An Environmental Assessment of Interlocking Concrete Blocks Mixed with Sugarcane Residues Produced in Okinawa

Abstract

1. Introduction

2. Interlocking Concrete Blocks

2.1. Materials

2.2. Concrete Mixture

2.3. Preparation of Blocks

2.4. Flexural Strength Test

3. Environmental Assessment

3.1. Goal and Scope

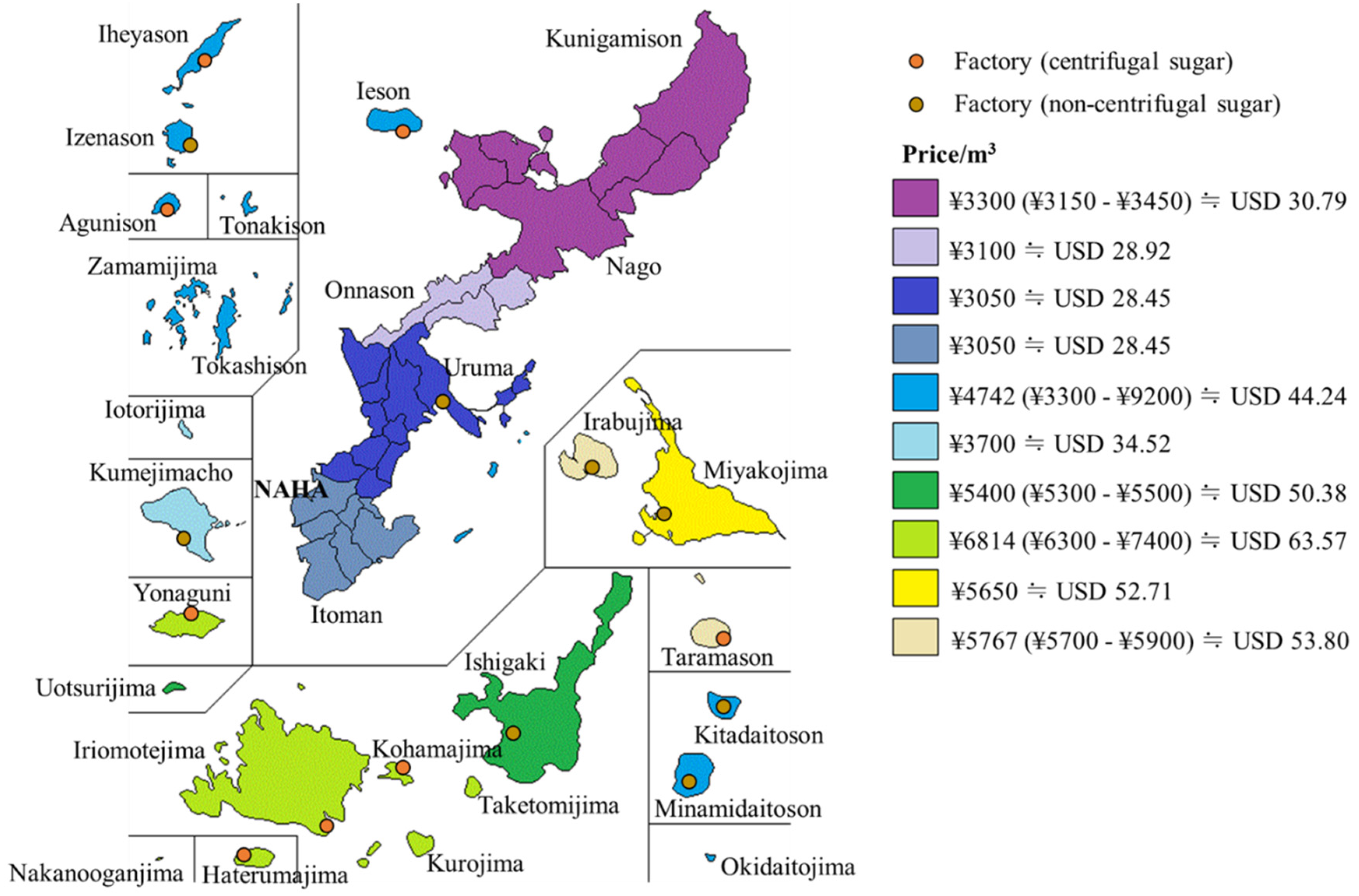

3.2. System Boundaries of Scenarios

3.3. Inventory

4. Results and Discussion

4.1. Flexural Strength Test

4.2. Environmental Load Associated With Production of Interlocking Concrete Blocks

4.3. Cost Analysis Associated With Production of Interlocking Concrete Blocks

5. Conclusions

6. Future Plans

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- FAO. FAOSTAT Online Database. Available online: http://faostat.fao.org/ (accessed on 30 October 2019).

