Techno-Economic Evaluation of Hybrid Energy Systems Using Artificial Ecosystem-Based Optimization with Demand Side Management

Abstract

:1. Introduction

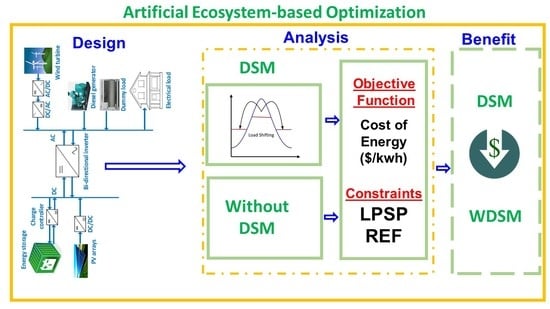

- A new application of Artificial Ecosystem-based Optimization is utilized for the first time to achieve optimal sizing of HES by minimizing the Cost of Energy (COE);

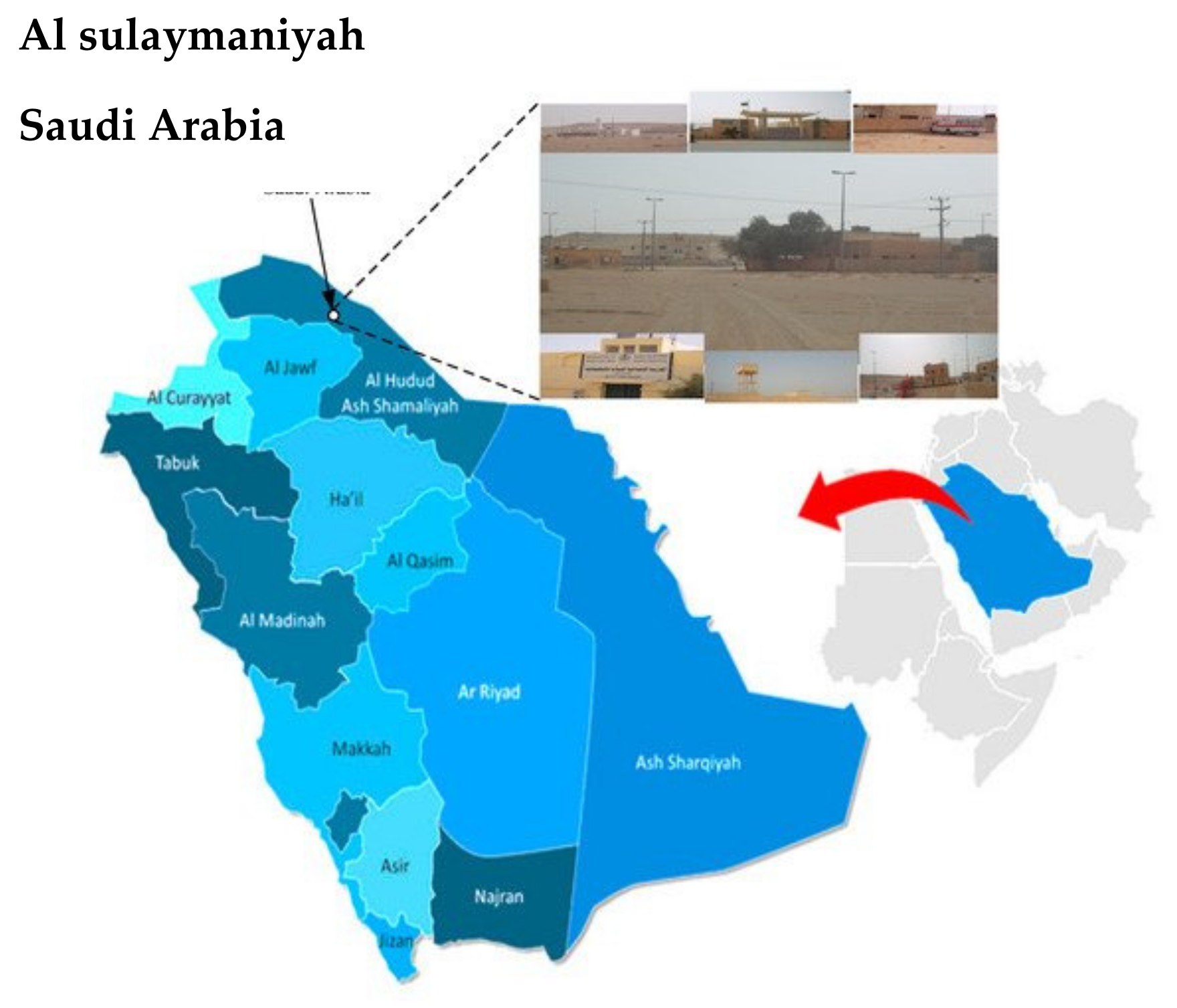

- Renewable Energy Fraction (REF) and Loss of Power Supply Probability (LPSP) are utilized to achieve stand-alone HES consisting of PV/WTGs/battery/diesel for Al Sulaymaniyah village, Saudi Arabia;

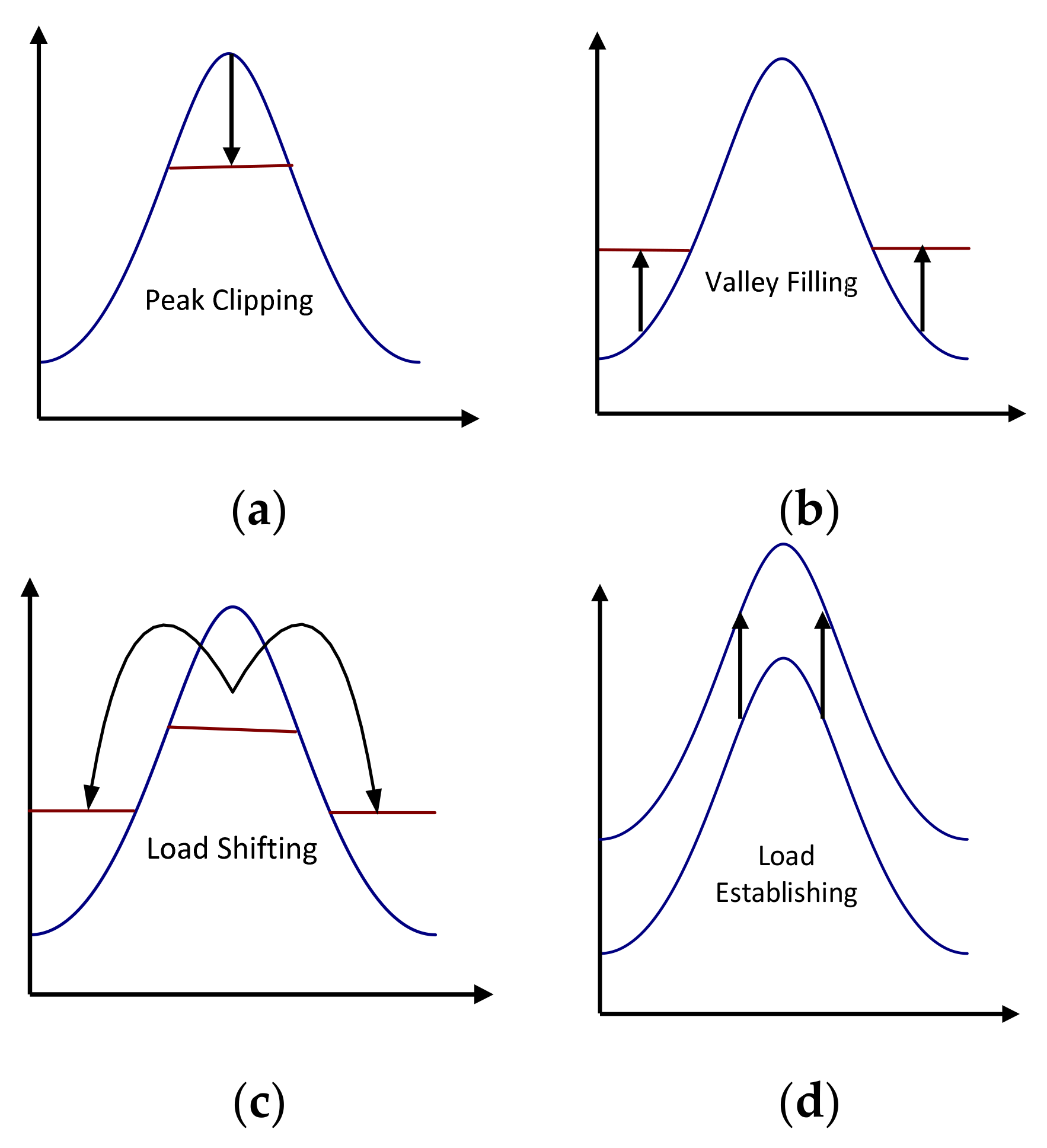

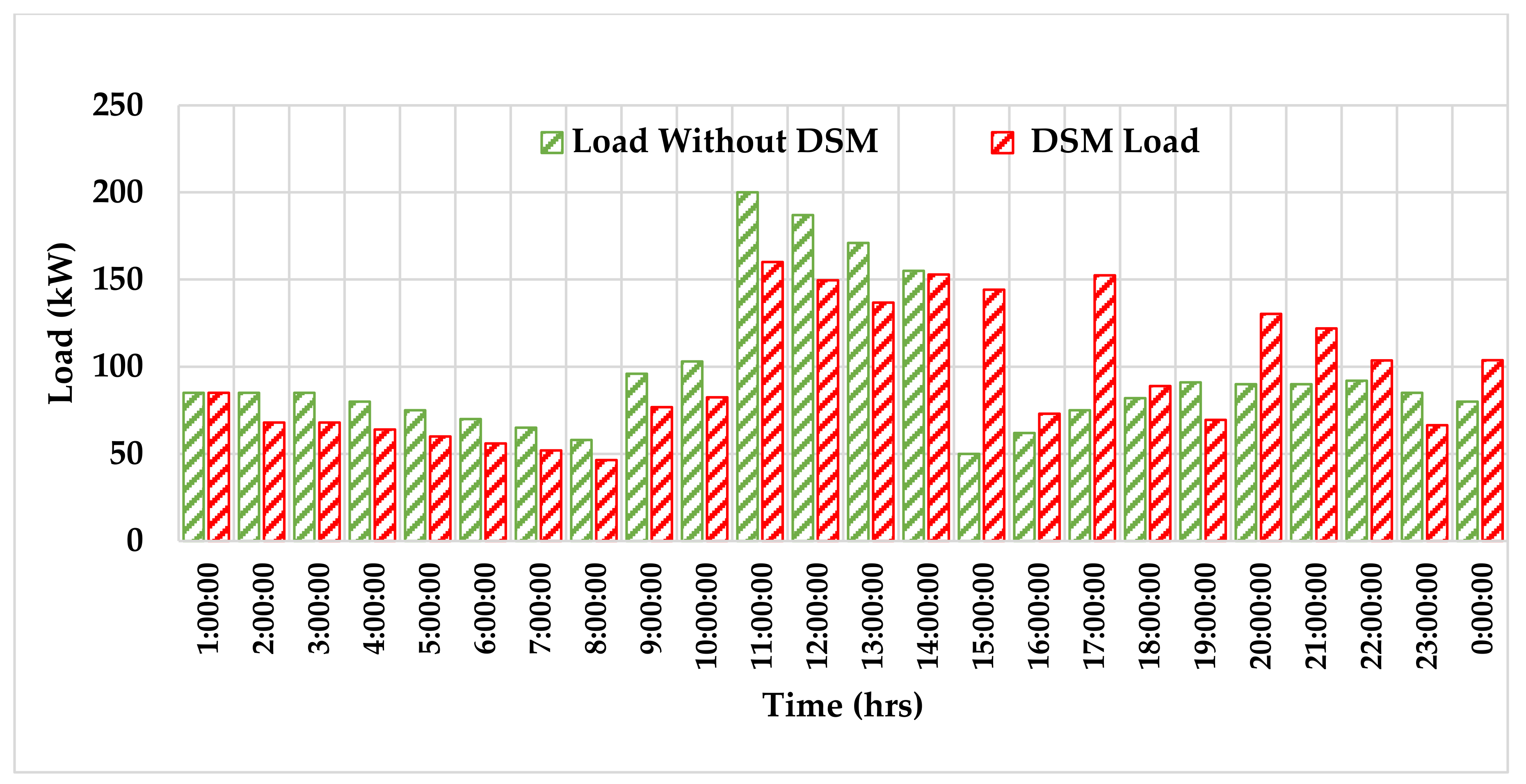

- A load-shifting strategy based on the available renewable is employed for the DSM to achieve a minimal cost of energy;

