Improving Energy Efficiency of Irrigation Wells by Using an IoT-Based Platform

Abstract

1. Introduction

2. Related Work

2.1. Efficient Energy Management in Pumping

2.2. Use of IOT-Based Solutions for Water Management

How IOT Helps in Efficiency Management

- Energy management in buildings: Terroso-Saenz et al. [23] show us a platform that applies data mining techniques, focusing mainly on consumption prediction and pattern discovery or fault tolerance to change behaviors, and thus have the potential to reduce energy consumption.

- Water supply: Luna et al. [24] present a hybrid method to improve the energy efficiency of a water supply system. The application of a genetic algorithm to improve the water pumping program provides two solutions: one focused on minimizing the cost/energy related to the use of pumps, and another focused on the same objective but keeping the water storage in the tanks within safer and optimized levels.

- Smart cities: the work developed by Brundu et al. [25] propose a distributed IoT platform capable of gathering, processing and analyzing energy consumption data and structural characteristics of systems and buildings in a district, integrating different data sources, historical data collection and real-time data from heterogeneous IoT devices.

- Manufacturing: Wang et al. [26] develop a method of energy efficiency for manufacturing companies with high energy consumption. Here, IoT technologies are applied to detect raw production data in real-time, including energy consumption data and resource status data. This uses multi-level event modeling and complex event processing to produce key energy performance indicators that extend production performance indicators into the realm of energy efficiency.

2.3. Analysis of Pump Performance (Energy Perspective)

- The characteristic curve describes the pump’s behavior as a function of the head (energy per unit mass that the pump can supply to the fluid) and the flow (quantity of liquid that passes through a section in a given period). The pump manufacturer provides this curve.

- The optimal pump efficiency curve.

- The system curve represents the flow rate at which our pump is working.

- Shifting consumption to cheaper hours (an action that does not save energy but does reduce costs) thanks to the integration of electricity tariffs into the system.

- The valves’ regulation to adapt the operating point of a pump to the maximum performance regime thanks to the monitoring of the EEP indicator and the elements that are part of a well.

- The sectorization or modification of it when the water distribution network is already monitored, and only the appropriate ones need to be opened and closed.

- Installation of new equipment such as frequency converters due to sub-optimal pump performance.

- Replacement or modification of existing ones because they have completed their range of working hours and are out of range.

- Installation of pipe sections or valves to be divided into sectors when low-pressure values are observed.

3. Proposed Solution

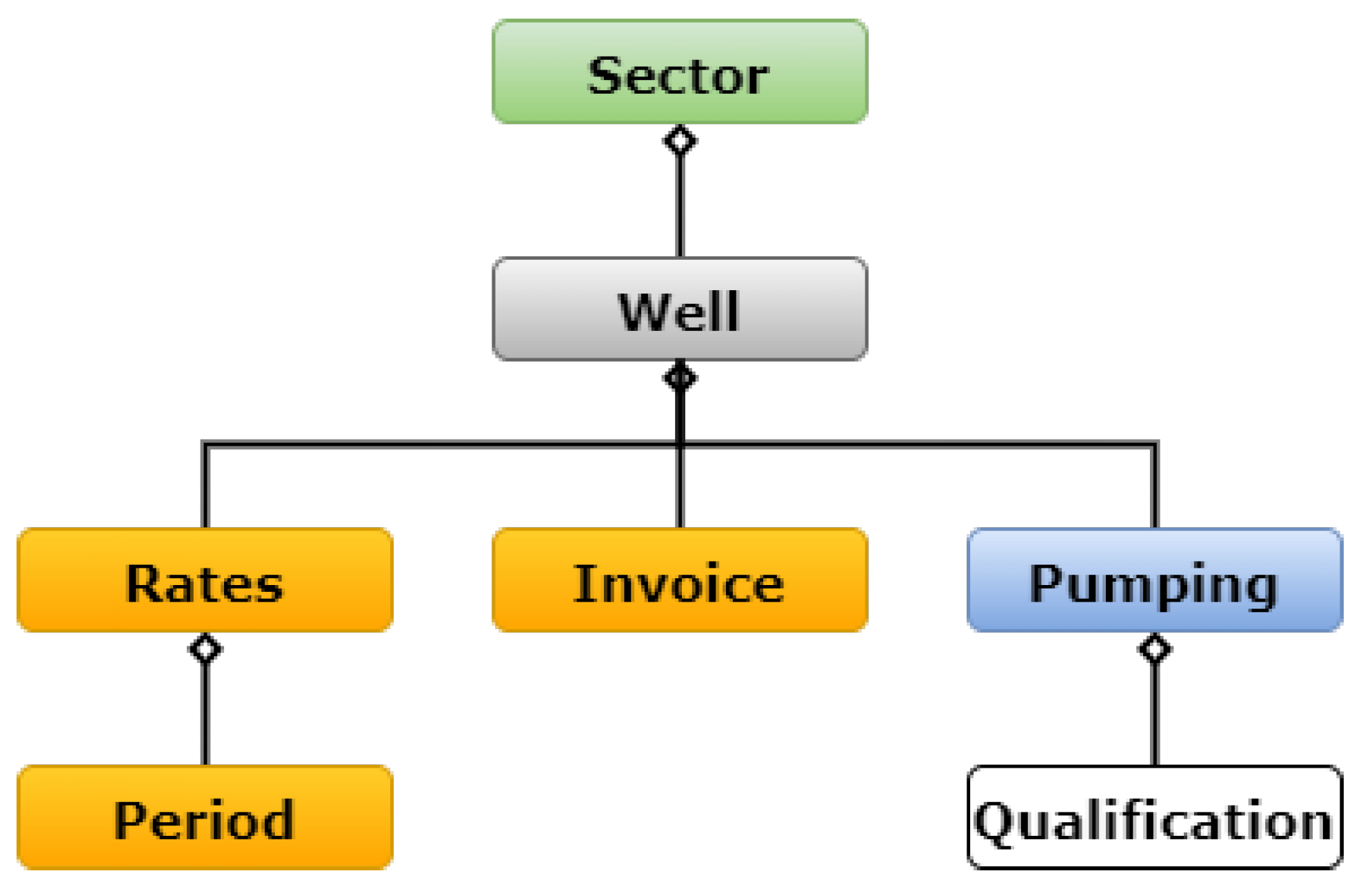

3.1. Modeling for Efficient Use of Irrigation Pumps

- Pumps, represented by Pumping, defines the characteristic parameters recorded by the pump: pressure, motor temperature or head. Furthermore, based on the data obtained, we can obtain the pump’s energy efficiency and classify the irrigation pump according to its efficiency through the entity Qualification.

