A Non-Isolated High Gain Step-Up DC/DC Converter Based on Coupled Inductor with Reduced Voltage Stresses

Abstract

1. Introduction

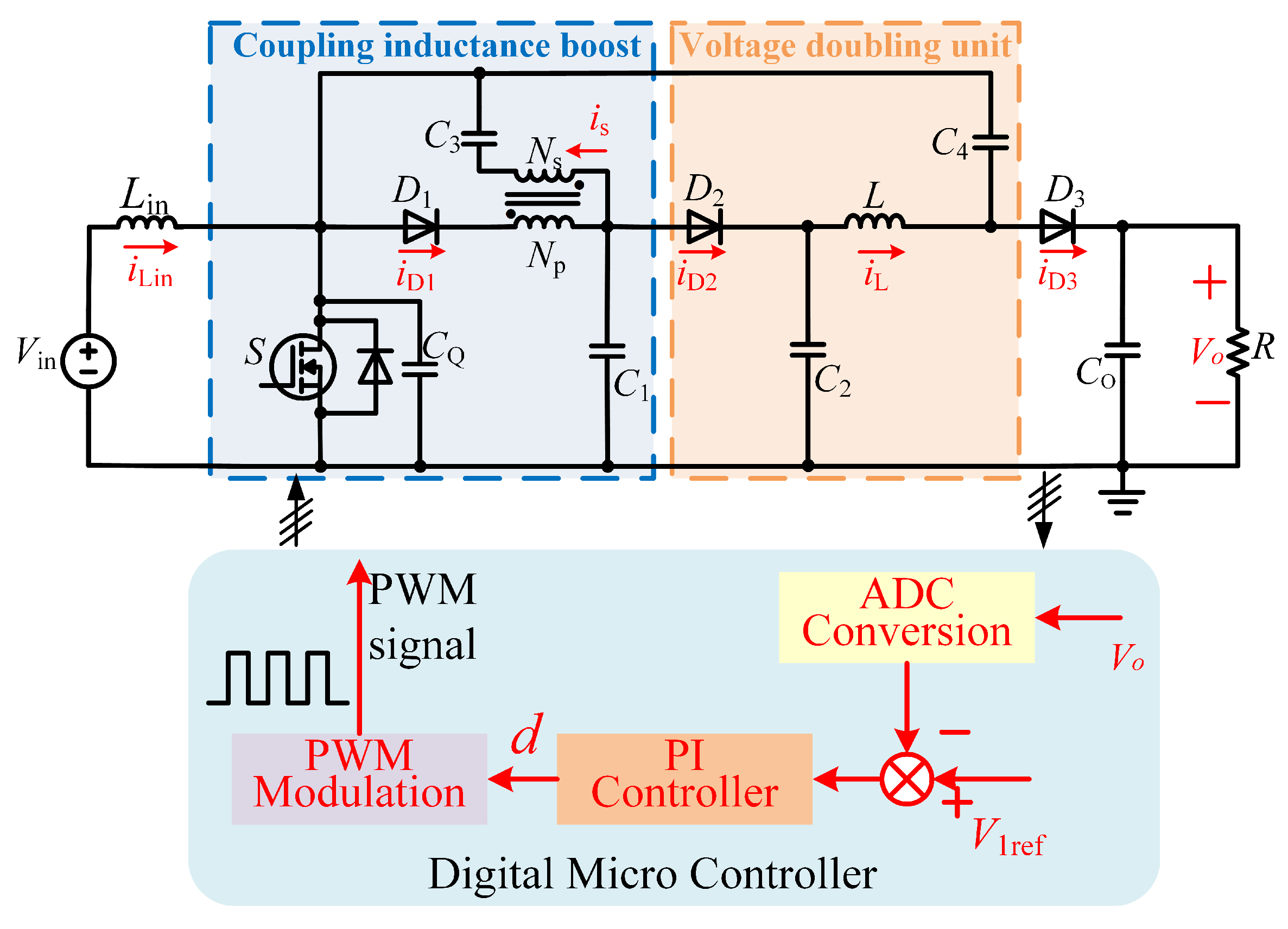

2. Coupled Inductance-Based High-Gain DC/DC Conversion System Configuration

2.1. System Configuration

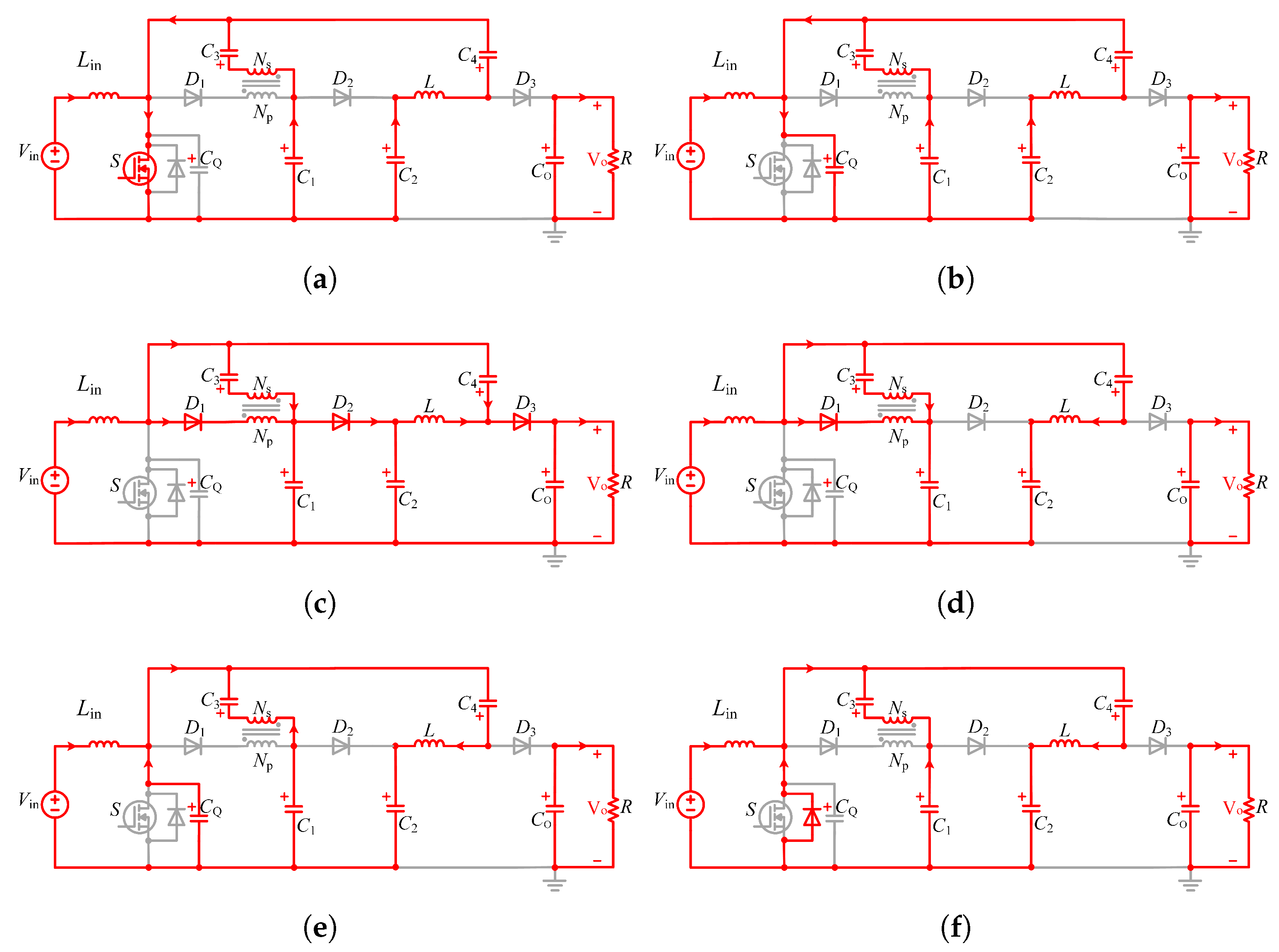

2.2. Operation Principle of the Proposed Converter

3. System Performance Analysis

