A System Dynamics Stability Model for Discrete Production Ramp-Up

Abstract

1. Introduction

2. Related Research

3. Materials and Methods

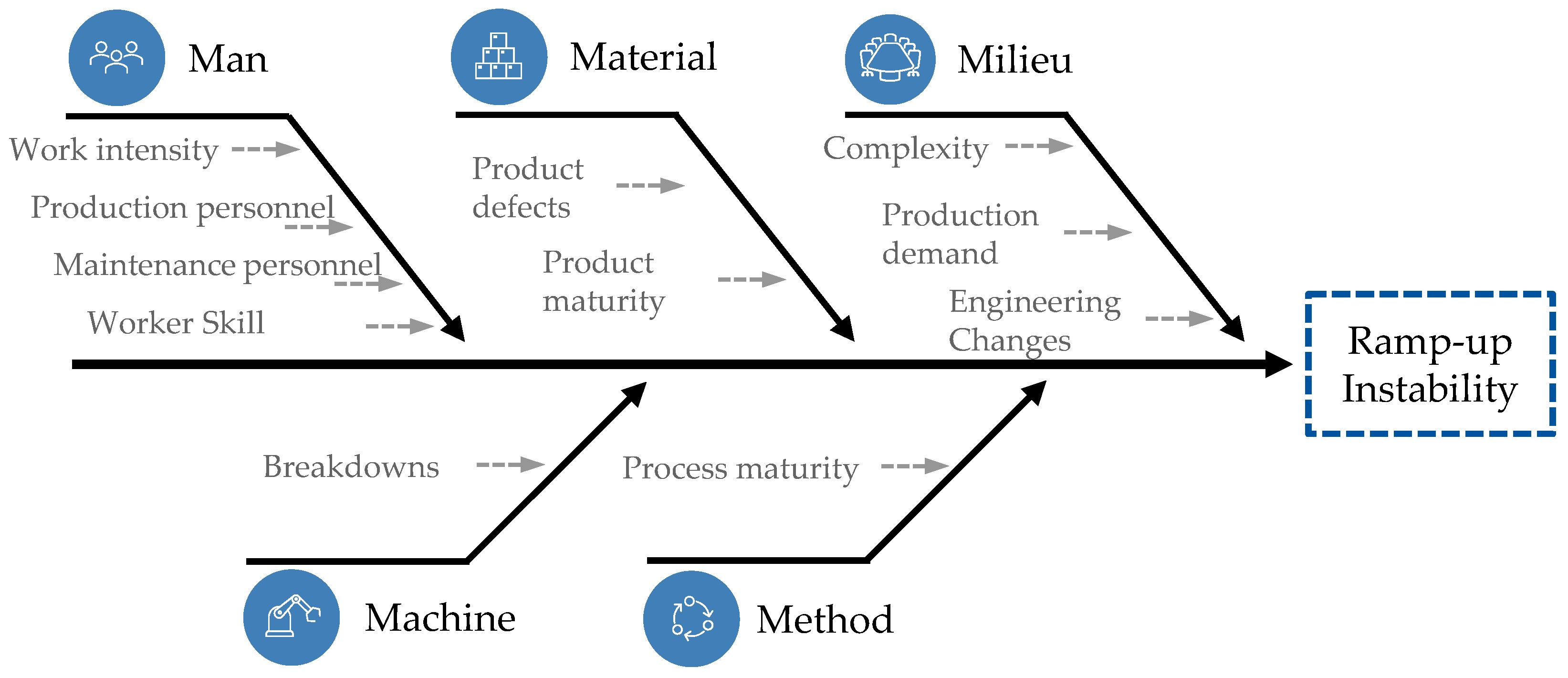

