In this section, we present the analysis and synthesis of the reviewed papers. The process that we followed included the following steps:

3.1. Cost Estimation and Maintenance Planning

The area of “cost estimation and maintenance planning” includes algorithms that are able to recommend the most appropriate maintenance actions according to the company’s policies and the estimations regarding the potential impacts and risks of the candidate actions. In this way, the algorithms aim at minimizing long-term costs, thus enabling the scheduling and planning of mitigating maintenance actions.

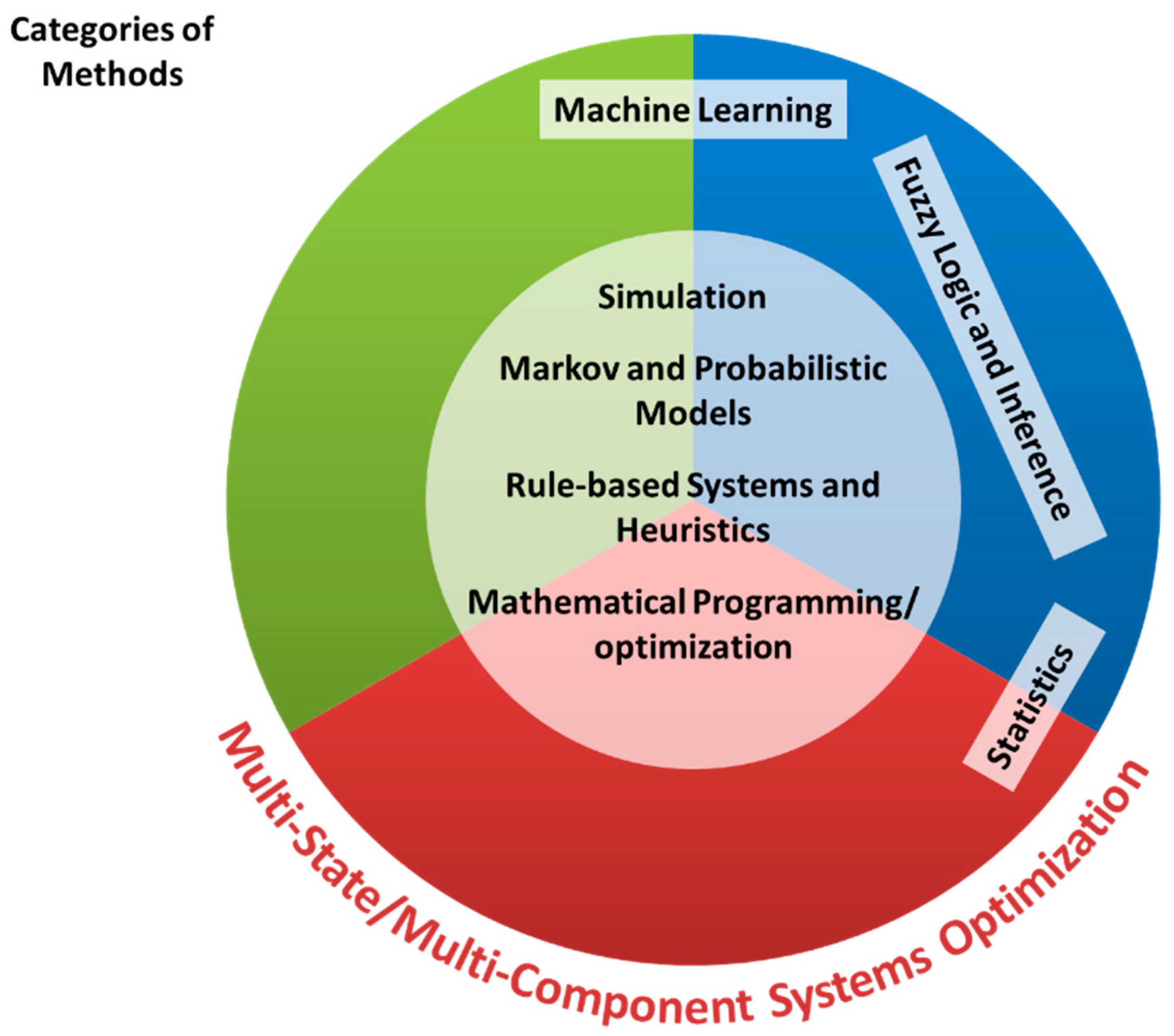

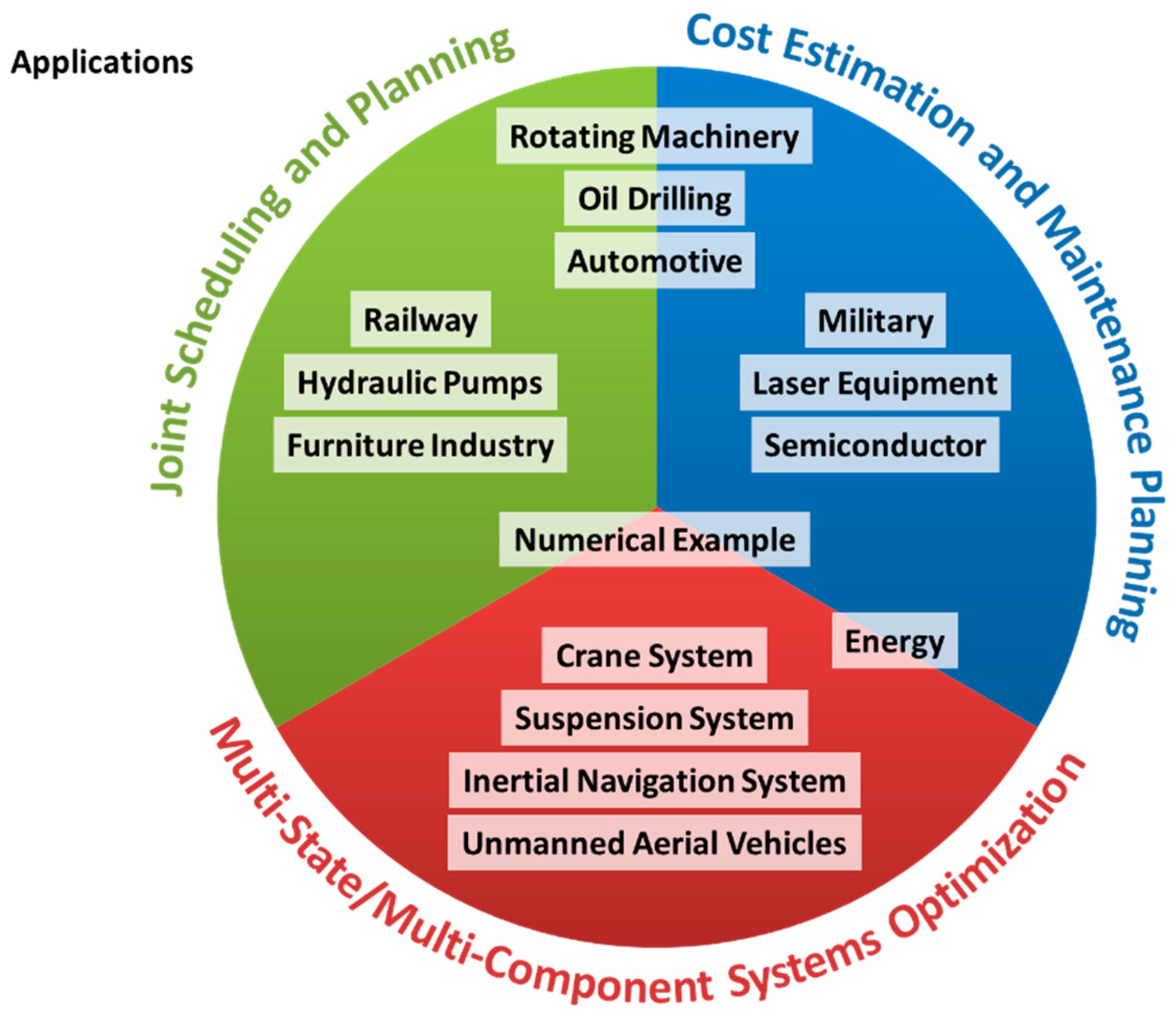

Table 5 presents the methods that are used in the papers belonging to this area of contribution, while

Table 6 presents the applications in the context of which the proposed algorithms and methods are evaluated. As shown in

Table 5, mathematical programming/optimization methods are widely used, while there is also a considerable amount of research on rule-based systems and heuristics as well as on Markov models. As shown in

Table 6, applications on rotating machinery and on energy have gathered research interest the most.

