Abstract

Phasing out fossil fuels to renewables is currently a global priority due to the climate change threat. Advocacy for biomass use as an energy source requires assessing the quality biomass and ecological impacts of bioenergy supply chains. This study evaluated the quality of biomass residues from orchards and silviculture transported from different Northern and Central Italy locations and the carbon footprint of a biomass power plant. The total greenhouse emissions were calculated based on primary data for 2017 according to the ISO/TS 14067. All the residue samples showed their suitability for biofuel use. Ash content was relatively low on average (3–5% d.m.), except for grapevine residues (18% d.m.). The lower heating value was within the expected range of 15–21 MJ kg−1 for plant species. The average GHG emission from the power plant was 17.4 g CO2 eq./MJ of electrical energy, with the energy conversion (38%) and transportation of biomass (34%) phases being the main impact contributors. For this study, impacts of residual agricultural residue were about half that of residues from forest management, mainly due to chipping and greater transport distance. Results show that sourcing residual biomass materials for electricity generation close to power plants significantly reduce GHG emissions compared to conventional fossil fuels.

Keywords:

residues; energy; sustainability; wood; carbon savings; green; global warming; climate change 1. Introduction

The threat of climate change and the need to ensure environmental sustainability has become a global agenda. Emissions from anthropic activities are considered the main driver for warming the planet [1]. The IPCC 2021 report indicates that the global surface temperature rose by 1.10 °C between 2000 and 2020 [2]. Extreme weather events are projected to increase, posing a threat to ecological, economic, and social sustainability. Current severe challenges of climate change include the emission of high amounts of greenhouse gases (GHG), the depletion of non-renewable resources, and the increasing amount of waste [3]. Thus, there are concerted efforts globally to find solutions that will prevent and mitigate these challenges.

The energy sector is the most predominant sector responsible for climate change. Global energy-related CO2 emissions are heading for their second-largest annual increase ever, with the energy sector estimated to be responsible for 73% of CO2 emissions [4]. The electricity and heat sector contributes significantly to GHG emissions and accounts for about 44% of energy sector emissions [5]. According to Enerdata, Europe is the third-largest energy consumer behind Asia and North America [6]. Thus, the EU, in its quest to achieve net-zero CO2 emissions coupled with a significant reduction in other GHG emissions, has implemented several actions to be taken. Some of these actions include: maximizing energy efficiency, maximizing the use of renewable energy sources, circular economy implementation, tackling residual CO2 emissions through carbon capture and storage [7,8,9]. The relative contributions of different fossil fuels to total energy-related CO2 emissions appear to change over time [4,6]. Petroleum which accounted for 40% of global energy-related CO2 in 2004, is projected to decline to 36% in 2030. However, natural gas combustion and coal should increase from 20% and 39% to 21% and 43% in 2030, respectively. Considering coal is the most carbon-intensive of fossil fuels, this poses an environmental challenge [5]. The energy sector was responsible for about 80% of GHG emissions produced in the EU in 2018. However, owing to the COVID-19 global pandemic, energy consumption fell by 4% in 2020 due to lockdown measures and transport restrictions. The same was valid for global energy production, which fell by 6% in 2020 [6]. For instance, primary energy consumption in Italy reduced from 149 Mtoe in 2019 to 137 Mtoe in 2020, while energy production increased from 34 Mtoe to 35 Mtoe for the same period [6]. The situation has returned to normalcy in 2021 due to emerging markets with global energy demand projected to increase by 4.6% [4].

There is a surge in need for new systems for renewable energy generation worldwide. The over-exploitation, decrease in availability, growing difficulty in supply, and increased sensitivity to energy–environment dimensions of fossil fuels, such as oil and natural gas, have facilitated the advocacy for renewable energy sources [10]. Renewables are in fourth place after oil, coal, and natural gas in global quantitative production [11]. The EU has implemented several energy policies to promote renewable energy from renewable sources with a 20% renewable energy target by 2020 [9] and is currently discussing reaching a 40% by 2030. Among renewable energy sources, biomass could reduce the net GHG emitted per unit of electricity generated and be interesting for energy generation for domestic use near the biomass farm, including biogas for transportation [12,13,14,15]. Biomass generally refers to the biodegradable fraction of products, waste, and residues of biological origin from agriculture, forestry, and related industries [9]. It is a versatile source that can generate heat, electricity, and liquid biofuels [16]. However, to advocate for extensive biomass use as an energy source, it is crucial to assess the ecological impacts of biomass cultivation through land-use changes, including displacement, the introduction of invasive alien species, and other effects on biodiversity, food production, and climate change.

According to 2014 data from ISTAT and the Ministry of Economic Development (MISE) in Italy, the gross domestic consumption of energy amounted to 172.99 Mtoe, of which 142.83 Mtoe imported from abroad, equivalent to 82.5% of total consumption [10]. The agro-energy supply chain in Italy is an evolving sector, mostly directly related to agriculture and forest biomass that serve as fuel for electricity and heat generation. Between 2000 and 2020, electricity generation from primary solid biofuels has increased significantly from 425 GWh to 4430 GWh in Italy [17]. Renewable sources contribute 45% to the current national energy mix used to produce electricity fed into the Italian electricity system. From an energy point of view, this is of interest due to its potential for significant CO2 emission savings compared to fossil fuels and net-zero CO2 neutrality. Solid biomass, sometimes regarded as waste, is considered less expensive economically. Therefore, with increasing global and local energy requirements and the urgent need to decrease the percentage of energy products purchased abroad, woody biomass presents a viable opportunity to be harnessed.

Although European and national policies promote the use of residual biomass materials for electricity generation, it is essential to consider the quality and characteristics of these materials. The low quality of biomass, often defined in its inherent features (high moisture content, low energy density, low bulk density, varying size, and shape), hinders its full exploitation [18]. The motivations to assess solid biofuel properties include economic, technical, and environmental reasons. Woody biomass residues are generally heterogeneous and may originate from branches, stem wood, barks, and leaves of different species. The dissimilarities in physical properties and chemical composition can affect a biomass power plant’s combustion efficiency, maintenance, and logistics, partly limiting its energy and environmental sustainability [19]. Therefore, it is imperative to implement an adequate system to monitor and discriminate solid biofuel quality used in power plants. Biofuel quality control of physical characteristics such as particle size, bulk density, moisture content, net calorific value, and chemical composition such as ash content is essential for power plants and other stakeholders. Ash content indirectly contributes to dust emission and operational problems such as fouling, slagging, and corrosion [20,21], based on the ash chemical composition and specific chemical elements such as chloride (Cl) and sulfur (S) [22]. In addition to nitrogen content (N), these elements undergo reactions to form emitted pollutants, such as nitrogen oxides, sulfur dioxide, and hydrogen chloride [21].

The burgeoning interest in sustainability reporting has enhanced economic, environmental, and social development communication. Environmental sustainability assessment studies have become paramount in providing accurate and reliable information to help address the climate change challenge. The Life Cycle Assessment (LCA) is a measurement tool recognized internationally for performing environmental impact assessment studies [23]. The carbon footprint of products (CFP), a specific ecological impact assessment for greenhouse gas emissions, on energy production and consumption have increased steadily over the past decade, particularly in the EU [24]. Companies are encouraged to report impacts related to their activities in the energy sector. Energy companies rely on impact assessment studies to highlight environmental hotspots along their production chains to develop mitigation strategies for improvement. Impact assessment studies are currently available on energy production from different sources. Most of these studies focused on impacts associated with coal power plants [25,26,27,28]; others concentrated on solar power plants [29,30], hydropower plants [31,32,33], geothermal power plants [34,35,36,37], and natural gas [38]. Medeiros et al. [39] also assessed the carbon footprint of energy generation from microalgae biomass.

