Abstract

The main source of power in Electric Vehicles (EVs) is derived from batteries. An efficient cell model is extremely important for the development of complex algorithms like core temperature estimation, State of Health (SOH) estimation and State of Charge (SOC) estimation. In this paper, a new methodology for improving the SOC estimation using Equivalent Cell Model (ECM) approach is proposed. The modeling and simulations were performed using MATLAB/Simulink software. In this regard, a Li polymer cell was modeled as a single Resistor-Capacitor (RC) pair (R0, R1 and C1) model using PowerTrain blockset in MATLAB/Simulink software. To validate the developed model, a NASA dataset was used as the reference dataset. The cell model was tuned against the NASA dataset for different currents in such a way that the error in the terminal voltages (difference in terminal voltage between the dataset and the ECM) is <±0.2 V. The mean error and the standard deviation of the error were 0.0529 and 0.0310 respectively. This process was performed by tuning the cell parameters. It was found that the cell parameters were independent of the nominal capacity of the cell. The cell parameters of Li polymer and the Li ion cells (NASA dataset) were found be almost identical. These parameters showed dependence on SOC and temperature. The major challenge in a battery management system is the parameter estimation and prediction of SOC, this is because the degradation of battery is highly nonlinear in nature. This paper presents the parameter estimation and prediction of state of charge of Li ion batteries by implementing different machine learning techniques. The selection of the best suited algorithm is finalized through the performance indices mainly by evaluating the values of R- Squared. The parameters were trained using various Machine Leaning (ML) techniques for regression data analysis using Simulink. A study on Support Vector Machine (SVM) technique was carried out for the simulated and tuned data. It is concluded that the SVM algorithm was best suited. A detailed analysis on the errors associated with the algorithms was also carried out. Later, these parameters were trained using various Machine Leaning (ML) techniques for regression data analysis using Simulink. A study on SVM technique was carried out for the simulated and tuned data. It is concluded that the SVM algorithm was best suited. A detailed analysis on the errors associated with the algorithms was also carried out.

1. Introduction

Fossil fuels like petrol and diesel are used to drive conventional automobiles. Emission of Green House Gases (GHG) is a major concern caused by the conventional automobiles leading to changes in climate. Hence, the current transportation has to be driven from alternate sources of energy to tackle the problems related to air contamination. Electric Vehicles (EV), Hybrid Electric Vehicles (HEV) and Plug-in HEV (PHEV) have gained supreme significance in recent years. Re-chargeable battery packs are used as the main source of power to drive EVs. In order to maximize the power derived from the battery and enable user safety, power electronic converters are used [1].

Typical examples of few energy storage systems are (a) Batteries, (b) Fuel Cells (FCs) and (c) Ultra-Capacitors (Ucs). By means of electrochemical reactions, the chemical energy contained within the active materials directly into electrical energy in batteries. In primary batteries, the chemical reaction is irreversible. However, in secondary reversible chemical reaction occurs after a successful re-charge. Some of the examples of primary batteries are Alkaline and Zinc batteries. Nickel Cadmium and Lithium (Li) ion batteries are examples of secondary battery. Amongst the various chemistries, Lithium (Li) ion batteries are popularly used for powering EV as they possess high energy and specific densities. Li ion batteries possess several advantages compared to other ESDs, namely, (a) low self-discharge and (b) portability.

In the past several researchers have proposed different cell models [2] for efficient computation of SOC and SOH [3]. The mathematical model can be differentiated as physics-based and stochastic models. The physics-based models are complex models and highly accurate as they involve the electrochemical dynamics. The stochastic models are developed based on the discrete Markov chain. Due to the lower complexity and computational efforts, the electrical equivalent models are preferred [4].

The cell parameters for 1-RC pair using analytical method were shown in [5] based on the voltage polarization. However, for the estimation of multiple RC pairs, the standard procedure was not shown. In [6], a complex model consisting of five RC pairs of Li polymer cell was modeled using MATLAB/Simulink. It was proved that the cell parameters were dependent on the SOC and temperature but not on the C rate.

In [7], different methods used for the estimation of SOC using the conventional methods and data-driven approaches were shown. Some examples of the conventional approaches are (a) Kalman Filter, (b) Coulomb Counting and (c) Extended Kalman Filter. Some of the data-driven techniques used for SOC estimation are (a) Support Vector Regression (SVN), (b) Linear Regression and (c) Neural Network. It is noted that the neural network provided highest accuracy of 97.9% compared to all other methods. These data-driven techniques, however, were used for SOC estimation only and not for the cell parameter estimation.

In [8], cell parameters for a Li ion 18650 cell were estimated using a Modified Adaptive Forgetting Factor-Based Recursive Least Square (MAFF-RLS). RLS is one the popular algorithms used for cell parameter estimation. One of the major drawbacks of this algorithm is that it fails to provide accurate results for fast dynamic systems. As the number of data points increases, the error in the estimation increases. Hence, the concept of forgetting factor (λ) [7] was introduced to address the drawbacks of RLS algorithm. To stabilize and maintain high accuracy the optimal selection of λ is mandatory. Different current profiles viz., US06 and DST were used for the estimation. The error in the terminal voltage for the different currents was analyzed. It was shown that the Maximum Absolute Error (MAE) for MAFF RLS was smallest compared to RLS and FFRLS. A comparative analysis between different machine learning algorithms for the estimation of cell parameters is not shown in this paper.