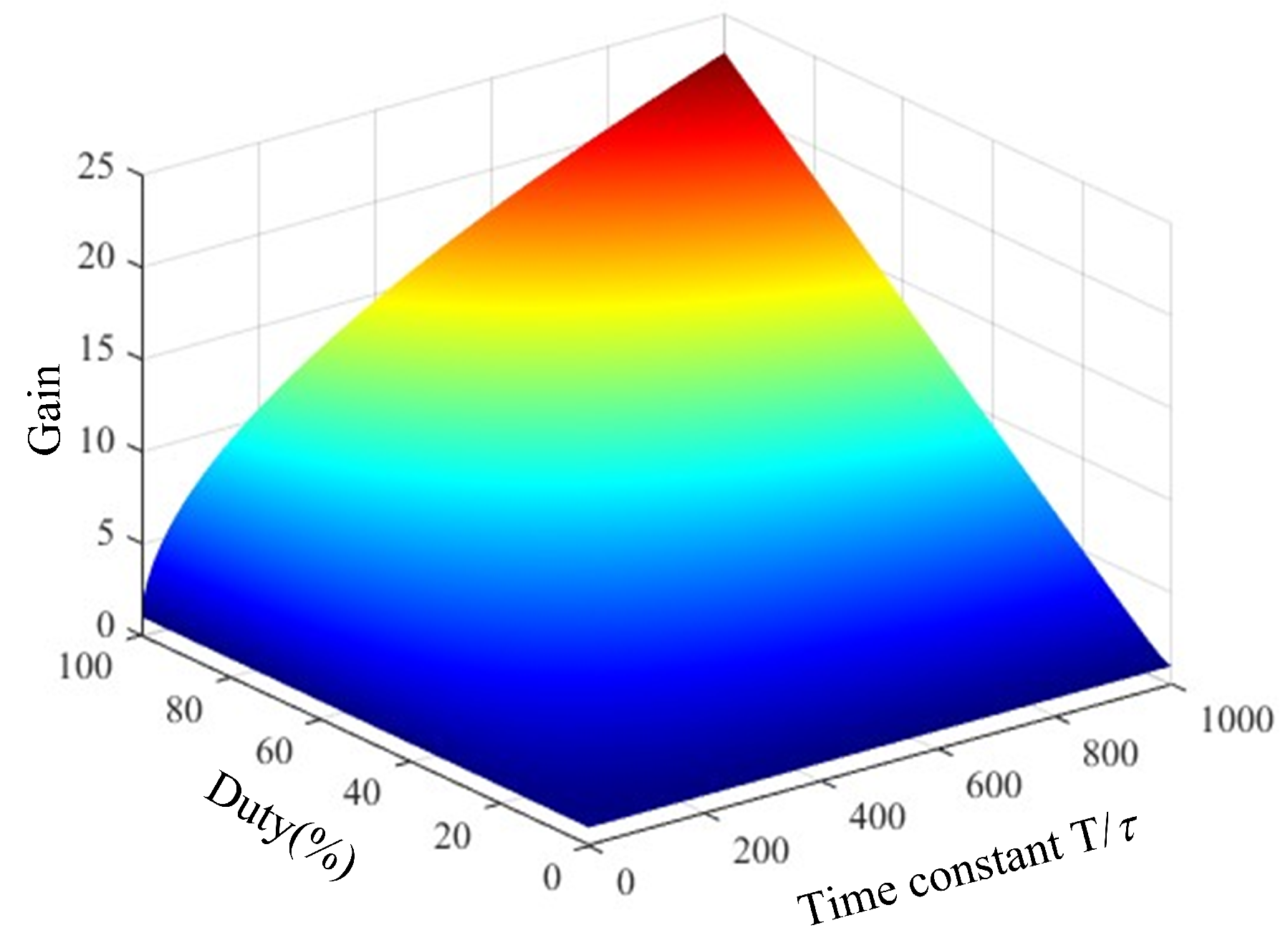

3.1. Output Voltage Gain of the System

3.2. Analysis of Voltage Stress on Capacitors and Inductors

3.3. Analysis of Voltage Stress on Power Switches

3.4. Performance Comparison of Different Converters

3.5. Soft Switching Condition

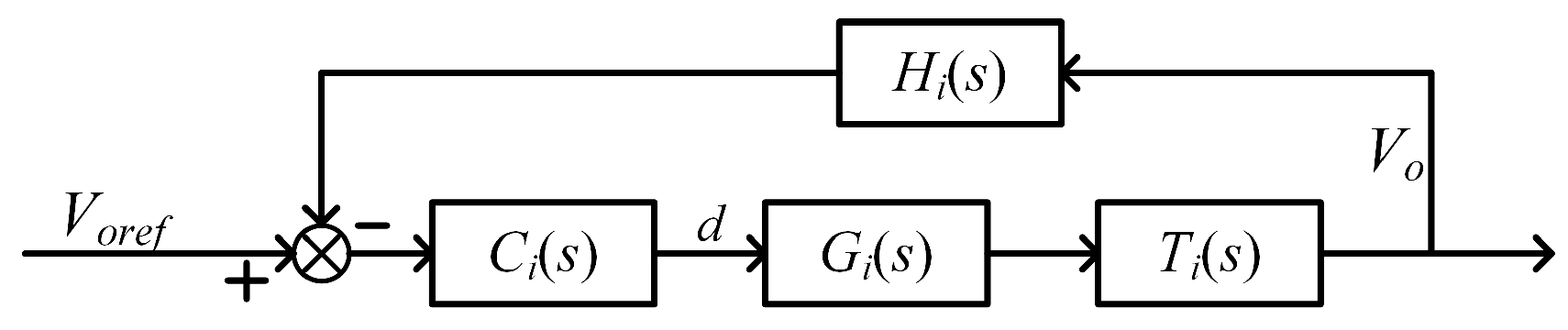

4. Control System Design

5. Analysis of Simulation Results

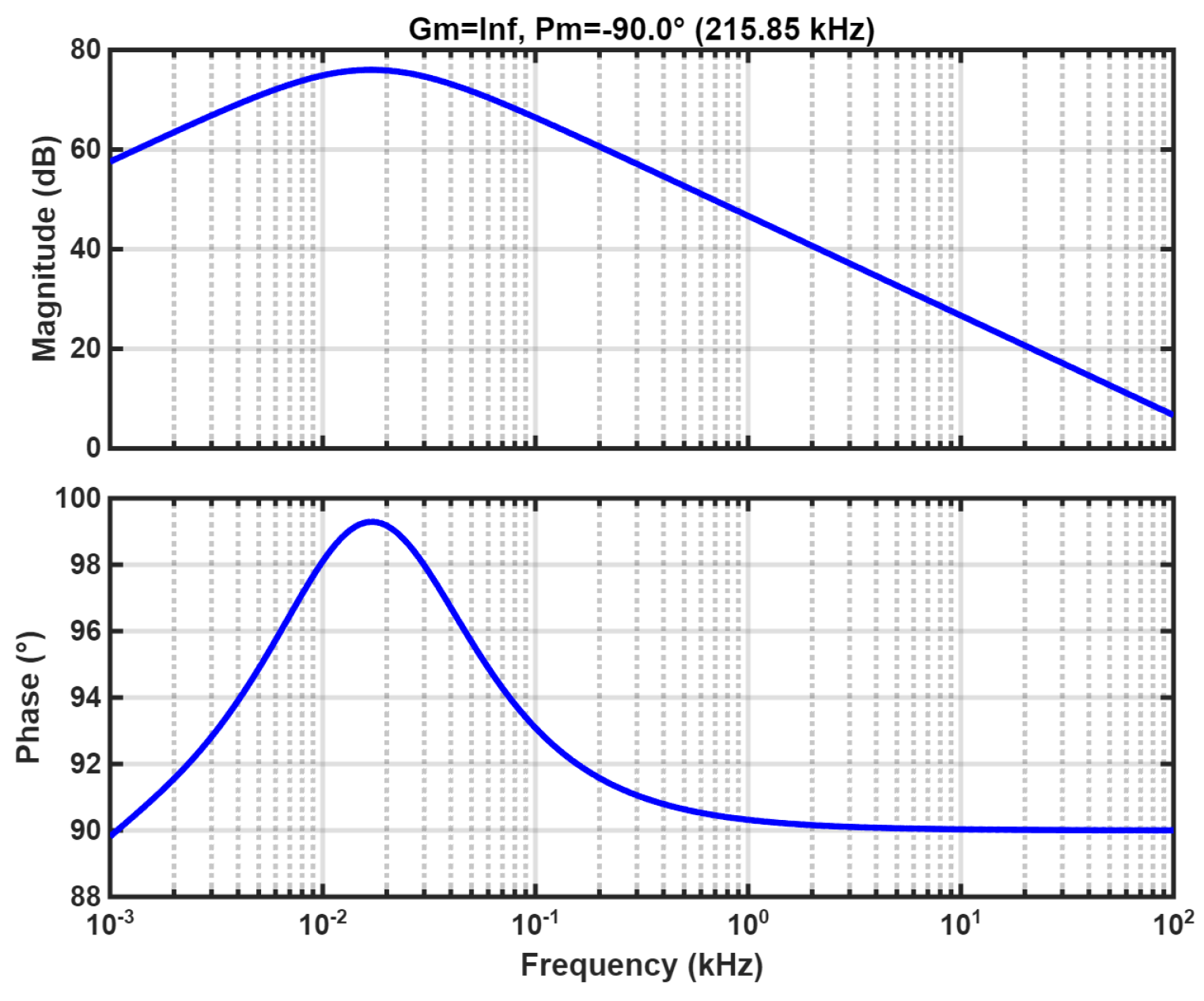