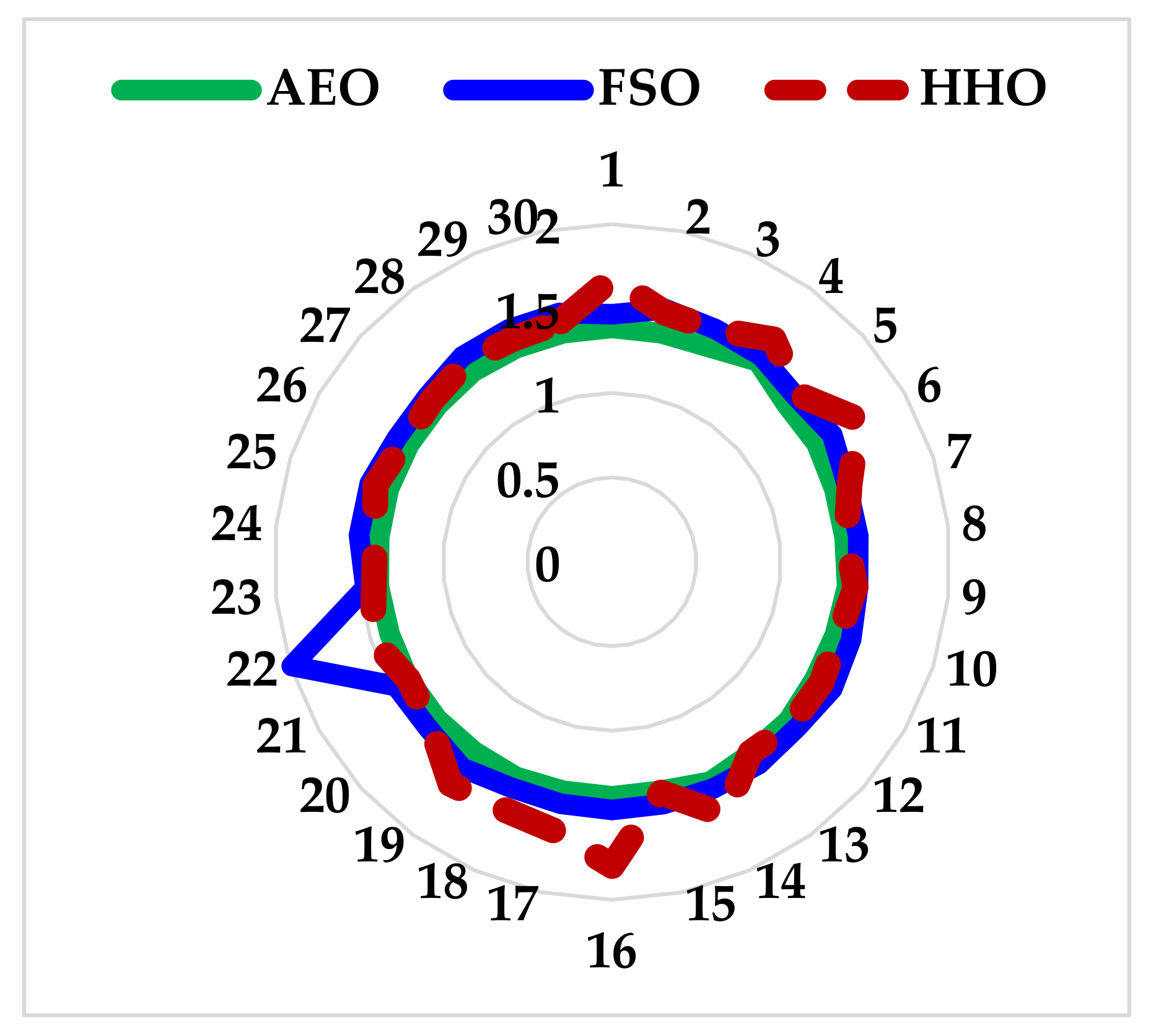

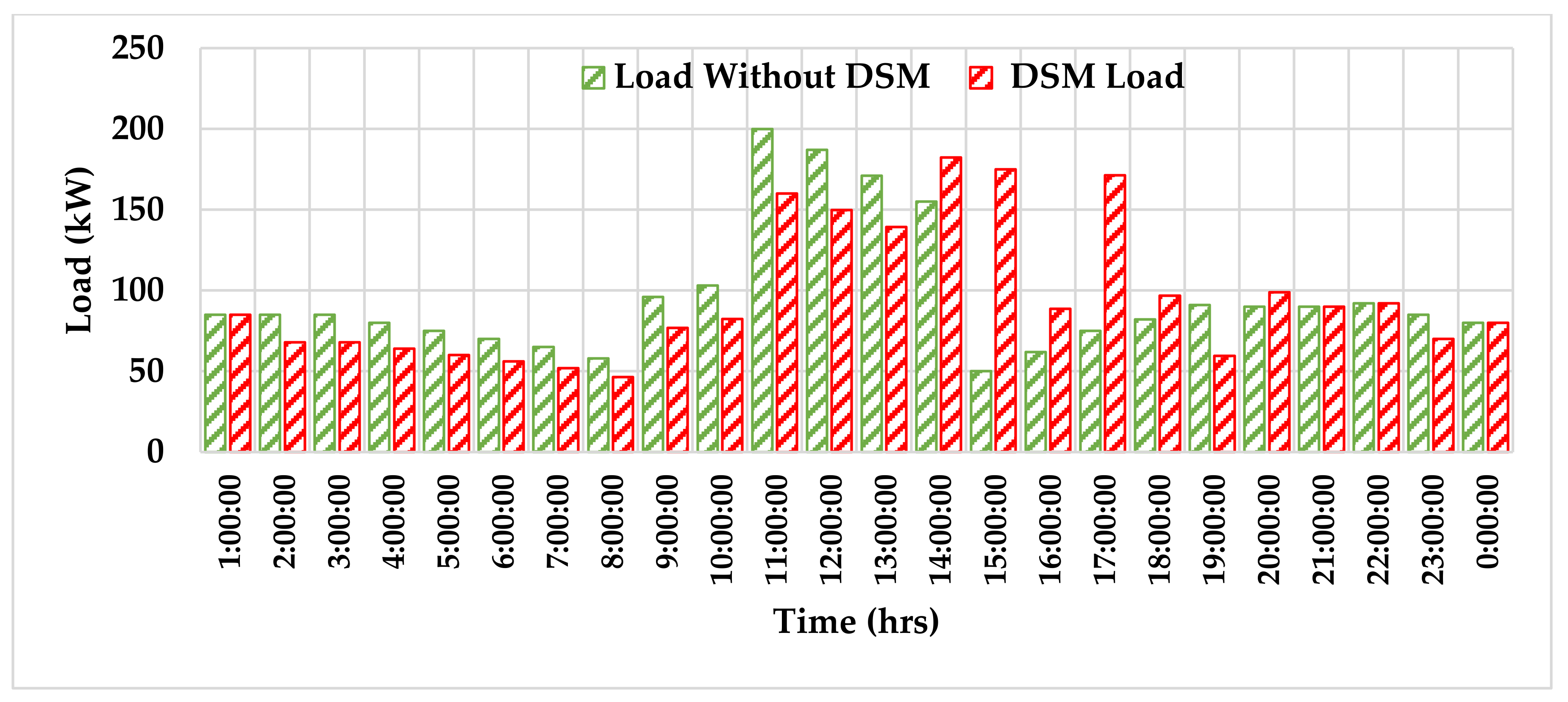

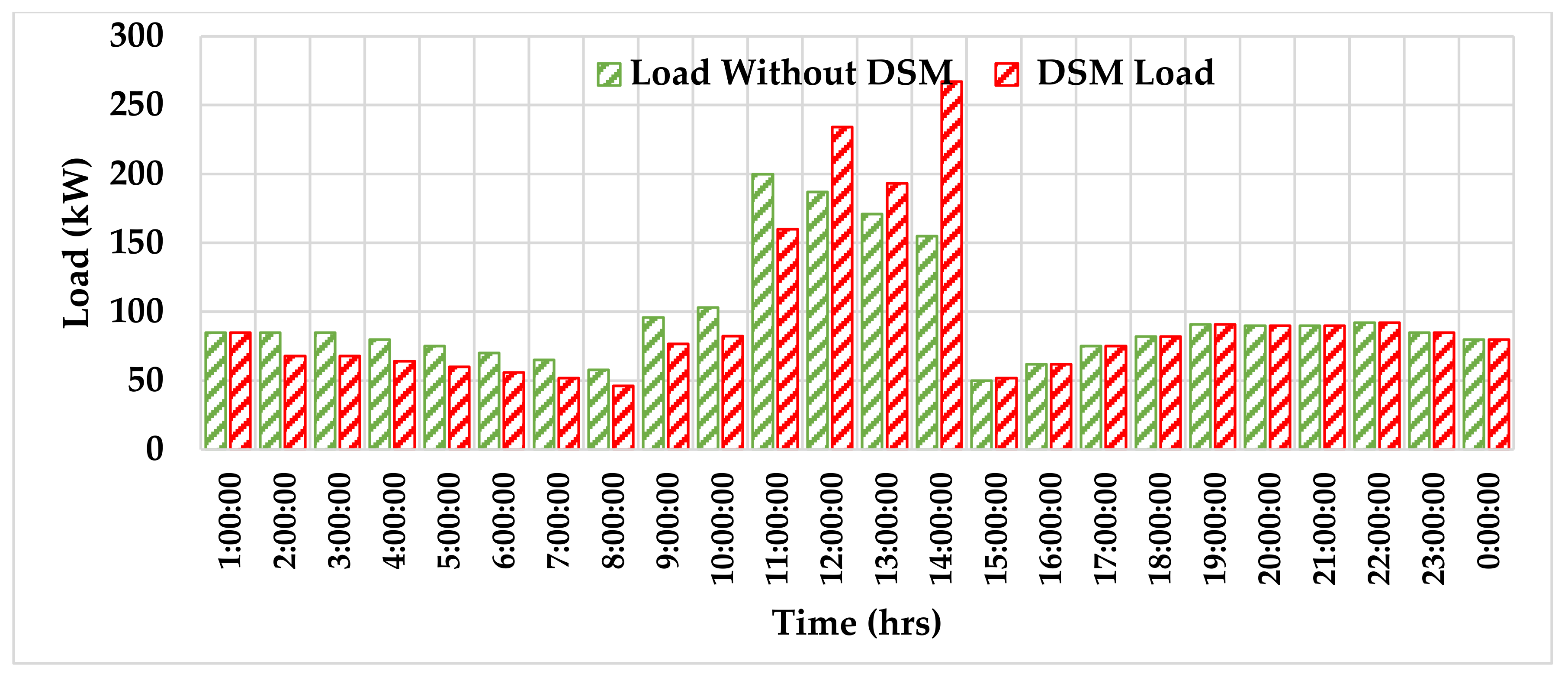

- AEO is compared to FSA and HHO with DSM and without DSM in achieving the COE and to verify its efficacy;

