Abstract

The design of analog computing systems requires significant human resources and domain expertise due to the lack of automation tools to enable these highly energy-efficient, high-performance computing nodes. This work presents the first automated tool flow from a high-level representation to a reconfigurable physical device. This tool begins with a high-level algorithmic description, utilizing either our custom Python framework or the XCOS GUI, to compile and optimize computations for integration into an Integrated Circuit (IC) design or a Field Programmable Analog Array (FPAA). An energy-efficient embedded speech classifier benchmark illustrates the tool demonstration, automatically generating GDSII layout or FPAA switch list targeting.

1. The Movement towards Programmable Analog Synthesis

The current lack of available analog synthesis tools makes constructing programmable analog systems, particularly energy-efficient analog and mixed-signal computing systems, significantly more difficult than digital systems. Analog computing typically is more energy efficient than digital computing, starting from Mead’s Hypothesis (1990) [1] and its experimental verification (2004) [2]. Analog computation and system designs (e.g., [3,4,5]) demonstrate improved energy efficiency (>) and area efficiency (>) both in custom IC design and large-scale Field Programmable Analog Arrays (FPAA) [2,4] compared with digital solutions. The opportunities in any analog or physical computing space [6], particularly for energy-efficient computations, require tools that empower engineers to practically deploy these techniques in commercial timescales.

This effort looks to develop a high-level analog/mixed-signal synthesis tool (Figure 1), utilizing the decades of development in digital synthesis, that uses and builds upon the unique aspects of analog computing capabilities. Digital synthesis, including both FPGAs and custom ICs, from high-level representations (e.g., Python, MATLAB, Verilog) has become a common and familiar practice for digital IC design and targeting of FPGA devices, enabling tool abstraction for compiling from such representations [7] as well as research into automated generation of digital standard cells [8]. Digital standard-cell libraries are ubiquitous for custom digital IC design. Open-source (e.g., LegUp [9]) and commercial (e.g., Vitis HLS [10]) tools arose from the efforts of customized high-level compilers for rapid accelerator design. Recent Multi-Level Intermediate Representation (MLIR) [11] efforts aim to build reusable and extensible compiler infrastructure [12] including algorithm-centric Python-based programming and synthesis flow for FPGA [13] and IC synthesis [14].

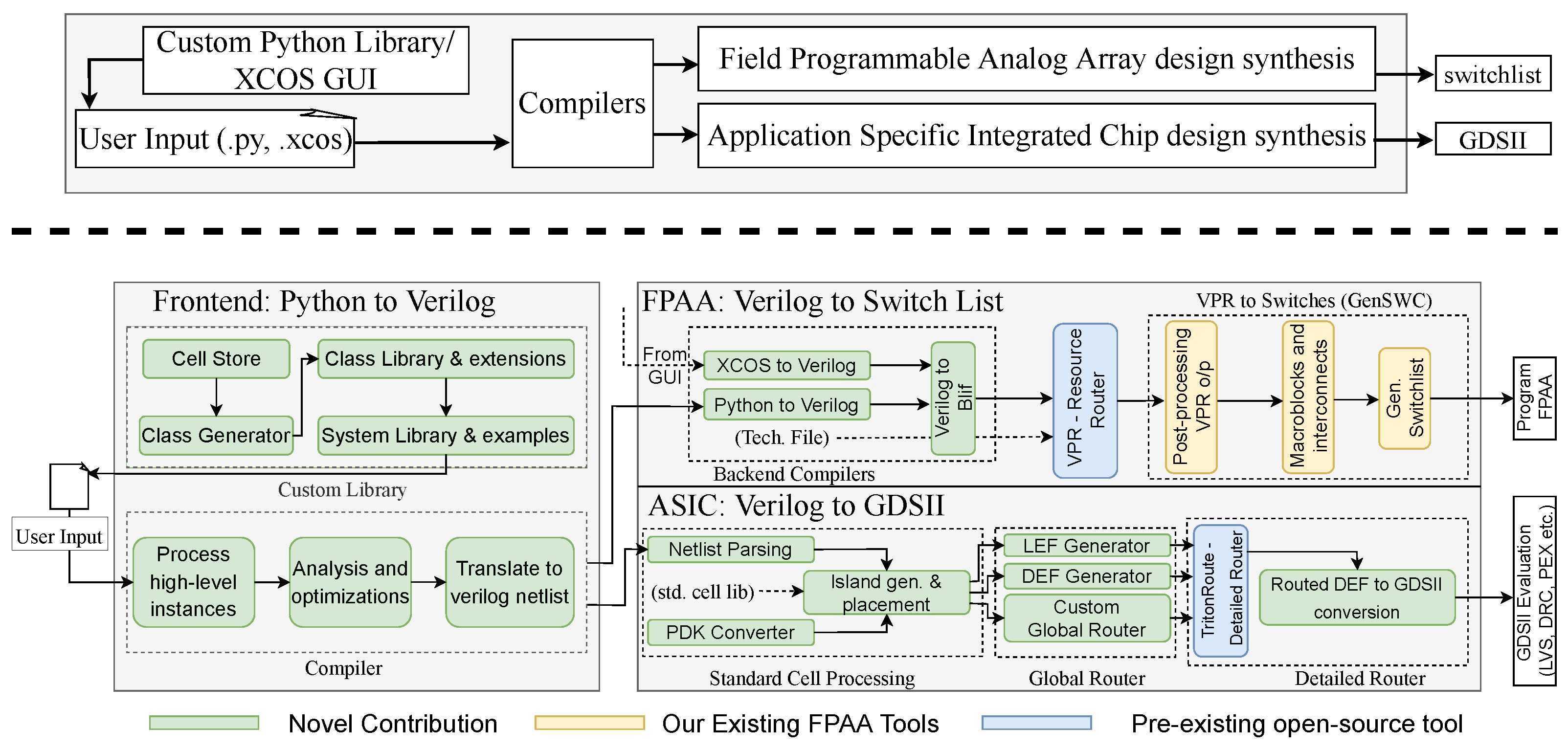

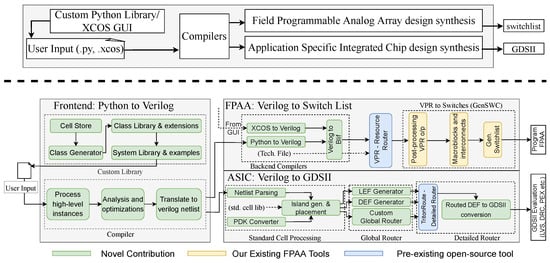

Figure 1.

The analog synthesis tool flow to generate a design on a large-scale Field Programmable Analog Array (FPAA) or an Application-Specific Integrated Circuit (ASIC). A single user-supplied high-level description goes through multiple lowering steps to reach the targeted output, either GDSII or a switch list. For targeting an FPAA, a design can either be specified through the GUI in XCOS (a pre-existing flow) or through the new text-based Python flow. Users construct circuits and systems using class objects provided in the Python cell library that mirror the palette browser in the XCOS library, and the description is then lowered into a Verilog syntax. The FPAA path lowers to Blif netlist, fitting into our preexisting flow compiling a switch list to target the FPAA. For targeting an ASIC, users perform similar steps to construct a system from Python objects with cells made available in the provided library. Those Python objects are then converted to a Verilog netlist before being fed to the layout synthesis modules, which handle placement and global routing. These serve as inputs to the open-source detailed router (TritonRoute [15]) to convert the guide to a path. That path is merged with the placement file to create a final output layout file.

In contrast, analog synthesis for analog system design and analog computing is nearly non-existent. Initial efforts in analog synthesis often focused on low-level analog components, such as creating an op-amp or similar low level of circuit complexity [16,17,18,19,20]. Recent interest in analog tool development follows these directions [21,22,23], building only a few blocks (e.g., current source, differential pair) to make a small analog component (e.g., amplifier, small data converter). A different approach more consistent with digital synthesis for targeting configurable devices and new ICs requires a different approach built upon recent efforts in analog computation abstraction [24]. Recent efforts in FPAAs [4,25,26,27,28], particularly computational analog blocks (CABs) and CLBs within a dense Manhattan routing fabric (e.g., [4]), created the initial pressure to develop analog synthesis tools [29], building on VPR/VTR [30] to actualize system level designs, leading to recent work in programmable analog standard cells [31].

This effort focuses on developing the first integrated toolset (Figure 1) enabling synthesis from a high-level description (e.g., Python, XCOS) to a targeted programmable analog/mixed-signal computation large-scale Field Programmable Analog Array (FPAA) and/or Integrated Circuit (IC) layout (GDSII). This tool (Figure 1) provides a unified Python framework, as well as XCOS GUI description, for targeting an FPAA as well as IC layout generation, creating a lightweight (∼MBs), easily installable tool without dependencies on other projects, enabling the development of programable analog island blocks enabling floor planning and placement. The FPAA targeting builds upon initial FPAA analog tools [29] (e.g., GenSWC: our local CAB/CLB place and route Python tool to create a targetable switch list) including the open source VPR toolset [30] with additional components developed for this effort (Figure 1). The simplicity of island architecture channels enables a faster global router with low-order polynomial (vs. exponential) time complexity. Although this discussion focus on the difficult analog and digital interfaces, this mixed-signal tool is capable of digital component integration. The tool chain (Figure 1) integrates with pre-existing tools to expand the wider open-source ecosystem.

The parallel development of the formalization of analog computation leading to technology-applicable benchmarks [32] and programmable analog standard cells [31,33] are two important parallel developments enabling this toolflow development, further differentiating this toolflow from other approaches. The abstraction and formulation of analog computation enables meaningful analog system benchmarks, enabling tool-based architectural design space exploration to determine the best analog/mixed-signal computing architectures [32]. Ongoing current efforts on fast simulation for analog verification will be essential to the design exploration, although beyond the scope of this effort. The acoustic benchmark (Case I) [32], an end-to-end embedded speech classifier, is used to illustrate our tool, where all of these benchmarks (acoustic, vision, communications, and filters) are relevant for these tools and will be part of later efforts. The recent development (and ongoing development in several IC processes) of programmable analog standard cell libraries [31,33], with standard CMOS Floating-Gate (FG) devices enabling programmability (e.g., 14 bit, 10 year lifetimes [34]), allows for these tools to use a digital synthesis (Figure 1) for analog synthesis components. The toolflow that synthesizes layout (to a GDS file for fabrication) utilizes recent standard cell libraries [33,35], using these components in a flow similar to digital synthesis (Figure 1) but with a floating-gate aware design flow. Analog programmability reduces the block complexity of an analog library, not relying on a huge number of blocks setting parameters (e.g., bias currents) through multiple transistor sizes. Creative uses of digital standard cells for analog design (e.g., [36]) to enable some synthesizable analog simply expand the available capabilities. This effort drastically decreases the design time, design cost, and design uncertainty of system analog/mixed-signal ICs, potentially opening up a technology-independent foundation to automate analog design, as well as making greater energy efficiency optimizations possible.

