adequate against parameter variations and external disturbances [

26], which consequently affect the tracking accuracy, stability and dynamics of the controlled system [

27]. Thus, the negative effects of these disturbances cannot be mitigated utilizing the VCS-PI controllers with fixed gains [

27].

As the WECS is a non-linear system, a well-developed non-linear controller can overcome the limitations of PI and PID controllers and achieve superior control performance in the face of uncertainties and external disturbances [

28]. Researchers have proposed various advanced non-linear control techniques for the variable-speed WECSs in recent years, including back-stepping-based control [

29], adaptive control [

30], predictive control [

31], intelligent control based on artificial neural networks and fuzzy logic systems [

32,

33,

34,

35,

36] and Sliding Mode Control (SMC) [

25,

37,

38]. SMC has been deemed the most suitable control method for the WECS because of its strong robustness. However, the primary drawback of first-order SMC is the chattering phenomenon, which causes high oscillations around the equilibrium point and vibrations in the electrical machines and mechanical parts of the system due to the discontinuous nature of the control action [

39,

40]. This issue has led to SMC’s rejection by designers for certain industrial applications. Therefore, various improvement studies have focused on reducing chattering, which is considered the main issue of SMC. Saturation or sigmoid functions can be used instead of the discontinuous control action to attenuate chattering, ensuring continuous control. However, this control law drives the system state trajectories towards the sliding surface’s vicinity rather than towards the sliding surface itself, affecting control robustness under disturbances [

41,

42]. In addition, the higher-order sliding mode algorithm is deployed in order to reduce the chattering phenomenon. However, this method requires higher-order real-time derivatives of the outputs [

43]. In [

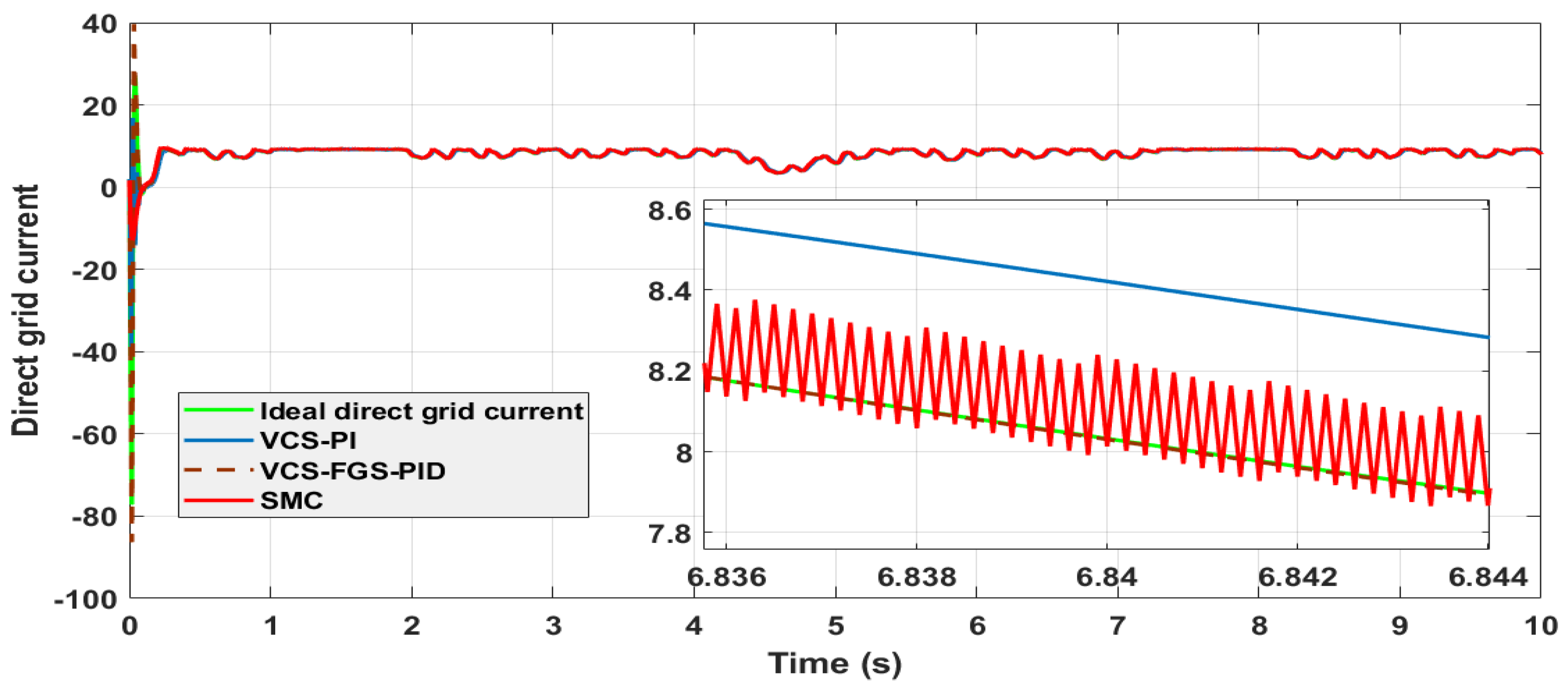

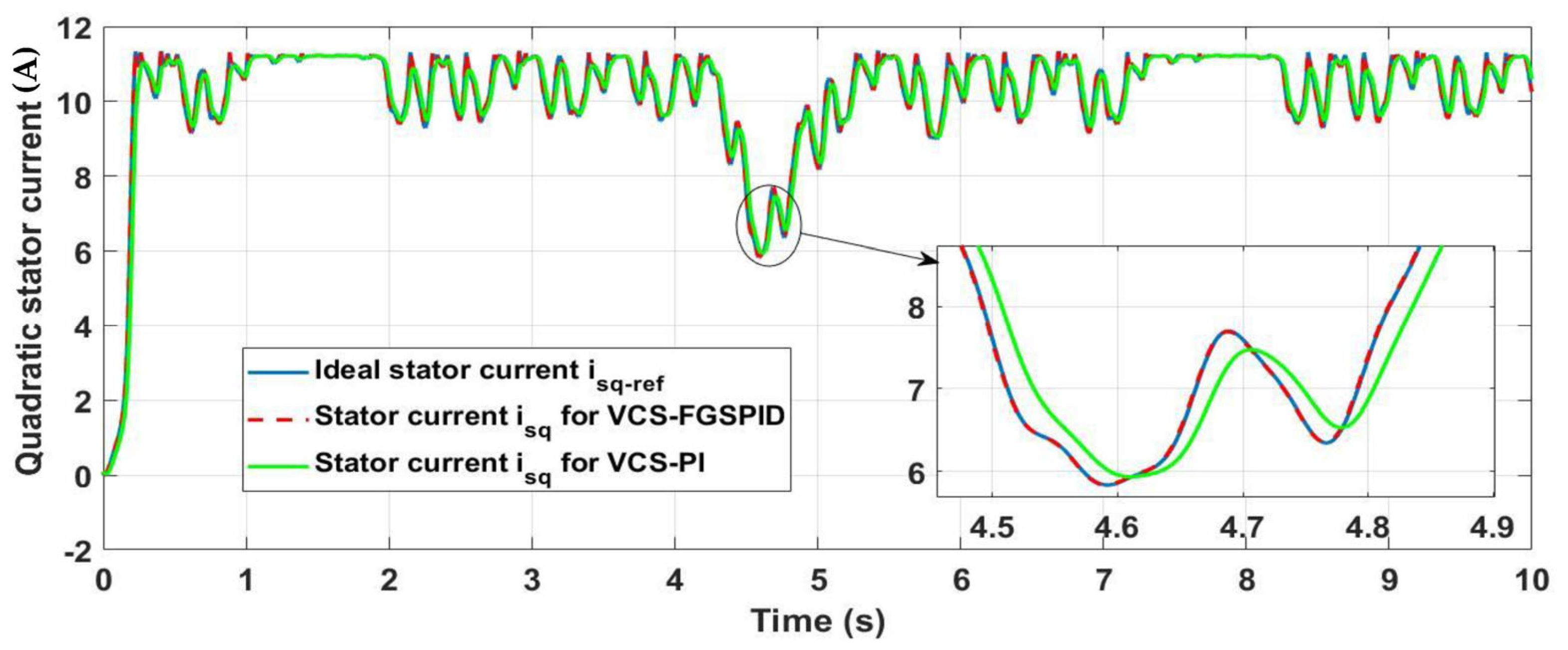

25], the authors put forward an SMC for a grid connected to a WECS based on a PMSG. Indeed, the SMC was suggested to replace the PI controllers used in the wind generator control strategies. The SMC would offer good performance in terms of stability, good dynamic and fast response, but it would cause high oscillations in the electromagnetic torque, the quadratic stator current, the direct grid current and the injected active and reactive power. In [

30], the authors proposed a Classical Tip Speed Ratio technique with PI (CTSR-PI) controller for a wind turbine generator. The performance of the CTSR-PI controller was tested using simulation studies, and it offered good performance in terms of dynamic response and under wind condition variations, but it had limitations such as poor tracking accuracy. In the same context, the authors put forward Adaptive Control Tip Speed Ratio Integral Backstepping (AC-TSR-IBS) in order to overcome the limitations of the CTSR-PI controller, but its performance was not evaluated under parameter variations. In [

44], the authors suggested a Neuro Second-Order SMC (SOSMC) technique based on artificial-neural-network controllers with Fuzzy Space Vector Modulation (NSOSMC-FSVM) to control the reactive and active power of the doubly fed induction generator. These controllers were compared with the SOSMC-control-based traditional space vector technique, and the performances of the two controllers were tested with simulation studies. The NSOSMC-FSVM offered good performance compared to SOSMC in terms of robustness under wind condition variations and tracking accuracy, but it had limitations such as the complexity of algorithm implementation. Moreover, the implementation of large neural networks required an important processing time. In addition, the SOSMC needed information about the sliding surface and its derivate [

45]. In [

46], the authors proposed two neural networks to automate the tuning of PID parameters; the creation of the data took approximately 120 h to generate million samples of data. It spent a significant amount of time training, which made the implementation in real-time more complex.