As mentioned earlier, the LCA studies have extensively assessed the environmental impacts of various biomass scenarios. However, the wide variability in system boundaries require more in-depth studies. Insights on the effects of large biomass power plant operations, considering the quality of biomass material, processing of different biomass materials, the transportation of the biomass material, and the pre-treatment of the material, are needed. Although quantifying and analyzing the environmental burden of energy generation from biomass sources is essential, it has not been sufficiently explored in Italy. Using residual woody biomass, otherwise considered a waste, as valuable raw material for power plants is necessary for a circular economy. Therefore, this study aims to assess the residual biomass quality and carbon footprint of an actual biomass powerplant in Italy, specifically related to virgin and residual wood biomass and agricultural residue as fuel for electricity production. The goal is to characterize the carbon footprint of power production by valorizing biomass streams of low quality of vast territorial distribution, identifying possible hotspots, and suggesting improvement options to enhance the efficiency of the energy production chain.

2. Materials and Methods

This chapter is divided into two main parts. The first section covers assessing the physical and chemical characteristics of the residual biomass materials used by the power plant company. The second section describes the carbon footprint assessment of the company based on the life cycle approach. Further details are provided below.

2.1. Biomass Quality and Characterization

2.1.1. Biomass Material

The power plant company processes different biomass materials from various sources and places. According to the company, the residual biomass materials are distinguished based on plant species, the part of the plant used, or the particle size, as shown in Table 1.

Table 1.

Classification and description of residual biomass materials.

2.1.2. Quality Analysis on the Biomass Materials

The biomass quality and characterization assessment were carried out on more than one hundred samples provided by the power plant. The quality of the collected samples was established by measuring moisture content, high heating value (HHV), ash content, carbon, hydrogen, nitrogen content, oxygen content, chlorine, and sulfur due to their influence on economic, environmental, and energy aspects. All analyses were carried out following current ISO standards on solid biofuel characterization and have been summarized in Table 2. Lower Heating value was calculated from HHV, hydrogen content, and moisture content.

Table 2.

Proximate and ultimate analyses of biomass materials with corresponding reference methods.

The analyses were performed at the Biomass Lab of Università Politecnica delle Marche (www.biomasslab.it, accessed on 1 December 2021).

2.2. Carbon Footprint Assessment

The Carbon Footprint of Products (CFP) measures the total GHG emissions directly or indirectly caused by an activity or accumulated over a product’s life stages [46]. It is expressed as CO2 equivalents and based on a life cycle assessment using the simple impact category of climate change. The CFP methodology follows the ISO 14067 standard [47]. Life cycle assessment (LCA) is a standardized scientific methodology for assessing the impacts related to the life cycle of a product or service. The LCA concept consists of four main inter-related phases, goal and scope definition, Life Cycle Inventory (LCI), Life Cycle Impact Assessment (LCIA), and Interpretation, following the ISO 14040/14044 standards [48,49]. The LCA is an iterative and flexible tool that allows for modifications in the different phases until the final objective is satisfied. This present study’s methodology, data, and assumptions are detailed in the following sections. The case study was treated using the carbon footprint method.

2.2.1. Description of the Company

The company, San Marco Bioenergie (SMB) Spa, is a member of the Bioenergie group and manages the biomass power plant in Bando d’Argenta in the province of Ferrara, Emilia-Romagna region, Italy. The company aims to distribute energy produced from renewable sources for sustainable energy development. With an estimated 23 MW net of installed power, the plant at Bando is the largest biomass plant in Northern and Central Italy. It is one of the most efficient plants, producing net electricity with over 25% efficiency. Its annual energy production of about 180,000 MWh is equivalent to the requirements of approximately 27,000 inhabitants. The power plant includes two identical units with a net electric capacity of about 10 MWe each; the boiler technology is based on an air-cooled grate and a steam generator with a nominal capacity of 46 ton/h of superheated steam. The associated steam turbine is a full condensation type with an air-cooled generator. Both lines are equipped with a superheated steam generator, a steam turbine, and a connected electric generator and systems to reduce atmospheric emissions in line with the most advanced technology available (BAT). The biomass used for combustion is virgin and of vegetable origins. The biomass is the residue of specially cultivated fruit plants, woodland, and poplar maintenance. The plant has rigorous and innovative procedures for origin qualification and biomass acceptance, defined according to the kind of biomass supplied.

2.2.2. Goal and Scope Definition

The study’s goal is to determine the potential contribution of the SMB renewable electricity production chain to the global warming impact category (GWP) and form the basis for identifying possible improvement strategies. This contribution is quantified by assessing greenhouse gases (GHG) emissions which are emitted directly or indirectly during the life cycle. The intended use in the medium term is to quantify the product’s sustainability and provide valuable information to the client to evaluate initiatives to reduce the calculated impact and thus increase the environmental sustainability of their productions. End-users of this study are the client, any clients who purchase the product under analysis, and any other stakeholder involved to varying degrees in the production, processing, and distribution of the asset itself and interested in aspects of sustainability.

The scope of this study is the carbon footprint, defined as the total carbon emissions from the entire life cycle of products and services related to the SMB renewable electricity production chain, according to the boundaries defined in the sections below.

2.2.3. System Boundary

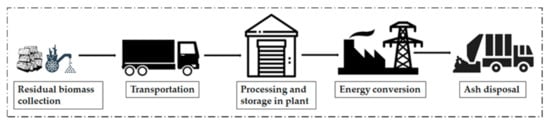

The production system analysis can be divided into four main phases, each characterized by incoming and outgoing flows and specific operations, as shown in Figure 1. The system boundaries indicate which unitary processes (and related flows) fall within the analysis conducted. Data from all phases were considered, including the impact due to the production and transport of all the inputs present in the supply chain (fuels, electricity, chemicals, etc.). The approach used is the “cradle to gate” type (from the cradle to the company gate) and considers the ash disposal phase within the system.

Figure 1.

The system boundary of the phases considered for electricity generation from woody and vegetable biomass.

2.2.4. Functional Unit

Following other industry studies and technical regulations, the 1 MJ of renewable electricity SMB is the chosen functional unit. The functional unit (FU) is the reference basis for mathematical calculations regarding the impacts of the flows into and out of the defined system. As established by the reference standards, the FU must be consistent with the study’s goal.