In [9], the cell parameters for 1 RC pair and the SOC for new and aged cells were estimated using Offline Genetic Algorithm Optimization and Smooth Variable Structure Filter (SVSF) based estimation respectively. The upper and lower threshold limits for the parameters were fixed. An objective function was used to minimize the error between the output terminal voltage and the measured terminal voltage. It was shown that for the accuracy in SOC estimation, the battery parameters have to be continuously updated and cannot remain as constant values. Three different current profiles based on the drive cycle pattern were used to estimate the cell parameters and the SOC. The main drawback of this paper is that the estimation of cell parameters were not performed on multiple ML algorithms for the regression data.

The cell parameter estimation plays a vital role in building BMS algorithms like SOC, SOH and thermal management system. In this paper, a universal method for tuning the cell model against any standard dataset is proposed. A cell model of 1-RC pair was developed using MATLAB/Simulink for 10 Ah capacity. The cell parameters were tuned against the NASA (2.1 Ah) dataset using manual tuning such that the difference in the terminal voltages (cell model and the NASA dataset) is <±0.2 V. Later, using various learning techniques the cell parameters were estimated. The data obtained is trained for various models to get a suitable prediction model for the parameter estimation.

In this paper,

- (a)

- A Universal cell model consisting of 1-RC pair is modeled using MATLAB/Simulink using the ECM approach.

- (b)

- A new methodology is adopted for better estimation of SOC by tuning the cell parameters.

- (c)

- The obtained cell parameters are independent of the chemistry of the cell. However, dependent on SOC and ambient temperature.

- (d)

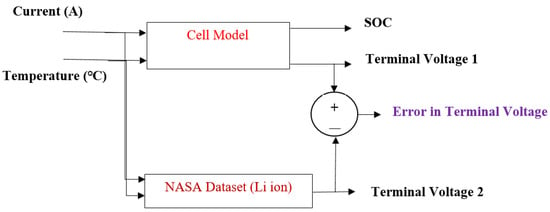

- The cell parameters are tuned using trial and error method such that the difference in the voltages is <±0.2 V for accurate estimation of SOC and using this model, any cell model of any chemistry can be tuned against any standard dataset as shown in Figure 1.

- (e)

- Multiple ML techniques are used to estimate the cell parameters. SVM provided the highest accuracy is the cell estimation.

Figure 1.

Tuning performed for cell parameter estimation.

The paper is split into five different sections. In Section 1, an introduction about the topic is provided. In Section 2, an insight on the different cell models is shown. Section 3 shows the cell modeling technique used to estimate the battery parameters using MATLAB/Simulink. The tuning of cell model against the standard NASA dataset is shown in Section 4. Section 5 provides an overview of various machine learning algorithms used for estimating the cell parameters. Section 6 and Section 7 provide the conclusions and the recommendation for future work.

2. Cell Modeling

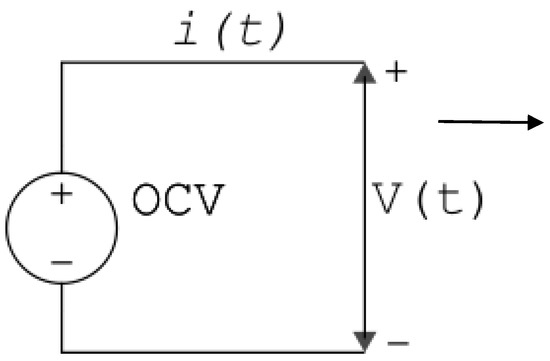

An ideal cell model can be represented as a voltage source as shown in Figure 2. This model is called as the poor voltage model as it does not contain any component that depicts a voltage drop.

Figure 2.

Poor Voltage Method.