- Electric Rates, represented by Rates, tells us the type of rate associated with each pump. Each rate has an associated number of periods, Period, where the associated rate period is defined for each month and the total number of hours of the day. The price of the hours is variable and is defined by the associated operator a few days before.

- Invoices, represented by Invoice are the invoices provided by the energy supplier. They must show the average price, both fixed and variable, for each of the tariff bands associated with the well, as well as the consumption generated in kW.

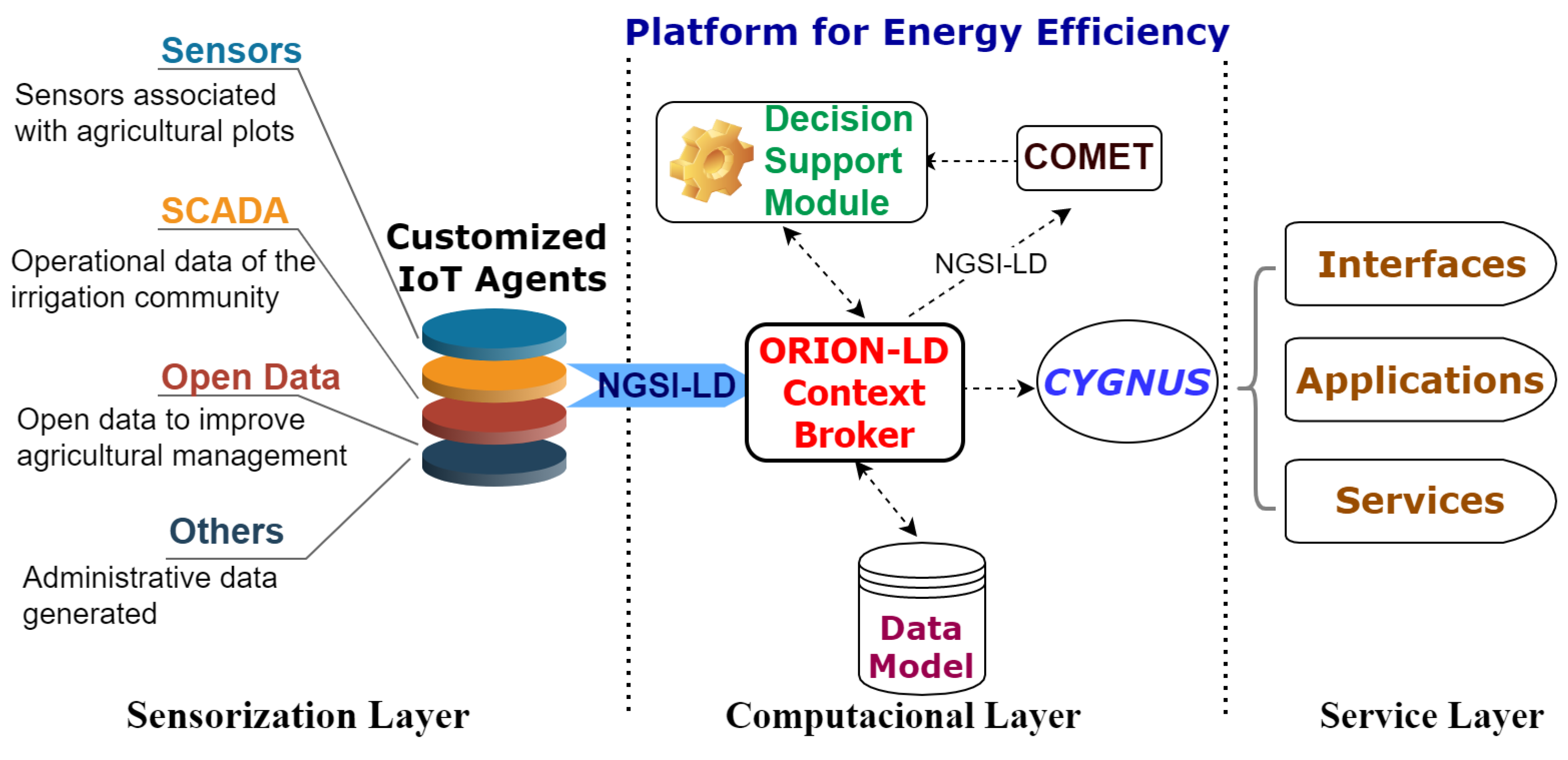

3.2. Platform Architecture

- Generating visualizations and stacked graphs allowing predictive control of pumping.

- Developing control parameters using actionable information or defining intelligent strategies for the use of electric rates.

- Transmitting the generated control parameters to the actuators or generating alerts based on the calculated indicators.

3.3. Decision-Making Support

- Technical guides of the pump performance curves and technical data of the wells’ infrastructures.

- Audits or energy studies carried out previously.

- Expert experience in energy and hydraulic management

- Data on the evolution of the energy market and its tariffs.

- Values in real-time of the sensors located in the facilities.

- Experiences and data from other farms and other professional institutions related to the energy or hydraulic environment.

- Contrasting Analysis Phase: In this phase, all the data sets, internal or external, are collected to improve the decision-making on the pumping efficiency; in each of the time series of the different variables, we can find gaps or wrong data. This failure in the data can be produced by defective sensors or by failure in the communications. These missing values affect the performance of the system and must be addressed accordingly. The detection of the anomalous data occurs because the system detects that its value is not within the thresholds previously defined for each of the variables that form part of the system. At this time, the value is replaced or eliminated. In this work, the missing values are replaced by their appropriate values using a linear regression technique and use the annotations made manually by the guards responsible for the installations. Once the data have been pre-processed, they are incorporated into an information model, which allows the interoperability of the proposed solution to be increased. Therefore, the information, when interacting with each other, is not only connected but understood.