Moreover, combining fuzzy logic technology with a PI controller can guarantee tracking quality even with high model uncertainties. In [

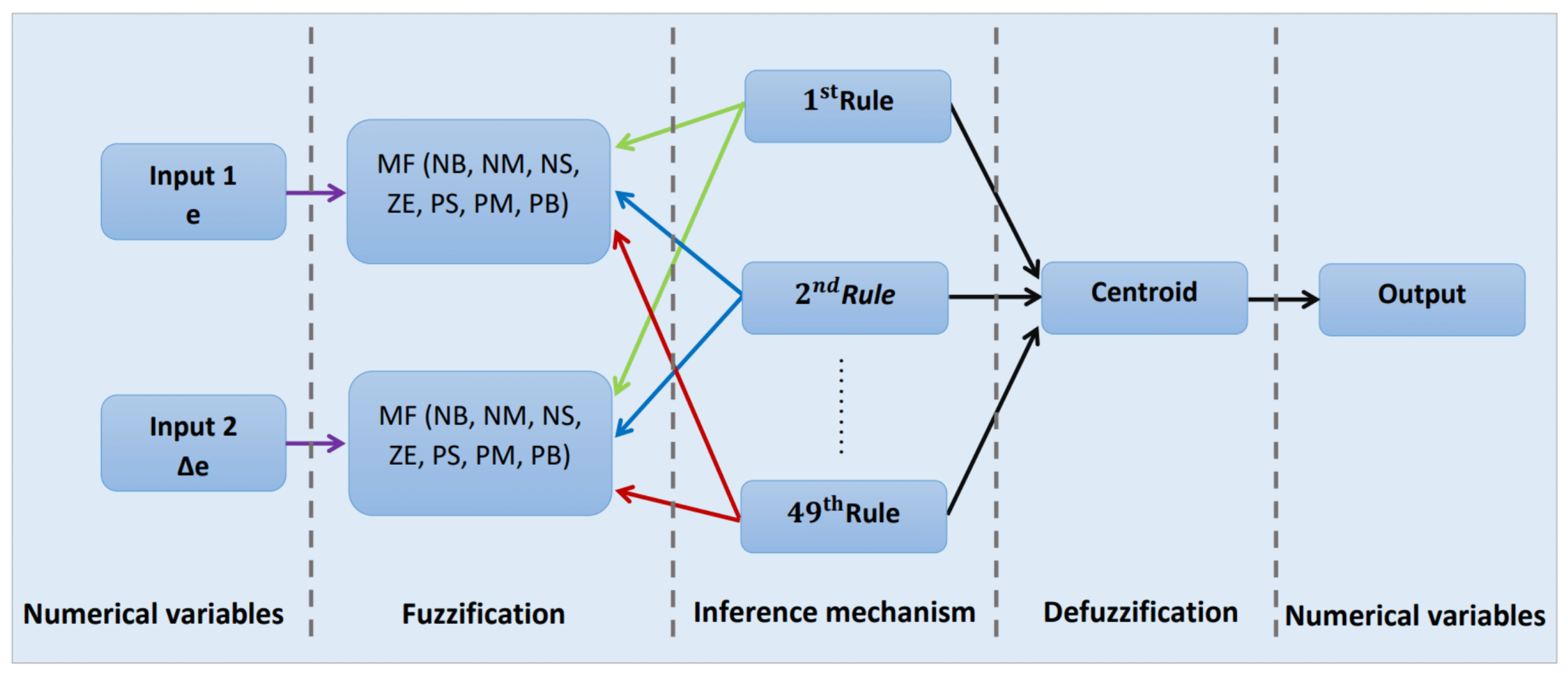

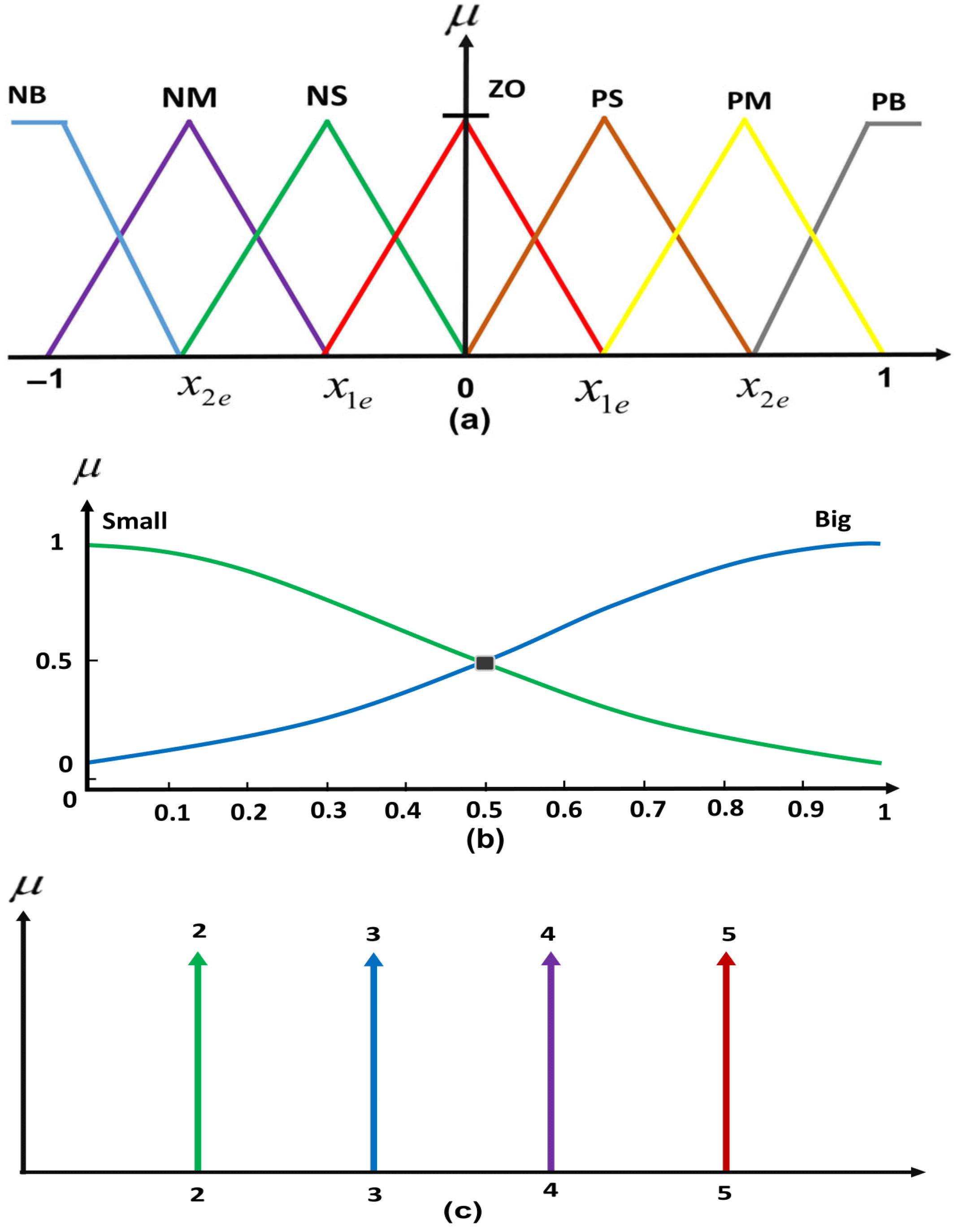

47], the authors comparatively studied PI linear and fuzzy logic controllers for an active grid-interfacing inverter in order to compensate the harmonic produced by the nonlinear system. The harmonics induced by the PI controller were high when compared to the FLC-based controller. In fact, fuzzification can help mitigate the effect of nonlinearities and disturbances in several ways [

48]. Firstly, it allows for the representation of complex nonlinear relationships between the input and output variables. This means that the control system can handle nonlinearities that may be difficult to model using traditional control methods. Secondly, fuzzification allows handling uncertainties and imprecise information. In traditional control systems, uncertainties and disturbances can cause the system to behave unpredictably. Fuzzy logic can handle uncertainties by representing the input and output variables as fuzzy sets, which allows for reasoning with degrees of membership. Finally, the FLC can adjust the controller parameters dynamically based on the changes in the input signals. Fuzzy rules can be designed to modify the control output based on the magnitude and direction of the disturbance, which can reduce the sensitivity of the control system to external disturbances. Fuzzy Gain Scheduling (FGS) combined with PID control is a powerful method for controlling complex and nonlinear systems such as the WECS. Fuzzy logic allows the controller to adapt in real-time to changing operating conditions, which is critical for ensuring the optimal performance and stability of the system [

48].