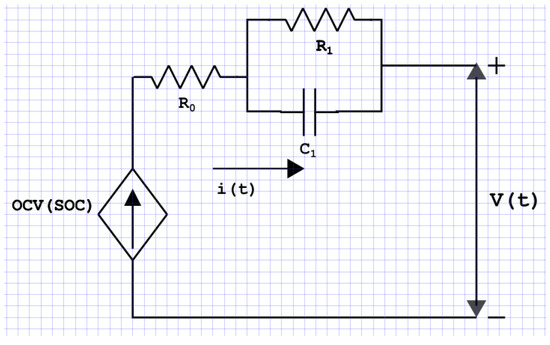

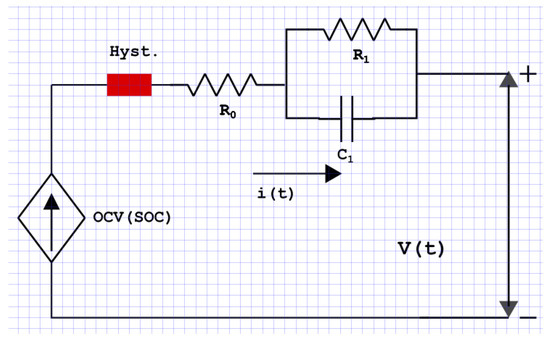

The Simple Cell Model is the next approach for cell modeling. This model contains a resistance called Equivalent Series Resistance (ESR, R0) in series with the voltage source [4]. Open Circuit Voltage (OCV) portrays the drop in the voltage due to the flow of the current in R0. The limitation of this model is that the complete dynamics of the cell are not considered. In addition, the dependence on the SOC on the cell parameters is not considered. Hence, a modified version called Thevenin’s Cell Model was proposed. This model is described as a pair of polarizing resistor (R1) and polarizing capacitor (C1) in series with the R0. It was shown that when a discharge current pulse is supplied to the cell, its voltage (VT) decays and goes down to a lower value. VT diffuses to the OCV during the resting phase. This phenomenon is modeled as a delay circuit by combining a pair of RC in series with R0. This is also referred to as the Equivalent Circuit Model (ECM). Higher order RC pairs are used for pulse charging application and helps in capturing high frequency transients [4]. Figure 3 shows the 1-RC model for a cell consisting of R0, polarizing resistance R1 and capacitance C1.

Figure 3.

1-RC pair model. Where V is the terminal voltage (V), VOCV is the Open Circuit Voltage (V).

In order to estimate the cell parameters, a pulse characterization test is employed to estimate the parameters [5]. R0 and R1arein the range of mΩ and C1 in kF.

Complex cell models with multiple RC pairs are used for capturing high frequency transients in the current and they provide highly accurate results. However, as the number of RC pairs increase, the computation time and the memory requirement drastically increase. Modeling of n-RC pairs for a Li polymer battery is shown in Figure 4.

Figure 4.

n-RC pair model.

3. Extraction of Dataset Using MATLAB/Simulink

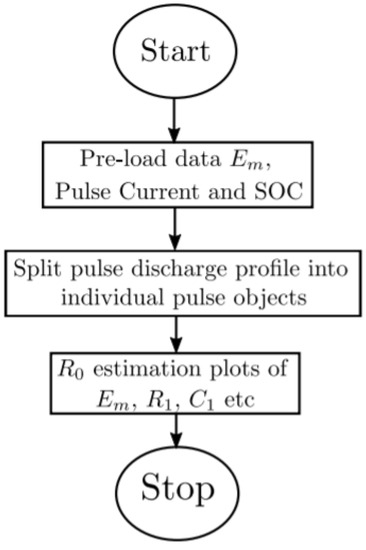

The cell parameters (R0, R1, …, R5, C1, C2, …, C5) can be estimated using the PowerTrain blockset using MATLAB/Simulink. Figure 5 shows the flowchart employed for the estimation. This estimation was used to initially obtain the cell parameter values. These values were used as reference values for ML algorithms, as shown in Section 4.

Figure 5.

Cell Parameter Estimation.

For the estimation process, Simulink optimization tool box, Parallel Computing Toolbox and Curve Fitting tool box are used for estimating Em (VOCV) and Cell parameters. Experiments (OCV, current and SOC data) on a 10 Ah Li polymer Cell were performed and stored in the form of a .mat file. Some of the user-defined parameters were Em, R0 and ambient temperature (Tamb). An estimated plot of Em was cut up into numerous pulses based on the time constants (τ = RnCn). Based on user defined inputs, Em and R0 were estimated. Finally, the ECM was transferred from MATLAB to Simulink environment using parameters defined in the ‘Equivalent Cell Model (ECM)’. Table 1 indicates the initial ECM estimates provided.

Table 1.

Initial ECM estimates for a 10 Ah Li polymer cell.

4. Tuning Parameters Based on NASA Dataset

NASA dataset provides information on voltage response to randomly generated current profiles. The dataset contains pulse charging and discharging cycles after a fixed interval of time [10].

The cell parameters obtained for the Li polymer cell were tuned against NASA dataset such that the difference between the terminal voltage obtained from the Cell model and the NASA dataset was lower than the threshold (±0.2 V). Table 2 shows the specifications of Li ion 18650 cell.

Table 2.

Specifications of Li ion 18650 cell.