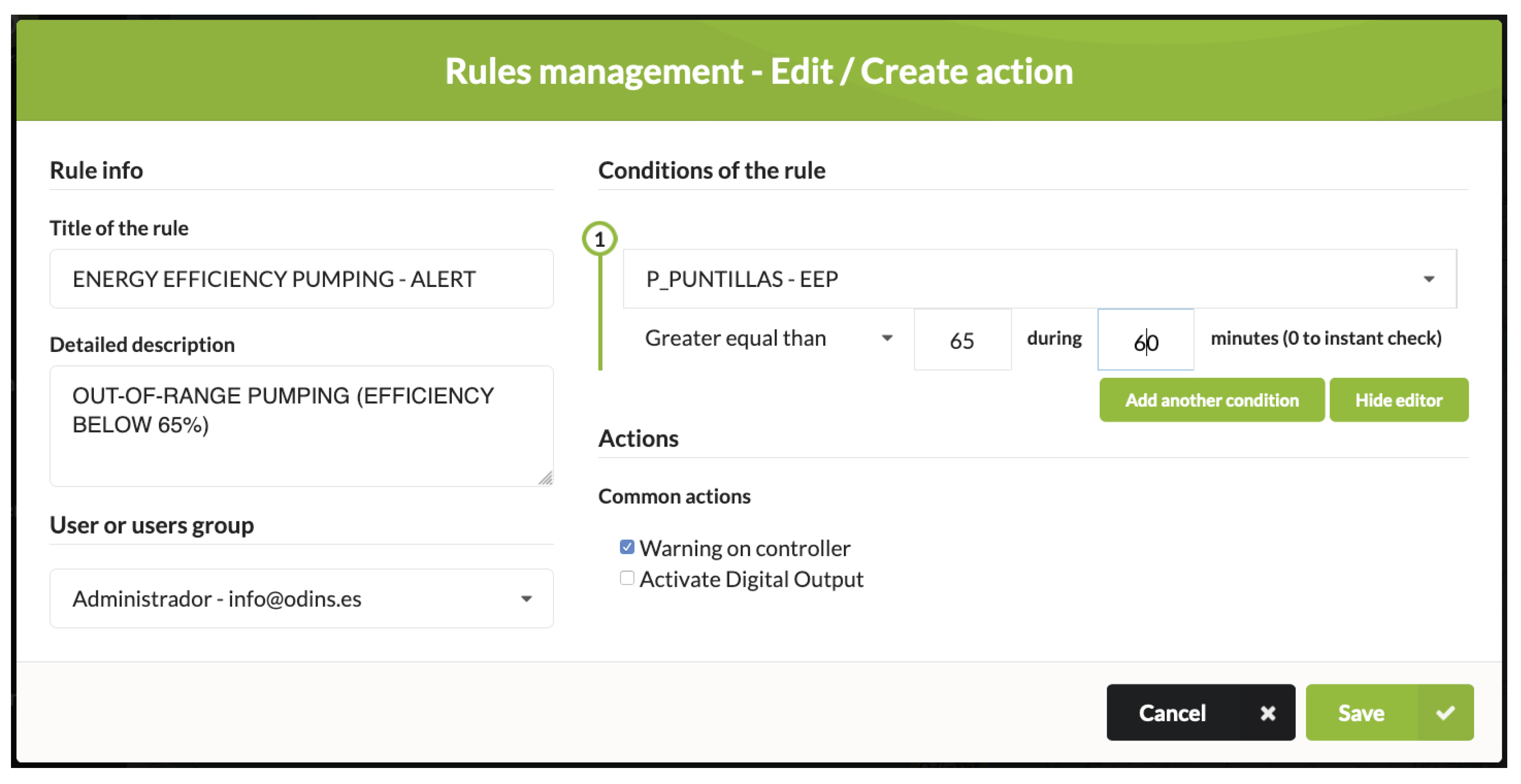

- Efficiency Forecasting Phase: This phase is responsible for generating exhaustive information on the daily evolution of the irrigation wells’ performance, based on each well’s characterization, energy consumption and the average water flow obtained from each pumping. The EEP of each pumping is calculated, and the next day’s value is predicted, based on the programming of each well and the accumulated history. The wells’ optimal efficiency thresholds are defined, as well as the measures to be adopted and the periodicity of the generation of the alerts. At the same time, it is verified which day and at what time each pumping will start to determine that the most economical tariff section has been chosen. If this is not the case, a section with a better electricity tariff is recommended.