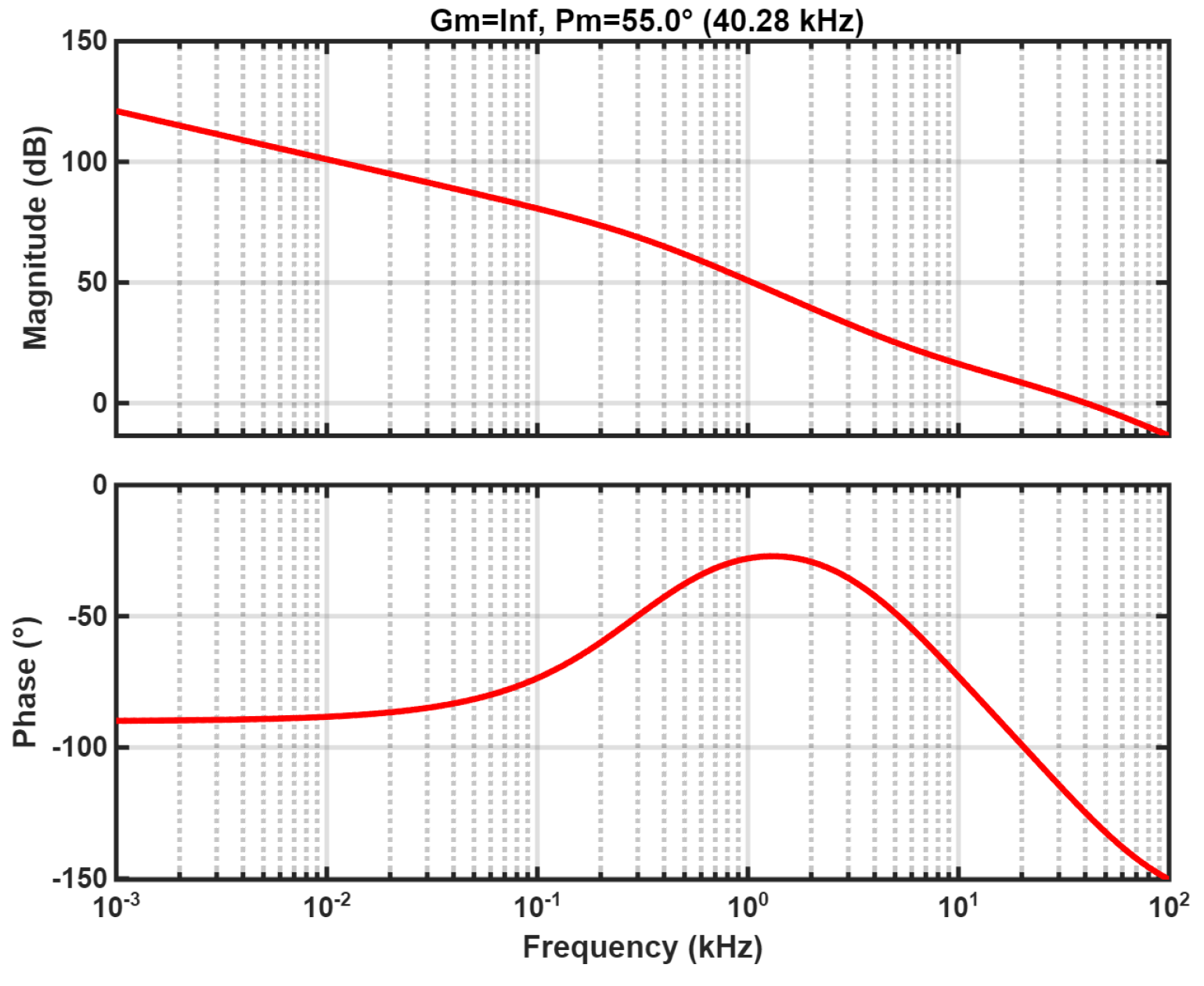

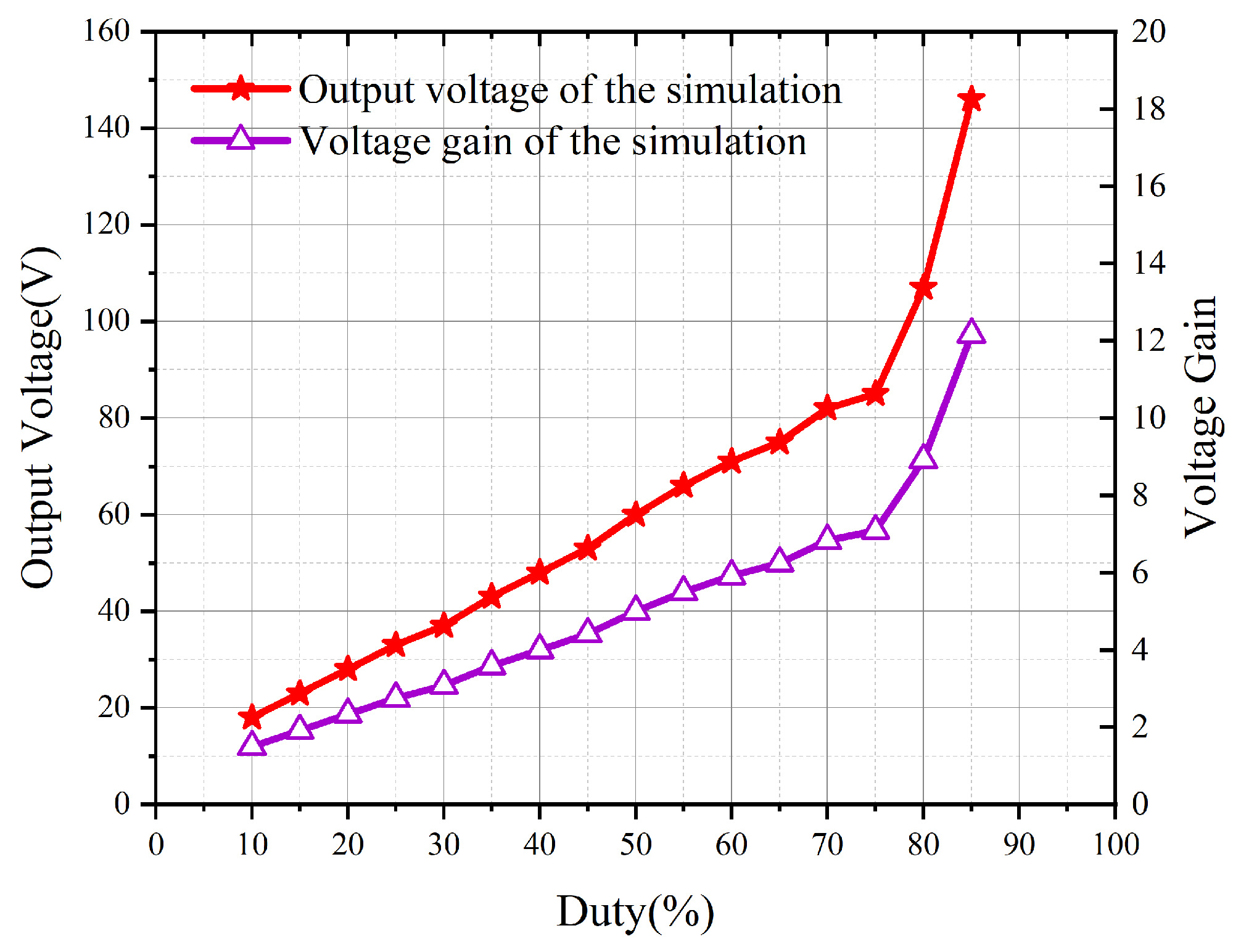

5.1. Open-Loop Scanning

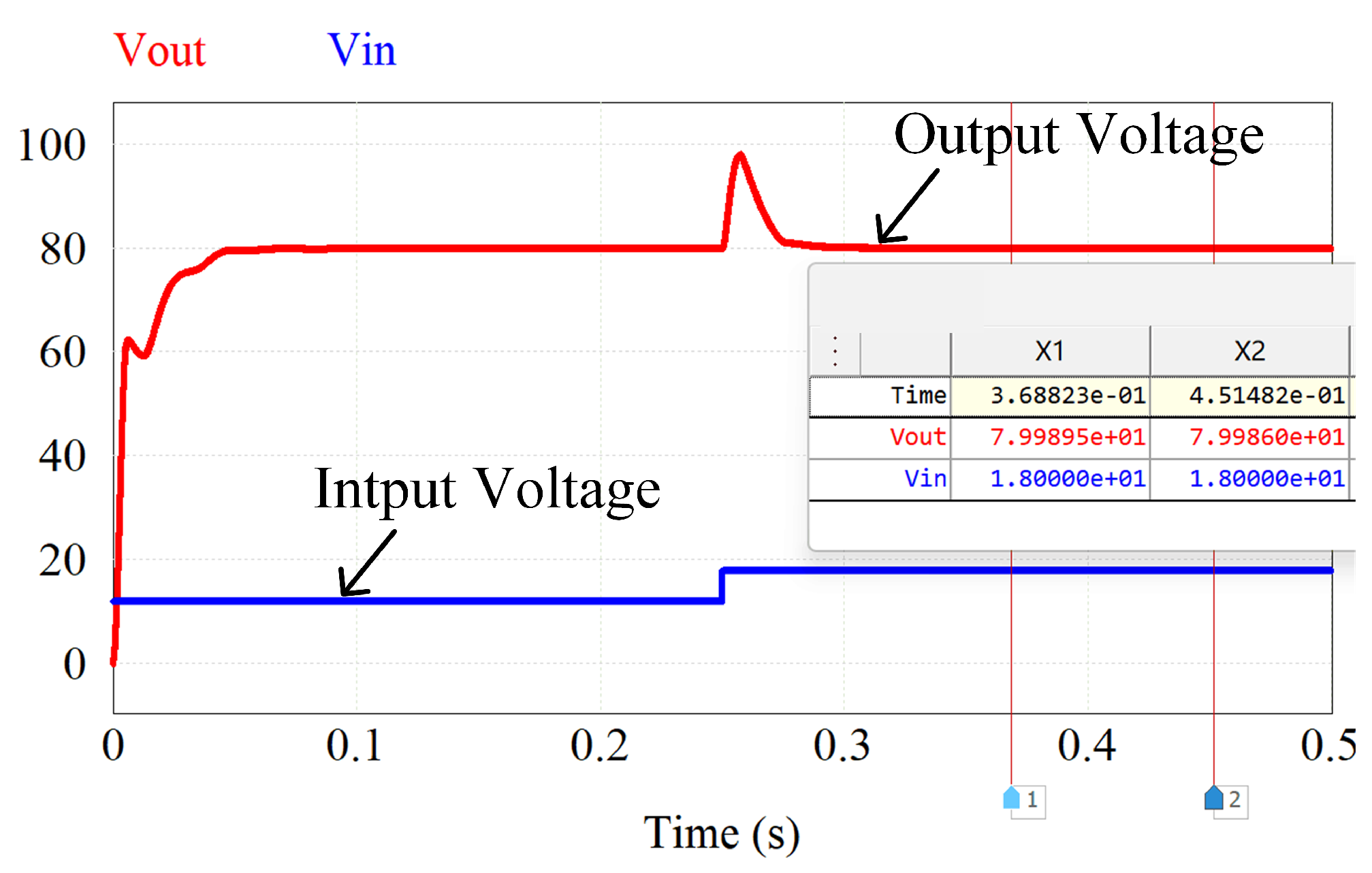

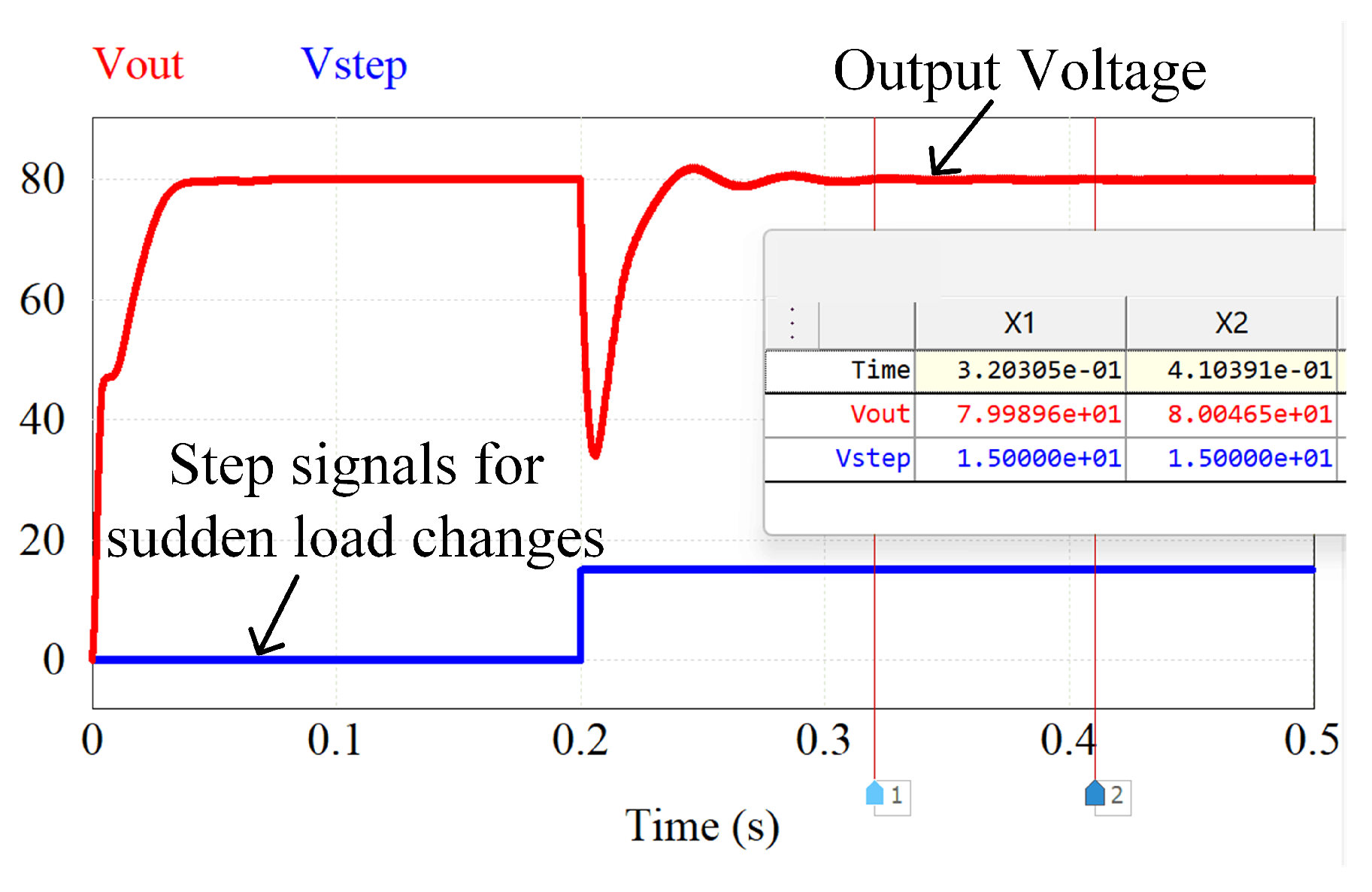

5.2. Closed-Loop Simulation

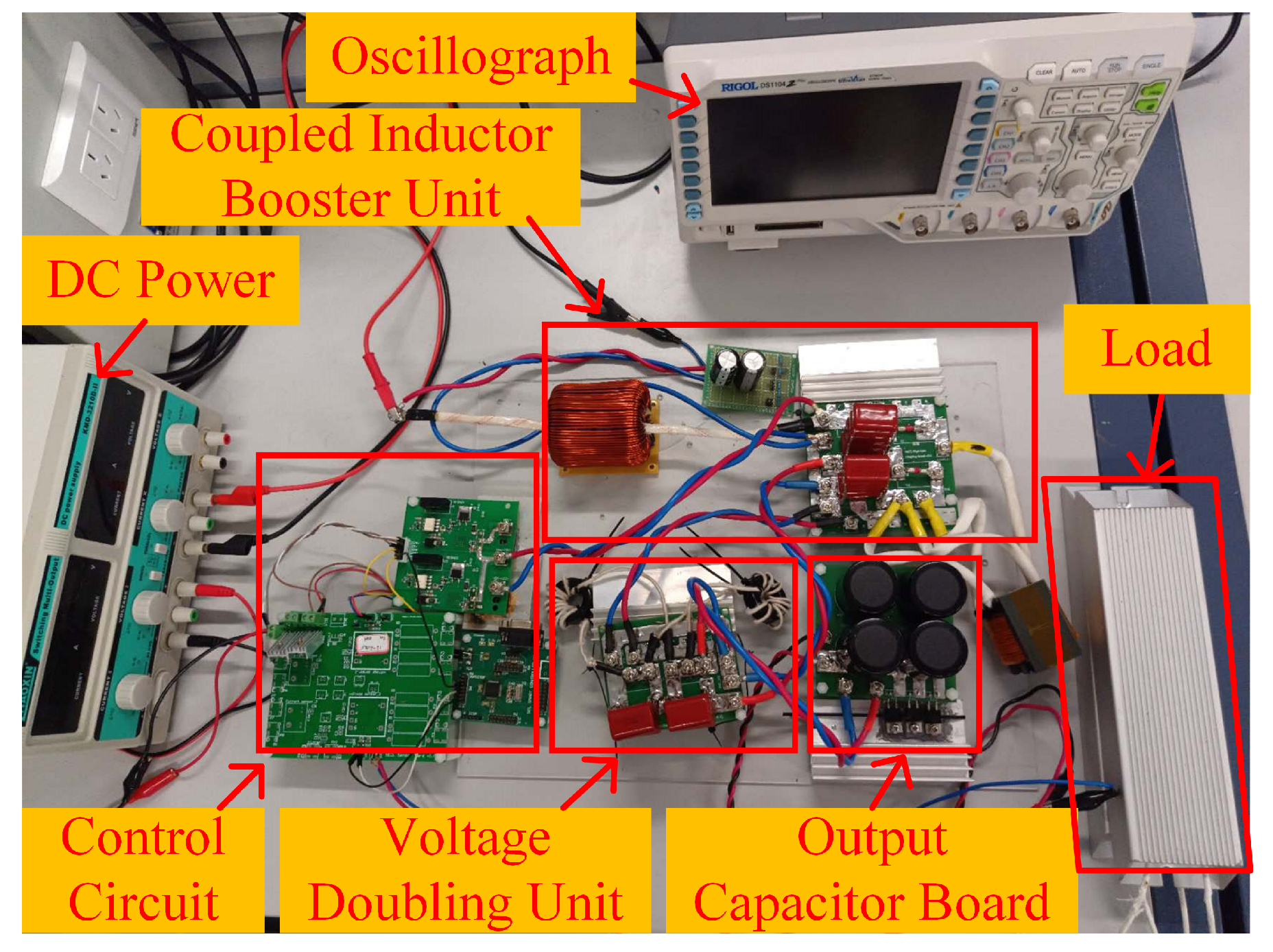

6. Analysis of Experimental Results

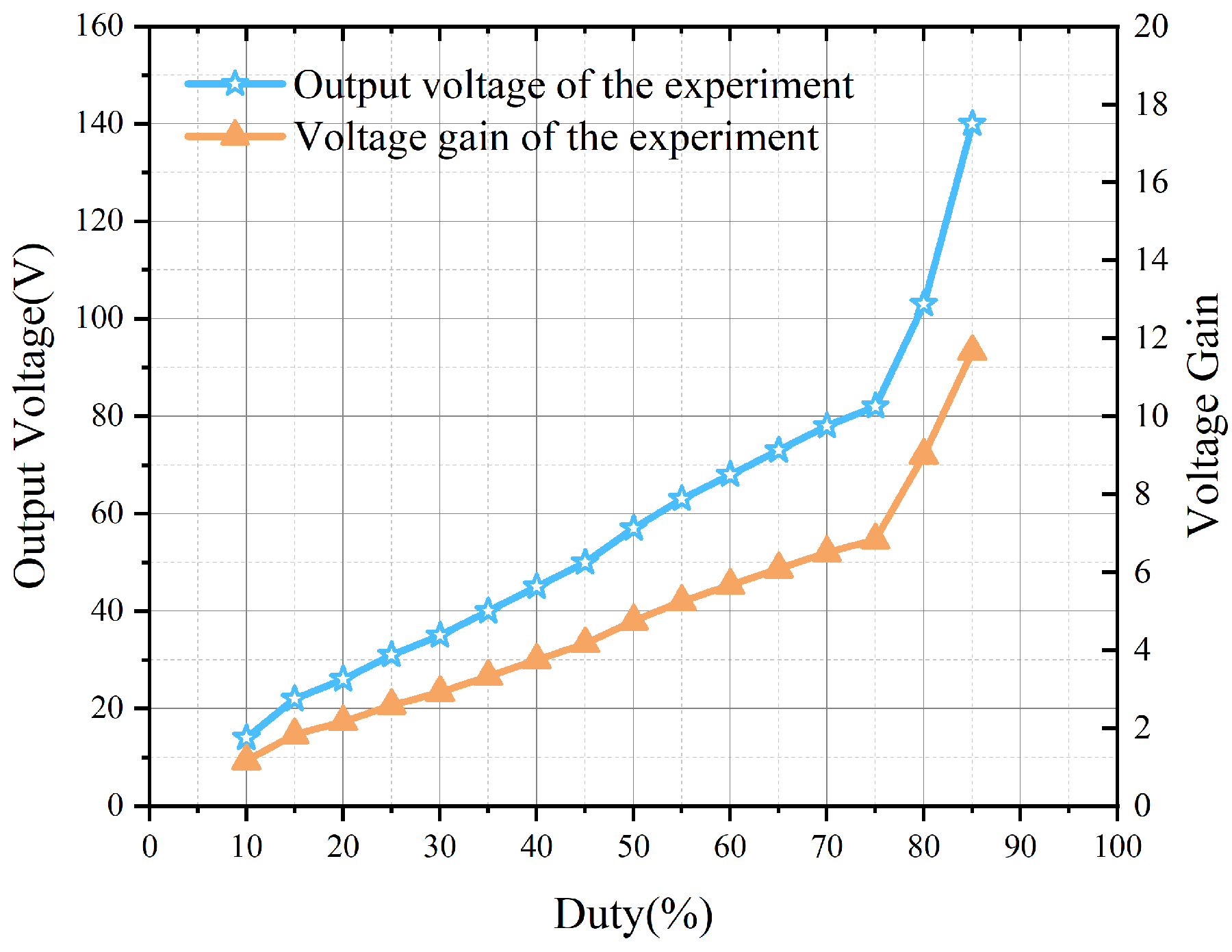

6.1. Open-Loop Scanning

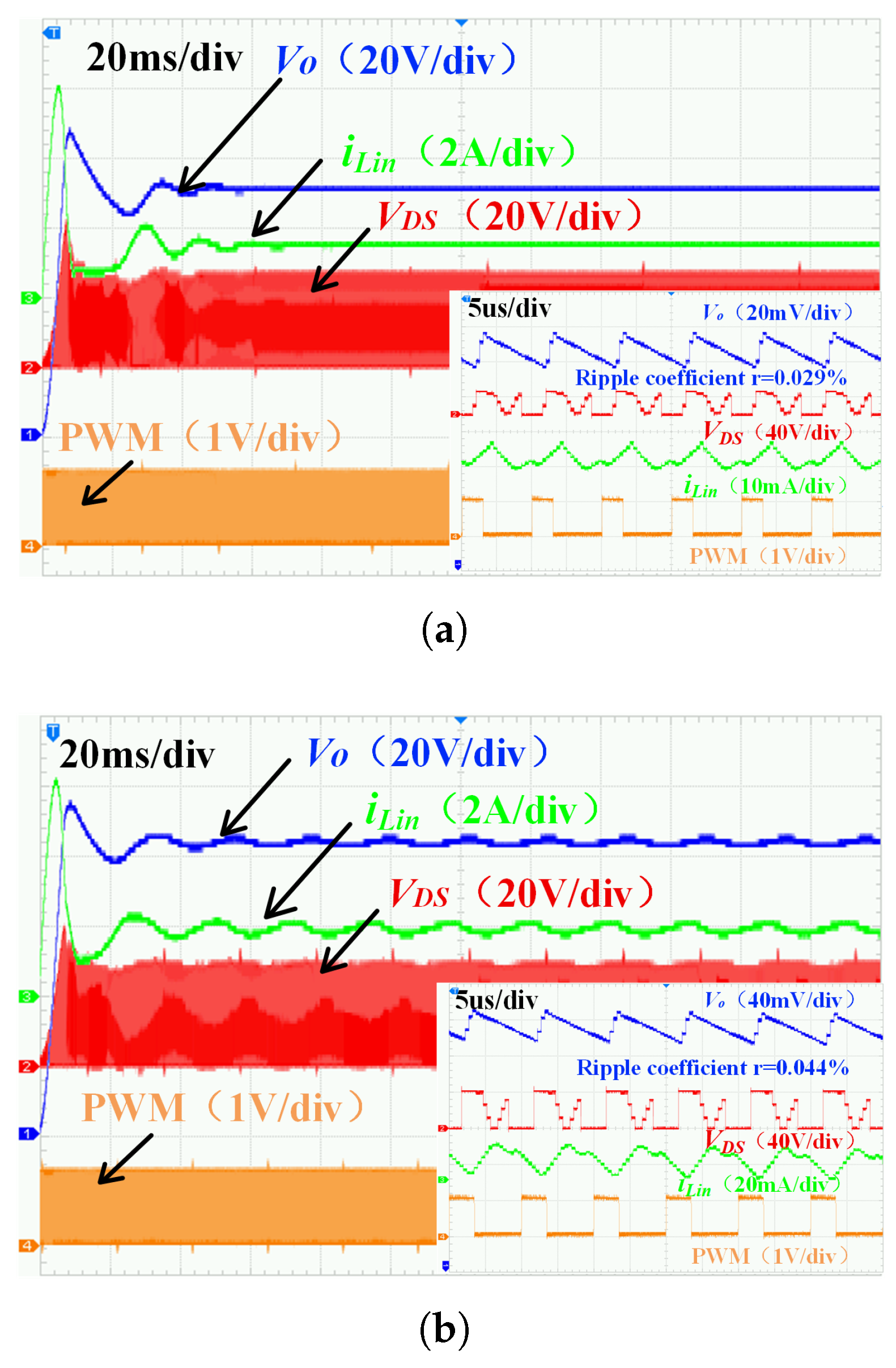

6.2. Closed-Loop Scanning of the Converter