2.2.5. Transportation to the Company

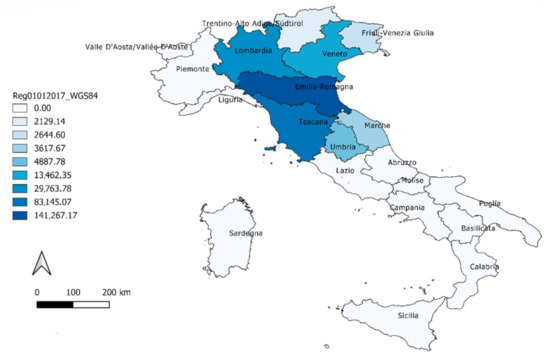

Biomass material in the form of wood chips or pre-ground is transported from the field to the plant. The residual biomass materials were transported from different provinces in Italy’s north and central parts to the power plant located in the Emilia-Romagna region. Trentino-Alto Adige, Friuli-Venezia Giulia, Lombardia, Veneto, Emilia-Romagna, Toscana, Marche were the regions the residual materials were obtained from, as shown in Figure 2. Tractors with a semi-trailer walking floor system having a loading volume of 92 m3 are used to transport wood chips. The standard tractors used are DAF XF 510 (euro 6); MAN 480 (euro 6). A truck + trailer system, generally tipping and demountable, with volume 60 m3, is used to transport pre-ground and bulk wood material. The commonly used truck is the IVECO Stralis, on average 5 euros and 6 euros. Based on these, similar transport means reported in the Agri-footprint database (Transport, truck > 20 t, EURO5, empty return/GLO Energy) with variable loading factors were selected to assess their impact, considering the load factor of each trip made. The load factor varied between 50–100% with an average of 73%, primarily dependent on the particle size and shape of the residual material. Table 3 reports the average quantity of the residual biomass materials transported from different provinces to the power plant. In all, 12,514 road trips were analyzed for transporting varying amounts of biomass materials from other locations to the power plant. Based on the quantity of biomass transported and the distance covered, the tkm for each trip was calculated. In total, about 39 million tkm were calculated for 2017, considering that the annual average amount of biomass used by SMB corresponds to 138.5 tkm/ton of biomass and 0.059 tkm/MJ EE (electrical energy).

Figure 2.

Regional distribution of raw biomass supply (tons) for SMB.

Table 3.

The average quantity of biomass transported to the power plant from different locations.

2.2.6. Load Factor

Based on the biomass typology, the load factor of the transported biomass was computed by expressing the quantity of material transported in terms of the maximum load transported by the truck. The CO2 emissions relating to the load factor were then estimated based on the reference for the lower limit from the SimaPro software shown in Table 3.

2.2.7. Emissions for Transport

Emissions from transport refer to the emission of CO2 per transport unit by the distance covered. The transport emissions were computed by comparing the actual load factor for each trip to the reference load factors in Table 4. Based on the quantity of material transported over the specified distance and using the reference emissions dependent on the different ranges reported in Table 4, the total emission for transportation was calculated using the equation:

where LF = Load factor, LHV = Lower Heating Value of biomass type.

Table 4.

Estimated specific CO2 emissions by load factor g CO2 eq./tkm (source SimaPro, EURO 5–6, Empty return).

2.2.8. Processing and Storage of Biomass

This phase consists of different operations, including unloading that affects all the products arriving at the plant, screening and grinding operations (when needed), and internal handling. The chipping of wood residues from forest management before transporting was included.

2.2.9. Energy Conversion

It concerns the process of energy conversion by combustion. This phase includes all the consumption of materials and energy necessary for the operation of the plant, including the fumes treatment system. In this phase, the reference flow is considered regarding electricity production. On the contrary, the heat is not recovered.

2.2.10. Emissions for Processing and Energy Conversion Phases

The processing phase encompasses the chipping operations, energy conversion, and ash treatment before disposal. Emissions for chipping were determined as the product of the amount of wood chips transport, and a reference characterization factor of 14.4 g CO2 eq./kg wood chips produced was obtained from the Ecoinvent v.3.01 database (Wood chipping, mobile chipper, in forest, {RoW}|processing|Alloc Def, U) [50]. Wood biomass combustion releases flue gas containing substances such as CO, NOx, SOx, HCl, CO2, H2O, N2, Polycyclic aromatic hydrocarbons, and unreacted surplus O2. These substances can be harmful, corrosive, and pollute the environment [51]. Thus, flue gas treatment through adsorption or chemical filtration is required before the fumes are released into the atmosphere. Emissions for other input materials were also calculated based on the quantity of materials per FU, shown in Table 5, by their corresponding characterization factors from the SimaPro software. The power plant’s efficiency was about 25%.

Table 5.

The life cycle inventory of the processing and energy conversion phases.

2.2.11. Ash Disposal

The company disposes of ash from biomass combustion by landfilling. The quantities of bottom and fly ash produced by SMB in 2017 were considered (bottom ash: 6399 t; fly ash: 3388 t). 90% of the landfill was carried out in Verona and 10% in Pisa. The vehicle used to transport fly ash is a roll-off IVECO Stralis (40 m3) with an average load per journey of about 18 t. A tractor, such as those for transporting biomass, is used for the bottom ashes (euro 5) with an average load of 30 t/trip and 40 m3 of volume.

2.2.12. Data and Data Quality

The analysis examined actual primary data referring to the production of SMB electricity in 2017 (to have a more mediated production value over time, especially for the inputs related to fumes treatment and processes in the plant). A total of 12,514 records corresponding to as many transports were analyzed for each record, different types of data were recorded such as quantity transported, supplier, province, municipality, and place of origin of the material, traceability data, description of the material (species, product family), humidity, data of means of transport and trailers. Other data, such as load factors, were calculated from the primary data collected. For the transport phase to the plant, all the transports carried out in 2017 were considered. All the data used relate to the specific company in question, and all the processes in the inventory represent national conditions or are calculated as a global average. In this study, all data referring to the material and energy flows used for the different phases was provided by the SMB company based on the administration of questionnaires and obtained from documentation relating to the traceability and quality systems already in place. The secondary data used include various processes selected from the Ecoinvent v.3.01 dataset [50] and generally refer to the production and transport of the inputs used. For uncertainty analysis, data variability in this study only relates to background processes such as inputs production in the databases selected as secondary data.

2.2.13. Assumptions and Allocation Procedures

The system under analysis has only one function: producing renewable electricity. Therefore, no allocation procedures were carried out.

2.2.14. Comparison of Results

References to the European Commission’s Directive 2018/2001 [52] were also considered to compare the impact of electricity generation from fossil sources (Fossil Fuel Comparator). Although the COM 2018 Directive [53] is not, in fact, a technical standard (such as the carbon footprint), it adopts calculation principles similar to the standards mentioned. The method to determine GHG emissions from the production and use of biofuels according to the EU sustainability criteria is based on the following procedure in the Directive (EU) 2018/2001 [52] and EU REDcert scheme [54]:

where E = total emissions from the use of the fuel; eec = emissions from the extraction or cultivation of raw materials; el = annualized emissions from carbon stock changes caused by land-use change; ep = emissions from processing; etd = emissions from transport and distribution; eu = emissions from the fuel in use; esca = emission saving from soil carbon accumulation via improved agricultural management; eccs = emission saving from carbon capture and geological storage; eccr = emission saving from carbon capture and replacement; and eee = emission saving from excess electricity from cogeneration.

E = eec + el + ep + etd + eu − esca − eccs − eccr − eee

GHG emissions from biomass fuels (E) are expressed in terms of grams of CO2 equivalent per MJ of biofuel (g CO2 eq./MJ). GHG from raw materials and intermediate products are represented in grams of CO2 equivalent per ton of dry feedstock and intermediate products (g CO2 eq./t dry).

