Abstract

The impact of heat production from vineyard pruning pellets has been evaluated in this paper. The study considers two different systems: the first one based on a mobile pelletizer (PS1) and the second one based on a stationary pellet plant (PS2). The analysis conducted is from “cradle to grave”; the systems under analysis includes pruning harvesting, transport to storage area, pelletization (mobile system or stationary production plant), transport to consumer and combustion. The functional unit selected is 1 MJ of thermal energy produced. The impact assessment calculation methods selected are Eco-Indicator 99 (H) LCA Food V2.103/Europe EI 99 H/A with a midpoint and endpoint approach, and ReCiPe Midpoint (H) V1.10. Considering Life Cycle Assessment results, Eco-indicator shows a total impact of 4.25 and 4.07 mPt for mobile pelletizer and stationary pellet plant, respectively. Considering the three damage categories, PS1 has values of 2.4% (Human Health), 3.8% (Ecosystem Quality) and 17.3% (Resources), more impactful than PS2. Contribution analysis shows that direct emissions are the major damage contributor, followed by wood ash management. From a comparison between the baseline scenario and a scenario with an avoided product (wood ash as a standard potassium fertilizer), PS1 and PS2 with an avoided product approach are 41% and 40% less impactful than in the baseline scenarios. When testing the impact of mobile pelletizer while considering transportation as a factor, a reduction of distance for pellet has been evaluated. Reducing the distance from 100 to 10 km, the total impact of PS1 almost reaches the impact of PS2 with a difference of around 4.6% (Eco-indicator 99 method). The most impactful processes are pellet production, direct emissions and ash management, while a less impactful factor is the electricity consumption. Transportation shows the lowest impact. Considering the ReCiPe impact calculation method with a midpoint approach, the results confirm what was found with Eco-indicator 99; the PS1 shows a slightly higher impact than PS2.

1. Introduction

The climate strategies and targets of the European Union (EU) have led to the establishment of a table of actions with a time horizon of about 40 years; a program of this length demonstrates the attention that the EU pays towards environmental issues. The first part of this program, approved under Directive 2009/28/EC, is currently nearing its conclusion. In 2020 the climate and energy package [1] will end, enabling the application of the Climate and Energy Framework 2030.

Although the objectives set by the 2020 energy package have been fundamentally achieved, the challenge of implementing the climate and energy framework and the even greater challenge of developing a low-carbon economy for 2050 will test European countries with regard to identifying systems and resources to reduce or even eliminate the carbon balance of activities related to the energy and transport sectors.

One of the most promising materials that can help achieve the climate strategies and target goals is biomass [2], from which bioenergy can be obtained through different procedures. According to the EU and several authors [3,4,5,6,7], bioenergy is crucial to achieving the objectives of the climate strategies and targets, although biomass materials are represented by a strongly heterogeneous set of biogenic materials that are difficult to standardize and model [8]. Biomass is also considered to be carbon neutral because the CO2 emitted by its combustion is the carbon dioxide stored during the growth of the biomass itself [9], and in general terms, biomass is also a temporary carbon sinking system. Lignocellulosic biomass is the most widespread and economically viable biomass option [10], and in the context of crop residues, it is the main raw material of lignocellulosic biomass obtained from agriculture [11,12]; it is therefore fundamental for sustainable biofuel production. In Europe it has been considered that between 2013 and 2020, the production of advanced biofuels doubled as an effect of the limitations imposed on fossil fuels, and due to the best environmental performances of renewable sources in reducing greenhouse gas (GHG) emissions [12].

Despite the numerous opportunities available, there are also critical issues related to the general sustainability of biofuels and the nature of the biomass from which they derive: residual biomass represents 46% of total biomass production for agricultural areas at the European level, with about 442 Mt as the average annual value of production from 2006 to 2015 [11].

Wood pellet is a renewable biofuel produced from sawdust or other milled woody materials. International standards defined the product requirements for wood pellets [13], and allowed them to turn into a commodity. Over the past 10 years, the production of wood pellets has increased steadily, driven by a corresponding constantly rising demand. For 2006, wood pellets production was estimated to be between 6 and 7 Mt, which expanded to a global level of 14.3 Mt in 2010 and exceeded 26 Mt in 2015 [14].

