Adaptive State-of-Charge Estimation for Lithium-Ion Batteries by Considering Capacity Degradation

Abstract

1. Introduction

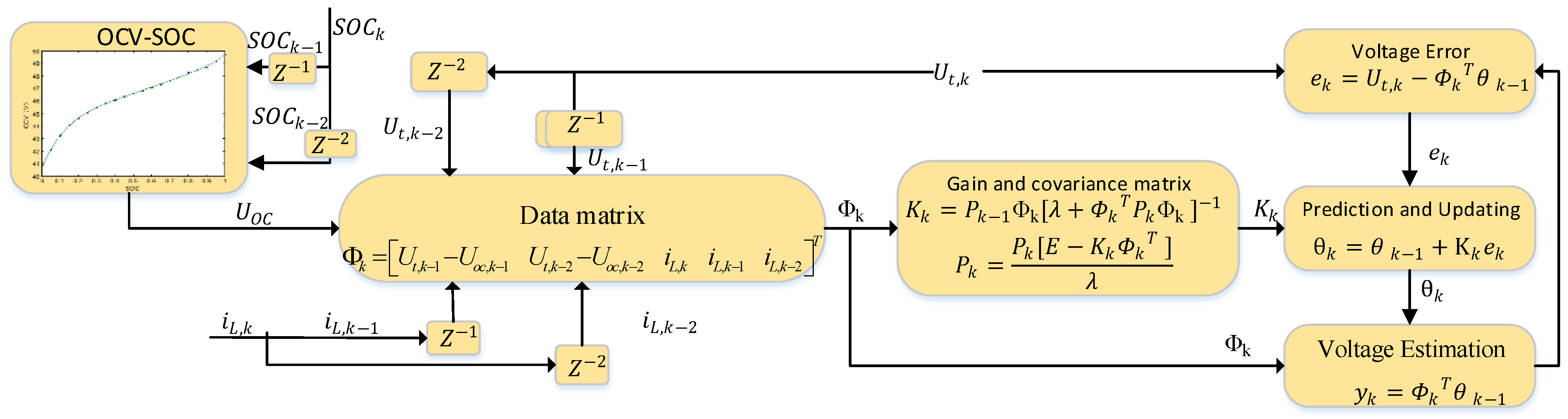

2. Battery Model and Parameter Identification

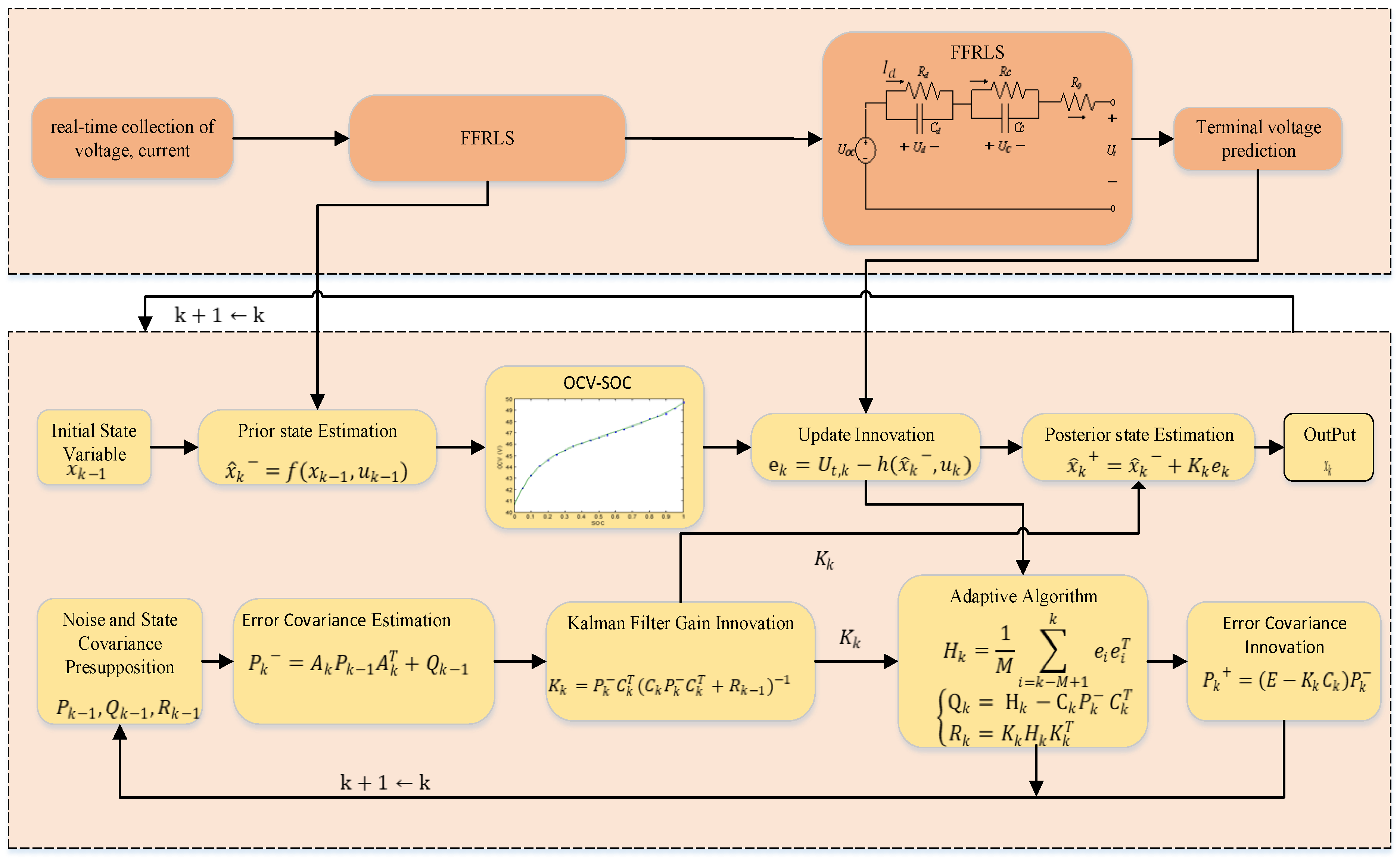

3. AEKF-Based SOC Estimation

Sensitivity Analysis of SOC Estimation to Capacity Degradation