This analog and mixed signal HLS compilation from a Python- or XCOS-level description (Figure 1) is the focus of the following sections. After reviewing current efforts in FPAAs and programmable analog standard cell concepts (Section 2), the discussion starts with the syntax descriptions and extensions required for the tools (Section 3, Figure 2), including Python descriptions (Section 3.1) and Verilog descriptions (Section 3.2). The discussion first develops the FPAA-targeting algorithms to convert Python or XCOS High-Level Synthesis (HLS) to switch list (Section 4), including lowering Python code to Verilog (Section 4.1), lowering Graphical XCOS to Verilog HDL (Section 4.2), compiling Verilog to a switch list (Section 4.3) with vectorized representations (Section 4.4), and addressing the challenges of this compilation (Section 4.5). The discussion continues by developing the IC synthesis-targeting algorithms (Section 5) using these programmable analog standard cells including the netlist and GDS parser (Section 5.1), the LEF and DEF generator (Section 5.3), the first-pass global router (Section 5.4), and the final routed DEF to GDSII converter utilizing open-source TritonRoute (Section 5.5). The discussion then demonstrates the tool using the acoustic classifier benchmark [32] for the FPAA targeting as well as IC GDS generator (Section 6).

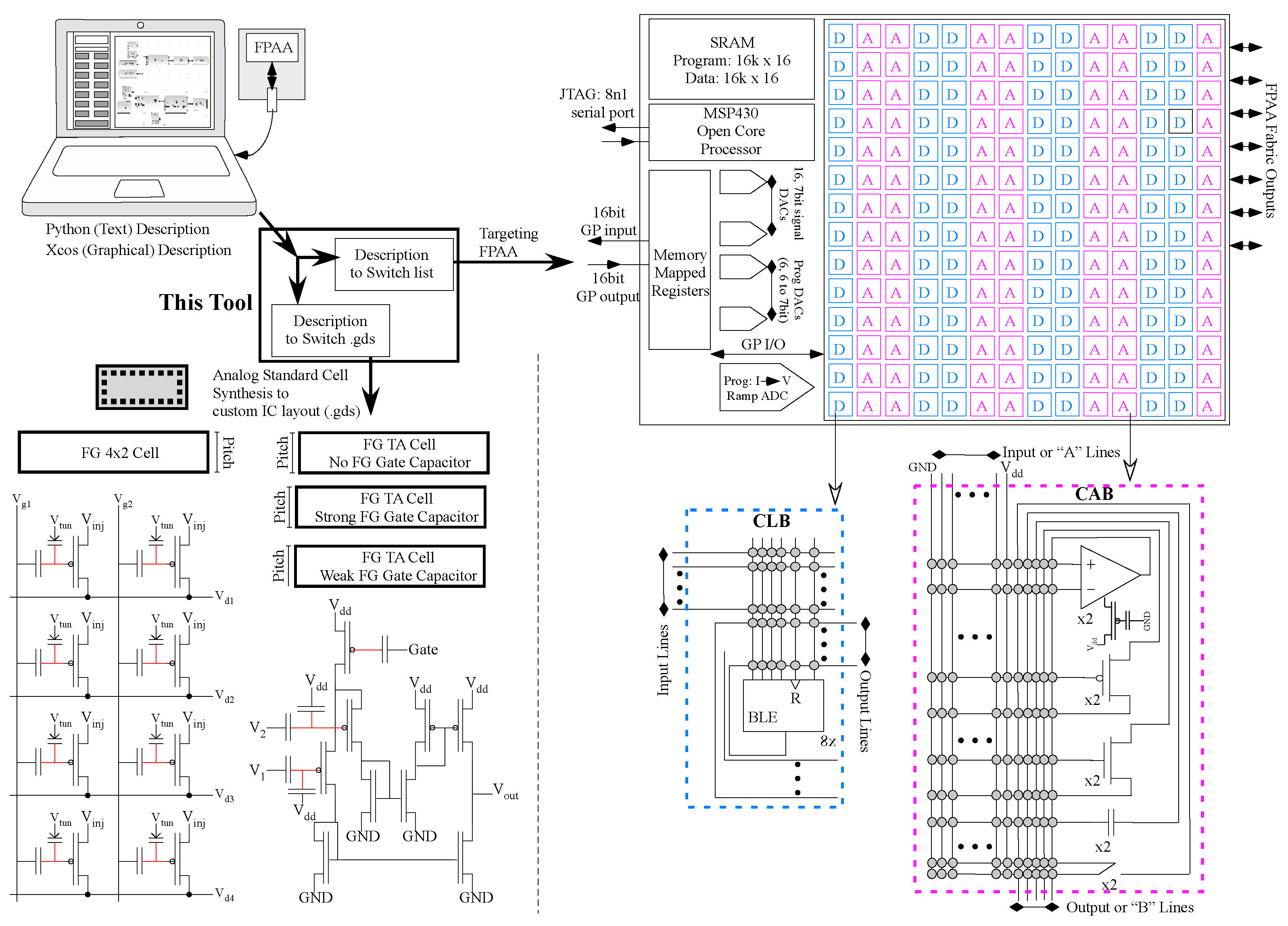

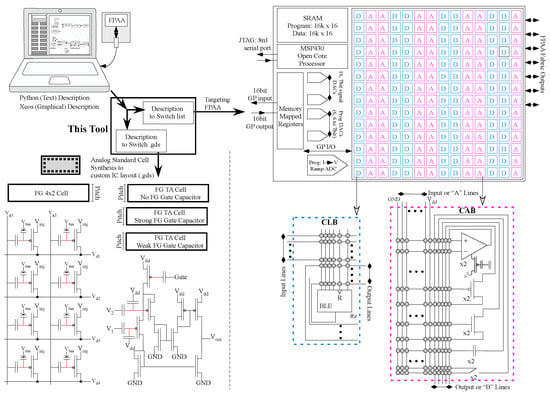

Figure 2.

Our analog synthesis tool uses a high-level description (e.g., Python, XCOS) and generates either a switch list to target an FPAA device or a layout file (.gds) to fabricate a custom IC. The FPAA synthesis requires abstraction of multiple blocks in the Computational Analog Blocks (CAB), in the Computational Logic Blocks (CLB), in the block routing, and in the system infrastructure (e.g., P [37], 7-bit signal DACs) to generate the switch list. The layout synthesis requires abstraction of programmable analog standard cells with additional digital standard cells to generate the layout file. The SoC FPAA that incorporates analog + digital Manhattan routing infrastructure allows for interdigitated Analog (A) CAB and Digital (D) CLB components. The development of analog standard cells followed from the abstraction, CAB evolution, and hands-on use of these FPAAs.

2. FPAAs and Analog Standard Cells

The first discussion overviews FPAAs and analog standard cell approaches, as our analog synthesis tool utilizes recent FPAA devices as well as recent programable analog standard cell developments. The SoC FPAA (Figure 2) and earlier families of FG-enabled FPAAs demonstrated a number of core concepts, as elucidated from early large-scale FPAA techniques in 2002 to today’s devices [4]. FPAAs have analog components plus routing between analog and digital components, similar to FPGAs. Early programmable analog arrays [38,39,40] and early commercial devices (e.g., EPAC [41] or Anadigm [42]) were useful for glue logic and small occasional computations. Today’s FPAAs show considerable capabilities in ultra-low power computation, signal processing, and embedded machine learning [4] from ICs fabricated in a 350 nm CMOS process. Programmable analog FG techniques have demonstrated precision components [4] built on work enabling programmable design for temperature [43].

As predicted by Mead [1], analog computing techniques result in a 1000× improvement in power or energy efficiency and a 100× improvement in area efficiency compared to digital computing. Computation in routing [4] enables 1000× improvements in computational energy efficiency compared to custom digital [4] and retains the custom analog computational energy efficiency [2] on an FPAA. The emerging demand for low-power high-efficiency analog and mixed-signal computing (e.g., computation-intensive machine-learning applications) requires real-time to near-zero latency computing for ultra-low-energy applications.

Large-scale programmability is essential for these FPAA devices and is typically instantiated using analog-programmable FG devices available in standard CMOS for the memory and routing elements. Today’s SoC FPAA [44] utilizes 600,000 programmable parameters in 350 nm CMOS. Analog programming of the single FG pFET device fabric enables computation in routing fabric as well as CAB elements [4]. FG parameters tend to provide a 1000× advantage over other silicon memory approaches at roughly the 8–10-bit level [4]. FG devices have demonstrated longevity (10 year lifetime) across multiple IC processes from 2 m to 40 nm linewidths [4] with precision (e.g., 14-bit) targeted (re)programming of heterogeneous arrangements of FG devices [34]; FG devices enable directly eliminating mismatch or setting desired targeting values in the configurable structure.

An analog standard-cell library (Figure 2) is the first step to synthesize large analog systems to IC layout, building on digital standard cell designs and their resulting abstractions. The development of analog standard cells follows from the abstraction, CAB evolution, and hands-on use of these FPAAs [31]. Early FPAA design tool development [4] gave the user an initial ability to create, model, and simulate analog and digital designs. Analog design tools before these FPAA tools have a brief history, including theoretical analog automation tools, as well as early FPAA ICs [45,46,47,48,49]. Macromodeling techniques, such as making a simplified algebraic or numerically simple ODE circuit model, remain a key framework for analog design [50,51]. Some techniques are coupled with digital tools for joint analog and digital system verification [52,53]. Custom analog IC design has little additional tool support other than low-level IC design tools. Many companies (e.g., [18]) have tried to automate the analog design process but failed because the solution was aimed at analog IC designers who are artistic critics of other analog designs.

