Influence of Growth Polarity Switching on the Optical and Electrical Properties of GaN/AlGaN Nanowire LEDs

Abstract

1. Introduction

2. Samples and Experimental Methods

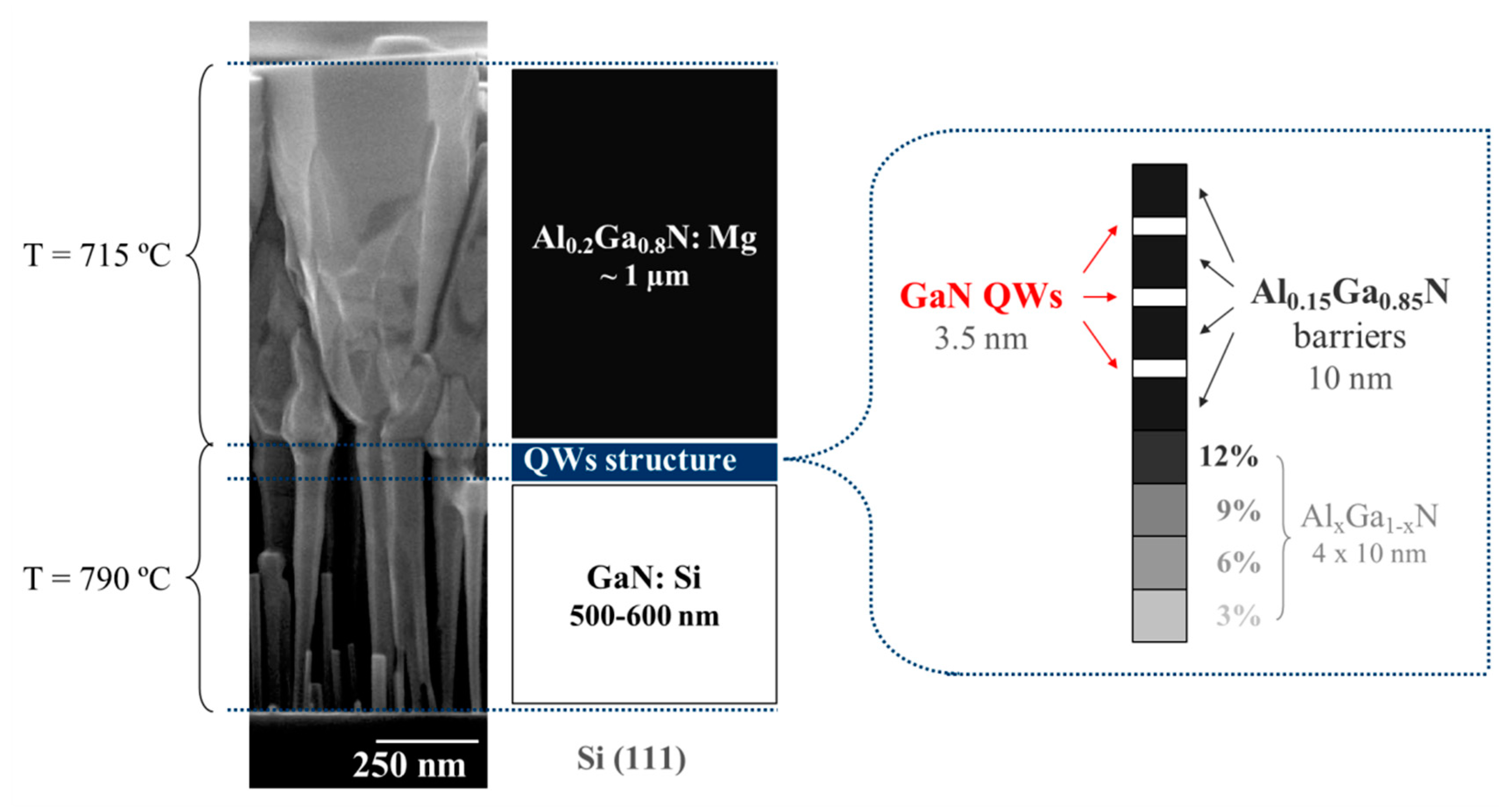

2.1. Samples

2.2. Methods

3. Results

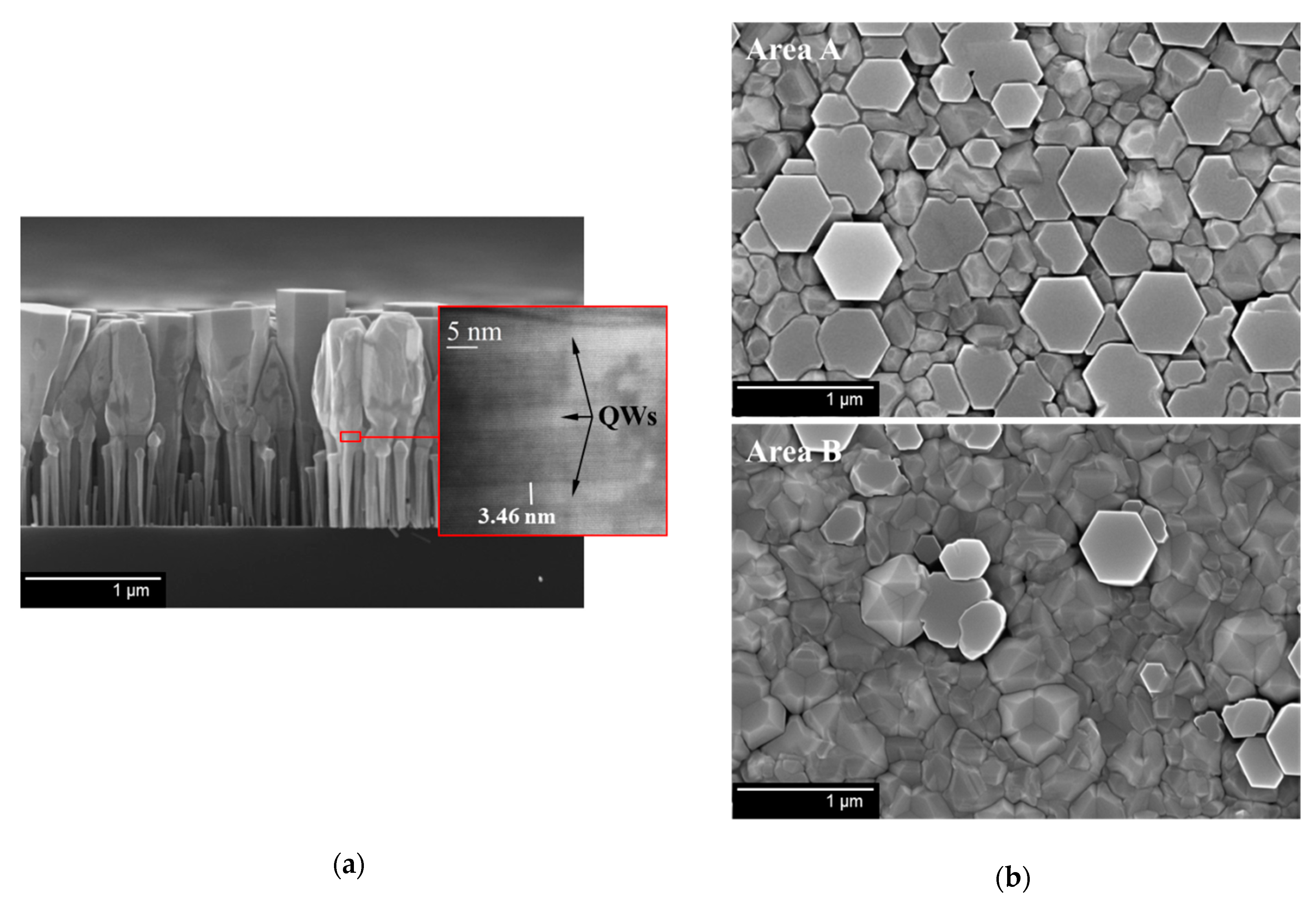

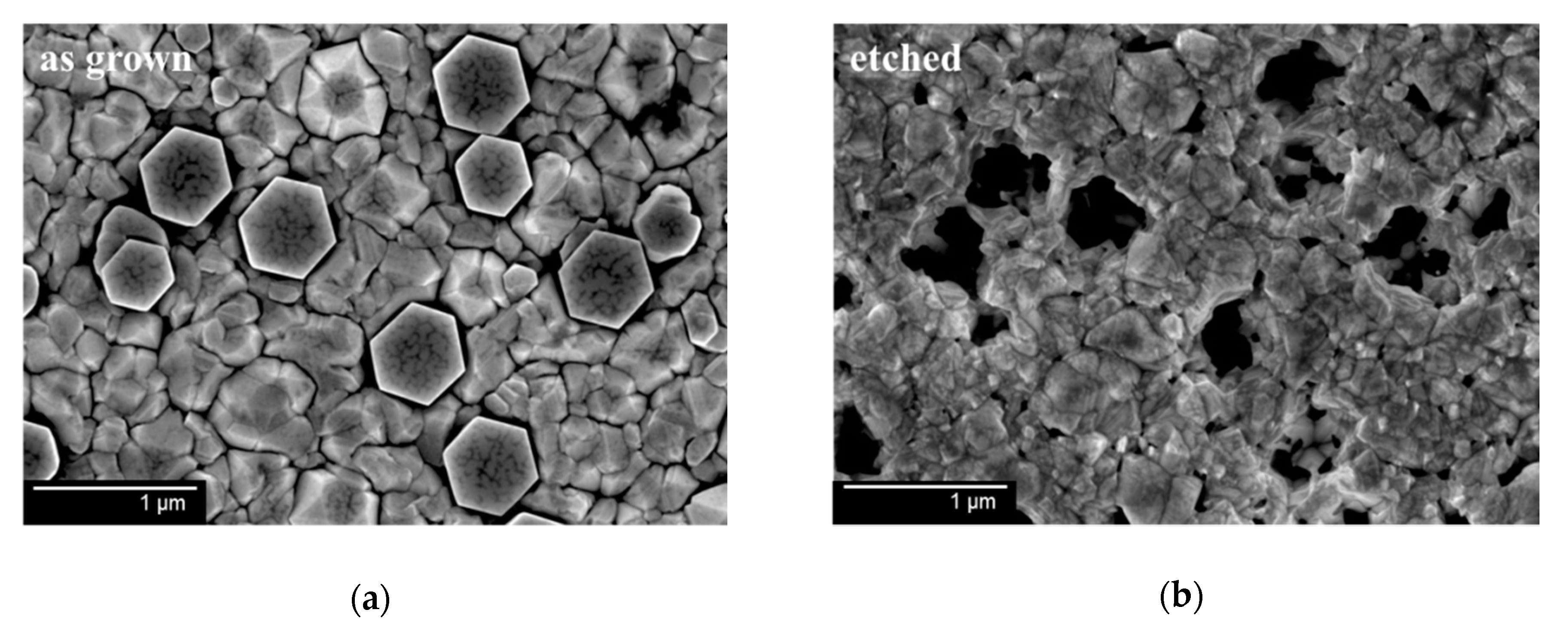

3.1. Morphology and Structure

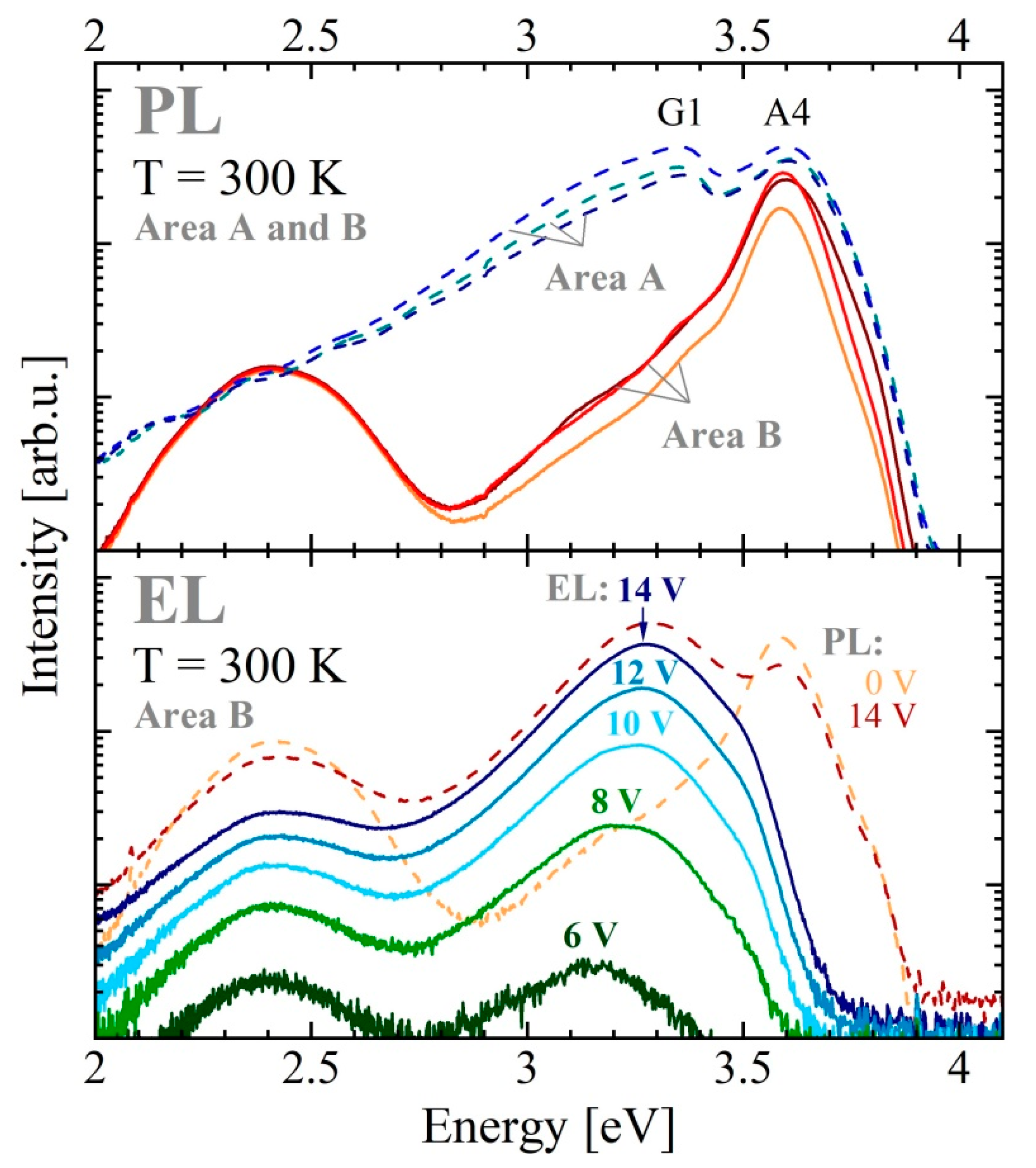

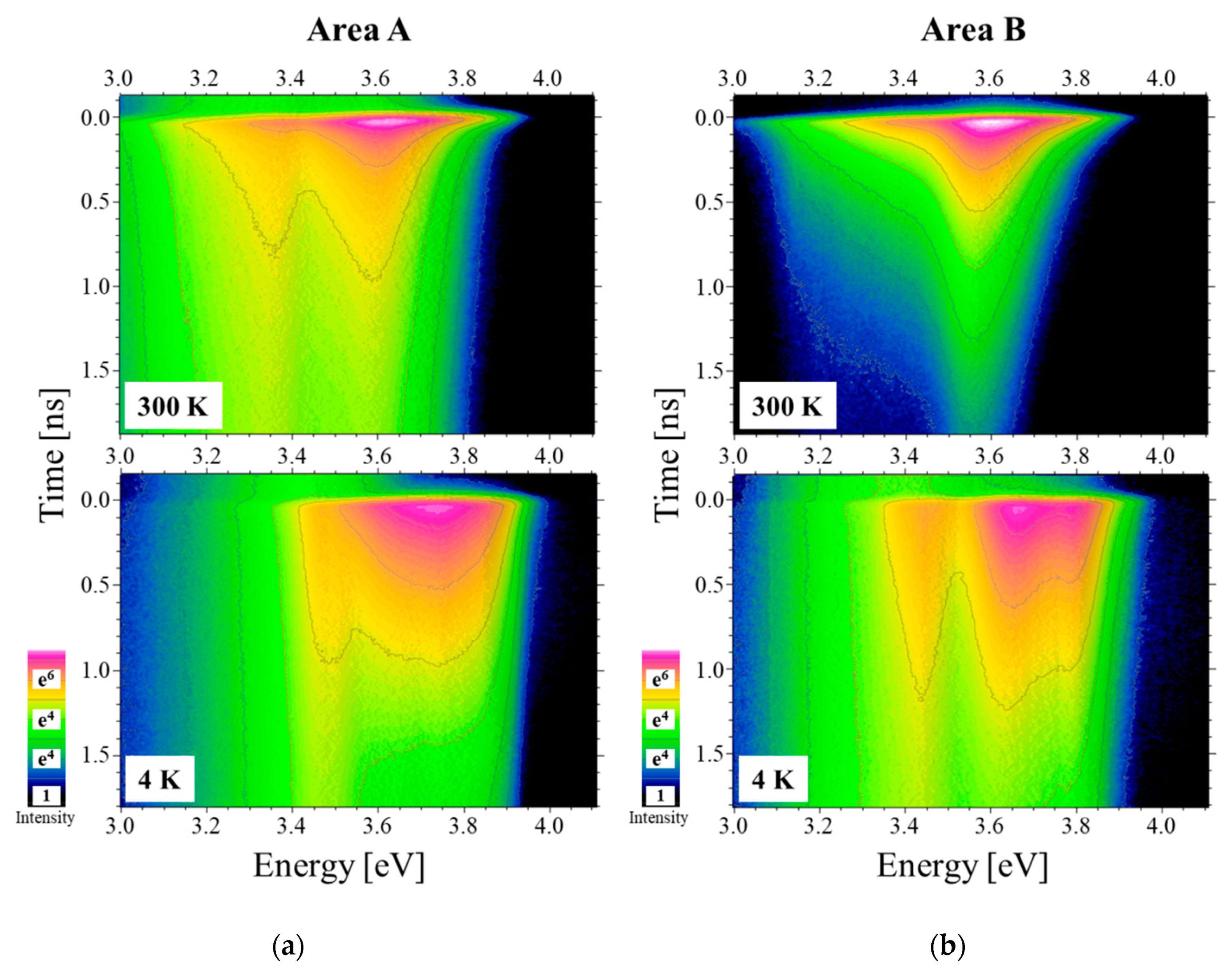

3.2. Macroscopic Electro- and Photoluminescence

3.3. Microscopic Optical and Electrical Properties

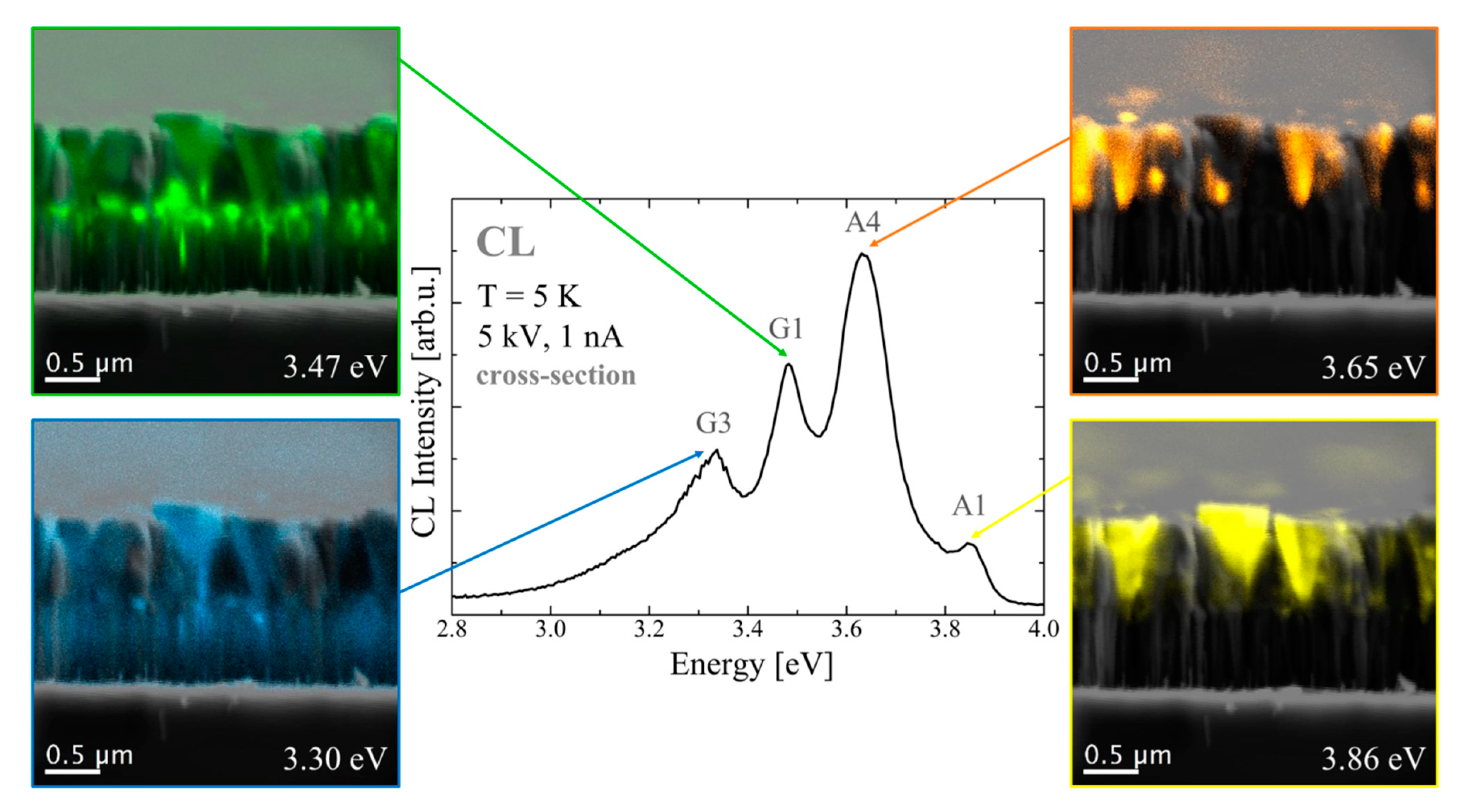

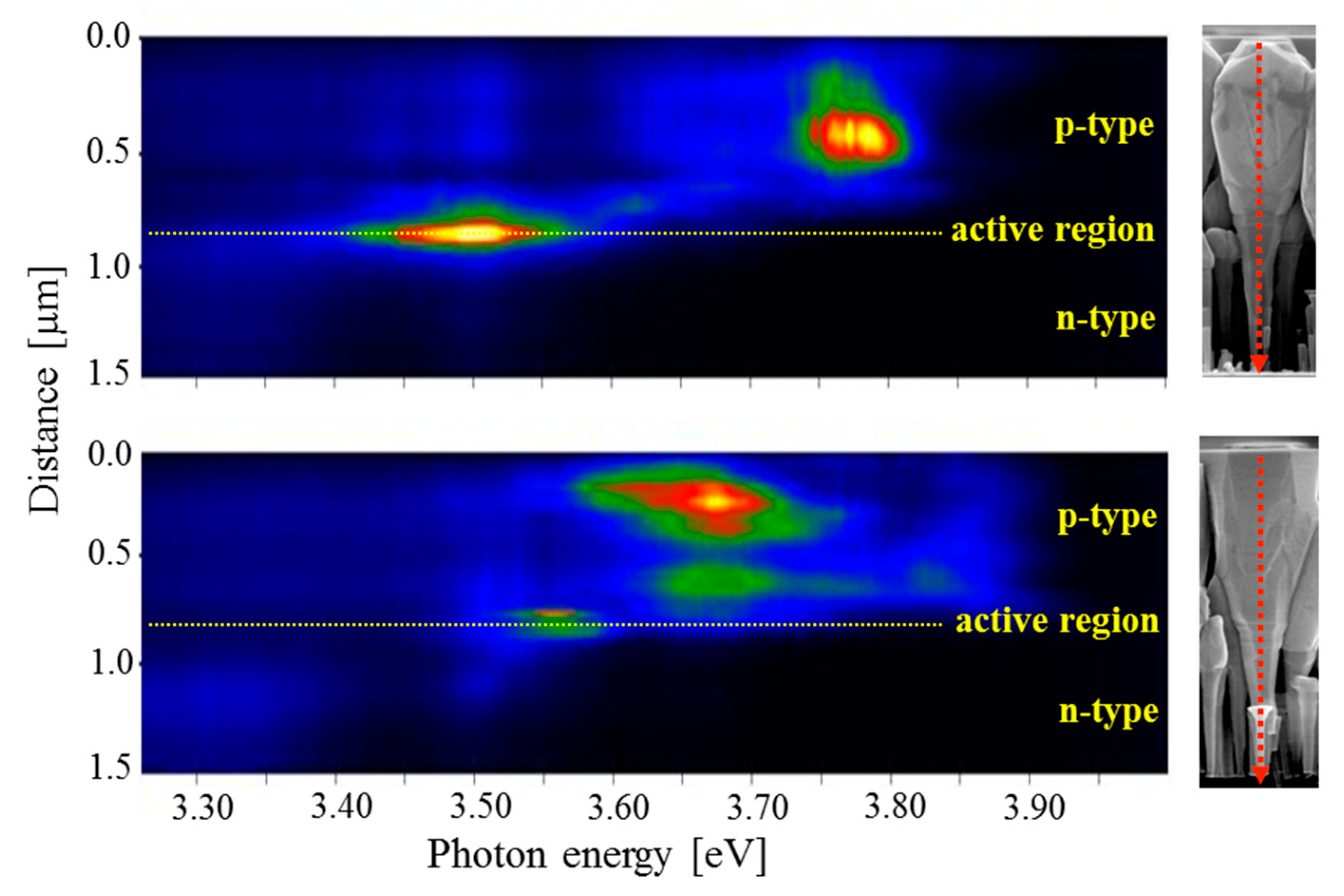

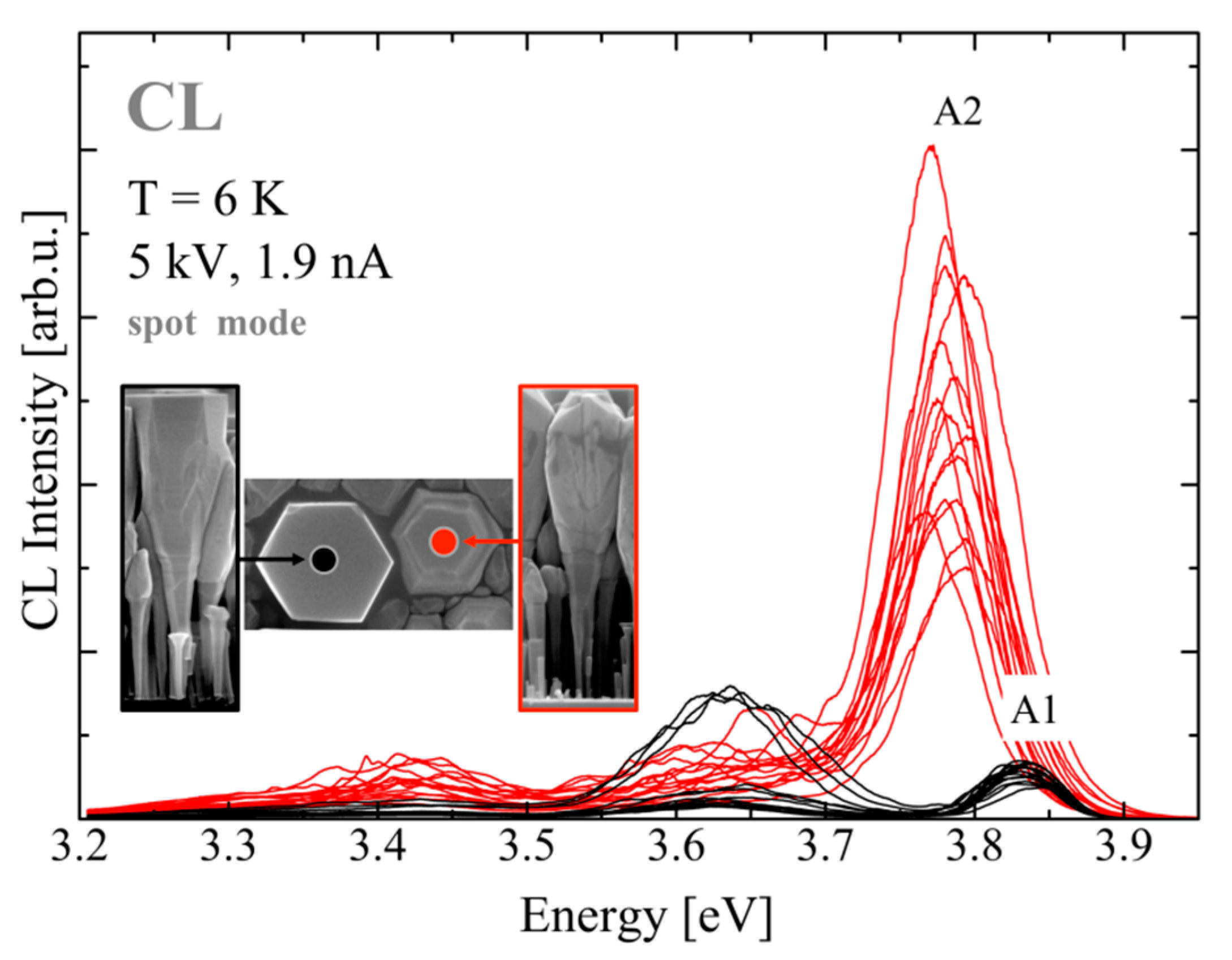

3.3.1. Cathodoluminescence Studies

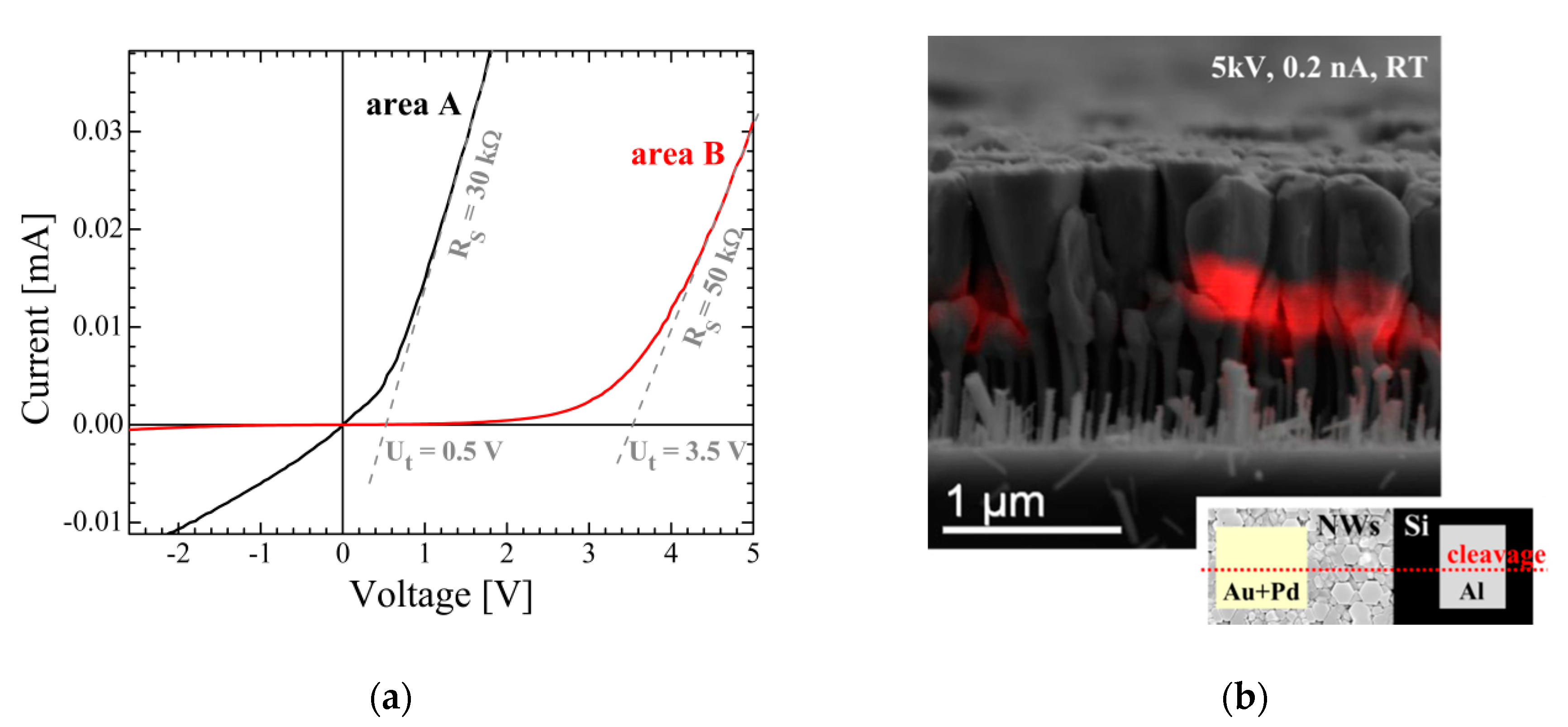

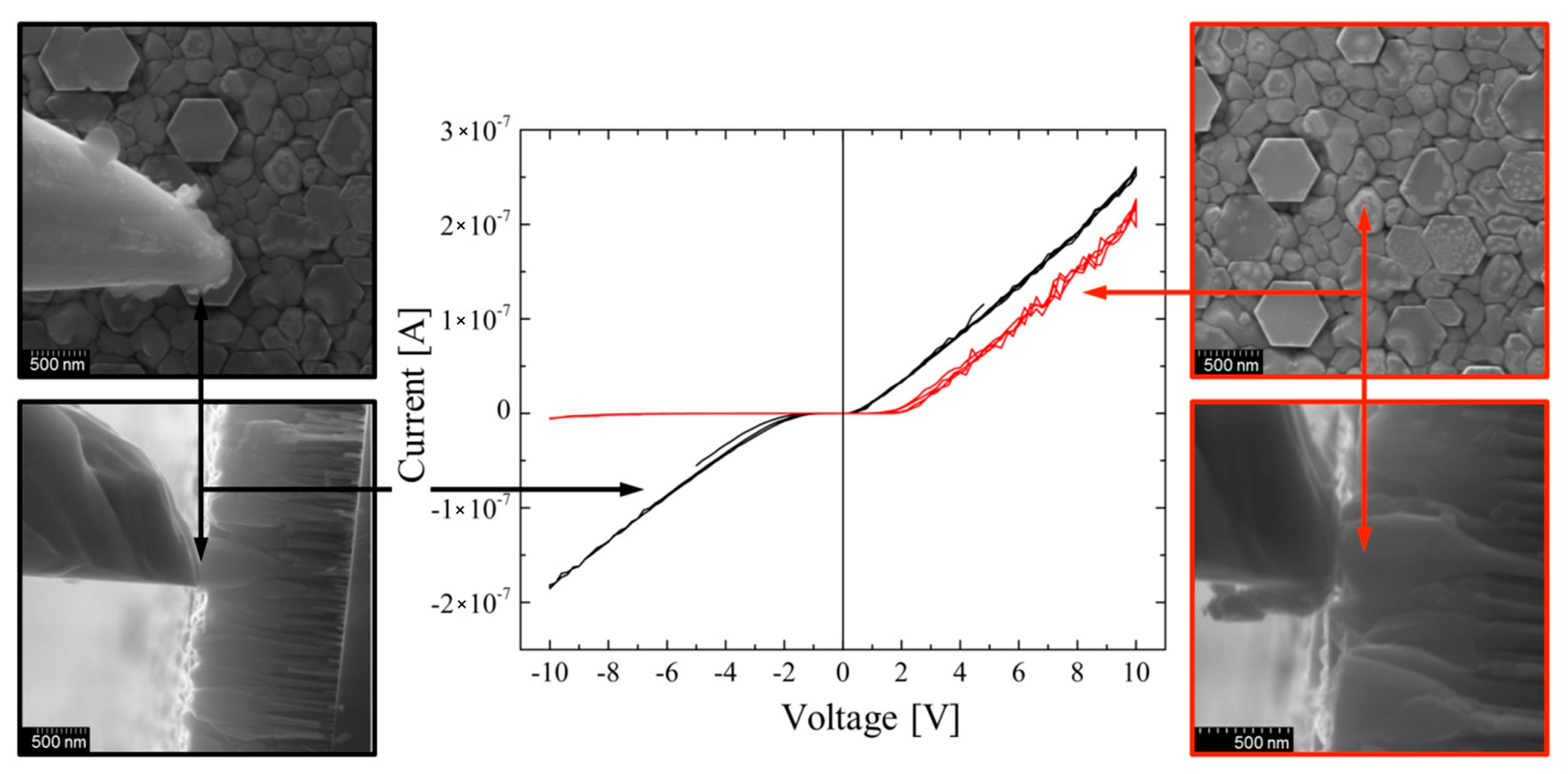

3.3.2. EBIC and Nano-Probe Results

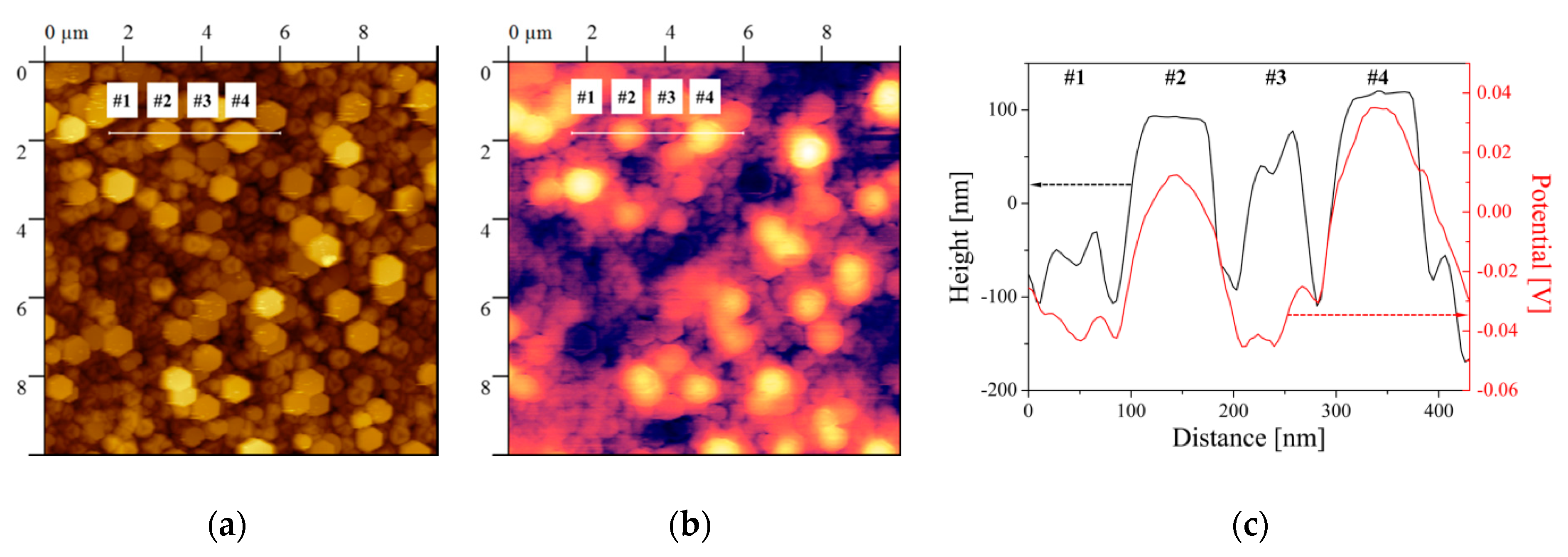

3.3.3. Kelvin Probe Force Microscopy

