Self-Assembly and Self-Repair during Motion with Modular Robots

Abstract

1. Introduction

- Demonstration that self-assembly and self-repair can be performed whilst a modular robotic organism is simultaneously engaged in another task.

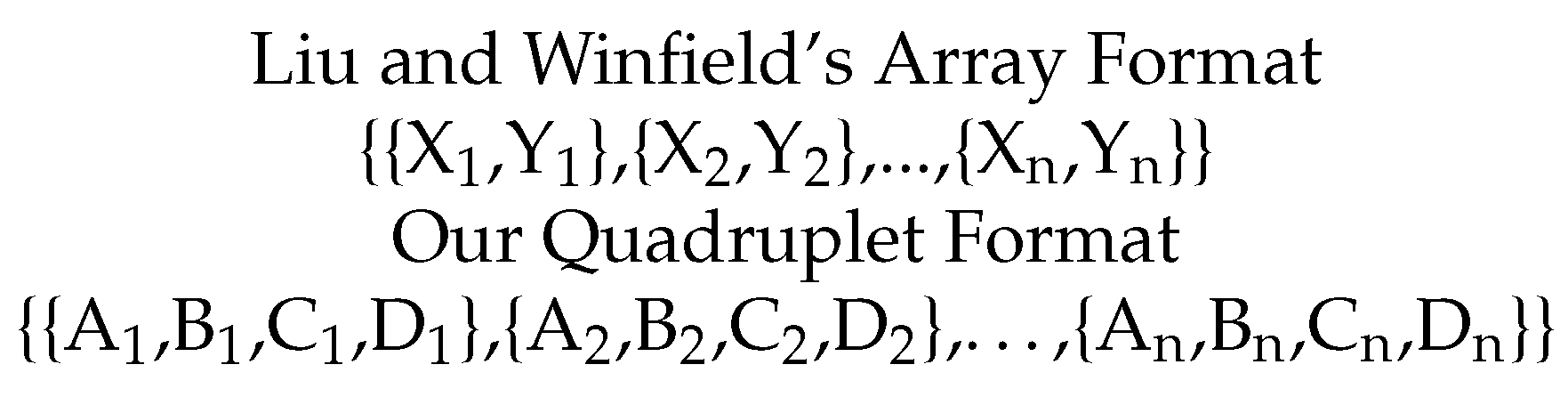

- A novel “Quadruplet” data structure for describing modular robotic structures.

- A series of algorithms designed to enable physically feasible self-repair and self-assembly by processing these “Quadruplet” data structures.

- Demonstration of the use of onboard sensors to enable the autonomous docking of modular robotic hardware to moving seed modules, using only minimal external (off-robot) infrastructure.

2. Previous Work

3. Developing a Modular Robotic Platform for Dynamic Self-Repair

- In a nuclear environment, operators will want to reduce heat and radiation exposure on robots. The less time spent in the hot radioactive environment during each monitoring mission, the longer a lifespan the robots will have before they succumb to effects such as neutron embrittlement.

- In a disaster zone scenario, unstable debris could collapse and crush a robot at any moment. Self-assembling and self-repairing robots would benefit from retaining the ability to rapidly move out of the way of falling objects, lest the operators find themselves having to rescue their robots before they can resume searching for survivors.

- Robots working on critical infrastructure may be required to perform repairs to the infrastructure while it is sustaining damage in real time. This requires the robot to maintain some elements of its group action while assembling or repairing itself. Failure to act quickly in these kind of situations could lead to extensive and irreparable damage to infrastructure, should a robot be slowed by its own self-assembly or self-repair procedures.

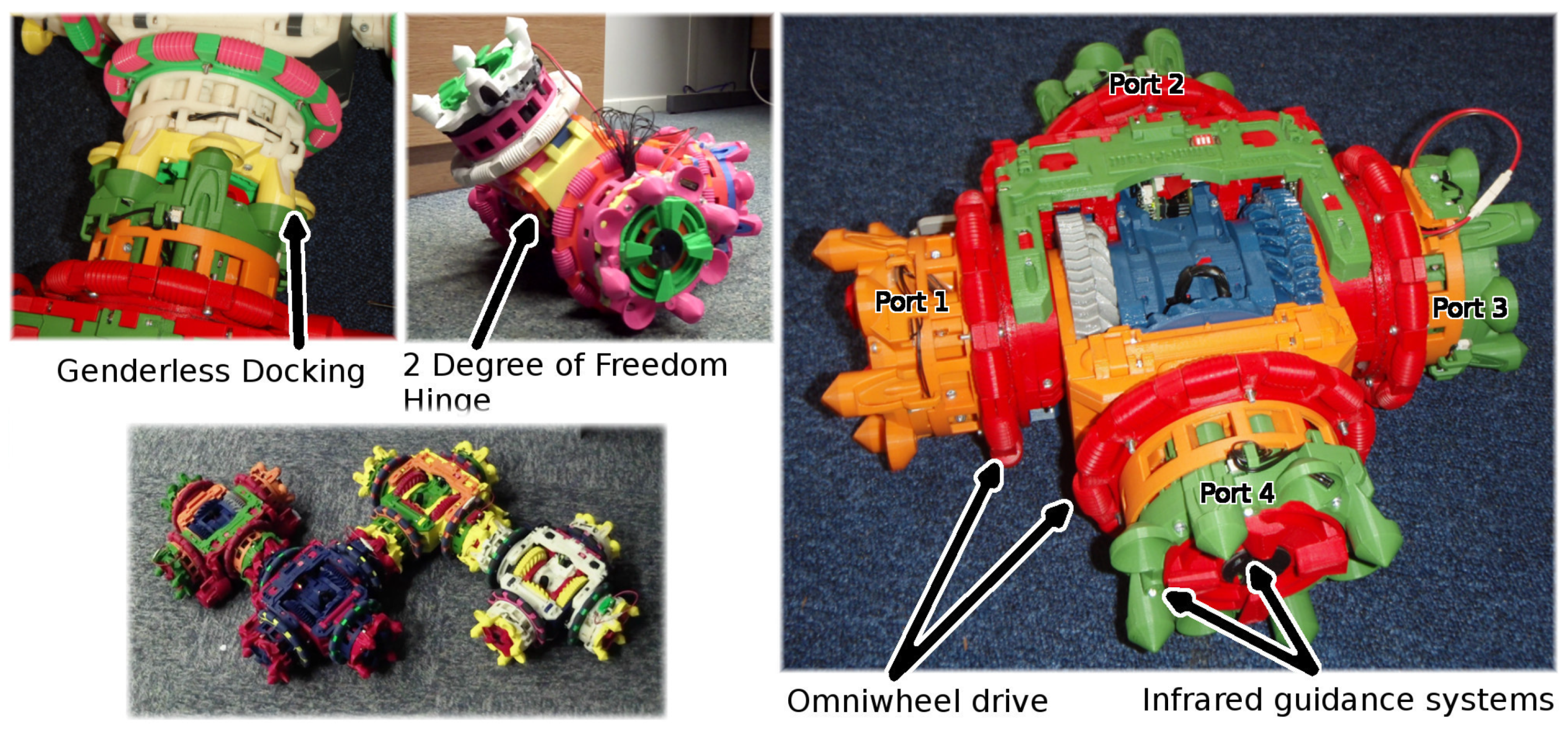

3.1. Omni-Pi-Tent

- Omnidirectional locomotion. This allows for maintaining a compass orientation decoupled from the driving direction, allowing for docking under a wider variety of circumstances, and also increases the mobility of docked structures. Refs. [42,43] were the only previous modular robots with omnidirectional drives.

- Self-contained sensor arrays to avoid reliance on external infrastructure. These limit sensing to that locally available, so scenarios more similar to real-world deployments of modular robots can be created. The robots have proximity and orientation sensors as well as a 5 KHz modulated IR system for docking guidance.

- Global and local communications using, respectively, Wi-Fi and line-of-sight 38 KHz IR LEDS. The Wi-Fi provides a global broadcast way in which to share data across the whole swarm, regardless of locations. The IR communication allows for local communications that can make use of directionality and range to convey implicit information beyond the data content of messages.