The pelletization process involves the densification of materials in terms of mass and energy. This effect is important for materials with a low bulk density, such as sawdust, straw and other herbaceous biomasses. This process reduces logistical costs, in turn enhancing the handling and feeding of the biomass [15].

Pellet quality is affected by the properties of raw materials and by the manufacturing process [16,17,18]. End-consumers are mainly affected by the energy content of the pellets, the emissions generated by pellet combustion and their effects on boiler and stove maintenance. Low-quality solid biofuels combustion can damage combustion equipment and produce slagging, corrosion and other operating problems, especially in small combustion devices.

The increase in the pellet market raised interest in producing pellets from woody residues coming from the forestry and agricultural sectors. The main issue associated with these materials is their relatively low and variable quality [3], but at the same time the use of residues is promoted for sustainability aspects. The use of residual raw materials for energy application is one of the main suggested strategies for mitigating various impacts.

One of the main sources of agricultural residues in Italy is vineyard pruning. The residue is currently considered as a problem by vineyard operators, who need to discard this material and often decide to burn it on fields, causing environmental pollution. A possible solution to this problem could be the production of agripellets from these pruning residues [19,20,21]. This would result in limiting the environmental problem caused by these pellets and simultaneously producing renewable energy. To evaluate this solution, the present study aims to assess the environmental impact of heat produced from vineyard pruning agripellets by means of a Life Cycle Assessment (LCA) [22,23]. Different scenarios considering mobile or stationary pellet systems, and based on primary data collected by the authors they were evaluated together with a comparison with other pellet and fossil alternatives. The mobile pellet system is an innovative solution already available on the market [24], but no studies on the sustainability assessment of this option are present in the literature. Although most studies consider direct emissions as estimated secondary data, in the present study such information was instead directly measured, and all the other information about pellet production is primary data.

2. Materials and Methods

2.1. Goal

The goal of the study is to assess the environmental impact of heat production and use, generated by the combustion of pellets produced from vineyard pruning residues. The functional unit (FU) selected is 1 MJ of heat production. Two different systems have been considered: PS1, considering a mobile pellet machine, and PS2, with a stationary pellet plant. PS1 and PS2 have been compared with two other alternative scenarios for heat production: AS1 (heat from methane), AS2 (heat from conventional pellet).

2.2. Scope

2.2.1. System Description

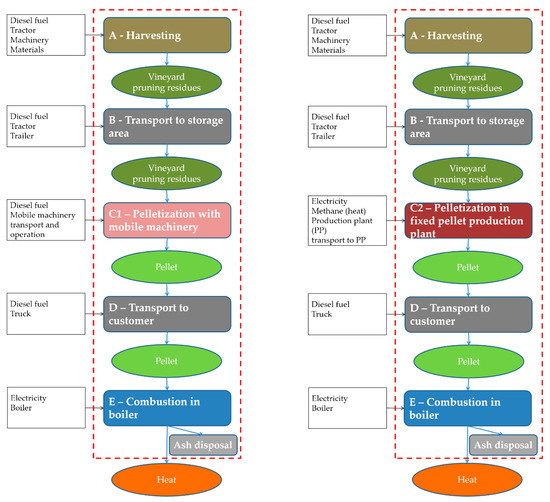

The study follows a cradle to grave perspective. The LCA model was developed considering the following subsystems:

- harvest of vineyard pruning residues (step A);

- transfer to storage area inside the vineyard district operated by tractor pulling a trailer (average distance 5 km) (step B);

- option (a) pelletization with mobile pellet machine (step C1); option (b) transport to the pellet plant and pelletization (step C2);

- pellet distribution to the consumer—only for PS1 (average distance 100 km) (step D), for PS2 it is assumed that the pellet production and heat generation are carried out in the same location;

- heat production in a 150 kW boiler (screw conveyor pellet boiler) (step E).

Two systems have been considered:

- PS1: steps A, B, C1, D, E;

- PS2: steps A, B, C2, E.

In step A, the harvest of vineyard pruning residues is carried out with a loader–shredder, a specific tractor-operated machinery (field capacity 1 ha/h) able to collect residues without contaminating the biomass with soil, and it also performs clear cutting to minimize the cut surface, limiting the related problems of biomass degradation during storage. The machine used is a patented pruning harvester, manufactured by Costruzioni Nazzareno (MAREV Alba 150 model).

Step B involves the use of a tractor pulling a trailer to transport the collected residues to a storage area, located at a mean distance of 5 km from the fields.