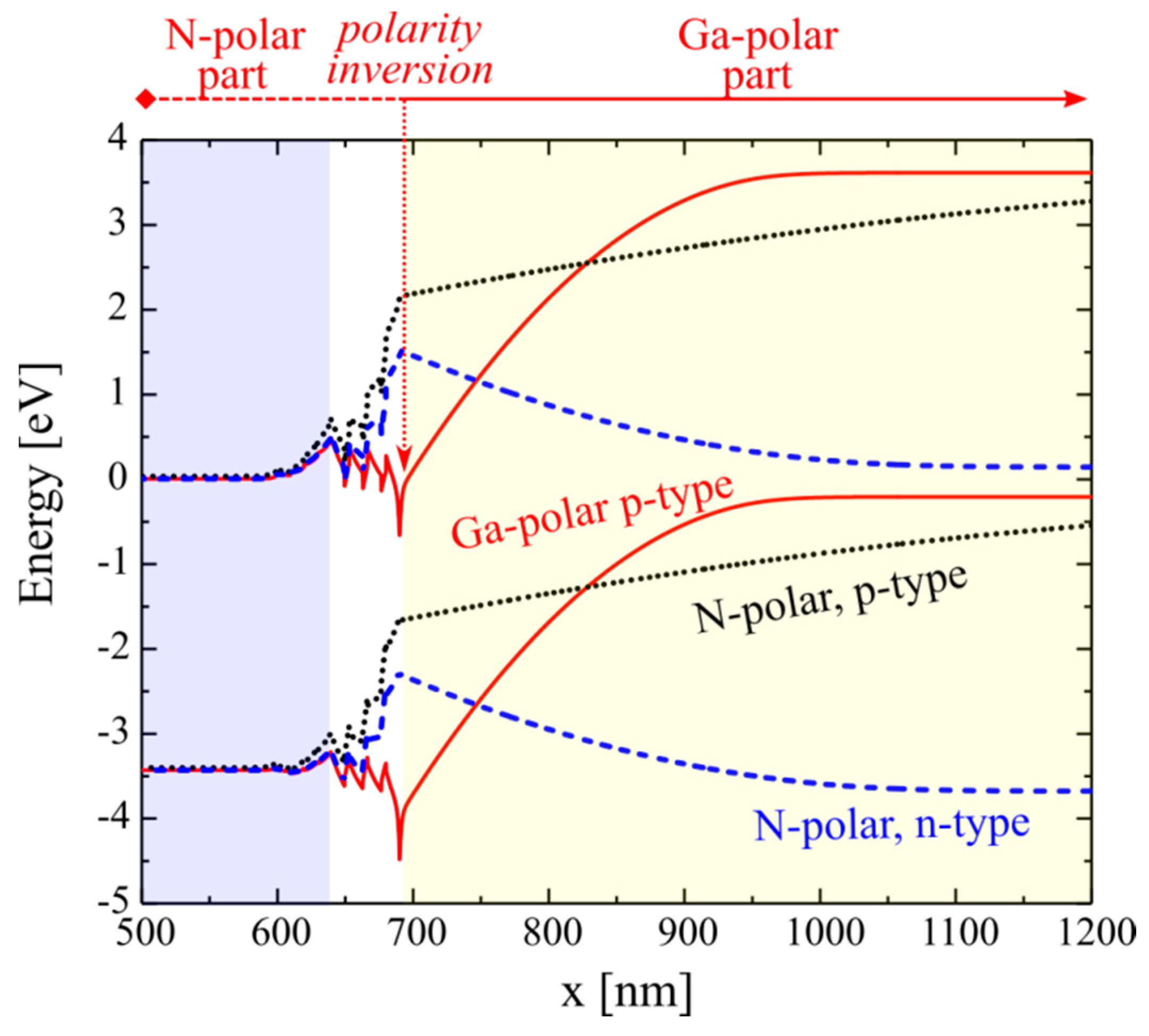

4. Discussion

5. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Seong, T.-Y.; Han, J.; Amano, H.; Morkoc, H. III-Nitride Based Light Emitting Diodes and Applications; Springer: Dordrecht, the Netherlands, 2013; ISBN 978-94-007-5863-6. [Google Scholar]

- Huang, J.-J.; Kuo, H.-C.; Shen, S.-C. Nitride Semiconductor Light-Emitting Diodes (LEDs), 1st ed.; Woodhead Publishing: Sawston, UK, 2013; ISBN 9780857099303. [Google Scholar]

- Wong, M.S.; Nakamura, S.; DenBaars, S.P. Review—Progress in High Performance III-Nitride Micro-Light-Emitting Diodes. ECS J. Solid State Sci. Technol. 2020, 9, 015012. [Google Scholar] [CrossRef]

- Romualdo, A.F.; Zhu Congyong, T.A.; Hadis, M. Group III Nitrides. In Springer Handbook of Electronic and Photonic Materials; Safa, K., Capper, P., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; p. 1536. ISBN 978-3-319-48933-9. [Google Scholar]