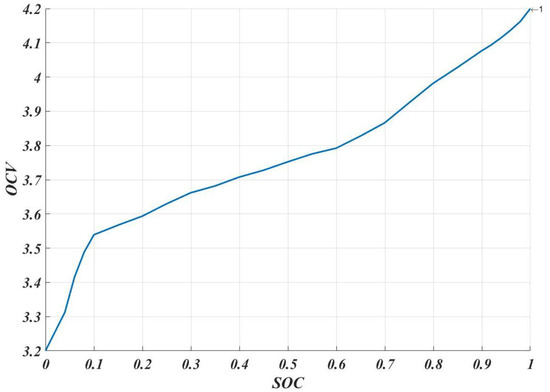

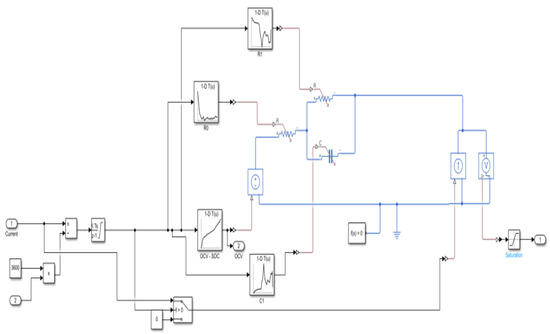

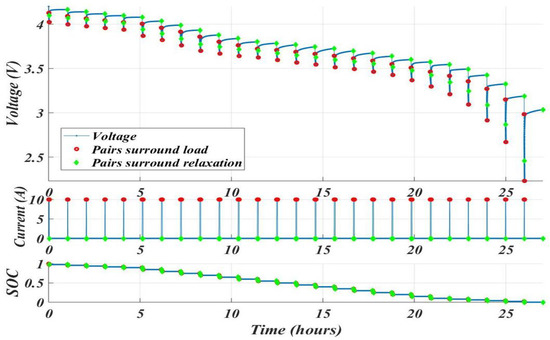

Figure 6 shows the OCV–SOC plot for NASA dataset. As shown in Table 2, cell voltage varies from 4.2 V to 3.2 V. Figure 7 shows the cell model developed using MATLAB/Simulink. The cell parameters are modeled as look tables and for the estimation of SOC, Coulomb Counter method (CC) is used shown in Equation (1). Figure 8 shows the voltage response of the Li polymer cell [5] for one RC pair. Figure 6 shows the OCV–SOC relationship for the Li ion cell as per the NASA dataset. As seen from Figure 6, the voltage varies from 3.2 V to 4.2 V for the NASA dataset.

where SOCt is the SOC at any given time, t, SOC0 is the initial SOC, C is the capacity in Ah, i is the current in A.

Figure 6.

OCV vs. SOC for NASA dataset.

Figure 7.

Cell Model developed using MATLAB/Simulink.

Figure 8.

Voltage response, current and the SOC range of Li polymer cell.

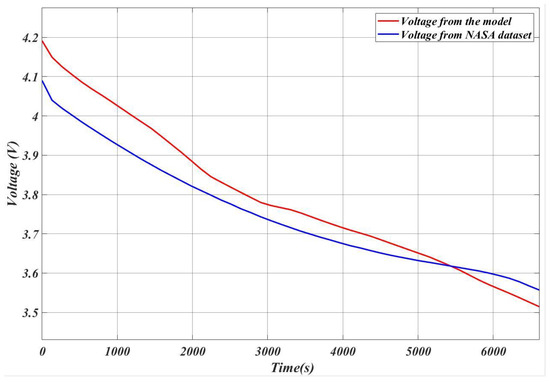

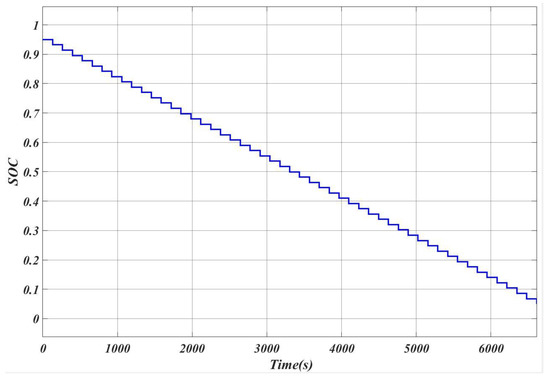

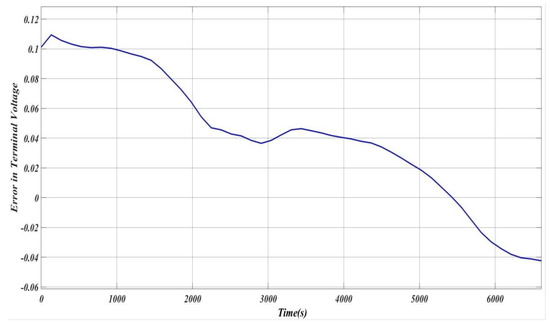

Figure 9 shows the terminal voltages for pulse discharge current profile. The corresponding SOC is shown in Figure 10. Figure 11 shows the error in the terminal voltage after tuning the cell parameters. It is observed from Figure 11 that the error in the terminal voltages is <±0.2 V with a mean error and standard deviation of 0.0529 and 0.0310 respectively. The curve fitting equation associated with error is shown in Equation (2). The R- squared/regression co-efficient was found to be 0.988.

where y is the error in terminal voltage (V) and x is time elapsed (s).

Figure 9.

Terminal voltages for pulse discharge profile.

Figure 10.

SOC vs. Time for pulse discharge.

Figure 11.

Error in voltages for pulse discharge.

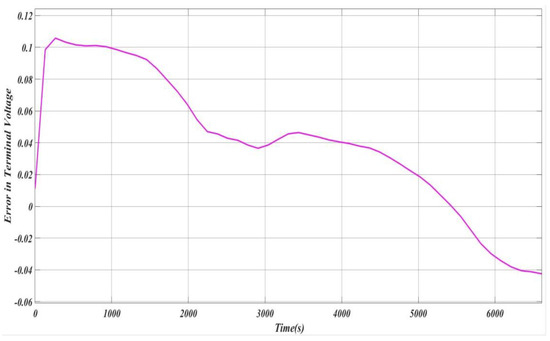

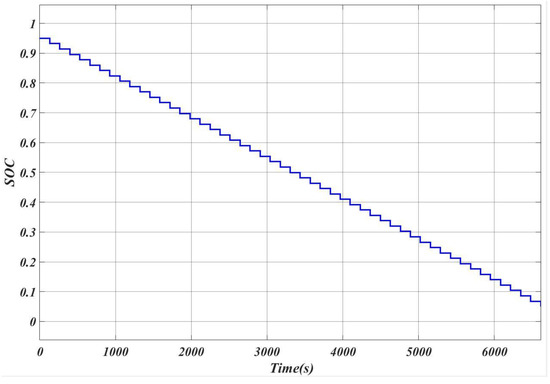

Figure 12 shows the error in the terminal voltage for reference discharge current. Figure 13 shows the plot of SOC for the complete cycle. As seen from Figure 13, the cell discharges from 100% to 10%.