For step C two alternative scenarios have been considered:

- in C1 a mobile pellet machine is transported for 15 km to the storage area and employed for pellet production. The mobile pellet machine is diesel fueled and is constituted by a mill, a loader and a pellet machine. A detailed description is reported in a specific paper [24];

- in C2 vineyard pruning residues are transported for 15 km from the storage area to a pellet plant.

In step D the pellet is distributed by truck to the consumer covering a distance of 100 km.

In step E the pellet is burnt in a 150 kW boiler for heat production.

For comparison purposes the production of heat from methane (AS1) and from conventional pellet (AS2) have been considered as alternative scenarios.

The FU used to normalize the inventory data is 1 MJ heat. This FU facilitates the comparison with AS1 and AS2.

2.2.2. System Boundaries and Inventory

The system boundaries are displayed in Figure 1. Data regarding the steps were collected by interviews and scientific literature as detailed below.

Figure 1.

System boundaries of heat production from pellet of vineyard pruning residues: PS1 (sx) and PS2 (dx).

Step A considers energy (diesel fuel) and materials consumptions related to the machinery use. The related data were provided by the operators (farmers and machine manufacturer) according to the results of tests carried out in Illasi municipality (Veneto region). Tests have been performed on a 30 years vineyard trained as “tendone”.

The collected vineyard pruning residues were stored on the field side and covered with waterproof sheets for about eight months, until a moisture content of 18% w/w was reached. It should be noted that, in relation to the environmental conditions, the storage period can be reduced to about one month.

Step B considers energy (diesel fuel) and emissions for loading, transporting and unloading residues.

Data were provided by operators and also include the mean distance to storage area, which is 5 km.

Both step C1 and C2 consider the energy required for the pelletization process (heat and electricity). In C1 the mobile pellet machine transportation, for about 15 km, is considered along with the related diesel consumption. Data were measured and provided by the mobile pellet machine manufacturer.

In C2 the vineyard pruning transportation is considered, which is about 15 km from the storage area to a 1000 kg/h pellet plant.

In step D the mean transport distance of about 100 km from the pellet production site to the customer is considered, including the truck and its diesel consumption.

Taking into account that the pellet of vineyard pruning residues is not a conventional pellet, specific combustion tests were carried out in a 150 kW boiler to collect data on step E.

The boiler efficiency, ashes and emissions were directly measured so as to evaluate the specific solid biofuel employed.

Ash disposal: the average ash content of air-dried vineyard pruning was measured using a thermogravimetric balance (mod. TGA701, LECO), heating the biomass material up to 550 °C until weight stability.

2.3. Description of the Mobile Pellet Production System

The main system elements are the grinding mill, a 3 m3 buffer tank (for the milled material collection) and the pelleting machine. The three parts are connected by pipes, through which the material is moved using a pneumatic system. All the elements are mounted on a trailer for road transport, so as to process the material directly on the field or in dedicated farm structures. The loading of biomass into the hopper can be performed either manually or mechanically. From here, a conveyor system transports the material to the refining mill, which pulverizes it until the correct particle size, suitable for densification, is obtained. An electric fan pushes the milled material inside the buffer tank, where it is stirred by a flywheel. The tank is equipped with a filter to reduce dust emission.

Subsequently, the material is transported to the press of the pelleting system. The pelletizer has a 6 mm diameter extruder, while the grinding mill has a grid of 1 mm mesh size.

The mobile pelletizer (Figure 2) is composed of the same elements as a fixed pelletizing plant. The system is constituted by a hopper, used to dose incoming material, and a grinder mill to reduce the particle size to 1 mm. From the grinder the wood dust is moved pneumatically to the storage tank, used to guarantee the regular input supply for the pelletizing machine. In the lower part of the tank a screw conveyor picks up a pre-set quantity of material and raises it up to feed the pelletizer. The last part of the system is the pelletizer (6 mm diameter extruder) formed by a screw feeding system and a horizontal compression system that forms the pellet, which is then released. The system working capacity is about 800 kg/h and all the parts are carried on a platform that can be combined with a transportation means, such as a truck or a tractor. The total weight of the machine is 3.35 t. Both the grinding mill and the pelleting system are powered by a 35 kW electrical engine.

Figure 2.