- Muñoz, E.; Monroy, E.; Pau, J.L.; Calle, F.; Omnès, F.; Gibart, P. III nitrides and UV detection. J. Phys. Condens. Matter 2001, 13, 7115–7137. [Google Scholar] [CrossRef]

- Zou, Y.; Zhang, Y.; Hu, Y.; Gu, H. Ultraviolet Detectors Based on Wide Bandgap Semiconductor Nanowire: A Review. Sensors 2018, 18, 2072. [Google Scholar] [CrossRef] [PubMed]

- Dwiliński, R.; Doradziński, R.; Garczyński, J.; Sierzputowski, L.; Kucharski, R.; Zając, M.; Rudziński, M.; Kudrawiec, R.; Strupiński, W.; Misiewicz, J. Ammonothermal GaN substrates: Growth accomplishments and applications. Phys. Status Solidi 2011, 208, 1489–1493. [Google Scholar] [CrossRef]

- Hashimoto, T.; Letts, E.; Hoff, S. Current status and future prospects of ammonothermal bulk GaN growth. Sensors Mater. 2013, 25, 155–164. [Google Scholar]

- Łucznik, B.; Pastuszka, B.; Grzegory, I.; Boćkowski, M.; Kamler, G.; Litwin-Staszewska, E.; Porowski, S. Deposition of thick GaN layers by HVPE on the pressure grown GaN substrates. J. Cryst. Growth 2005, 281, 38–46. [Google Scholar] [CrossRef]

- Fujito, K.; Kubo, S.; Nagaoka, H.; Mochizuki, T.; Namita, H.; Nagao, S. Bulk GaN crystals grown by HVPE. J. Cryst. Growth 2009, 311, 3011–3014. [Google Scholar] [CrossRef]

- Brandt, O.; Pfüller, C.; Chèze, C.; Geelhaar, L.; Riechert, H. Sub-meV linewidth of excitonic luminescence in single GaN nanowires: Direct evidence for surface excitons. Phys. Rev. B 2010, 81, 45302. [Google Scholar] [CrossRef]

- Glas, F. Critical dimensions for the plastic relaxation of strained axial heterostructures in free-standing nanowires. Phys. Rev. B 2006, 74, 121302. [Google Scholar] [CrossRef]

- Carnevale, S.D.; Kent, T.F.; Phillips, P.J.; Mills, M.J.; Rajan, S.; Myers, R.C. Polarization-Induced pn Diodes in Wide-Band-Gap Nanowires with Ultraviolet Electroluminescence. Nano Lett. 2012, 12, 915–920. [Google Scholar] [CrossRef]