4. Use Case and Experiment Results

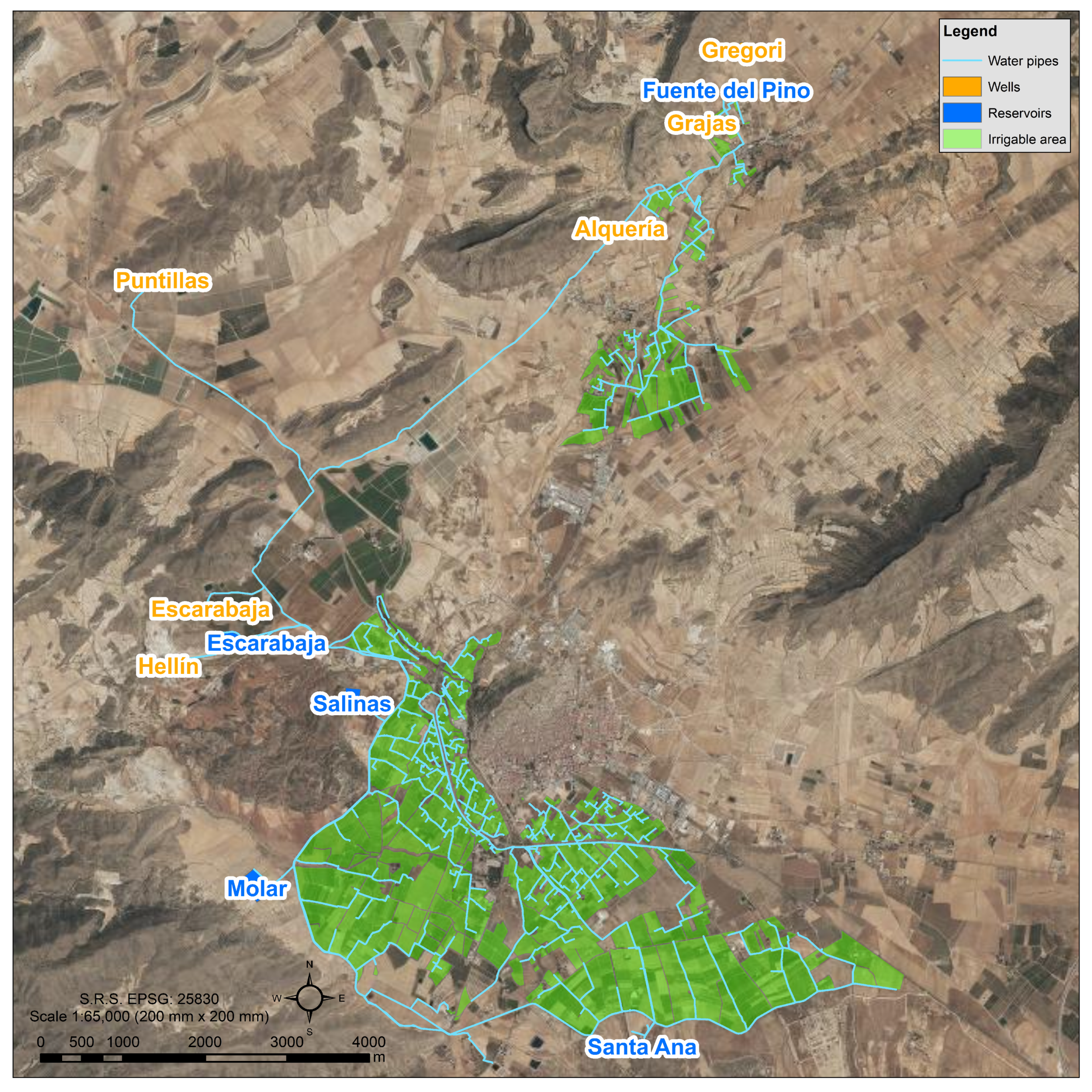

4.1. Scenario

4.2. Equipment and Implementation

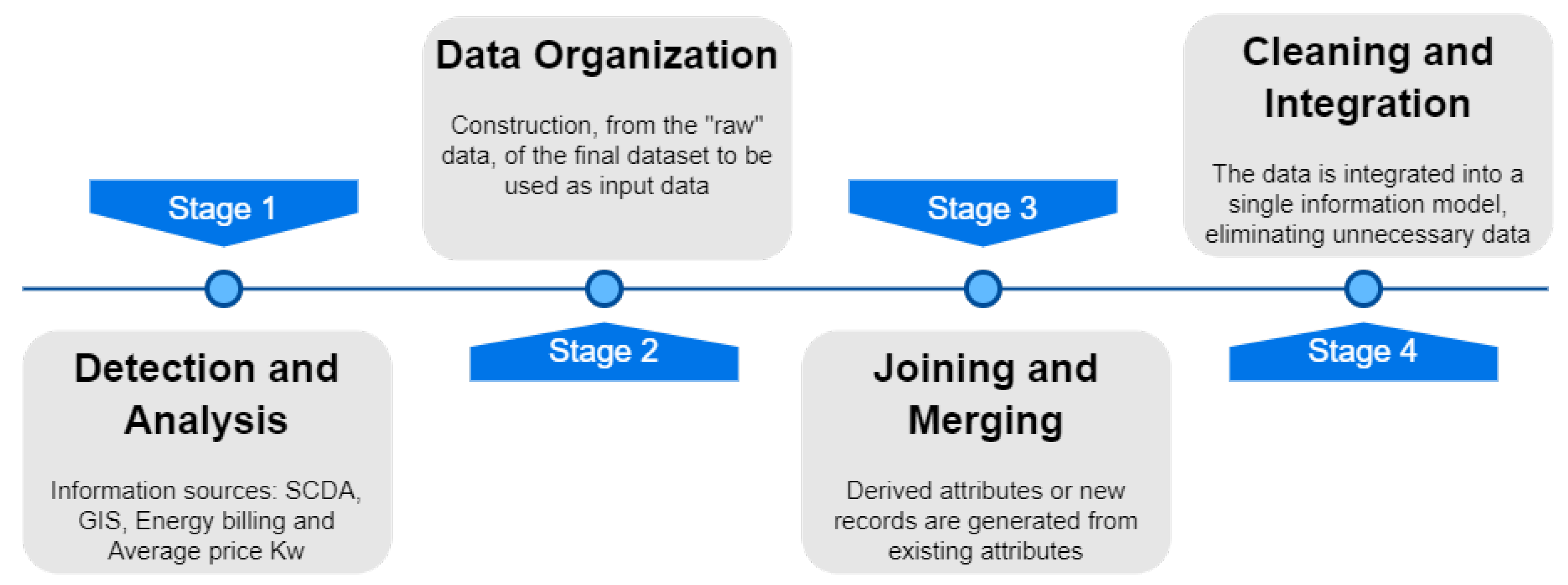

4.3. Data Description

- The data of the day will not be taken into account when carrying out maintenance or repairs

- If there is a 30% failure in the readings during a day, discard the day, but if it is an irrigation programming, discard it if it exceeds 10% of the operating hours.

4.4. Results

- *

- The system uses heterogeneous data from IoT sensors, control systems and electricity tariffs and integrates them into a single data model.