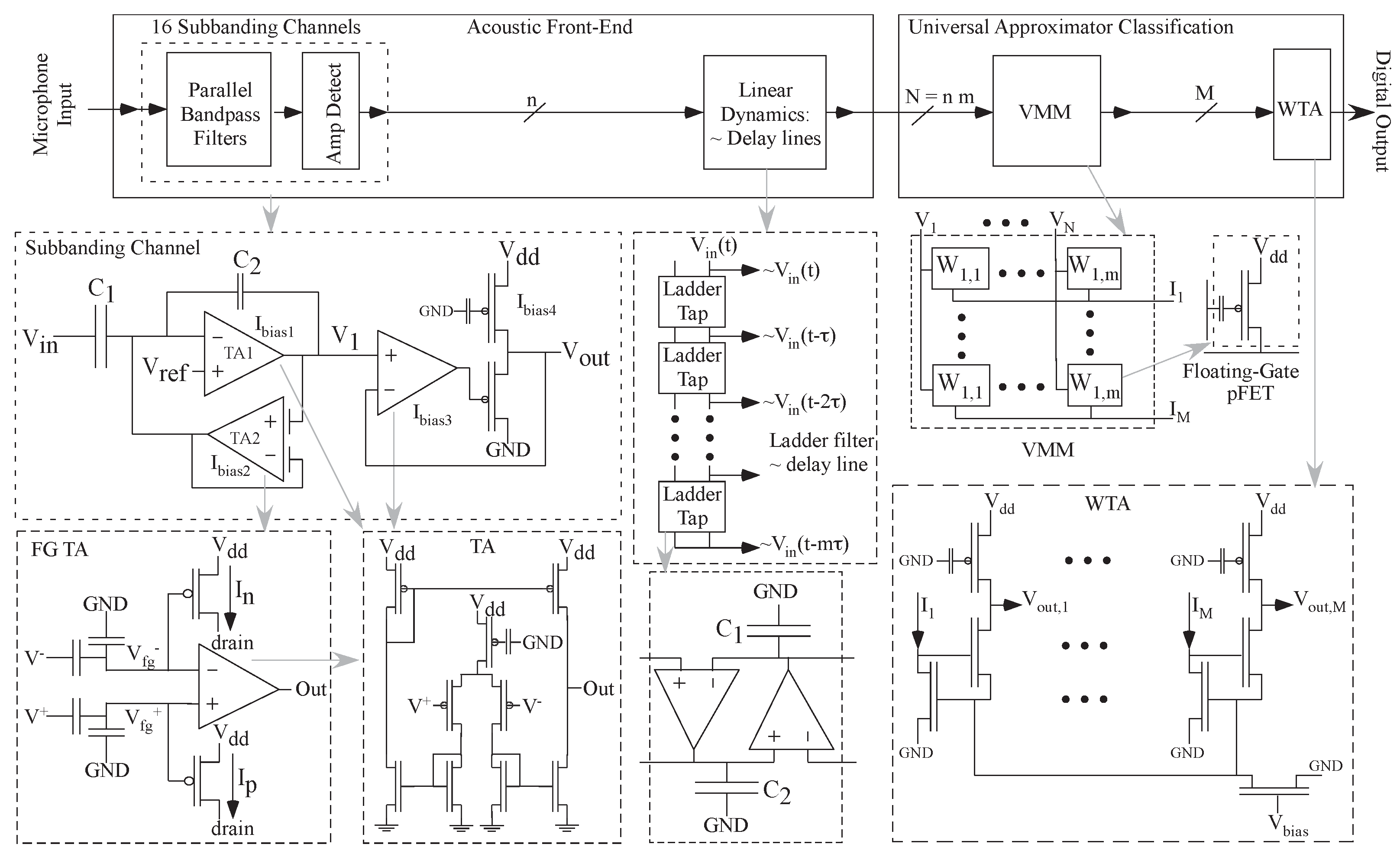

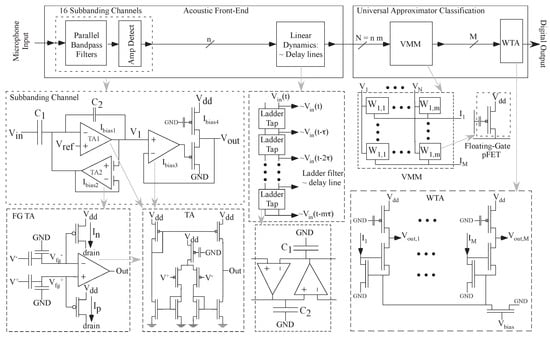

The acoustic benchmark (Case I, [32]) is a small vocabulary (e.g., 2–5 word) command word classifier (Figure 3). Multiple hand-designed and targeted limited versions of this application have been demonstrated on the SoC FPAA device [44,54]. The analog front-end blocks utilize tunable C BPF and resulting amplitude detectors and delay blocks followed by a Vector-Matrix Multiplier (VMM) + Winner-Take-All (WTA) classifier block. The VMM + WTA classifier is a universal approximator in a single neural network layer [54]. The VMM weights are programmable and can be trained off-line or using this embedded system.

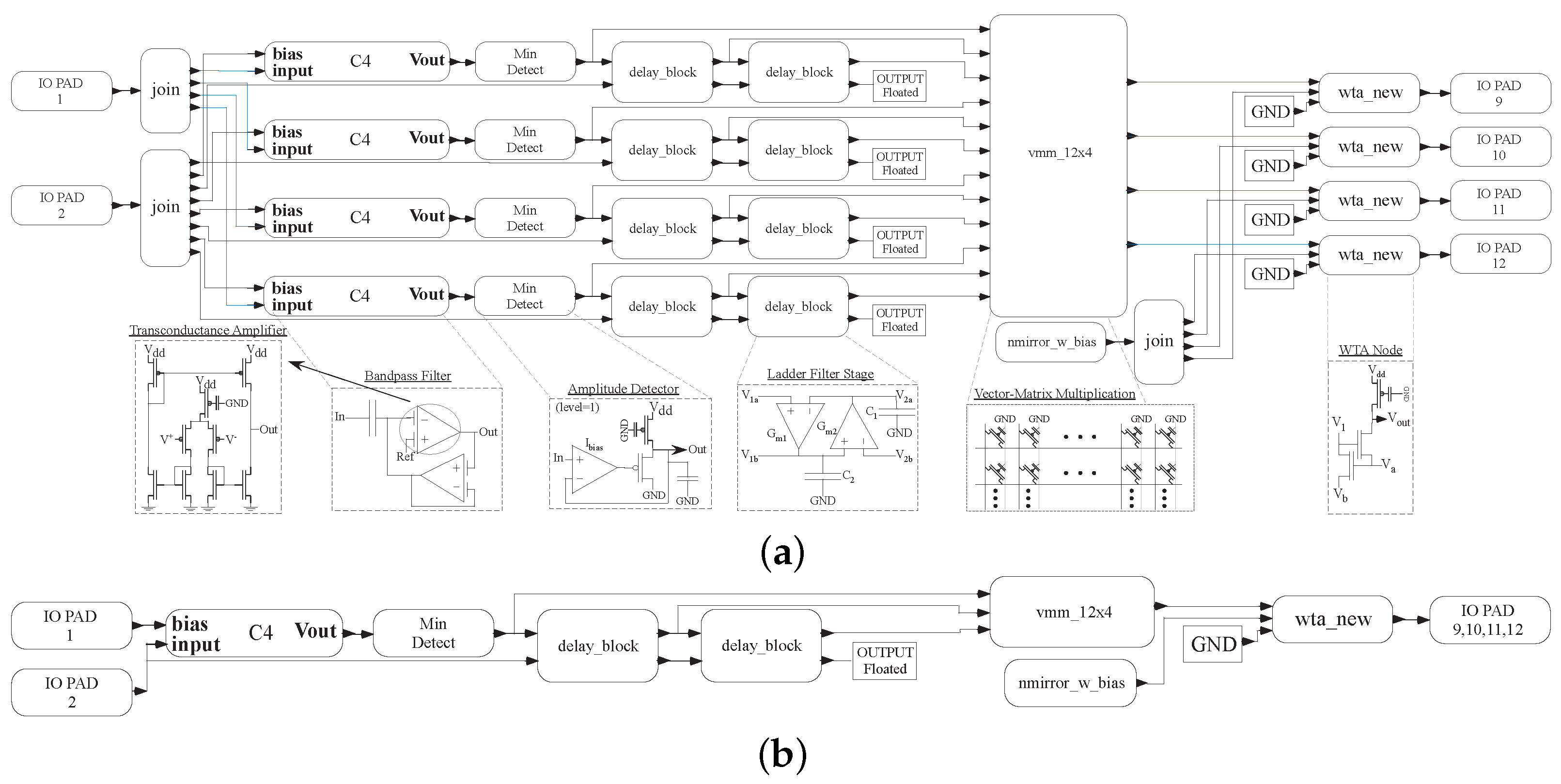

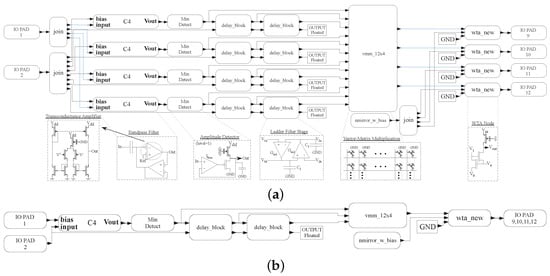

Figure 3.

Block diagram abstracting our typical FPAA implementation for the acoustic classifier problem. The Analog Front-End (AFE) computation consists of subbanding BandPass Filters (BPF) and amplitude-detecting blocks comprising programmable TA components. The programmable C BPF use FG components for setting bias currents and providing significant linear range (≈700 mV [55]). Further delays of these amplitude components are set through programmable ladder filters to enable classification with multiple spectrum sequences. The Universal Approximator Classification part is a fully programmable Vector-Matrix Multiplication (VMM) computation followed by a Winner-Take-All (WTA) computation with programmable thresholds. Programmable analog design makes these techniques practical.

3. Python and Verilog Syntax Descriptions and Extensions

Analog synthesis requires designing circuits at different levels of abstraction. The tool takes user-generated high-level analog systems in the Python language and automatically generates Verilog code and lower representations for FPAA prototyping and ASIC synthesis. We choose the Python language implementation for four main reasons.

Ease of use: Python’s syntax is simple and intuitive, and it offers a large number of libraries to cooperate with when designing FPAA circuits (e.g., Numpy).

Productivity: Python’s high-level abstractions and built-in data types make it possible to write concise and expressive code. This can result in faster development times and fewer errors than writing HDL code.

Flexibility: Python is a versatile language that can be easily tweaked to accommodate FPAA syntax flow. In addition, as an interpreted language, its on-the-fly execution can enable dynamic and interactive programming for the FPAA compiler.

Integration: Python has excellent portability, which makes it easier to integrate with other programming languages and tools.

Not all Python descriptions would be possible at this stage for the resulting synthesis, as well as initial further tool development. At this time, the Python tool allows for functions of various blocks, as well as it allows for Python to be used to calculate parameters and values that would be inserted into these functions. In time, other functions will be enabled into this compilation. This section describes the tool flow and the introduced syntax extensions to the Python (Section 3.1) and Verilog languages (Section 3.2).

3.1. Python Interface

The Python interface requires considering the unified cell library, class library & extensions, and system library.

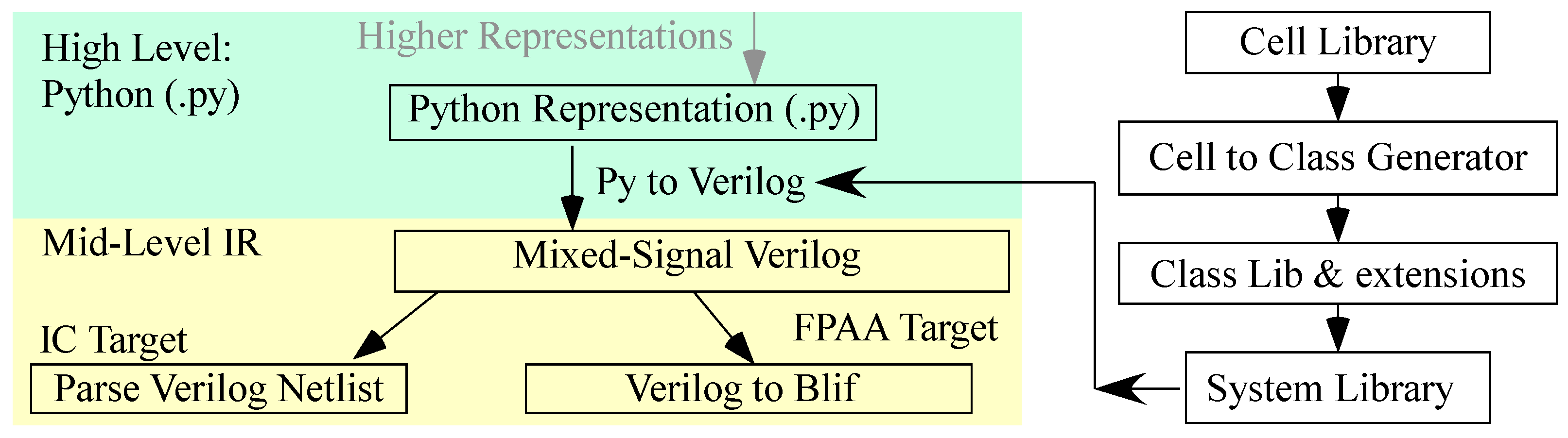

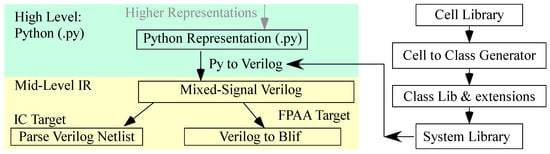

Unified Cell Library starts the Python flow (Figure 4), holding information on programmable FPAA building blocks and standard cell library designs. The blocks store parameterized information (e.g., FG biases) while the cells store pin and process node information (Listing 1). Building blocks and standard cells alike can be updated by users as the need arises.

| Listing 1. Example of FPAA blocks and ASIC cells in cell library. |

{"C4":{"type": "FPAA", "board": ["3.0", "3.0a"],"Gain_Bias":3e-6," Gain_Bias_n":1e-6,"Gain_Bias_p":1e-6,"Feedback_bias":"3e-9"," Feedback_bias_n":"1e-9","Feedback_bias_p":"1e-9","num_caps":"6"}, "Scanner": { "type": "ASIC" , "process": ["65nm"], "pins": ["INPUT1_1", "INPUT1_2", "INPUT1_3", "INPUT1_4", "RESET_B_1", "OUTPUT", "CLK1", "D", "VPWR", "GND"] } } |

Figure 4.