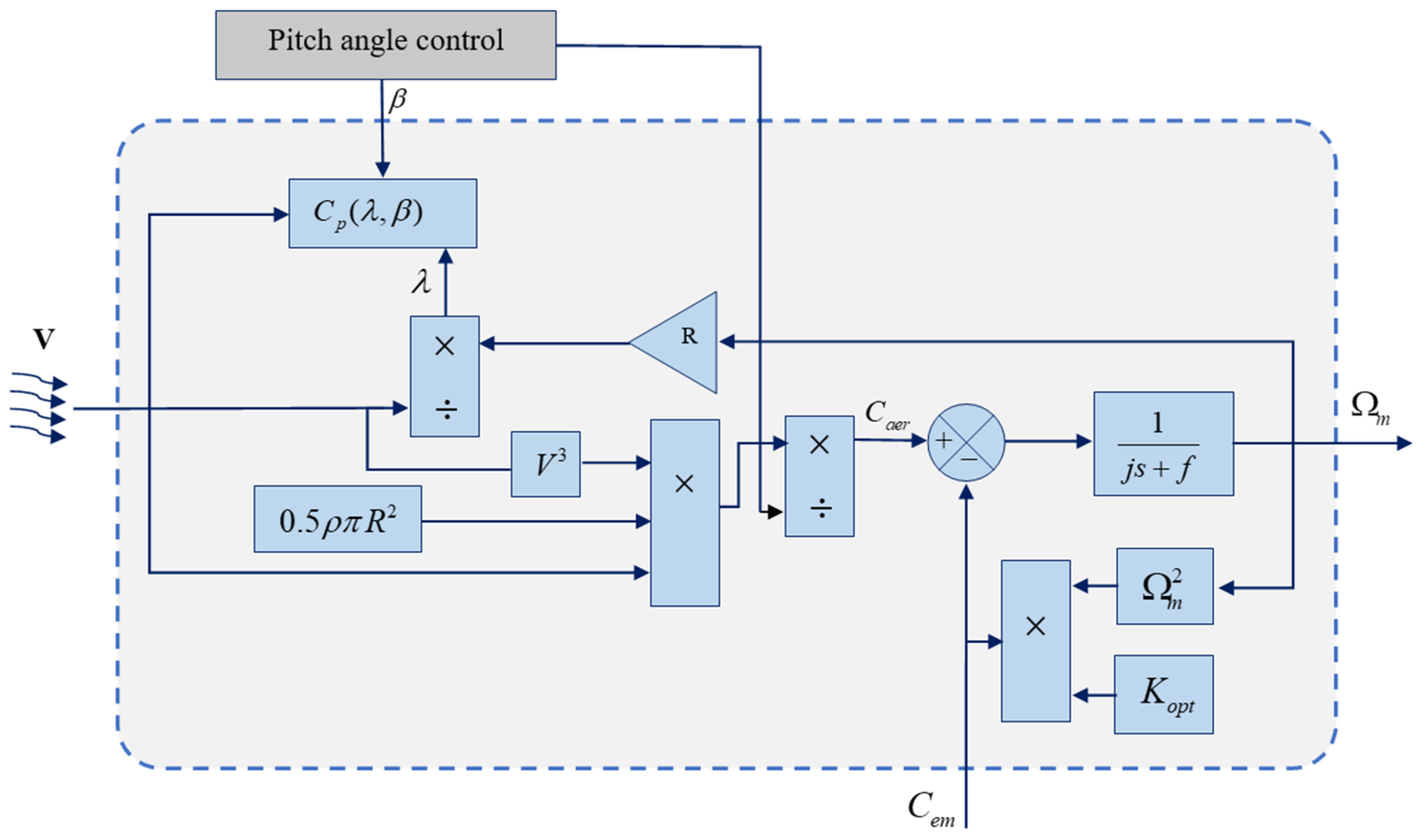

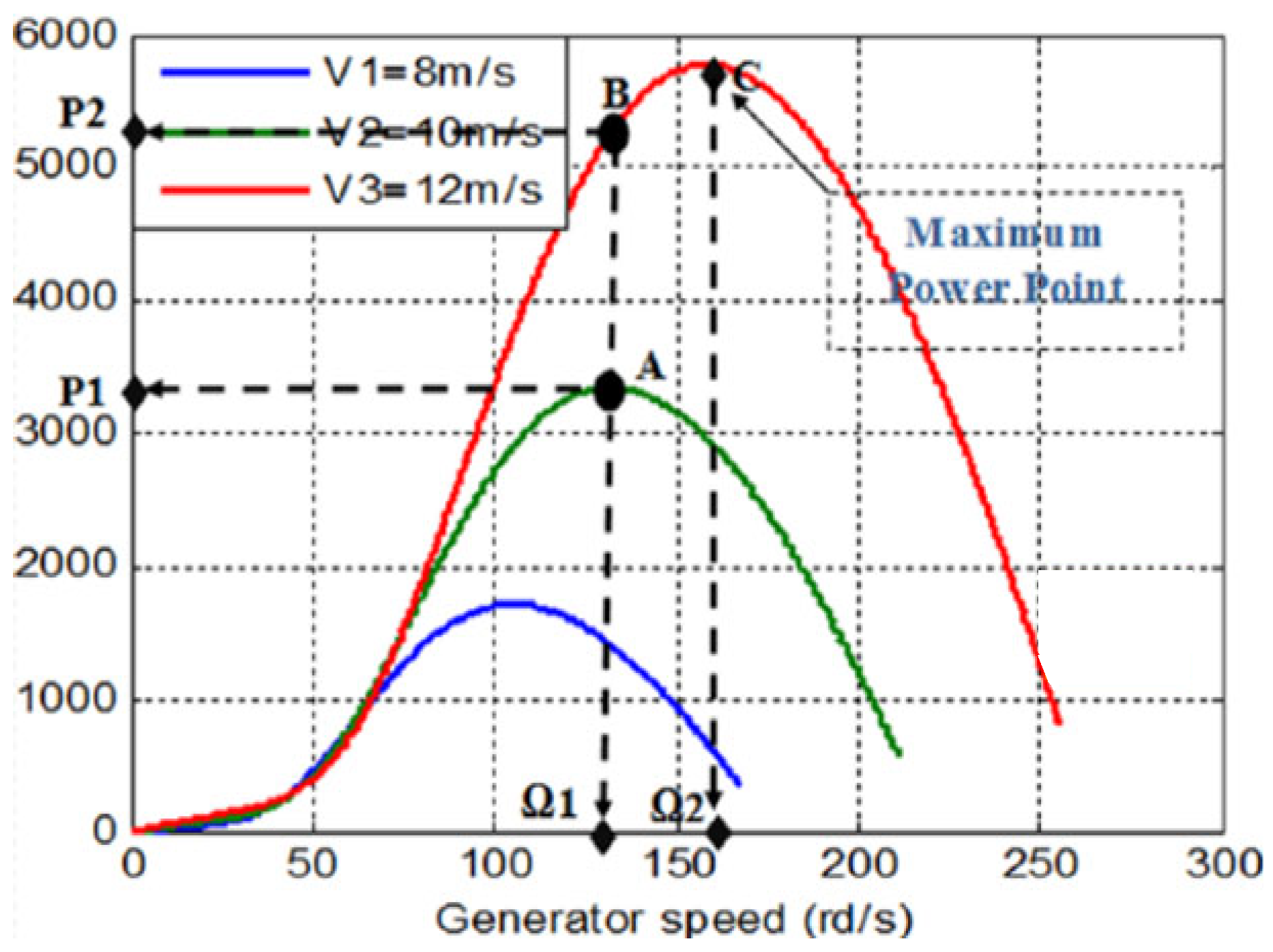

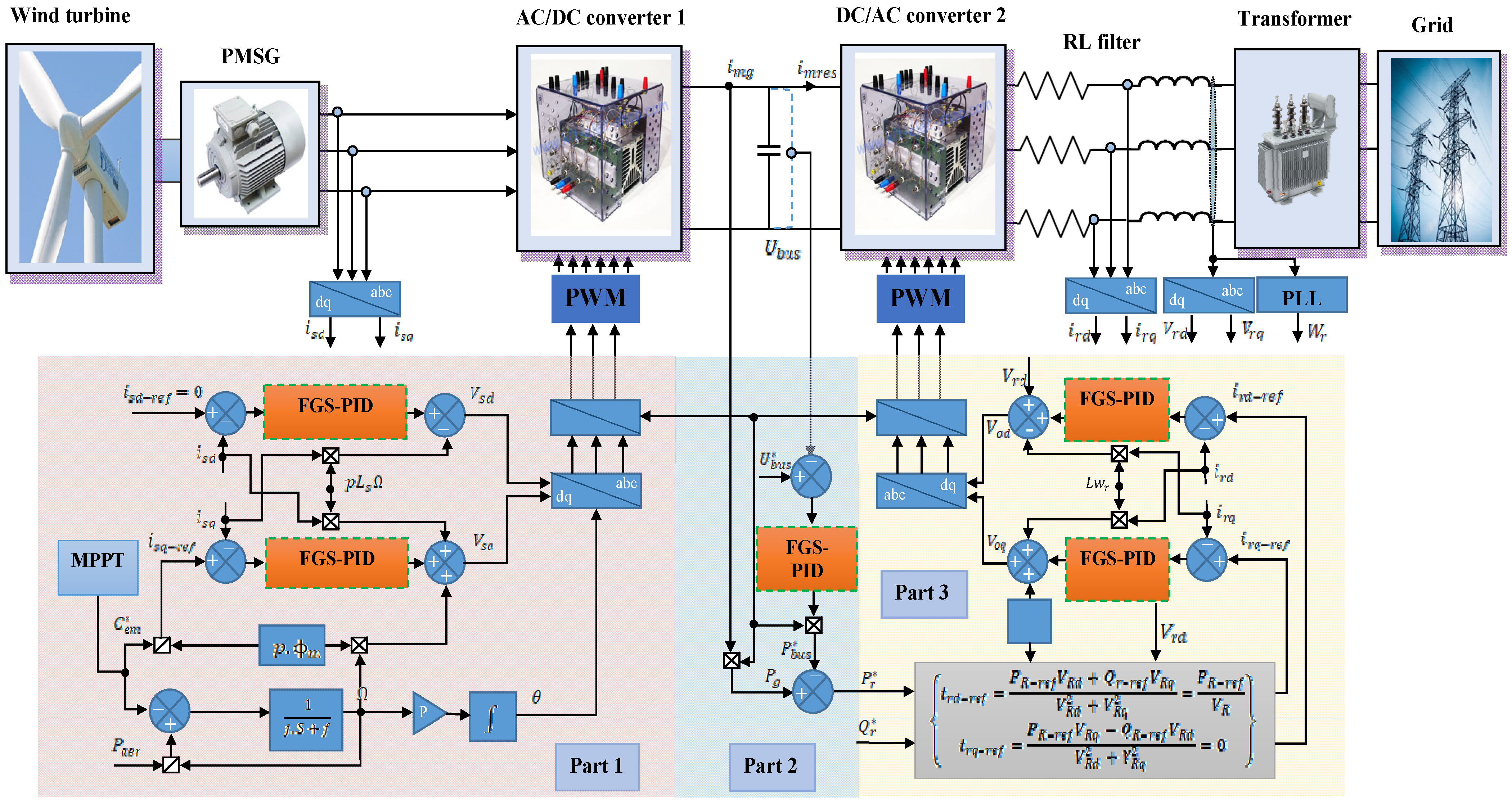

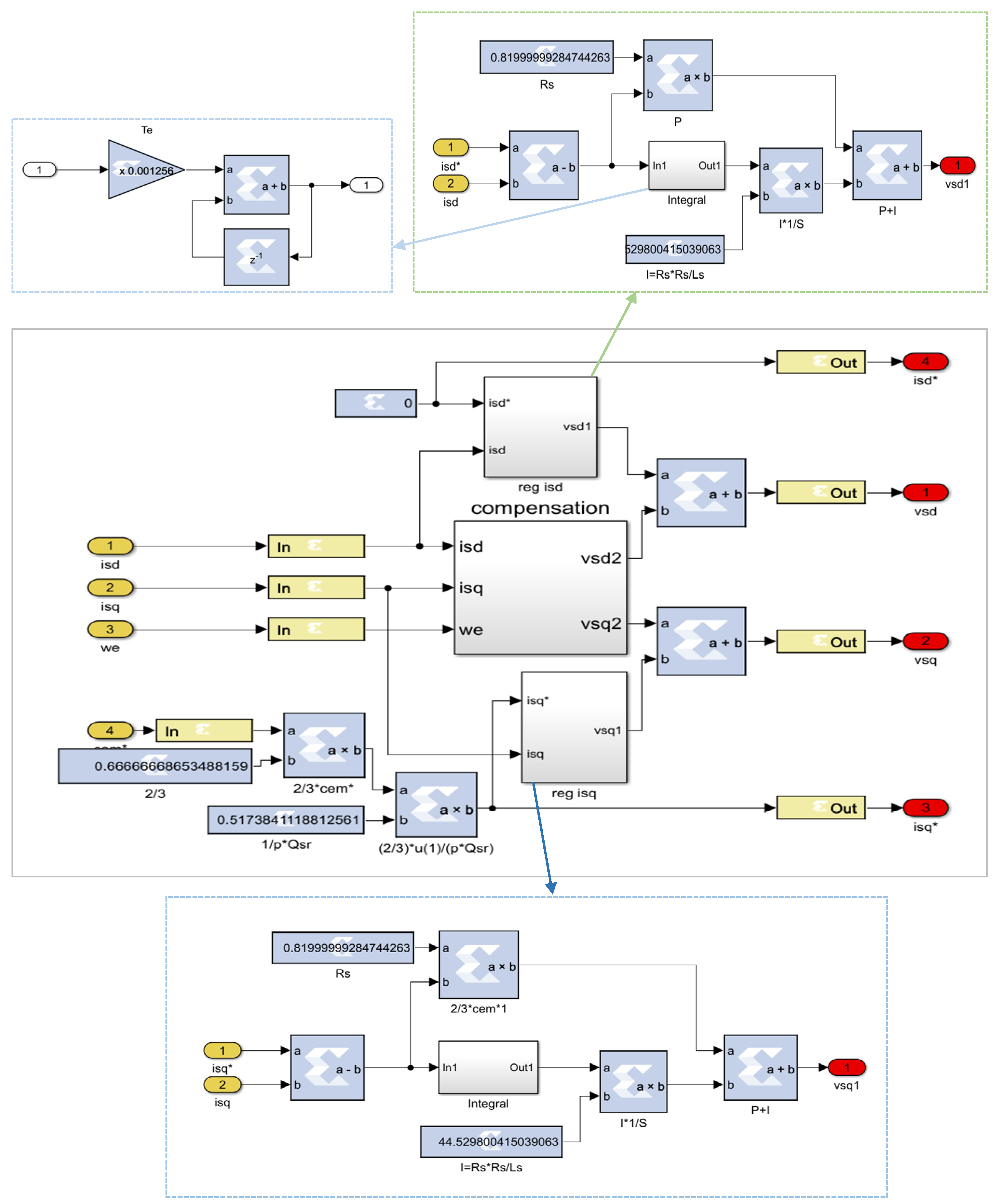

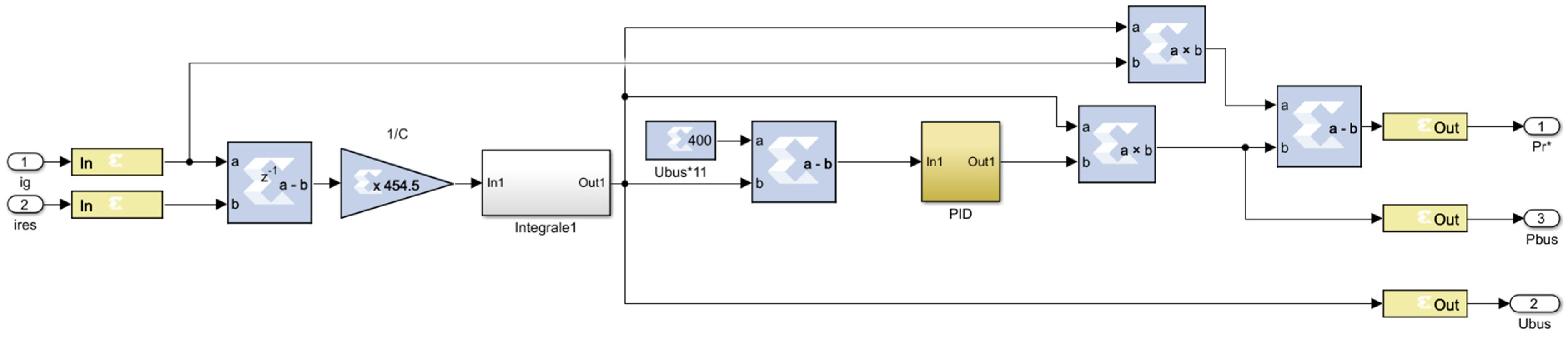

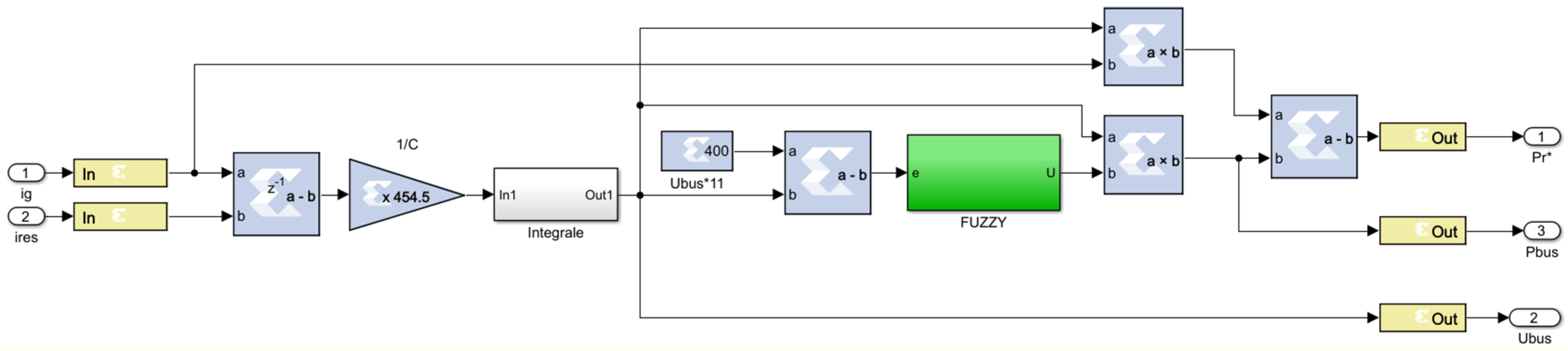

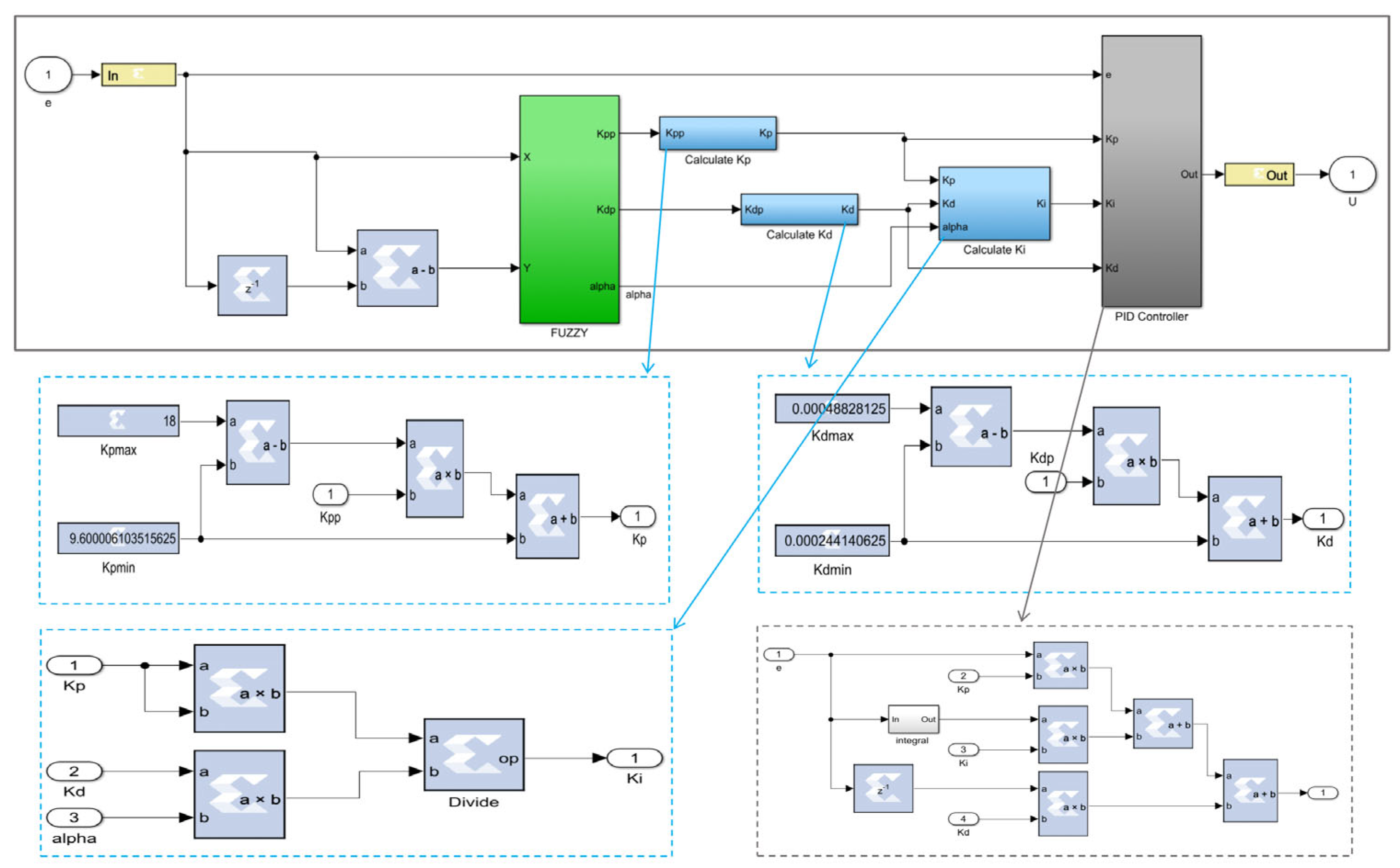

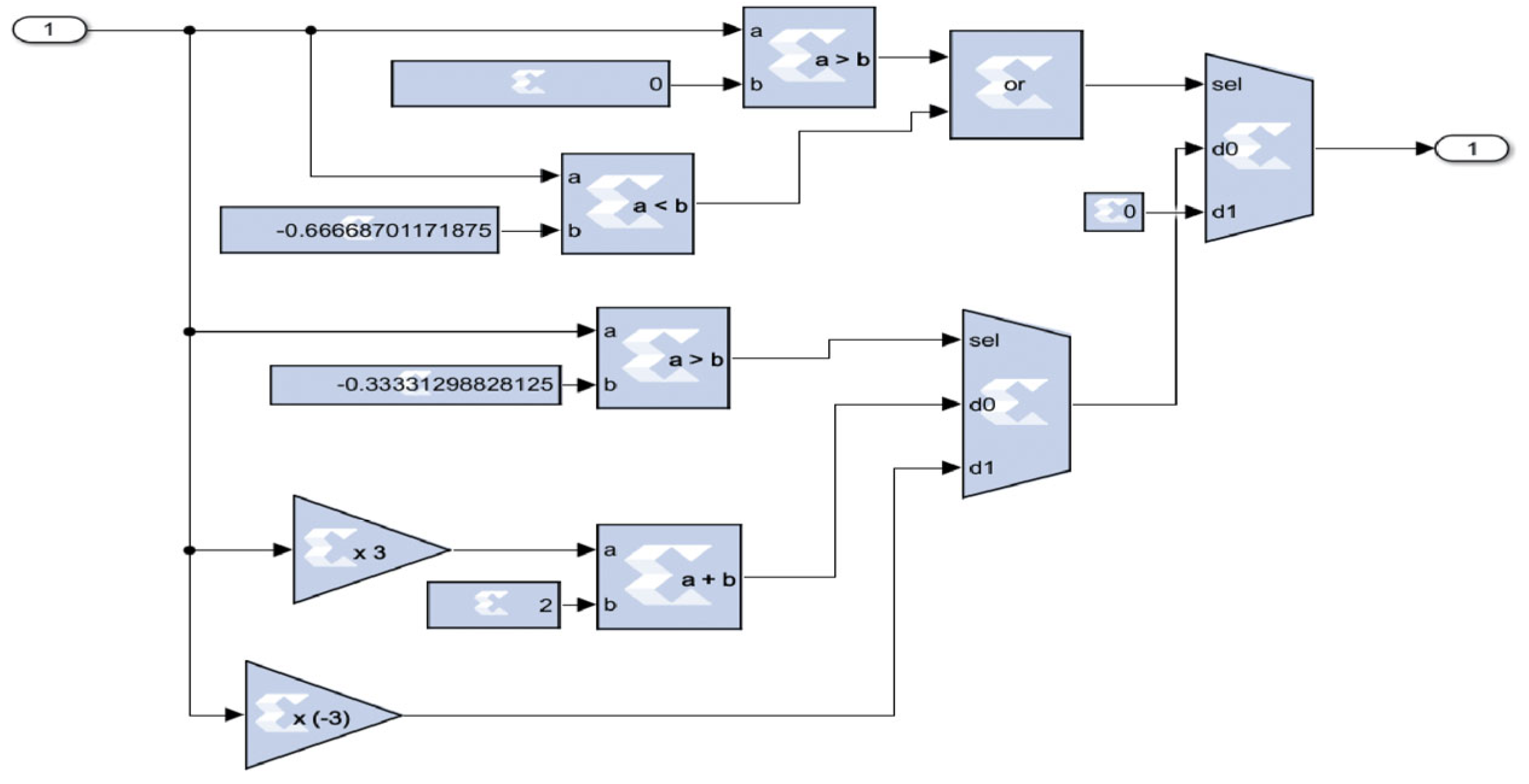

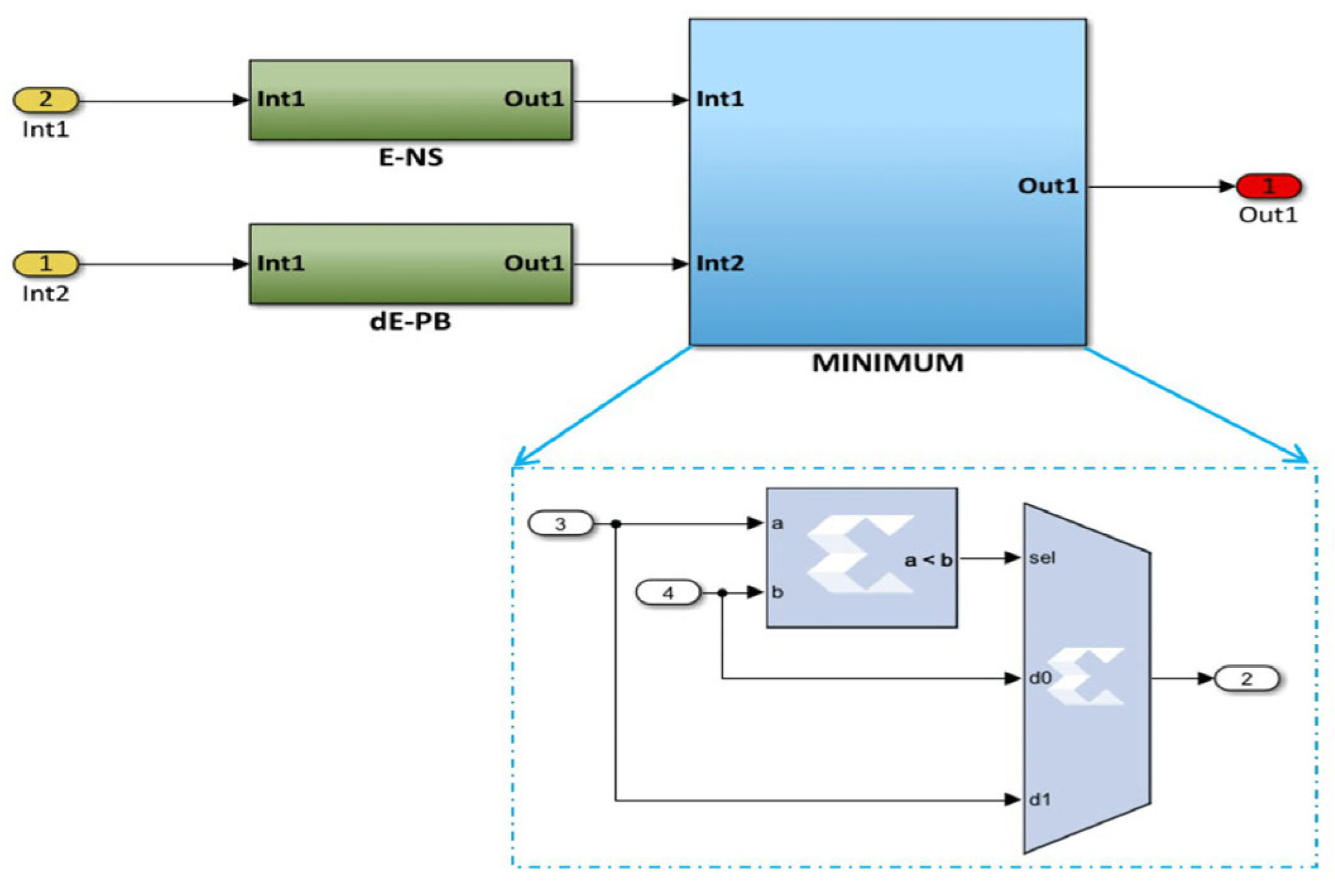

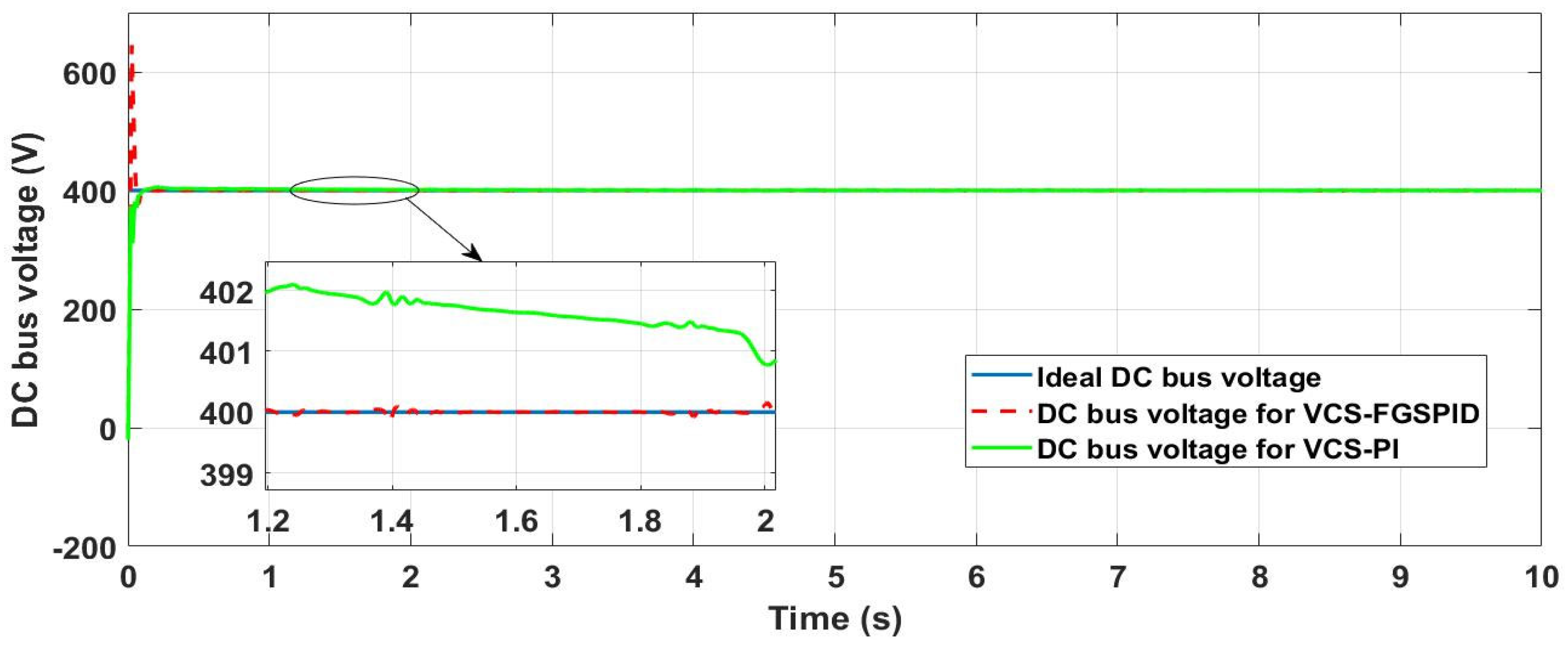

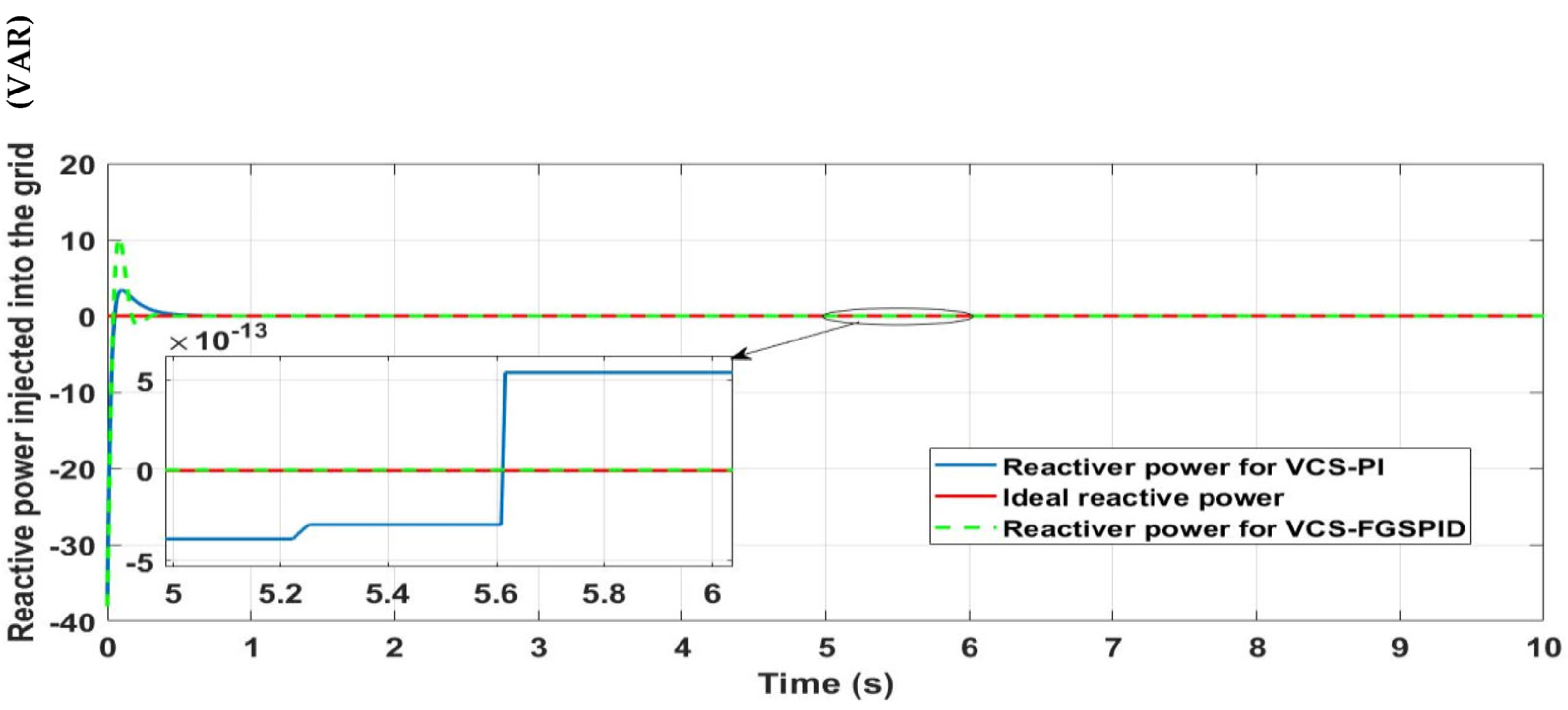

In this context, the first contribution of this paper consists of combining Vector Control Strategies with FGS based on a PID (VCS-FGS-PID) to control higher performance of a grid-connected WECS. The control system is divided into three parts: (i) VCS-FGS-PID for the PMSG-side converter, (ii) VCS-FGS-PID