Figure 12.

Error in voltages for reference discharge.

Figure 13.

SOC vs. Time for reference discharge.

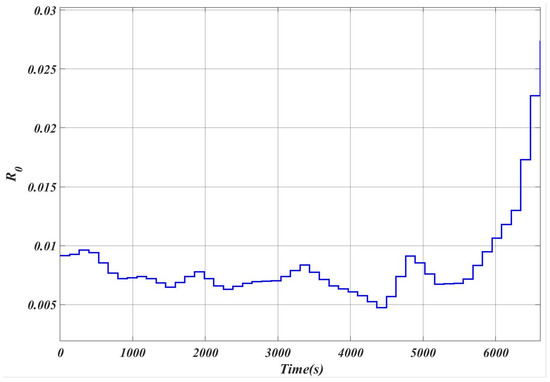

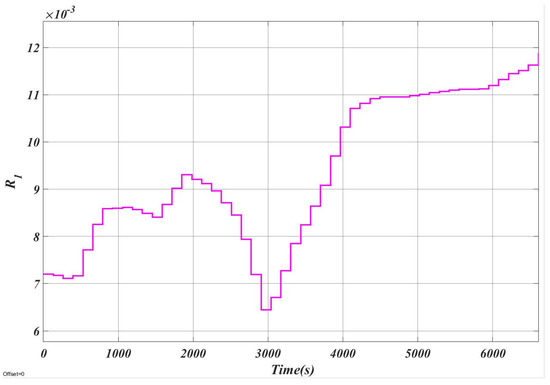

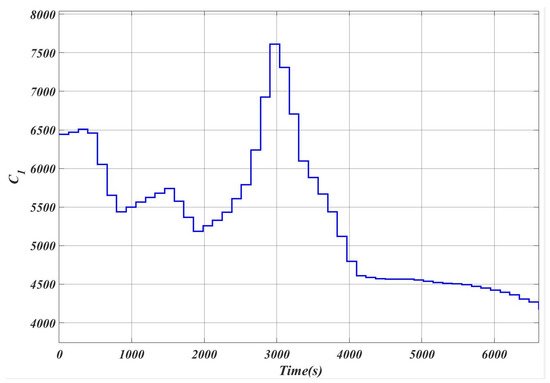

The cell parameters R0, R1 and C1 vary as a function of SOC. Figure 14 and Figure 15 show the variation of R0 and R1 respectively. It is observed that R0 and R1 gradually increase after the completion of the discharge cycle. Figure 16 shows the variation of C1 with respect to time.

Figure 14.

R0 vs. Time.

Figure 15.

R1 vs. Time.

Figure 16.

C1 vs. Time.

5. Machine Leaning Technique for Parameter Estimation

The challenging function in the BMS is the parameter estimation for good prediction and control. The application of Li ion batteries is rapidly increasing, hence for the sophisticated application the safety and reliable operation need to be carefully ensured. Considering this as the major certainty, the machine learning technique against conventional is adopted. Machine learning for parameter estimation has proved various applications with reliable and efficient prediction of states associated with it. The state of the art of the machine learning–based approach has been reviewed by researchers [11,12]. Various parameters affect the performance of Li ion due to which the conditions associated with operation such as over discharge and over charge may lead to catastrophic failure. The model-based approaches determine the accuracy and reliability, but developing a highly accurate model may be challenge due to nonlinear characteristics of internal parameters. Such a challenge can be overcome by ML-based techniques. The two major data collections of the battery parameters, the physical information and the correlation between the linear and nonlinear internal external parameters, could reduce the knowledge specific model with the machine learning.