Mobile pelletizer machine. From the left: hopper, mill grinder, storage tank, pellet machine (courtesy of Costruzioni Nazzareno Srl).

2.4. Boiler Description

The boiler used for combustion tests is a KWB model Powerfire TDS 150 located in Cascina Clarabella, a farmhouse situated between Iseo and Corte Franca (province of Brescia, Italy); the combustion system is based on a rotating grate and a cyclonic combustion chamber. The total efficiency of the boiler is about 92.5%. The analyzer used to evaluate the gas composition is a gas analyzer (mod Vario plus, MRU). Total suspended particles (TSP) were collected by an automatic isokinetic sampler (mod. Isostack Basic, TECORA).

2.5. Pellet Characteristics

Table 1 reports the specific characterization of the vineyard pruning pellets considered, essential as inventory information. Analyses have been conducted in the Biomass Lab of the Department of Agricultural, Food and Environmental Sciences (D3A)—Università Politecnica delle Marche—using specific equipment as required by the technical standards mentioned in the table.

Table 1.

Characterization of vineyard pruning pellet for proximate, ultimate and heating parameters.

With respect to heat production, the information related to both the used machinery and the electricity consumption refer to similar processes contained in the Ecoinvent Database. Quite the opposite is the case for the vineyard pellet combustion emissions; since the impacts related to some categories are very significant, a series of measurements of CO, NOx, SOx, hydrocarbons, particulate matter and ashes in the boiler were carried out. This considers the real characteristics of this biofuel and its behavior in real combustion devices.

2.6. Impact Assessment

The impact assessment methods selected are Eco-Indicator 99 (H) LCA Food V2.103/Europe EI 99 H/A with an endpoint approach and ReCiPe Midpoint (H) V1.10. The Eco-Indicator 99 includes 11 impact categories as reported in Table 2 at the midpoint level; they are grouped and weighed in three damage categories at the endpoint level: Human Health, Ecosystem Quality and Resources.

Table 2.

Eco-Indicator 99 method, impact categories and units.

The selected ReCiPe method has 18 impact categories, as reported in Table 3. The utilized version is the hierarchist one, with the hierarchist European normalization model.

Table 3.

ReCiPe method, impact categories and units at midpoint level.

The impact assessment methods previously described have been selected for comparison purposes with other studies on LCA of pellet produced from woody biomass.

3. Results and Discussion

Analysis of the Produced Pellets

Considering the direct emissions for CO, NOx and TSP (total suspended particles), the results of measurements are 4.8 × 10−5 kg/MJ, 1.2 × 10−4 kg/MJ and 7.2 × 10−5 kg/MJ, respectively.

Table 4 shows the results for Eco-indicator 99 for PS1 and PS2. The first option (mobile pelletizer system) shows a higher impact (around 4.3%) than PS2; this is due to the impact generated by transportation of the pellet mobile system, and to the impact relative to the wood ash mixture. The pellet production indicates the lower impact of the pellet production plant than the mobile system, but with very limited differences.

Table 4.

Total impact and contribution of PS1 and PS2, method adopted: Eco-indicator 99 (H) LCA Food V2.103/Europe EI 99 H/A with endpoint approach.

The actual impact evaluation considers ashes as a residue with no specified value, and a potential use as fertilizer or raw material for fertilizers production. Unfortunately, due to the absence of essential information, it would be incorrect to define a standard allocation procedure for input/output of ashes. In this paper two different approaches have been considered and evaluated in order to underline the differences between waste management and the avoided impact procedure for ashes. In the first case (baseline) a process for ash disposal has been considered, applying a negative value in order to exclude from the total impact the one derived from the ash disposal. In the second case (avoided product), following the standard approach, ashes have been considered as a substitute for potassium fertilizer. In Table 5 the results of the analysis are reported.

Table 5.

Impact Eco-indicator 99 for PS1 and PS2 baseline (considering avoided ash waste management) and PS1 and PS2 avoided product (considering the avoided production of potassium fertilizer).