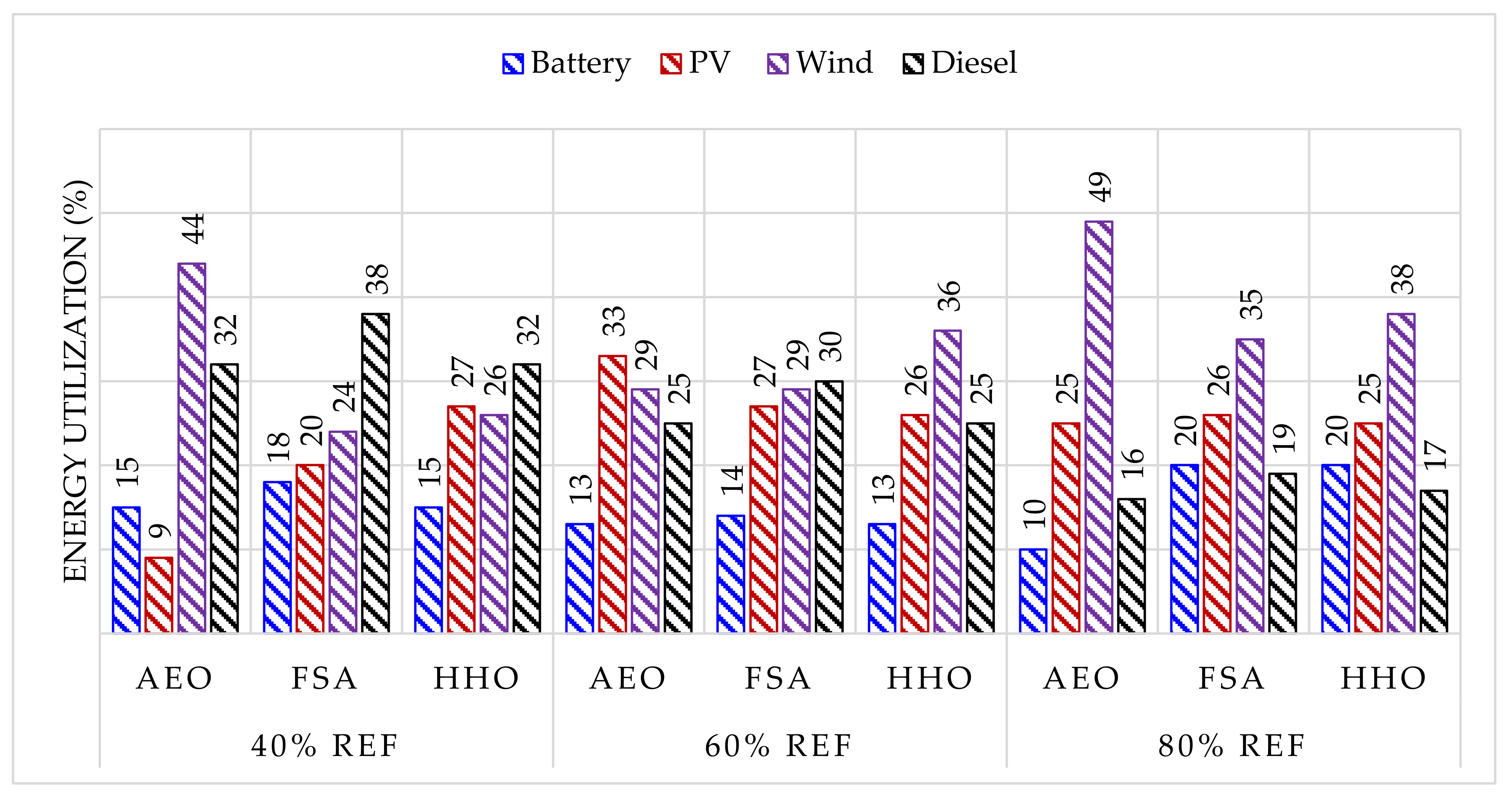

- Different values of REF at 40%, 60%, and 80% are utilized as constraints to determine the COE with DSM and without DSM;

- The results demonstrated the effectiveness of AEO to achieve the lowest COE, both with DSM and without DSM.