- Mustafa, G.; Joyia, F.A.; Anwar, S.; Parvaiz, A.; Khan, M.S. Biotechnological Interventions for the Improvement of Sugarcane Crop and Sugar Production; Sugarcane-Technology and Research; IntechOpen: London, UK, 2018. [Google Scholar]

- Prusty, J.K.; Patro, S.K.; Basarkar, S.S. oncrete using agro-waste as fine aggregate for sustainable built environment–A review. Int. J. Sustain. Built Environ. 2016, 5, 312–333. [Google Scholar] [CrossRef]

- Teixeira, S.R.; Arenales, A.; de Souza, A.E.; da Silva Magalhães, R.; Peña, A.F.V.; Aquino, D.; Freire, R. Sugarcane bagasse: Applications for energy production and ceramic materials. J. Solid Waste Technol. Manag. 2015, 229–238. [Google Scholar] [CrossRef]

- Sales, A.; Lima, S.A. Use of Brazilian sugarcane bagasse ash in concrete as sand replacement. Waste Manag. 2010, 30, 1114–1122. [Google Scholar] [CrossRef] [PubMed]

- Almeida, F.C.R.; Sales, A.; Moretti, J.P.; Mendes, P.C.D. Sugarcane bagasse ash sand (SBAS): Brazilian agroindustrial by-product. Constr. Build. Mater. 2015, 82, 31–38. [Google Scholar] [CrossRef]

- Martirena Hernández, J.F.; Middendorf, B.; Gehrke, M.; Budelmann, H. Use of wastes of the sugar industry as pozzolana in lime-pozzolana binders: Study of the reaction. Cem. Concr. Res. 1998, 28, 1525–1536. [Google Scholar] [CrossRef]

- Chusilp, N.; Jaturapitakkul, C.; Kiattikomol, K. Effects of LOI of ground bagasse ash on the compressive strength and sulfate resistance of mortars. Constr. Build. Mater. 2009, 23, 3523–3531. [Google Scholar] [CrossRef]

- Umamaheswaran, K.; Batra, V.S. Physico-chemical characterisation of Indian biomass ashes. Fuel 2008, 87, 628–638. [Google Scholar] [CrossRef]

- Rovani, S.; Santos, J.J.; Corio, P.; Fungaro, D.A. An Alternative and Simple Method for the Preparation of Bare Silica Nanoparticles Using Sugarcane Waste Ash, an Abundant and Despised Residue in the Brazilian Industry. J. Braz. Chem. Soc. 2019, 30, 1524–1533. [Google Scholar] [CrossRef]

- Faria, K.C.P.; Gurgel, R.F.; Holanda, J.N.F. Recycling of sugarcane bagasse ash waste in the production of clay bricks. J. Environ. Manag. 2012, 101, 7–12. [Google Scholar] [CrossRef]

- Schettino, M.A.S.; Holanda, J.N.F. Characterization of Sugarcane Bagasse ash Waste for Its Use in Ceramic Floor Tile. Procedia Mater. Sci. 2015, 8, 190–196. [Google Scholar] [CrossRef]

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- Van Ruijven, B.J.; van Vuuren, D.P.; Boskaljon, W.; Neelis, M.L.; Saygin, D.; Patel, M.K. Long-term model-based projections of energy use and CO2 emissions from the global steel and cement industries. Resour. Conserv. Recycl. 2012, 112, 15–36. [Google Scholar] [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Utilization of solid waste materials as alternative fillers in asphalt mixes: A review. Constr. Build. Mater. 2020, 234, 117271. [Google Scholar] [CrossRef]

