Condition-Based Maintenance of HVAC on a High-Speed Train for Fault Detection

Abstract

1. Introduction

2. Reliability-Centered Maintenance

- Initiation and planning—establishing a plan of analysis and the operating context;

- Functional failure analysis—identifying the failure modes, causes, effects and criticalities of each component;

- Task selection—selecting the appropriate maintenance task and interval;

- Implementation;

- Continuous improvement—monitor the effectiveness of the maintenance plan to ensure continuous improvement.

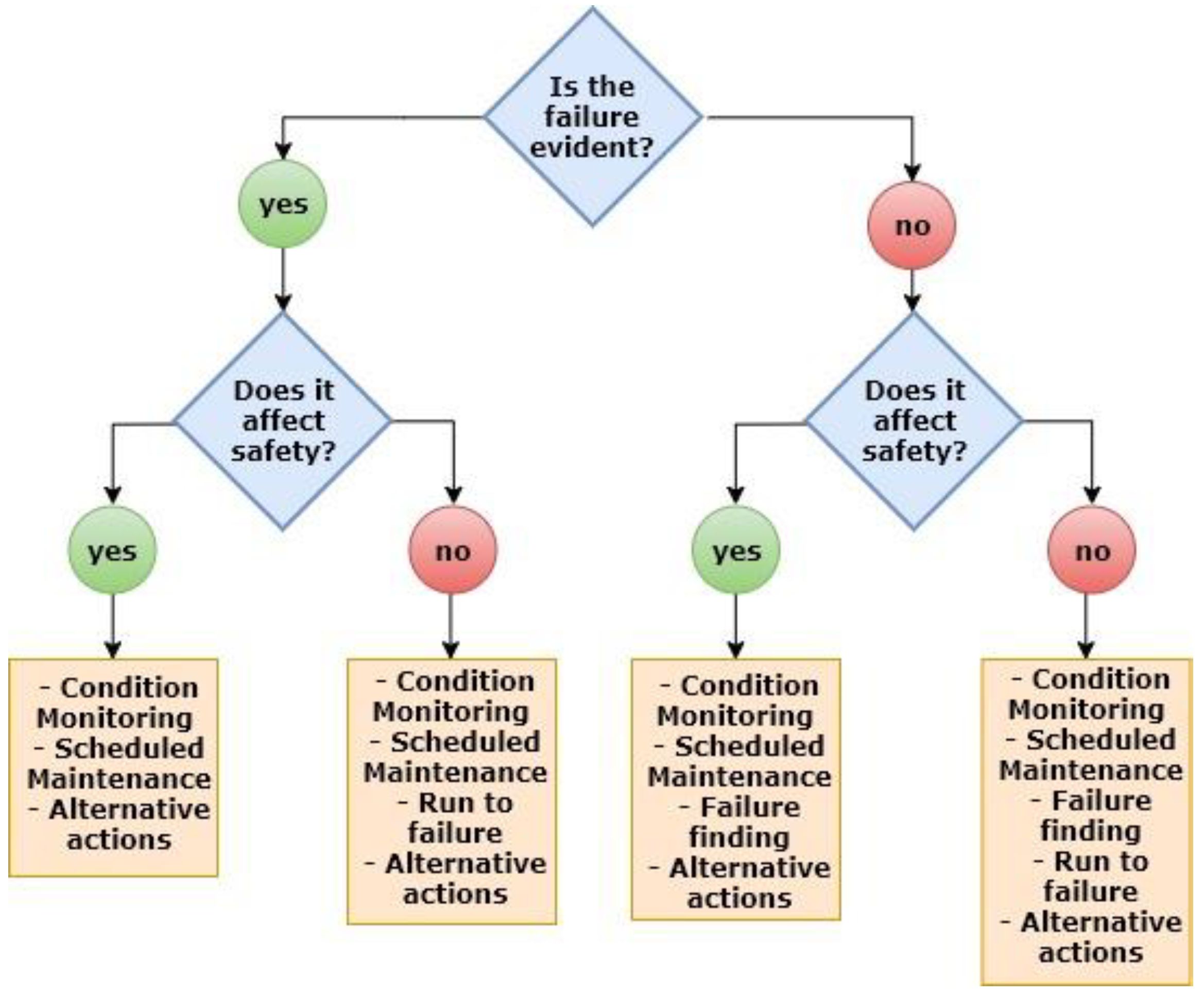

- Failure finding is applicable only to hidden failure. This task can be either an inspection or a function test to determine whether an item would still perform its required function if demanded [36];

- Scheduled maintenance is divided into scheduled restoration and scheduled replacement. This task consists of the scheduled refurbishment or replacement of an item or its components;

- Condition monitoring is a continuous task that allows users to detect the health state of the system by monitoring some contextual parameter that could indicate the degradation and wear-out of the monitored item. Condition monitoring is able to indicate that the failure mode can be expected to occur if no corrective action is taken [37,38];

- No preventive maintenance is performed if no maintenance action is required (i.e., Run to Failure);

- Alternative actions may be performed, as suggested by the designers and maintenance experts.