Parameters such as el, esca, eccs, eccr, and eee are only applicable under specific assumptions and can be eliminated in the case of residual biofuel as irrelevant. Emissions arising from biofuels are also considered zero, as they are biogenic and therefore excluded in the calculations.

Thus, the final estimate of GHG emissions in this case study is based on the following formula:

E = ecc + ep + etd

However, in our study and in line with the EU Directive, ecc was considered zero as residual biomass material is used.

The calculated GHG emissions from our study are also compared to results from similar studies found in the literature.

2.2.15. Greenhouse Gas Emissions Savings from Biofuel

Finally, to better assess the extent of the impact, we calculated the GHG emissions savings based on the EU Directive formula:

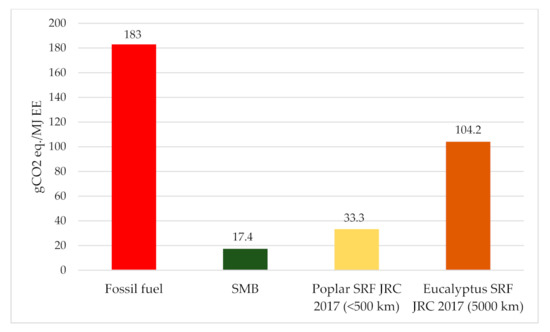

where Ef = total emissions for fossil fuels, a standard value of 183 g CO2 eq./MJ EE as fossil fuel comparator (FFC) [55], and Eb are the total emissions from the biofuel, this is currently one of the primary methods for assessing the sustainability of renewable energy production in Europe. The standard supply chain is energy production from the European energy mix, which is replaced by the supply chain from renewable sources, the SMB supply chain. We compared the CO2 emissions from reference supply chains for electricity production to evaluate the potential savings achievable by replacing the typical fossil supply chain and two popular short-rotation coppices supply chains (poplar and eucalyptus) [56].

Saving = (Ef − Eb)/Ef

3. Results

The summarized results for the quality parameters analyzed on the different biomass samples are reported in Table 5. Except for moisture content, all other results were expressed on a dry matter basis. The biomass typologies generally showed similar result trends for the different analyzed parameters. For most analyses, samples from conifer, orchard, hardwood, and precious woodchip recorded identical values. However, vine samples values were substantially higher for ash and nitrogen content and much lower for carbon and lower heating value (LHV). The vines’ relatively higher mean value ash content could be due to residual soil particles from harvesting. The mean results and standard deviations of the biomass materials are detailed in Table 6.

Table 6.

Results of characterization analysis performed on the biomass typologies.

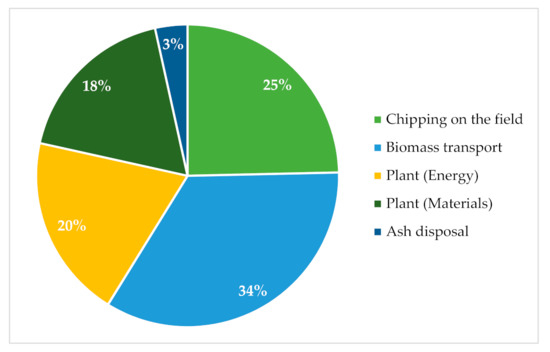

In summary, as shown in Table 7, the average impact associated with 1 MJ of SMB electricity production is 17.445 g CO2 eq. The plant and transport of biomass are the primary impact contributors, followed by chipping in the field, while the disposal of the ashes affects relatively little. Figure 3 graphically represents the percentage contribution of the various phases considered to the previously calculated impact in the life cycle.

Table 7.

The LCIA results of the SMB electricity production (all the values are expressed in g CO2 eq./MJ EE).

Figure 3.

Percentage contribution of the various stages of the life cycle to the average SMB impact.

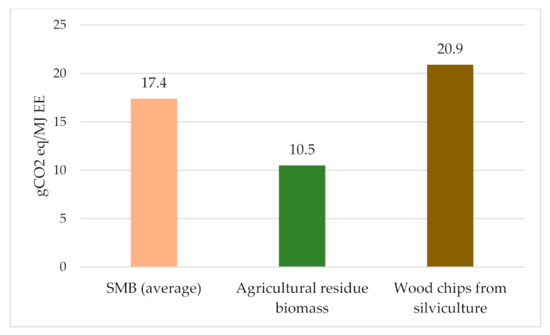

Figure 4 presents the average disaggregated GHG impacts associated with electricity generation at SMB. Energy impacts from wood chips from silviculture residues are almost twice the impacts of agricultural residue biomass. The lower global warming potential value of farm residues was mainly driven by the absence of the chipping operation and the relatively shorter distance over which the biomass is transported due to the proximity of the farm locations to the powerplant.

Figure 4.

Energy impact from SMB biomass: average and specific biomass typology (expressed in g CO2 eq./MJ EE).

4. Discussion

4.1. Biomass Quality and Characterization

Lignocellulosic biomass composition varies widely and often depends on its primary organic components (cellulose, hemicellulose, and lignin). The biomass source, species, climatic conditions, and other factors influence biomass composition [57]. Moisture content for the biomass typologies analyzed in this study ranged between 30 and 40%, which conforms to the company’s standards. The moisture content of biomass varies widely, ranging between 10 and 70% [57,58]. The water content influences the combustion and flue gas volume produced per energy unit. The LHV of the fuel decreases with increasing moisture content. High moisture content can decrease the quality of biomass combustion by causing ignition issues and reducing the combustion temperature. The presence of water in biomass influences its behavior during pyrolysis and affects the physical properties and quality of the pyrolysis gases [58]. Moreover, a high moisture content results in increased fuel usage, generating large flue gas amounts incurring additional operational, environmental, and economic costs.

The mean ash content values of the samples were between the ranges of 2–5%, except for vine. The composition of biomass ash is strongly dependent on the species and part of the biomass plant. The ash content of wood biomass is usually between 1 and 8% [57], while Vassilev et al. [59] reported a mean of 4.8% d.m. for wood residue ash content. The agricultural residue ash content varies between 1 and 19% d.m. [57]. Sulfur and chlorine contents were below 0.1% for all the samples analyzed in this study (Table 6). Nitrogen contents for wood biomass were below 0.6%, similar to a range of 0.1 to 0.5% on a dry basis reported by Vakkilainen [60]. The comparatively higher ash content (18% d.m.) and nitrogen content (0.82% d.m.) of vine residue are typical of biomass from agricultural residues, which can be attributed to the use of fertilizer and soil quality. Garcia et al. [61] reported an average ash content of 13.3% d.m. for grapevine residue. Other factors that can influence ash content include plant species or part of the plant, plant age, environmental conditions, growing processes, fertilizer and pesticide doses used, harvesting time, collection technique, transport, storage, pollution, processing, and contamination by dirt. Also, in terms of the plant part used, leaves have ash higher content than branches, bark, and roots [59,62]. Emissions from sulfur (SO2), nitrogen (NO, NO2), particulate emissions are air pollutants from biomass combustion that have significant environmental and health implications. Chlorine can also be either found in the dust as solid NaCl and KCl or can exit in flue gases as HCl and Cl2 after combustion [60]. Residual biomass with low ash content is ideal since ash management in removal, treatment, and disposal in landfill areas increases economic, environmental, and social costs for energy plants.