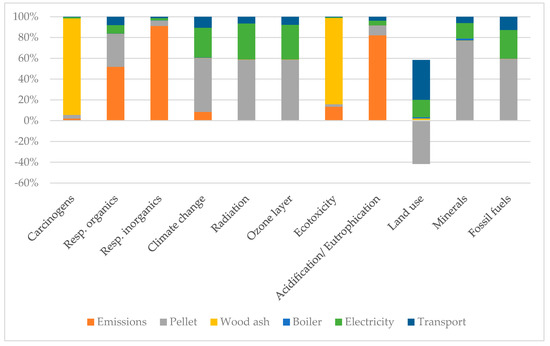

Employing a midpoint approach, the contribution analysis of PS1 shows the high impact of the wood ash mixture on carcinogens and ecotoxicity; the pellet production instead has more impact on respiratory (organics and inorganics) and acidification/eutrophication. The infrastructures (mobile pellet plant and boiler) show a relevant impact on climate change, radiation, ozone layer, minerals and fossil fuels. For land use, the pellet production shows a negative impact (credit) of about 25%. Electricity has a relevant impact only on climate change, radiation, ozone layer and fossil fuels (Figure 3).

Figure 3.

Eco-indicator 99 midpoint approach PS1.

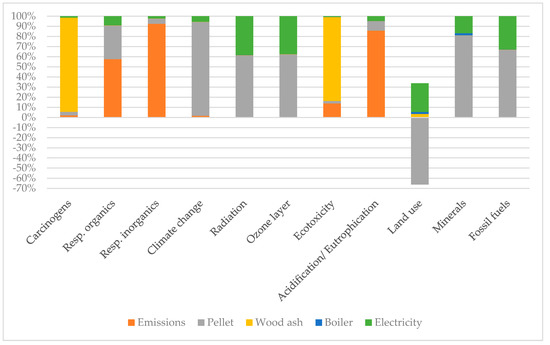

Ecoindicator 99 for PS2 (Figure 4) shows the relevant effects of direct emissions on Respiratory organics, Respiratory inorganics and Acidification/Eutrophication. On land use, the impact of the pellet is negative, as in the previous case, but it makes a relevant contribution in all the other categories except Carcinogens, Respiratory inorganics, Ecotoxicity and Acidification/Eutrophication.

Figure 4.

Eco-indicator 99 midpoint approach PS2.

The last consideration is about transport impact: a simulation has been conducted in order to evaluate how much the transport of a pellet from the mobile pelletizer system (PS1) should be reduced in order to reach the impact of the pelletization plant scenario (PS2). As shown in Table 6, considering a final transport of 10 km instead of 100 km (distance set in the baseline scenario), the impact of PS1 (with reduced transport distance) is almost the same as that of PS2.

Table 6.

Impact comparison for PS2 and PS1 with a reduced pellet transportation distance (from 100 to 10 km). LCIA method Ecoindicator 99 endpoint approach.

Considering ReCiPe Midpoint (H) V1.10, total impact and contribution are reported in Table 7 for PS1 and Table 8 for PS2.

Table 7.

Contribution analysis for PS1 using ReCiPe Midpoint (H) V1.10 characterization model.

Table 8.

Contribution analysis for PS2 using ReCiPe Midpoint (H) V1.10 characterization model.

The direct emissions have an impact mainly on TA, ME, POF, PMF and TET. Pellet boiler has a relevant impact on ULO, NLT and MD. Wood ash management is the major contributor to FE, HT, TET and MET, while for all the other impact categories the contribution is negligible. Pellet production makes a relevant contribution to CC, OD, IR, ALO, ULO, NLT, WD, MD and FD, while less impact is reported for all the other categories. Electricity has an impact on all the categories, but this is higher for CC, OD, IR, ALO, WD and FD. PS1 pellet transportation only has a relevant impact on ULO, and its impact is less evident on all the other categories. The negative impact of wood ash on NLT should be mentioned. This negative impact is due to the approach used in baseline ash management.

From the comparison of PS1 with AS1, AS2 and the heat production of the short rotation coppice (SRC) pellet [25], reported in Table 9, it is clear that PS1 and AS1 have the same total impact, but considering the single damage categories, PS1 shows a higher impact on Human Health, while AS1 has a higher impact on Resources. Regarding AS2, the Ecoinvent process selected considers a 50 kW boiler (instead the 150 kW one of PS1), and the impact calculated is higher than PS1 and AS1. Regarding heat from SRC, the impact distribution between the damage categories is quite similar to that for PS1, except for Resources. This is due to the use of agricultural inputs for SRC that are completely allocated to the wood produced. On the contrary, for vineyard pruning, no input or impact allocations have been considered.