2. Al Sulaymaniyah Site Description and Meteorological Data

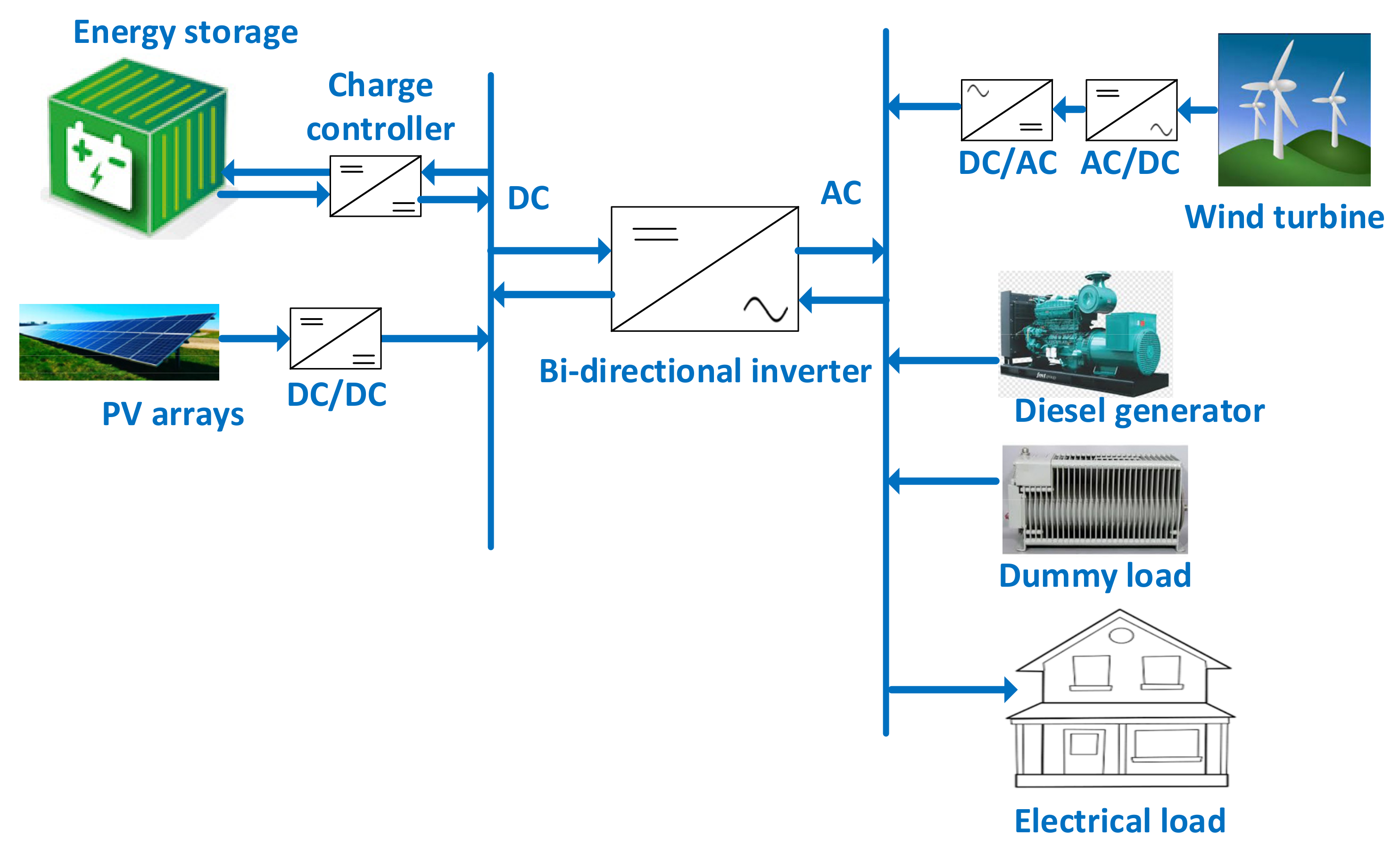

3. Configuration of the HES

3.1. PV Modelling

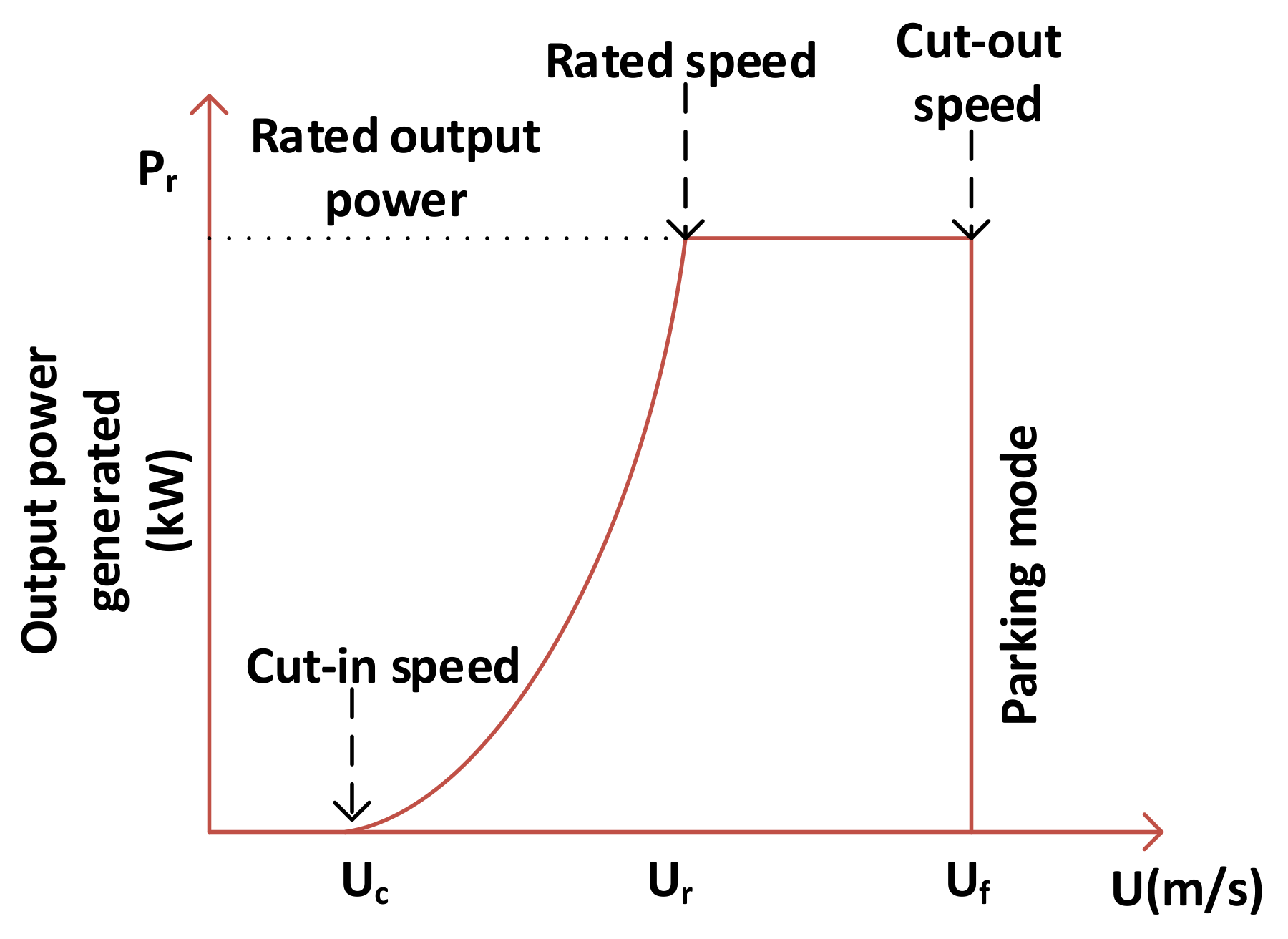

3.2. Wind Turbine Generator (WTG) Modelling

3.3. Storage System Modelling

3.4. Diesel Generator

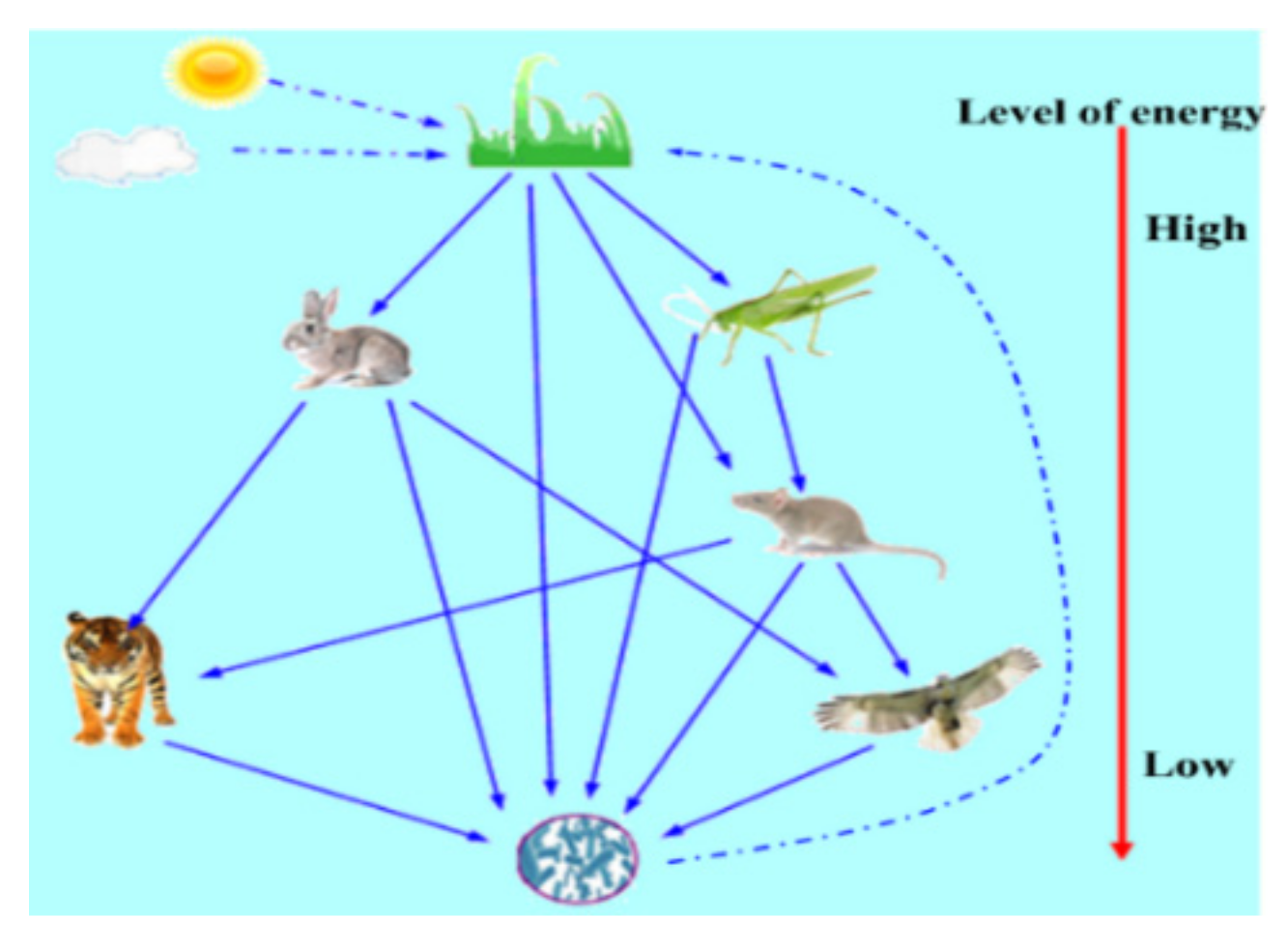

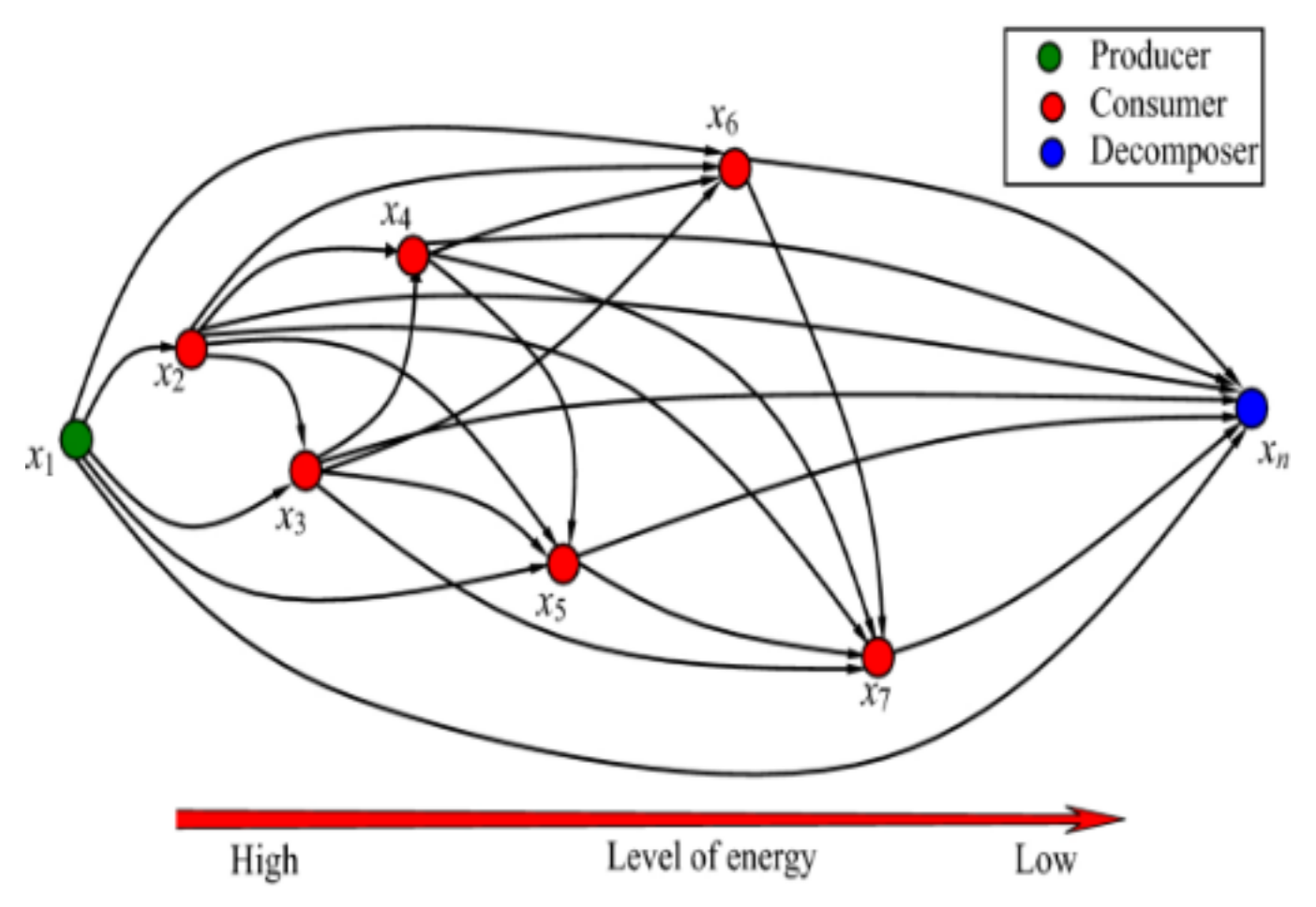

4. Artificial Ecosystem-Based Optimization (AEO)

4.1. Producer

4.2. Consumption

4.3. Decomposers

4.4. Termination

| Algorithm 1: Pseudocode of Artificial Ecosystem-based Optimization for optimal the sizing of HES |

| 1. Initialization: Random initialization of AEO ecosystem, x1, and evaluation of fitness, ffi; xq = best solution established so far. 2. While the halt condition is not obtained, perform: First Stage: Production Individual x1, update its position with (7). Second Stage: Consumption Individual x1 (i = 2, …,n) Herbivorous act occurs If , the individual update is carried out using (12) Omnivorous act occurs Else if 1/3 and rand < 2/3 the update to individual is carried out using (14) Carnivorous act occurs Else the individual update is carried out with (13) End if End if Third stage: Decomposition Individual update is carried out with (15) Individual fitness is calculated Best position found so far is updated, xq End while Fourth Stage: Termination Return xq |