- Kent, T.F.; Carnevale, S.D.; Sarwar, A.T.M.; Phillips, P.J.; Klie, R.F.; Myers, R.C. Deep ultraviolet emitting polarization induced nanowire light emitting diodes with Alx Ga1−x N active regions. Nanotechnology 2014, 25, 455201. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Wang, R.; Chu, S.; Mi, Z. Molecular Beam Epitaxy of III-Nitride Nanowires: Emerging Applications From Deep-Ultraviolet Light Emitters and Micro-LEDs to Artificial Photosynthesis. IEEE Nanotechnol. Mag. 2019, 13, 6–16. [Google Scholar] [CrossRef]

- Zhao, C.; Alfaraj, N.; Chandra Subedi, R.; Liang, J.W.; Alatawi, A.A.; Alhamoud, A.A.; Ebaid, M.; Alias, M.S.; Ng, T.K.; Ooi, B.S. III-nitride nanowires on unconventional substrates: From materials to optoelectronic device applications. Prog. Quantum Electron. 2018, 61, 1–31. [Google Scholar] [CrossRef]

- Barrigón, E.; Heurlin, M.; Bi, Z.; Monemar, B.; Samuelson, L. Synthesis and Applications of III–V Nanowires. Chem. Rev. 2019, 119, 9170–9220. [Google Scholar] [CrossRef] [PubMed]

- Ristić, J.; Calleja, E.; Fernández-Garrido, S.; Cerutti, L.; Trampert, A.; Jahn, U.; Ploog, K.H. On the mechanisms of spontaneous growth of III-nitride nanocolumns by plasma-assisted molecular beam epitaxy. J. Cryst. Growth 2008, 310, 4035–4045. [Google Scholar] [CrossRef]

- Liu, R.; Bell, A.; Ponce, F.A.; Chen, C.Q.; Yang, J.W.; Khan, M.A. Luminescence from stacking faults in gallium nitride. Appl. Phys. Lett. 2005, 86, 31–34. [Google Scholar] [CrossRef]

- Korona, K.P.; Reszka, A.; Sobanska, M.; Perkowska, P.S.; Wysmołek, A.; Klosek, K.; Zytkiewicz, Z.R. Dynamics of stacking faults luminescence in GaN/Si nanowires. J. Lumin. 2014, 155. [Google Scholar] [CrossRef]