- *

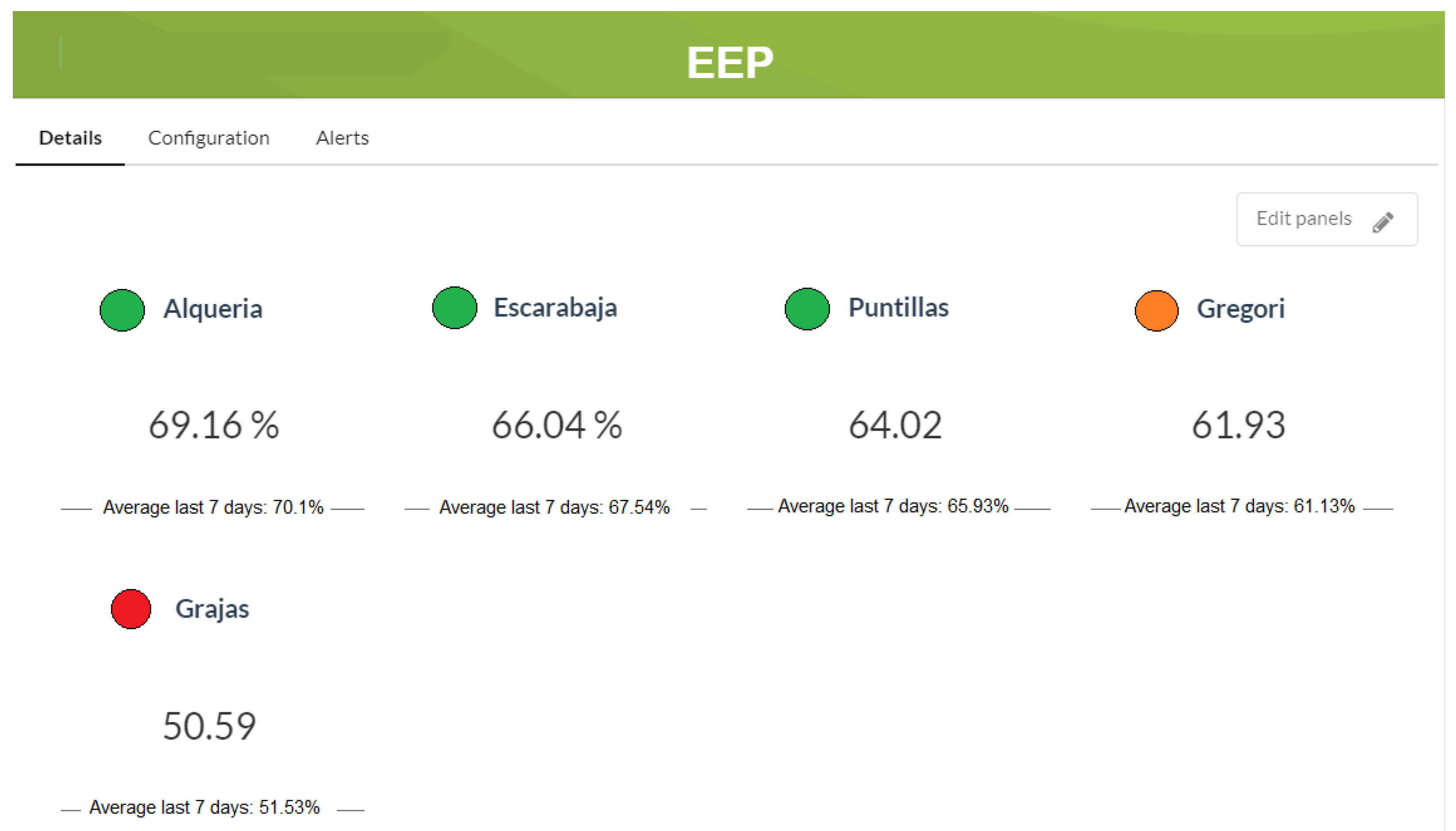

- The system performs data analysis, generates alerts and predicts pumping energy efficiency through indicators.

- All the information is integrated into a single platform, which avoids consulting the information in multiple solutions.