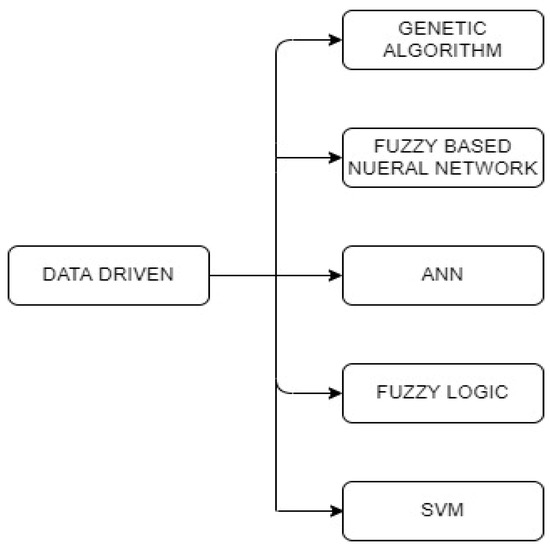

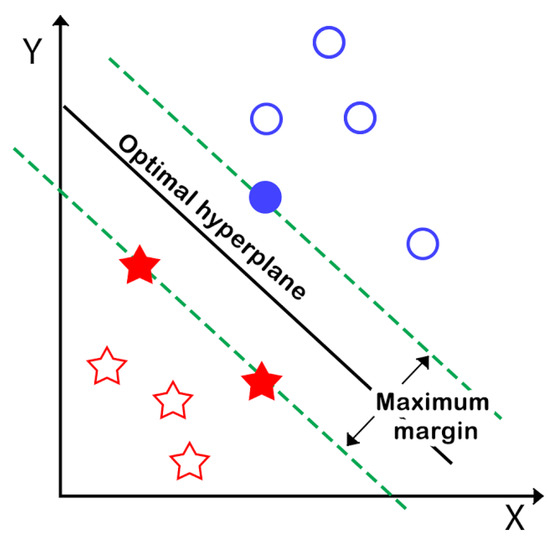

Parameter estimation can be approach through least square or through the filter based on a model-based approach. In a non-model-based approach it can be through data-driven or knowledge-based approaches, and various methods available are highlighted in Figure 17. In this research, a data-driven approach is adopted, in specific under machine learning, the Regression approach, which is an unsupervised technique, is adopted for parameter estimation. For any highly complex quadratic programming, the SVM is used for solving regression problems [13]. The typical criteria for finding optimal separation boundaries are to maximize the distance between the hyper plane and the nearest data point of any cluster. SVM is becoming a powerful tool for regression analysis in highly nonlinear systems like Li ion battery (LIB). Different kernel functions and regression algorithms are used to transform the nonlinear model to linear model which makes the analysis much easier [14].

Figure 17.

Parameter Estimation Methods.

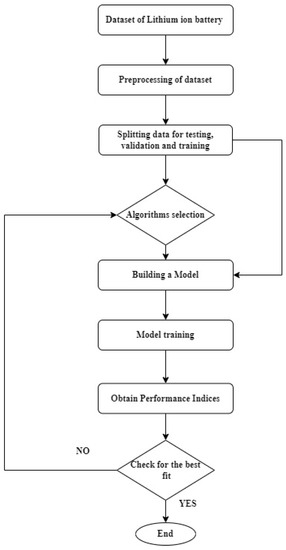

The major challenge in a battery management system is the parameter estimation and prediction of SOC, and this is because the degradation of battery is highly nonlinear in nature. This section presents the parameter estimation and prediction of state of charge of Lithium ion batteries by implementing different machine learning techniques. The selection of the best suited algorithm is finalized through the performance indices mainly by evaluating the values of R-Squared, MSE and RMSE. For the estimation of the parameters to be done, the data is mainly taken from the training dataset. This dataset is used for the data-driven algorithmic models. The obtained data from the Li ion batteries are further preprocessed, where the dataset is re-sampled, normalized and they are split and separated for training, validation and for testing. These separated data in the training set is selected for the algorithm training and further used for building the model. Algorithms are selected for training the model, which evaluates the performance indices, through which a suitable algorithm can be selected for estimation and prediction. These steps are summarized in the flow chart shown in Figure 18.

Figure 18.

Flow chart for steps to follow to choose a best fit algorithm.

In any conventional method which can be used for parameter estimation, there could be errors associated due to manual calculations [11]. Hence, to overcome this, SVM is adopted. Some of the steps associated with parameter estimation and prediction are as follows: First, the raw data is collected from the simulation. The cross validation is done by leave-one-out procedure, dividing the data into training and validation sets. A stationary test is conducted; the test was carried with Unit root test, to remove the non-stationary. The backward difference operator was considered only if such a situation was present. The estimation of parameters is done by maximum likelihood, and AIC is used for model selection. Finally, the predicted model is forecasted by checking the Mean Absolute Error. The most frequently used model for describing parameter estimation is SVM. With the SVM models the future readings or the current reading is given by the function of previous reading. There are various algorithms like Artificial Neural Network (ANN), Gaussian process regression, Linear regression, Support Vector Machine, etc.; the model can be trained for all these algorithms and the best fit algorithm can be selected through the evaluation of performance indices. ANN has an exceptional potential to construct a non-linear mapping between the input and output parameters. These types of algorithmic approach mainly depend on quality and quantity of data [15].

SVM is an established probabilistic type knowledge-based algorithm which includes the neural network and Markov chain technique to address the uncertain conditions which are present externally and internal electrochemical mechanisms. This algorithm in ML is used for the construction of predictive model and for forecasting the charging curve. ML is mainly used to construct accurate SOC and is used for validation under a wide range of operating conditions. Among various algorithms, SVM gives the best fit and the regression is represented in Figure 19.

Figure 19.

Representation of Support vector machine [15].

The empirical formula to calculate the predicted output is given as

where is the predicted output, W is the weights, K is the Kernel trick, is the support vectors and B is the Bias. The systematic steps to develop SVM algorithm is to train the model, import the input features from the simulation of the model then analyze the correlation and directivity of the data, split the data for training and validation. Once the data is split for training, an appropriate Kernel function needs to be selected for training the dataset. The performance indices are evaluated and the model is tested with the testing data. To evaluate the results of the predicted SOC, comparison between the predicted SOC with the experimental values has to be performed. The performance metrics are therefore assessed by different metrics like Root Mean Square Error (RMSE), Mean Square Error (MSE) and R-squared, as shown in Equations (4)–(6). RMSE is a good measure of accuracy, but is applicable to comparing model predictions with data and not between variables. R squared is a statistical indicator that describes the amount of uncertainty explained by an independent variable [16,17].