- Faleschini, F.; Zanini, M.A.; Pellegrino, C.; Pasinato, S. Sustainable management and supply of natural and recycled aggregates in a medium-size integrated plant. Waste Manag. 2016, 49, 146–155. [Google Scholar] [CrossRef] [PubMed]

- Seki, H.; Otsuki, N. Properties of Aggregates in Okinawa for Use of Concrete Materials; Technical Note of the Port and Harbour Research Institute; Ministry of Transportation: Tokyo, Japan, 1976; Volume 240. (In Japanese)

- Okinawa Prefectural Civil Engineering Construction Department. Okinawa Prefectural Civil Engineering Construction Department, Detailed Design Unit Price List, October 2019; Okinawa Prefectural Civil Engineering Construction Department: Naha, Japan, 2019; Available online: https://www.pref.okinawa.jp/site/doboku/gijiken/tanka/documents/r110_tanka.pdf (accessed on 27 May 2020). (In Japanese)

- Kai, K.C. Sekisan Shiryo; January 2020 Issue. Keizai Chosa Kai: Tokyo, Japan, 2020. (In Japanese).

- Okinawa Prefectural Government. Prefecture Sugar Production Related Organizations; Okinawa Prefectural Government. Available online: https://www.pref.okinawa.jp/site/norin/togyo/index.html (accessed on 27 June 2020). (In Japanese).

- Ribeiro, B.; Yamashiki, Y.; Yamamoto, T. A study on mechanical properties of mortar with sugarcane bagasse fiber and bagasse ash. J. Mater. Cycles Waste Manag. 2020. [Google Scholar] [CrossRef]

- Japan to Cut Coal-Fired Power Generation by 90%; NHK World Japan: Tokyo, Japan. Available online: https://www3.nhk.or.jp/nhkworld/en/news/20200702_19/ (accessed on 3 July 2020).

- Ferreira, C.R.; Tavares, S.S.; Ferreira, B.H.M.; Fernandes, A.M.; Fonseca, S.J.G.; de Oliveira, C.A.; Teixeira, R.L.P.; de Gouveia, L.L. Comparative study about mechanical properties of strutural standard concrete and concrete with addition of vegetable fibers. Mater. Res. 2017, 20, 102–107. [Google Scholar] [CrossRef]

- Cabral, M.R.; Fiorelli, J.; Junior, H.S.; Lagacé, R.; Godbout, S.; Palacios, J.H. Study of the Potential Use of the Sugarcane Bagasse in Cement-Panels. In Proceedings of the 10th International Conference on Composite Science and Technology, Lisbon, Portugal, 2–4 September 2015. [Google Scholar]

- Arsène, M.; Okwo, A.; Bilba, K.; Soboyejo, A.B.O.; Soboyejo, W.O. Chemically and thermally treated vegetable fibers for reinforcement of cement-based composites. Mater. Manuf. Process. 2007, 22, 214–227. [Google Scholar] [CrossRef]

- Ribeiro, B.; Yamamoto, T.; Yamashiki, Y. A Study on the Reduction in Hydration Heat and Thermal Strain of Concrete with Addition of Sugarcane Bagasse Fiber. Materials 2020, 13, 13. [Google Scholar] [CrossRef]

- De Brito, J.; Robles, R. Recycled aggregate concrete (RAC) methodology for estimating its long-term properties. Indian J. Eng. Mater. Sci. 2010, 17, 449–462. [Google Scholar]

- Kawai, K. Environmental load evaluation of concrete. Concr. J. 2012, 50, 554–561. (In Japanese) [Google Scholar]

- Concrete Engineering Series; Japan Society of Civil Engineers: Tokyo, Japan, 2004; Volume 62.