The detailed Python library representation for the synthesis tool. When new circuits are designed, their relevant information is added to the cell library in the .json format. A module then auto-generates Python class objects for each cell. These definitions make up the class library. The flow allows for an extended class library where users can increase the functionality of auto-generated classes with custom functions. Instances of these classes are then used in the system library to create larger designs. Users use system library components as well as their own components (e.g., modifying components) in their main program.

Class library and extensions abstract the information from the cell library in the form of Python classes that can be instantiated as objects during use. The tool (Listing 2) automates the creation of base Python classes, enabling easy user updates to the cell library. The extensions allow for further customization that can be made by expert users, which will be unaffected by automated updates to the base classes. Modifications from simplified mapping of pins to FG bias calculation from a given specification can be implemented and executed by the compiler.

| Listing 2. Example of class-level abstraction and extension. |

# Base: class_lib.pyclass BPF(std_cell): def __init__(self,input, num_instances = 1, cell_type = ’ASIC’, colsel2 = None, colsel1 = None, gate1= None, out = None, gate2 = None ): self.colsel2 = colsel2 self.colsel1 = colsel1 self.gate1 = gate1 self.out = out self.gate2 = gate2 # Extension: class_lib_ext.pyclass BPF(BPF): def __init__(self, input, num_instances = 1, cell_type = ’ASIC’, select = None, gate = None, output =None ): super().__init__(input, num_instances, cell_type) self.colsel2 = select[0] self.gate1 = gate[0] self.colsel1 = select[1] self.out = output self.gate2 = gate[1] class LPF(LPF): def set_center_freq(freq):c_cap = 10e-12 Gm = 2*3.1415*freq*c_cap Ut = 25e-3 kappa = 0.8 self.Feedback_bias = (Gm*2*Ut)/Kappa |

System Library and Main Program define the larger scale applications from the blocks and cells described above (Listing 3). For FPAAs, blocks comprise either a single element or multiple connected elements within a CAB or multiple CAB blocks. The blocks in the cell library give a sufficient overview of the blocks required for synthesis, where further discussion of designing CAB blocks is described elsewhere [29]. For custom IC layout, a similar gathering of standard cells into an island architecture enables effective placement and routing within an island and in a larger design, as initially introduced [31]. FG cells can utilize multiple FG elements, resulting in tight routing that is not desirable to enforce on non-FG-based cells and the resulting routing tracks. The FG cells with tight routing are grouped together on one side of the island, and the non-FG cells are grouped together on the other side. Cells that are a combination of FG and non-FG cells are placed in the middle. These islands create single-use modular functions enabing standard place and route for the larger custom IC design. These techniques will be the subject of future publications, although this description is sufficient for the algorithms in this discussion.

| Listing 3. Vectorized example of an embedded speech classifier system and the compiler API. |

# FPAA_system_examples.pyimport class_lib_ext as fgdef alice_vectorized():inpad1 = fg.inpad([1]) inpad2 = fg.inpad([2]) c4_out = fg.c4_sp([inpad1, inpad2], num_instances=4, Gain_Bias=[0.00003, 0.00004, 0.00005, 0.00006], Gain_Bias_p=np.arange(0.0001, 0.0005, 0.0001)) min_det_out = fg.Min_detect(c4_out, num_instances=4) gnd = fg.gnd() [delay_stg1, delay_stg2] = fg.delay_block([min_det_out, gnd], num_instances=4)() [delay_stg3, _] = fg.delay_block([delay_stg1, delay_stg2], num_instances=4)() vmm_out = fg.vmm_12x4([min_det_out, delay_stg1, delay_stg3], num_instances=4) nmirror_out = fg.nmirror_w_bias(nmirror_out) wta_out = fg.wta_new([vmm_out, nmirror_out, gnd], num_instances=4) outpad = fg.outpad(wta_out, [9, 10, 11, 12]) # Main.pyimport FPAA_system_examplesimport fg_compilers as fcfc.fpaa_compile(alice_vectorized) |

3.2. Verilog Interface

The Verilog interface code is extended for FPAA and ASIC Verilog definitions.

FPAA Verilog is extended from standard Verilog for handling analog circuits (Listing 4). The FPAA targeting requires programming parameter handling in addition to net connections. The FPAA Verilog file contains a module-by-module definition for each component. Each module starts with the module name declaration, the input and output net names (as applicable), the parameter declarations (extended from standard Verilog), and an “endmodule” statement. In standard Verilog, the “assign” statement is used to declare net connection or logic outputs; this tool uses “assign” statements to define programming parameters, something that does not exist in digital definitions. Each parameter is handled by a single “assign” statement by assigning a value to each parameter name. In a vectorized multiple block setting, the parameters are assigned as a list to a parameter name.

| Listing 4. FPAA Verilog excerpt describing a vectorized minimum detection circuit routed to four input and four output pads on the FPAA. |

module pad_in(); output [3:0] net1; assign pad_num = [1,2,3,4];endmodule

module Min_detect(); input [3:0] net1; output [3:0] net2; assign block_num = 4; assign Min_detect_ls = [0,0,0,0]; assign Min_detect_fgswc_ibias = [5.000D-086,6.000D-08,7.000D-08,8.000D-08]; assign Min_detect_ota0_ibias = [0.000002,0.000003,0.000004,0.000005];endmodule

module pad_out(); input [3:0] net2; assign pad_num = [5,6,7,8];endmodule

|

ASIC Verilog compilation utilizes additional parameters required for the GDSII placement and routing synthesis flow, including the relative location of the cell within its island and the connections (Listing 5). Each cell is called a module instance with relevant information passed as parameters. The island number defines which group of cells that particular cell shares FG infrastructre with while row and column communicate the horizontal and vertical offsets within the group. This syntax also extends to vectorized blocks that refer to a matrix of cells, indicated by the matrix row and matrix column fields. Routing nets are identified by shared net names, which connect two or more terminals across multiple cells.

| Listing 5. ASIC Verilog excerpt describing standard cell islands and their connections. |

module TOP();GateMuxSwc_Tile I__7 (.island_num(0), .row(2), .col(4), .matrix_row(1), .matrix_col(6)); GateDecoder I__9 (.island_num(0), .row(1), .col(4), .sigin0(c_net0), ... , .sigin11(c_net11)); AFE I__10 (.island_num(1), .row(1), .col(1), .sigout0(c_net0), ... , .sigout11(c_net11)); endmodule |

4. FPAA Flow Algorithms: Python High-Level Synthesis to Switch List

With the code structure, extensions, and syntax established, the discussion focuses on the lowering and compiling code for the FPAA targeting and IC synthesis. This section describes the algorithmic process by which high-level Python descriptions are turned into a switch list targeting specific transistors to be programmed on a reconfigurable analog device (FPAA). The Python syntax, building on native Python syntax, has particular extensions, parameters, and procedures for the resulting algorithms for FPAA and IC layout generation. While the defined FPAA Python syntax passes native Python syntax checks, it may fail semantic checks in some cases. The discussion develops the FPAA targeting algorithms to convert Python or XCOS High-Level Synthesis (HLS) to switch List (Section 4), including lowering Python code to Verilog (Section 4.1), lowering Graphical XCOS to Verilog HDL (Section 4.2), compiling Verilog to a switch list (Section 4.3) with vectorized representations (Section 4.4), and addressing the challenges of this compilation (Section 4.5).

4.1. Lowering Python Code to Verilog

The core principle of the FPAA HLS compiler is to maximize the use of native syntax and resolve any special cases. The conversion process (Algorithm 1) is decomposed into three steps:

| Algorithm 1 Algorithm to lower Python high-level representations to Verilog |

|

An Abstract Syntax Tree (AST) is a data structure used in computer programming that represents the syntactic structure of source code in a tree-like format. As an intermediate representation, AST provides a hierarchical way to access different levels of code components recursively. By traversing the AST, the converter can extract every wanted detail appearing in the syntax and discard redundant details. The translation should guarantee the net interconnection correctness to ensure the desired functionality.

The symbol table allows the compiler to keep track of the objects used in the program and their corresponding properties. By going through the symbol table, the compiler can also detect errors in semantics analysis. Simultaneously with symbol table generation, the net assignment must also be completed to ensure correct block interconnection (more details in Section 4.5). To take advantage of the powerful native Python interpreter, the FPAA compiler takes two-way paths to maintain the symbol table.

Interpreter path: For most standard cells whose definitions do not violate the native syntax and semantics rules, the FPAA compiler calls the Python interpreter to construct corresponding standard cell objects and then creates new entries in the symbol table.

AST parsing path: For certain hardware-specific standard cells, their syntax has implications for hardware implementation. This means they are legal in a hardware context but fail native Python semantic legality checks. For example, the nmirror cell outputs the same variable as the input. In Python syntax, this would be expressed as , which does not make sense in Python since variables cannot be referenced before declaration. Therefore, the FPAA compiler parses special cases and handles them accordingly for the symbol table.

Once the compiler generates the symbol table, it has all the information needed to reconstruct the Verilog code. The code generation process handles two main aspects to ensure consistency between Python and Verilog code.

Semantic analysis: Semantics analysis in the FPAA compiler checks net assignment correctness and resolves possible vectorization based on the design;

Reformatting: Verilog has a parallel programming paradigm, unlike high-level languages that are sequential. To address this discrepancy, reformatting Verilog code is crucial to ensuring accurate translation.

4.2. Lowering Graphical XCOS to Verilog HDL

Because XCOS files are stored in XML, an object-oriented text format, they can be extracted into objects (nets, blocks) with a built-in Python package. This built-in XML parsing tool generates a tree structure with all the XCOS objects consistent with object-oriented programming. The two most important objects in this conversion are blocks and explicit links. Blocks are actual block components, and explicit links are net connections. Each block and net object includes its own unique id and parent id. The block objects also include the block name and block parameter values. The algorithm (Algorithm 2) iterates through the entire XCOS file, finds all the net connections and their parent blocks, and finally writes the Verilog output module by module based on the connections.

