Basalt Rock Powder in Cementitious Materials: A Systematic Review

Abstract

1. Introduction

2. Cementitious Materials

3. Mining Industry

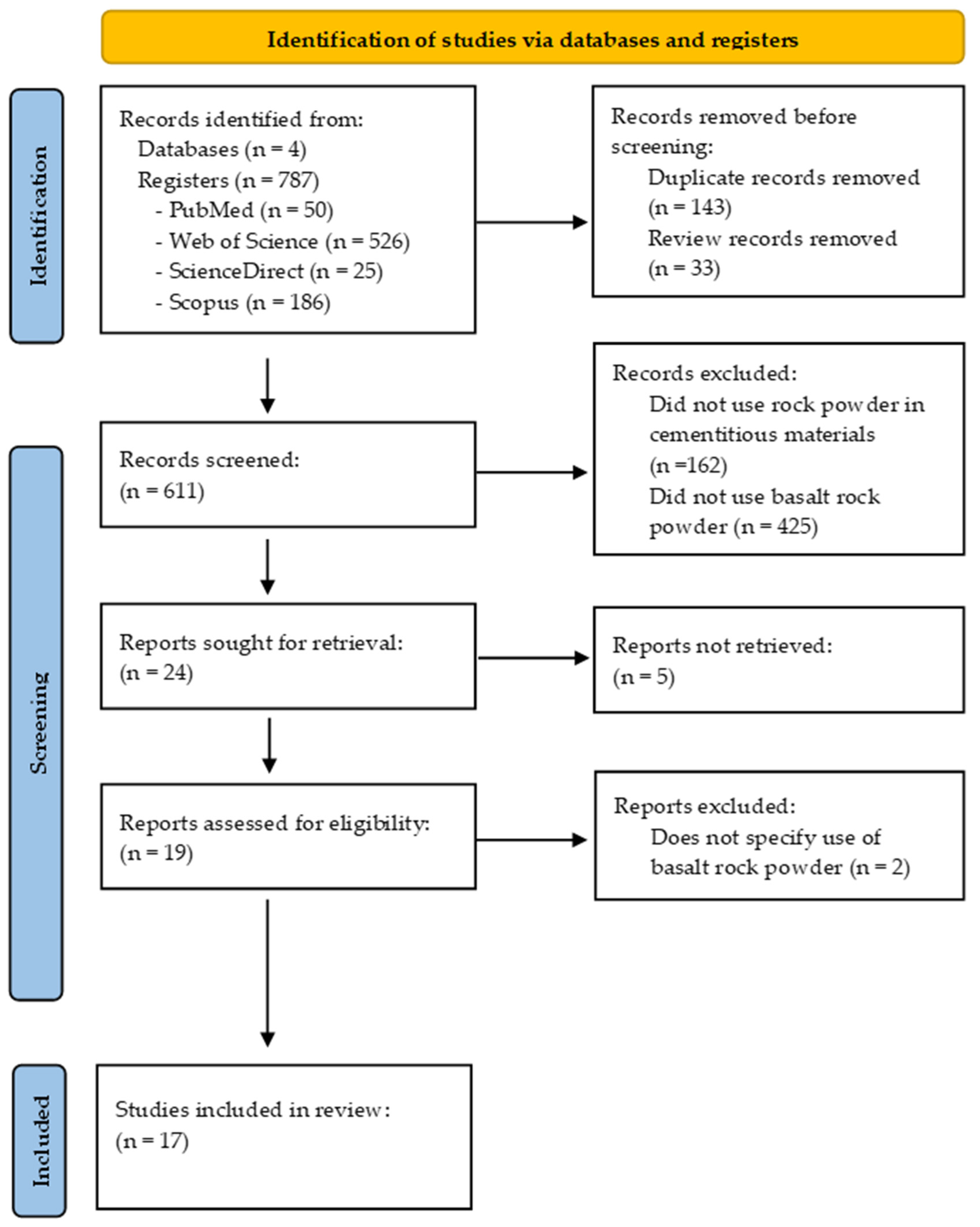

4. Characteristics of Rock Dust

5. Materials and Methods

6. Results

7. Discussion

7.1. Effect on Mechanical Resistance

7.2. Pozzolanic Activity and Durability

7.3. Sustainability

7.4. Cost and Embodied Carbon Footprint

7.5. Future Perspectives

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Woerden, V.F. What a Waste 2.0: A Global Snapshot of Solid. Waste Management to 2050; World Bank Publications: Chicago, IL, USA, 2018. [Google Scholar]