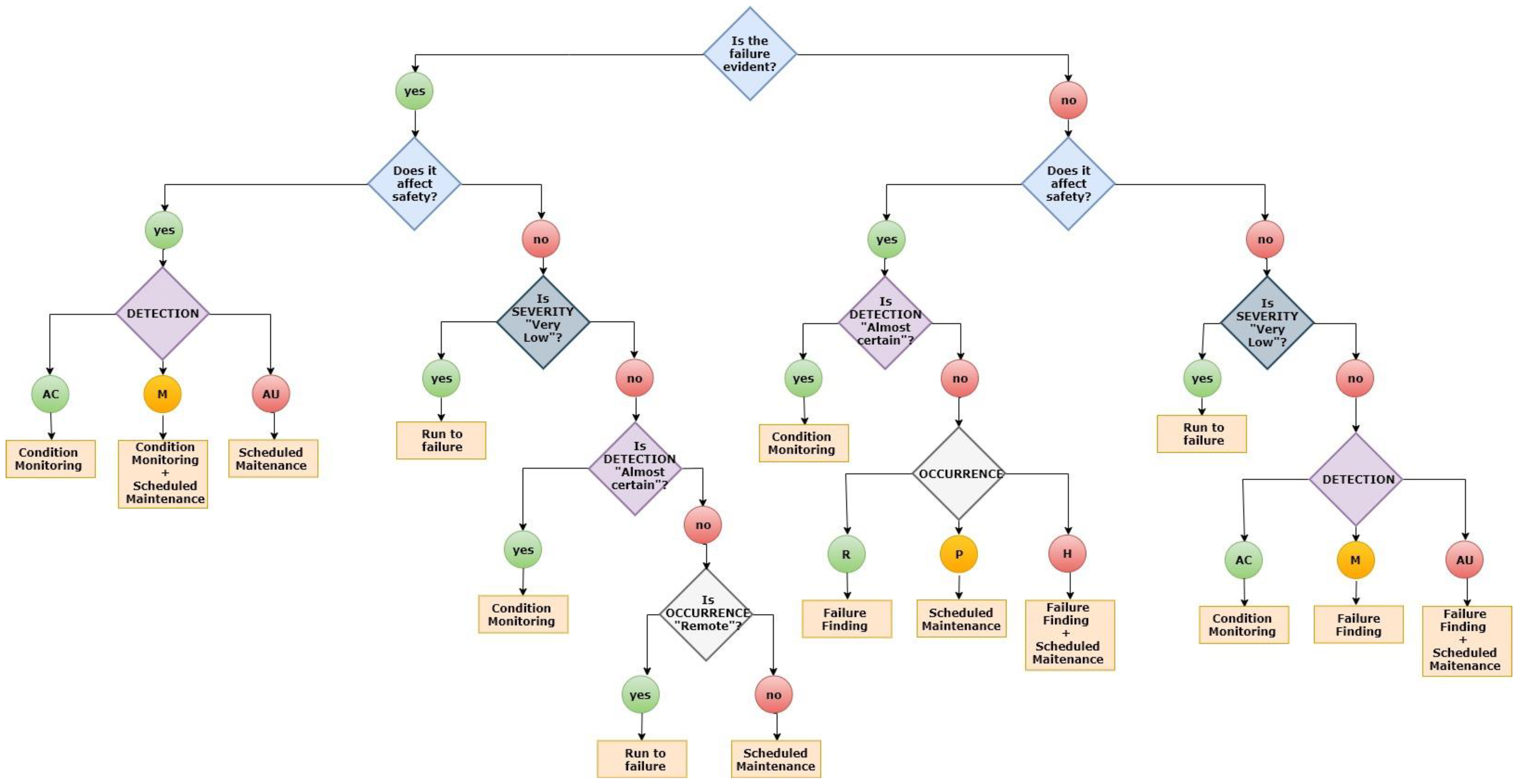

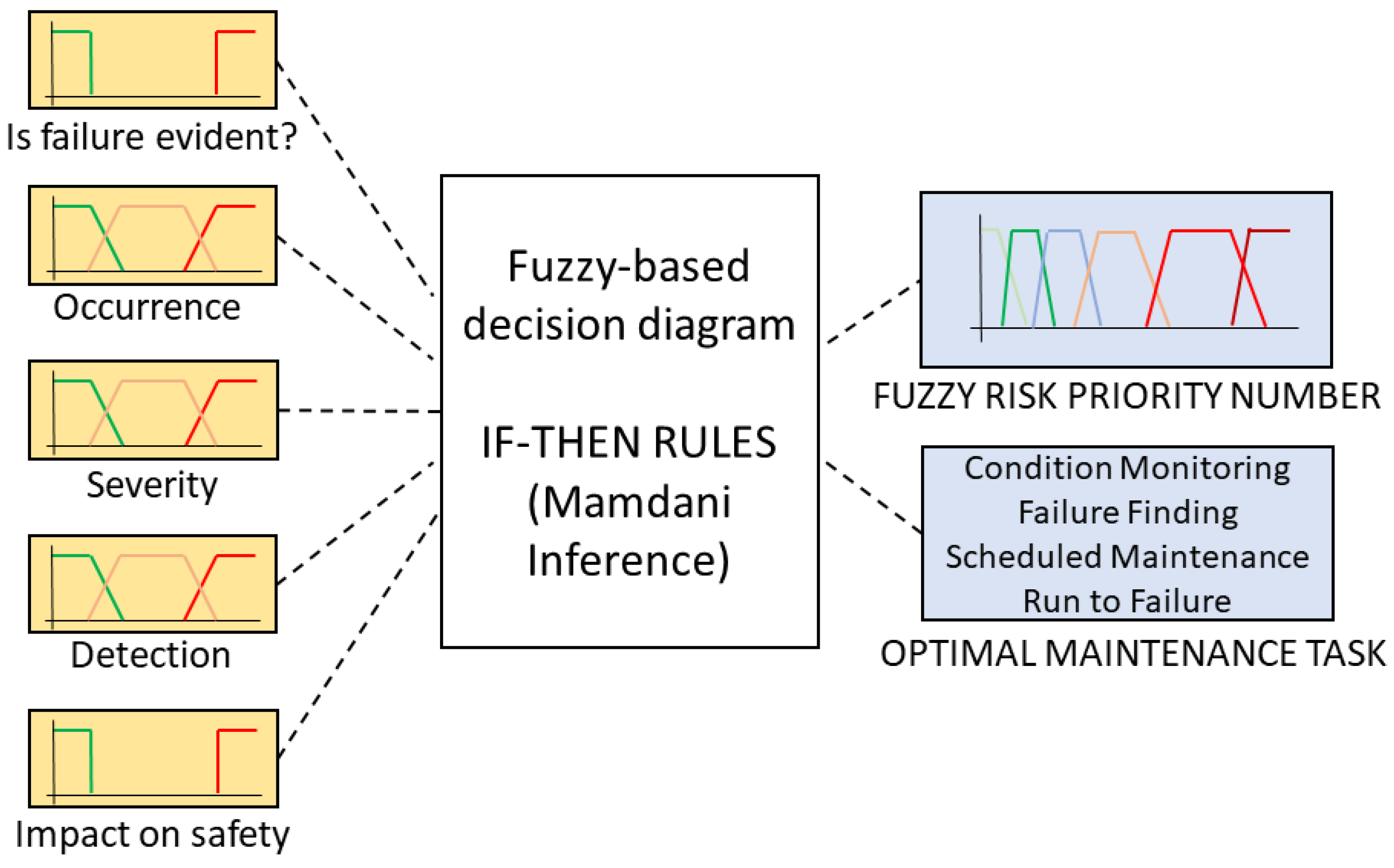

3. Proposed Approach: Fuzzy-Based RCM

- Whether the failure is hidden or evident;