for the grid-side converter and (iii) a FGS-PID for regulating the DC bus voltage. The VCS-FGS-PID for the PMSG-side converter consists of controlling the electromagnetic torque, the PMSG speed, the quadratic stator current and the direct stator current. It uses the electromagnetic torque reference as an input, which is generated by a Maximum Power Point Tracking (MPPT) algorithm. Moreover, the VCS-FGS-PID of the grid-side converter is used for controlling the active and reactive power injected to the grid. It is also used to adjust the voltage and frequency in order to achieve a satisfactory level of security of the power system. The FGS-PID is suggested in this paper thanks to its robustness under external disturbances such as sudden wind speed variations and internal disturbances. As an advanced approach, the VCS-FGS-PID approach is distinguished by its good performance under the aforementioned disturbances. This is done in real-time by tuning gains of PID controllers [

47]. The aforementioned three parts of the control system, which are designed and implemented in hardware using a Field-Programmable Gate Array (FPGA), differ from other published work.

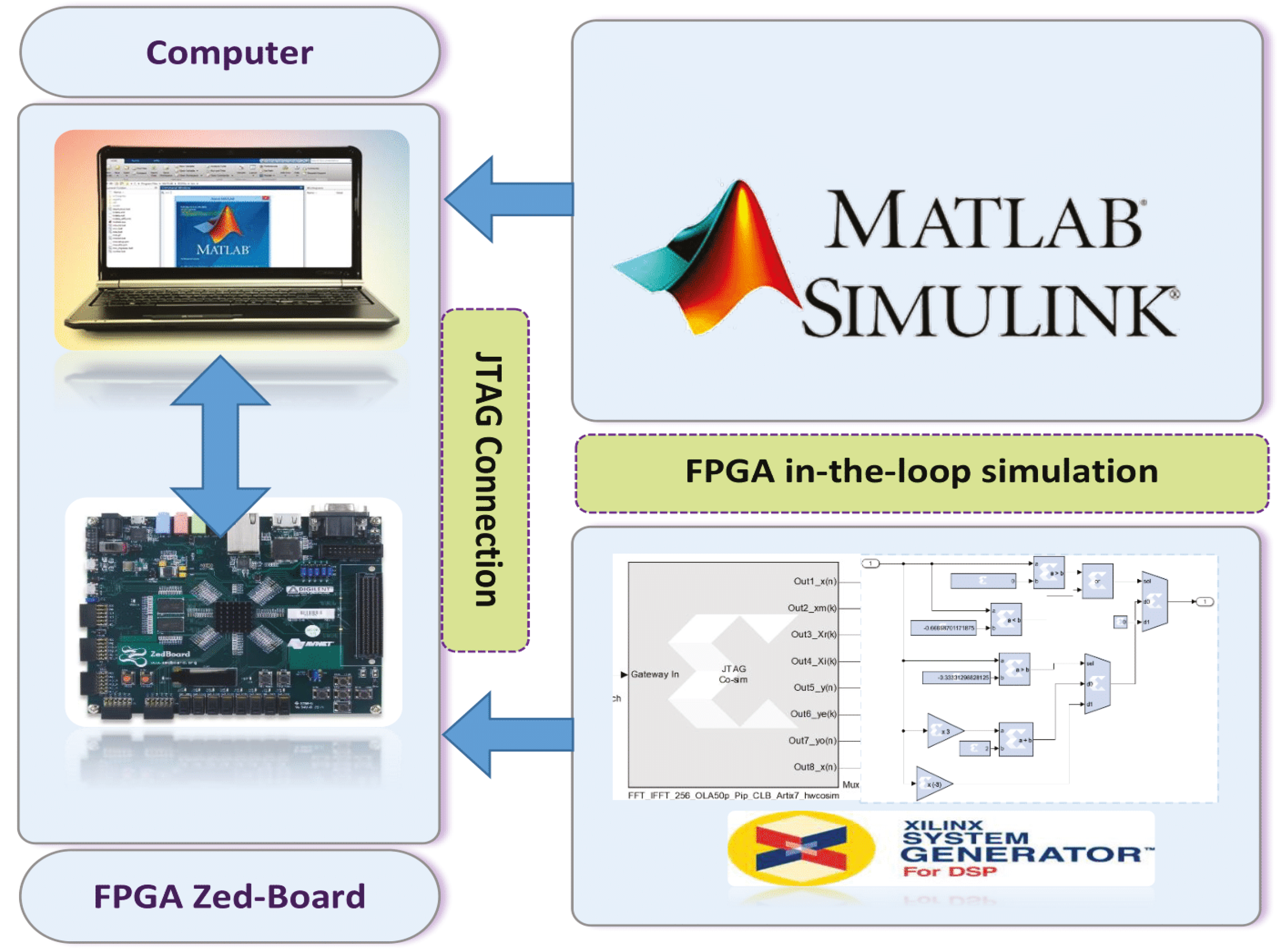

Currently, the control algorithms of electrical systems are implemented usually on two programmable-technology types: FPGAs and Digital Signal Processing (DSP). The DSP has a limiting factor of short execution time, and this is because of the control algorithm’s serial processing. In order to overcome the limitations of DSP, FPGAs can be considered a preferred solution. The benefits of using hardware FPGAs are multiple: (i) rapid prototyping, (ii) reduced execution time due to parallel processing and (iii) ability to use too-heavy control methods as regards computing time [

49]. Thus, FPGAs have been used in varied research work [

49,

50,

51,

52]. Two main methods have been used to implement control algorithms on FPGAs, namely the Xilinx System Generator (XSG) and programming Very-high-speed integrated circuit Hardware Description Language (VHDL) [

53,

54,

55,

56]. For the suggested control algorithm, a VHDL code is generated by the XSG tool. The XSG tool is chosen because it is flexible, simple and rapid.