4. Adaptive SOC Estimator Based on Degradation Model

4.1. SOC Estimator Based on Degradation Model

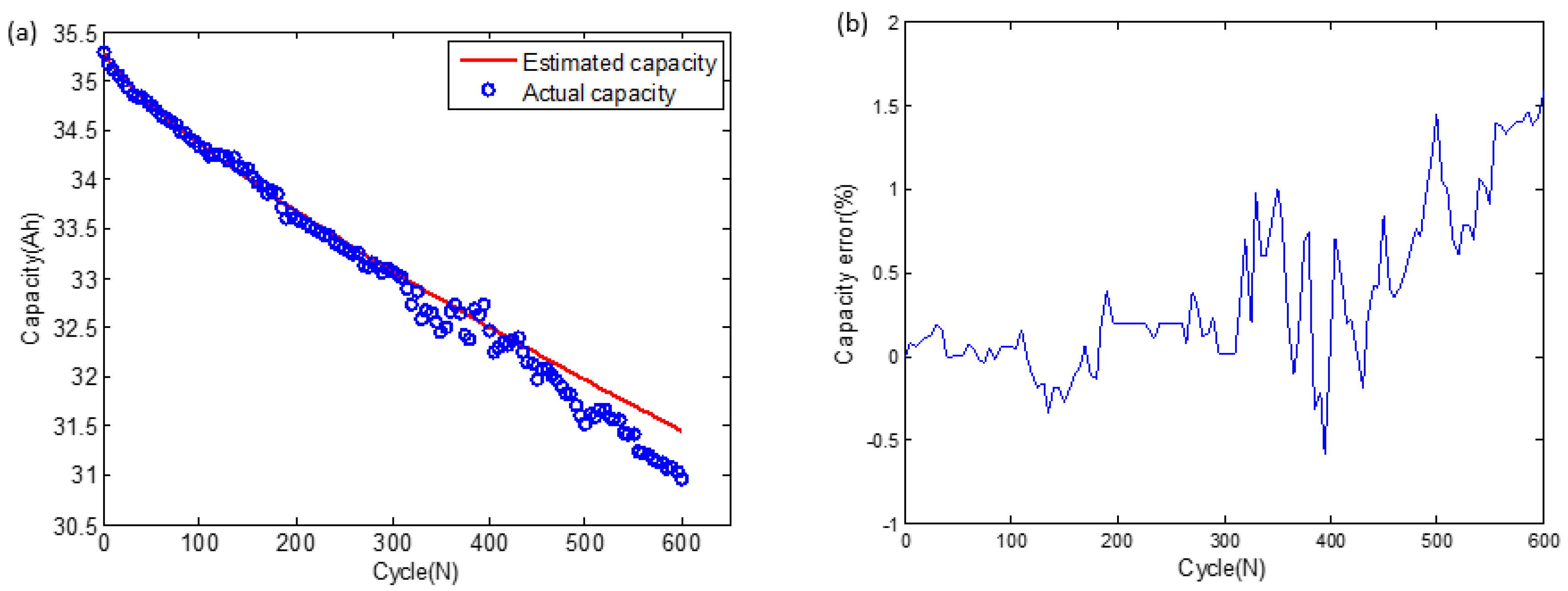

4.2. Lithium-Ion Battery Degradation Model

4.2.1. Lithium-Ion Battery Degradation Model under Static Conditions

- (1)

- Capacity degradation model under constant temperature

- (2)