- Whether the failure has safety consequences on the system;

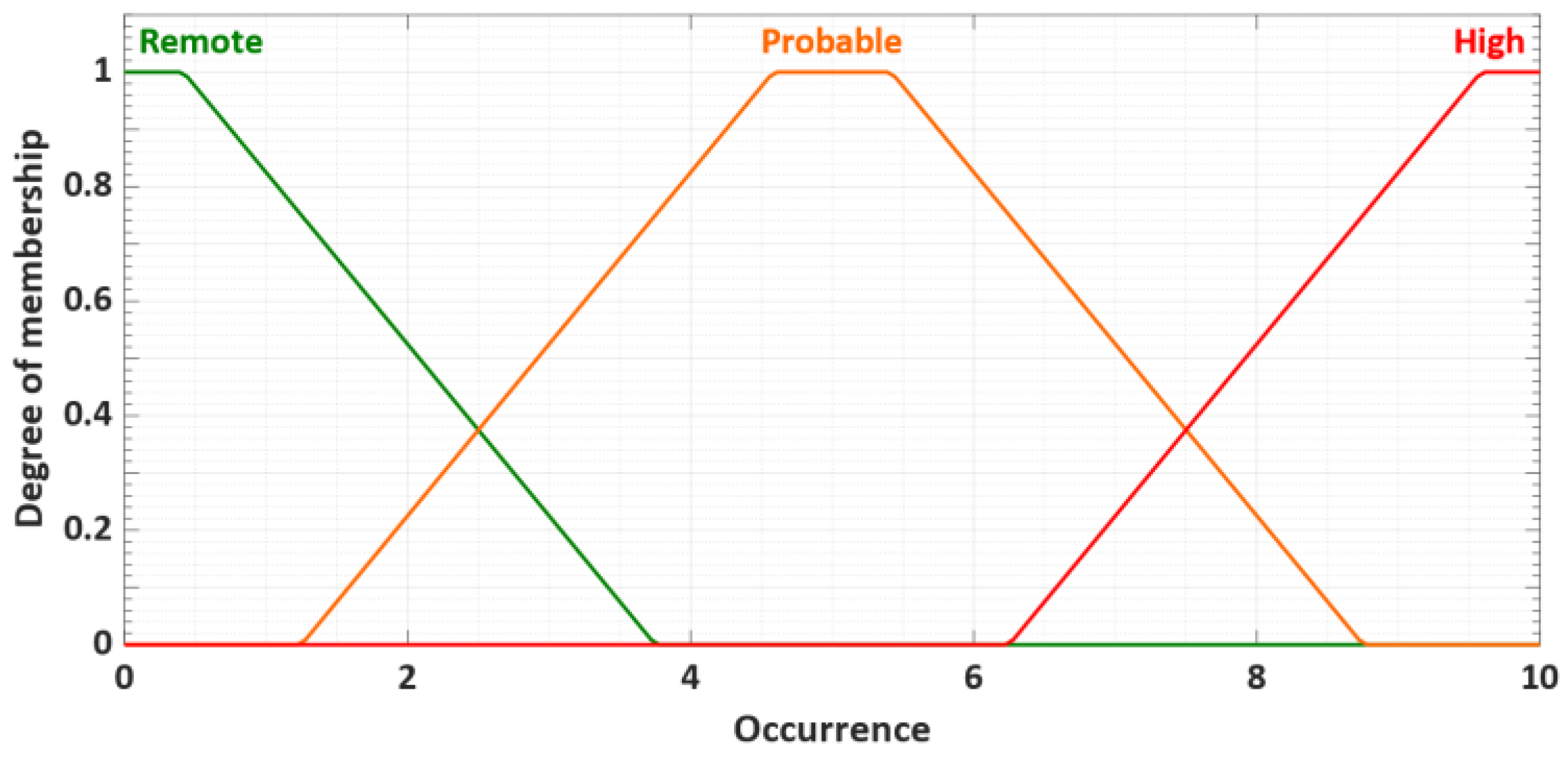

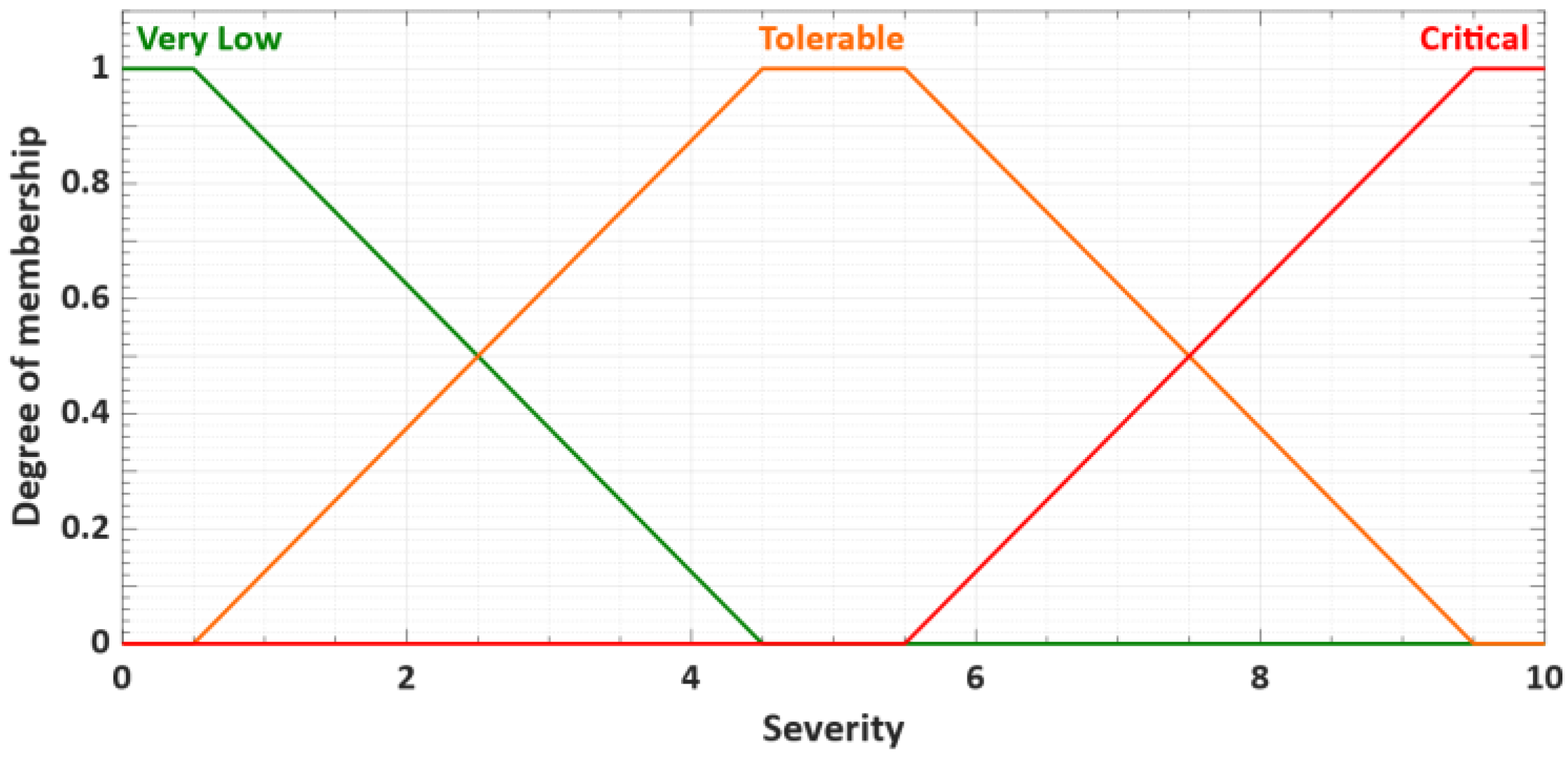