The stochastic nature of the degradation process as well as the uncertainty existing in prognostic algorithms leads to high uncertainty also in the decision-making process. For this reason, many papers have tackled these challenges. Hong et al. [

20] investigate the influence of stochastic degradation on optimal maintenance decisions. Tang et al. [

21] proposed a method for an optimal maintenance policy on the basis of residual life estimation for a slowly degrading system subject to soft failure and condition monitoring. The optimization problem is formulated and solved in a semi-Markov decision process framework in order to minimize the long-run expected average cost. A similar method is proposed for tackling the presence of competing risks (soft and hard failure) in a degrading system [

22]. Xu et al. [

23] proposed a method for optimized replacement decisions on the basis of remaining useful life (RUL) estimation. Wan et al. [

24,

25] propose a collaborative maintenance planning system that manages information and knowledge to support decision-making in maintenance process planning. Chen et al. [

26] propose a fuzzy logic system that allows operators to optimize real-time operation and maintenance scheduling. Yildirim et al. [

26] present a maintenance framework that integrates the sensor-driven predictive maintenance technologies with optimal maintenance scheduling models. Fouladirad et al. [

27] propose an approach for global optimization of costs for a gradually deteriorating system subject to change in the deterioration rate. Si et al. [

28] propose a method that considers not only the expectation of the maintenance cost but also its variability. Lepenioti et al. [

29] exploited the recent advancements of machine learning for performing prescriptive analytics on the basis of enterprise and operational data. To do this, the authors applied multi-objective reinforcement learning for providing decisions based upon the predictions of a deep learning algorithm. Hoong et al. [

30] propose an algorithm that self-learns an optimal maintenance policy and provides actionable recommendation for each equipment with the use of deep reinforcement learning.

Several papers take into account the current level of degradation that is derived from the analysis of the indicators measured by sensors instead of predictions about future failure modes, while they usually process batches of data at pre-defined sampling times. However, such approaches are not optimal when decisions are taken under time constraints increasing the maintenance costs of the manufacturing company.

The majority of research works regarding cost estimation and maintenance planning do not adopt a data-driven approach for decision-making, and thus they are limited to specific problems, domains, and industries. That is why mathematical programming/optimization and rule-based systems are the most common categories of methods. Consequently, they cannot be transferred to a different production process with similar challenges in a straightforward way. The most generic approaches aiming at tackling the challenges of the smart factory are presented in [

31,

32,

33,

34]. Terkaj et al. [

31] propose the use of an ontology-based virtual factory in order to enable in situ simulation for assessing the future impact of maintenance planning decisions. Susto et al. [

32] proposed an approach with dynamical decision rules in the context of a multiple classifier machine learning methodology aiming at minimizing the expected cost. Bousdekis et al. [

33] utilized proactive event-driven computing in maintenance decision-making and represent the decision-making process instead of the physical process. Roccheta and Bellani [

34] developed a reinforcement learning framework for the prognostic-based optimal management of the maintenance of power grids. The authors of [

35] investigated the use of the particle swarm optimization algorithm to quantify the effect of RUL uncertainty on predictive maintenance planning by integrating it with a random sampling-based strategy to select a sequence that performs better for different values of RUL associated with different jobs.

The majority of the algorithms rely on the assumption of perfect maintenance or replacement, without considering imperfect maintenance actions with various degrees. Imperfect maintenance actions for deteriorating systems were considered only in three papers. Do et al. [

5] investigated the impacts of imperfect maintenance actions to propose an adaptive maintenance policy that can help to select optimal (perfect or imperfect) maintenance actions at each inspection time according to the remaining useful life (RUL) estimation. Wu et al. [

36] propose an optimization model in order to minimize the total cost of imperfect degradation-based maintenance by determining an optimal interval of condition monitoring and the degradation level after imperfect repairs. Bumblauskas et al. [

37] propose proactive event-driven decision methods based on Markov Decision Process (MDP) and optimization models for recommending both perfect and imperfect maintenance actions at optimal times with respect to costs.