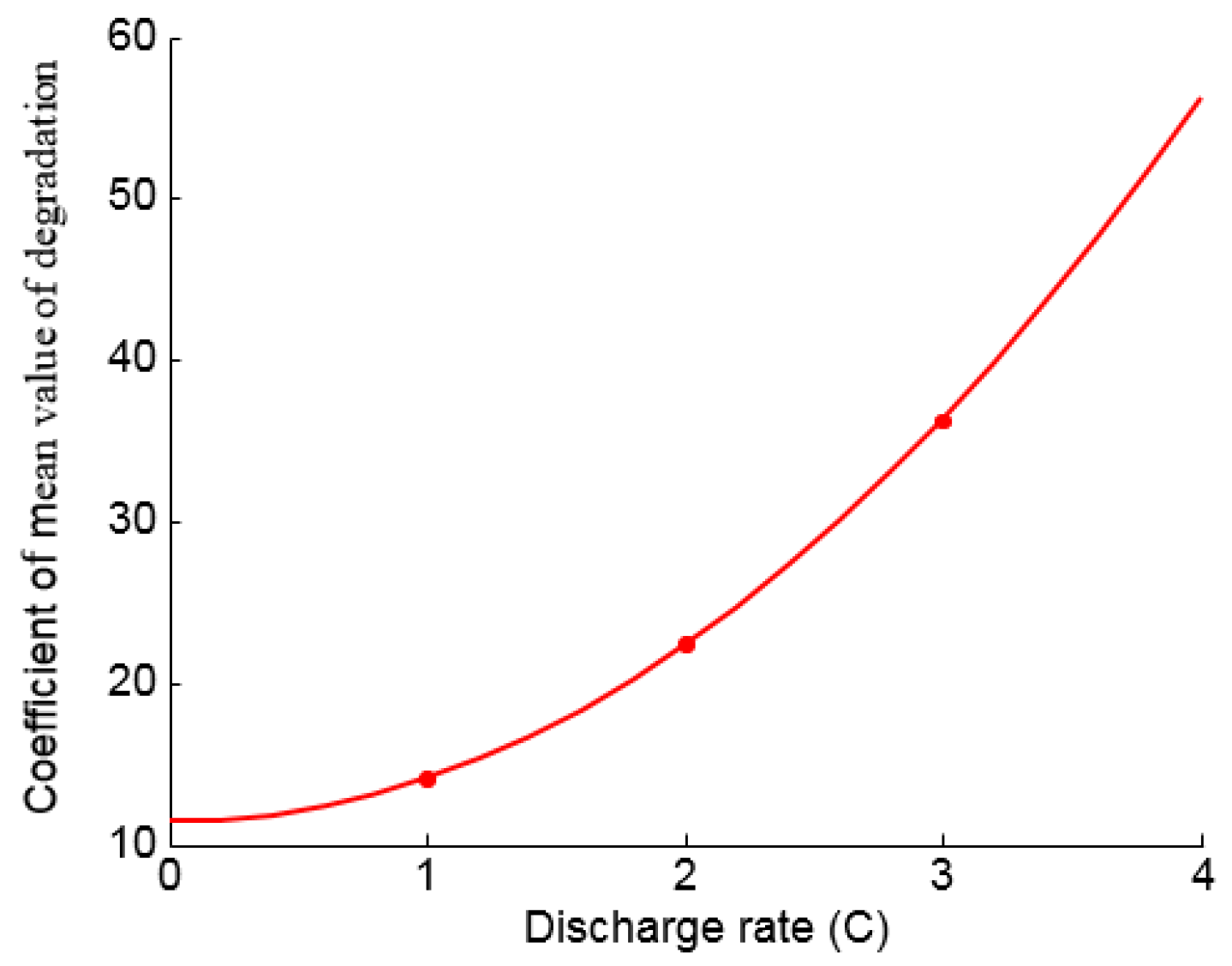

- Battery capacity model under constant discharge rate

- (3)