- Parr, J.F.; Sullivan, L.A. Sugarcane the Champion Crop at Carbon Sequestration; Canegrower: Brisbane, Australia, 2007; pp. 14–15. [Google Scholar]

- Cooper, C.D. Introduction to Environmental Engineering; Waveland Press: Long Grove, IL, USA, 2014. [Google Scholar]

- Arimura, T.H.; Abe, T. The impact of the Tokyo emissions trading scheme on office buildings: What factor contributed to the emission reduction? Environ. Econ. Policy Stud. 2020. [Google Scholar] [CrossRef]

| Properties | Materials | ||||||

|---|---|---|---|---|---|---|---|

| Surface Layer | Base Layer | ||||||

| WPC | QS | C | G | S | BFL | BS | |

| Density (g/cm3) | 3.05 | 2.60 | 3.16 | 2.68 | 2.68 | 0.49 | 1.29 |

| Total alkali content (%) | 0.1 | — | 0.56 | — | — | — | — |

| Specific surface area (cm2/g) | 3440 | — | 3280 | — | — | — | — |

| Loss on ignition (%) | 2.79 | — | 2.26 | — | — | — | — |

| Layer | Composites | Residues | Residues | w/c | Unit (kg/m3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | (Vol. %) | WPC | QS | C | W | G | S | BFL | BS | CA | |||

| Surface | ― | ― | ― | 0.25 | 582.6 | 1721.7 | ― | 145.6 | ― | ― | ― | ― | 1.2 |

| Base | C | ― | ― | 0.15 | ― | ― | 436.1 | 64.0 | 1068.0 | 1068.0 | ― | ― | 1.1 |

| BFL2 | Bagasse Fiber | 2 | ― | ― | 1046.6 | 1046.6 | 7.8 | ― | 1.1 | ||||

| BS | Bagasse Fiber | 2 | ― | ― | 993.2 | 993.2 | 7.8 | 51.4 | 1.1 | ||||

| Bagasse Sand | 5 | ― | ― | ||||||||||

| Unit | Carbon Dioxide | Sulfur Oxide | Nitrogen Oxide | Dust and Soot | |

|---|---|---|---|---|---|

| (*) | (kg-CO2/*) | (kg-SOx/*) | (kg-NOx/*) | (kg-PM/*) | |

| Fine aggregate | kg/t | 3.7 | 0.00860 | 0.00586 | 0.00199 |

| Coarse aggregate | kg/t | 2.9 | 0.00607 | 0.00415 | 0.00141 |

| Dump truck | km·t | 0.117 | 0.0000901 | 0.000875 | 0.0000735 |

| Vessel | km·t | 0.162 | 0.00280 | 0.00470 | 0.0000721 |

| Scenario | Transportation | Route | Distance (km) | |

|---|---|---|---|---|

| From/To | Fine and Coarse Aggregate | Residues | ||

| Main Island | dump truck 1 | Motobu/Uruma | 51.4 | ― |

| dump truck 2 | Uruma/Uruma | ― | 9.5 | |

| Minamidaito | dump truck 3 | Motobu/Naha | 85.7 | ― |

| dump truck 4 | Minamidaito/Minamidaito | ― | 5.5 | |

| vessel 1 | Naha/Minamidaito | 388 | ― | |

| Yonaguni | dump truck 5 | Yonaguni/Yonaguni | ― | 6.0 |

| vessel 2 | Ishigaki/Yonaguni | 131 | ― | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ribeiro, B.; Uchiyama, T.; Tomiyama, J.; Yamamoto, T.; Yamashiki, Y. An Environmental Assessment of Interlocking Concrete Blocks Mixed with Sugarcane Residues Produced in Okinawa. Resources 2020, 9, 93. https://doi.org/10.3390/resources9080093

Ribeiro B, Uchiyama T, Tomiyama J, Yamamoto T, Yamashiki Y. An Environmental Assessment of Interlocking Concrete Blocks Mixed with Sugarcane Residues Produced in Okinawa. Resources. 2020; 9(8):93. https://doi.org/10.3390/resources9080093

Chicago/Turabian StyleRibeiro, Bruno, Tadaaki Uchiyama, Jun Tomiyama, Takashi Yamamoto, and Yosuke Yamashiki. 2020. "An Environmental Assessment of Interlocking Concrete Blocks Mixed with Sugarcane Residues Produced in Okinawa" Resources 9, no. 8: 93. https://doi.org/10.3390/resources9080093

APA StyleRibeiro, B., Uchiyama, T., Tomiyama, J., Yamamoto, T., & Yamashiki, Y. (2020). An Environmental Assessment of Interlocking Concrete Blocks Mixed with Sugarcane Residues Produced in Okinawa. Resources, 9(8), 93. https://doi.org/10.3390/resources9080093