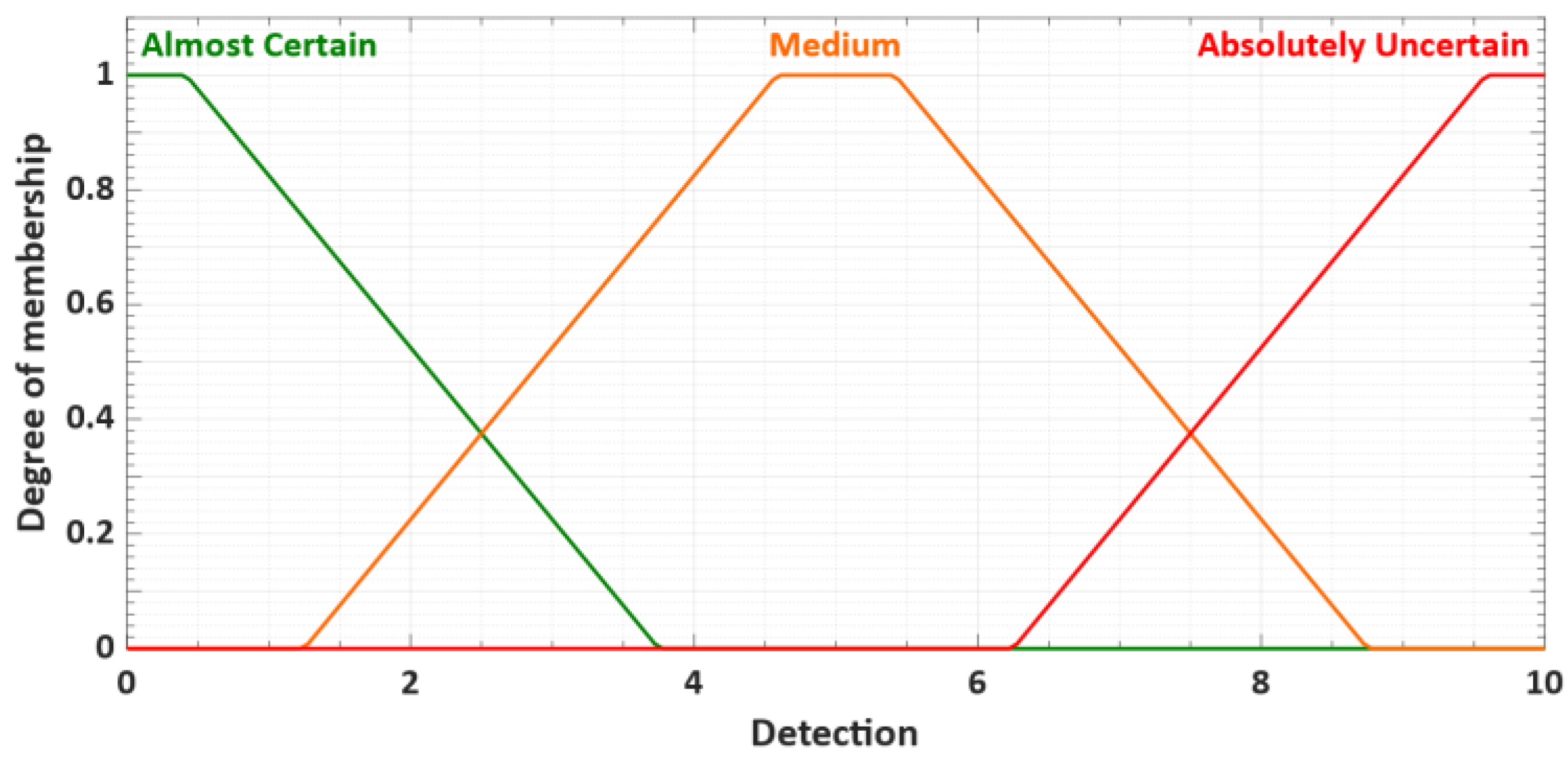

- What the membership functions of occurrence, severity and detection are.