5. Power Management Approach

6. Demand Side Management (DSM)

7. Reliability Indices

7.1. Loss of Power Supply Probability

7.2. Renewable Energy Fraction (REF)

8. Objective Function

9. Simulation Results and Discussions

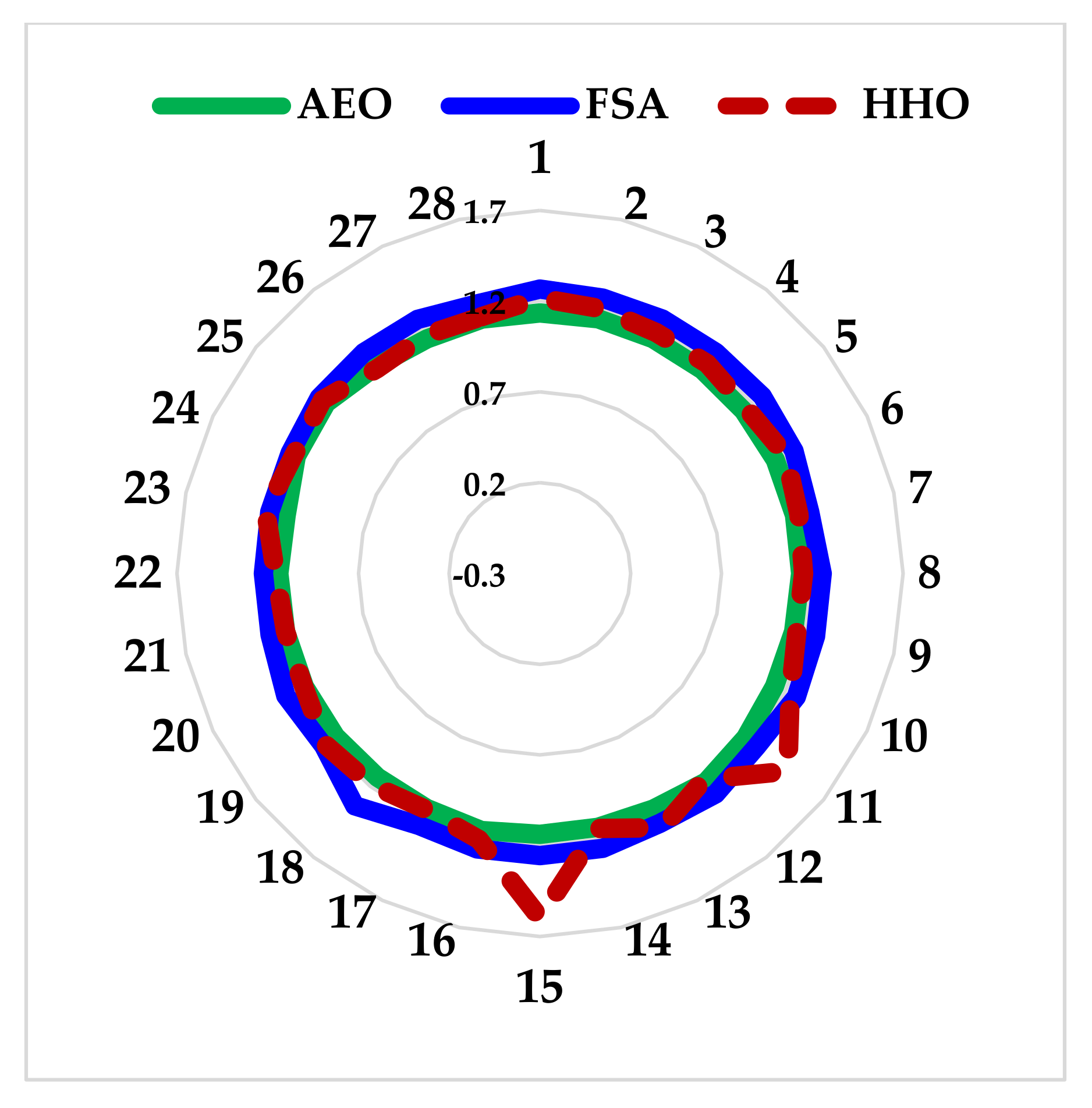

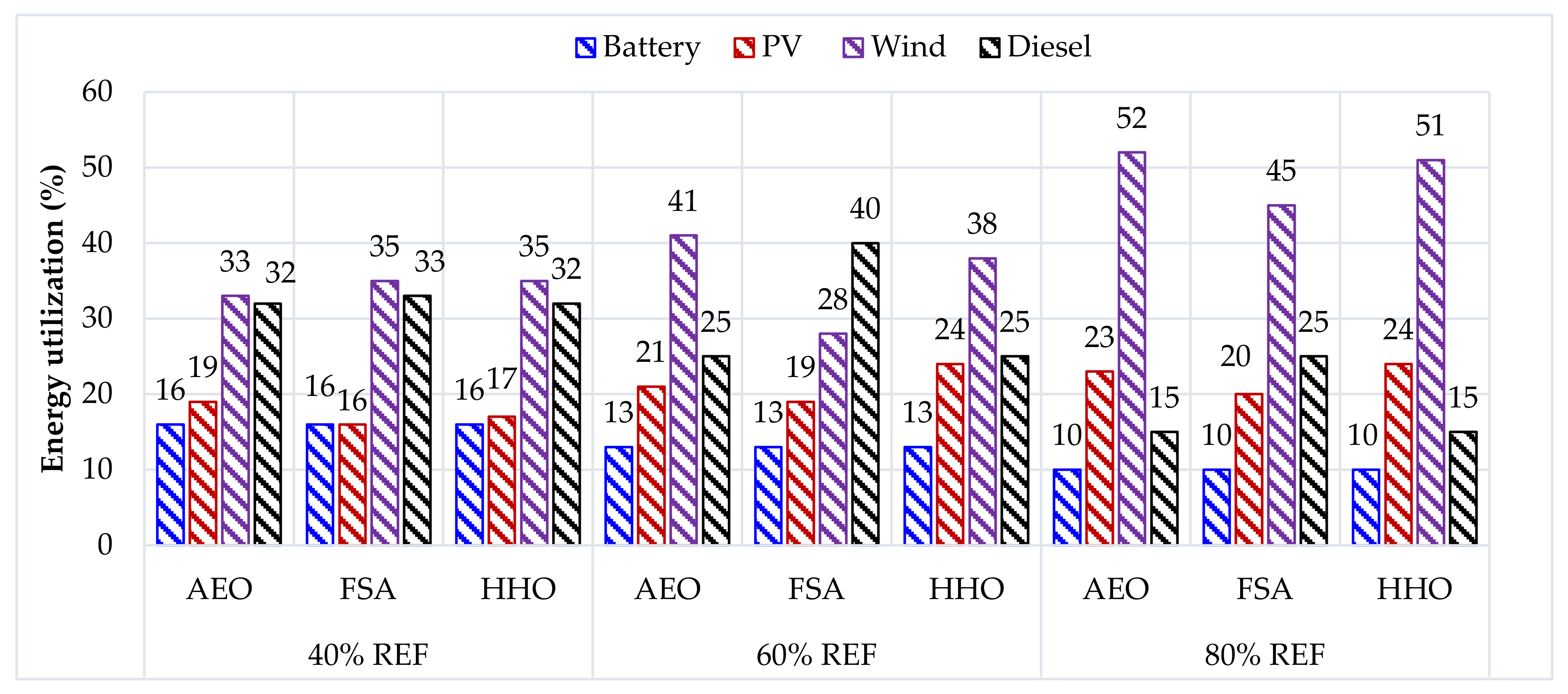

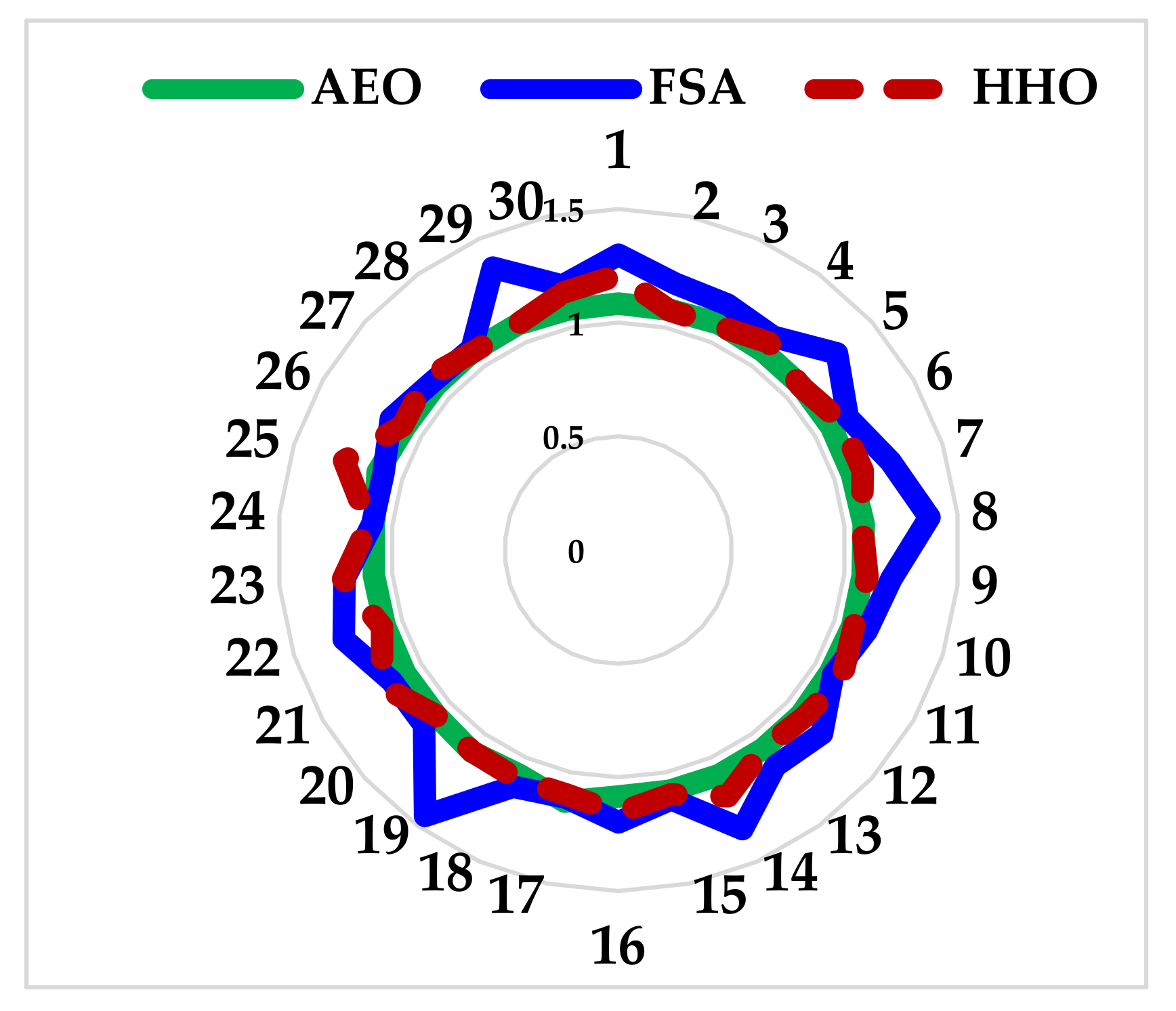

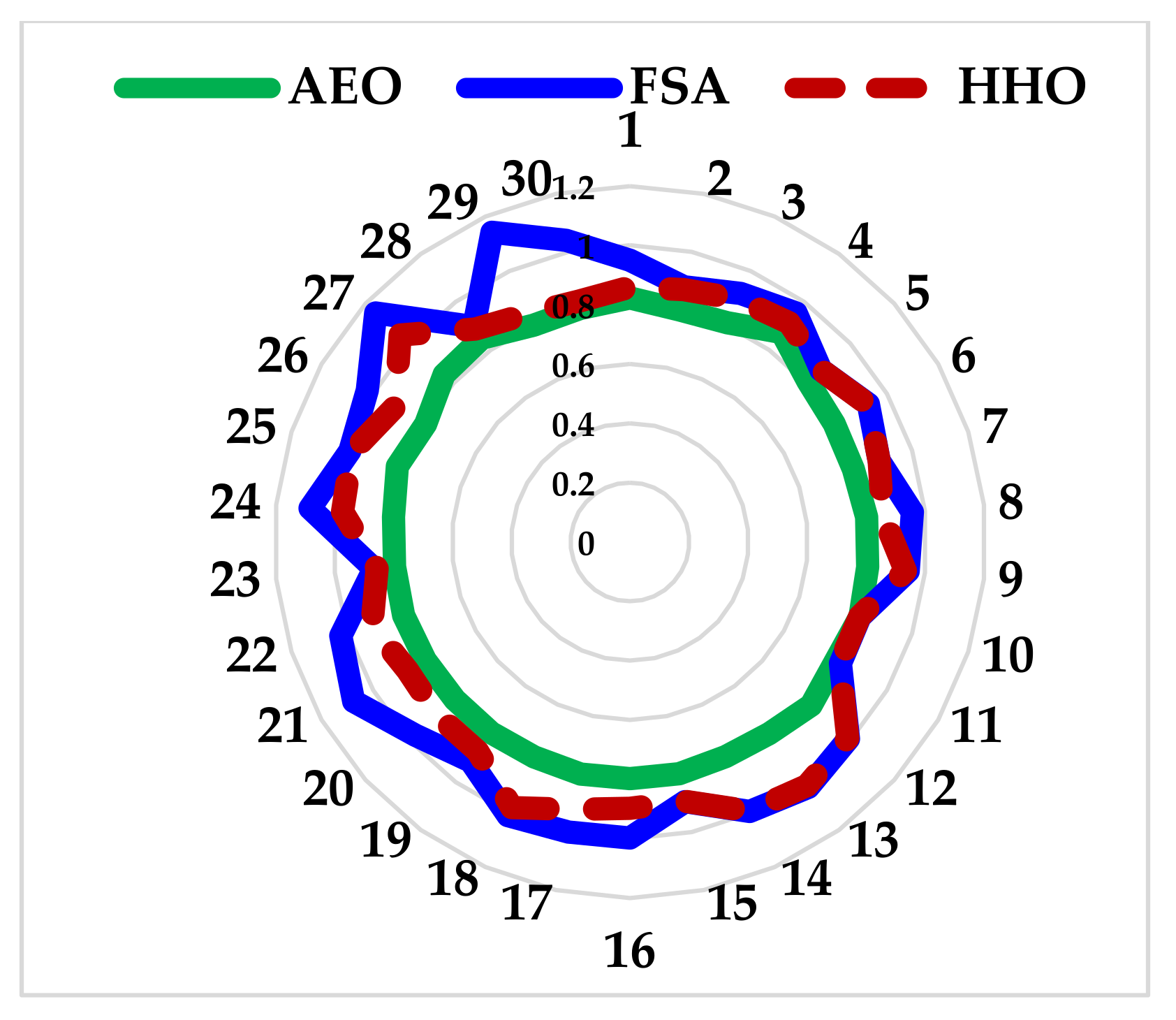

9.1. Optimal Sizing of the HES without DSM

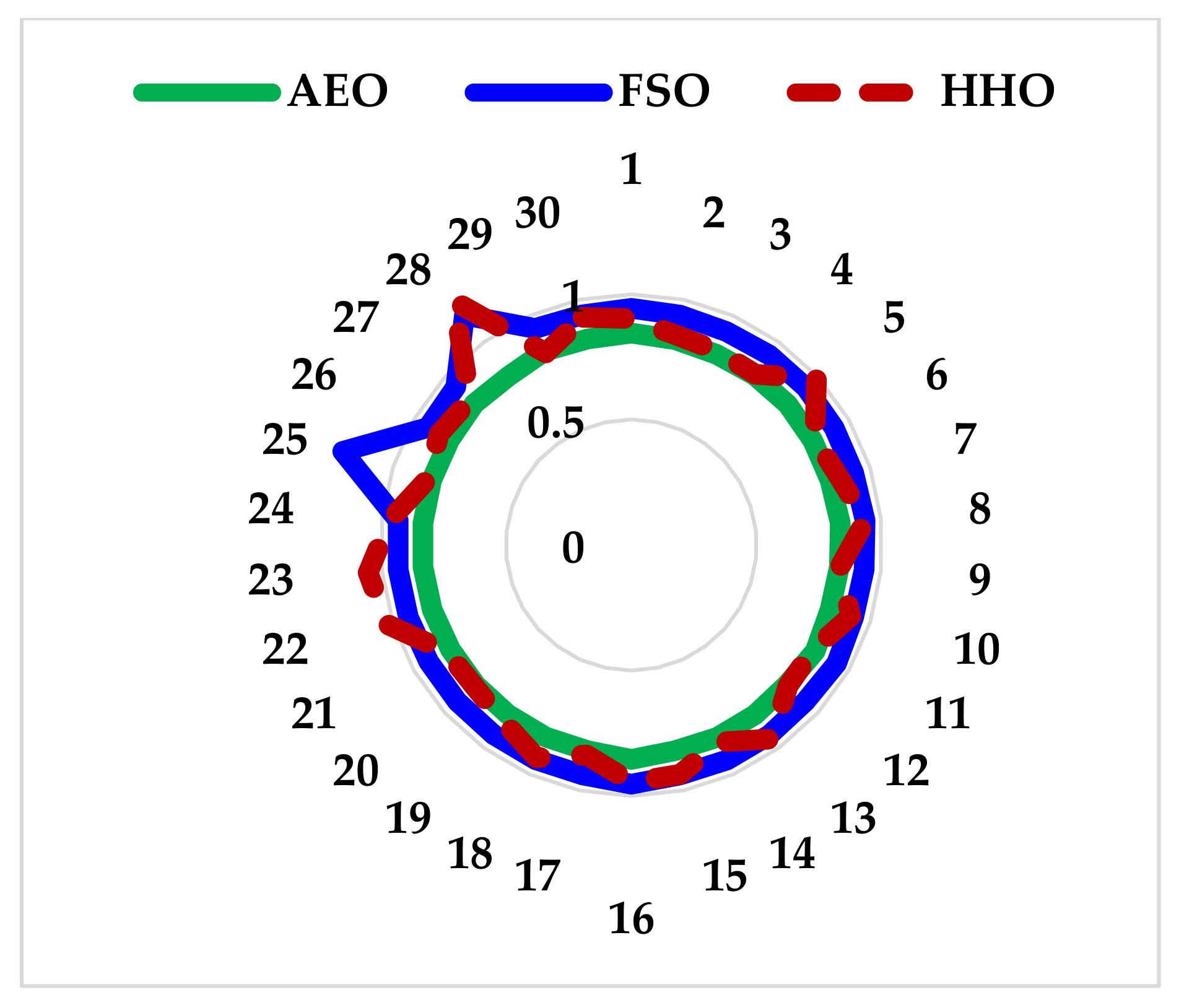

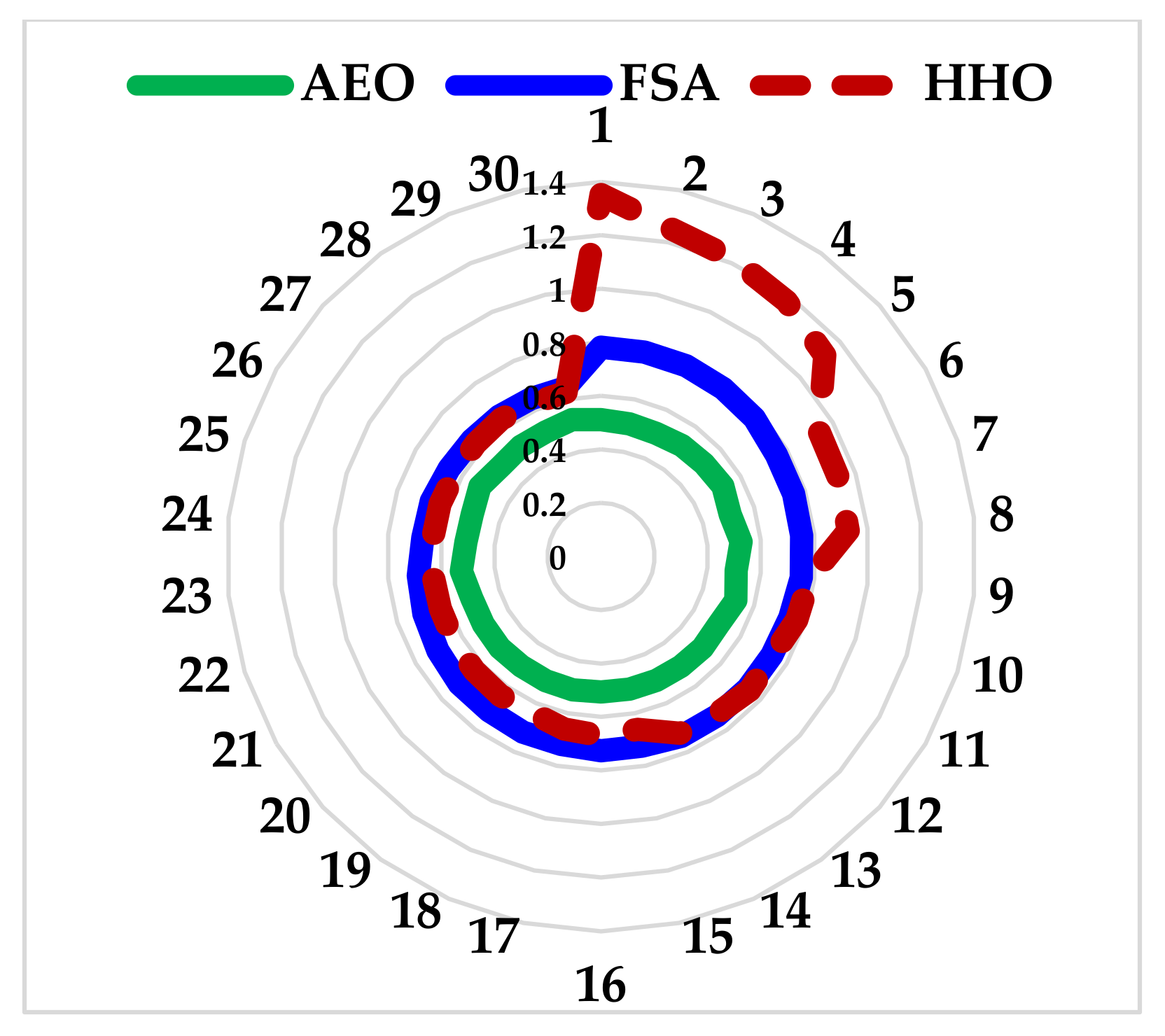

9.2. Optimal Sizing of the HES with DSM

9.3. COE with DSM and without DSM

10. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AEO | Artificial Ecosystem-based Optimization |

| COE | Cost of Energy |

| CRF | Capital Recovery Factor |

| DMOPSO | Dynamic Multi-Objectives Particle Swarm Optimization |

| DSM | Demand Side Management |

| FSA | Future Search Optimization |

| HES | Hybrid Energy System |

| HHO | Harris Hawk Optimization |

| HS | Harmony Search |

| LOEE | Loss of Energy Expected |

| LOLE | Loss of Load Expected |

| LOLH | Loss of Load Hours |

| LPSP | Loss of Power Supply Probability |

| MPP | Maximum Power Point |

| PFT | Power Failure Time |

| REF | Renewable Energy Fraction |

| RES | Renewable Energy Resources |

| SOC | State of Charge |

| STCs | Standard Test Conditions |

| STD | Standard Deviation |

| WTG | Wind Turbine Generator |

| a | Linear weighting coefficient |

| A, B | Fuel constants |

| σ | Total output power |

| αp | Power temperature coefficient |

| CDsl | Annual fuel consumption |

| CF | Cost of fuel per liter |