Biofuels consist primarily of carbon, hydrogen, and oxygen (CHO). Most of the carbon is converted in the combustion process to carbon dioxide (CO2) and most of the hydrogen to water vapor (H2O). Generally, biomass has less carbon, more oxygen, and higher hydrogen content than coal. Apart from biomass from the vineyard (39% d.m.), the mean carbon content ranged between 43 and 51% d.m. Hydrogen content for all samples ranged between 4 and 6% d.m., while oxygen content was in the range of 40–43% d.m., except for vine (37% d.m.), Table 6. Lignocellulosic biomass composition regarding CHO is similar. Typical (dry) weight percentages for C, H, and O are 30 to 60%, 5 to 6%, and 30 to 45%, respectively [58]. Lower heating values (LHV) ranging between 15 and 19 MJ kg−1 d.m. for the samples analyzed in this study fall within the typical energy contents of different types of biomass [62]. LHV is highly influenced by the water content of the biomass and is an important parameter that describes the suitability and value of biomass use as biofuel. High carbon and hydrogen content and low oxygen content increase the biomass’s heating value [58].

4.2. Carbon Footprint of Biomass Power Plant

The results from the study show that GHG emissions associated with electricity generation from agricultural and silviculture residues are comparably lower to other energy sources, considering plant efficiency of about 25%. Our findings on emissions from electricity production from residual woody and agricultural biomass for electricity generation complement other studies showing bioenergy’s environmental sustainability (Table 8). The impact related to the plant (38%) is the highest, determined to a similar extent using material inputs (especially urea) and energy (electricity from the grid and diesel). The contribution of biomass transport is very similar (34%), followed by chipping in the field (25%). The disposal of ashes is less significant (3%). It is also possible to differentiate the impact of SMB energy production from further details by considering the different biomasses used. We compared the average SMB energy impact (all kinds of biomass), SMB energy impact only from residual agricultural biomass, and SMB energy impact only from wood chips from forest maintenance (Figure 5). The energy production chain from residual agricultural biomass is less impactful, about half than wood chips from forest maintenance. The relative proximity of the orchards to the power plant in the Emilia-Romagna region explains the lower impacts associated with residual agricultural biomass. In the case of wood chips from forest maintenance, this difference is due to the need to chip in the field and the higher average distance. Transportation of biomass materials, especially the type of transport means and distance, has been shown to significantly impact the overall GHG emissions from biomass electricity generation [14,63,64,65,66]. Thus, the sourcing of biomass raw material warrants careful consideration during power plant construction.

Table 8.

A literature review on GHG emissions for electricity generation from biomass materials.

Figure 5.

Comparison between the average impact of biomass energy production from SMB, the fossil reference FFC, and two chains from SRF (JRC, 2015). Data expressed in g CO2 eq./MJ EE.

Several factors need to be considered in assessing the environmental sustainability of producing electricity from biomass. The biomass typology, biomass cultivation, conversion technology, and distance for transported biomass significantly affect emissions. Table 8 and Table 9 summarize impact assessment studies conducted on GHG emissions related to electricity generation from different biomass typologies expressed in g CO2 eq./kWhe. Results vary greatly depending on the phases considered in the system boundary. Generally, high emissions are associated with biomass cultivation due to fertilizer and pesticide use, power plant construction, and conversion technology used. The result from our study, 63 g CO2 eq./kWhe, was relatively lower compared to previous studies reported in Table 8. Additionally, in this study, the net biogenic CO2 emissions released from the combustion of the biomass material were considered to be zero based on the general assumption in many bioenergy LCAs that CO2 will be removed from the atmosphere by biomass regrowth [67,68].

Table 9.

The considered processes within the system boundaries in the analyzed studies.

Biomass is converted to electricity via three main technology categories: pyrolysis, gasification, and direct combustion. Pyrolysis involves the heat destruction of biomass under anaerobic conditions, without the addition of steam or air to produce gases and condensable vapors [69]. Gasification involves partial oxidation of biomass under steam-controlled oxygen to produce combustible gases with a high calorific value. Product gases are fed into a combined cycle gas turbine, while direct combustion is the complete oxidation of biomass in excess air to produce carbon dioxide and water. Hot flue gases heat process water to steam, which propels a turbine, usually via a Rankine cycle [70]. Although gasification and pyrolysis appear more popular than combustion due to their higher efficiency, they require more process control and investment [71]. Loucao et al. [72] and Briones-Hidrovo et al. [73] reported low emissions values for IGCC (integrated gasification combined cycle) in comparison with combustion–Rankine cycles systems. However, the boiler technology of the SMB power plant is based on an air-cooled grate and a steam generator. The combustion system is equipped with a superheated steam generator, a steam turbine, and a connected electric generator and systems to reduce atmospheric emissions in line with the most advanced technology available (BAT), which accounts for the overall low GHG emissions.

4.3. GHG Emissions Savings

The emission savings obtainable by replacing these supply chain with the SMB renewable supply chain is shown in Figure 5. The savings on the fossil supply chain with the SMB renewable supply chain is 90.5%. Considering the SMB electricity production for the year 2017, this saving, in absolute terms, is equal to 106,594 tons of CO2 eq. The emissions savings in this study is comparable to varying range levels of 25–88%, with a mean of 71% reported in the reviewed studies. The phases considered within the system boundary, especially cultivation, energy conversion, and inclusion of biogenic CO2, account for the differences.

5. Conclusions

With global energy trends moving towards phasing fossil fuels to renewables, GHG emissions from electricity generation from biomass supply chains are vital to their sustainability and promotion. Biomass quality significantly affects various technical, economic, and environmental aspects for generating electricity. We assessed the chemical and ultimate analysis for the different biomass typologies used by the SMB power plant. All the residues’ samples showed good features, signifying their suitability for biofuel use. However, residue from vine recorded high ash content (18%), possible for an agricultural residue. The LHV of the biomass analyzed on a dry basis fell in the expected range of 15–21 MJ kg−1 for plant species.

This study presents a partial life cycle assessment of the supply chain emissions related to generating electricity from residual biomass from orchards and forest management, excluding impacts from plant construction and dismantling. Variability in data was mainly associated with the biomass type, transportation distance of biomass. Emissions from electricity generated from the power plant are 17.4 g CO2 eq./MJ EE. The savings obtainable by replacing the reference fossil supply chain (FFC) with the SMB renewable supply chain is 90.5%. The SMB supply chain, characterized by residual biomass, is significantly more sustainable than the supply chains based on dedicated forest biomass due to high impacts from biomass cultivation and transportation of biomass. It is worthy to note that these results are based on data related to the system boundary considered in the study (described under Section 2.2). Local sourcing biomass materials with an efficient logistics system does not only present environmental benefits but significant economic advantages regarding various logistics aspects of biomass transport and energy distribution. As policymakers and interested stakeholders reduce GHG emissions related to the electricity sector by promoting renewable biomass energy, an ideal situation worthy of consideration would be sourcing biomass materials relatively close to the power plant, as shown in this study.