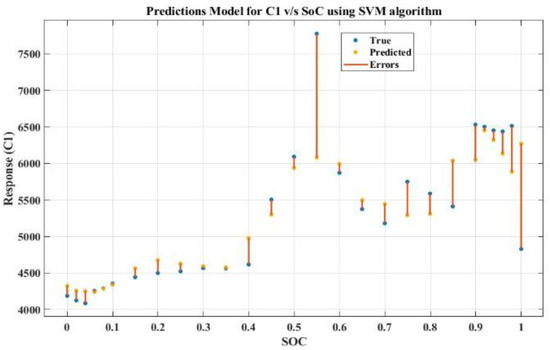

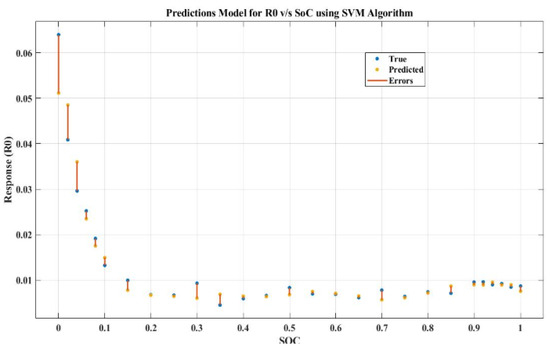

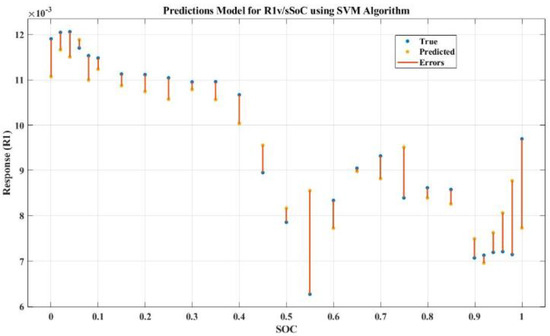

Using the SVM technique, the parameter estimation and the prediction error is found to be least for the SOC vs. R0. The cell parameters R0, R1 and C1 vary as a function of SOC. The R squared obtained for validation is 0.76, 0.7 and 0.95, with a prediction speed of 30 to 50 s for C1, R0 and R1 with function of SOC respectively. Figure 20, Figure 21 and Figure 22 clearly project the prediction of parameters with the errors obtained. In the prediction model for the C1 vs. SOC, only one point deviates, which precedes the cause of larger error. Table 3 shows R-squared mean value for parameter estimation. The parameters can be estimated with the prediction model for better control of SOC with respective to C1, R0 and R1. Table 4 shows a comparison between various ML techniques used for cell parameter estimation.

Figure 20.

Prediction model for parameter estimation: C1 vs. SOC.

Figure 21.

Prediction model for parameter estimation: R0 vs. SOC.

Figure 22.

Prediction model for parameter estimation: R1 vs. SOC.

Table 3.

R-squared mean value for parameter estimation.

Table 4.

Cell parameter estimation using different techniques.

6. Conclusions

Cell modeling is the basic building block in any BMS. They are extremely important for building complex BMS algorithms. In this work, a simulation-based study is carried out to estimate the cell parameters using the terminal voltages. The proposed method is extremely useful and provides accurate SOC results. Initially, the cell parameters (1-RC) for Li polymer battery of 10 Ah nominal capacity were estimated using MATLAB/Simulink. Later, a cell model using Simscape was realized using MATLAB/Simulink to tune the cell parameters against the standard NASA test data. The tuning was performed such that Vterminal_cellmodel–Vterminal_testdata < ±0.2 V. It is found that the cell parameters for a Li polymer cell and Li ion 18650 cell closely match. The simulated cell parameter values were used as the reference values for the ML algorithms. SVM is an established probabilistic type knowledge-based algorithm which includes the neural network and Markov chain technique to address the uncertain conditions which are present in external and internal electrochemical mechanisms. This algorithm in ML is used for the construction of predictive model and for forecasting the charging curve. ML is mainly used to construct accurate SOC and is used for validation under a wide range of operating conditions. Among various algorithms, SVM gives a best fit and the regression. For the best fit SVM technique is adopted, which gives a good prediction model with respect to SOC and associated parameters for the estimation of parameters for a better control and efficiency which is evaluated through the R squared obtained. For the best fit, SVM technique is adopted, which gives a good prediction model with respect to SOC and associated parameters for the estimation of parameters for a better control and efficiency. It was found that the cell parameters (R0, R1 and C1) are functions of SOC and ambient temperature. However, they showed no dependence on the magnitude of current. Hence, the training results need further tuning only if the temperature and the OCV range change.

7. Discussion and Recommendation for Further Research

In this work, the cell parameters were estimated for a Li ion cell based on the parameters obtained for a Li polymer cell using PowerTrain blockset in MATLAB/Simulink software. During the tuning process, negative temperatures were not included in the dataset and, hence, for negative temperatures, additional training is required. In addition, the tuning can be further improved by tuning R1 and C1 values as they play an important role in the dynamics of the cell behavior. From the prediction and estimation of the cell parameters using ML, a new model can be developed from the trained parameters which can be further used for better SOC estimation.