4.3. From Verilog to Switches

The Verilog file is lowered to an extended Blif file definition for FPAA targeting [29], and passed to VPR [30] for global FPAA place and route to generate the switch list. The switch list defines the physical FPAA programming. Our tool uses a lark-based Verilog parsing package to generate a Blif file from the Verilog definition by parsing all the modules into objects and listing every object. The Verilog format describes the circuit module by module for a straightforward conversion to Blif (Algorithm 3). The Blif file passes through VPR to generate the global CAB routing. The FPAA architecture details in XML format are supplied to VPR with the Blif file. VPR generates a placement file (.place), a packed netlist file (.net), and a routing file (.route), which are passed to GenSWCS code [29] to produce a switch list to program the FPAA.

4.4. Circuit Vectorization

Vectorization in Verilog refers to defining multi-bit signals or data types using vector notation, enabling Verilog designers to efficiently create complex data types and signals. Python’s array operations serve as counterparts to vectorization using arrays or lists. Vectorization enables more expressive code, reducing the manual effort required for large system design. The improved readability can facilitate addressing error-prone issues and benefit code review and debugging.

| Algorithm 2 Algorithms to lower XCOS high-level representations to Verilog. |

|

| Algorithm 3 Algorithm to lower from Verilog to Blif |

|

Vectorization of the acoustic classifier benchmark system significantly reduced code size. The original Python code spanned 37 lines and 2095 characters. The corresponding Verilog code used 303 lines and 5888 characters. After vectorization, the Python code decreased to 11 lines and 776 characters (70% fewer lines, 63% fewer characters). The Verilog code decreased to 95 lines and 2761 characters (69% fewer lines, 53% fewer characters). Compared to Verilog code, Python code for Alice compressed Verilog code by 88% in lines and 72% in characters. Undoubtedly, the vectorized FPAA Python high-level synthesis significantly enhanced the code expressiveness.

4.5. Challenges in Conversion

The semantics gap between Verilog and Python can overcome key challenges:

Special case handler: Most special case challenges come from the hardware intrinsic that is illegal in high-level programming, e.g., the nmirror case mentioned in Section 4.1. Some other special cases are because of uniqueness in the standard cell. For example, and cells do not have an input net. These unique standard cells can be handled by AST parsing path (also in Section 4.1).

Net assignment: Correct net assignment is essential for determining the correctness of block interconnections. A reliable symbol table avoids problems such as duplicate net assignments, unassigned nets, and false net references. In addition to a well-maintained symbol table, semantic analysis during code generation also plays an important role in resolving net assignment problems such as unassigned entries.

Standard-cell-aware vectorization: Vectorization depends on semantics and standard cell features. Since cells have varying I/O nets, the input may exceed cell requirements. Thus, input net slicing must account for standard cells. Special cases also pose challenges, such as (=0 V) cells, which have only one instance that can be shared by all standard cells, requiring vectorization based on the connected standard cell.

5. IC Synthesis Flow Algorithms

The ASIC compiler converts Python objects into the ASIC-specific Verilog syntax as defined in Section 3.2. A combination of the Verilog file, a standard cell library, and a Process Design Kit (PDK) are fed to the GDS synthesis modules to generate the final result. The PDK is specified as an LEF file from any example cells in the process and a layer map describing the stack of said process. Optionally, given PDK information of two compatible process nodes (i.e., similar geometry), standard cells could be converted between processes using the built-in PDK converter. Common layers can be remapped and contact sizes adjusted to match the destination format. The discussion develops the IC synthesis targeting algorithms (Section 5) using these programmable analog standard cells including the netlist and GDS parser (Section 5.1), the LEF and DEF generator (Section 5.3), the first-pass global router (Section 5.4), and the final routed DEF to GDSII converter utilizing open-source TritonRoute (Section 5.5).

5.1. Netlist and GDS Parser

The initial step takes in a Verilog file and uses a lark-based parser to extract module instantiations and parameter information from the input netlist. A preprocessing step generates a unique list of instantiated modules to allow for multiple calls to a cell. This enables the next phase, which is GDS parsing. The binary format of the file is converted to text, which contains records of all individual polygons making up subcells and connections within the cell. The highest level module is then reconstructed by calculating the dimensions of all subcells, pulling in previously defined cells when needed. This process also extracts pin information of the top cell, accounts for rotated or mirrored subcells, and avoids redefining reused cells, as that would violate the GDS standard. This process of reconstruction allows arbitrary standard cells to be recombined into larger GDS files, which are later used for placement. This cell information is parsed into a data structure that the island generation algorithm uses.

5.2. Island Generation and Placement

The grouping of tightly related cells to share peripheral circuits, particularly FG cells, brought forth the idea of an island approach. Islands consist of a gradient of heavily FG-dependent cells to cells with no FGs at all. These cells are designed to abutt for space efficiency and to reduce routing complexity. The FG cells require additional control lines for programming and operation, as well as row and column program select lines. Non-FG cells benefit from having additional available routing tracks. During FG programming, including parallel island programming, the circuits collapse into a programmable crossbar array.

A preprocessing step sorts cells into separate islands, and these islands are arranged to place the bottom left cell at the first position (Algorithm 4), allowing the row-based structure of the placement algorithm to work upwards from the cell that is least likely to be missing. The tool handles column width estimation for placing matrices (or cells) in an offset position and places all sub-islands while storing all cell and sub island locations. Sub islands refer to situations where die dimensions do not allow for all cells to abutt, requiring cells who share nearby signals to route to each other. For example, a decoder tree for gate side control might not fit vertically within the allotted space for core island height.

| Algorithm 4 Algorithm to lower from Verilog to GDS: cell and island placement |

|

5.3. LEF and DEF Generator

Given a process technology LEF, the task is to generate the design LEF file. The module inserts the appropriate technology LEF specification for the current design and adds in all pin definitions extracted from GDS. New standard cells in the same process require only a GDS file, and not a new LEF file. To create a DEF file for a design, the module specifies database units, die size, and track spacing. It generates tracks based on die space and track size. Component placement and blockages (i.e., metal shielding, up to stop layer, over cells to prevent routing) are also handled. Parsing of all nets and generation of correct instance-pin connections for both matrices and single cells are taken care of as well.

5.4. Global Router

A custom track-based global router is used to generate a guide file for all nets defined in the DEF file. Given an instance name and net, it will figure out the location of the pin either within a matrix or as a cell. A bounding box will then be generated to extend the pin outside the cell if needed. This creates a directional access pattern for the net connections. Access patterns are either horizontal (top or bottom facing pins) or vertical (left or right facing pins). In the sub case of up/down, the metal stack also exists, but once an appropriate metal layer is reached, the access patterns return to the previous two cases. A net will consist of any arbitrary combination of pins following the defined access patterns. To route a net, the tool will pick an empty track aligned with the globally defined track spacing and extend across all pins orthogonal to that routing direction. If pins on the net exist outside the current channel, the tool moves into the subsequent channel to connect said pins along a selected track in the new routing direction. The global router also extends this approach to handle padframe routing. Nets connected to a frame and multiple pins would first have the detailed pin connections handled by the approach described above then extend into the global track space where they are routed to a frame.

An alternative approach considered was to construct a Minimum Spanning Tree (MST) for each net, decompose it into two terminal points using Steiner decomposition, and use a heuristic search algorithm such as A* pathfinding to connect the points. However, there are two main reasons for why this approach was not chosen. The first is that our island architecture approach lends itself to creating a heavily channel-based structure where tracks are convenient, and the second is that heuristic approaches such as A* tend to be very memory-intensive, and worst-case time complexity grows at a rate of , where d is the depth of the solution and b is the branching factor. This approach is commonly used in contemporary routing tools and contributes to the long run times to generate a connected solution. In contrast, the track-based approach has a worst-case time complexity of , where N is the number of tracks in the routing direction and P is the number of polygons already placed. As for space complexity, it only keeps track of placed polygons as opposed to all possible solutions when searching for an optimal solution in unbounded A*. Ultimately, the effort put into standard cell designs abutting and the island architecture create a situation where one need not pay the costs of the alternative approach to guarantee a solution.

5.5. Routed DEF to GDSII Converter

The detailed router (TritonRoute [15]) produces a routed DEF file that needs to be converted to a final output by merging with the GDS file generated during placement. This module parses routed nets and creates polygons in the output GDS (Algorithm 5). The routed DEF only produces a path, so net thickness, metal layers, and contact definitions need to be added. Extra parsing of the LEF file is required for unspecified contact information that may not have been provided as output in the DEF file. Once this step is completed, the final GDSII layout is created.