The Life Cycle Assessment methodology, although very useful, is also characterized by some limitations. Although the ISO standard gives a consensus definition for LCA and provides a general framework for conducting an assessment, much interpretation is dependent on the expert conducting the evaluation, which may lead to high variation among results for even the same product. The wide variation is evident in emission results for biomass materials from previous works, even for the same system boundary considered. Other limitations include time and resource constraints in gathering inventory data, missing impact data and models for LCIA, data uncertainty challenges, environmental burden allocation across co-products, and assigning credit for avoided burden. Despite these limitations, the LCA offers a robust environmental tool in the movement toward sustainability.

Author Contributions

Conceptualization, G.T. and D.D.; methodology, D.D. and A.I.; software, A.I.; validation, A.I. and K.A.B.-Y.; formal analysis, A.I., K.A.B.-Y. and T.G.; investigation, A.I. and G.T.; resources, G.T.; data curation, D.D. and A.I.; writing—original draft preparation, D.D., A.I., and T.G.; writing—review and editing, K.A.B.-Y. and G.T.; visualization, A.I.; supervision, G.T. and D.D.; project administration, G.T.; funding acquisition, G.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by San Marco Bioenergie SpA, research contract “Valorizzazione energetica di biomasse residuali: stato dell’arte, screening qualitativo e sostenibilità dell’approvvigionamento”. Project Leader Giuseppe Toscano.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the analyses and interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Masson-Delmotte, V.; Zhai, P.; Pirani, A.; Connors, S.L.; Péan, C.; Berger, S.; Caud, N.; Chen, Y.; Goldfarb, L.; Gomis, M.I.; et al. (Eds.) Full Report Chapter 3: Human Influence on the Climate System. In Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2021. [Google Scholar]

- Masson-Delmotte, V.; Zhai, P.; Pirani, A.; Connors, S.L.; Péan, C.; Berger, S.; Caud, N.; Chen, Y.; Goldfarb, L.; Gomis, M.I.; et al. (Eds.) Summary for Policymakers. In Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2021; Volume 18. [Google Scholar]

- Janik, A.; Ryszko, A.; Szafraniec, M. Greenhouse gases and circular economy issues in sustainability reports from the energy sector in the European union. Energies 2020, 13, 5993. [Google Scholar] [CrossRef]

- IEA. Global Energy Review 2021: Assessing the Effects of Economic Recoveries on Global Energy Demand and CO2 Emissions in 2021; IEA: Paris, France, 2021. [Google Scholar]

- Anderson, J.; Fergusson, M.; Valsecchi, C. An overview of global greenhouse gas emissions and emissions reduction scenarios for the future. Eur. Parliam. 2007, 2, 11. [Google Scholar]

- Enerdata. Global Energy Statistical Yearbook 2021; Enerdata: Grenoble, France, 2021. [Google Scholar]

- Delbeke, J.; Runge-Metzger, A.; Slingenberg, Y.; Werksman, J. The paris agreement. In Towards a Climate-Neutral Europe; Curbing Trend; Routledge: London, UK, 2019; pp. 24–45. [Google Scholar] [CrossRef]

- European Commission. A Clean Planet for All. A European Long-Term Strategic Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy; Com (2018) 773; European Commission: Brussels, Belgium, 2018; p. 114. [Google Scholar]

- Schöpe, M. Renewable energy directive. Eur. Wind Energy Conf. Exhib. 2008, 1, 32–38. [Google Scholar]

- Rotatori, M.; Di Franco, S.; Mosca, S.; Salvatori, R. Study on the Environmental Effects Related to the Use of Solid Biomass for the Production of Electricity; CNR-IIA; Institute on Air Pollution: Monterotondo, Italy, 2019; Available online: https://www.centralemercure.it/wp-content/uploads/2020/06/Studio-sugli-effetti-ambientali-uso-biomassa-EBS-2019.pdf (accessed on 28 October 2021).

- IEA. World Energy Outlook 2019 Executive Summary. In World Energy Outlook 2019; IEA: Paris, France, 2019. [Google Scholar]

- Kimming, M.; Sundberg, C.; Nordberg, Å.; Baky, A.; Bernesson, S.; Norén, O.; Hansson, P.A. Biomass from agriculture in small-scale combined heat and power plants—A comparative life cycle assessment. Biomass Bioenergy 2011, 35, 1572–1581. [Google Scholar] [CrossRef]

- Mann, M.K.; Spath, P.L. Life Cycle Assessment of a Biomass Gasification Combined-Cycle Power System; National Renewable Energy Lab.: Golden, CO, USA, 1997. [Google Scholar] [CrossRef][Green Version]

- Beagle, E.; Belmont, E. Comparative life cycle assessment of biomass utilization for electricity generation in the European Union and the United States. Energy Policy 2019, 128, 267–275. [Google Scholar] [CrossRef]

- Uusitalo, V.; Havukainen, J.; Manninen, K.; Höhn, J.; Lehtonen, E.; Rasi, S.; Soukka, R.; Horttanainen, M. Carbon footprint of selected biomass to biogas production chains and GHG reduction potential in transportation use. Renew. Energy 2014, 66, 90–98. [Google Scholar] [CrossRef]

- Lam, H.L.; Varbanov, P.; Klemeš, J. Minimising carbon footprint of regional biomass supply chains. Resour. Conserv. Recycl. 2010, 54, 303–309. [Google Scholar] [CrossRef]

- IEA. Electricity Generated from Biofuels and Waste by Sources—Italy. 2021. Available online: www.iea.org/data-and-statistics/data-product/renewables-information (accessed on 2 September 2021).

- Anukam, A.; Mamphweli, S.; Reddy, P.; Meyer, E.; Okoh, O. Pre-processing of sugarcane bagasse for gasification in a downdraft biomass gasifier system: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 66, 775–801. [Google Scholar] [CrossRef]

- Toscano, G.; Leoni, E.; Feliciangeli, G.; Duca, D.; Mancini, M. Application of ISO standards on sampling and effects on the quality assessment of solid biofuel employed in a real power plant. Fuel 2020, 278, 118142. [Google Scholar] [CrossRef]

- Deboni, T.L.; Simioni, F.J.; Brand, M.A.; Lopes, G.P. Evolution of the quality of forest biomass for energy generation in a cogeneration plant. Renew. Energy 2019, 135, 1291–1302. [Google Scholar] [CrossRef]

- Fournel, S.; Palacios, J.H.; Morissette, R.; Villeneuve, J.; Godbout, S.; Heitz, M.; Savoie, P. Influence of biomass properties on technical and environmental performance of a multi-fuel boiler during on-farm combustion of energy crops. Appl. Energy 2015, 141, 247–259. [Google Scholar] [CrossRef]

- Toscano, G.; Riva, G.; Foppa Pedretti, E.; Corinaldesi, F.; Mengarelli, C.; Duca, D. Investigation on wood pellet quality and relationship between ash content and the most important chemical elements. Biomass Bioenergy 2013, 56, 317–322. [Google Scholar] [CrossRef]

- Fauzi, R.T.; Lavoie, P.; Sorelli, L.; Heidari, M.D.; Amor, B. Exploring the current challenges and opportunities of Life Cycle Sustainability Assessment. Sustainability 2019, 11, 636. [Google Scholar] [CrossRef]

- Saeed, A.; Noreen, U.; Azam, A.; Tahir, M.S. Does csr governance improve social sustainability and reduce the carbon footprint: International evidence from the energy sector. Sustainability 2021, 13, 3596. [Google Scholar] [CrossRef]