Table 9.

Comparison between different systems of heat production (method used: Ecoindicator 99).

The results of this study show that, in comparison to a big pelletizing plant, the production of a vineyard pruning pellet with a mobile system is slightly more impactful. Considering different approaches to ash management, such as negative values or avoided product, the relative impact is significantly different and higher for PS1 and PS2 baseline scenarios. This means that the avoided product (avoided production of potassium fertilizer) choice is relevant, and must be carefully considered so as to obtain the most accurate evaluation of the process under analysis. As regards the pellet transportation (PS1), it has an impact of low relevance, but is one of the unit process that can be subject to variations in order to simulate the effects on the final impact, and to define scenarios which, although only slightly improving sustainability, can then be really applied. In detail, by reducing the distance from 100 to 10 km, the relative impact is reduced by around 2%, approaching the impact of PS2. Compared to the reference supply chain (methane), both the considered pellet production scenarios are slightly different from, and relatively lower than, methane. It should be noted that pelletization is likely to be a substitute for more impactful fossil fuels like LPG, and the impact saving should be significantly higher in that case.

Considering the ReCiPe method with the midpoint approach, the impact of PS1 is higher than PS2 for all the considered categories. The contribution analysis shows that the most impactful unit processes are pellet production, direct emissions from pellet combustion and ash management. The less impactful ones are boiler, electricity and transportation (for PS1).

The choice of the ash management system, which represents the third contributor to the total impact, makes a substantial difference to the total impact. In the baseline scenario, the ashes are considered as a normal input, to which a negative value is applied (equivalent to the ash value per functional unit). In the alternative scenario, however, as suggested by many authors, the ashes are considered through an avoided product approach; specifically, the ashes are considered as a substitute for a common potassium fertilizer. The resulting impact is appreciably different, and in favor of the avoided product scenario that shows a lower impact. The reference standard considers the avoided product as one of the best procedures for estimating the impact of co-products or by-products with a potential use. In this specific case, to consider ashes as a potassium fertilizer may not be the best choice due to the low standardization of the ashes and the possible regulatory limits which make ashes unsuitable to use as a fertilizer, and therefore make the replacement procedure difficult to apply. Another noteworthy issue relates to the negative impact of pellet production on the category of Land Use for the Eco-indicator 99 with midpoint approach, due to the use of residual biomass produced by the vine production chain. For ReCiPe, the negative impact of ash on natural land transformation has a similar justification.

4. Conclusions

The impacts of the production and use methods related to vineyard pruning pellets assessed in this case study, using the life cycle assessment method and the Eco-indicator 99 characterization model, are 4.07 mPt and 4.25 mPt for the fixed pelletizing plant and mobile pelletizer, respectively. Regarding Eco-indicator, the major contributors to the final impact are emissions and ash management, which contribute mostly to human health and ecosystem quality. Compared to a standard production chain for heat production that employs methane, the impact found is similar or slightly lower, and the only differences are found in relation to the contribution to damage categories. Vineyard pruning pellet production and combustion contribute mostly to human health and ecosystem quality, while on the other hand methane has a higher impact on resources. Despite the similar total impact, the different distribution of impacts is due to the peculiarities of each production chain. The use of methane as a heat source is by nature more strongly associated with its impact on the use of resources, and less on its impacts on the ecosystem and human health, due to the high efficiency of the combustion systems used and also to the nature of the fuel itself. When the vineyard pruning pellet comes from agricultural systems instead, the raw product and the pellet have more impact on human health and the ecosystem because of the use of transportation means, and agricultural inputs and outputs. The 90% reduction of transportation distance for PS1 leads to a decrease of total impact of about 2%. Compared to the reference chain (methane), the heat produced by the vineyard pruning pellet is less impactful thanks to a reduced use of resources. Considering other studies [25] on heat production by the pellet, it is possible to find values considerably lower than the ones obtained for this case study. In detail, the impact is significantly lower for the human health category, is almost the same for ecosystem quality, and is slightly higher for resources. These differences could be due to the more efficient combustion resulting from a better fuel quality. The impact distribution found by Fantozzi et al. [25] with respect to PS1 and PS2 is due to the use of more resources for wood production (input of fertilizers and fuels for SRC field operations).