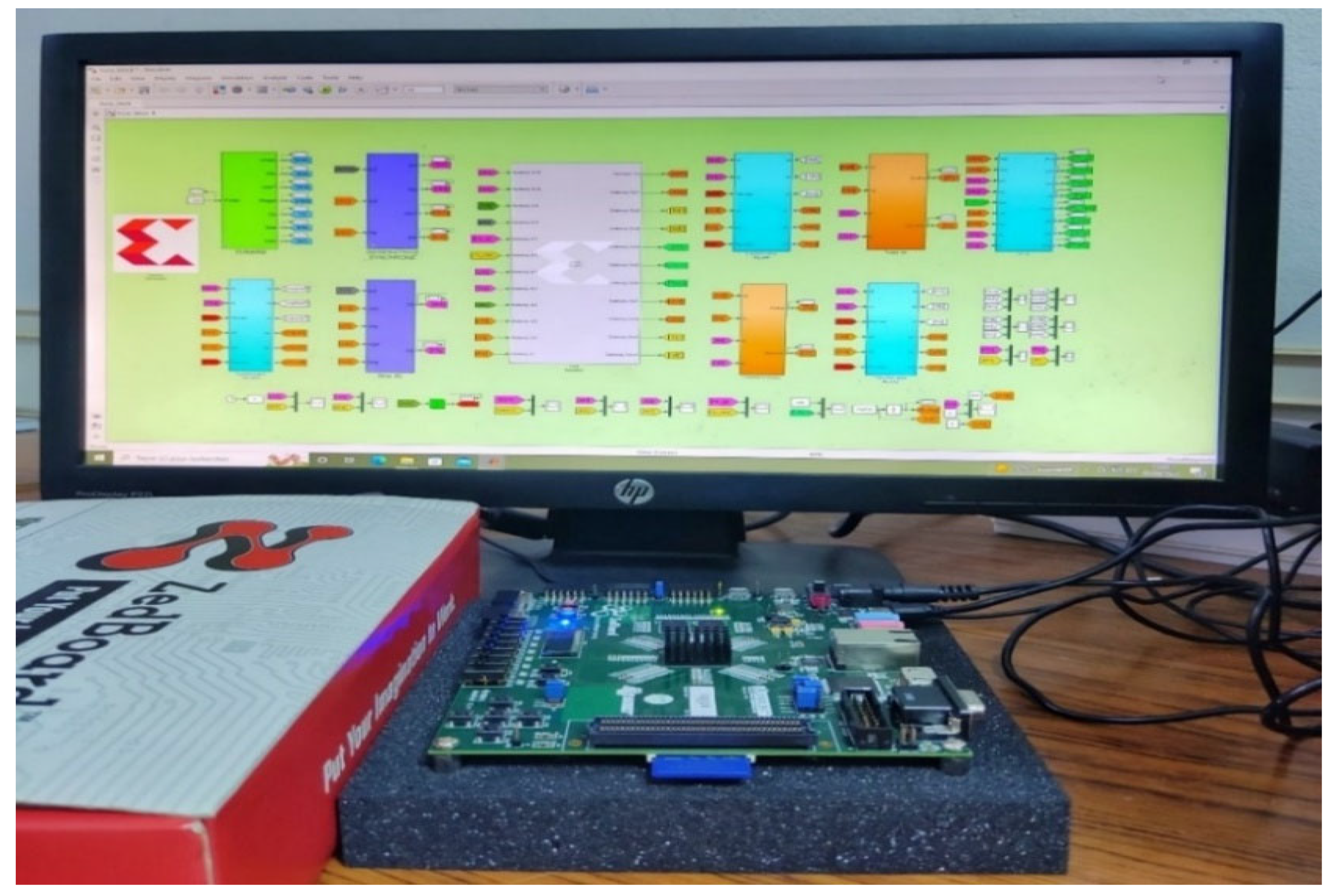

Within this framework, the second contribution of this paper is to design, with the XSG, and implement, on an FPGA board of the suggested VCS-FGS-PID algorithm for the PMSG-side converter, the suggested VCS-FGS-PID of the grid-side converter and the FGS-PID for regulating the DC bus voltage. Concerning the WECS, it is composed of a wind turbine that derives a PMSG and is connected to the power grid via an RL filter and a power electronics interface containing two converters interconnected by one common DC bus. The novelty and the main contributions of this paper theoretically, by simulation and by hardware in the loop co-simulation, are as follows:

- (i)