- Koornneef, J.; van Keulen, T.; Faaij, A.; Turkenburg, W. Life cycle assessment of a pulverized coal power plant with post-combustion capture, transport and storage of CO2. Int. J. Greenh. Gas Control 2008, 2, 448–467. [Google Scholar] [CrossRef]

- Kucukvar, M.; Tatari, O. A comprehensive life cycle analysis of cofiring algae in a coal power plant as a solution for achieving sustainable energy. Energy 2011, 36, 6352–6357. [Google Scholar] [CrossRef]

- Han, X.; Chen, N.; Yan, J.; Liu, J.; Liu, M.; Karellas, S. Thermodynamic analysis and life cycle assessment of supercritical pulverized coal-fired power plant integrated with No.0 feedwater pre-heater under partial loads. J. Clean. Prod. 2019, 233, 1106–1122. [Google Scholar] [CrossRef]

- Rasheed, R.; Javed, H.; Rizwan, A.; Sharif, F.; Yasar, A.; Tabinda, A.B.; Ahmad, S.R.; Wang, Y.; Su, Y. Life cycle assessment of a cleaner supercritical coal-fired power plant. J. Clean. Prod. 2021, 279, 123869. [Google Scholar] [CrossRef]

- Piemonte, V.; de Falco, M.; Tarquini, P.; Giaconia, A. Life Cycle Assessment of a high temperature molten salt concentrated solar power plant. Sol. Energy 2011, 85, 1101–1108. [Google Scholar] [CrossRef]

- Whitaker, M.B.; Heath, G.A.; Burkhardt, J.J.; Turchi, C.S. Life cycle assessment of a power tower concentrating solar plant and the impacts of key design alternatives. Environ. Sci. Technol. 2013, 47, 5896–5903. [Google Scholar] [CrossRef]

- Hanafi, J.; Riman, A. Life cycle assessment of a mini hydro power plant in Indonesia: A case study in Karai River. Procedia CIRP 2015, 29, 444–449. [Google Scholar] [CrossRef]

- Scherer, L.; Pfister, S. Hydropower’s biogenic carbon footprint. PLoS ONE 2016, 11, e0161947. [Google Scholar] [CrossRef] [PubMed]

- Pfister, S.; Nauser, I. Greenhouse Gas Emissions of Selected Hydropower Reservoirs; ETH Zurich: Zurich, Switzerland, 2020. [Google Scholar]

- Tomasini-Montenegro, C.; Santoyo-Castelazo, E.; Gujba, H.; Romero, R.J.; Santoyo, E. Life cycle assessment of geothermal power generation technologies: An updated review. Appl. Therm. Eng. 2017, 114, 1119–1136. [Google Scholar] [CrossRef]

- Frick, S.; Kaltschmitt, M.; Schröder, G. Life cycle assessment of geothermal binary power plants using enhanced low-temperature reservoirs. Energy 2010, 35, 2281–2294. [Google Scholar] [CrossRef]

- Buonocore, E.; Vanoli, L.; Carotenuto, A.; Ulgiati, S. Integrating life cycle assessment and emergy synthesis for the evaluation of a dry steam geothermal power plant in Italy. Energy 2015, 86, 476–487. [Google Scholar] [CrossRef]

- Karlsdottir, M.R.; Heinonen, J.; Palsson, H.; Palsson, O.P. Life cycle assessment of a geothermal combined heat and power plant based on high temperature utilization. Geothermics 2020, 84, 101727. [Google Scholar] [CrossRef]

- Singh, B.; Strømman, A.H.; Hertwich, E. Life cycle assessment of natural gas combined cycle power plant with post-combustion carbon capture, transport and storage. Int. J. Greenh. Gas Control 2011, 5, 457–466. [Google Scholar] [CrossRef]

- Medeiros, D.L.; Sales, E.A.; Kiperstok, A. Energy production from microalgae biomass: Carbon footprint and energy balance. J. Clean. Prod. 2015, 96, 493–500. [Google Scholar] [CrossRef]

- ISO 14780:2017; Solid Biofuels—Sample Preparation. ISO: Geneva, Switzerland, 2017.

- ISO 18134-1:2015; Solid Biofuels—Determination of Moisture Content—Oven Dry Method. ISO: Geneva, Switzerland, 2015.

- BS EN ISO 18125:2017; Solid Biofuels—Determination of Calorific Value. BSI Standards Publication: London, UK, 2017.

- ISO 18122:2015; Solid Biofuels—Determination of Ash Content. ISO: Geneva, Switzerland, 2015.

- ISO 16948:2015; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. BSI Standards Publication: London, UK, 2015.

- ISO 16994:2016; Solid Biofuels—Determination of Total Content of Sulfur and Chlorine. ISO: Geneva, Switzerland, 2016.

- Wiedmann, T.; Minx, J. A Definition of ‘Carbon Footprint’. Science 2007, 1, 1–11. [Google Scholar]

- ISO 14067:2018; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. ISO: Geneva, Switzerland, 2018.

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Frischknecht, R.; Hischier, R.; Weidema, B.; Althaus, H.-J.; Bauer, C.; Doka, G.; Dones, R.; Hellweg, S.; Humbert, S.; Jungbluth, N.; et al. Implementation of Life Cycle Impact Assessment Methods Data v1.1 (2004). In Ecoinvent Report No. 3; Ecoinvent Centre: Dübendorf, Switzerland, 2004; p. 116. [Google Scholar]

- Ivanova, N.; Gugleva, V.; Dobreva, M.; Pehlivanov, I.; Stefanov, S.; Andonova, V. Combustion of Biomass Fuel and Residues: Emissions Production Perspective. In Developments in Combustion Technology; Kyprianidis, K., Skvaril, J., Eds.; IntechOpen: London, UK, 2016; p. 31. [Google Scholar]

- European Parliament Directive (EU). 2018/2001 of the European Parliament and of the Council on the promotion of the use of energy from renewable sources. Off. J. Eur. Union 2018, 2018, 82–209. [Google Scholar]

- Commissione Europea. Comunicazione Della Commissione. Un Pianeta Pulito per Tutti; Commissione Europea: Bruxelles, Belgium, 2018. [Google Scholar]

- Redcert GMBH. Scheme Principles for GHG Calculation; Version EU 05; Redcert GMBH: Bonn, Germany, 2021; pp. 5–7. [Google Scholar]

- European Council. National overall targets for the share of energy from renewable sources in gross final consumption of energy in 2020. Share of energy from renewable sources in gross final consumption of energy, 2005 (S 2005). Target for share of energy from renewable sources. In Annex. 1 to 12. Proposal for a Directive of the European Parliament and of the Council on the Promotion of the Use of Energy from Renewable Sources; European Council: Brussels, Belgium, 2017; pp. 19–64. [Google Scholar]

- Giuntoli, J.; Agostini, A.; Edwards, R.; Marelli, L. Solid and gaseous bioenergy pathways, Input values and GHG emissions: Calculated according to methodology set in COM (2010) 11 and SWD(2014) 259. In JRC Science and Policy Reports; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Anukam, A.; Berghel, J. Biomass Pretreatment and Characterization: A Review. In Biotechnological Applications of Biomass; Basso, T., Basso, L.C., Eds.; IntechOpen: London, UK, 2020; Volume I, pp. 1–17. ISBN 978-1-83881-182-2. [Google Scholar]