Author Contributions

Conceptualization, S.S. and C.C.S.; methodology, S.S.; software, S.S.; validation, S.S., C.C.S.; formal analysis, S.S.; investigation, S.S.; resources, C.C.S.; data curation, S.S.; writing—original draft preparation, S.S., C.C.S.; writing—review and editing, S.S., C.C.S.; visualization, S.S.; supervision, S.W.; project administration, S.W.; funding acquisition, S.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Surya, S.; Supriya, P.; Williamson, S.S. A Comprehensive Study on DC–DC and DC–AC Converters in Electric and Hybrid Electric Vehicles. In E-Mobility. EAI/Springer Innovations in Communication and Computing; Kathiresh, M., Kanagachidambaresan, G.R., Williamson, S.S., Eds.; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Sumukh, S.; Rao, V.; Williamson, S.S. Comprehensive Review on Smart Techniques for Estimation of State of Health for Battery Management System Application. Energies 2021, 14, 4617. [Google Scholar] [CrossRef]

- Shahab, N.; Gladwin, D.T.; Stone, D.A. A systematic review of lumped-parameter equivalent circuit models for real-time estimation of lithium-ion battery states. J. Power Sources 2016, 316, 183–196. [Google Scholar]

- Plett, G.L. Cell Management Systems, Volume I: Cell Modeling; Artech House: Norwood, MA, USA, 2015. [Google Scholar]

- Surya, S.; Channegowda, J.; Datar, S.D.; Jha, A.S.; Victor, A. Accurate battery Modeling Based on Pulse Charging using MATLAB/Simulink. In Proceedings of the 2020 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Jaipur, India, 16–19 December 2020; IEEE: New York, NY, USA, 2020. [Google Scholar]

- Kumar, A.A.; Kulkarni, S.S. Comparative Study of Mathematical Models and Data Driven Models for Cell Performance Parameter Estimation. In Proceedings of the 2020 Third International Conference on Advances in Electronics, Computers and Communications (ICAECC), Bengaluru, India, 11–12 December 2020; IEEE: New York, NY, USA, 2020. [Google Scholar]

- Shrivastava, P.; Soon, T.K.; Idris, M.Y.B.; Mekhilef, S. Lithium-ion Cell Model Parameter Identification Using Modified Adaptive Forgetting Factor-Based Recursive Least Square Algorithm. In Proceedings of the 2021 IEEE 12th Energy Conversion Congress & Exposition-Asia (ECCE-Asia), Singapore, 24–27 May 2021; IEEE: New York, NY, USA, 2021. [Google Scholar]

- Li, R.; Wang, Z.; Yu, J.; Lei, Y.; Zhang, Y.; He, J. Dynamic parameter identification of mathematical model of lithium-ion Cell based on least square method. In Proceedings of the 2018 IEEE International Power Electronics and Application Conference and Exposition (PEAC), Shenzhen, China, 4–7 November 2018; IEEE: New York, NY, USA, 2018. [Google Scholar]

- Ryan, A.; Rahimifard, S.; Habibi, S. Offline parameter identification and soc estimation for new and aged electric vehicles batteries. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 19–21 June 2019; IEEE: New York, NY, USA, 2019. [Google Scholar]

- Bole, B.; Kulkarni, C.; Daigle, M. “Randomized Battery Usage Data Set”, NASA Ames Prognostics Data Repository. Available online: http://ti.arc.nasa.gov/project/prognostic-data-repository (accessed on 28 December 2021).

- Samanta, A.; Chowdhuri, S.; Williamson, S.S. Machine Learning-Based Data-Driven Fault Detection/Diagnosis of Lithium-Ion Battery: A Critical Review. Electronics 2021, 10, 1309. [Google Scholar] [CrossRef]

- Venugopal, P.; Reka, S.S. State of Charge Estimation of Lithium Batteries in Electric Vehicles Using IndRNN. IETE J. Res. 2021. [Google Scholar] [CrossRef]

- Nagarale, S.D.; Patil, B.P. A Review on AI based Predictive Battery Management System for E-Mobility. Test Eng. Manag. 2020, 83, 15053–15064. [Google Scholar]

- Rivera-Barrera, J.P.; Muñoz-Galeano, N.; Sarmiento-Maldonado, H.O. SoC estimation for lithium-ion batteries: Review and future challenges. Electronics 2017, 6, 102. [Google Scholar] [CrossRef] [Green Version]

- Chandran, V.; Patil, C.K.; Karthick, A.; Ganeshaperumal, D.; Rahim, R.; Ghosh, A. State of charge estimation of lithium-ion battery for electric vehicles using machine learning algorithms. World Electr. Veh. J. 2021, 12, 38. [Google Scholar] [CrossRef]

- Khumprom, P.; Yodo, N. A Data-Driven Predictive Prognostic Model for Lithium-ion Batteries based on a Deep Learning Algorithm. Energies 2019, 12, 660. [Google Scholar] [CrossRef] [Green Version]

- Stighezza, M.; Bianchi, V.; De Munari, I. FPGA Implementation of an Ant Colony Optimization Based SVM Algorithm for State of Charge Estimation in Li-Ion Batteries. Energies 2021, 14, 7064. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).