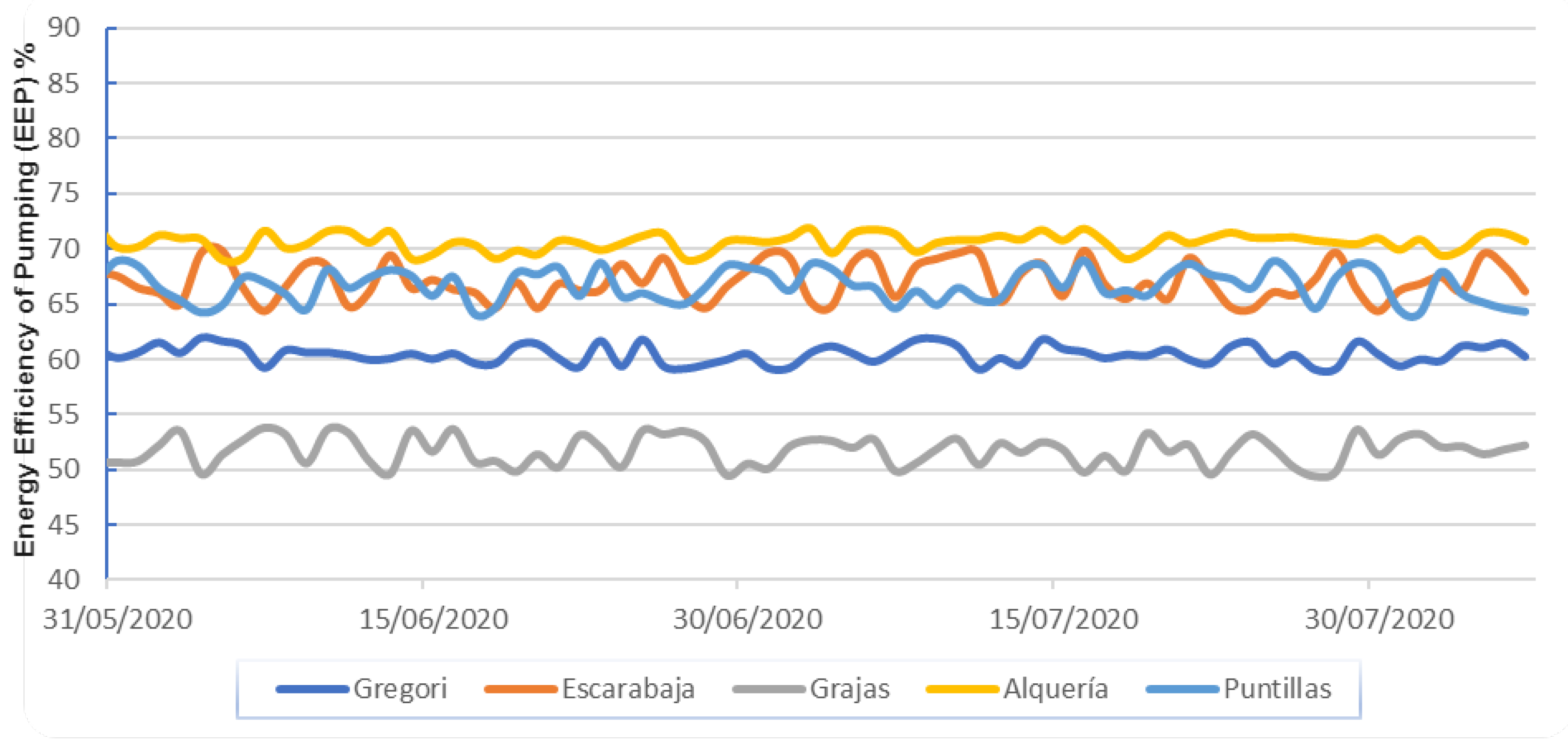

- The daily calculation of the EEP indicator is integrated to monitor the pumping efficiency, which, together with monitoring other variables (pressures, motor temperature or flow rates), allows us to anticipate decreases in performance.

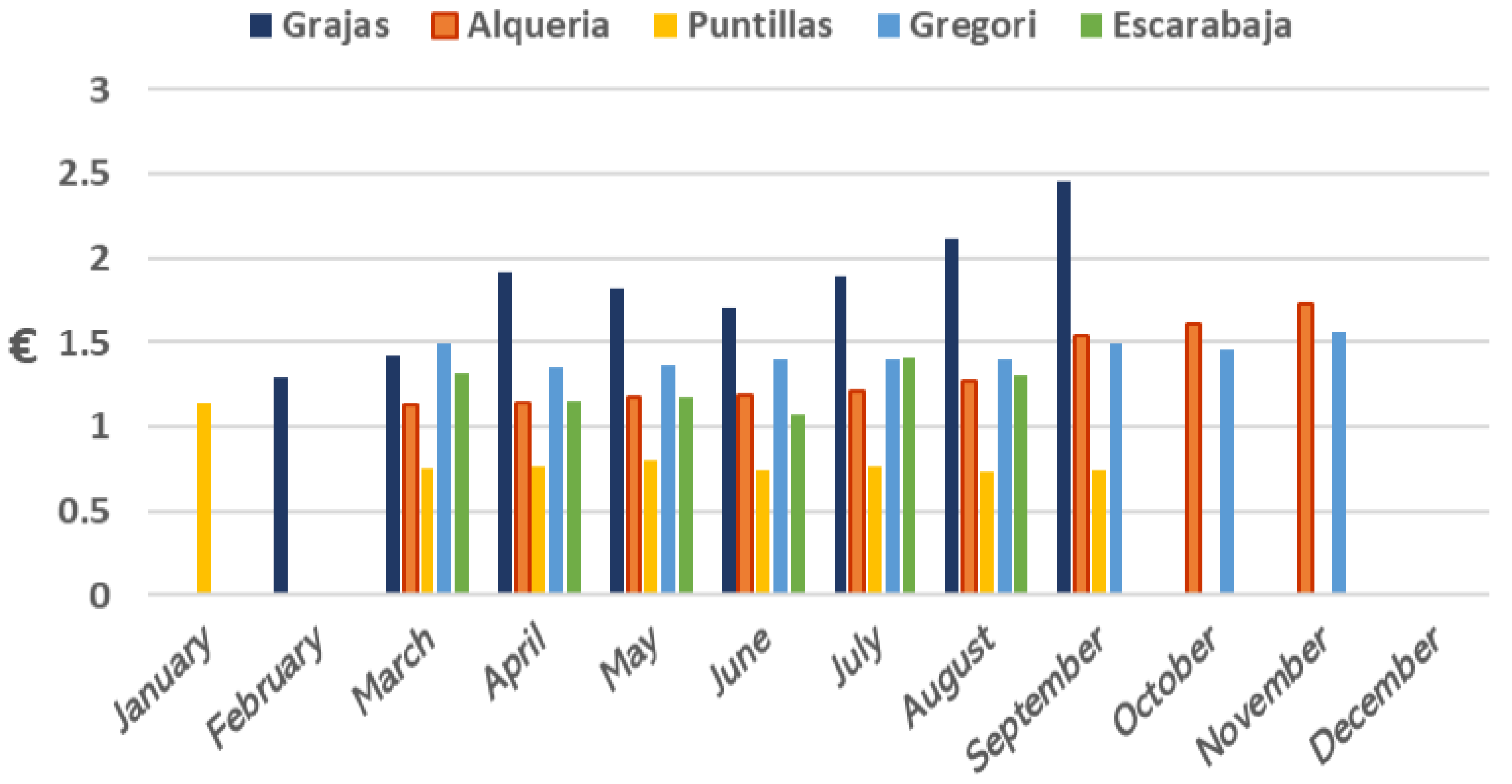

- For the following days, electricity rate are consulted to advise the lowest timetable to avoid higher consumption.

- Reports on the wells’ efficiency are sent to the companies in charge of their maintenance, for improving the planned revisions and avoiding unnecessary visits. With this measure, the community is in talks with the companies to reduce the annual cost of maintenance or improve their services.