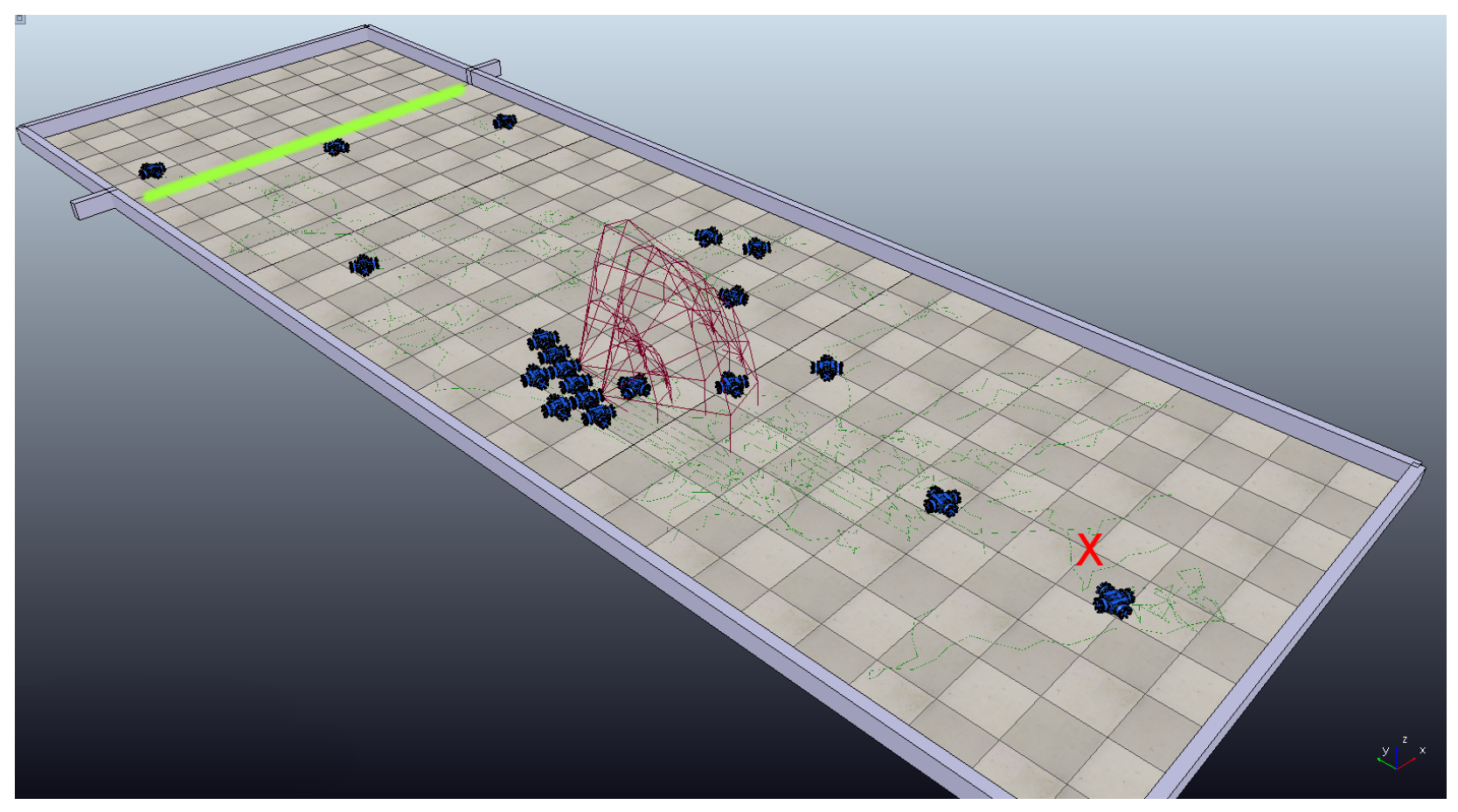

3.2. Simulating Omni-Pi-Tent

- As detailed in [7], experiments using docking-port hardware provided experimental data on the analogue strengths of the docking guidance signal with both range and angle from a recruiting port. An empirical polynomial model was fitted to this data using R [45]. This model is called within the V-REP simulation to provide sensor readings based on relative robot positions. Other measurements from real-world hardware tests were used to inform further simulation parameters.

- Simulated Omni-Pi-tent units run independent controllers. Each has access to functions that can read sensor data and send actuator commands for that module, much in the way that code running on the real robots does. The controllers run at 20 “ticks” per second in simulation, which matches the default rate at which controllers on the real hardware run.

- Information sharing between the modules is handled using V-REP’s “signal” and “custom datablock” features. Line-of-sight (IR) messages are handled so they are available to be read in later timesteps only by robots within the correct relative spatial regions to receive such a message in the real-world. Global (Wi-Fi) messages are passed to all modules and carry information that modules can act upon in later timesteps.

4. Self-Assembly Strategies

4.1. Wandering

4.2. The Docking Procedure

- A message-type identifier;

- Temporary and permanent ID numbers for the recruiting robot and, in some cases, the approaching robot;

- The global compass angle of the recruiting robot and details of any motion it is currently performing;

- Details of which docking ports are to be used by the recruiting and approaching robots.