Despite the low saving achievable with the use of pellets derived from vineyard pruning residues, in all the cases it should be pointed out that the use of this solid biofuel can simultaneously help avoid the combustion of these materials directly on the field without a specific combustion device. This can save a significant amount of direct emissions affecting global warming, and even reduce more ecosystem toxicity and impacts on human health.

Author Contributions

Conceptualization, D.D. and G.T.; methodology, A.I. and D.D.; software, A.I.; validation, E.F.P., S.F. and A.I.; formal analysis, D.D., A.I. and S.F.; investigation, A.I. and D.D.; resources, A.I. and D.D.; data curation, A.I. and D.D.; writing—original draft preparation, A.I. and D.D.; writing—review and editing, A.I., D.D., E.F.P. and G.T.; visualization, A.I.; supervision, D.D. and G.T.; project administration, A.I. and D.D.; funding acquisition, E.F.P and G.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

| FU | Functional Unit |

| LPG | Liquefied Petroleum Gas |

| PS1 | Production System 1, composed of steps A, B, C1, D, E |

| PS2 | Production System 2, composed of steps A, B, C2, E |

| PS1avoided | PS1 with avoided product approach |

| PS2avoided | PS2 with avoided product approach |

| AS1 | Alternative System 1, boiler system powered by methane |

| AS2 | Alternative System 2, boiler system powered by wood pellet |

| CC | Climate Change |

| OD | Ozone Depletion |

| TA | Terrestrial Acidification |

| FE | Freshwater Eutrophication |

| ME | Marine Eutrophication |

| HT | Human Toxicity |

| POF | Photochemical Oxidant Formation |

| PMF | Particulate Matter Formation |

| TET | Terrestrial Eco-Toxicity |

| FET | Freshwater Eco-Toxicity |

| MET | Marine Eco-Toxicity |

| IR | Ionising Radiation |

| ALO | Agricultural Land Occupation |

| ULO | Urban Land Occupation |

| NLT | Natural Land Transformation |

| WD | Water Depletion |

| MD | Mineral Resource Depletion |

| FD | Fossil fuel Depletion |

References

- European Union. DIRECTIVE 2009/28/EC (Renewable Energy Directive) on the Promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC. 2009. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32009L0028 (accessed on 15 July 2020).

- Statuto, D.; Frederiksen, P.; Picuno, P. Valorization of Agricultural By-Products within the “Energyscapes”: Renewable Energy as Driving Force in Modeling Rural Landscape. Nat. Resour Res. 2019, 28, 111–124. [Google Scholar] [CrossRef]

- Duca, D.; Toscano, G.; Pizzi, A.; Rossini, G.; Fabrizi, S.; Lucesoli, G.; Servili, A.; Mancini, V.; Romanazzi, G.; Mengarelli, C. Evaluation of the characteristics of vineyard pruning residues for energy applications: Effect of different copper-based treatments. J. Agric. Eng. 2016, 47, 22–27. [Google Scholar] [CrossRef]

- Pizzi, A.; Foppa Pedretti, E.; Duca, D.; Rossini, G.; Mengarelli, C.; Ilari, A.; Mancini, M.; Toscano, G. Emissions of heating appliances fuelled with agropellet produced from vine pruning residues and environmental aspects. Renew. Energy 2018, 121, 513–520. [Google Scholar] [CrossRef]

- European Union—Directorate General for Research and Innovation. Innovating for Sustainable Growth: A Bioeconomy for Europe. 2012. Available online: https://op.europa.eu/en/publication-detail/-/publication/1f0d8515-8dc0-4435-ba53-9570e47dbd51 (accessed on 15 July 2020).

- Zawiślak, K.; Sobczak, P.; Kraszkiewicz, A.; Niedziółka, I.; Parafiniuk, S.; Kuna-Broniowska, I.; Tanas, W.; Zukiewicz-Sobczak, W.; Obidzinski, S. The use of lignocellulosic waste in the production of pellets for energy purposes. Renew. Energy 2020, 145, 997–1003. [Google Scholar] [CrossRef]

- Kumari, D.; Singh, R. Pretreatment of lignocellulosic wastes for biofuel production: A critical review. Renew. Sustain. Energy Rev. 2018, 90, 877–891. [Google Scholar] [CrossRef]

- Fowler, P.; Krajačić, G.; Lončar, D.; Duić, N. Modeling the energy potential of biomass—H2RES. Int. J. Hydrogen Energy 2009, 34, 7027–7040. [Google Scholar] [CrossRef]