- The fuzzy risk priority number (FRPN) assessed combining occurrence, severity and detection. FRPN is described using six trapezoidal membership functions;

- The optimal maintenance task, a linguistic variable assessed using all five inputs according to the decision diagram illustrated in Figure 5.

4. Case Study: RCM Assessment of HVAC for High-Speed Trains

- Compressor

- ○

- FM_C1: motor does not start on demand.

- ○

- FM_C2: incorrect signal from thermostat.

- ○

- FM_C3: pump gas leakage.

- ○

- FM_C4: sticking internal valve.

- ○

- FM_C5: internal overload motor protection.

- Electronic Control Card (ECC)

- ○

- FM_E1: electronic control failure.

- Watchdog

- ○

- FM_W1: watchdog does not act when the control fails.

- IGBT module

- ○

- FM_I1: short/open circuit.

- ○

- FM_I2: parameter drift.

- UPS

- ○

- FM_U1: no output power.

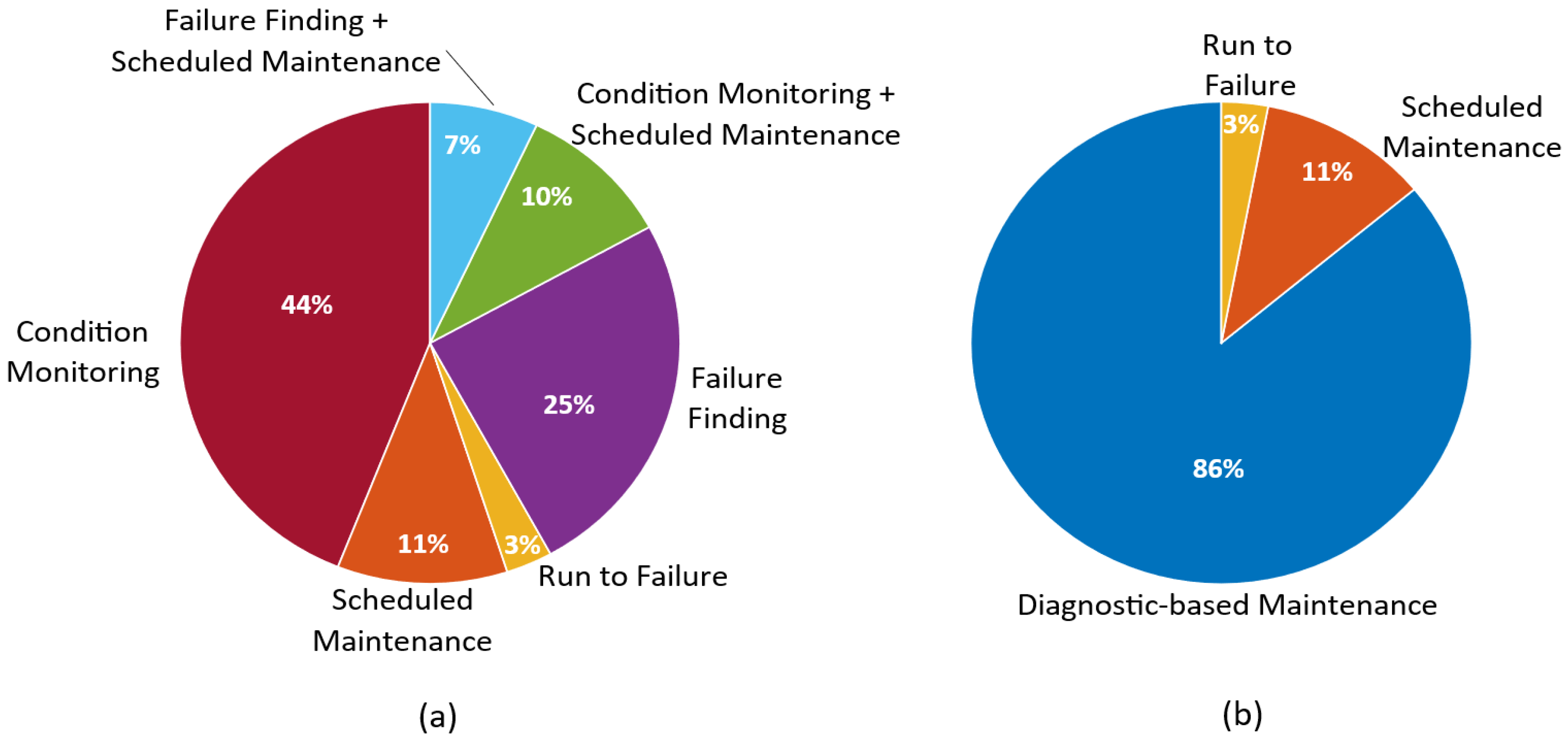

- FM_C1: “failure finding plus scheduled maintenance”. Failure finding is implemented every month; in this way it is possible to obtain a larger interval for the scheduled maintenance (6 months).

- FM_C2: “no preventive maintenance (run to failure)”. The failure of the thermostat does not represent critical damage for the system; therefore, corrective maintenance could be implemented.

- FM3_C3: “scheduled maintenance”. Operations on the pump are scheduled every 3 months.

- FM_C4: “condition monitoring”. The valve is monitored continuously using a position transducer and a pressure transmitter.

- FM_C5: “condition monitoring”. Several sensors are implemented to monitor the state of the compressor, including temperature, vibration, pressure and load sensors.

- FM_E1: “condition monitoring plus scheduled maintenance”. The electronic board is monitored continuously by a dedicated device equipped with temperature, humidity and vibration transducers. These parameters are extremely useful to identify the health state of electronics. Moreover, the diagnostic device also uses interrogation algorithms and residual life computational algorithms. Furthermore, scheduled maintenance (in the form of visual inspection) is required once a year.

- FM_W1: “failure finding plus scheduled maintenance”. Failure finding is implemented every month, while scheduled maintenance (in the form of visual inspection and manual HW/SW testing) is required every year.

- FM_I1: “condition monitoring”. The IGBT is monitored continuously using a temperature transducer and two power meters used to provide both input/output voltage and current.

- FM_I2: “failure finding”. Failure finding is implemented every month to check the health state of the IGBT.