- Pfüller, C.; Corfdir, P.; Hauswald, C.; Flissikowski, T.; Kong, X.; Zettler, J.K.; Fernández-Garrido, S.; Doǧan, P.; Grahn, H.T.; Trampert, A.; et al. Nature of excitons bound to inversion domain boundaries: Origin of the 3.45-eV luminescence lines in spontaneously formed GaN nanowires on Si(111). Phys. Rev. B 2016, 94, 1–11. [Google Scholar] [CrossRef]

- Korona, K.P.; Zytkiewicz, Z.R.; Sobanska, M.; Sosada, F.E.; Drózdz, P.A.; Klosek, K.; Tchutchulashvili, G. Reflectance and fast polarization dynamics of a GaN/Si nanowire ensemble. J. Phys. Condens. Matter 2018, 30, 315301. [Google Scholar] [CrossRef]

- Tchoulfian, P.; Donatini, F.; Levy, F.; Dussaigne, A.; Ferret, P.; Pernot, J. Direct imaging of p-n junction in core-shell GaN wires. Nano Lett. 2014, 14, 3491–3498. [Google Scholar] [CrossRef]

- Ambacher, O.; Majewski, J.; Miskys, C.; Link, A.; Hermann, M.; Eickhoff, M.; Stutzmann, M.; Bernardini, F.; Fiorentini, V.; Tilak, V.; et al. Pyroelectric properties of Al(In)GaN/GaN hetero- and quantum well structures. J. Phys. Condens. Matter 2002, 14, 3399–3434. [Google Scholar] [CrossRef]

- Klosek, K.; Sobanska, M.; Tchutchulashvili, G.; Zytkiewicz, Z.R.; Teisseyre, H.; Klopotowski, L. Optimization of nitrogen plasma source parameters by measurements of emitted light intensity for growth of GaN by molecular beam epitaxy. Thin Solid Films 2013, 534, 107–110. [Google Scholar] [CrossRef]

- Binder, J.; Korona, K.P.; Wysmołek, A.; Kamińska, M.; Köhler, K.; Kirste, L.; Ambacher, O.; Zaja̧c, M.; Dwiliński, R. Dynamics of thermalization in GaInN/GaN quantum wells grown on ammonothermal GaN. J. Appl. Phys. 2013, 114, 223504. [Google Scholar] [CrossRef]

- Sobanska, M.; Korona, K.P.; Zytkiewicz, Z.R.; Klosek, K.; Tchutchulashvili, G. Kinetics of self-induced nucleation and optical properties of GaN nanowires grown by plasma-assisted molecular beam epitaxy on amorphous AlxOy. J. Appl. Phys. 2015, 118, 184303. [Google Scholar] [CrossRef]

- Wierzbicka, A.; Zytkiewicz, Z.R.; Kret, S.; Borysiuk, J.; Dluzewski, P.; Sobanska, M.; Klosek, K.; Reszka, A.; Tchutchulashvili, G.; Cabaj, A.; et al. Influence of substrate nitridation temperature on epitaxial alignment of GaN nanowires to Si(111) substrate. Nanotechnology 2013, 24, 035703. [Google Scholar] [CrossRef] [PubMed]

- Kolkovsky, V.; Zytkiewicz, Z.R.; Korona, K.P.; Sobanska, M.; Klosek, K. Structural, electrical, and optical characterization of coalescent p-n GaN nanowires grown by molecular beam epitaxy. J. Appl. Phys. 2015, 118, 224307. [Google Scholar] [CrossRef]

- Zúñiga-Pérez, J.; Consonni, V.; Lymperakis, L.; Kong, X.; Trampert, A.; Fernández-Garrido, S.; Brandt, O.; Renevier, H.; Keller, S.; Hestroffer, K.; et al. Polarity in GaN and ZnO: Theory, measurement, growth, and devices. Appl. Phys. Rev. 2016, 3, 041303. [Google Scholar] [CrossRef]

- Li, D.; Sumiya, M.; Yoshimura, K.; Suzuki, Y.; Fukuda, Y.; Fuke, S. Characteristics of the GaN Polar Surface during an Etching Process in KOH Solution. Phys. Status Solidi 2000, 180, 357–362. [Google Scholar] [CrossRef]

- Ng, H.M.; Parz, W.; Weimann, N.G.; Chowdhury, A. Patterning GaN Microstructures by Polarity-Selective Chemical Etching. Jpn. J. Appl. Phys. 2003, 42, L1405–L1407. [Google Scholar] [CrossRef]

- Hestroffer, K.; Leclere, C.; Bougerol, C.; Renevier, H.; Daudin, B. Polarity of GaN nanowires grown by plasma-assisted molecular beam epitaxy on Si(111). Phys. Rev. B 2011, 84, 245302. [Google Scholar] [CrossRef]

- Korona, K.P.; Wysmołek, A.; Pakuła, K.; Stȩpniewski, R.; Baranowski, J.M.; Grzegory, I.; Łucznik, B.; Wróblewski, M.; Porowski, S. Exciton region reflectance of homoepitaxial GaN layers. Appl. Phys. Lett. 1996, 69, 788–790. [Google Scholar] [CrossRef]

- Korona, K.P. Dynamics of excitonic recombination and interactions in homoepitaxial GaN. Phys. Rev. B Condens. Matter Mater. Phys. 2002, 65, 1–8. [Google Scholar] [CrossRef]

- Lefebvre, P.; Morel, A.; Gallart, M.; Taliercio, T.; Allègre, J.; Gil, B.; Mathieu, H.; Damilano, B.; Grandjean, N.; Massies, J. High internal electric field in a graded-width InGaN/GaN quantum well: Accurate determination by time-resolved photoluminescence spectroscopy. Appl. Phys. Lett. 2001, 78, 1252–1254. [Google Scholar] [CrossRef]

- Gustafsson, A. Nanowire-based structures for infrared to ultraviolet emitters studied by cathodoluminescence. J. Microsc. 2016, 262, 134–141. [Google Scholar] [CrossRef] [PubMed]

- Thonke, K.; Tischer, I.; Hocker, M.; Schirra, M.; Fujan, K.; Wiedenmann, M.; Schneider, R.; Frey, M.; Feneberg, M. Nanoscale characterisation of semiconductors by cathodoluminescence. IOP Conf. Ser. Mater. Sci. Eng. 2014, 55, 55. [Google Scholar] [CrossRef]

- Reszka, A.; Wierzbicka, A.; Sobczak, K.; Jahn, U.; Zeimer, U.; Kuchuk, A.V.; Pieniążek, A.; Sobanska, M.; Klosek, K.; Zytkiewicz, Z.R.; et al. An influence of the local strain on cathodoluminescence of GaN/Al x Ga 1−x N nanowire structures. J. Appl. Phys. 2016, 120, 194304. [Google Scholar] [CrossRef]

- Drouin, D.; Couture, A.R.; Joly, D.; Tastet, X.; Aimez, V.; Gauvin, R. CASINO V2.42—A Fast and Easy-to-use Modeling Tool for Scanning Electron Microscopy and Microanalysis Users. Scanning 2007, 29, 92–101. [Google Scholar] [CrossRef]

- Keller, S.; Fichtenbaum, N.A.; Furukawa, M.; Speck, J.S.; Denbaars, S.P.; Mishra, U.K. Growth and characterization of N-polar InGaNGaN multiquantum wells. Appl. Phys. Lett. 2007, 90, 1–4. [Google Scholar] [CrossRef]

- Rigutti, L.; Tchernycheva, M. Electrical and Electro-Optical Characterization of Semiconductor Nanowires, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 9780444595515. [Google Scholar]

- Tchernycheva, M.; Neplokh, V.; Zhang, H.; Lavenus, P.; Rigutti, L.; Bayle, F.; Julien, F.H.; Babichev, A.; Jacopin, G.; Largeau, L.; et al. Core-shell InGaN/GaN nanowire light emitting diodes analyzed by electron beam induced current microscopy and cathodoluminescence mapping. Nanoscale 2015, 7, 11692–11701. [Google Scholar] [CrossRef]

- Tiagulskyi, S.; Yatskiv, R.; Faitová, H.; Kučerová, Š.; Vaniš, J.; Grym, J. Electrical properties of nanoscale p-n heterojunctions formed between a single ZnO nanorod and GaN substrate. Mater. Sci. Semicond. Process. 2020, 107, 104808. [Google Scholar] [CrossRef]