- Capacity degradation under compound stress

4.2.2. Lithium-Ion Battery Degradation Model under Dynamic Conditions

5. Experiments and Results

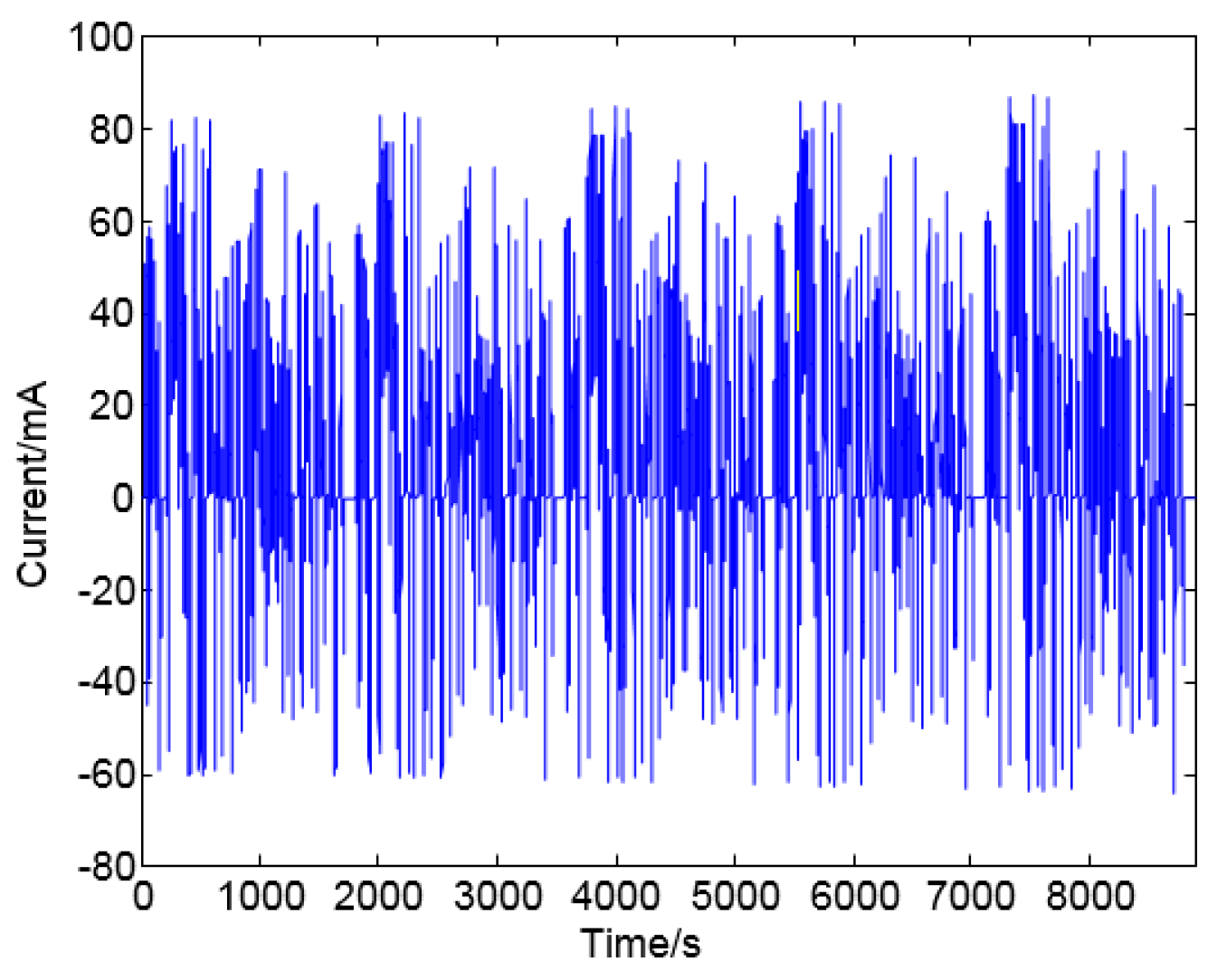

5.1. Dataset of Battery

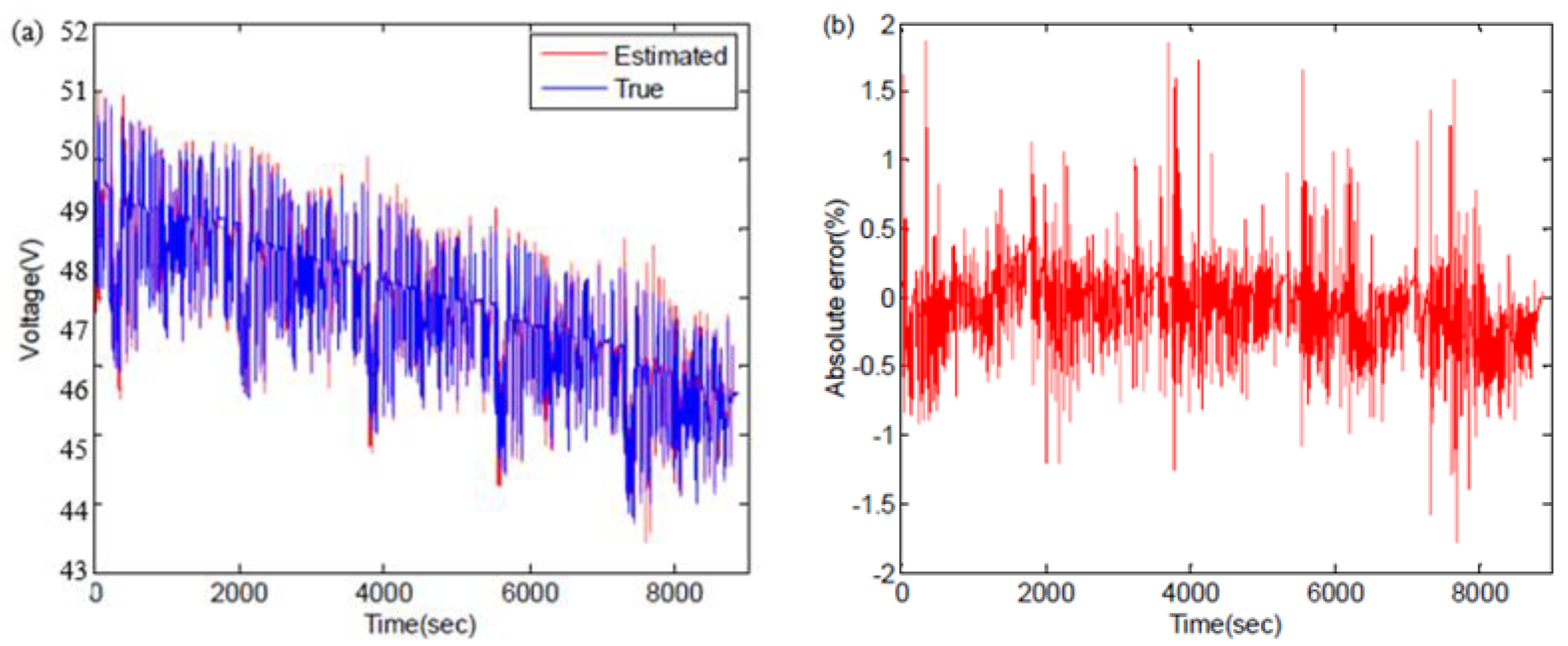

5.2. SOC Estimation Results

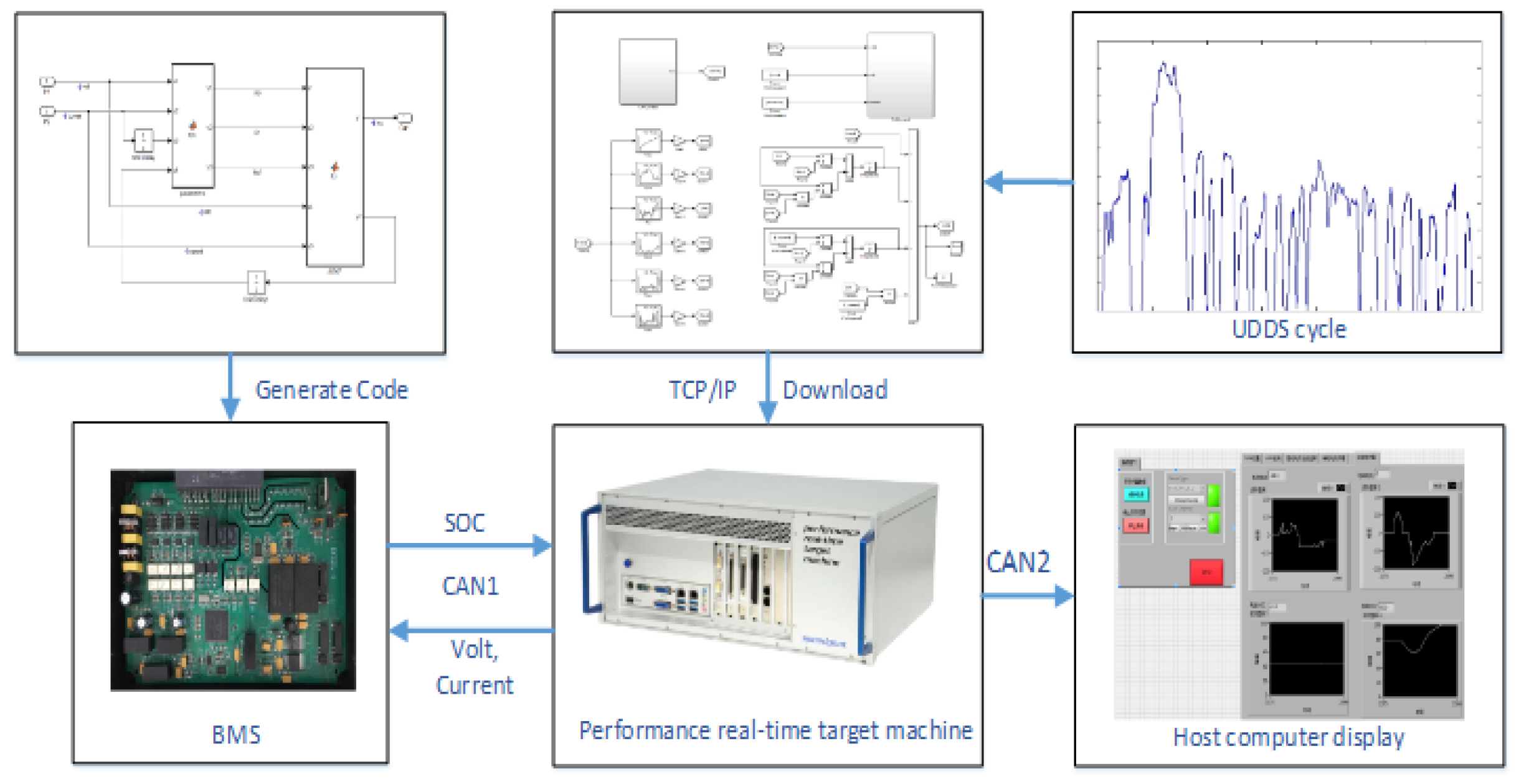

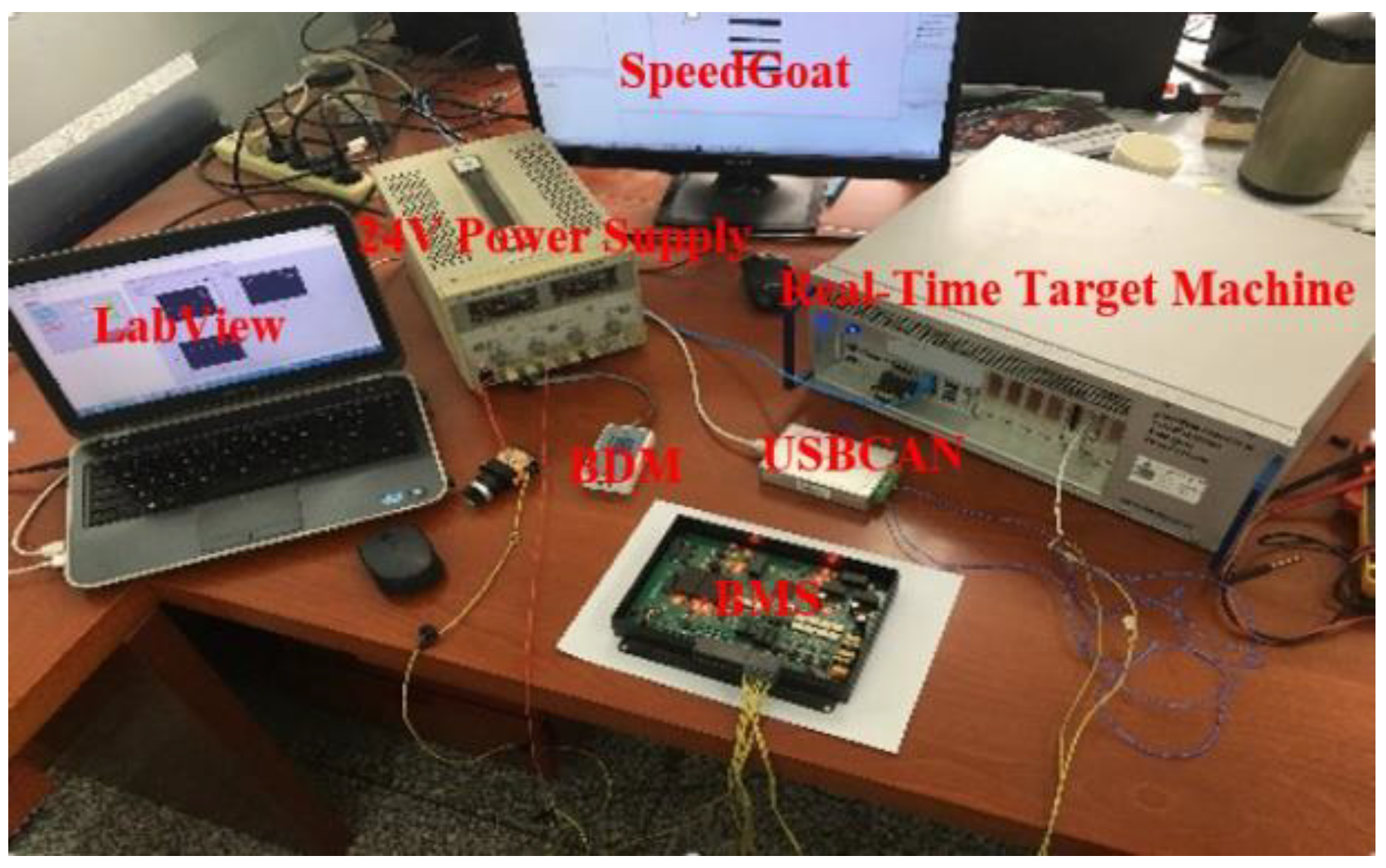

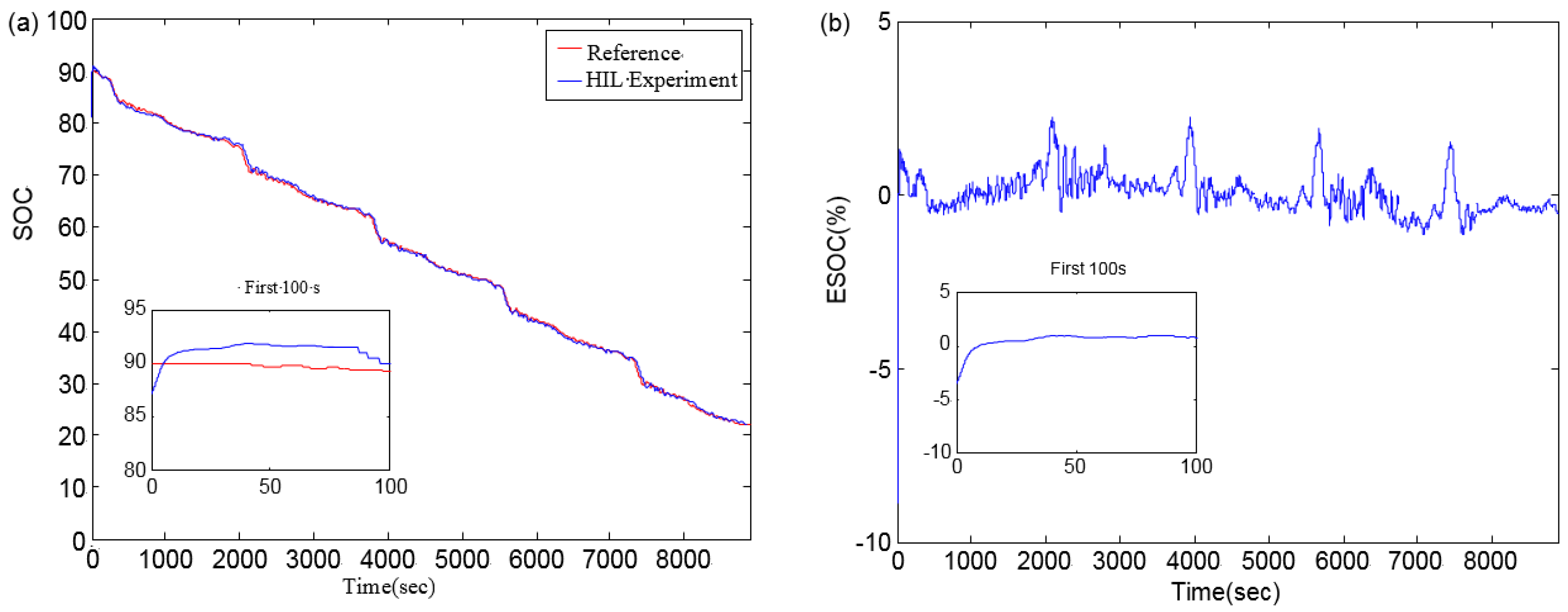

5.3. Hardware-in-the-Loop Validation

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SOC | State of charge |

| EVs | Electrical vehicles |

| AEKF | Adaptive Extended Kalman filter |

| FFRLS | Forgetting factor recursive least squares |

| K | Fitting coefficient |

| F | Pressure |

| T | Temperature |