5. Conclusions and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Garcia, D.J.; You, F. The water-energy-food nexus and process systems engineering: A new focus. Comput. Chem. Eng. 2016, 91, 49–67. [Google Scholar] [CrossRef]

- Singh, A. Poor quality water utilization for agricultural production: An environmental perspective. Land Use Policy 2015, 43, 259–262. [Google Scholar] [CrossRef]

- Martinho, V.J.P.D. Energy consumption across European Union farms: Efficiency in terms of farming output and utilized agricultural area. Energy 2016, 103, 543–556. [Google Scholar] [CrossRef]

- Kosior, K. Digital transformation in the agri-food sector–opportunities and challenges. Roczniki 2018. [Google Scholar] [CrossRef]

- Walter, A.; Finger, R.; Huber, R.; Buchmann, N. Opinion: Smart farming is key to developing sustainable agriculture. Proc. Natl. Acad. Sci. USA 2017, 114. [Google Scholar] [CrossRef]

- Ciruela-Lorenzo, A.M.; Aguila-Obra, D.; Rosa, A.; Padilla-Meléndez, A.; Plaza-Angulo, J.J. Digitalization of Agri-cooperatives in the Smart Agriculture Context. Proposal of a Digital Diagnosis Tool. Sustainability 2020, 12, 1325. [Google Scholar] [CrossRef]

- Quintiliani, C.; Creaco, E. Using additional time slots for improving pump control optimization based on trigger levels. Water Resour. Manag. 2019, 33, 3175–3186. [Google Scholar] [CrossRef]

- Turci, L.D.O.; Wang, J.; Brahmia, I. Adaptive and improved multi-population based nature-inspired optimization algorithms for water pump station scheduling. Water Resour. Manag. 2020, 34, 2869–2885. [Google Scholar] [CrossRef]

- Makaremi, Y.; Haghighi, A.; Ghafouri, H.R. Optimization of pump scheduling program in water supply systems using a self-adaptive NSGA-II; a review of theory to real application. Water Resour. Manag. 2017, 31, 1283–1304. [Google Scholar] [CrossRef]

- Salomons, E.; Housh, M. Practical real-time optimization for energy efficient water distribution systems operation. J. Clean. Prod. 2020, 275, 124148. [Google Scholar] [CrossRef]

- Tarjuelo, J.M.; Rodriguez-Diaz, J.A.; Abadía, R.; Camacho, E.; Rocamora, C.; Moreno, M.A. Efficient water and energy use in irrigation modernization: Lessons from Spanish case studies. Agric. Water Manag. 2015, 162, 67–77. [Google Scholar] [CrossRef]

- Mardani, A.; Zavadskas, E.K.; Streimikiene, D.; Jusoh, A.; Khoshnoudi, M. A comprehensive review of data envelopment analysis (DEA) approach in energy efficiency. Renew. Sustain. Energy Rev. 2017, 70, 1298–1322. [Google Scholar] [CrossRef]

- Hadipour, M.; Derakhshandeh, J.F.; Shiran, M.A. An experimental setup of multi-intelligent control system (MICS) of water management using the Internet of Things (IoT). ISA Trans. 2020, 96, 309–326. [Google Scholar] [CrossRef] [PubMed]

- García, L.; Parra, L.; Jimenez, J.M.; Lloret, J.; Lorenz, P. IoT-Based Smart Irrigation Systems: An Overview on the Recent Trends on Sensors and IoT Systems for Irrigation in Precision Agriculture. Sensors 2020, 20, 1042. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Wang, J.; Sangaiah, A.K.; Xie, Y.; Yin, X. Analysis and prediction of water quality using LSTM deep neural networks in IoT environment. Sustainability 2019, 11, 2058. [Google Scholar] [CrossRef]

- Li, T.; Xia, M.; Chen, J.; Zhao, Y.; De Silva, C. Automated water quality survey and evaluation using an IoT platform with mobile sensor nodes. Sensors 2017, 17, 1735. [Google Scholar] [CrossRef]

- Zamora-Izquierdo, M.A.; Santa, J.; Martínez, J.A.; Martínez, V.; Skarmeta, A.F. Smart farming IoT platform based on edge and cloud computing. Biosyst. Eng. 2019, 177, 4–17. [Google Scholar] [CrossRef]

- Muñoz, M.; Guzmán, J.; Sánchez, J.; Rodríguez, F.; Torres, M.; Berenguel, M. A New IoT-based Platform for Greenhouse Crop Production. IEEE Internet Things J. 2020. [Google Scholar] [CrossRef]

- Franco, J.D.; Ramirez-delReal, T.A.; Villanueva, D.; Gárate-García, A.; Armenta-Medina, D. Monitoring of Ocimum basilicum seeds growth with image processing and fuzzy logic techniques based on Cloudino-IoT and FIWARE platforms. Comput. Electron. Agric. 2020, 173, 105389. [Google Scholar] [CrossRef]

- Kamienski, C.; Soininen, J.P.; Taumberger, M.; Dantas, R.; Toscano, A.; Salmon Cinotti, T.; Filev Maia, R.; Torre Neto, A. Smart water management platform: Iot-based precision irrigation for agriculture. Sensors 2019, 19, 276. [Google Scholar] [CrossRef]

- Brewster, C.; Roussaki, I.; Kalatzis, N.; Doolin, K.; Ellis, K. IoT in Agriculture:Designing a Europe-Wide Large-Scale Pilot. IEEE Commun. Mag. 2017, 55, 26–33. [Google Scholar] [CrossRef]

- Shrouf, F.; Miragliotta, G. Energy management based on Internet of Things: Practices and framework for adoption in production management. J. Clean. Prod. 2015, 100, 235–246. [Google Scholar] [CrossRef]

- Terroso-Saenz, F.; González-Vidal, A.; Ramallo-González, A.P.; Skarmeta, A.F. An open IoT platform for the management and analysis of energy data. Future Gener. Comput. Syst. 2019, 92, 1066–1079. [Google Scholar] [CrossRef]

- Luna, T.; Ribau, J.; Figueiredo, D.; Alves, R. Improving energy efficiency in water supply systems with pump scheduling optimization. J. Clean. Prod. 2019, 213, 342–356. [Google Scholar] [CrossRef]

- Brundu, F.G.; Patti, E.; Osello, A.; Del Giudice, M.; Rapetti, N.; Krylovskiy, A.; Jahn, M.; Verda, V.; Guelpa, E.; Rietto, L.; et al. IoT software infrastructure for energy management and simulation in smart cities. IEEE Trans. Ind. Inform. 2016, 13, 832–840. [Google Scholar] [CrossRef]