- Khan, A.A.; de Jong, W.; Jansens, P.J.; Spliethoff, H. Biomass combustion in fluidized bed boilers: Potential problems and remedies. Fuel Process. Technol. 2009, 90, 21–50. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Song, Y.C.; Li, W.Y.; Feng, J. Ash contents and ash-forming elements of biomass and their significance for solid biofuel combustion. Fuel 2017, 208, 377–409. [Google Scholar] [CrossRef]

- Vakkilainen, E.K. Solid Biofuels and Combustion; Elsevier: Amsterdam, The Netherlands, 2017; ISBN 9780128043899. [Google Scholar]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Characterization of Spanish biomass wastes for energy use. Bioresour. Technol. 2012, 103, 249–258. [Google Scholar] [CrossRef]

- Saidur, R.; Abdelaziz, E.A.; Demirbas, A.; Hossain, M.S.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Pergola, M.; Rita, A.; Tortora, A.; Castellaneta, M.; Borghetti, M.; De Franchi, A.S.; Lapolla, A.; Moretti, N.; Pecora, G.; Pierangeli, D.; et al. Identification of suitable areas for biomass power plant construction through environmental impact assessment of forest harvesting residues transportation. Energies 2020, 13, 2699. [Google Scholar] [CrossRef]

- Butnar, I.; Rodrigo, J.; Gasol, C.M.; Castells, F. Life-cycle assessment of electricity from biomass: Case studies of two biocrops in Spain. Biomass Bioenergy 2010, 34, 1780–1788. [Google Scholar] [CrossRef]

- Chary, K.; Aubin, J.; Guindé, L.; Sierra, J.; Blazy, J.M. Cultivating biomass locally or importing it? LCA of biomass provision scenarios for cleaner electricity production in a small tropical island. Biomass Bioenergy 2018, 110, 1–12. [Google Scholar] [CrossRef]

- Lindholm, E.L.; Berg, S.; Hansson, P.A. Energy efficiency and the environmental impact of harvesting stumps and logging residues. Eur. J. For. Res. 2010, 129, 1223–1235. [Google Scholar] [CrossRef]

- Cherubini, F.; Strømman, A.H. Life cycle assessment of bioenergy systems: State of the art and future challenges. Bioresour. Technol. 2011, 102, 437–451. [Google Scholar] [CrossRef]

- Muench, S.; Guenther, E. A systematic review of bioenergy life cycle assessments. Appl. Energy 2013, 112, 257–273. [Google Scholar] [CrossRef]

- Ganesh, A.; Banerjee, R. Biomass pyrolysis for power generation—A potential technology. Renew. Energy 2001, 22, 9–14. [Google Scholar] [CrossRef]

- Bain, R.L.; Overend, R.P.; Craig, K.R. Biomass-fired power generation. Fuel Process. Technol. 1998, 54, 1–16. [Google Scholar] [CrossRef]

- Evans, A.; Strezov, V.; Evans, T.J. Sustainability considerations for electricity generation from biomass. Renew. Sustain. Energy Rev. 2010, 14, 1419–1427. [Google Scholar] [CrossRef]

- Loução, P.O.; Ribau, J.P.; Ferreira, A.F. Life cycle and decision analysis of electricity production from biomass—Portugal case study. Renew. Sustain. Energy Rev. 2019, 108, 452–480. [Google Scholar] [CrossRef]

- Briones-Hidrovo, A.; Copa, J.; Tarelho, L.A.C.; Gonçalves, C.; Pacheco da Costa, T.; Dias, A.C. Environmental and energy performance of residual forest biomass for electricity generation: Gasification vs. combustion. J. Clean. Prod. 2021, 289, 125680. [Google Scholar] [CrossRef]

- Rafaschieri, A.; Rapaccini, M.; Manfrida, G. Life cycle assessment of electricity production from poplar energy crops compared with conventional fossil fuels. Energy Convers. Manag. 1999, 40, 1477–1493. [Google Scholar] [CrossRef]

- Carpentieri, M.; Corti, A.; Lombardi, L. Life cycle assessment (LCA) of an integrated biomass gasification combined cycle (IBGCC) with CO2 removal. Energy Convers. Manag. 2005, 46, 1790–1808. [Google Scholar] [CrossRef]

- Puy, N.; Rieradevall, J. Environmental assessment of post-consumer wood and forest residues gasification: The case study of Barcelona metropolitan area. Biomass Bioenergy 2010, 34, 1457–1465. [Google Scholar] [CrossRef]

- Siegl, S.; Laaber, M.; Holubar, P. Green electricity from biomass, Part I: Environmental impacts of direct life cycle emissions. Waste Biomass Valoriz. 2011, 2, 267–284. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, L.; Yang, S.; Pang, M. A Hybrid Life-Cycle Assessment of Nonrenewable Energy and Greenhouse-Gas Emissions of a Village-Level Biomass Gasification Project in China. Energies 2012, 5, 2708–2723. [Google Scholar] [CrossRef]

- Röder, M.; Whittaker, C.; Thornley, P. How certain are greenhouse gas reductions from bioenergy? Life cycle assessment and uncertainty analysis of wood pellet-to-electricity supply chains from forest residues. Biomass Bioenergy 2015, 79, 50–63. [Google Scholar] [CrossRef]

- Paengjuntuek, W.; Boonmak, J.; Mungkalasiri, J. Environmental Assessment of Integrated Biomass Gasification Fuel Cell for Power Generation System. Int. J. Environ. Sci. Dev. 2015, 6, 445–450. [Google Scholar] [CrossRef]

- Nian, V. The carbon neutrality of electricity generation from woody biomass and coal, a critical comparative evaluation. Appl. Energy 2016, 179, 1069–1080. [Google Scholar] [CrossRef]

- da Costa, T.P.; Quinteiro, P.; Tarelho, L.A.; Arroja, L.; Dias, A.C. Environmental impacts of forest biomass-to-energy conversion technologies: Grate furnace vs. fluidised bed furnace. J. Clean. Prod. 2018, 171, 153–162. [Google Scholar] [CrossRef]

- Yang, Q.; Zhou, H.; Zhang, X.; Nielsen, C.P.; Li, J.; Lu, X.; Yanga, H.; Chen, H. Hybrid life-cycle assessment for energy consumption and greenhouse gas emissions of a typical biomass gasification power plant in China. J. Clean. Prod. 2018, 205, 661–671. [Google Scholar] [CrossRef]

- Siregar, K.; Luthfi Machsun, A.; Sholihati, S.; Alamsyah, R.; Ichwana, I.; Christian Siregar, N.; Syafriandi, S.; Sofiah, I.; Miharza, T.; Muhammad Nur, S.; et al. Life Cycle Impact Assessment on Electricity Production from Biomass Power Plant System through Life Cycle Assessment (LCA) Method using Biomass from Palm Oil Mill in Indonesia. E3S Web Conf. 2020, 188, 00018. [Google Scholar] [CrossRef]

- Zang, G.; Zhang, J.; Jia, J.; Lora, E.S.; Ratner, A. Life cycle assessment of power-generation systems based on biomass integrated gasification combined cycles. Renew. Energy 2020, 149, 336–346. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).