| De | Decomposer model |

| El(t) | Total load demand |

| he | Weight coefficients |

| Global irradiance under normal conditions | |

| Global irradiance under STC | |

| GT,NOCT | Solar irradiance with respect to NOCT |

| fpv | De-rating factor |

| ηMPP | Maximum Power Point (MPP) efficiency of PV module |

| ηMPP,STC | Efficiency under STCs |

| ηinυ | Net inverter efficiency |

| ηbattery | Round trip efficiency of battery |

| NOCT | Operating cell nominal temperature |

| Lw | Lower boundary |

| lt | Load shift |

| Pr | PV rated power |

| PDsl(t) | Generated power of diesel |

| PR | Nominal power |

| PV power | |

| Wind power | |

| Load | |

| Pwind | Wind rated power |

| Ppv | Rated solar power |

| Pbat | Rated battery power |

| Surplus renewable energy | |

| q | Population number |

| r, r1 | Random number |

| Tc,STC | PV temperatures under STC |

| Tc | PV temperatures under normal conditions |

| Ta | Ambient Temperature |

| Ta,NOCT | Ambient temperature with respect to NOCT |

| we | Weight coefficients |

| uc | Cut-in speed |

| ur | Rated speed |

| xrandi | Random individual |

| Up | Upper boundary |

| xq | Best individual |

| uf | Cut-out frequency |

| univ | Inverter efficiency |

References

- Fekete, H.; Kuramochi, T.; Roelfsema, M.; Elzen, M.; den Forsell, N.; Höhne, N.; Luna, L.; Hans, F.; Sterl, S.; Olivier, J.; et al. A review of successful climate change mitigation policies in major emitting economies and the potential of global replication. Renew. Sustain. Energy Rev. 2021, 137, 110602. [Google Scholar] [CrossRef]