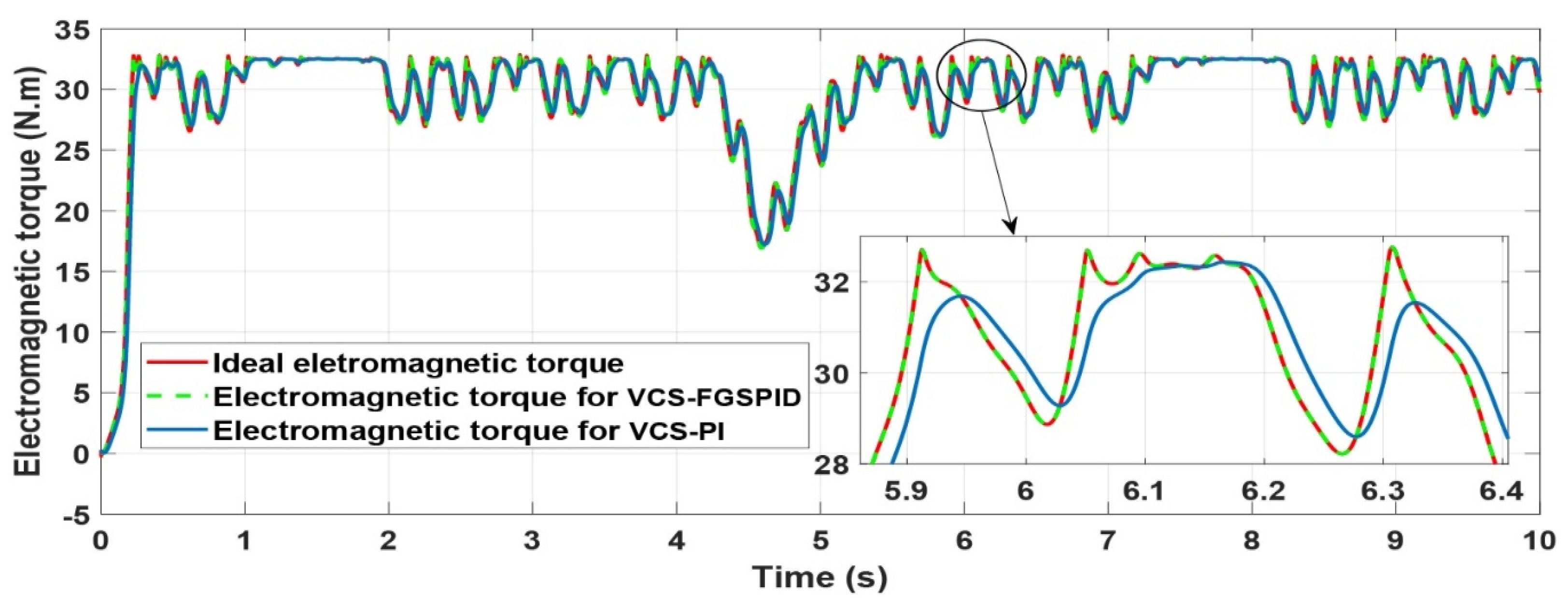

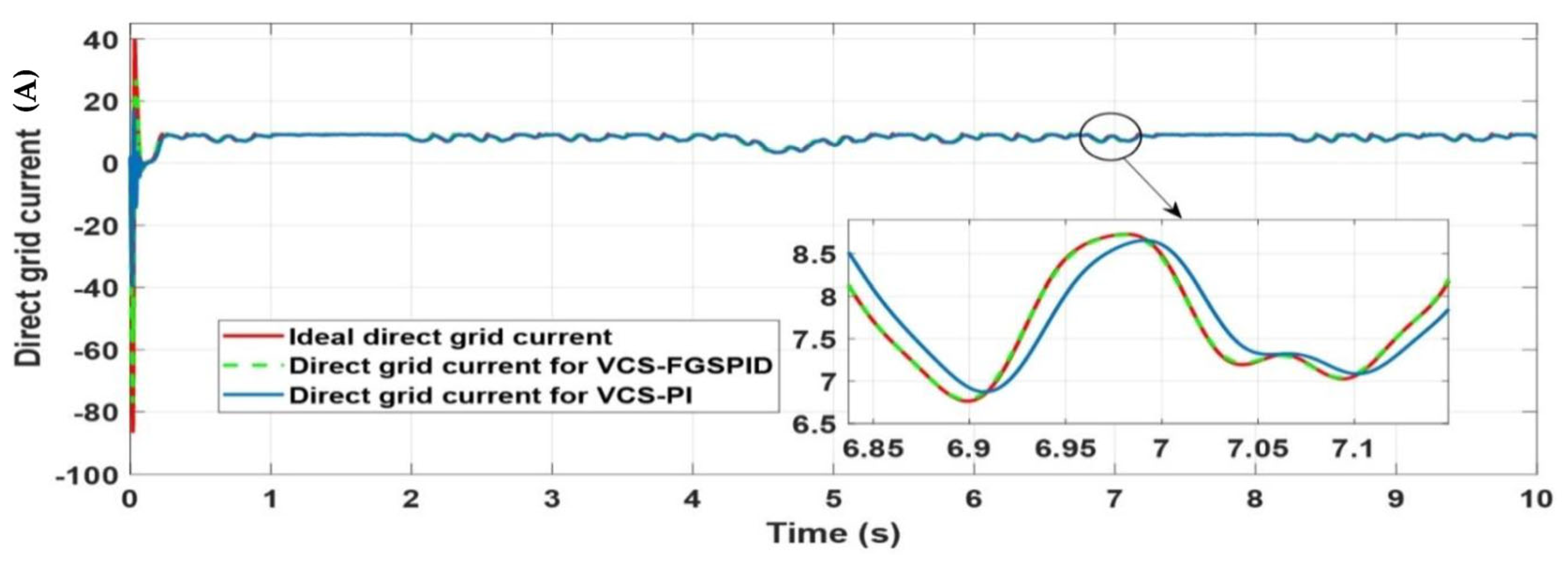

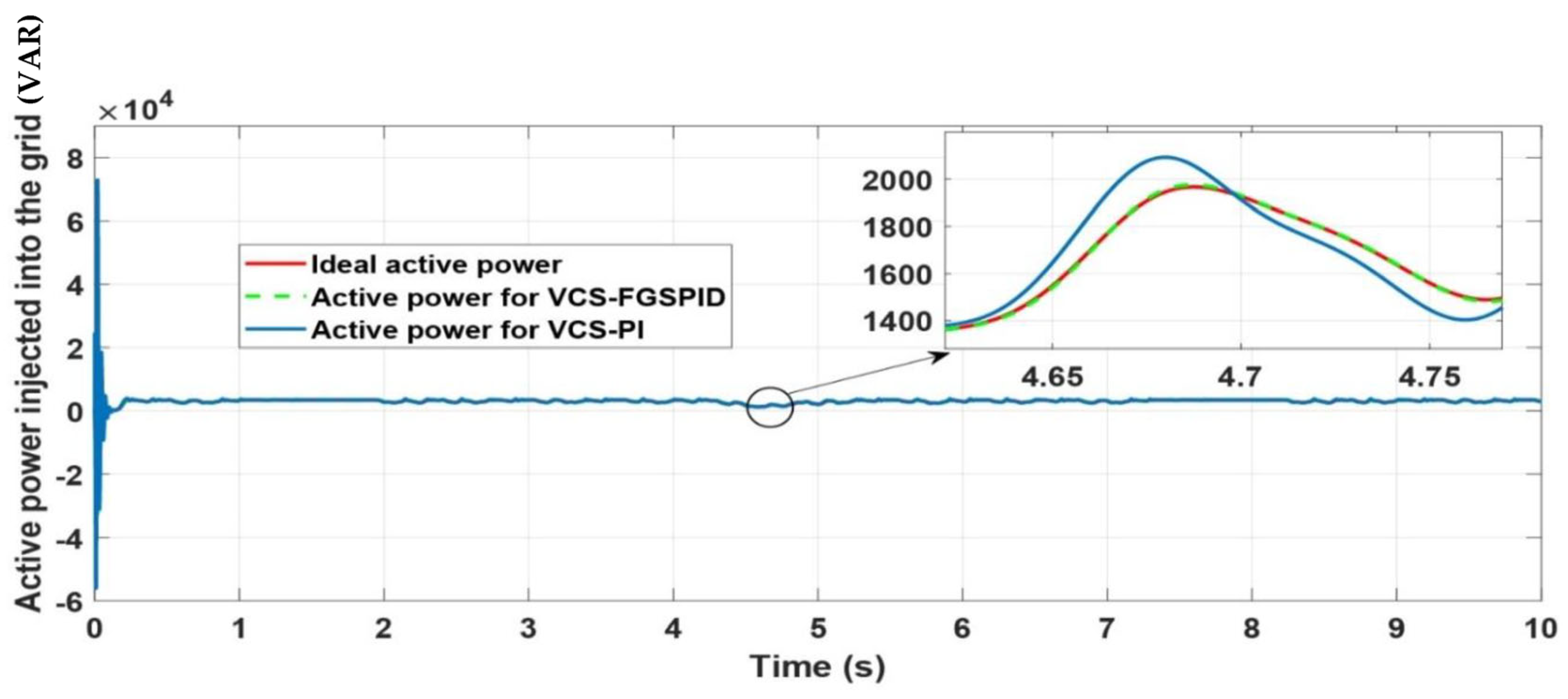

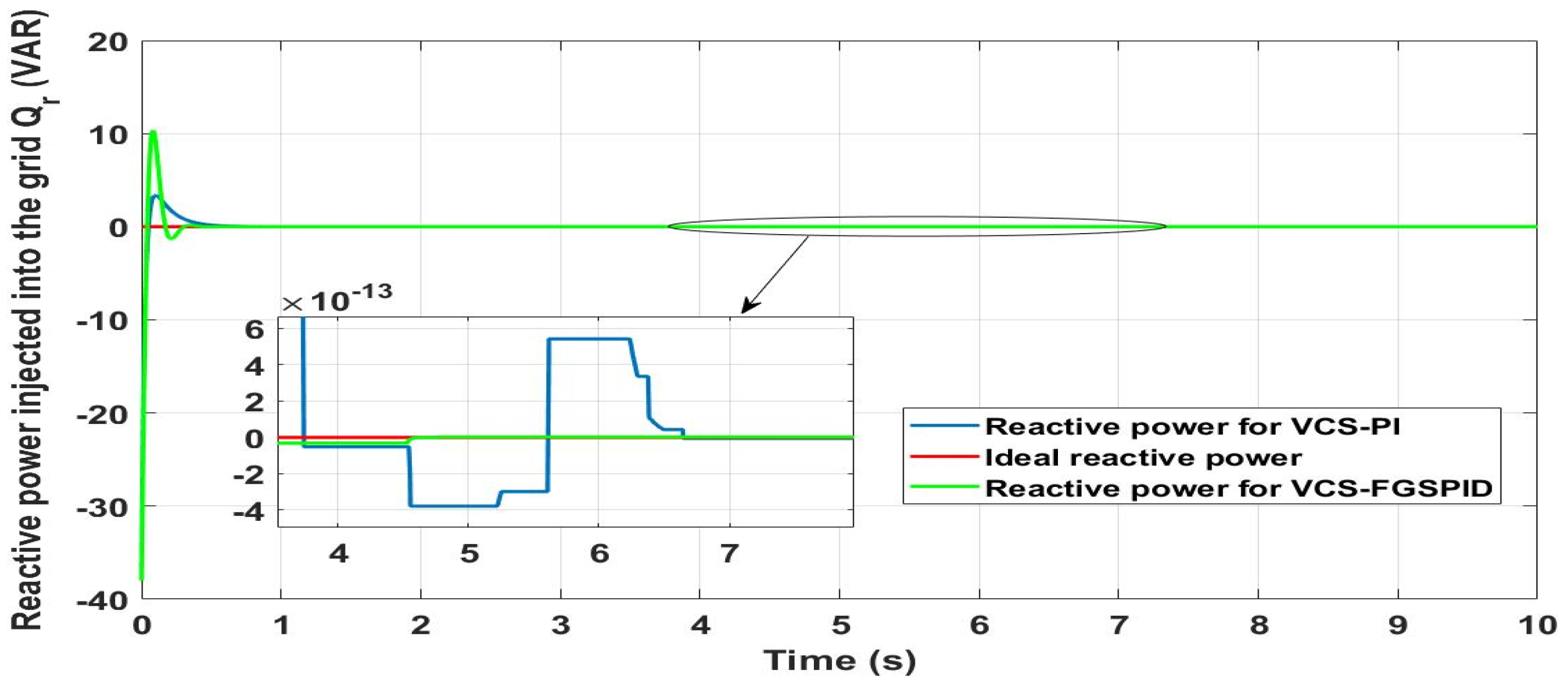

Robust VCS-FGS-PID approaches are proposed for controlling the electromagnetic torque, the stator current’s quadratic component, the DC injected into the grid, the active and the reactive power injected into the grid and the DC bus voltage. The suggested approach can ensure good performance in terms of tracking and accuracy, as well as high robustness under stator resistance variations. The proposed control strategies will guarantee excellent robustness under stator resistance variations and good tracking accuracy of the controlled variables even under high fluctuations of the wind speed;

- (ii)

The algorithms of the suggested VCS-FGS-PID and the FGS-PID of DC bus voltage are designed utilizing the XSG tool in order to verify the WECS behaviors via simulation and to automatically generate a VHDL code;

- (iii)

A real Hardware co-simulation of the suggested VCS-FGS-PID algorithms using an FPGA Zed-Board AES-Z7EV-7Z020-G is carried out before the final experimental validation step in order to avoid damage risks and guarantee the experimental operation. It also reduces the overall time allowed for the experimentation, the prototyping time, the time to market and the designed system cost.

The rest of the article is organized as follows. The various system elements are modeled in

Section 2. In

Section 3, the conventional VCS-PI and the VCS-FGS-PID are discussed to ensure robust control of the WECS. The FPGA hardware architecture of the VCS-PI and the proposed VCS-FGS-PID, as well as their synthesis and implementation, are described in

Section 4. In

Section 5, the two control methods are implemented and simulated under the XSG, and a comparison between both controllers with and without parameter variations is presented, followed by a comparison with other studies. Finally,

Section 6 concludes this work and opens new perspectives.

6. Conclusions

In this article, the development and hardware implementation of two control schemes (VCS-FGS-PID and VCS-PI) applied to a grid-connected variable-speed WECS have been discussed. There are two major aims for the control of the WECS. The first one is the PMSG-side converter control, which allows the wind turbine to extract the maximal power. The second one is the grid-side control, which aims to maintain the operation in a unity power factor by controlling the reactive and active power transferred into the power grid. This controller also regulates the DC bus voltage. The first control scheme based on the FGS-PID controller has been compared to the second one based on the conventional PI controller. For a better evaluation of varied control technique performance, a comparative study has been extended under varied stator resistance. The VCS-FGS-PID controller has been developed for solving any limit of the conventional VCS-PI controller as regards performance and stability under the nonlinearity behavior of the WECS.

For the hardware implementation, the XSG has been utilized for implementing the suggested control technique on the FPGA. The proposed approach hardware implementation is simple and quick thanks to a novel method based on the XSG. The various simulation results show the superior performance of the VCS-FGS-PID controller when compared to the conventional VCS-PI controller in terms of response time, stability properties, dynamics, tracking and accuracy under the high fluctuation of the wind speed and the varied stator resistance. The implementation result shows the FPGA efficiency in terms of execution time. Indeed, it has been quite short when compared to the dSPACE execution time, owing to parallel processing. The short execution time increases the machine performance and reduces the torque, as well as stator current disturbance, allowing more complicated algorithms to be implemented. Finally, the XSG implementation approach may be thought of as an important tool for implementing real-time hardware FPGAs as well as complicated and preferred WECS control algorithms.

Nevertheless, there are other challenges remaining to be solved in our future work such as the verification of the suggested VCS-FGS-PID method performance according to real experimental results. Moreover, the authors will focus on the integration of a battery energy storage system for the WECS. This could involve developing new control strategies and power management systems to optimize the output power, and subsequently obtain a perfect wind system able of ensuring a continuous load supply without fluctuations.