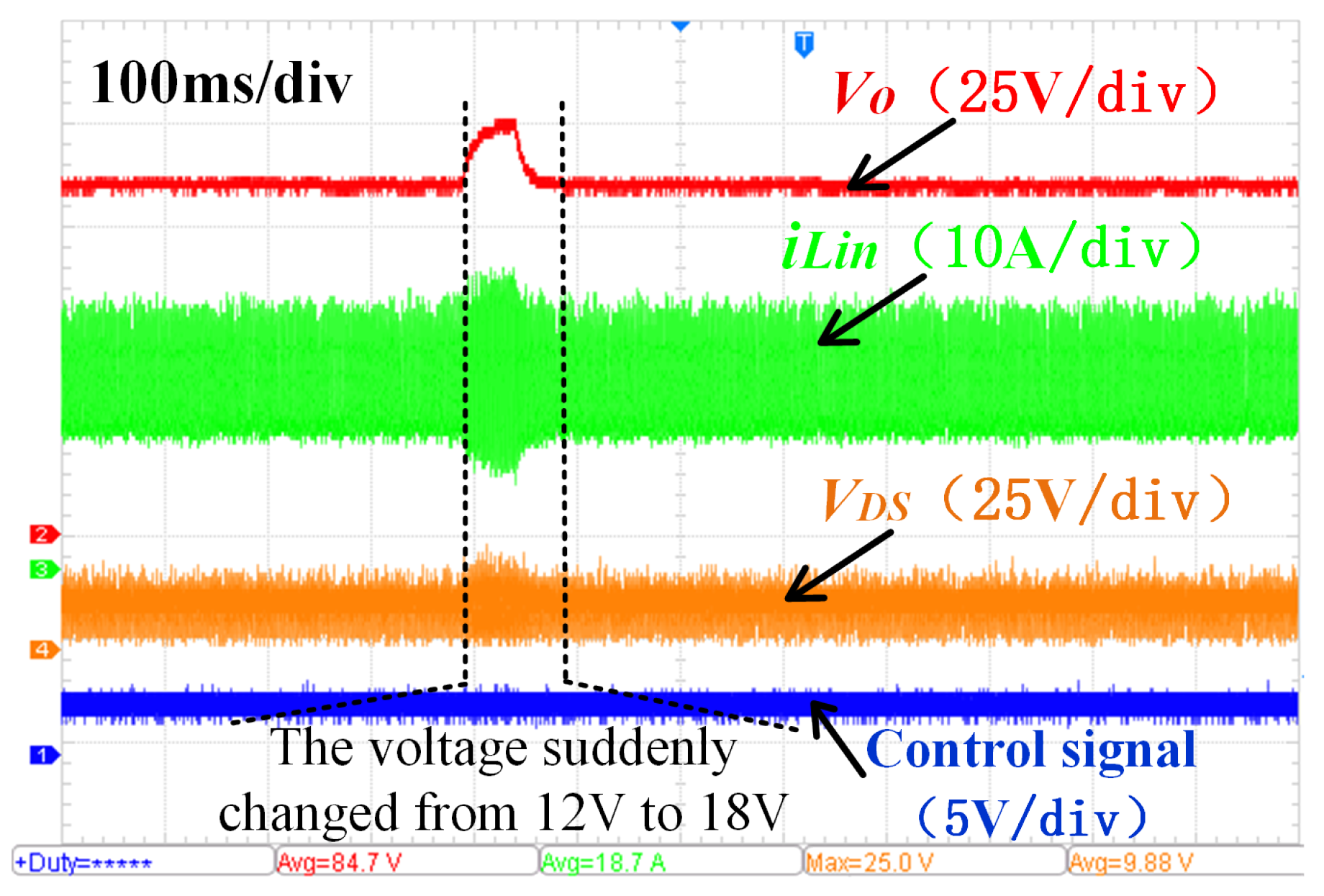

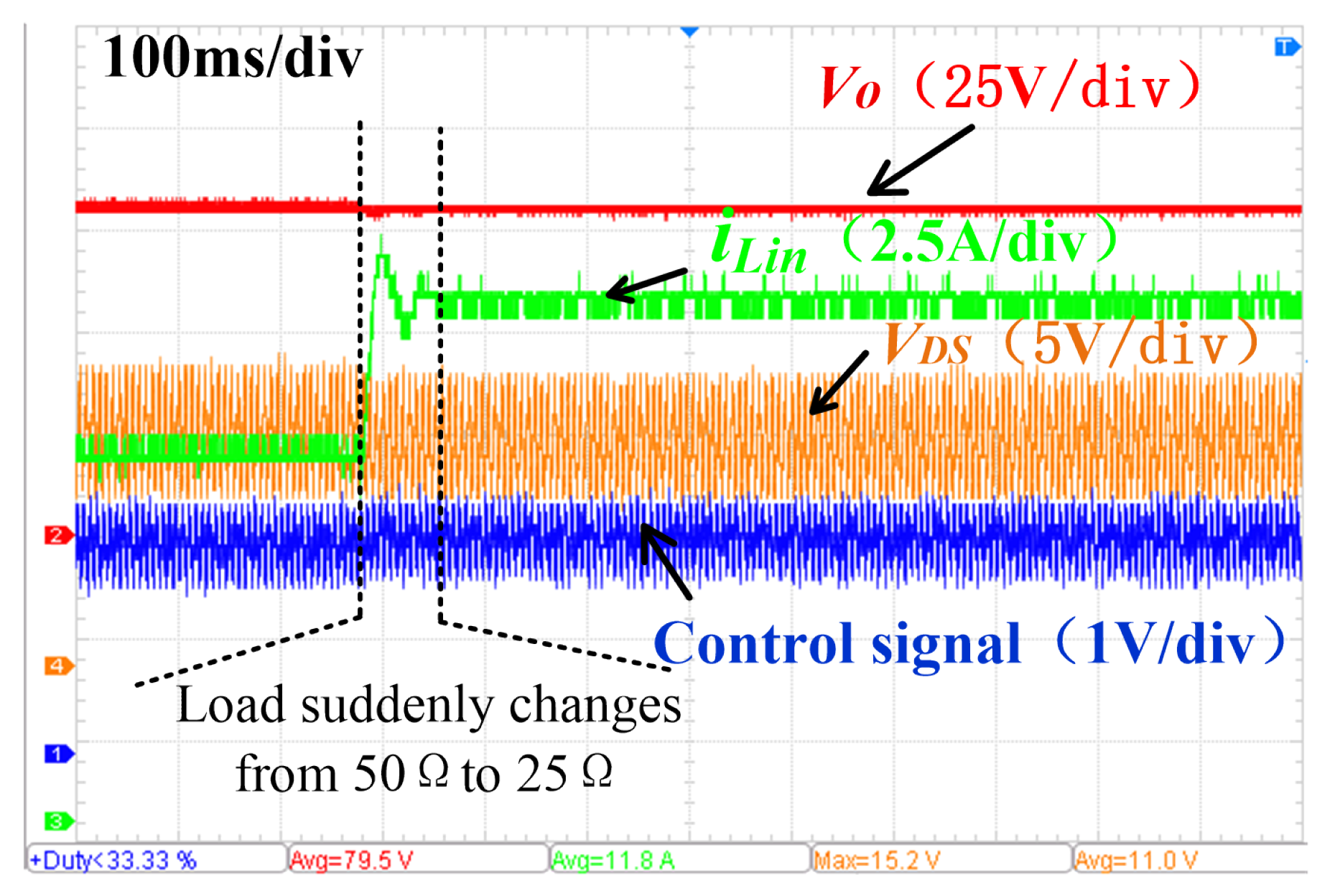

6.3. Transformer Dynamic Response Performance Experiment

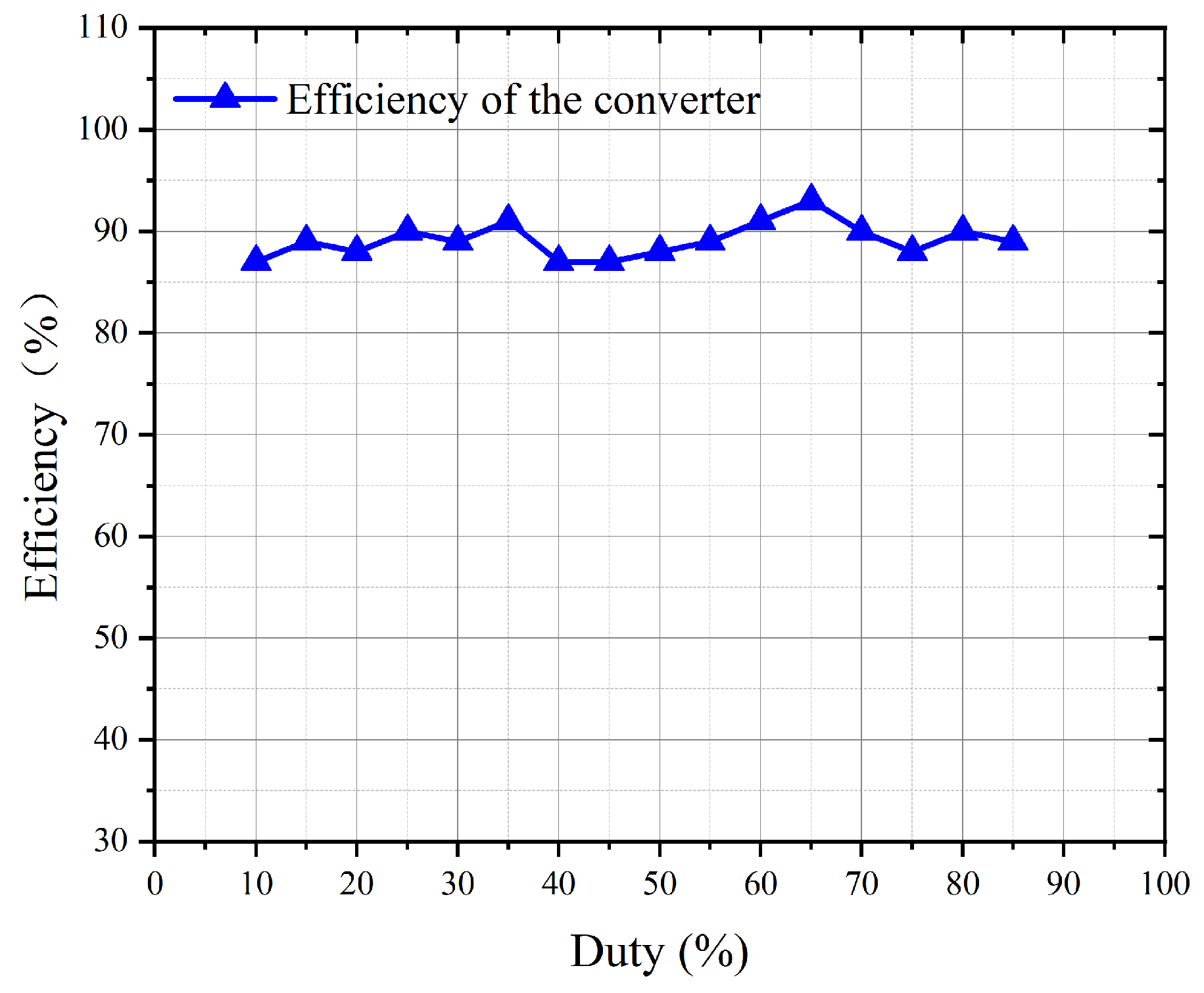

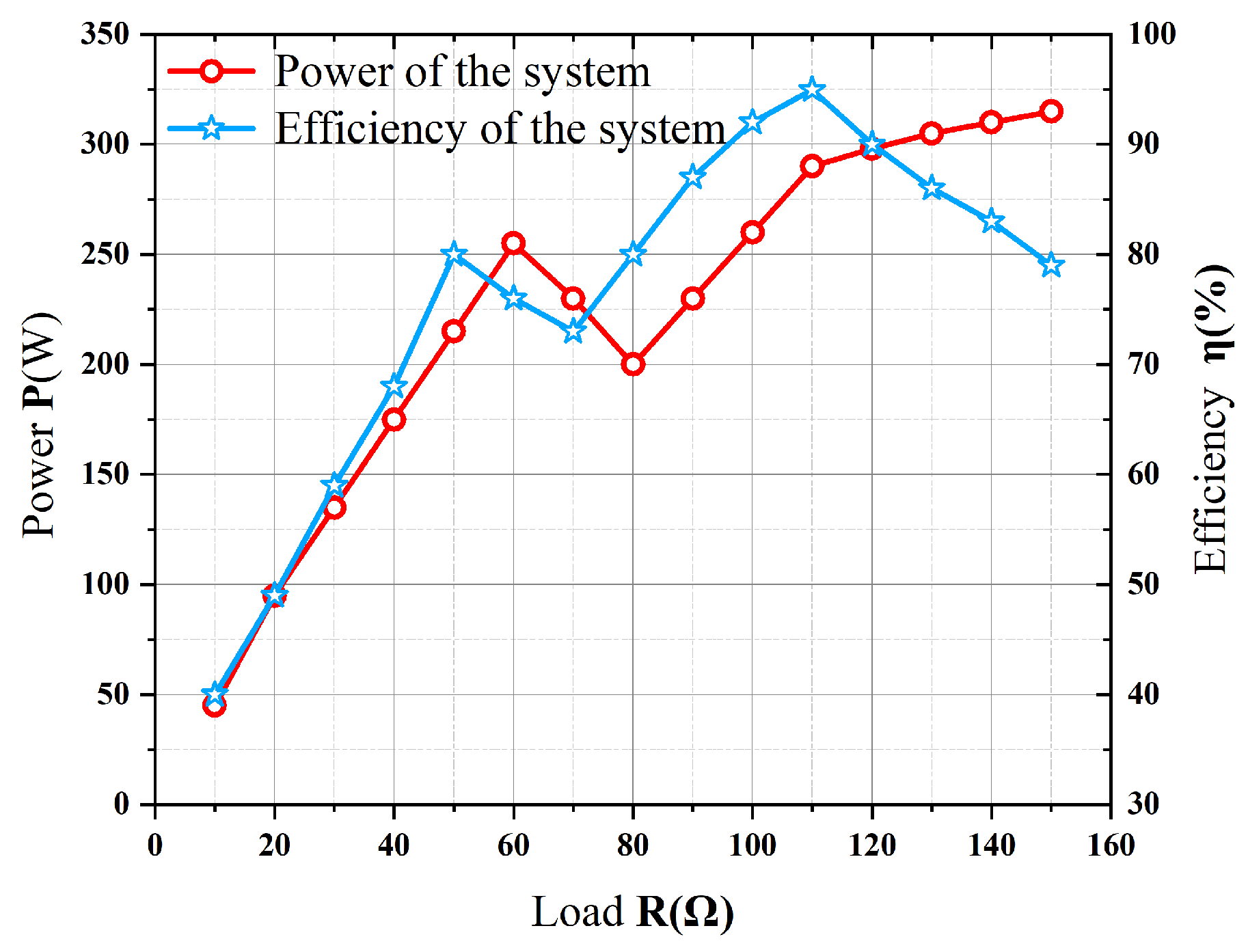

6.4. Full Load Range Efficiency Test

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Angizeh, F.; Bae, J.; Chen, J.; Klebnikov, A.; Jafari, M.A. Impact Assessment Framework for Grid