- Mateus, R.; Neiva, S.; Bragança, L.; Mendonça, P.; Macieira, M. Sustainability Assessment of an Innovative Lightweight Building Technology for Partition Walls–Comparison with Conventional Technologies. Build. Environ. 2013, 67, 147–159. [Google Scholar] [CrossRef]

- Ash, S. U.S. Geological Survey Mineral Commodity Summaries 2019; US Geological Survey: Reston, VA, USA, 2019. [CrossRef]

- Luo, W.; Wang, H.; Li, X.; Wang, X.; Wu, Z.; Zhang, Y.; Lian, X.; Li, X. Mechanical Properties of Reactive Powder Concrete with Coal Gangue as Sand Replacement. Materials 2022, 15, 1807. [Google Scholar] [CrossRef] [PubMed]

- Rashad, A.M. A Preliminary Study on the Effect of Fine Aggregate Replacement with Metakaolin on Strength and Abrasion Resistance of Concrete. Constr. Build. Mater. 2013, 44, 487–495. [Google Scholar] [CrossRef]

- Vardhan, K.; Siddique, R.; Goyal, S. Strength, Permeation and Micro-Structural Characteristics of Concrete Incorporating Waste Marble. Constr. Build. Mater. 2019, 203, 45–55. [Google Scholar] [CrossRef]

- Sunny, J.E.; Varghese, R.A.; John, P.S.; Kassim, R. Application of Basalt and It’s Products in Civil Engineering. Int. J. Eng. Technol. Res. 2020, 9, 2–7. [Google Scholar]

- Durastanti, C.; Moretti, L. Assessing the Climate Effects of Clinker Production: A Statistical Analysis to Reduce Its Environmental Impacts. Clean. Environ. Syst. 2024, 14, 100204. [Google Scholar] [CrossRef]

- Dobiszewska, M.; Bagcal, O.; Beycioğlu, A.; Goulias, D.; Köksal, F.; Niedostatkiewicz, M.; Ürünveren, H. Influence of Rock Dust Additives as Fine Aggregate Replacement on Properties of Cement Composites—A Review. Materials 2022, 15, 2947. [Google Scholar] [CrossRef]

- Sosoi, G.; Abid, C.; Barbuta, M.; Burlacu, A.; Balan, M.C.; Branoaea, M.; Vizitiu, R.S.; Rigollet, F. Experimental Investigation on Mechanical and Thermal Properties of Concrete Using Waste Materials as an Aggregate Substitution. Materials 2022, 15, 1728. [Google Scholar] [CrossRef]

- Qiao, H.; Ndahirwa, D.; Li, Y.; Liang, J. The Feasibility of Basalt Rock Powder and Superfine Sand as Partial Replacement Materials for Portland Cement and Artificial Sand in Cement Mortar. Res. Appl. Mater. Sci. 2019, 1, 1–9. [Google Scholar] [CrossRef]

- Mohsin, M.; Zhu, Q.; Naseem, S.; Sarfraz, M.; Ivascu, L. Mining Industry Impact on Environmental Sustainability, Economic Growth, Social Interaction, and Public Health: An Application of Semi-Quantitative Mathematical Approach. Processes 2021, 9, 972. [Google Scholar] [CrossRef]

- ANM—Agência Nacional de Mineração. Anuário Mineral Brasileiro: Principais Substâncias Metálicas 2019; ANM: Brasilia, Brasil, 2020.