| Algorithm 5 Algorithm to lower from Verilog to GDS: DEF to GDSII converter |

|

6. Tool Demonstration Using the Acoustic Classifier Benchmark

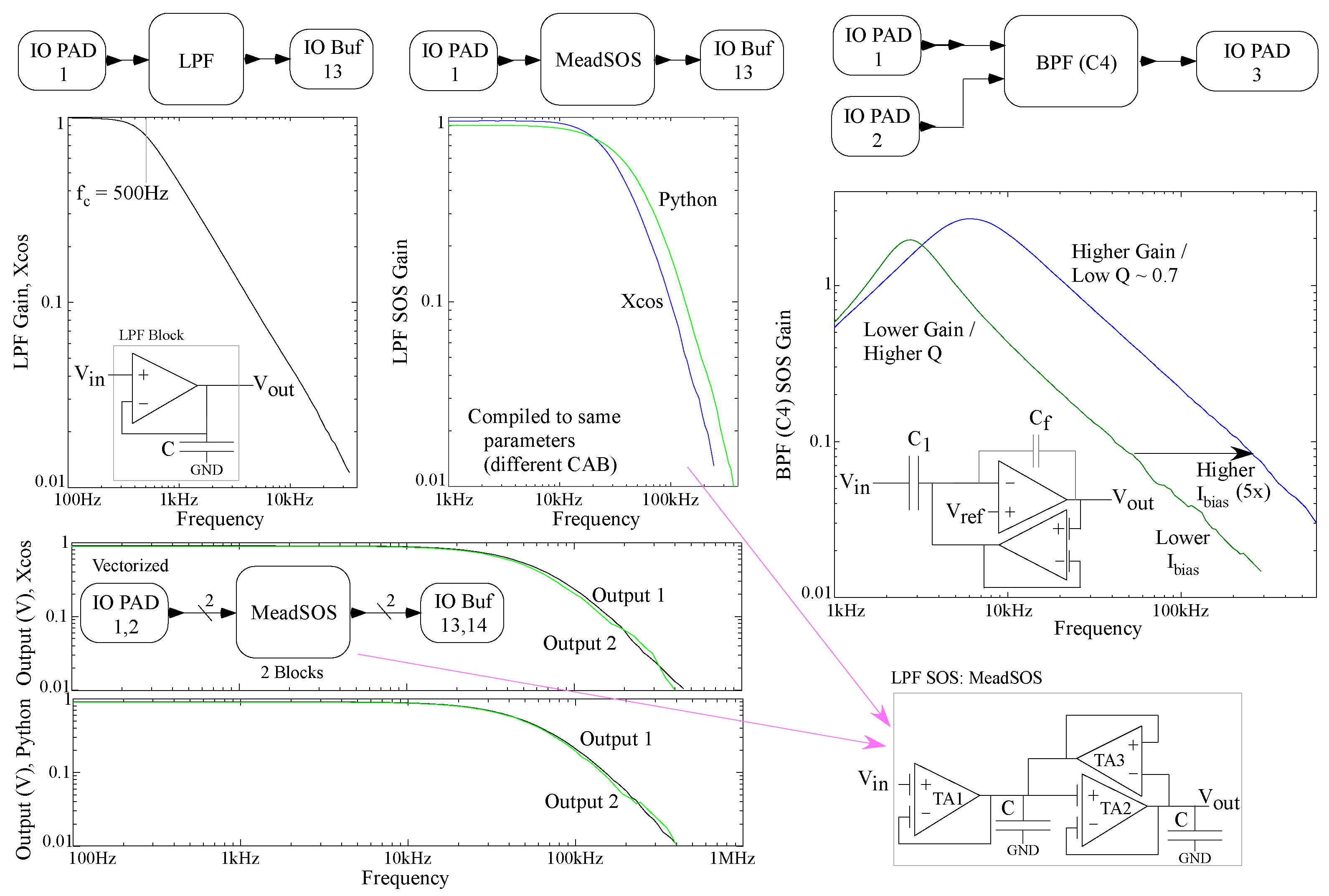

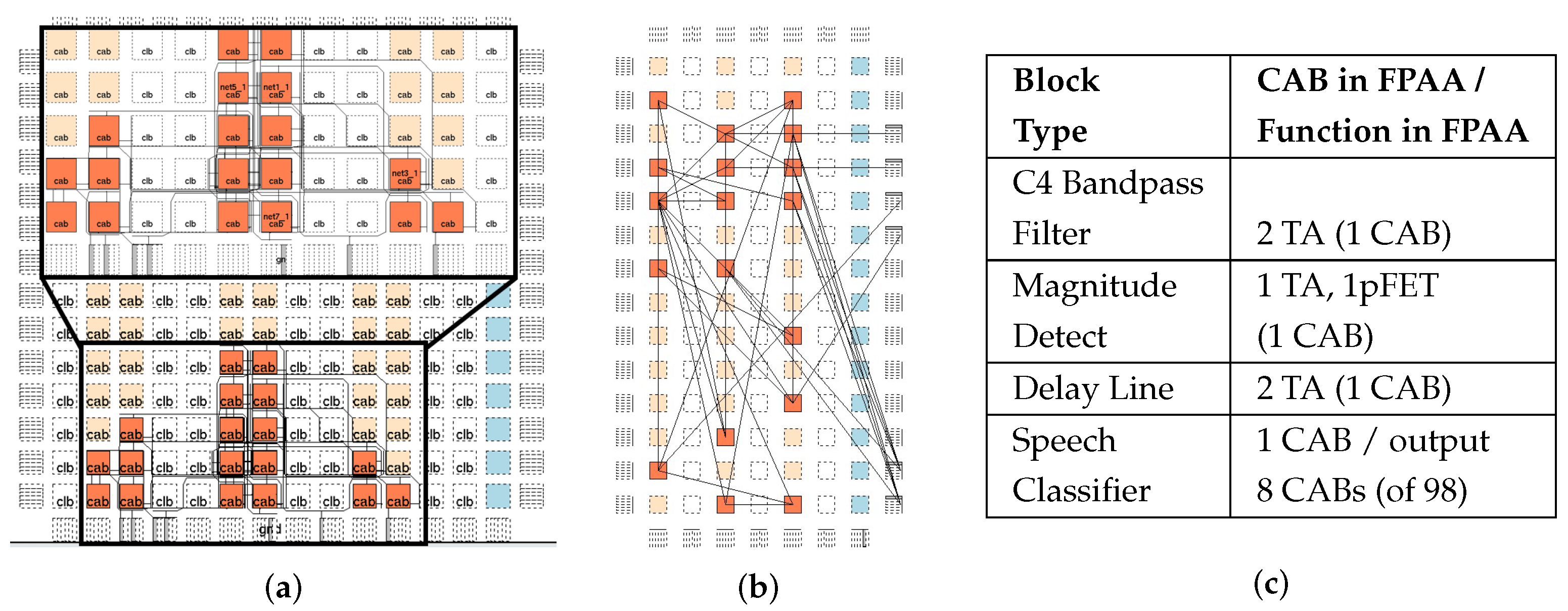

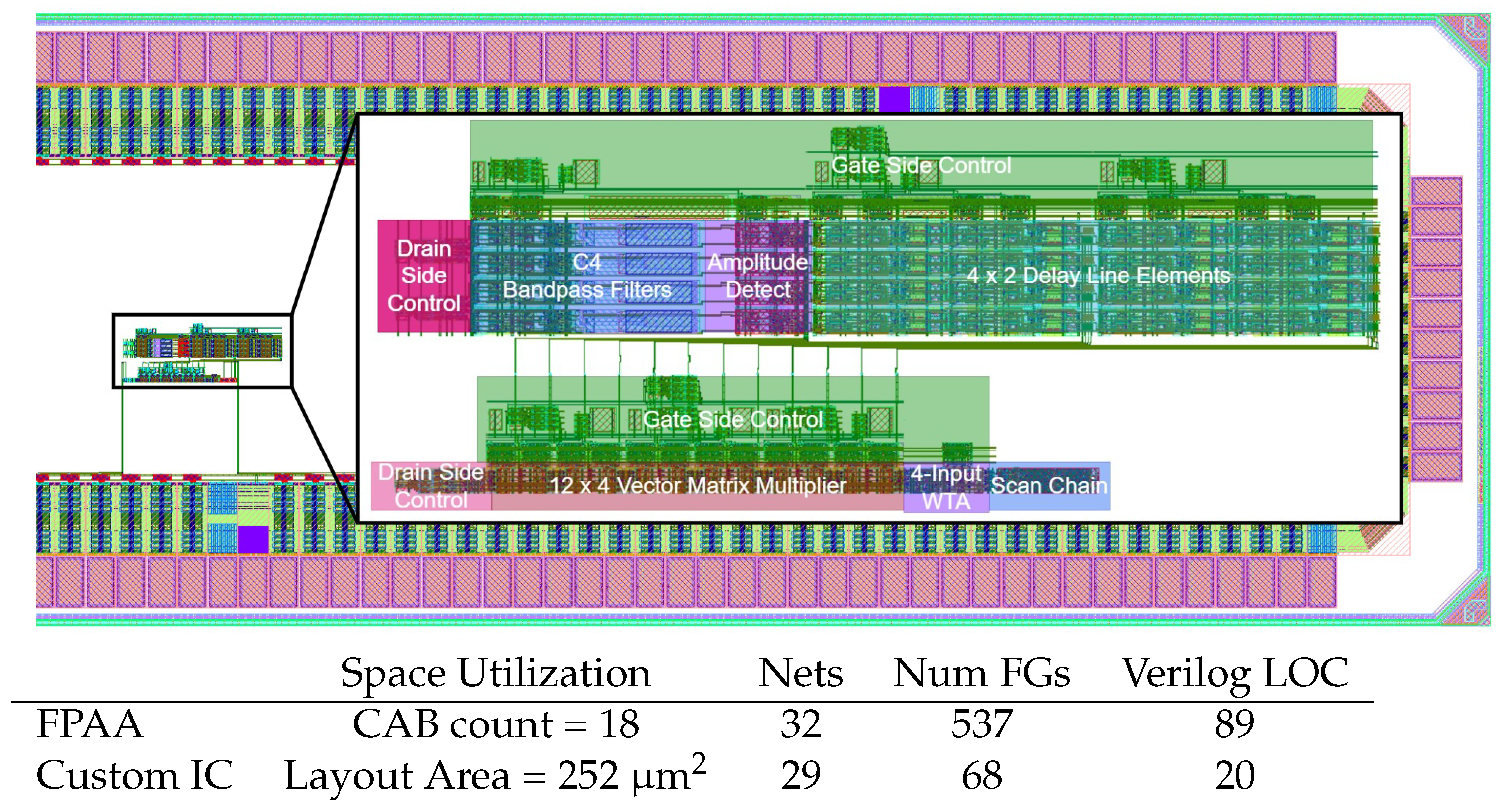

The tool capabilities are demonstrated by compiling the acoustic classifier benchmark (Figure 5 and Figure 6) from a high-level representation to a switch list for an FPAA design as well as a GDS file for IC fabrication on a 65 nm CMOS process with internally designed FG-based standard cells (Figure 7). One of the formulations of the benchmark was generated in XCOS (Figure 5) to demonstrate the XCOS tool flow. The computational flow included four frequency band frequency decomposition, amplitude detection, ladder-filter delay stages, and embedded classification through a vector-matrix multiplication and winner-take-all classifier [54]) for command-word recognition. The signal path computation is analog throughout this formulation.

Figure 5.

The acoustic classifier benchmark circuit for four BPF stages, two delays, and four classified outputs. The benchmark is shown in (a) scalar and (b) vectorized XCOS graphical representation. The vectorized benchmark representation uses signal buses of width of 4 everywhere except for the input signal and reference (pin 1 and 2) with a width of 1.

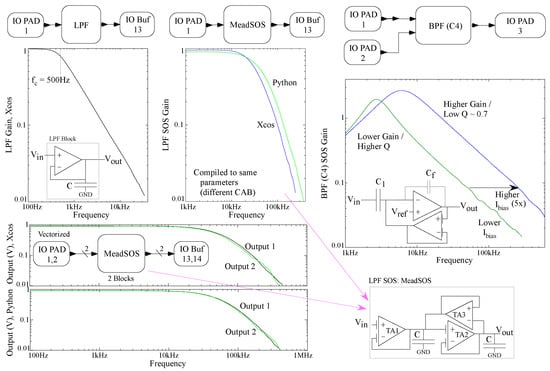

Figure 6.

Data measurements from circuits programmed onto the current FPAA using XCOS and Python as the high-level definition. The first-order low-pass filter circuit is able to closely follow the input 500 Hz cut-off frequency. The second-order band-pass (C) filter successfully exhibits different corner frequencies depending on the bias current of the two FG TAs. The low-pass second-order (MeadSOS) filter (LPF) directly compares between the two flows, as the plots from Python and XCOS flows are compiled with the same parameters. The slight difference is due to mismatch of different CABs. A vectorized Mead second-order low-pass filter is also shown. Even when vectorized, the two flows produce nearly the same result.

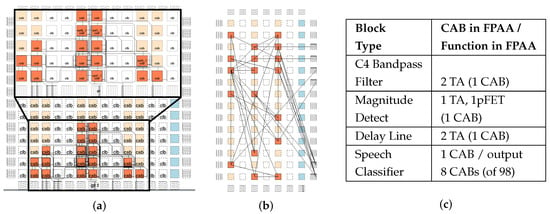

Figure 7.

The acoustic classifier benchmark circuit targeted to an existing FPAA device showing the VPR routing for the (a) scalar and (b) vectorized benchmark forms (Figure 5). (c) Blocks used in the FPAA synthesis and their utilization for the SoC FPAA [44].