- FM_U1: “condition monitoring”. The UPS is monitored continuously in order to check the health state of the battery using voltage, and current measurements are used to estimate the residual capacity of the battery.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- D’Emilia, G.; Gaspari, A.; Natale, E. Measurements for Smart Manufacturing in an Industry 4.0 Scenario A Case-Study on A Mechatronic System. In Proceedings of the 2018 Workshop on Metrology for Industry 4.0 and IoT, Brescia, Italy, 16–18 April 2018; pp. 1–5. [Google Scholar]

- D’Emilia, G.; Gaspari, A.; Hohwieler, E.; Laghmouchi, A.; Uhlmann, E. Improvement of defect detectability in machine tools using sensor-based condition monitoring applications. Procedia CIRP 2018, 67, 325–331. [Google Scholar] [CrossRef]

- Petritoli, E.; Leccese, F.; Spagnolo, G.S. In-Line Quality Control in Semiconductors Production and Availability for Industry 4.0. In Proceedings of the 2020 IEEE International Workshop on Metrology for Industry 4.0 & IoT, Rome, Italy, 3–5 June 2020; pp. 665–668. [Google Scholar]

- Abate, F.; Carratù, M.; Liguori, C.; Paciello, V. A low cost smart power meter for IoT. Measurement 2019, 136, 59–66. [Google Scholar] [CrossRef]

- Catelani, M.; Ciani, L.; Venzi, M. Sensitivity analysis with MC simulation for the failure rate evaluation and reliability assessment. Measurement 2015, 74, 150–158. [Google Scholar] [CrossRef]

- Sakib, N.; Wuest, T. Challenges and opportunities of condition-based predictive maintenance: A review. Procedia CIRP 2018, 78, 267–272. [Google Scholar] [CrossRef]

- Ciani, L.; Guidi, G.; Patrizi, G.; Venzi, M. System Maintainability Improvement using Allocation Procedures. In Proceedings of the 2018 IEEE International Systems Engineering Symposium (ISSE), Rome, Italy, 1–3 October 2018; pp. 1–6. [Google Scholar]

- Capriglione, D.; Carratu, M.; Pietrosanto, A.; Sommella, P. Online fault detection of rear stroke suspension sensor in motorcycle. IEEE Trans. Instrum. Meas. 2019, 68, 1362–1372. [Google Scholar] [CrossRef]

- Catelani, M.; Ciani, L.; Guidi, G.; Patrizi, G. Maintainability improvement using allocation methods for railway systems. ACTA IMEKO 2020, 9, 10–17. [Google Scholar] [CrossRef]

- Catelani, M.; Ciani, L. Experimental tests and reliability assessment of electronic ballast system. Microelectron. Reliab. 2012, 52, 1833–1836. [Google Scholar] [CrossRef]

- IEC 60300-3-11 Dependability Management—Part 3-11—Application Guide—Reliability Centred Maintenance; IEC: Geneva, Switzerland, 2009.

- IEC 60812 Failure Modes and Effects Analysis (FMEA and FMECA); IEC: Geneva, Switzerland, 2018.

- Catelani, M.; Ciani, L.; Galar, D.; Patrizi, G. Risk assessment of a wind turbine: A new FMECA-based tool with RPN threshold estimation. IEEE Access 2020, 8, 20181–20190. [Google Scholar] [CrossRef]

- Huang, J.; You, J.-X.; Liu, H.-C.; Song, M.-S. Failure mode and effect analysis improvement: A systematic literature review and future research agenda. Reliab. Eng. Syst. Saf. 2020, 199, 106885. [Google Scholar] [CrossRef]

- Birolini, A. Reliability Engineering; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 9783662542088. [Google Scholar]

- Soltanali, H.; Rohani, A.; Abbaspour-Fard, M.H.; Parida, A.; Farinha, J.T. Development of a risk-based maintenance decision making approach for automotive production line. Int. J. Syst. Assur. Eng. Manag. 2019, 11, 236–251. [Google Scholar] [CrossRef]

- Ciani, L.; Guidi, G.; Patrizi, G. A Critical comparison of alternative risk priority numbers in failure modes, effects, and criticality analysis. IEEE Access 2019, 7, 92398–92409. [Google Scholar] [CrossRef]

- Fischer, K.; Besnard, F.; Bertling, L. Reliability-centered maintenance for wind turbines based on statistical analysis and practical experience. IEEE Trans. Energy Convers. 2012, 27, 184–195. [Google Scholar] [CrossRef]

- Pandey, A.; Sonwane, P.M. Implementation of Reliability Centred Maintenance for Transformer. In Proceedings of the 2016 International Conference on Automatic Control and Dynamic Optimization Techniques (ICACDOT), Pune, India, 9–10 September 2016; pp. 578–581. [Google Scholar]

- Rafiei, M.; Khooban, M.-H.; Igder, M.A.; Boudjadar, J. A novel approach to overcome the limitations of reliability centered maintenance implementation on the smart grid distance protection system. IEEE Trans. Circuits Syst. II Express Briefs 2020, 67, 320–324. [Google Scholar] [CrossRef]

- Tirapong, K.; Titti, S. Reliability Improvement of Distribution System Using Reliability Centered Maintenance. In Proceedings of the 2014 IEEE PES T&D Conference and Exposition, Chicago, IL, USA, 14–16 April 2014; pp. 1–5. [Google Scholar]

- Khorshidi, H.A.; Gunawan, I.; Ibrahim, M.Y. Reliability Centered Maintenance Using System Dynamics Approach. In Proceedings of the 2015 IEEE International Conference on Industrial Technology (ICIT), Seville, Spain, 17–19 March 2015; pp. 1932–1936. [Google Scholar]

- Chen, Z.; He, Y.; Zhao, Y.; Han, X.; Liu, F.; Zhou, D.; Wang, W. Mission reliability-oriented selective maintenance optimization for intelligent multistate manufacturing systems with uncertain maintenance quality. IEEE Access 2019, 7, 109804–109816. [Google Scholar] [CrossRef]

- Selvik, J.T.; Aven, T. A framework for reliability and risk centered maintenance. Reliab. Eng. Syst. Saf. 2011, 96, 324–331. [Google Scholar] [CrossRef]