- Clausen, L.T.; Rudolph, D. Renewable energy for sustainable rural development: Synergies and mismatches. Energy Policy 2020, 138, 111289. [Google Scholar] [CrossRef]

- Alturki, F.A.; Omotoso, H.O.; Al-Shamma’a, A.A.; Farh, H.M.H.; Alsharabi, K. Novel Manta Rays Foraging Optimization Algorithm Based Optimal Control for Grid-Connected PV Energy System. IEEE Access 2020, 8, 187276–187290. [Google Scholar] [CrossRef]

- Al-Shamma’a, A.A.; Omotoso, H.O.; Noman, A.M.; Alkuhayli, A.A. Grey Wolf Optimizer Based Optimal Control for Grid-Connected PV System. In Proceedings of the IECON 2020 the 46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 19–21 October 2020; pp. 2863–2867. [Google Scholar]

- Ramesh, M.; Saini, R.P. Dispatch strategies based performance analysis of a hybrid renewable energy system for a remote rural area in India. J. Clean. Prod. 2020, 259, 120697. [Google Scholar] [CrossRef]

- Das, B.K.; Hassan, R.; Tushar, M.S.H.K.; Zaman, F.; Hasan, M.; Das, P. Techno-economic and environmental assessment of a hybrid renewable energy system using multi-objective genetic algorithm: A case study for remote Island in Bangladesh. Energy Convers. Manag. 2021, 230, 113823. [Google Scholar] [CrossRef]

- Das, M.; Singh, M.A.K.; Biswas, A. Techno-economic optimization of an off-grid hybrid renewable energy system using metaheuristic optimization approaches–Case of a radio transmitter station in India. Energy Convers. Manag. 2019, 185, 339–352. [Google Scholar] [CrossRef]

- Ramesh, M.; Saini, R. Demand Side Management based techno-economic performance analysis for a stand-alone hybrid renewable energy system of India. Energy Sources Part A Recover. Util. Environ. Eff. 2021, 1–29. [Google Scholar] [CrossRef]

- Lujano-Rojas, J.M.; Dufo-López, R.; Bernal-Agustín, J.L. Probabilistic modelling and analysis of stand-alone hybrid power systems. Energy 2013, 63, 19–27. [Google Scholar] [CrossRef]

- Alsayed, M.; Cacciato, M.; Scarcella, G.; Scelba, G. Design of hybrid power generation systems based on multi criteria decision analysis. Sol. Energy 2014, 105, 548–560. [Google Scholar] [CrossRef]

- Hung, D.Q.; Mithulananthan, N.; Bansal, R.C. Analytical strategies for renewable distributed generation integration considering energy loss minimization. Appl. Energy 2013, 105, 75–85. [Google Scholar] [CrossRef]

- Luna-Rubio, R.; Trejo-Perea, M.; Vargas-Vázquez, D.; Ríos-Moreno, G.J. Optimal sizing of renewable hybrids energy systems: A review of methodologies. Sol. Energy 2012, 86, 1077–1088. [Google Scholar] [CrossRef]

- Askarzadeh, A. Distribution generation by photovoltaic and diesel generator systems: Energy management and size optimization by a new approach for a stand-alone application. Energy 2017, 122, 542–551. [Google Scholar] [CrossRef]

- Sharafi, M.; ElMekkawy, T.Y. A dynamic MOPSO algorithm for multiobjective optimal design of hybrid renewable energy systems. Int. J. Energy Res. 2014, 38, 1949–1963. [Google Scholar] [CrossRef]

- Ghorbani, N.; Kasaeian, A.; Toopshekan, A.; Bahrami, L.; Maghami, A. Optimizing a hybrid wind-PV-battery system using GA-PSO and MOPSO for reducing cost and increasing reliability. Energy 2018, 154, 581–591. [Google Scholar] [CrossRef]

- Baghaee, H.R.; Mirsalim, M.; Gharehpetian, G.B.; Talebi, H.A. Reliability/cost-based multi-objective Pareto optimal design of stand-alone wind/PV/FC generation microgrid system. Energy 2016, 115, 1022–1041. [Google Scholar] [CrossRef]

- Koutroulis, E.; Kolokotsa, D.; Potirakis, A.; Kalaitzakis, K. Methodology for optimal sizing of stand-alone photovoltaic/wind-generator systems using genetic algorithms. Sol. Energy 2006, 80, 1072–1088. [Google Scholar] [CrossRef]

- Al-Shamma’a, A.A.; Addoweesh, K.E. Techno-economic optimization of hybrid power system using genetic algorithm. Int. J. Energy Res. 2014, 38, 1608–1623. [Google Scholar] [CrossRef]

- Kolhe, M.L.; Ranaweera, K.M.I.U.; Gunawardana, A.G.B.S. Techno-economic sizing of off-grid hybrid renewable energy system for rural electrification in Sri Lanka. Sustain. Energy Technol. Assess. 2015, 11, 53–64. [Google Scholar] [CrossRef]

- Wang, R.; Li, G.; Ming, M.; Wu, G.; Wang, L. An efficient multi-objective model and algorithm for sizing a stand-alone hybrid renewable energy system. Energy 2017, 141, 2288–2299. [Google Scholar] [CrossRef]

- Farh, H.M.H.; Al-Shaalan, A.M.; Eltamaly, A.M.; Al-Shamma’a, A.A. A novel severity performance index for optimal allocation and sizing of photovoltaic distributed generations. Energy Rep. 2020, 6, 2180–2190. [Google Scholar] [CrossRef]

- Farh, H.M.H.; Al-Shaalan, A.M.; Eltamaly, A.M.; Al-Shamma’A, A.A. A Novel Crow Search Algorithm Auto-Drive PSO for Optimal Allocation and Sizing of Renewable Distributed Generation. IEEE Access 2020, 8, 27807–27820. [Google Scholar] [CrossRef]

- Kaluthanthrige, R.; Rajapakse, A.D.; Lamothe, C.; Mosallat, F. Optimal Sizing and Performance Evaluation of a Hybrid Renewable Energy System for an Off-Grid Power System in Northern Canada. Technol. Econ. Smart Grids Sustain. Energy 2019, 4, 4. [Google Scholar] [CrossRef] [Green Version]

- Farh, H.M.H.; Eltamaly, A.M.; Al-Shaalan, A.M.; Al-Shamma’a, A.A. A novel sizing inherits allocation strategy of renewable distributed generations using crow search combined with particle swarm optimization algorithm. IET Renew. Power Gener. 2021, 15, 1436–1450. [Google Scholar] [CrossRef]

- Moslehi, K.; Kumar, R. A Reliability Perspective of the Smart Grid. IEEE Trans. Smart Grid 2010, 1, 57–64. [Google Scholar] [CrossRef]

- Logenthiran, T.; Srinivasan, D.; Khambadkone, A.M.; Aung, H.N. Multiagent System for Real-Time Operation of a Microgrid in Real-Time Digital Simulator. IEEE Trans. Smart Grid 2012, 3, 925–933. [Google Scholar] [CrossRef]

- Logenthiran, T.; Srinivasan, D.; Shun, T.Z. Demand Side Management in Smart Grid Using Heuristic Optimization. IEEE Trans. Smart Grid 2012, 3, 1244–1252. [Google Scholar] [CrossRef]

- Kumar, S.; Kaur, T.; Upadhyay, S.; Sharma, V.; Vatsal, D. Optimal Sizing of Stand Alone Hybrid Renewable Energy System with Load Shifting. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 1–20. Available online: https://www.tandfonline.com/doi/full/10.1080/15567036.2020.1831107 (accessed on 8 November 2021). [CrossRef]

- Alturki, A.F.; Farh, M.H.H.; Al-Shamma’a, A.A.; Al Sharabi, K. Techno-Economic Optimization of Small-Scale Hybrid Energy Systems Using Manta Ray Foraging Optimizer. Electronics 2020, 9, 2405. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, L.; Zhang, Z.; Al Sharabi, K. Artificial ecosystem-based optimization: A novel nature-inspired meta-heuristic algorithm. Neural Comput. Appl. 2020, 32, 9383–9425. [Google Scholar] [CrossRef]

- Elsisi, M.; Wang, L.; Zhang, Z.; Al Sharabi, K. Future search algorithm for optimization. Evol. Intell. 2019, 12, 21–31. [Google Scholar] [CrossRef]

- Heidari, A.A.; Mirjalili, S.; Faris, H.; Aljarah, I.; Mafarja, M.; Chen, H. Harris hawks optimization: Algorithm and applications. Futur. Gener. Comput. Syst. 2019, 97, 849–872. [Google Scholar] [CrossRef]

- Belfkira, R.; Zhang, L.; Barakat, G. Optimal sizing study of hybrid wind/PV/diesel power generation unit. Sol. Energy 2011, 85, 100–110. [Google Scholar] [CrossRef]

- Akhtari, M.R.; Baneshi, M. Techno-economic assessment and optimization of a hybrid renewable co-supply of electricity, heat and hydrogen system to enhance performance by recovering excess electricity for a large energy consumer. Energy Convers. Manag. 2019, 188, 131–141. [Google Scholar] [CrossRef]

- Borhanazad, H.; Mekhilef, S.; Gounder Ganapathy, V.; Modiri-Delshad, M.; Mirtaheri, A. Optimization of micro-grid system using MOPSO. Renew. Energy 2014, 71, 295–306. [Google Scholar] [CrossRef]