- Dobiszewska, M.; Bagcal, O.; Beycioğlu, A.; Goulias, D.; Köksal, F.; Płomiński, B.; Ürünveren, H. Utilization of Rock Dust as Cement Replacement in Cement Composites: An Alternative Approach to Sustainable Mortar and Concrete Productions. J. Build. Eng. 2023, 69, 106180. [Google Scholar] [CrossRef]

- Almeida, L.N.B.; Josué, T.G.; Nogueira, O.H.L.; Dias, D.T.; Tusset, A.M.; Dos Santos, O.A.A.; Lenzi, G.G. Quarry Residue: Treatment of Industrial Effluent Containing Dye. Catalysts 2021, 11, 852. [Google Scholar] [CrossRef]

- Almeida, L.N.B.; Josue, T.G.; Nogueira, O.H.L.; Ribas, L.S.; Fuziki, M.E.K.; Tusset, A.M.; Santos, O.A.A.; Lenzi, G.G. The Adsorptive and Photocatalytic Performance of Granite and Basalt Waste in the Discoloration of Basic Dye. Catalysts 2022, 12, 1076. [Google Scholar] [CrossRef]

- Gameiro, F.; de Brito, J.; Correia da Silva, D. Durability Performance of Structural Concrete Containing Fine Aggregates from Waste Generated by Marble Quarrying Industry. Eng. Struct. 2014, 59, 654–662. [Google Scholar] [CrossRef]

- DNPM—Departamento Nacional de Produção Mineral. Economia Mineral Do Brasil; DNPM: Brasília, Brasil, 2009.

- ASTM C33/C33M-13; Standard Specification for Concrete Aggregates. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- ACI Bulletin E1-07; Aggregates for Concrete. American Concrete Institute Committee: Farmington Hills, MI, USA, 2007.

- Almeida, N.; Branco, F.; de Brito, J.; Santos, J.R. High-Performance Concrete with Recycled Stone Slurry. Cem. Concr. Res. 2007, 37, 210–220. [Google Scholar] [CrossRef]

- Bacarji, E.; Toledo Filho, R.D.; Koenders, E.A.B.; Figueiredo, E.P.; Lopes, J.L.M.P. Sustainability Perspective of Marble and Granite Residues as Concrete Fillers. Constr. Build. Mater. 2013, 45, 1–10. [Google Scholar] [CrossRef]

- Vardhan, K.; Goyal, S.; Siddique, R.; Singh, M. Mechanical Properties and Microstructural Analysis of Cement Mortar Incorporating Marble Powder as Partial Replacement of Cement. Constr. Build. Mater. 2015, 96, 615–621. [Google Scholar] [CrossRef]

- Galetakis, M.; Soultana, A. A Review on the Utilisation of Quarry and Ornamental Stone Industry Fine By-Products in the Construction Sector. Constr. Build. Mater. 2016, 102, 769–781. [Google Scholar] [CrossRef]

- Al-Kharabsheh, B.N.; Moafak Arbili, M.; Majdi, A.; Ahmad, J.; Deifalla, A.F.; Hakamy, A.; Majed Alqawasmeh, H. Feasibility Study on Concrete Made with Substitution of Quarry Dust: A Review. Sustainability 2022, 14, 15304. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Rev. Pan. Salud. Publica. Pan. Am. J. Public Health 2022, 46, e112. [Google Scholar] [CrossRef]

- Ouzzani, M.; Hammady, H.; Fedorowicz, Z.; Elmagarmid, A. Rayyan—A Web and Mobile App for Systematic Reviews. Syst. Rev. 2016, 5, 210. [Google Scholar] [CrossRef]

- Quillbot. Available online: https://quillbot.com/ (accessed on 15 April 2025).