4.3. The “In Organism” State

4.4. Defining Structures for Omni-Pi-Tent

4.5. Recruitment with Omni-Pi-Tent

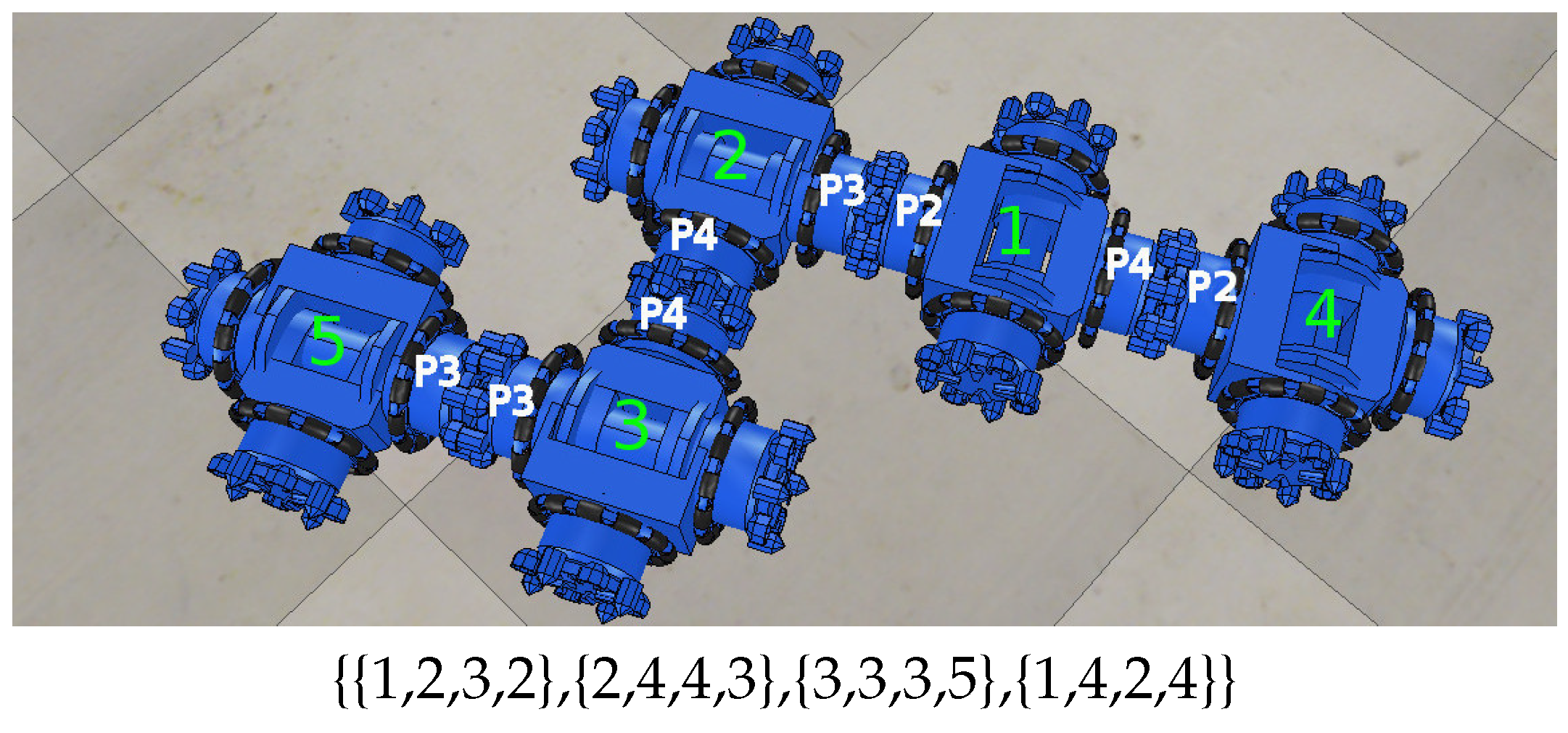

4.6. Mergeable Nervous Systems for Omni-Pi-Tent

4.7. Docking While in Motion

5. Self-Assembly Experiments

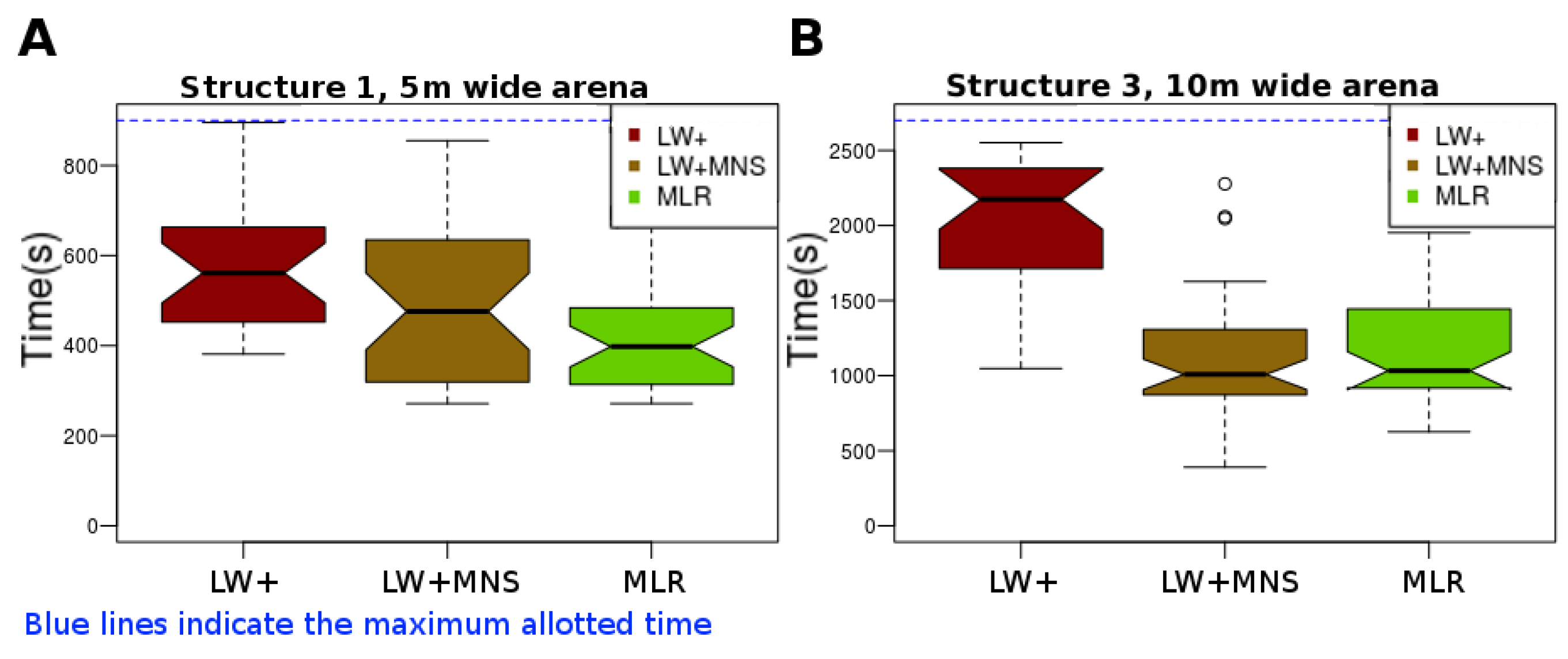

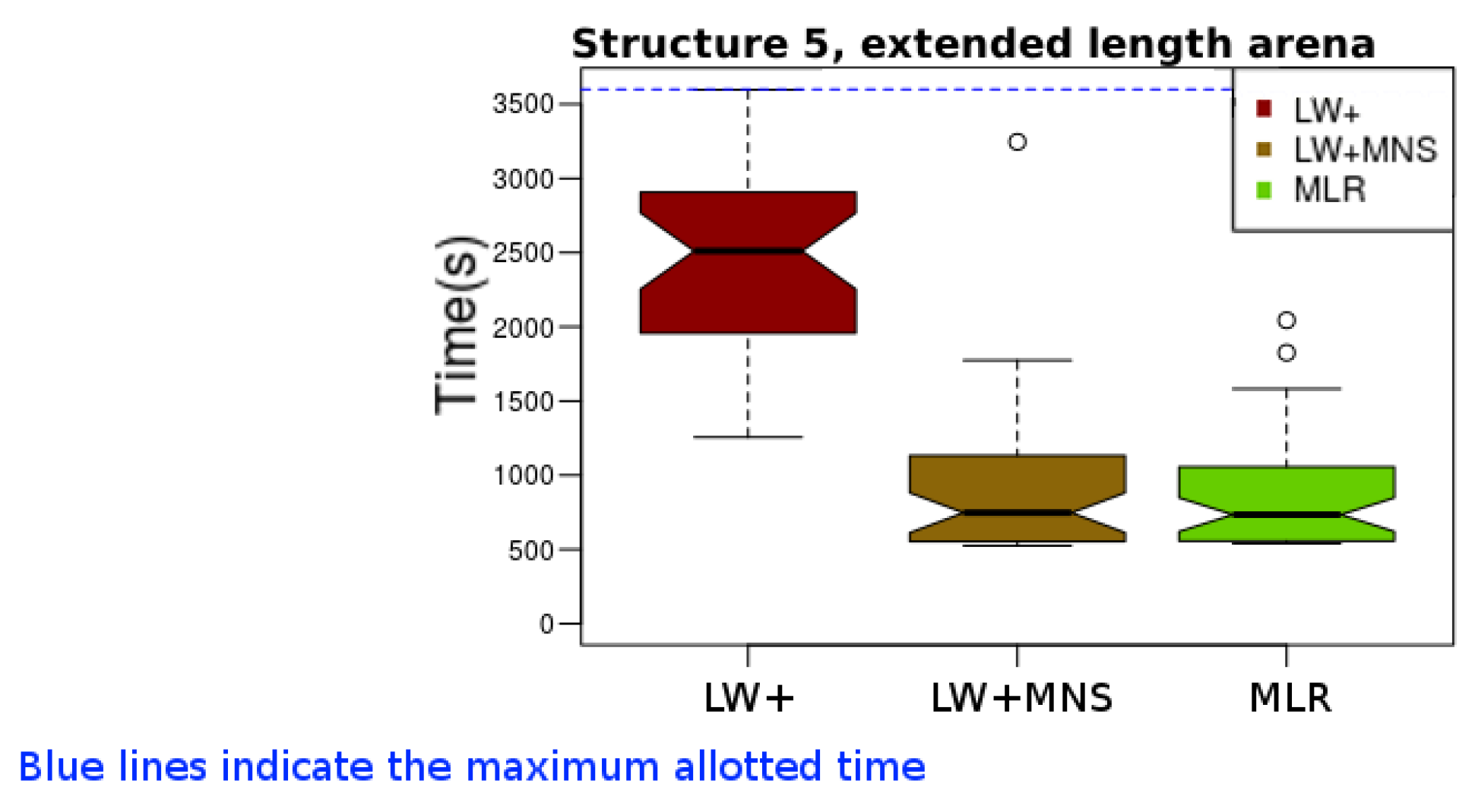

Self-Assembly Results

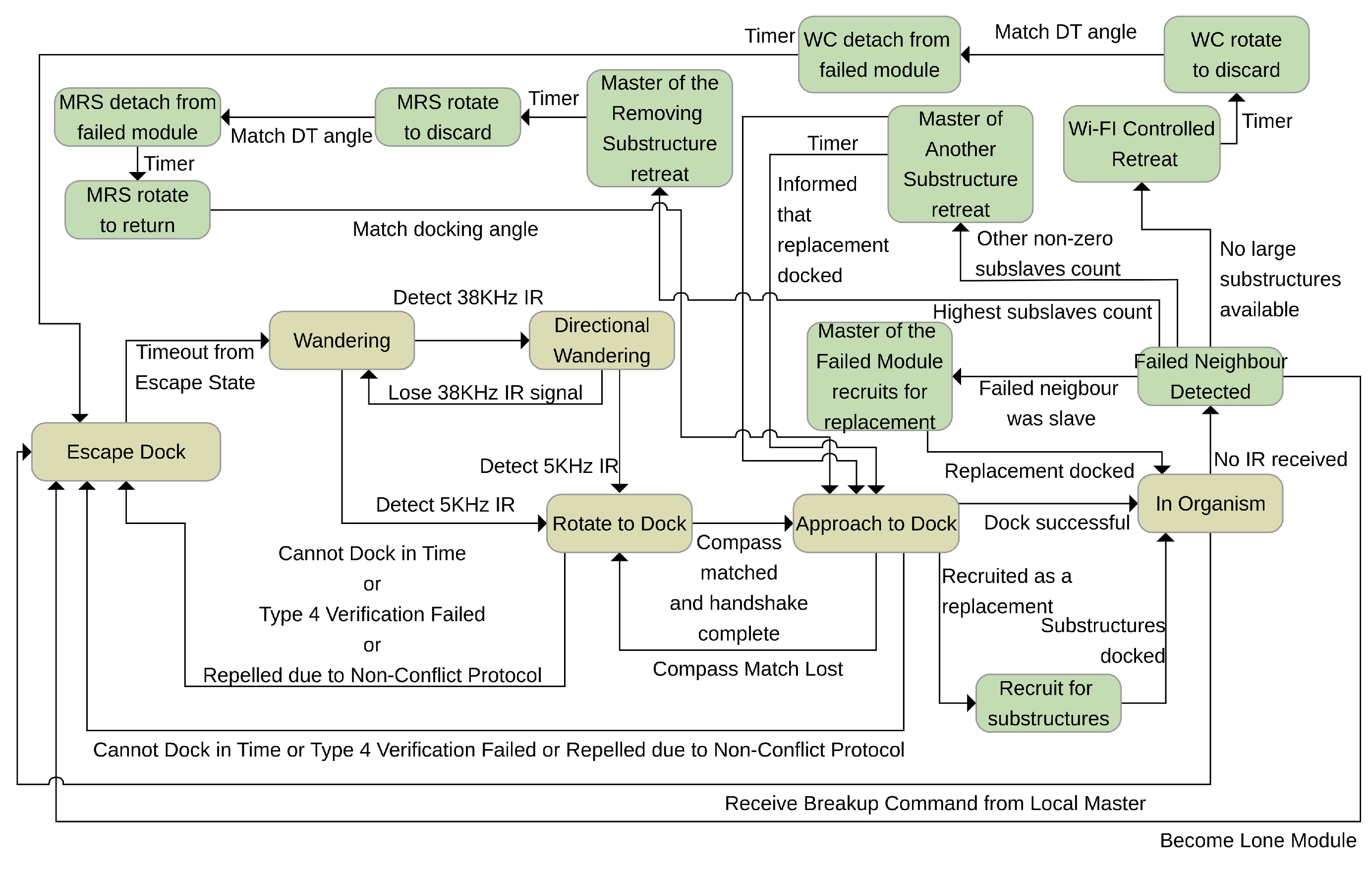

6. Self-Repair Strategies

- Master to the Failed Module (MFM), The robot that is specified in the Quadruplet list as the failed module’s immediate master handles the re-recruitment side of the self-repair procedure.

- Master of the Removing Substructure (MRS), One of the failed module’s slaves will be promoted to act as the MRS. The MRS will control the substructure responsible for dragging away the failed module, will safely dispose of the failed module, and will then guide itself back to the replacement module such that it, and its attached substructure, can reconnect to the main structure.

- Master of Another Substructure (MAS), Robots that were slaves to the failed module and have slaves of their own also form substructures. These substructures retreat and lurk at distance from the main structure until the failed module is replaced before returning to rebuild it. The use of MAS substructures means multiple substructures can be preserved.

- Lone Module (LM), Modules that served as slaves to the failed module and which have no slaves themselves enter the “Escape Dock” state, detach from the structure and become “Wandering” modules.

- Replacement Module (RM), The RM starts as a free-wandering module. However, once it completes the IR handshaking procedure involved in the transition from “Rotate to Dock” to “Approach to Dock”, it behaves differently to an ordinary recruited module. For any connections that the Recruitment List requires it to recruit for, instead of sending a general IR recruitment message, it sends a specialised addressed message only readable by the MRS and MAS modules.