The FPAA formulation enables compilation from a high-level representation (XCOS/Python) to compilable hardware. Acoustic circuits, including first- and second-order Low-Pass Filter (LPF) as well as Bandpass Filter (BPF), composed of multiple TA elements, compile from both XCOS and Python definitions to working experimental measurements (Figure 6). The XCOS representation (Figure 5) and equivalent Python representation (a simple version of Case I Acoustic Benchmark [32]) were both reduced to equivalent Verilog representations to be targeted on an FPAA, routed on the device with VPR (Figure 7) and our GenSWC tool with identical results. The vectorized and non-vectorized representations are lowered into an expanded and flattened Blif netlist representation that directly passes to VPR for place and route in the FPAA device. The VPR routing uses a capacitance, and therefore line-length, minimization constraint, as that basic constraint also minimizes the required energy. This routing metric has been sufficient for multiple SoC FPAA designs [44] over many years, and the tools did not require any modifications at this level. Each block in the design as well as an integrated system have been validated in previous work, and the tool’s switch list was compared to those to ensure correctness.

The acoustic benchmark is a programmable end-to-end microphone-to-symbol command-word recognition problem that requires some form of embedded Machine Learning (ML) for the solution. One of the command-word datasets (Case I) is from the TIMIT [56] or TI digits database [57]. This implementation utilizes a VMM+WTA universal approximator ML classifier. Typical solutions use a bandpass filterbank and amplitude detection for the incoming signals in a near exponential spacing of center frequencies (e.g., 50 Hz to 10 kHz) that model the human cochlea dynamics (e.g., [44], preserving the highest signal and frequency information while refining the data representation). Programmability enables the parameters and classification, as well as repeatable front-end computing structures that eliminate the effect of mismatch, resulting in a near-ideal transfer function for each filter channel.

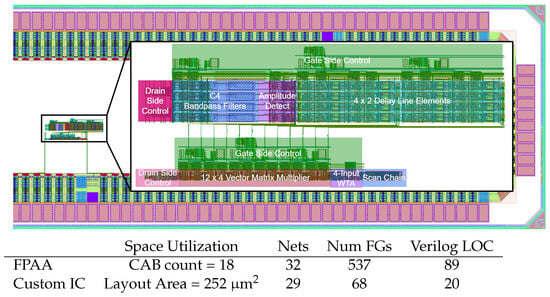

The Python representation lowered to the Verilog level was formulated into two islands for the IC synthesis (Figure 8). The tool generated and placed both islands, and after pin definitions, the islands were fed back into the tool and routed together. The design maintained DRC rule checks starting from DRC-clean standard cells and the detailed router obeyed the technology LEF design rules to avoid violations. For usage details, the IC flow took 3.66 s with peak memory usage of 13.5 MB to generate a placed GDSII file and produce a routed guide file. The detailed router took 8:38 min with peak memory usage of 2.5 GB. Given the size of this particular IC layout with its nearly 1000 transistors, a full post-layout simulation is challenging for a real acoustic input. The need to enable large-scale simulations with realistic analog signals motivates current research in fast analog simulation tools that reasonably predict measured results building on the existing FPAA simulation tool framework [58], similar to digital simulation tools.

Figure 8.

Synthesized layout (65 nm CMOS) of the acoustic classifier benchmark into a padframe. The layout includes the core system blocks, gate and drain side FG programming control, and peripheral circuitry, which have been added to control, interface, and read out the results of the system. A table summary for metrics for the Acoustic Classifier Benchmark (Case I), including the number of Space Utilization, FG elements, Nets, and Verilog Lines Of Code (LOC). A total of 11 lines of Python code convert into these FPAA, and Custom IC Layout (GDSII) area uses standard cells in a widely available 65 nm CMOS process.

7. Summary and Discussion

This work developed and demonstrated the first major step for a high-level analog/mixed-signal synthesis tool starting from a high-level description (Python and XCOS) to a physical implementation in a single toolflow. The physical implementation either provides the switch-list file for targeting an FPAA or provides the GDSII file describing a new custom IC. The HLS tool description included syntax descriptions and extensions (Python and Verilog), the lowering of Python or Graphical XCOS to Verilog, then Verilog to netlist and then to the targeted output, either the switch list for targeting an FPAA or the LEF and DEF and routed GDS for a custom IC. The custom IC synthesis utilizes recent efforts in the development of programmable analog standard cells [31,33]. FPAA devices enable rapid prototyping of analog circuits that is not feasible in most places today, empowered by programmable FG analog circuits. This tool creates a lightweight (∼MBs), easily installable tool without dependencies on other projects, enabling development of programable analog island blocks enabling floor planning and placement.

The tool demonstrated automatically generating GDSII layout or FPAA switch list for the acoustic benchmark (Case I) [32] as well as some smaller circuit test cases. This end-to-end embedded acoustic classifier in both synthesis flows compiles bandpass filters, delay elements, VMM blocks, and WTA circuits using smaller elements (FG FETs and programmable TAs) as core blocks either in an FPAA device or in the programmable analog standard cells. The acoustic benchmark case is published elsewhere (e.g., [44,54]) on this FPAA, and the tool outputs were functionally identical to those previous designs.

This analog and mixed-signal HLS tool enables analog system design with abstraction at multiple levels of design, greatly advancing analog synthesis beyond simple blocks (e.g., current source, differential pair), creating standard analog components (e.g., amplifier, small data converter) [16,17,18,19,20,21,22,23,23]. Our approach allows for fine-grain design (transistor-level) as well as multiple higher levels of abstraction, circuit programmable at each level, enabling a wider community to use analog design tools as compared to experienced analog designers.

This analog synthesis tool is part of a larger effort to enable design space exploration for new analog system ICs that can be a mixture of FPAA fabric and custom blocks for a range of applications (e.g., the full acoustic across a range of CMOS technology nodes through our recent development of programmable analog standard cells (e.g., 130 nm CMOS [33] and other CMOS processes). This system optimization should include evaluation of area and resource allocation, energy and power, SNR, and delay and latency, that, in turn, require fast large analog system simulation to evaluate and eventually verify. Simulating 10 s of audio (20 kHz frequency) for a system of 1000 transistors, such as the synthesized custom IC, requires over 10 simulation nodes before even considering the complexity of SPICE circuit modeling (e.g., EKV) or the ODE simulator complexity (e.g., ODE45). Simulation of these typical 1TMAC (MAC = Multiply ACcumulate) systems is fairly impractical except on larger servers as opposed to traditional analog circuits of 10 s of transistors (typical of other analog tools [21,22]) with a couple periods of a sine or square wave input. In practice, these system designs will be significantly larger for acoustic classifiers, not to mention other benchmark problems (e.g., vision benchmark). Our current efforts on fast simulation for analog verification are beyond the scope of this discussion, and it becomes essential for the larger verification of these systems in the same way as fast abstracted simulation for digital exploration and verification. From this wider perspective, these automation tools are capable of drastically decreasing the design time, design cost, and design uncertainty of system analog/mixed-signal ICs, potentially opening up a technology-independent foundation to automate analog design, as well as a greater number of analog computing and energy-efficient systems.

Author Contributions

Conceptualization, J.H. and C.H.; Methodology, A.I., L.Y. and J.H.; Software, A.I., L.Y. and H.Y.; Formal analysis, A.I., L.Y. and J.H.; Writing—original draft, J.H., A.I. and L.Y.; Writing—review and editing, J.H., A.I. and C.H.; Supervision, J.H. All authors have read and agreed to the published version of the manuscript.

Funding

Partial funding for the development of this effort came from NSF (grant number: 2212179).

Data Availability Statement

The tool link is available off of our website: https://hasler.ece.gatech.edu, accessed on 7 August 2023.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mead, C. Neuromorphic electronic systems. Proc. IEEE 1990, 78, 1629–1636. [Google Scholar] [CrossRef]

- Chawla, R.; Bandyopadhyay, A.; Srinivasan, V.; Hasler, P. A 531 nW/MHz, 128 × 32 current-mode programmable analog vector-matrix multiplier with over two decades of linearity. In Proceedings of the IEEE 2004 Custom Integrated Circuits Conference, Orlando, FL, USA, 6 October 2004; p. 651. [Google Scholar]

- Hu, M.; Strachan, J.P.; Li, Z.; Grafals, E.M.; Davila, N.; Graves, C.; Lam, S.; Ge, N.; Yang, J.J.; Williams, R.S. Dot-product engine for neuromorphic computing: Programming 1T1M crossbar to accelerate matrix-vector multiplication. In Proceedings of the 2016 53nd ACM/EDAC/IEEE Design Automation Conference (DAC), Austin, TX, USA, 5–9 June 2016; pp. 1–6. [Google Scholar]

- Hasler, J. Large-Scale Field Programmable Analog Arrays. IEEE Proc. 2020, 108, 1283–1302. [Google Scholar] [CrossRef]

- Xiao, T.P.; Bennett, C.H.; Feinberg, B.; Agarwal, S.; Marinella, M.J. Analog architectures for neural network acceleration based on non-volatile memory. Appl. Phys. Rev. 2020, 7, 031301. [Google Scholar] [CrossRef]

- Hasler, J.; Black, E. Physical Computing: Unifying Real Number Computation to Enable Energy Efficient Computing. J. Low Power Electron. Appl. 2021, 11, 14. [Google Scholar] [CrossRef]

- Khailany, B.; Fojtik, M.; Klinefelter, A.; Krimer, E.; Pellauer, M.; Pinckney, N.; Ren, H.; Shao, Y.S.; Venkatesan, R.; Zhang, Y.; et al. A Modular Digital VLSI Flow for High-Productivity SoC Design. In Proceedings of the GOMAC, Miami, FL, USA, 12–15 March 2018; pp. 452–455. [Google Scholar]

- Alon, E. CRAFT Generator-Based Hardware Design—Digital. In Proceedings of the GOMAC (PEARC’19), Chicago, IL, USA, 28 July–1 August 2019; pp. 448–451. [Google Scholar]

- Canis, A.; Choi, J.; Aldham, M.; Zhang, V.; Kammoona, A.; Anderson, J.H.; Brown, S.; Czajkowski, T. LegUp: High-level synthesis for FPGA-based processor/accelerator systems. In Proceedings of the 19th ACM/SIGDA International Symposium on Field Programmable Gate Arrays, Monterey, CA, USA, 27 February–1 March 2011; pp. 33–36. [Google Scholar]

- Vitis High-Level Synthesis. Available online: https://www.xilinx.com/products/design-tools/vivado/integration/esl-design.html (accessed on 7 August 2023).

- Lattner, C.; Amini, M.; Bondhugula, U.; Cohen, A.; Davis, A.; Pienaar, J.; Riddle, R.; Shpeisman, T.; Vasilache, N.; Zinenko, O. MLIR: Scaling Compiler Infrastructure for Domain Specific Computation. In Proceedings of the 2021 IEEE/ACM International Symposium on Code Generation and Optimization (CGO), Seoul, Republic of Korea, 27 February–3 March 2021; pp. 2–14. [Google Scholar] [CrossRef]

- CIRCT Project under MLIR Framework. Available online: https://circt.llvm.org/ (accessed on 7 August 2023).