- Cihan, M.T.; Aral, İ.F. Application of AI Models for Predicting Properties of Mortars Incorporating Waste Powders under Freeze-Thaw Condition. Comput. Concr. 2022, 29, 187–199. [Google Scholar]

- Tammam, Y.; Uysal, M.; Canpolat, O.; Kuranlı, Ö.F. Effect of Waste Filler Materials and Recycled Waste Aggregates on the Production of Geopolymer Composites. Arab. J. Sci. Eng. 2023, 48, 4823–4840. [Google Scholar] [CrossRef]

- Dobiszewska, M.; Beycioğlu, A. Physical Properties and Microstructure of Concrete with Waste Basalt Powder Addition. Materials 2020, 13, 3503. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Zhou, S.; Dong, J. Investigation into Pozzolanic Activity Component of Basalt and Pumice. J. Mater. Civ. Eng. 2020, 32, 1–8. [Google Scholar] [CrossRef]

- Tammam, Y.; Uysal, M.; Canpolat, O. Effects of Alternative Ecological Fillers on the Mechanical, Durability, and Microstructure of Fly Ash-Based Geopolymer Mortar. Eur. J. Environ. Civ. Eng. 2022, 26, 5877–5900. [Google Scholar] [CrossRef]

- Aral, İ.F.; Cihan, M.T. Investigation of Properties of Mortars Containing Waste Stone Powder Instead of Sand Under Freezing-Thawing Effect. IOP Conf. Ser. Earth Environ. Sci. 2019, 362, 012169. [Google Scholar] [CrossRef]

- Abdellahi, S.B.; Hejazi, S.M. Effect of Glass and Polypropylene Fibers in Cementitious Composites Containing Waste Stone Powder. J. Ind. Text. 2015, 45, 152–168. [Google Scholar] [CrossRef]

- Ye, F.; Feng, Q.; Qiao, H.; Zhu, X.; Su, L.; Xue, C.; Cao, H.; Zhang, L. Study on Multi-Objective Matching Ratio Optimization and Strength Development Law of Basalt Stone Powder Composite Cementitious Materials. Constr. Build. Mater. 2024, 417, 135088. [Google Scholar] [CrossRef]

- Lentz, L.C.; Antunes, E.G.P. Analysis of the Influence of Partial Replacement of Mineral Aggregate by Basaltic Rock Dust on the Production of Industrialized Adhesive Mortar. Mater. Constr. 2021, 71, e240. [Google Scholar] [CrossRef]

- Balawi, M.; Beck, K.; Belayachi, N.; Brunetaud, X. Evaluation of Fresh-State Application Performance of a Coating Mortar Based on Aerial Lime and Tuffeau Powder from Stone Sawing Waste. Mater. Struct. 2025, 58, 79. [Google Scholar] [CrossRef]

- Rodrigues da Silva, K.; de Jesus, F.B.T.; Inocente, J.; Arcaro, S.; Raupp-Pereira, F.; Montedo, O.R.K. Basalt-Containing Pressed Cement Plates for Construction Systems: Technological and Toxicological Characterization. J. Mater. Civ. Eng. 2022, 34, 1–11. [Google Scholar] [CrossRef]

- Matos, P.R.d.; Sakata, R.D.; Gleize, P.J.P.; de Brito, J.; Repette, W.L. Eco-Friendly Ultra-High Performance Cement Pastes Produced with Quarry Wastes as Alternative Fillers. J. Clean. Prod. 2020, 269, 122308. [Google Scholar] [CrossRef]

- Schankoski, R.A.; Pilar, R.; de Matos, P.R.; Prudêncio, L.R.; Ferron, R.D. Fresh and Hardened Properties of Self-Compacting Concretes Produced with Diabase and Gneiss Quarry by-Product Powders as Alternative Fillers. Constr. Build. Mater. 2019, 224, 659–670. [Google Scholar] [CrossRef]

- Labbaci, Y.; Labbaci, B.; Abdelaziz, Y.; Mekkaoui, A.; Alouani, A. The Use of the Volcanic Powders as Supplementary Cementitious Materials for Environmental-Friendly Durable Concrete. Constr. Build. Mater. 2017, 133, 468–481. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, Q.; Li, F. Tests on Properties of Proto-Machine-Made Sand and Strength of Cement Mortar Affected by Stone Powder. Appl. Mech. Mater. 2011, 71, 4365–4368. [Google Scholar] [CrossRef]

- Ye, F.; Qiao, H.; Feng, Q.; Tian, Y.; Su, L.; Fu, Y. Study on Multi-Performance Optimization of Basalt Stone Powder Supplementary Cementitious Materials. J. Build. Eng. 2023, 80, 108018. [Google Scholar] [CrossRef]