- Zakikhani, K.; Nasiri, F.; Zayed, T. Availability-based reliability-centered maintenance planning for gas transmission pipelines. Int. J. Press. Vessel. Pip. 2020, 183, 104105. [Google Scholar] [CrossRef]

- Yssaad, B.; Abene, A. Rational reliability centered maintenance optimization for power distribution systems. Int. J. Electr. Power Energy Syst. 2015, 73, 350–360. [Google Scholar] [CrossRef]

- He, D.; Zhang, X.; Ge, C.; Chen, E. A novel reliability-centred opportunistic maintenance strategy for metro train complex system. IEEE Intell. Transp. Syst. Mag. 2020. [Google Scholar] [CrossRef]

- Afzali, P.; Keynia, F.; Rashidinejad, M. A new model for reliability-centered maintenance prioritisation of distribution feeders. Energy 2019, 171, 701–709. [Google Scholar] [CrossRef]

- Rahmati, S.H.A.; Ahmadi, A.; Karimi, B. Multi-objective evolutionary simulation based optimization mechanism for a novel stochastic reliability centered maintenance problem. Swarm Evol. Comput. 2018, 40, 255–271. [Google Scholar] [CrossRef]

- Piasson, D.; Bíscaro, A.A.P.; Leão, F.B.; Mantovani, J.R.S. A new approach for reliability-centered maintenance programs in electric power distribution systems based on a multiobjective genetic algorithm. Electr. Power Syst. Res. 2016, 137, 41–50. [Google Scholar] [CrossRef]

- Heo, J.-H.; Kim, M.-K.; Park, G.-P.; Yoon, Y.T.; Park, J.K.; Lee, S.-S.; Kim, D.-H. A reliability-centered approach to an optimal maintenance strategy in transmission systems using a genetic algorithm. IEEE Trans. Power Deliv. 2011, 26, 2171–2179. [Google Scholar] [CrossRef]

- Catelani, M.; Ciani, L.; Galar, D.; Patrizi, G. Optimizing maintenance policies for a yaw system using reliability-centered maintenance and data-driven condition monitoring. IEEE Trans. Instrum. Meas. 2020, 69, 6241–6249. [Google Scholar] [CrossRef]

- Bowles, J.B.; Peláez, C.E. Fuzzy logic prioritization of failures in a system failure mode, effects and criticality analysis. Reliab. Eng. Syst. Saf. 1995, 50, 203–213. [Google Scholar] [CrossRef]

- Yang, Z.; Bonsall, S.; Wang, J. Fuzzy rule-based Bayesian reasoning approach for prioritization of failures in FMEA. IEEE Trans. Reliab. 2008, 57, 517–528. [Google Scholar] [CrossRef]

- Dağsuyu, C.; Göçmen, E.; Narlı, M.; Kokangül, A. Classical and fuzzy FMEA risk analysis in a sterilization unit. Comput. Ind. Eng. 2016, 101, 286–294. [Google Scholar] [CrossRef]

- Lienhardt, B.; Hugues, E.; Bes, C.; Noll, D. Failure-finding frequency for a repairable system subject to hidden failures. J. Aircr. 2008, 45, 1804–1809. [Google Scholar] [CrossRef]

- Ciani, L.; Bartolini, A.; Guidi, G.; Patrizi, G. Condition Monitoring of Wind Farm Based on Wireless Mesh Network. In Proceedings of the 16th IMEKO TC10 Conference 2019: Testing, Diagnostics and Inspection as a Comprehensive Value Chain for Quality and Safety, Berlin, Germany, 3–4 September 2019. [Google Scholar]

- Bhargava, C.; Sharma, P.K.; Senthilkumar, M.; Padmanaban, S.; Ramachandaramurthy, V.K.; Leonowicz, Z.; Blaabjerg, F.; Mitolo, M. Review of health prognostics and condition monitoring of electronic components. IEEE Access 2020, 8, 75163–75183. [Google Scholar] [CrossRef]

- Bowles, J. An assessment of RPN prioritization in a failure modes effects and criticality analysis. J. IEST 2004, 47, 51–56. [Google Scholar] [CrossRef]

- Certa, A.; Enea, M.; Galante, G.M.; La Fata, C.M. ELECTRE TRI-based approach to the failure modes classification on the basis of risk parameters: An alternative to the risk priority number. Comput. Ind. Eng. 2017, 108, 100–110. [Google Scholar] [CrossRef]

- Carpitella, S.; Certa, A.; Izquierdo, J.; La Fata, C.M. A combined multi-criteria approach to support FMECA analyses: A real-world case. Reliab. Eng. Syst. Saf. 2018, 169, 394–402. [Google Scholar] [CrossRef]

- Upadhya, M.S. Fuzzy logic-based failure mode effect and criticality analysis—A case study of water filters of a company. J. Comput. Appl. 2013, VI, 89–93. [Google Scholar]

- Wang, Y.-M.; Chin, K.-S.; Poon, G.K.K.; Yang, J.-B. Risk evaluation in failure mode and effects analysis using fuzzy weighted geometric mean. Expert Syst. Appl. 2009, 36, 1195–1207. [Google Scholar] [CrossRef]

- Chang, K.-H.; Cheng, C.-H. Evaluating the risk of failure using the fuzzy OWA and DEMATEL method. J. Intell. Manuf. 2011, 22, 113–129. [Google Scholar] [CrossRef]

- Kutlu, A.C.; Ekmekçioğlu, M. Fuzzy failure modes and effects analysis by using fuzzy TOPSIS-based fuzzy AHP. Expert Syst. Appl. 2012, 39, 61–67. [Google Scholar] [CrossRef]

- Mamdani, E.H.; Assilian, S. An experiment in linguistic synthesis with a fuzzy logic controller. Int. J. Man. Mach. Stud. 1975, 7, 1–13. [Google Scholar] [CrossRef]

- Sugeno, M.; Kang, G. Structure identification of fuzzy model. Fuzzy Sets Syst. 1988, 28, 15–33. [Google Scholar] [CrossRef]

- Tsukamoto, Y. An approach to fuzzy reasoning method. In Advances in Fuzzy Set Theory and Applications; Gupta, M.M., Ragade, R.K., Yager, R.R., Eds.; North-Holland Publishing Company: Amsterdam, The Netherlands, 1979; pp. 137–149. [Google Scholar]