- Huang, S.; Wu, K.; Jeong, H.; Wang, C.; Chen, D.; Hwu, W.M. Pylog: An algorithm-centric python-based FPGA programming and synthesis flow. In Proceedings of the The 2021 ACM/SIGDA International Symposium on Field-Programmable Gate Arrays, Virtual, 28 February– 2 March 2021; pp. 227–228. [Google Scholar]

- Ye, H.; Hao, C.; Jeong, H.; Huang, J.; Chen, D. ScaleHLS: Achieving Scalable High-Level Synthesis through MLIR. In Proceedings of the Workshop on Languages, Tools, and Techniques for Accelerator Design (LATTE’21), Virtual, 15 April 2021. [Google Scholar]

- Kahng, A.B.; Wang, L.; Xu, B. TritonRoute: The Open-Source Detailed Router. IEEE Trans. Comput. Aided Des. Integr. Circuits Syst. 2021, 40, 547–559. [Google Scholar] [CrossRef]

- Bowman, R.J. Introduction to CMOS analog standard cell ASIC design. In Proceedings of the IEEE ASIC Seminar, Rochester, NY, USA, 25–28 September 1989; pp. T2–1.1–1.4. [Google Scholar]

- Shinbara, S. Analog Standard Cell. U.S. Patent 5,302,864, 29 March 1994. [Google Scholar]

- Barcelona Design. Company Is Not in Business Any Longer (Started in 1999); Link Provided as a Reference. Available online: http://www.barcelonadesign.com (accessed on 7 August 2023).

- Toumazou, C.; Moschytz, G.S.; Gilbert, B. Trade-Offs Analog Circuit Design: The Designer’s Companion; Kluwer Publishers: Amsterdam, The Netherlands, 2002. [Google Scholar]

- D’Mello, D.; Gulak, P. Design Approaches to Field-Programmable Analog Integrated Circuits. Analog. Integr. Circuits Signal Process. 1998, 17, 7–34. [Google Scholar] [CrossRef]

- Dhar, T.; Kunal, K.; Li, Y.; Madhusudan, M.; Poojary, J.; Sharma, A.K.; Xu, W.; Burns, S.M.; Harjani, R.; Hu, J.; et al. ALIGN: A System for Automating Analog Layout. IEEE Des. Test 2021, 38, 8–18. [Google Scholar] [CrossRef]

- Chen, H.; Liu, M.; Xu, B.; Zhu, K.; Tang, X.; Li, S.; Lin, Y.; Sun, N.; Pan, D.Z. MAGICAL: An Open-Source Fully Automated Analog IC Layout System from Netlist to GDSII. IEEE Des. Test 2021, 38, 19–26. [Google Scholar] [CrossRef]

- Ajayi, T.; Kamineni, S.; Cherivirala, Y.K.; Fayazi, M.; Kwon, K.; Saligane, M.; Gupta, S.; Chen, C.H.; Sylvester, D.; Blaauw, D.; et al. An Open-source Framework for Autonomous SoC Design with Analog Block Generation. In Proceedings of the 2020 IFIP/IEEE 28th International Conference on Very Large Scale Integration (VLSI-SOC), Salt Lake City, UT, USA, 5–7 October 2020; pp. 141–146. [Google Scholar] [CrossRef]

- Hasler, J.; Kim, S.; Natarajan, A. Enabling Energy-Efficient Physical Computing through Analog Abstraction and IP Reuse. J. Low Power Electron. Appl. 2018, 8, 47. [Google Scholar] [CrossRef]

- Cowan, G.; Melville, R.; Tsividis, Y. A VLSI analog computer/digital computer accelerator. IEEE J. Solid State Circuits 2006, 41, 42–53. [Google Scholar] [CrossRef]

- Rumberg, B.; Graham, D.W. A Low-Power Field-Programmable Analog Array for Wireless Sensing. In Proceedings of the Sixteenth International Symposium on Quality Electronic Design (ISQED), Santa Clara, CA, USA, 2–4 March 2015. [Google Scholar]

- Kelly, B.; Rumberg, B.; Graham, D.; Kulathumani, V. Reconfigurable analog signal processing for wireless sensor networks. In Proceedings of the IEEE Midwest CAS, Columbus, OH, USA, 4–7 August 2013; pp. 221–224. [Google Scholar]

- Rumberg, B.; Graham, D.; Clites, S.; Kelly, B.; Navidi, M.; Dilello, A.; Kulathumani, V. RAMP: Accelerating wireless sensor design with a reconfigurable analog/mixed-signal platform. In Proceedings of the ACM/IEEE Conference on Information Processing in Sensor Networks, Seattle, WA, USA, 13–16 April 2015; pp. 47–58. [Google Scholar]

- Kim, S.; Shah, S.; Wunderlich, R.; Hasler, J. CAD synthesis tools for floating-gate SoC FPAAs. Des. Autom. Embed. Syst. 2021, 25, 161–176. [Google Scholar] [CrossRef]

- Luu, J.; Goeders, J.; Wainberg, M.; Somerville, A.; Yu, T.; Nasartschuk, K.; Nasr, M.; Wang, S.; Liu, T.; Ahmed, N.; et al. VTR 7.0: Next Generation Architecture and CAD System for FPGAs. IEEE ASIC Semin. 2014, 7, 6:1–6:30. [Google Scholar] [CrossRef]

- Hasler, J.; Muldrey, B.; Hardy, P. A CMOS Programmable Analog Standard Cell Library in Skywater 130 nm Open-Source Process. In Proceedings of the Workshop on Open-Source EDA Technology, WOSET, Virtual, 4 November 2021. [Google Scholar]

- Hasler, J.; Hao, C. Programmable Analog System Benchmarks Leading to Efficient Analog Computation Synthesis. ACM Trans. Reconfigurable Technol. Syst. 2023, in press. [Google Scholar] [CrossRef]

- Hasler, J.; Ayyappan, P.R.; Ige, A.; Mathew, P. A 130 nm CMOS Programmable Analog Standard Cell Library. IEEE Circuits Syst. I 2023. submitted. [Google Scholar]

- Kim, S.; Hasler, J.; George, S. Integrated Floating-Gate Programming Environment for System-Level ICs. IEEE Trans. VLSI 2016, 24, 2244–2252. [Google Scholar] [CrossRef]

- Hasler, J.; Shah, S. An SoC FPAA Based Programmable, Ladder-Filter Based, Linear-Phase Analog Filter. IEEE Trans. Circuits Syst. I Regul. Pap. 2021, 68, 592–602. [Google Scholar] [CrossRef]

- Palumbo, G.; Scotti, G. A Novel Standard-Cell-Based Implementation of the Digital OTA Suitable for Automatic Place and Route. J. Low Power Electron. Appl. 2021, 11, 42. [Google Scholar] [CrossRef]

- OpenMSP430 Project: Open Core MSP430. Available online: http://opencores.org/projectopenmsp430 (accessed on 7 August 2023).

- Brooke, M.A. A Reconfigurable General Purpose Analog Integrated Circuit. Ph.D. Thesis, University Southern California, Los Angeles, CA, USA, 1988. [Google Scholar]

- Sivilotti, M.A. Wiring Considerations in Analog VLSI Systems, with Application to Field-Programmable Networks (VLSI). Ph.D. Thesis, California Institute of Technology, Pasadena, CA, USA, 1991. [Google Scholar]

- Lee, E.K.F.; Gulak, P.G. A CMOS field programmable analog array. IEEE J. Solid-State Circuits 1991, 26, 1860–1867. [Google Scholar] [CrossRef]

- Klein, H.W. The EPAC architecture: An expert cell approach to field programmable analog circuits. In Proceedings of the IEEE Midwest CAS, Ames, IA, USA, 21 August 1996; pp. 169–172. [Google Scholar]

- Anadigm. Specifically Generic Analog Functions for FPAAs: Anadigm Says. EE Times, 28 September 2004. [Google Scholar]

- Shah, S.; Toreyin, H.; Hasler, J.; Natarajan, A. Models and Techniques For Temperature Robust Systems On A Reconfigurable Platform. J. Low Power Electron. Appl. 2017, 7, 21. [Google Scholar] [CrossRef]

- George, S.; Kim, S.; Shah, S.; Hasler, J.; Collins, M.; Adil, F.; Wunderlich, R.; Nease, S.; Ramakrishnan, S. A Programmable and Configurable Mixed-Mode FPAA SoC. IEEE Trans. VLSI 2016, 24, 2253–2261. [Google Scholar] [CrossRef]

- Ganesan, S.; Vemuri, R. FAAR: A router for field-programmable analog arrays. In Proceedings of the Twelfth International Conference on VLSI Design, Goa, India, 7–10 January 1999; pp. 556–563. [Google Scholar]

- Ganesan, S.; Vemuri, R. A methodology for rapid prototyping of analog systems. In Proceedings of the International Conference Computer Design, Austin, TX, USA, 10–13 October 1999; pp. 482–488. [Google Scholar]

- Ganesan, S.; Vemuri, R. Digital Partitioning for Field-Programmable Mixed-Signal Systems. In Proceedings of the ARVLSI, Salt Lake City, UT, USA, 14–16 March 2001; pp. 172–185. [Google Scholar]

- Ganesan, S.; Vemuri, R. Behavioral partitioning in the synthesis of mixed analog-digital systems. In Proceedings of the IEEE DAC, Las Vegas, NV, USA, 18–22 June 2001; pp. 133–138. [Google Scholar]

- Doboli, A.; Vemuri, R. Exploration-Based High-Level Synthesis of Linear Analog Systems Operating at Low/Medium Frequencies. IEEE Trans. CAD 2003, 22, 1556–1568. [Google Scholar] [CrossRef]

- Boyle, G.; Cohn, B.; Pederson, D.; Solomon, J. Macromodeling of Integrated Circuit Operational Amplifier. IEEE J. Solid-State Circuits 1974, 9, 353–363. [Google Scholar] [CrossRef]

- Casinovi, G. A macromodeling algorithm for analog circuits. IEEE Trans. Comput. Aided Des. Integr. Circuits Syst. 1991, 10, 150–160. [Google Scholar] [CrossRef]

- Kim, J.; Jerradit, M.; Lim, B.; Horowitz, M. Leveraging designer’s intent: A path toward simpler analog CAD tools. In Proceedings of the IEEE CICC, San Jose, CA, USA, 13–16 September 2009; pp. 613–620. [Google Scholar]

- Liao, S.; Horowitz, M. A verilog piecewise-linear analog behavior model for mixed-signal validation. IEEE Trans. Circuits Syst. I 2014, 61, 2229–2235. [Google Scholar] [CrossRef]

- Hasler, J.; Shah, S. SoC FPAA Hardware Implementation of a VMM+WTA Embedded Learning Classifier. IEEE J. Emerg. CAS 2018, 8, 28–37. [Google Scholar]

- Hasler, J. A Programmable On-chip Hopf Bifurcation Circuit. IEEE Trans. Circuits Syst. I Regul. Pap. 2022, 69, 4958–4968. [Google Scholar] [CrossRef]

- Garofolo, J.S.; Lamel, L.; Fisher, W.; Fiscus, J.; Pallett, D.; Dahlgren, N. TIMIT Acoustic-Phonetic Continuous Speech Corpus. In Proceedings of the Linguistic Data Consortium, Philadelphia, PA, USA, 27–29 March 1983; Available online: https://github.com/philipperemy/timit (accessed on 7 August 2023).

- Leonard, R.G.; Doddington, G.R. TI Digits Database. 1993. Available online: https://catalog.ldc.upenn.edu/docs/LDC93S10/tidigits.readme.html (accessed on 7 August 2023).

- Collins, M.; Hasler, J.; George, S. An Open-Source Toolset Enabling Analog–Digital Software Codesign. J. Low Power Electron. Appl. 2016, 6, 3. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).