6.1. Detecting Failed Modules

6.2. Processing Recruitment Lists

6.3. Removing the Failed Module

6.4. Mergeable Nervous Systems over Wi-Fi

6.5. Recruiting a Replacement

6.6. Guiding the Substructures

6.7. Dynamic Master Switching

7. Self-Repair Experiments

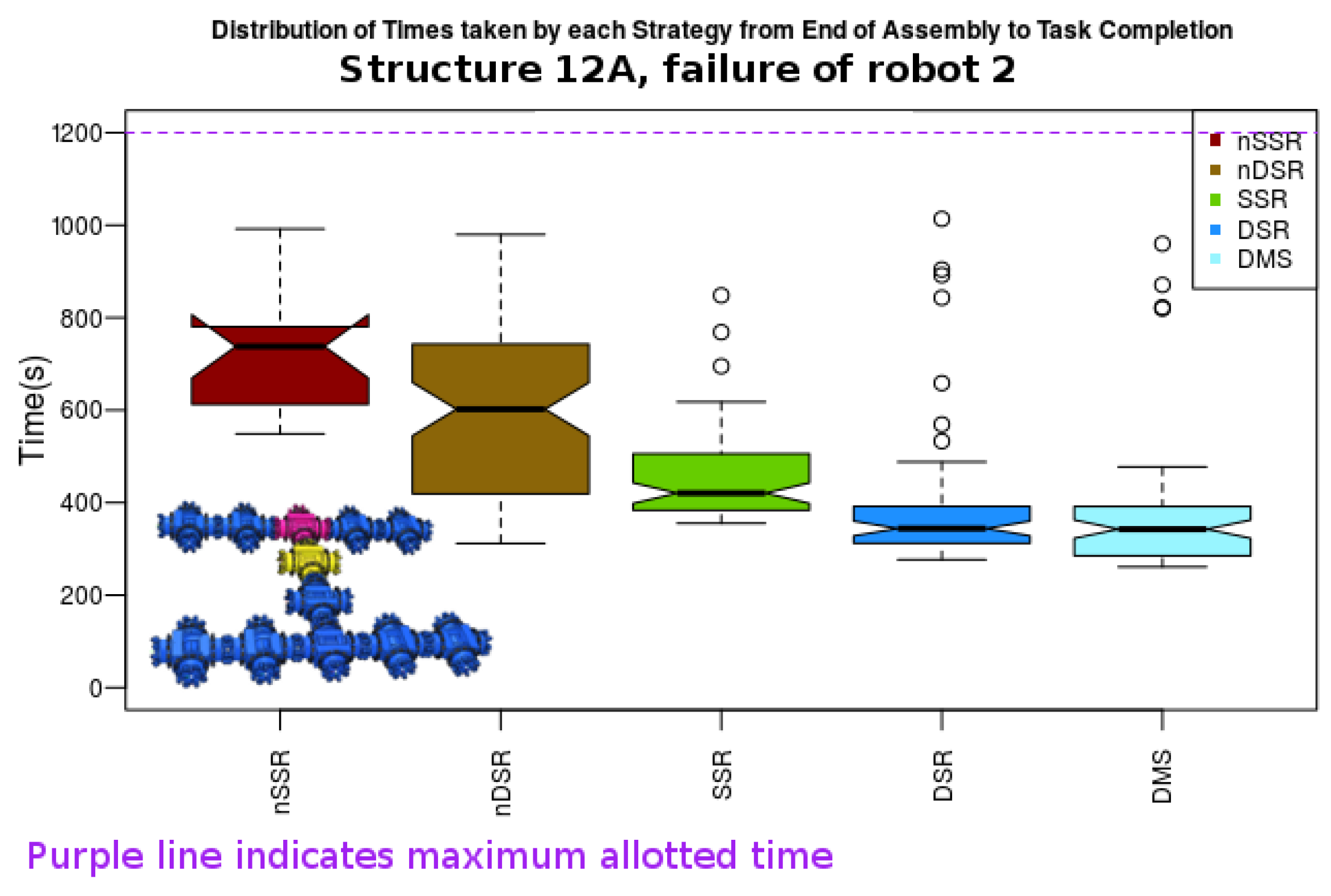

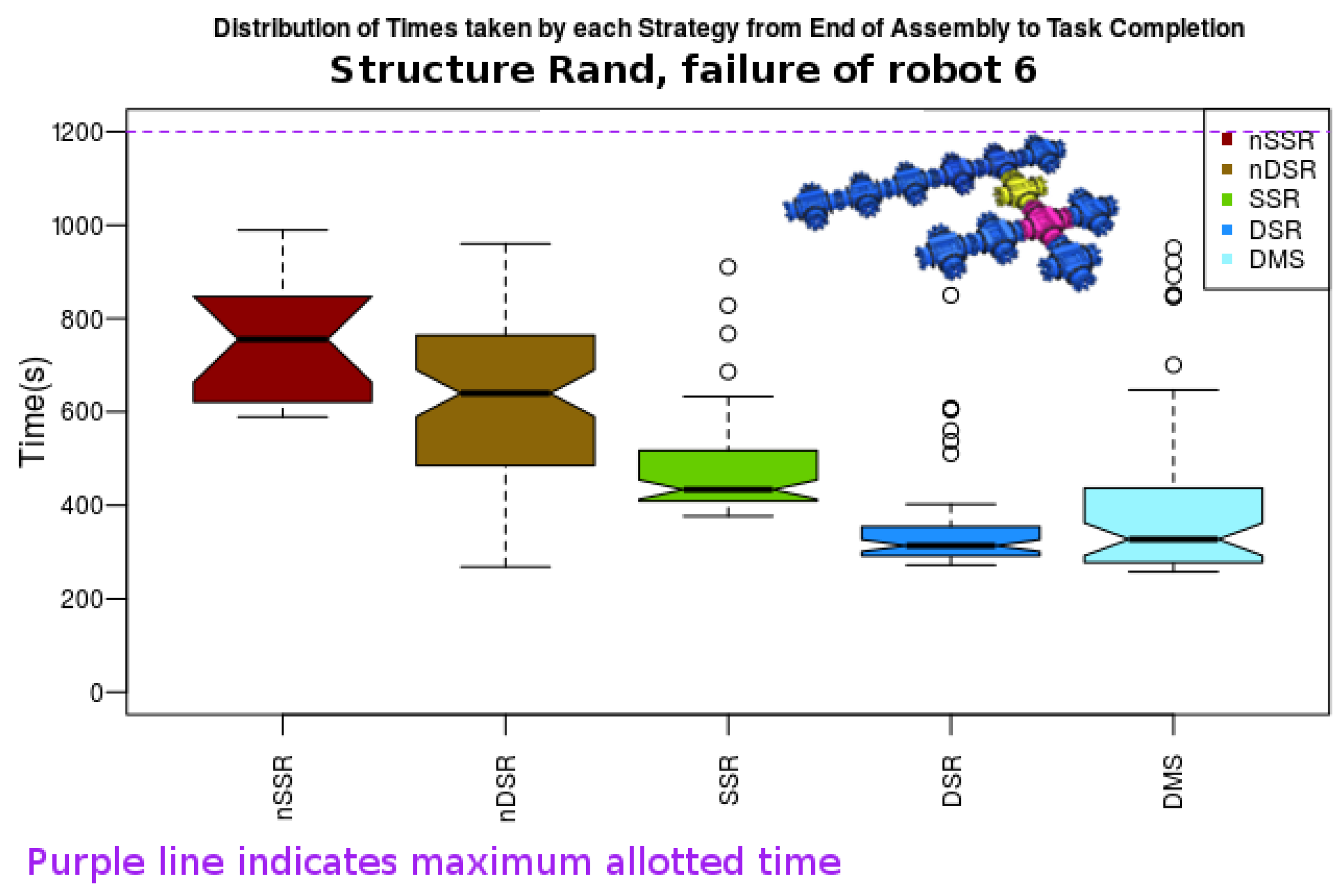

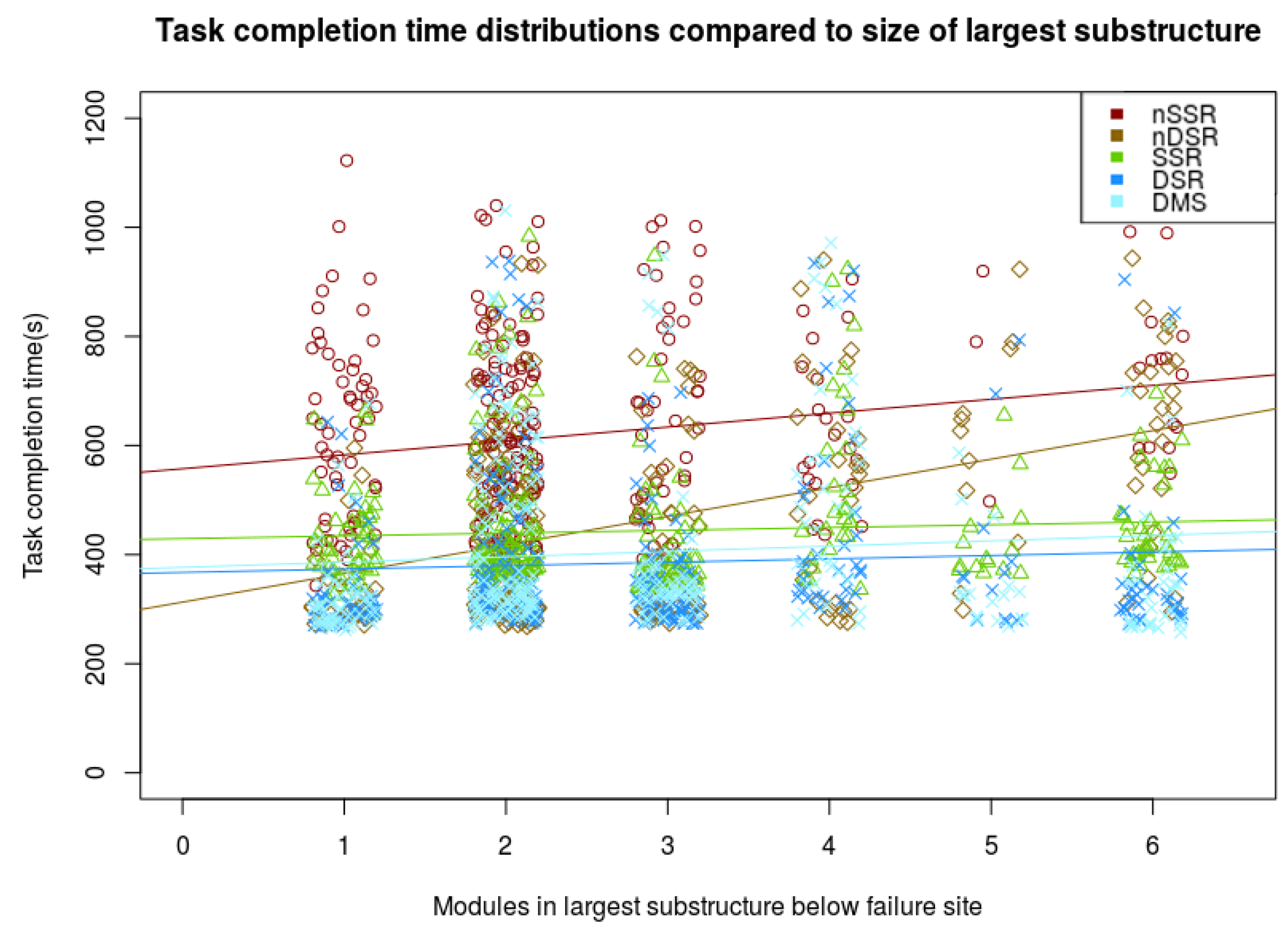

Self-Repair Results

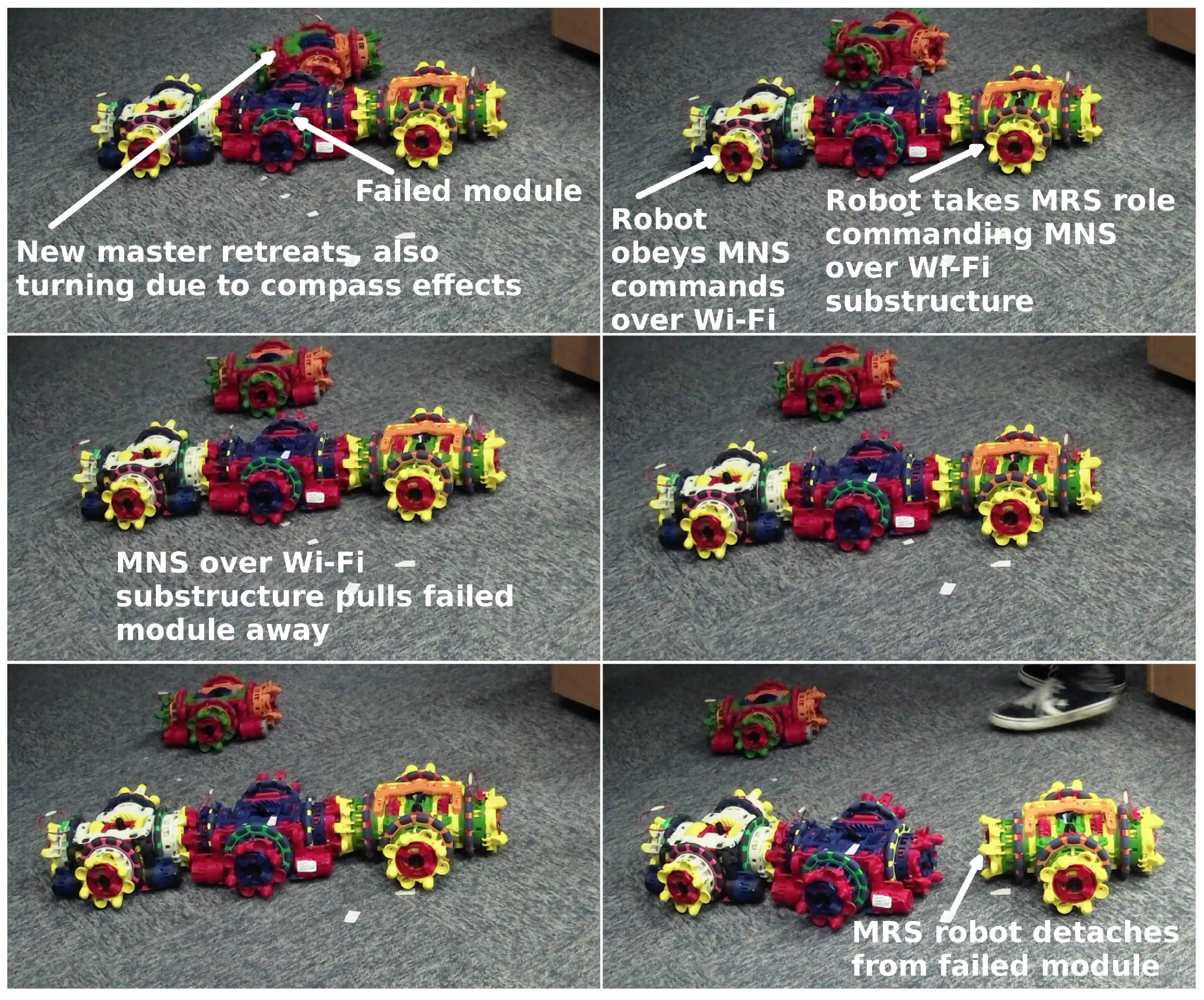

8. Hardware Demonstration of Principles

Self-Repair and the Reality Gap

9. Discussion

9.1. Self-Assembly

9.2. Self-Repair

10. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MNS | Mergeable nervous systems |

| LW+ | Liu and Winfield inspired self-assembly |

| LW + MNS | LW+ with MNS capabilities |

| MLR | Multi-Layered Recruitment |

| MFM | Master to the failed module |

| MRS | Master of the removing substructure |

| MAS | Master of another substructure |

| LM | Lone module |

| RM | Replacement module |

| nSSR | Naive static self-repair |

| nDSR | Naive dynamic self-repair |

| SSR | Static self-repair |

| DSR | Dynamic self-repair |

| DMS | Dynamic Master Switching |

References

- Fukuda, T.; Nakagawa, S. Dynamically reconfigurable robotic system. In Proceedings of the 1988 IEEE International Conference on Robotics and Automation, Philadelphia, PA, USA, 24–29 April 1988; pp. 1581–1586. [Google Scholar] [CrossRef]

- Yim, M.; Shen, W.M.; Salemi, B.; Rus, D.; Moll, M.; Lipson, H.; Klavins, E.; Chirikjian, G.S. Modular self-reconfigurable robot systems [grand challenges of robotics]. IEEE Robot. Autom. Mag. 2007, 14, 43–52. [Google Scholar] [CrossRef]

- Levi, P.; Kernbach, S. Symbiotic Multi-Robot Organisms: Reliability, Adaptability, Evolution; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010; Volume 7. [Google Scholar] [CrossRef]

- Davey, J.; Kwok, N.; Yim, M. Emulating self-reconfigurable robots-design of the SMORES system. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Algarve, Portugal, 7–12 October 2012; pp. 4464–4469. [Google Scholar] [CrossRef]

- Kernbach, S.; Meister, E.; Scholz, O.; Humza, R.; Liedke, J.; Ricotti, L.; Jemai, J.; Havlik, J.; Liu, W. Evolutionary robotics: The next-generation-platform for on-line and on-board artificial evolution. In Proceedings of the 2009 IEEE Congress on Evolutionary Computation, Trondheim, Norway, 18–21 May 2009; pp. 1079–1086. [Google Scholar] [CrossRef]

- Parrott, C.; Dodd, T.J.; Groß, R. HyMod: A 3-DOF hybrid mobile and self-reconfigurable modular robot and its extensions. In Distributed Autonomous Robotic Systems; Springer: Berlin/Heidelberg, Germany, 2018; pp. 401–414. [Google Scholar] [CrossRef]