3.2. Joint Scheduling and Planning

As presented in

Section 3.1, most cost estimation and maintenance planning approaches do not address factors such as production costs, equipment availability, spare parts inventory, and transportation costs, to name a few. This limitation in prior research paved the way for newer joint scheduling and planning approaches aiming at optimizing jointly manufacturing processes, including maintenance. For example, maintenance planning should be coordinated with spare parts ordering and possible delays, as well as inventory cost management.

Table 7 presents the methods that are used in the papers belonging in this area of contribution, while

Table 8 presents the applications in the context of which the proposed algorithms and methods are evaluated. As shown in

Table 7, mathematical programming/optimization methods are widely used (due to the fact that most of the algorithms are limited to specific problems, domains, and industries), while there is also a considerable amount of research on Markov models. As shown in

Table 8, most of the papers in this area evaluate their results in numerical examples, without dealing with case studies. The evaluation of joint scheduling and planning methods in various application domains and real-life case studies is still at its dawn.

Similar to the previous area, most of the joint scheduling and planning algorithms rely on the assumption of perfect maintenance or replacement. From the reviewed papers, only [

38,

39] deal with decision methods capable of recommending both perfect and imperfect maintenance actions. Moreover, apart from [

40], the rest of the reviewed papers were involved with single-component systems.

Joint scheduling and planning deal with approaches that optimize predictive maintenance decisions jointly with

Jiang et al. [

41] investigated the impact of inventory deterioration on predictive maintenance decision-making. Van Horenbeek and Pintelon [

42] quantified the added value of predictive information (RUL) in dynamic joint maintenance and inventory decision-making. Bousdekis et al. [

43] propose a proactive event-driven decision model for joint predictive maintenance and spare parts inventory optimization in the frame of the e-maintenance concept. Bousdekis et al. [

44] propose a proactive event-driven model for joint maintenance and logistics optimization for recommending optimal (perfect or imperfect) maintenance actions and associated spare parts orders along with optimal timing.

Kouedeu et al. [

38] examined the joint analysis of the optimal production and maintenance planning policies for a manufacturing system subject to random failures and repairs. Jafari and Makis [

45] considered the joint optimization of economic manufacturing quantity and maintenance policy. The problem was formulated and solved in the semi-Markov decision process framework in order to minimize the long-run expected average cost per unit time. Cinus et al. [

46] propose a decision support system that processes sensor data and Key Performance Indicators (KPIs) using an artificial neural network (ANN)-based knowledge system and integrates the maintenance actions within the weekly production schedule. Mourtzis et al. [

47,

48] propose an augmented reality mobile application, interfaced with a shop-floor scheduling tool, in order to enable the operator to decide on immediately calling AR remote maintenance or scheduling maintenance tasks for later along with production tasks. Liu et al. [

49] present an integrated decision model that coordinates predictive maintenance decisions on the basis of prognostics information with single-machine scheduling decisions so that the total expected cost is minimized. Zhai et al. [

50] propose a decision model for predictive maintenance and job shop scheduling for machine deterioration under time-varying operational conditions. Nguyen et al. [

51] present a dynamic model for predictive maintenance policy formulated on the basis of partially observable markov decision processes. Mi et al. [

52] proposed an integrated decision-making approach supported by digital twin-driven cooperative awareness and interconnection framework.

Product quality ([

53,

54])

Lee and Ni [

53] present an approach for determining maintenance and product dispatching policies and the relationship between machine degradation and product quality. They used a Markov decision process for long-term decision-making and integer programming for short-term decision-making. Gu et al. [

54] present an algorithm tackling the co-effect between manufacturing system component reliability and product quality. The algorithm results in the optimal maintenance strategy, obtained by optimizing the quality cost, maintenance cost, and interruption cost simultaneously.

Supplier selection ([

44])

Bousdekis et al. [

44] propose an approach for real-time, event-driven proactive supplier selection with the use of Markowitz portfolio optimization theory, on the basis of the optimal times for replacement and ordering the spare parts. The algorithm is triggered by real-time, sensor-driven predictions about future failures and future spare parts prices.