| t | Cycles |

| LIBs | Lithium-ion batteries |

| Rd,i | Discharge rate |

References

- Xu, Y.; Hu, M.; Zhou, A.; Li, Y.; Li, S.; Fu, C.; Gong, C. State of Charge Estimation for Lithium-Ion Batteries Based on Adaptive Dual Kalman Filter. Appl. Math. Modell. 2019, 77. [Google Scholar] [CrossRef]

- Li, J.; Ye, M.; Jiao, S.; Meng, W.; Xu, X. A Novel State Estimation Approach Based on Adaptive Unscented Kalman Filter for Electric Vehicles. IEEE Access 2020, 8, 185629–185637. [Google Scholar] [CrossRef]

- Chaoui, H.; Ibe-Ekeocha, C.C. State of Charge and State of Health Estimation for Lithium Batteries Using Recurrent Neural Networks. IEEE Trans. Veh. Technol. 2017, 66, 8773–8783. [Google Scholar] [CrossRef]

- Yang, J.; Xia, B.; Shang, Y.; Huang, W.; Mi, C. Adaptive State-of-Charge Estimation Based on a Split Battery Model for Electric Vehicle Applications. IEEE Trans. Veh. Technol. 2017, 66, 10889–10898. [Google Scholar] [CrossRef]

- Wang, W.; Wang, X.; Xiang, C.; Wei, C.; Zhao, Y. Unscented Kalman Filter-based Battery SOC Estimation and Peak Power Prediction Method for Power Distribution of Hybrid Electric Vehicles. IEEE Access 2018, 6, 35957–35965. [Google Scholar] [CrossRef]

- Xiong, R.; Yu, Q.; Wang, L.; Lin, C. A novel method to obtain the open circuit voltage for the state of charge of lithium ion batteries in electric vehicles by using H infinity filter. Appl. Energy 2017, 207, 346–353. [Google Scholar] [CrossRef]

- Gil1, R.P.A.; Johanyák, Z.C.; Kovács, T. Surrogate model based optimization of traffic lights cycles and green period ratios using microscopic simulation and fuzzy rule interpolation. Int. J. Artif. Intell. 2018, 16, 20–40. [Google Scholar]

- Guo, F.; Hu, G.; Xiang, S.; Zhou, P.; Hong, R.; Xiong, N. Amulti-scale parameter adaptive method for state of charge and parameter estimation of lithium-ion batteries using dual Kalman filters. Energy 2019, 178, 79–88. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, L.; Zhao, X.; Qiang, J. A GA optimization for lithium-ion battery equalization based on SOC estimation by NN and FLC. Int. J. Electr. Power Energy Syst. 2015, 73, 318–328. [Google Scholar] [CrossRef]