- Senguttuvan, K.; Selvaraj, S.; Periasamy, I.M.G. Reduction of Carbon Footprint by Development of Green Concrete with Incorporation of Quarry Rock Dust, Activated Slag and Sisal Fibers. Matéria 2024, 29, e20240306. [Google Scholar] [CrossRef]

- Pakkiyachandran, M.; Sathiparan, N. Comparative Study on Quarry Waste, Manufactured Sand, Quarry Dust as River Sand Replacement in Cement Mortar: Mechanical Characteristics, Durability, and Eco-Benefit. Materialia 2025, 40, 102395. [Google Scholar] [CrossRef]

- Tammam, Y.; Uysal, M.; Canpolat, O. Durability Properties of Fly Ash-Based Geopolymer Mortars with Different Quarry Waste Fillers. Comput. Concr. 2022, 29, 335–346. [Google Scholar] [CrossRef]

- Pereira, V.S.; Morais, C.R.d.S.; Rodrigues, P.A.; De Aquino, J.L.S.; Dantas Filho, F.F. Composites of Cement Matrix Containing Residue of PET Bottles and Stone Dust Replacing the Conventional Materials-Physical Chemistry and Mechanics Evaluations. Mater. Sci. Forum 2012, 727, 587–591. [Google Scholar] [CrossRef]

- Yee, J.C.; Cheah, C.B.; Tan, L.E.; Chong, A.K.M.; Chee, S.Y. Strength and Fluid Transport Properties of GGBS Blended Cementitious Composite with Crushed Seashells and Quarry Dust Fine Aggregate. Constr. Build. Mater. 2025, 465, 140134. [Google Scholar] [CrossRef]

- Hefni, Y. Experimental Study to Preapare a Compatible Mortar for Filling the Cracks in Archaeological Basaltic Stones at Abu Sir, Egypt. Egypt. J. Archaeol. Restor. Stud. 2022, 12, 165–174. [Google Scholar] [CrossRef]

- Ma, R.; Zhang, L.; Song, Y.; Lin, G.; Qian, X.; Qian, K. Recycling Stone Powder as a Partial Substitute for Cementitious Materials into Eco-Friendly Manufactured Sand Ultra-High Performance Concretes: Towards Cleaner and More Cost-Effective Construction Production. J. Build. Eng. 2024, 92, 109772. [Google Scholar] [CrossRef]

- Silva, L.H.P.; de Paiva, F.F.G.; Tamashiro, J.R.; Kinoshita, A. Potential of Bamboo Leaf Ash as Supplementary Binder Materials—A Systematic Literature Review. J. Build. Eng. 2023, 71, 106547. [Google Scholar] [CrossRef]

- Ramos da Silva, A.; Friol Guedes de Paiva, F.; Henrique Pereira Silva, L.; Fernando dos Santos, L.; Roefero Tolosa, G.; Eloizo Job, A.; Pérez Galvín, A.; López-Uceda, A.; Rainho Teixeira, S.; Kinoshita, A.; et al. Evaluation of Pozzolanic Activity and Environmental Assessment of Cement Composites with Lubricating Oil Re-Refining Ash. Constr. Build. Mater. 2023, 376, 130980. [Google Scholar] [CrossRef]

- Rodier, L.; Villar-Cociña, E.; Ballesteros, J.M.; Junior, H.S. Potential Use of Sugarcane Bagasse and Bamboo Leaf Ashes for Elaboration of Green Cementitious Materials. J. Clean. Prod. 2019, 231, 54–63. [Google Scholar] [CrossRef]