- Peck, R.H.; Timmis, J.; Tyrrell, A.M. Omni-pi-tent: An omnidirectional modular robot with genderless docking. In Proceedings of the Annual Conference Towards Autonomous Robotic Systems, London, UK, 3–5 July 2019; Springer: Cham, Switzerland, 2019; pp. 307–318. [Google Scholar] [CrossRef]

- Hancher, M.D.; Hornby, G.S. A modular robotic system with applications to space exploration. In Proceedings of the 2nd IEEE International Conference on Space Mission Challenges for Information Technology (SMC-IT’06), Pasadena, CA, USA, 17–20 July 2006; pp. 1–8. [Google Scholar] [CrossRef]

- Baca, J.; Hossain, S.; Dasgupta, P.; Nelson, C.A.; Dutta, A. Modred: Hardware design and reconfiguration planning for a high dexterity modular self-reconfigurable robot for extra-terrestrial exploration. Robot. Auton. Syst. 2014, 62, 1002–1015. [Google Scholar] [CrossRef]

- Murray, L. Fault Tolerant Morphogenesis in Self-Reconfigurable Modular Robotic Systems. Ph.D. Thesis, University of York, York, UK, 2013. [Google Scholar]

- Jahanshahi, M.R.; Shen, W.M.; Mondal, T.G.; Abdelbarr, M.; Masri, S.F.; Qidwai, U.A. Reconfigurable swarm robots for structural health monitoring: A brief review. Int. J. Intell. Robot. Appl. 2017, 1, 287–305. [Google Scholar] [CrossRef]

- Peck, R.H.; Timmis, J.; Tyrrell, A.M. Towards Self-repair with Modular Robots During Continuous Motion. In Proceedings of the Towards Autonomous Robotic Systems: 19th Annual Conference, TAROS 2018, Bristol, UK, 25–27 July 2018; Springer: Berlin/Heidelberg, Germany, 2018; Volume 10965, pp. 457–458. [Google Scholar]

- Liu, W.; Winfield, A.F. Autonomous morphogenesis in self-assembling robots using IR-based sensing and local communications. In Proceedings of the International Conference on Swarm Intelligence, Brussels, Belgium, 8–10 September 2010; Springer: Berlin/Heidelberg, Germany, 2010; pp. 107–118. [Google Scholar] [CrossRef]

- Tomita, K.; Murata, S.; Kurokawa, H.; Yoshida, E.; Kokaji, S. Self-assembly and self-repair method for a distributed mechanical system. IEEE Trans. Robot. Autom. 1999, 15, 1035–1045. [Google Scholar] [CrossRef]

- Rohmer, E.; Singh, S.P.; Freese, M. V-REP: A versatile and scalable robot simulation framework. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 1321–1326. [Google Scholar] [CrossRef]

- Groß, R.; Dorigo, M. Self-assembly at the macroscopic scale. Proc. IEEE 2008, 96, 1490–1508. [Google Scholar] [CrossRef]

- Rus, D.L.; Gilpin, K.W. Modular robot systems. IEEE Robot. Autom. Mag. 2010, 17, 38–55. [Google Scholar] [CrossRef]

- Tucci, T.K.; Piranda, B.; Bourgeois, J. A distributed self-assembly planning algorithm for modular robots. In Proceedings of the International Conference on Autonomous Agents and Multiagent Systems, Stockholm, Sweden, 10–15 July 2018. [Google Scholar] [CrossRef]