- Wang, W.; Yang, H.; Zhang, Y.; Xu, J. IoT-enabled real-time energy efficiency optimisation method for energy-intensive manufacturing enterprises. Int. J. Comput. Integr. Manuf. 2018, 31, 362–379. [Google Scholar] [CrossRef]

- Pelli, T.; Hitz, H. Energy indicators and savings in water supply. J. Am. Water Work. Assoc. 2000, 92, 55–62. [Google Scholar] [CrossRef]

- Moreno, M.; Córcoles, J.; Moraleda, D.; Martinez, A.; Tarjuelo, J. Optimization of underground water pumping. J. Irrig. Drain. Eng. 2010, 136, 414–420. [Google Scholar] [CrossRef]

- Abadía, R.; Rocamora, C.; Ruiz, A. Protocolo de auditoría energética en comunidades de regantes. Instituto para Diversificación y Ahorro de la Energía, IDAE. Ser. Divulg. Ahorr. Y Efic. Energética En Agric. 2008, 10. Available online: https://www.idae.es/file/10565/download?token=ml5HNpfM (accessed on 8 September 2020).

- Abadia, R.; Rocamora, C.; Ruiz, A.; Puerto, H. Energy efficiency in irrigation distribution networks I: Theory. Biosyst. Eng. 2008, 101, 21–27. [Google Scholar] [CrossRef]

- FIWARE Foundation, e.V. FIWARE Open Source Platform for the Smart Digital Future. Available online: http://www.fiware.org/ (accessed on 24 September 2020).

- SpecWorks, O. NGSI 9/10 Information Model. 2019. Available online: http://www.openmobilealliance.org/release/NGSI/ (accessed on 31 July 2020).

- ETSI. Context Information Management (CIM); NGSI-LD API. Available online: https://www.etsi.org/deliver/etsi_gs/CIM/001_099/009/01.01.01_60/gs_CIM009v010101p.pdf (accessed on 28 September 2020).

- López-Morales, J.A.; Martínez, J.A.; Skarmeta, A.F. Digital Transformation of Agriculture through the Use of an Interoperable Platform. Sensors 2020, 20, 1153. [Google Scholar] [CrossRef] [PubMed]

- Pick, R.A. Benefits of decision support systems. In Handbook on Decision Support Systems 1; Springer: Berlin/Heidelberg, Germany, 2008; pp. 719–730. [Google Scholar]

- Beynon, M.; Rasmequan, S.; Russ, S. A new paradigm for computer-based decision support. Decis. Support Syst. 2002, 33, 127–142. [Google Scholar] [CrossRef]

- Kellogg, G.; Champin, P.; Longley, D. JSON-LD 1.1–a JSON-Based Serialization for Linked Data; Technical Report; W3C.2019. Available online: https://hal.archives-ouvertes.fr/hal-02141614v2/document (accessed on 2 October 2020).

- Region, T.P.M.; IMIDA. Weather Report of the Last Recorded Hourly Data. Available online: https://datosabiertos.regiondemurcia.es/imida/catalogo/medio-ambiente/informe-meteorologico-del-ultimo-dato-horario-registrado (accessed on 1 October 2020).

- Iberdrola. Access to Customers. Available online: https://www.iberdrola.es/webclifr/#/login (accessed on 3 October 2020).

- OMIE. Section Day-Ahead Market. Day-Ahead Market Hourly Prices in Spain. Available online: https://www.omie.es/en/file-access-list?parents (accessed on 3 October 2020).

| Year | Consumption | Extraction | Flow | Cost | |

|---|---|---|---|---|---|

| kWh | m | m/s | € | € m/year | |

| 2016 | 3,933,576 | 3,934,227 | 312 | 393,512 | 0.1001 |

| 2017 | 3,680,921 | 3,561,273 | 342 | 421,644 | 0.1184 |

| 2018 | 3,596,833 | 3,027,871 | 323 | 455,290 | 0.1504 |

| Dataset | Type | Source |

|---|---|---|

| SCADA | csv file | Community’s own |

| AutoCAD | dgw file | Community’s own |

| GIS | Geodatabase | External company |

| Wheather Stations | Open Data | IMIDA [38] |

| Water analysis | Excel file | CEBAS |

| Electricity market operator | FTP | Iberdrola [39] |

| Electricity company bills | Excel file | OMIE [40] |

| Year 1 | Year 2 | Year 3 | Year 4 | Year 5 | Total | |

|---|---|---|---|---|---|---|

| Implementation costs | 39,000 € | - | - | - | - | 39,000 € |

| Maintenance costs | - | 5000 € | 6000 € | 6000 € | 6000 € | 23,000 € |

| Reduction in energy bills | - | 43,500 € | 35,235 € | 32,190 € | 28,275 € | 139,200 € |

| Estimated benefit | −39,000 € | 38,500 € | 29,235 € | 26,190 € | 22,275 € | 77,200 € |

| Estimated accumulated benefit | −39,000 € | −500 € | 28,735 € | 54,925 € | 77,200 € |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Morales, J.A.; Martínez, J.A.; Skarmeta, A.F. Improving Energy Efficiency of Irrigation Wells by Using an IoT-Based Platform. Electronics 2021, 10, 250. https://doi.org/10.3390/electronics10030250

López-Morales JA, Martínez JA, Skarmeta AF. Improving Energy Efficiency of Irrigation Wells by Using an IoT-Based Platform. Electronics. 2021; 10(3):250. https://doi.org/10.3390/electronics10030250

Chicago/Turabian StyleLópez-Morales, Juan A., Juan A. Martínez, and Antonio F. Skarmeta. 2021. "Improving Energy Efficiency of Irrigation Wells by Using an IoT-Based Platform" Electronics 10, no. 3: 250. https://doi.org/10.3390/electronics10030250

APA StyleLópez-Morales, J. A., Martínez, J. A., & Skarmeta, A. F. (2021). Improving Energy Efficiency of Irrigation Wells by Using an IoT-Based Platform. Electronics, 10(3), 250. https://doi.org/10.3390/electronics10030250