- Eid, A.; Kamel, S.; Korashy, A.; Khurshaid, T. An Enhanced Artificial Ecosystem-Based Optimization for Optimal Allocation of Multiple Distributed Generations. IEEE Access 2020, 8, 178493–178513. [Google Scholar] [CrossRef]

| Parameters | Values | Unit | |

|---|---|---|---|

| Battery | Depth of Discharge | 60 | % |

| Round-trip efficiency | 80 | % | |

| O&M Cost | 5 | USD/kWh/year | |

| Capital cost | 200 | USD/kWh | |

| Life span | 5 | years | |

| Photovoltaic Module | O&M Cost | 15 | USD/kW/year |

| Capital cost | 1000 | USD/kW | |

| Efficiency | 16 | % | |

| Life span | 20 | years | |

| WTG | Hub-height | 60 | M |

| Cut-in/cut-off/ rated Speed | 3/25/9.5 | m/s | |

| O&M Cost | 30.33 | USD/KW/year | |

| Capital cost | 1300 | USD/kW | |

| Life span | 20 | years | |

| DC/AC Converter | Life span | 10 | years |

| Capital cost | 133 | USD/kW | |

| Diesel Generator | Life span | 15,000 | hours |

| Capital cost | 300 | USD/kW | |

| O&M Cost | 0.012 | USD/kWh | |

| Project Factors | Interest rate | 3 | % |

| Life span | 20 | years | |

| Inflation rate | 2 | % |

| COE (USD/kWh) | Pbatt (kW) | PV (kW) | Pw (kW) | Pdiesel (kW) | Surplus (%) | ||

|---|---|---|---|---|---|---|---|

| AEO | Optimal | 1.383630 | 62.46 | 167.98 | 102.14 | 168.56 | 35.05 |

| Mean | 1.393066 | 59.96 | 154.99 | 108.26 | 168.50 | 35.82 | |

| Max | 1.467197 | 61.53 | 81.25 | 142.95 | 171.01 | 40.19 | |

| STD | 0.016362 | 10.03 | 25.08 | 10.71 | 1.29 | 1.11 | |

| FSA | Optimal | 1.463650 | 0.00 | 166.14 | 111.88 | 164.88 | 36.17 |

| Mean | 1.500501 | 34.71 | 161.68 | 109.69 | 167.88 | 37.12 | |

| Max | 1.993242 | 37.52 | 156.82 | 109.91 | 166.11 | 40.00 | |

| STD | 0.23622 | 28.89 | 67.40 | 19.13 | 8.76 | 4.07 | |

| HHO | Optimal | 1.392138 | 60.77 | 147.83 | 110.09 | 168.35 | 35.32 |

| Mean | 1.500154 | 57.73 | 122.63 | 123.51 | 173.22 | 38.55 | |

| Max | 1.799334 | 47.34 | 7.50 | 190.97 | 189.51 | 51.14 | |

| STD | 0.106058 | 26.01 | 65.86 | 29.47 | 6.33 | 4.05 |

| COE (USD/kWh) | Pbatt (kW) | PV (kW) | Pw (kW) | Pdiesel (kW) | Surplus (%) | ||

|---|---|---|---|---|---|---|---|

| AEO | Optimal | 1.133689 | 69.55 | 190.20 | 129.39 | 162.26 | 39.27 |

| Mean | 1.143942 | 65.13 | 180.08 | 135.52 | 162.00 | 40.39 | |

| Max | 1.206799 | 50.35 | 102.23 | 177.15 | 162.26 | 46.53 | |

| STD | 0.016446 | 8.80 | 28.97 | 14.17 | 1.00 | 1.83 | |

| FSA | Optimal | 1.134227 | 66.36 | 185.97 | 131.59 | 161.82 | 40.39 |

| Mean | 1.154109 | 27.32 | 198.22 | 133.23 | 159.85 | 41.24 | |

| Max | 1.177233 | 0.00 | 250.00 | 118.59 | 159.41 | 39.19 | |

| STD | 0.015713 | 31.73 | 19.06 | 7.21 | 1.66 | 2.11 | |

| HHO | Optimal | 1.138241 | 56.38 | 211.12 | 123.02 | 161.48 | 39.65 |

| Mean | 1.206398 | 62.38 | 157.37 | 146.20 | 165.00 | 42.25 | |

| Max | 1.596142 | 8.81 | 39.77 | 190.56 | 175.87 | 50.89 | |

| STD | 0.095449 | 29.07 | 58.09 | 26.11 | 5.46 | 3.37 |

| COE (USD/kWh) | Pbatt (kW) | PV (kW) | Pw (kW) | Pdiesel (kW) | Surplus (%) | ||

|---|---|---|---|---|---|---|---|

| AEO | Optimal | 0.832235 | 71.22 | 244.09 | 189.75 | 150.20 | 49.71 |

| Mean | 0.837487 | 66.17 | 224.90 | 200.15 | 149.78 | 51.3 | |

| Max | 0.853710 | 63.39 | 178.53 | 225.41 | 149.48 | 53.77 | |

| STD | 0.004773 | 10.14 | 18.05 | 9.25 | 1.23 | 2.53 | |

| FSA | Optimal | 1.224227 | 75.22 | 200.09 | 180.75 | 123.20 | 48.71 |

| Mean | 1.247038 | 60.17 | 221.90 | 210.15 | 159.78 | 50.3 | |

| Max | 1.336750 | 60.39 | 188.53 | 221.42 | 159.28 | 53.77 | |

| STD | 0.234455 | 22.41 | 67.05 | 29.25 | 8.23 | 3.13 | |

| HHO | Optimal | 0.835613 | 74.05 | 239.33 | 190.54 | 150.56 | 49.61 |

| Mean | 0.922779 | 73.36 | 203.67 | 190.57 | 155.05 | 47.8 | |

| Max | 1.702104 | 78.25 | 11.09 | 199.96 | 189.03 | 44.47 | |

| STD | 0.156130 | 20.19 | 53.99 | 11.74 | 7.85 | 2.33 |

| COE (USD/kWh) | Pbatt (kW) | PV (kW) | Pw (kW) | Pdiesel (kW) | Surplus (%) | ||

|---|---|---|---|---|---|---|---|

| AEO | Optimal | 1.077723 | 22.41 | 228.15 | 62.25 | 143.73 | 29.24 |

| Mean | 1.119163 | 41.46 | 164.24 | 86.23 | 149.94 | 29.93 | |

| Max | 1.267866 | 58.48 | 50.08 | 139.18 | 159.44 | 37.23 | |

| STD | 0.047366 | 12.68 | 50.36 | 21.67 | 3.68 | 2.59 | |

| FSA | Optimal | 1.087369 | 26.59 | 220.29 | 64.32 | 144.40 | 28.94 |

| Mean | 1.195678 | 10.33 | 215.97 | 68.28 | 143.48 | 30.38 | |

| Max | 1.445218 | 57.70 | 129.56 | 98.27 | 153.31 | 29.84 | |

| STD | 0.092633 | 16.50 | 77.73 | 31.46 | 12.79 | 5.96 | |

| HHO | Optimal | 1.087369 | 16.40 | 202.62 | 71.30 | 144.81 | 29.43 |

| Mean | 1.199288 | 53.89 | 123.47 | 103.10 | 156.13 | 32.11 | |

| Max | 1.445218 | 41.38 | 11.77 | 154.75 | 168.20 | 41.77 | |

| STD | 0.091652 | 24.77 | 67.14 | 29.99 | 7.48 | 4.23 |

| COE (USD/kWh) | Pbatt (kW) | PV (kW) | Pw (kW) | Pdiesel (kW) | Surplus (%) | ||

|---|---|---|---|---|---|---|---|

| AEO | Optimal | 0.792494 | 29.27 | 247.04 | 76.52 | 127.85 | 29.27 |

| Mean | 0.811080 | 37.90 | 208.59 | 90.92 | 132.09 | 37.90 | |

| Max | 0.922186 | 64.84 | 91.04 | 146.83 | 144.38 | 64.84 | |

| STD | 0.027468 | 15.01 | 35.78 | 15.93 | 3.78 | 3.01 | |

| FSA | Optimal | 0.816321 | 59.17 | 217.05 | 79.51 | 117.45 | 30.17 |

| Mean | 0.962236 | 37.90 | 208.59 | 90.92 | 132.09 | 36.91 | |

| Max | 1.152819 | 61.85 | 91.12 | 136.13 | 124.18 | 66.81 | |

| STD | 0.092889 | 15.01 | 35.78 | 15.93 | 3.78 | 6.02 | |

| HHO | Optimal | 0.814320 | 59.70 | 128.63 | 127.71 | 143.48 | 30.45 |

| Mean | 0.910234 | 59.70 | 128.63 | 127.71 | 143.48 | 35.15 | |

| Max | 1.115856 | 101.25 | 19.23 | 191.81 | 160.80 | 35.17 | |

| STD | 0.068200 | 24.95 | 52.29 | 27.79 | 6.51 | 5.12 |

| COE (USD/kWh) | Pbatt (kW) | PV (kW) | Pw (kW) | Pdiesel (kW) | Surplus (%) | ||

|---|---|---|---|---|---|---|---|

| AEO | Optimal | 0.503245 | 37.28 | 242.48 | 123.52 | 106.58 | 36.50 |

| Mean | 0.511628 | 36.54 | 215.42 | 136.24 | 108.43 | 37.82 | |

| Max | 0.528746 | 33.89 | 171.15 | 159.52 | 110.70 | 41.07 | |

| STD | 0.007268 | 17.74 | 22.49 | 10.57 | 2.36 | 1.42 | |

| FSA | Optimal | 0.644275 | 74.29 | 217.11 | 199.87 | 125.87 | 50.0 |

| Mean | 0.644275 | 77.73 | 172.01 | 192.91 | 147.81 | 46.33 | |

| Max | 0.781750 | 90.51 | 21.71 | 209.00 | 138.48 | 42.66 | |

| STD | 0.319604 | 19.94 | 70.91 | 9.09 | 12.90 | 4.3 | |

| HHO | Optimal | 0.627125 | 54.28 | 247.16 | 196.86 | 135.86 | 49.83 |

| Mean | 0.787858 | 78.79 | 176.08 | 194.92 | 147.84 | 45.34 | |

| Max | 1.353082 | 89.50 | 20.70 | 200.00 | 178.48 | 41.65 | |

| STD | 0.217370 | 18.93 | 74.90 | 8.06 | 11.89 | 3.3 |

| REF (%) | COE with DSM (USD/kWh) | Surplus Energy with DSM (%) | COE without DSM (USD/kWh) | Surplus Energy without DSM (%) | Percentage Energy Cost Saving (%) |

|---|---|---|---|---|---|

| 40 | 1.077723 | 29.24 | 1.38363 | 35.05 | 28.38 |

| 60 | 0.792494 | 29.27 | 1.133689 | 39.27 | 43.05 |

| 80 | 0.503245 | 36.5 | 0.832235 | 49.71 | 65.37 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Omotoso, H.O.; Al-Shaalan, A.M.; Farh, H.M.H.; Al-Shamma’a, A.A. Techno-Economic Evaluation of Hybrid Energy Systems Using Artificial Ecosystem-Based Optimization with Demand Side Management. Electronics 2022, 11, 204. https://doi.org/10.3390/electronics11020204

Omotoso HO, Al-Shaalan AM, Farh HMH, Al-Shamma’a AA. Techno-Economic Evaluation of Hybrid Energy Systems Using Artificial Ecosystem-Based Optimization with Demand Side Management. Electronics. 2022; 11(2):204. https://doi.org/10.3390/electronics11020204

Chicago/Turabian StyleOmotoso, Hammed Olabisi, Abdullah M. Al-Shaalan, Hassan M. H. Farh, and Abdullrahman A. Al-Shamma’a. 2022. "Techno-Economic Evaluation of Hybrid Energy Systems Using Artificial Ecosystem-Based Optimization with Demand Side Management" Electronics 11, no. 2: 204. https://doi.org/10.3390/electronics11020204

APA StyleOmotoso, H. O., Al-Shaalan, A. M., Farh, H. M. H., & Al-Shamma’a, A. A. (2022). Techno-Economic Evaluation of Hybrid Energy Systems Using Artificial Ecosystem-Based Optimization with Demand Side Management. Electronics, 11(2), 204. https://doi.org/10.3390/electronics11020204