- Nehring, V.; Silva, L.H.P.; de Maria, V.P.K.; de Paiva, F.F.G.; Tamashiro, J.R.; dos Santos, L.F.; Teixeira, S.R.; Kinoshita, A. Recycling of Bamboo Leaves and Use as Pozzolanic Material to Mitigate Degradation of Cementitious Composites. Clean. Waste Syst. 2022, 3, 100053. [Google Scholar] [CrossRef]

| Advanced Search Keyword |

|---|

| TS = (((stone dust) OR (stone powder*) OR (rock dust) OR (rock powder*) OR (quarry dust) OR (quarry powder*) OR (quarry dust powder*) OR (gravel dust) OR (gravel powder*)) AND ((mortar) OR (cement composites))) |

| Author(s) | Composite | Application | Average Particle Size (μm) and Fineness Modulus (FM) | Replacement (%) of Cement or Aggregate | Compressive Strength (MPa) * |

|---|---|---|---|---|---|

| [29] | Mortar | Portland cement | - | 0% | ≈54.00 |

| 5% | ≈44.50 | ||||

| 10% | ≈42.00 | ||||

| Fine aggregates | - | 0% | ≈54.00 | ||

| 20% | ≈43.00 | ||||

| 30% | ≈46.00 | ||||

| [30] | Mortar | Fine aggregates | Average diameter < 2 mm; particle size ranging from 0.4 to 235 µm | 0% | ≈36.00 |

| 25% | ≈41.00 | ||||

| 50% | ≈42.00 | ||||

| 75% | ≈20.00 | ||||

| [31] | Concrete | Fine aggregates | Average diameter 20 µm; basalt powder particle ranging from 0.5 to 200 µm | 0% | ≈32.00 |

| 10% | ≈72.00 | ||||

| 20% | ≈75.00 | ||||

| 30% | ≈80.00 | ||||

| [32] | Mortar | Portland cement | Particle size ranging from 0.2 to ~45 µm | 0% | 48.90 |

| 30% | 36.50 | ||||

| [33] | Mortar | Fine aggregates | Particle size ranging from 0.4 to 200 µm | 0% | 62.89 |

| 25% | 64.67 | ||||

| 50% | 53.20 | ||||

| 75% | 51.20 | ||||

| [34] | Mortar | Fine aggregates | Average particle size ≤ 75 µm | 0% | ≈48.00 |

| 20% | ≈47.00 | ||||

| 30% | ≈46.00 | ||||

| [35] | Concrete | Filler | Particle size range 1–40 µm | 0% | ≈2.50 |

| 10% | ≈7.00 | ||||

| 15% | ≈7.50 | ||||

| 20% | ≈8.00 | ||||

| 50% | ≈6.50 | ||||

| [36] | Blended cementitious composite | Quarry dust with crushed seashells as fine aggregates | Particle size range 4.75 mm–0.075 mm; FM 3.6 ± 0.1 | 0% | ≈60.00 |

| 20% | ≈63.00 | ||||

| 30% | ≈68.00 | ||||

| 40% | ≈70.00 | ||||

| 50% | ≈72.00 | ||||

| 60% | ≈71.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almeida, M.P.B.; Gomes, L.d.S.S.; Silva, A.R.; Tamashiro, J.R.; Paiva, F.F.G.; Silva, L.H.P.; Kinoshita, A. Basalt Rock Powder in Cementitious Materials: A Systematic Review. Resources 2025, 14, 86. https://doi.org/10.3390/resources14060086

Almeida MPB, Gomes LdSS, Silva AR, Tamashiro JR, Paiva FFG, Silva LHP, Kinoshita A. Basalt Rock Powder in Cementitious Materials: A Systematic Review. Resources. 2025; 14(6):86. https://doi.org/10.3390/resources14060086

Chicago/Turabian StyleAlmeida, Maryane Pipino Beraldo, Lays da Silva Sá Gomes, Alex Ramos Silva, Jacqueline Roberta Tamashiro, Fábio Friol Guedes Paiva, Lucas Henrique Pereira Silva, and Angela Kinoshita. 2025. "Basalt Rock Powder in Cementitious Materials: A Systematic Review" Resources 14, no. 6: 86. https://doi.org/10.3390/resources14060086

APA StyleAlmeida, M. P. B., Gomes, L. d. S. S., Silva, A. R., Tamashiro, J. R., Paiva, F. F. G., Silva, L. H. P., & Kinoshita, A. (2025). Basalt Rock Powder in Cementitious Materials: A Systematic Review. Resources, 14(6), 86. https://doi.org/10.3390/resources14060086