Integration of Energy Storage Systems and Renewable Energy Sources Toward Clean Energy Transition. IEEE Access 2023, 11, 134995–135005. [Google Scholar] [CrossRef]

- Bollen, J.; Hers, S.; van der Zwaan, B. An integrated assessment of climate change, air pollution, and energy security policy. Energy Policy 2010, 38, 4021–4030. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Zaman, K.; Zhang, Y. The relationship between energy-resource depletion, climate change, health resources and the environmental Kuznets curve: Evidence from the panel of selected developed countries. Renew. Sustain. Energy Rev. 2016, 62, 468–477. [Google Scholar] [CrossRef]

- Prabhakaran, P.; Agarwal, V. Novel Four-Port DC–DC Converter for Interfacing Solar PV–Fuel Cell Hybrid Sources With Low-Voltage Bipolar DC Microgrids. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 1330–1340. [Google Scholar] [CrossRef]

- Ramaprabha, R.; Sangeetha, S.; Blessy, R.A.; Lekhashree, R.; Meenakshi, P. Development of AC-DC Converter for Hybrid PV Integrated Microgrid System. Eng. Proc. 2025, 93, 10. [Google Scholar] [CrossRef]

- Lakshmi, M.; Hemamalini, S. Nonisolated High Gain DC–DC Converter for DC Microgrids. IEEE Trans. Ind. Electron. 2018, 65, 1205–1212. [Google Scholar] [CrossRef]