3.3. Multi-State and Multi-Component Systems Optimization

In many realistic problems, there are complex multi-component systems with uncertainties in the system reliability structure [

55], while the decision-making algorithms for single-component systems are not usually suitable for multi-component systems [

6]. To this end, “multi-state and multi-component systems optimization” includes algorithms that allow for the identification of intermediate stages of their health state and that take into account inter-component relations. These relations may be of a stochastic nature, implying that the degradation of one component may probably impact the condition of others. Relations may also be of economic nature, e.g., a positive economic relation implies that it can be more economical if two components are jointly maintained than if done separately.

Table 9 presents the methods that are used in the papers belonging in this area of contribution, while

Table 10 presents the applications in the context of which the proposed algorithms and methods are evaluated. As shown in

Table 9, mathematical programming/optimization methods are widely used, while there is also a considerable amount of research on rule-based systems and heuristics as well as on Markov and probabilistic models. As shown in

Table 10, most of the papers in this area evaluate their results in numerical examples, without dealing with case studies.

The complexity of multi-state and multi-component systems optimization poses challenges in their scalable and efficient implementation in the context of a data-driven manufacturing environment. Due to this complexity, the reviewed papers usually use algorithms taking advantage of more than one method [

56,

57,

58,

59,

60,

61,

62], as shown in

Table 9.

The dependencies in multi-state and multi-component systems deal with economic dependence, stochastic dependence, or a combination of both. Structural dependence among components was not investigated in the reviewed papers. Below, we describe the reviewed research work for each category of dependence.

Le and Tan [

63] proposed a multi-state strategy that combines both inspection and continuous monitoring to reduce unnecessary thorough inspection and to improve the system’s reliability. An optimal maintenance strategy was derived on the basis of an iterative algorithm to minimize the mean long-run cost-rate. They assumed that the maintenance is imperfect and the degradation is a continuous-time Markov process. Zhou et al. [

56] proposed a maintenance optimization method for a multi-state series-parallel system considering economic dependence and state-dependent inspection intervals. The objective function is the average revenue per unit time calculated on the basis of the semi-regenerative theory and the universal generating function (UGF).

Xia et al. [

64] proposed a method of multi-level scheduling in order to predict maintenance requirements according to machine degradation and maintenance opportunity. A global-objective model is used to make the machine-level decision for availability-effective and cost-effective maintenance intervals. Nguyen et al. [

59] presented an approach for multi-level decision-making for multi-component system with a complex structure. They utilized decision rules for optimally identifying a group of several components as well as a cost-based group improvement factor, taking into account the predictive reliability of the components, the economic dependencies, and the location of the components in the system. Keizer et al. [

62] proposed an algorithm for clustering predictive maintenance tasks for systems with both economic dependencies and redundancy with the use of a dynamic programming model.

Jiang et al. [

57] proposed an approach for providing a predictive maintenance policy for a complex structure by considering not only components’ RUL, but also the timing of when system reliability falls below a set threshold. Their approach balances three factors: components importance to the system, risk degree, and detection difficulty. Huynh et al. [

58] introduced a multi-level decision-making approach that puts forward an n-component deteriorating system with a k-out-of-n structure. On the basis of the degradation and failure model of the considered k-out-of- n system, the authors proposed two opportunistic predictive maintenance strategies with different types of maintenance decision-making. Lee and Pan [

55] presented a predictive maintenance scheme for complex systems by employing discrete time Markov chain models for modelling multiple degradation processes of components and a Bayesian network (BN) model for predicting system reliability.

Van Horenbeek and Pintelon [

42] presented a dynamic maintenance policy for multi-component systems that minimizes the long-term mean maintenance cost per unit time. The ability of the maintenance policy to react to changing component deterioration and dependencies within a multi-component system was quantified, and the results showed significant cost savings. Azadeh et al. [

60] proposed a model to evaluate the effectiveness of maintenance in multi-component systems using two system performance indicators: reliability and cost. To estimate the reliability and costs of the system, the authors developed the proposed Markovian discrete-event simulation model.

Li et al. [

61] focused on the stochastic dependence between components due to the common environment modelled by Lévy copulas. Wang et al. [

65] proposed an approach for group maintenance of multi-level systems, in which the reliability of a system is assessed using a Bayesian network (BN) of causes and effect as well as multi-objective programming that is used to optimize plans for joint maintenance of units and components.