- García, R.; Gil, M.V.; Rubiera, F.; Pevida, C. Pelletization of wood and alternative residual biomass blends for producing industrial quality pellets. Fuel 2019, 251, 739–753. [Google Scholar] [CrossRef]

- Tojo, S.; Hirasawa, T.; Qian, E.W. Pretreatment and Saccharification of Lignocellulosic Biomass. Res. Approaches Sustain. Biomass Syst. 2014, 7, 181–204. [Google Scholar] [CrossRef]

- García-Condado, S.; López-Lozano, R.; Panarello, L.; Cerrani, I.; Nisini, L.; Zucchini, A.; Van der Velde, M.; Baruth, B. Assessing lignocellulosic biomass production from crop residues in the European Union: Modelling, analysis of the current scenario and drivers of interannual variability. GCB Bioenergy 2019, 11, 809–831. [Google Scholar] [CrossRef]

- Bourguignon, D.; Vandenbussche, T. European Parliamentary Research Service: Advanced Biofuels: Technologies and EU Policy. Available online: https://www.europarl.europa.eu/thinktank/en/document.html?reference=EPRS_BRI(2017)603972 (accessed on 15 July 2020).

- UNI EN ISO 17225-2:2014. Biocombustibili Solidi—Specifiche e Classificazione del Combustibile—Parte 2: Definizione Delle Classi di Pellet di Legno; UNI, the Italian Organization for Standardization: Milan, Italy, 2014; Available online: http://store.uni.com/catalogo/uni-en-iso-17225-2-2014 (accessed on 15 July 2020).

- Thrän, D.; Peetz, D.; Schaubach, K. Global wood pellet industry and trade study 2017. IEA Bioenergy Task 40. 2017. Available online: https://www.ieabioenergy.com/publications/global-wood-pellet-industry-and-trade-study-2017/ (accessed on 15 July 2020).

- Toscano, G.; Duca, D.; Amato, A.; Pizzi, A. Emission from realistic utilization of wood pellet stove. Energy 2014, 68, 644–650. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Arshadi, M.; Gref, R.; Geladi, P.; Dahlqvist, S.A.; Lestander, T. The influence of raw material characteristics on the industrial pelletizing process and pellet quality. Fuel Process. Technol. 2008, 89, 1442–1447. [Google Scholar] [CrossRef]

- Ståhl, M.; Berghel, J.; Frodeson, S.; Granström, K.; Renström, R. Effects on Pellet Properties and Energy Use When Starch Is Added in the Wood-Fuel Pelletizing Process. Energy Fuels 2012, 26, 1937–1945. [Google Scholar] [CrossRef]

- Bisaglia, C.; Brambilla, M.; Cutini, M.; Bortolotti, A.; Rota, G.; Minuti, G.; Sargiani, R. Reusing pruning residues for thermal energy production: A mobile app to match biomass availability with the heating energy balance of agro-industrial buildings. Sustainability 2018, 10, 4218. [Google Scholar] [CrossRef]

- Algieri, A.; Andiloro, S.; Tamburino, V.; Zema, D.A. The potential of agricultural residues for energy production in Calabria (Southern Italy). Renew. Sustain. Energy Rev. 2019, 104, 1–14. [Google Scholar] [CrossRef]

- Colonna, N. Biomass to Energy Options to Avoid Open Burning Emissions: An Italian Successful Case Study. 2019. Available online: https://www.researchgate.net/publication/336799693_Biomass_to_Energy_options_to_avoid_open_burning_emissions_an_Italian_successful_case_study (accessed on 15 July 2020).

- ISO 14040-2006. Environmental Management—Life Cycle Assessment—Principles and Framework. 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 15 July 2020).

- ISO 14044-2006. Environmental Management—Life Cycle Assessment—Requirements and Guidelines. 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 15 July 2020).

- Toscano, G.; Alfano, V.; Scarfone, A.; Pari, L. Pelleting Vineyard Pruning at Low Cost with a Mobile Technology. Energies 2018, 11, 2477. [Google Scholar] [CrossRef]

- Fantozzi, F.; Buratti, C. Life cycle assessment of biomass chains: Wood pellet from short rotation coppice using data measured on a real plant. Biomass Bioenergy 2010, 34, 1796–1804. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).