- Dhananjaya, M.; Potnuru, D.; Manoharan, P.; Alhelou, H.H. Design and Implementation of Single-Input-Multi-Output DC-DC Converter Topology for Auxiliary Power Modules of Electric Vehicle. IEEE Access 2022, 10, 76975–76989. [Google Scholar] [CrossRef]

- Sojoudi, T.; Sarhangzadeh, M.; Olamaei, J.; Ardashir, J.F. An Extendable Bidirectional High-Gain DC–DC Converter for Electric Vehicle Applications Equipped With IOFL Controller. IEEE Trans. Power Electron. 2023, 38, 9767–9779. [Google Scholar] [CrossRef]

- Benhammou, A.; Tedjini, H.; Hartani, M.A.; Ghoniem, R.M.; Alahmer, A. Accurate and Efficient Energy Management System of Fuel Cell/Battery/Supercapacitor/AC and DC Generators Hybrid Electric Vehicles. Sustainability 2023, 15, 10102. [Google Scholar] [CrossRef]

- Rajabi, A.; Rajaei, A.; Tehrani, V.M.; Dehghanian, P.; Guerrero, J.M.; Khan, B. A Non-Isolated High Step-Up DC-DC Converter Using Voltage Lift Technique: Analysis, Design, and Implementation. IEEE Access 2022, 10, 6338–6347. [Google Scholar] [CrossRef]

- Qin, Y.; Yang, Y.; Li, S.; Huang, Y.; Tan, S.C.; Hui, S.Y. A High-Efficiency DC/DC Converter for High-Voltage-Gain, High-Current Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 2812–2823. [Google Scholar] [CrossRef]

- Alavi, P.; Mohseni, P.; Babaei, E.; Marzang, V. An Ultra-High Step-Up DC–DC Converter With Extendable Voltage Gain and Soft-Switching Capability. IEEE Trans. Ind. Electron. 2020, 67, 9238–9250. [Google Scholar] [CrossRef]

- Subhani, N.; May, Z.; Alam, M.K.; Khan, I.; Hossain, M.A.; Mamun, S. An Improved Non-Isolated Quadratic DC-DC Boost Converter with Ultra High Gain Ability. IEEE Access 2023, 11, 11350–11363. [Google Scholar] [CrossRef]

- Malvekar, S.A.; Bhattar, C.L.; B.Savakhande, V. Non-Isolated High Voltage Gain DC-DC Converters using Inductors for DC Microgrid. In Proceedings of the 2018 International Conference on Control, Power, Communication and Computing Technologies (ICCPCCT), Kannur, India, 23–24 March 2018; pp. 455–459. [Google Scholar] [CrossRef]

- Rajesh, R.; Prabaharan, N.; Santhosh, T.K. Design and Analysis of a Non-Isolated DC-DC Converter With a High-Voltage Conversion Ratio. IEEE Trans. Circuits Syst. II Express Briefs 2023, 70, 2036–2041. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, Q.; Zhu, J.; Lan, X. Dual-Channel Push–Pull Isolated Resonant Gate Driver for High-Frequency ZVS Full-Bridge Converters. IEEE Trans. Power Electron. 2019, 34, 4019–4024. [Google Scholar] [CrossRef]

- Tandon, S.; Rathore, A.K. Analysis and Design of Series LC Resonance-Pulse Based Zero-Current-Switching Current-Fed Half-Bridge DC–DC Converter. IEEE Trans. Ind. Electron. 2021, 68, 6784–6793. [Google Scholar] [CrossRef]

- Oluwasogo, E.S.; Cha, H. A Quadratic Quasi-Z-Source Full-Bridge Isolated DC–DC Converter With High Reliability for Wide Input Applications. IEEE Trans. Ind. Electron. 2022, 69, 10090–10100. [Google Scholar] [CrossRef]

- Liang, T.J.; Huynh, K.K.N.; Chen, K.H.; Huang, W.Y.; Tran, T.A.A. Forward–Flyback Integrated Converter With Voltage Clamping and Soft Switching. IEEE Trans. Power Electron. 2024, 39, 13365–13376. [Google Scholar] [CrossRef]

- Schmitz, L.; Martins, D.C.; Coelho, R.F. A Simple, Accurate Small-Signal Model of a Coupled-Inductor-Based DC-DC Converter Including the Leakage Inductance Effect. IEEE Trans. Circuits Syst. II Express Briefs 2021, 68, 2533–2537. [Google Scholar] [CrossRef]

- Tang, C.Y.; Lin, W.Z.; Tan, Y.C. An Active Clamp Flyback Converter With High Precision Primary-Side Regulation Strategy. IEEE Trans. Power Electron. 2022, 37, 10281–10289. [Google Scholar] [CrossRef]

- Veerachary, M.; Kumar, P. Analysis and Design of Quasi-Z-Source Equivalent DC–DC Boost Converters. IEEE Trans. Ind. Appl. 2020, 56, 6642–6656. [Google Scholar] [CrossRef]

- Singh, K.A.; Prajapati, A.; Chaudhary, K. High-Gain Compact Interleaved Boost Converter With Reduced Voltage Stress for PV Application. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 4763–4770. [Google Scholar] [CrossRef]

- Li, H.; Huang, C.; Liu, F.; Hongfan, L. Magnetic Integrated Boos-Cuk Combined Converter With Voltage Doubler Unit. Power Electron. 2021, 55, 103–107. [Google Scholar]

- Pan, C.T.; Lai, C.M. A High-Efficiency High Step-Up Converter With Low Switch Voltage Stress for Fuel-Cell System Applications. IEEE Trans. Ind. Electron. 2010, 57, 1998–2006. [Google Scholar] [CrossRef]

- Xing, X.; Ling, Q.; Jingfeng, M.; Yu, Y.; Bingying, D.; Lei, Z. Modularly Expandable ZVS High-Gain Converter with High Light-Load Efficiency and Reduced Power Components. Proc. CSEE 2024, 44, 3235–3248. [Google Scholar] [CrossRef]

- Guan, Y.; Cheng, Y.; Yao, T.; Wang, Y.; Wang, W.; Xu, D. A High-Performance DC–DC Converter With Soft Switching Characteristic and High Voltage Gain. IEEE Trans. Power Electron. 2022, 37, 12279–12288. [Google Scholar] [CrossRef]

- Xi, L.; Chunlin, L.; Zhaojun, S.; Tianqiang, W. High Voltage Gain DC/DC Converter Based on Coupled Inductor Voltage-doubler Cell. Electric Drive 2020, 50, 27–32. [Google Scholar] [CrossRef]

- Tseng, K.C.; Cheng, C.A.; Chen, C.T. High Step-Up Interleaved Boost Converter for Distributed Generation Using Renewable and Alternative Power Sources. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 5, 713–722. [Google Scholar] [CrossRef]

- Ardi, H.; Ajami, A.; Sabahi, M. A Novel High Step-Up DC–DC Converter With Continuous Input Current Integrating Coupled Inductor for Renewable Energy Applications. IEEE Trans. Ind. Electron. 2018, 65, 1306–1315. [Google Scholar] [CrossRef]

| Converter | Number of Switches | Number of Diodes | Switching Voltage Stress | Voltage Gain |

|---|---|---|---|---|

| Ref. [16] | 1 | 4 | ||

| Ref. [18] | 2 | 8 | ||

| Ref. [20] | 2 | 4 | ||

| Ref. [21] | 1 | 3 | ||

| Proposed converter | 1 | 3 |

| Mods | Model Number |

|---|---|

| 12 V | |

| 100 kHz | |

| DPF30I300PA | |

| , | |

| , | |

| 1 mH, | |

| n | |

| Load R |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Xu, S.; Jiang, W.; Hashimoto, S. A Non-Isolated High Gain Step-Up DC/DC Converter Based on Coupled Inductor with Reduced Voltage Stresses. J. Low Power Electron. Appl. 2025, 15, 48. https://doi.org/10.3390/jlpea15030048

Yang Y, Xu S, Jiang W, Hashimoto S. A Non-Isolated High Gain Step-Up DC/DC Converter Based on Coupled Inductor with Reduced Voltage Stresses. Journal of Low Power Electronics and Applications. 2025; 15(3):48. https://doi.org/10.3390/jlpea15030048

Chicago/Turabian StyleYang, Yuqing, Song Xu, Wei Jiang, and Seiji Hashimoto. 2025. "A Non-Isolated High Gain Step-Up DC/DC Converter Based on Coupled Inductor with Reduced Voltage Stresses" Journal of Low Power Electronics and Applications 15, no. 3: 48. https://doi.org/10.3390/jlpea15030048

APA StyleYang, Y., Xu, S., Jiang, W., & Hashimoto, S. (2025). A Non-Isolated High Gain Step-Up DC/DC Converter Based on Coupled Inductor with Reduced Voltage Stresses. Journal of Low Power Electronics and Applications, 15(3), 48. https://doi.org/10.3390/jlpea15030048