- Tiagulskyi, S.; Yatskiv, R.; Faitová, H.; Kučerová, Š.; Roesel, D.; Vaniš, J.; Grym, J.; Veselý, J. Highly Rectifying Heterojunctions Formed by Annealed ZnO Nanorods on GaN Substrates. Nanomaterials 2020, 10, 508. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, B.J.; Yang, W.-C.; Nemanich, R.J.; Gruverman, A. Scanning probe investigation of surface charge and surface potential of GaN-based heterostructures. Appl. Phys. Lett. 2005, 86, 112115. [Google Scholar] [CrossRef]

- Minj, A.; Cros, A.; Garro, N.; Colchero, J.; Auzelle, T.; Daudin, B. Assessment of Polarity in GaN Self-Assembled Nanowires by Electrical Force Microscopy. Nano Lett. 2015, 15, 6770–6776. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Waag, A. GaN based nanorods for solid state lighting. J. Appl. Phys. 2012, 111, 071101. [Google Scholar] [CrossRef]

- Wang, Z.T.; Yamada-Takamura, Y.; Fujikawa, Y.; Sakurai, T.; Xue, Q.K. Atomistic study of GaN surface grown on Si(111). Appl. Phys. Lett. 2005, 87, 032110. [Google Scholar] [CrossRef]

- Calarco, R.; Meijers, R.J.; Debnath, R.K.; Stoical, T.; Sutter, E.; Lüth, H. Nucleation and growth of GaN nanowires on Si(111) performed by molecular beam epitaxy. Nano Lett. 2007, 7, 2248–2251. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Li, W.; Cabalu, J.; Moustakas, T.D.; Smith, D.J.; Hervig, R.L. Efficient p -type doping of GaN films by plasma-assisted molecular beam epitaxy. Appl. Phys. Lett. 2004, 85, 4956–4958. [Google Scholar] [CrossRef]

- Ramachandran, V.; Feenstra, R.M.; Sarney, W.L.; Salamanca-Riba, L.; Northrup, J.E.; Romano, L.T.; Greve, D.W. Inversion of wurtzite GaN(0001) by exposure to magnesium. Appl. Phys. Lett. 1999, 75, 808–810. [Google Scholar] [CrossRef]

- Ptak, A.J.; Myers, T.H.; Romano, L.T.; Van De Walle, C.G.; Northrup, J.E. Magnesium incorporation in GaN grown by molecular-beam epitaxy. Appl. Phys. Lett. 2001, 78, 285–287. [Google Scholar] [CrossRef]

- Keller, S.; Dora, Y.; Wu, F.; Chen, X.; Chowdury, S.; Denbaars, S.P.; Speck, J.S.; Mishra, U.K. Properties of N-polar GaN films and AlGaN/GaN heterostructures grown on (111) silicon by metal organic chemical vapor deposition. Appl. Phys. Lett. 2010, 97, 1–4. [Google Scholar] [CrossRef]

- Romano, L.T.; Northrup, J.E.; Ptak, A.J.; Myers, T.H. Faceted inversion domain boundary in GaN films doped with Mg. Appl. Phys. Lett. 2000, 77, 2479–2481. [Google Scholar] [CrossRef]

- Green, D.S.; Haus, E.; Wu, F.; Chen, L.; Mishra, U.K.; Speck, J.S. Polarity control during molecular beam epitaxy growth of Mg-doped GaN. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2003, 21, 1804. [Google Scholar] [CrossRef]

- Monroy, E.; Hermann, M.; Sarigiannidou, E.; Andreev, T.; Holliger, P.; Monnoye, S.; Mank, H.; Daudin, B.; Eickhoff, M. Polytype transition of N-face GaN:Mg from wurtzite to zinc-blende. J. Appl. Phys. 2004, 96, 3709–3715. [Google Scholar] [CrossRef]

- Sarigiannidou, E.; Monroy, E.; Hermann, M.; Andreev, T.; Holliger, P.; Monnoye, S.; Mank, H.; Daudin, B.; Eickhoff, M. Phase transition by Mg doping of N-face polarity GaN. Phys. Status Solidi C Conf. 2005, 2, 2216–2219. [Google Scholar] [CrossRef]

- Wong, M.H.; Wu, F.; Mates, T.E.; Speck, J.S.; Mishra, U.K. Polarity inversion of N-face GaN by plasma-assisted molecular beam epitaxy. J. Appl. Phys. 2008, 104, 093710. [Google Scholar] [CrossRef]

- Wong, M.H.; Wu, F.; Speck, J.S.; Mishra, U.K. Polarity inversion of N-face GaN using an aluminum oxide interlayer. J. Appl. Phys. 2010, 108, 123710. [Google Scholar] [CrossRef]

- Sun, Q.; Selloni, A.; Myers, T.H.; Doolittle, W.A. Energetics of Mg incorporation at GaN(0001) and GaN (000 ) surfaces. Phys. Rev. B Condens. Matter Mater. Phys. 2006, 73, 1–9. [Google Scholar] [CrossRef]

- Li, L.K.; Jurkovic, M.J.; Wang, W.I.; Van Hove, J.M.; Chow, P.P. Surface polarity dependence of Mg doping in GaN grown by molecular-beam epitaxy. Appl. Phys. Lett. 2000, 76, 1740–1742. [Google Scholar] [CrossRef]

- Marini, J.; Mahaboob, I.; Hogan, K.; Novak, S.; Bell, L.D.; Shahedipour-Sandvik, F. Mg Incorporation Efficiency in Pulsed MOCVD of N-Polar GaN:Mg. J. Electron. Mater. 2017, 46, 5820–5826. [Google Scholar] [CrossRef]

- Zywietz, T.K.; Neugebauer, J.; Scheffler, M. The adsorption of oxygen at GaN surfaces. Appl. Phys. Lett. 1999, 74, 1695–1697. [Google Scholar] [CrossRef]

- Wetzel, C.; Suski, T.; Ager, J.W.; Weber, E.R.; Haller, E.E.; Fischer, S.; Meyer, B.K.; Molnar, R.J.; Perlin, P. Pressure induced deep gap state of oxygen in GaN. Phys. Rev. Lett. 1997, 78, 3923–3926. [Google Scholar] [CrossRef]

- Sumiya, M.; Yoshimura, K.; Ohtsuka, K.; Fuke, S. Dependence of impurity incorporation on the polar direction of GaN film growth. Appl. Phys. Lett. 2000, 76, 2098–2100. [Google Scholar] [CrossRef]

- Stolyarchuk, N.; Markurt, T.; Courville, A.; March, K.; Zúñiga-Pérez, J.; Vennéguès, P.; Albrecht, M. Intentional polarity conversion of AlN epitaxial layers by oxygen. Sci. Rep. 2018, 8, 14111. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.-R.; Singh, M.; Singh, J. Gate leakage suppression and contact engineering in nitride heterostructures. J. Appl. Phys. 2003, 94, 5826–5831. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reszka, A.; Korona, K.P.; Tiagulskyi, S.; Turski, H.; Jahn, U.; Kret, S.; Bożek, R.; Sobanska, M.; Zytkiewicz, Z.R.; Kowalski, B.J. Influence of Growth Polarity Switching on the Optical and Electrical Properties of GaN/AlGaN Nanowire LEDs. Electronics 2021, 10, 45. https://doi.org/10.3390/electronics10010045

Reszka A, Korona KP, Tiagulskyi S, Turski H, Jahn U, Kret S, Bożek R, Sobanska M, Zytkiewicz ZR, Kowalski BJ. Influence of Growth Polarity Switching on the Optical and Electrical Properties of GaN/AlGaN Nanowire LEDs. Electronics. 2021; 10(1):45. https://doi.org/10.3390/electronics10010045

Chicago/Turabian StyleReszka, Anna, Krzysztof P. Korona, Stanislav Tiagulskyi, Henryk Turski, Uwe Jahn, Slawomir Kret, Rafał Bożek, Marta Sobanska, Zbigniew R. Zytkiewicz, and Bogdan J. Kowalski. 2021. "Influence of Growth Polarity Switching on the Optical and Electrical Properties of GaN/AlGaN Nanowire LEDs" Electronics 10, no. 1: 45. https://doi.org/10.3390/electronics10010045

APA StyleReszka, A., Korona, K. P., Tiagulskyi, S., Turski, H., Jahn, U., Kret, S., Bożek, R., Sobanska, M., Zytkiewicz, Z. R., & Kowalski, B. J. (2021). Influence of Growth Polarity Switching on the Optical and Electrical Properties of GaN/AlGaN Nanowire LEDs. Electronics, 10(1), 45. https://doi.org/10.3390/electronics10010045