- Cui, D.; Xia, B.; Zhang, R.; Sun, Z.; Lao, Z.; Wang, W.; Sun, W.; Lai, Y.; Wang, M. A Novel Intelligent Method for the State of Charge Estimation of Lithium-Ion Batteries Using a Discrete Wavelet Transform-Based Wavelet Neural Network. Energies 2018, 11, 995. [Google Scholar] [CrossRef]

- Hu, J.; Ju, J.; Lin, H.; Li, X.; Jiang, C.; Qiu, X.; Li, W. State-of-charge estimation for battery management system using optimized support vector machine for regression. J. Power Sources 2014, 269, 682–693. [Google Scholar] [CrossRef]

- Smith, K.A.; Rahn, C.D.; Wang, C.Y. Model-Based Electrochemical Estimation and Constraint Management for Pulse Operation of Lithium Ion Batteries. IEEE Trans. Control Syst. Technol. 2010, 18, 654–663. [Google Scholar] [CrossRef]

- Ye, M.; Guo, H.; Cao, B. A model-based adaptive state of charge estimator for a lithium-ion battery using an improved adaptive particle filter. Appl. Energy 2017, 190, 740–748. [Google Scholar] [CrossRef]

- Xiong, R.; Sun, F.; Chen, Z.; He, H. A data-driven multi-scale extended Kalman filtering based parameter and state estimation approach of lithium-ion olymer battery in electric vehicles. Appl. Energy 2014, 113, 463–476. [Google Scholar] [CrossRef]

- He, W.; Williard, N.; Chen, C.; Pecht, M. State of charge estimation for electric vehicle batteries using unscented kalman filtering. Microelectron. Reliab. 2013, 53, 840–847. [Google Scholar] [CrossRef]

- Nejad, S.; Gladwin, D.T.; Stone, D.A. On-chip implementation of Extended Kalman Filter for adaptive battery states monitoring. In Proceedings of the 42nd Annual Conference of the IEEE Industrial Electronics Society (IECON 2016), Florence, Italy, 24–27 October 2016; pp. 5513–5518. [Google Scholar] [CrossRef]

| Number of Cycles | 1 | 50 | 100 | 150 | 200 | 250 | 300 | |

|---|---|---|---|---|---|---|---|---|

| Temperature | 20 °C | 35.37 Ah | 35.06 Ah | 34.84 Ah | 34.64 Ah | 34.45 Ah | 34.27 Ah | 34.10 Ah |

| 40 °C | 35.23 Ah | 34.44 Ah | 33.86 Ah | 33.35 Ah | 32.87 Ah | 32.41 Ah | 31.97 Ah | |

| Discharge rate | 1C | 35.37 Ah | 35.06 Ah | 34.84 Ah | 34.64 Ah | 34.45 Ah | 34.27 Ah | 34.10 Ah |

| 2C | 35.87 Ah | 35.38 Ah | 35.02 Ah | 34.71 Ah | 34.41 Ah | 34.13 Ah | 33.86 Ah | |

| 3C | 35.59 Ah | 34.79 Ah | 34.21 Ah | 33.69 Ah | 33.21 Ah | 32.75 Ah | 32.31 Ah | |

| C-Rate | f2 (Rd) | h2 (Rd) |

|---|---|---|

| 1C | 13.99 | 0.7935 |

| 2C | 22.24 | 0.7921 |

| 3C | 36.24 | 0.7927 |

| Parameter | Value |

|---|---|

| Rated capacity | 35 Ah |

| Charging cut-off voltage | 4.2 V |

| Discharging cut-off voltage | 3.0 V |

| Rated voltage | 3.7 V |

| Cathode material | LiMn2O4 |

| Internal resistance | ≤1.0 mΩ |

| Constant Volume | Available Capacity (Ah) |

|---|---|

| First | 30.52 |

| Second | 30.12 |

| Third | 30.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, P.; Li, J.; Sun, C.; Yang, G.; Sun, F. Adaptive State-of-Charge Estimation for Lithium-Ion Batteries by Considering Capacity Degradation. Electronics 2021, 10, 122. https://doi.org/10.3390/electronics10020122

Xu P, Li J, Sun C, Yang G, Sun F. Adaptive State-of-Charge Estimation for Lithium-Ion Batteries by Considering Capacity Degradation. Electronics. 2021; 10(2):122. https://doi.org/10.3390/electronics10020122

Chicago/Turabian StyleXu, Peipei, Junqiu Li, Chao Sun, Guodong Yang, and Fengchun Sun. 2021. "Adaptive State-of-Charge Estimation for Lithium-Ion Batteries by Considering Capacity Degradation" Electronics 10, no. 2: 122. https://doi.org/10.3390/electronics10020122

APA StyleXu, P., Li, J., Sun, C., Yang, G., & Sun, F. (2021). Adaptive State-of-Charge Estimation for Lithium-Ion Batteries by Considering Capacity Degradation. Electronics, 10(2), 122. https://doi.org/10.3390/electronics10020122