- Bererton, C.; Khosla, P.K. Towards a team of robots with repair capabilities: A visual docking system. In Experimental Robotics VII; Springer: Berlin/Heidelberg, Germany, 2001; pp. 333–342. [Google Scholar] [CrossRef]

- Rubenstein, M.; Payne, K.; Will, P.; Shen, W.M. Docking among independent and autonomous CONRO self-reconfigurable robots. In Proceedings of the IEEE International Conference on Robotics and Automation, New Orleans, LA, USA, 26 April–1 May 2004; ICRA’04. Volume 3, pp. 2877–2882. [Google Scholar] [CrossRef]

- Rubenstein, M.; Cornejo, A.; Nagpal, R. Programmable self-assembly in a thousand-robot swarm. Science 2014, 345, 795–799. [Google Scholar] [CrossRef] [PubMed]

- Doursat, R. Organically grown architectures: Creating decentralized, autonomous systems by embryomorphic engineering. In Organic Computing; Springer: Berlin/Heidelberg, Germany, 2009; pp. 167–199. [Google Scholar] [CrossRef]

- Nagpal, R. Programmable Self-Assembly: Constructing Global Shape Using Biologically-Inspired Local Interactions and Origami Mathematics. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2001. [Google Scholar]

- Werfel, J. Biologically realistic primitives for engineered morphogenesis. In Proceedings of the International Conference on Swarm Intelligence, Beijing, China, 12–15 June 2010; Springer: Berlin/Heidelberg, Germany, 2010; pp. 131–142. [Google Scholar] [CrossRef]

- Stoy, K. Using cellular automata and gradients to control self-reconfiguration. Robot. Auton. Syst. 2006, 54, 135–141. [Google Scholar] [CrossRef]

- Dutta, A.; Dasgupta, P.; Nelson, C. Distributed configuration formation with modular robots using (sub) graph isomorphism-based approach. Auton. Robots 2019, 43, 837–857. [Google Scholar] [CrossRef]

- Li, H.; Wang, T.; Chirikjian, G.S. Self-assembly Planning of a Shape by Regular Modular Robots. Adv. Reconfig. Mech. Robot. II 2016, 36, 867–877. [Google Scholar] [CrossRef]

- Yim, M.; Shirmohammadi, B.; Sastra, J.; Park, M.; Dugan, M.; Taylor, C.J. Towards robotic self-reassembly after explosion. In Proceedings of the 2007 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Diego, CA, USA, 29 October–2 November 2007; pp. 2767–2772. [Google Scholar] [CrossRef][Green Version]

- Christensen, A.L.; O’Grady, R.; Dorigo, M. SWARMORPH-script: A language for arbitrary morphology generation in self-assembling robots. Swarm Intell. 2008, 2, 143–165. [Google Scholar] [CrossRef]

- Baca, J.; Yerpes, A.; Ferre, M.; Escalera, J.A.; Aracil, R. Modelling of modular robot configurations using graph theory. In Proceedings of the International Workshop on Hybrid Artificial Intelligence Systems, Burgos, Spain, 24–26 September 2008; Springer: Berlin/Heidelberg, Germany, 2008; pp. 649–656. [Google Scholar] [CrossRef]

- Liu, C.; Lin, Q.; Kim, H.; Yim, M. SMORES-EP, a Modular Robot with Parallel Self-assembly. arXiv 2021, arXiv:2104.00800. [Google Scholar]

- Wei, H.; Li, D.; Tan, J.; Wang, T. The distributed control and experiments of directional self-assembly for modular swarm robots. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 4169–4174. [Google Scholar] [CrossRef]

- Murata, S.; Yoshida, E.; Kurokawa, H.; Tomita, K.; Kokaji, S. Self-repairing mechanical systems. Auton. Robots 2001, 10, 7–21. [Google Scholar] [CrossRef]

- Fitch, R.; Rus, D.; Vona, M. A basis for self-repair robots using self-reconfiguring crystal modules. In Proceedings of the Intelligent Autonomous Systems, Singapore, 22–25 June 2000; Volume 6, pp. 903–910. [Google Scholar]

- Ackerman, M.K.; Chirikjian, G.S. Hex-DMR: A modular robotic test-bed for demonstrating team repair. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, St Paul, MN, USA, 14–18 May 2012; pp. 4148–4153. [Google Scholar] [CrossRef]

- O’Grady, R.; Pinciroli, C.; Groß, R.; Christensen, A.L.; Mondada, F.; Bonani, M.; Dorigo, M. Swarm-bots to the rescue. In Proceedings of the European Conference on Artificial Life, Budapest, Hungary, 13–16 September 2009; Springer: Berlin/Heidelberg, Germany, 2009; pp. 165–172. [Google Scholar] [CrossRef]

- Arbuckle, D.; Requicha, A.A. Self-assembly and self-repair of arbitrary shapes by a swarm of reactive robots: Algorithms and simulations. Auton. Robots 2010, 28, 197–211. [Google Scholar] [CrossRef]

- Stoy, K.; Nagpal, R. Self-repair through scale independent self-reconfiguration. In Proceedings of the 2004 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (IEEE Cat. No. 04CH37566), Sendai, Japan, 28 September–2 October 2004; Volume 2, pp. 2062–2067. [Google Scholar] [CrossRef]

- Rubenstein, M.; Shen, W.M. Scalable self-assembly and self-repair in a collective of robots. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Louis, MO, USA, 10–15 October 2009; pp. 1484–1489. [Google Scholar] [CrossRef]

- Christensen, D.J. Experiments on fault-tolerant self-reconfiguration and emergent self-repair. In Proceedings of the 2007 IEEE Symposium on Artificial Life, Honolulu, HI, USA, 1–5 April 2007; pp. 355–361. [Google Scholar] [CrossRef]

- Mathews, N.; Christensen, A.L.; O’Grady, R.; Mondada, F.; Dorigo, M. Mergeable nervous systems for robots. Nat. Commun. 2017, 8, 439. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Song, G.; Liu, S.; Qiao, G.; Zhang, J.; Sun, H. A modular self-reconfigurable robot with enhanced locomotion performances: Design, modeling, simulations, and experiments. J. Intell. Robot. Syst. 2016, 81, 377–393. [Google Scholar] [CrossRef]

- Popesku, S.; Meister, E.; Schlachter, F.; Levi, P. Active wheel-An autonomous modular robot. In Proceedings of the 2013 6th IEEE Conference on Robotics, Automation and Mechatronics (RAM), Manila, Philippines, 12–15 November 2013; pp. 97–102. [Google Scholar] [CrossRef]

- Jakobi, N.; Husbands, P.; Harvey, I. Noise and the reality gap: The use of simulation in evolutionary robotics. In Proceedings of the European Conference on Artificial Life, Granada, Spain, 4–6 June 1995; Springer: Berlin/Heidelberg, Germany, 1995; Volume 929, pp. 704–720. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2013. [Google Scholar]

- Peck, R. Self-Repair during Continuous Motion with Modular Robots. Ph.D. Thesis, University of York, York, UK, 2021. [Google Scholar]

- Eiben, A.E.; Bredeche, N.; Hoogendoorn, M.; Stradner, J.; Timmis, J.; Tyrrell, A.; Winfield, A. The triangle of life: Evolving robots in real-time and real-space. In Proceedings of the European Conference on Artificial Life (ECAL-2013), Sicily, Italy, 2–6 September 2013; pp. 1–8. [Google Scholar] [CrossRef]

- Groß, R.; Bonani, M.; Mondada, F.; Dorigo, M. Autonomous self-assembly in swarm-bots. IEEE Trans. Robot. 2006, 22, 1115–1130. [Google Scholar] [CrossRef]