- Vedavarz, A.; Kumar, S.; Hussain, M.I. HVAC Handbook of Heating, Ventilation, and Air Conditioning for Design & Implementation, 4th ed.; Industrial Press Inc.: New York, NY, USA, 2013; ISBN 9780831131630. [Google Scholar]

- Sugarman, S.C. HVAC Fundamentals, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2007; ISBN 0881735590. [Google Scholar]

- Porges, F. HVAC Engineer Handbook, 11th ed.; Elsevier Science & Technology Books: Amsterdam, The Netherlands, 2001; ISBN 0750646063. [Google Scholar]

- Catelani, M.; Ciani, L.; Luongo, V.; Singuaroli, R. Evaluation of the Safe Failure Fraction for an Electromechanical Complex System: Remarks about the Standard IEC61508. In Proceedings of the 2010 IEEE Instrumentation & Measurement Technology Conference Proceedings, Austin, TX, USA, 3–6 May 2010; pp. 949–953. [Google Scholar]

| Occurrence (O) | Severity (S) | Detection (D) |

|---|---|---|

| Remote (R)—the mode has a remote probability of occurring | Very low (VL)—the mode has low/no impact on the system | Almost certain (AC)—the mode will almost certainly be detected |

| Probable (P)—the mode has a medium probability of occurring | Tolerable (T)—the mode causes deterioration in the system | Medium (M)—the mode will probably be detected |

| High (H)—the mode will likely occur | Critical (C)—the mode leads to serious damage in the system | Absolutely uncertain (AU)—the mode will hardly be detected |

| Failure Modes | Failure Causes | Local Effects | Global Effects |

|---|---|---|---|

| Compressor: Increases the pressure of the refrigerant gas | |||

| FM_C1 | Motor seizes up | Loss of pumping capacity | Loss of cooling capacity in the cabin |

| Internal failure | |||

| Blocked compressor | |||

| Damaged winding | |||

| FM_C2 | Overheating of compressor | Loss of protection | Possible damage of compressor |

| Thermostat dirty | |||

| FM_C3 | Mechanical failure | Loss of refrigerant pumping | Loss of cooling capacity in the cabin |

| Fretting compressor | |||

| FM_C4 | Internal failure | Loss of refrigerant gas pressure | Loss of cooling capacity in the cabin |

| Valve dirty | |||

| FM_C5 | Motor short circuits | Loss of pumping capacity and shortcircuit of compressor | Loss of cooling capacity in the cabin |

| Electric overload | |||

| Compressor motor protection failure | |||

| Electronic Control Card (ECC): Regulate, monitor and diagnose the HVAC | |||

| FM_E1 | Short circuit | Incorrect regulation of the temperature by the control card | Loss of cooling capacity in the cabin |

| ECC dirty | |||

| Defect in printed circuit | |||

| Overload of the ECC | |||

| Watchdog: Activates the emergency regulation mode | |||

| FM_W1 | Hardware failure | Incorrect regulation of temperature | Loss of emergency regulation capacity |

| Software failure | |||

| IGBT module: Electronic switch used to control the compressor | |||

| FM_I1 | Overcurrent | Loss of pumping capacity and short circuit of compressor | Loss of cooling capacity in the cabin |

| Overtemperature | |||

| Secondary breakdown | |||

| FM_I2 | Hot carrier injection | Insufficient current to drive the compressor | Loss of cooling capacity in the cabin |

| Electromigration | |||

| Temperature instability | |||

| UPS: Provides power for emergency ventilation if the overhead power line fails | |||

| FM_U1 | Electric failure | Complete loss of functionality | Loss of emergency ventilation |

| Ageing battery units | |||

| Failure Modes | O | S | D | Is Failure Evident? | Impact on Safety? |

|---|---|---|---|---|---|

| FM_C1 | High | Tolerable | Absolutely Uncertain | No | No |

| FM_C2 | Remote | Very low | Almost certain | Yes | No |

| FM_C3 | Probable | Tolerable | Medium | Yes | No |

| FM_C4 | Probable | Tolerable | Almost certain | No | No |

| FM_C5 | Remote | Tolerable | Almost certain | Yes | No |

| FM_E1 | Probable | Tolerable | Medium | Yes | Yes |

| FM_W1 | Probable | Tolerable | Absolutely uncertain | No | No |

| FM_I1 | Remote | Critical | Almost certain | Yes | No |

| FM_I2 | Remote | Tolerable | Medium | No | No |

| FM_U1 | Probable | Critical | Almost certain | No | Yes |

| Failure Mode | Selected Maintenance Task | |

|---|---|---|

| Proposed Fuzzy-Based RCM | Classic RCM: IEC 60300-3-11 | |

| FM_C3 | Scheduled Maintenance | Condition Monitoring OR Scheduled Maintenance OR Run to Failure OR Alternative actions |

| FM_I2 | Failure Finding | Condition Monitoring OR Scheduled Maintenance OR Failure Finding OR Run to Failure OR Alternative actions |

| FM_U1 | Condition Monitoring | Condition Monitoring OR Scheduled Maintenance OR Failure Finding OR Alternative actions |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciani, L.; Guidi, G.; Patrizi, G.; Galar, D. Condition-Based Maintenance of HVAC on a High-Speed Train for Fault Detection. Electronics 2021, 10, 1418. https://doi.org/10.3390/electronics10121418

Ciani L, Guidi G, Patrizi G, Galar D. Condition-Based Maintenance of HVAC on a High-Speed Train for Fault Detection. Electronics. 2021; 10(12):1418. https://doi.org/10.3390/electronics10121418

Chicago/Turabian StyleCiani, Lorenzo, Giulia Guidi, Gabriele Patrizi, and Diego Galar. 2021. "Condition-Based Maintenance of HVAC on a High-Speed Train for Fault Detection" Electronics 10, no. 12: 1418. https://doi.org/10.3390/electronics10121418

APA StyleCiani, L., Guidi, G., Patrizi, G., & Galar, D. (2021). Condition-Based Maintenance of HVAC on a High-Speed Train for Fault Detection. Electronics, 10(12), 1418. https://doi.org/10.3390/electronics10121418