- Seo, J.; Paik, J.; Yim, M. Modular reconfigurable robotics. Annu. Rev. Control Robot. Auton. Syst. 2019, 2, 63–88. [Google Scholar] [CrossRef]

| Name | Image | Widths (m) | Lengths (m) | Robots in Struct. | Robots in Scene | Num. of Layers |

|---|---|---|---|---|---|---|

| S1 |  | 3, 5 | 10 | 10 | 20 | 3 |

| S2 |  | 3, 5 | 10 | 5 | 20 | 2 |

| S3 |  | 10 | 10 | 15 | 30 | 4 |

| S4 |  | 3, 5, 10 | 10 | 10 | 20, 30 | 5 |

| S5 |  | 3, 5 | 10, 20 | 10 | 20 | 4 |

| Scenario | LW+ vs. LW + MNS | LW+ vs. MLR | LW + MNS vs. MLR |

|---|---|---|---|

| S1 R20 W3 | 0.81 | 0.85 | 0.45 |

| S1 R20 W5 | 0.64 | 0.76 | 0.58 |

| S2 R20 W3 | 0.94 | 0.96 | 0.27 |

| S2 R20 W5 | 0.89 | 0.93 | 0.27 |

| S3 R30 W10 | 0.94 | 0.92 | 0.41 |

| S4 R20 W3 | 0.73 | 0.74 | 0.61 |

| S4 R20 W5 | 0.97 | 0.94 | 0.48 |

| S4 R30 W10 | 0.75 | 0.63 | 0.35 |

| S4 R20 W5 Seed Changed | Inconclusive | Inconclusive | Inconclusive |

| S5 R20 W3 | 0.91 | 0.91 | 0.41 |

| S5 R20 W5 | 0.79 | 0.82 | 0.50 |

| S5 R20 W5 L20 | 0.96 | 0.98 | 0.50 |

| S5 R20 W5 Seed Changed | 0.72 | 0.70 | 0.51 |

| Name | Image | Temp. IDs of Fault Injected Modules | Recruitment List |

|---|---|---|---|

| 10B |  | 5, 7 | {{1,4,2,2},{1,3,3,3},{3,4,2,4}, {3,1,1,5},{5,4,2,6},{5,3,3,7}, {7,4,2,8},{7,1,1,9},{9,4,2,10}} |

| 12A |  | 2, 4 | {{1,4,2,2},{1,1,4,6},{1,3,4,5}, {5,2,4,8},{6,2,4,7},{2,4,4,3}, {3,2,4,4},{4,1,4,11},{4,3,4,10}, {11,2,4,12},{10,2,4,9}} |

| Rand |  | 6, 7, 9 | {{1,2,2,2},{1,3,2,3},{1,4,2,4}, {4,4,3,5},{1,1,2,6},{6,4,2,7}, {7,1,4,8},{7,3,2,9},{9,4,3,10}, {10,1,1,11},{11,3,3,12}} |

| S1 |  | 2, 5 | {{1,1,3,5},{1,3,1,2},{2,4,4,9}, {2,2,4,10},{2,3,2,3},{3,4,4,4}, {5,4,2,8},{5,1,2,6},{5,2,2,7}} |

| S2 |  | 4, 5 | {{1,1,1,4},{1,2,2,2},{1,3,2,3}, {4,3,2,5},{5,3,2,6},{5,4,4,7}} |

| S3 |  | 2, 10 | {{1,1,4,3},{1,2,4,10},{1,3,4,2}, {1,4,4,4},{4,2,2,5},{2,2,4,7}, {3,2,4,6},{7,3,3,8},{6,1,1,9}, {10,2,4,11},{11,1,2,12},{12,4,4,14}, {11,3,2,13},{13,4,4,15}} |

| S5 |  | 4, 7, 8 | {{1,1,4,4},{1,3,4,7},{1,4,1,2}, {2,3,3,3},{4,3,4,5},{5,2,4,6}, {7,2,4,8},{8,3,3,9},{9,4,1,10}} |

| Structure | ID of Failed Module | nSSR | nDSR | SSR | DSR | DMS |

|---|---|---|---|---|---|---|

| 10B | 5 | 3% | 95% | 45% | 72% | 81% |

| 10B | 7 | 15% | 99% | 58% | 72% | 87% |

| 12A | 2 | 15% | 79% | 81% | 62% | 72% |

| 12A | 4 | 78% | 99% | 56% | 61% | 54% |

| Rand | 6 | 15% | 77% | 69% | 62% | 52% |

| Rand | 7 | 40% | 71% | 61% | 62% | 51% |

| Rand | 9 | 12% | 75% | 62% | 60% | 64% |

| S1 | 2 | 53% | 97% | 63% | 82% | 94% |

| S1 | 5 | 45% | 97% | 99% | 98% | 97% |

| S2 | 4 | 61% | 98% | 98% | 91% | 82% |

| S2 | 5 | 67% | 100% | 99% | 100% | 99% |

| S3 | 2 | 3% | 81% | 32% | 35% | 68% |

| S3 | 10 | 5% | 69% | 60% | 49% | 69% |

| S5 | 4 | 90% | 99% | 91% | 53% | 78% |

| S5 | 7 | 18% | 98% | 74% | 56% | 81% |

| S5 | 8 | 68% | 98% | 99% | 74% | 85% |

| Structure | ID of Failed Module | nSSR vs. nDSR | nSSR vs. SSR | nSSR vs. DSR | nDSR vs. SSR | nDSR vs. DSR | SSR vs. DSR | nSSR vs. DMS | nDSR vs. DMS | SSR vs. DMS | DSR vs. DMS |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10B | 5 | 0.77 | 0.88 | 0.85 | 0.52 | 0.56 | 0.60 | 0.80 | 0.47 | 0.41 | 0.37 |

| 10B | 7 | 0.88 | 0.89 | 0.90 | 0.31 | 0.45 | 0.60 | 0.82 | 0.34 | 0.50 | 0.40 |

| 12A | 2 | 0.69 | 0.96 | 0.94 | 0.7 | 0.82 | 0.78 | 0.82 | 0.34 | 0.50 | 0.40 |

| 12A | 4 | 0.84 | 0.81 | 0.89 | 0.29 | 0.52 | 0.80 | 0.83 | 0.47 | 0.74 | 0.45 |

| Rand | 6 | 0.67 | 0.94 | 0.98 | 0.72 | 0.89 | 0.90 | 0.89 | 0.79 | 0.74 | 0.49 |

| Rand | 7 | 0.55 | 0.75 | 0.74 | 0.57 | 0.58 | 0.62 | 0.70 | 0.58 | 0.59 | 0.51 |

| Rand | 9 | 0.82 | 0.92 | 0.91 | 0.57 | 0.67 | 0.68 | 0.91 | 0.67 | 0.73 | 0.49 |

| S1 | 2 | 0.89 | 0.83 | 0.91 | 0.36 | 0.60 | 0.77 | 0.88 | 0.57 | 0.72 | 0.48 |

| S1 | 5 | 0.93 | 0.79 | 0.93 | 0.16 | 0.45 | 0.84 | 0.95 | 0.47 | 0.89 | 0.52 |

| S2 | 4 | 0.88 | 0.92 | 0.99 | 0.23 | 0.67 | 0.92 | 0.92 | 0.27 | 0.72 | 0.13 |

| S2 | 5 | 0.95 | 0.86 | 0.95 | 0.13 | 0.52 | 0.87 | 0.95 | 0.74 | 0.91 | 0.67 |

| S3 | 2 | 0.86 | 0.97 | 0.90 | 0.58 | 0.67 | 0.71 | 0.95 | 0.52 | 0.42 | 0.33 |

| S3 | 10 | 0.65 | 0.95 | 0.96 | 0.71 | 0.85 | 0.85 | 0.93 | 0.85 | 0.85 | 0.52 |

| S5 | 4 | 0.73 | 0.82 | 0.84 | 0.36 | 0.47 | 0.73 | 0.92 | 0.66 | 0.89 | 0.74 |

| S5 | 7 | 0.91 | 0.96 | 0.94 | 0.42 | 0.55 | 0.70 | 0.94 | 0.66 | 0.83 | 0.64 |

| S5 | 8 | 0.80 | 0.89 | 0.90 | 0.41 | 0.55 | 0.77 | 0.92 | 0.52 | 0.84 | 0.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peck, R.H.; Timmis, J.; Tyrrell, A.M. Self-Assembly and Self-Repair during Motion with Modular Robots. Electronics 2022, 11, 1595. https://doi.org/10.3390/electronics11101595

Peck RH, Timmis J, Tyrrell AM. Self-Assembly and Self-Repair during Motion with Modular Robots. Electronics. 2022; 11(10):1595. https://doi.org/10.3390/electronics11101595

Chicago/Turabian StylePeck, Robert H., Jon Timmis, and Andy M. Tyrrell. 2022. "Self-Assembly and Self-Repair during Motion with Modular Robots" Electronics 11, no. 10: 1595. https://doi.org/10.3390/electronics11101595

APA StylePeck, R. H., Timmis, J., & Tyrrell, A. M. (2022). Self-Assembly and Self-Repair during Motion with Modular Robots. Electronics, 11(10), 1595. https://doi.org/10.3390/electronics11101595