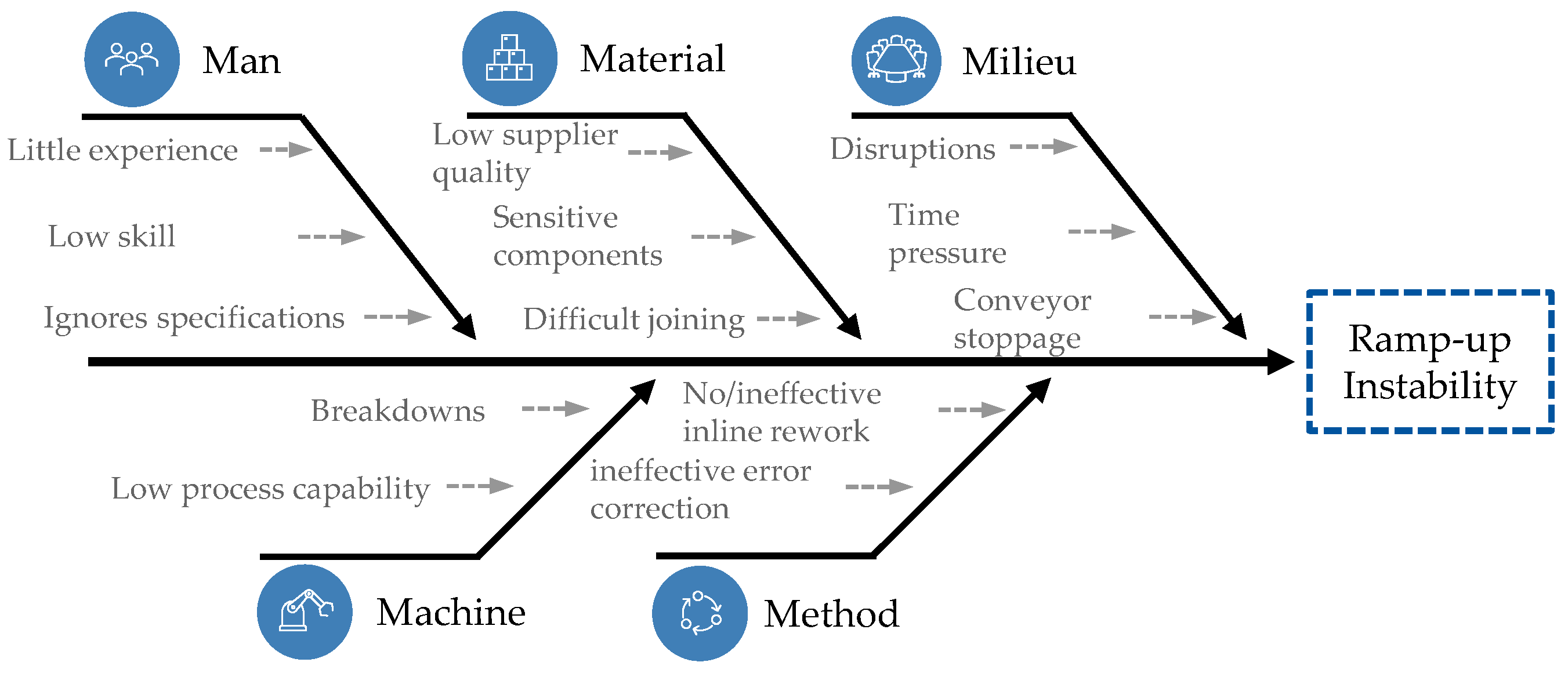

3.1. Descriptive Stability Model

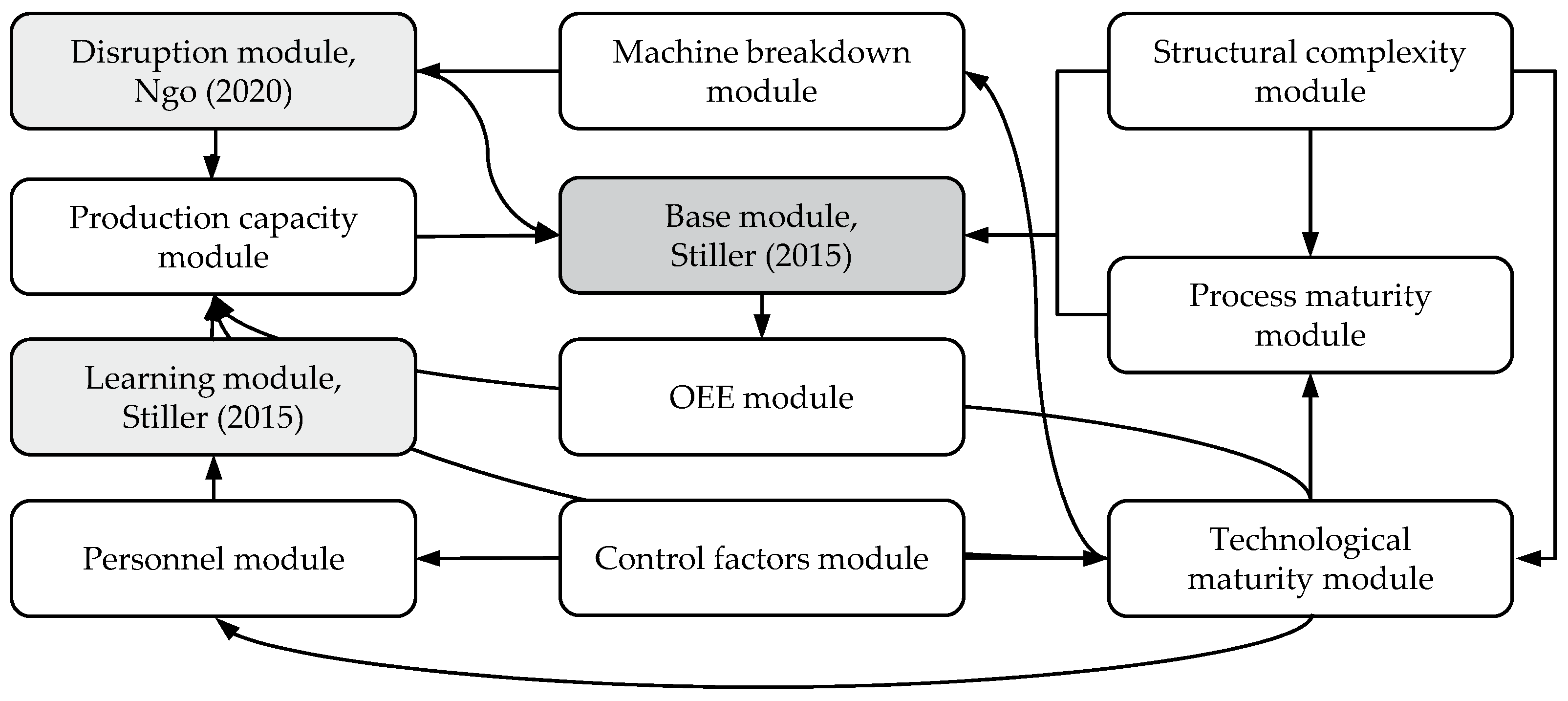

3.2. System Dynamics Simulation

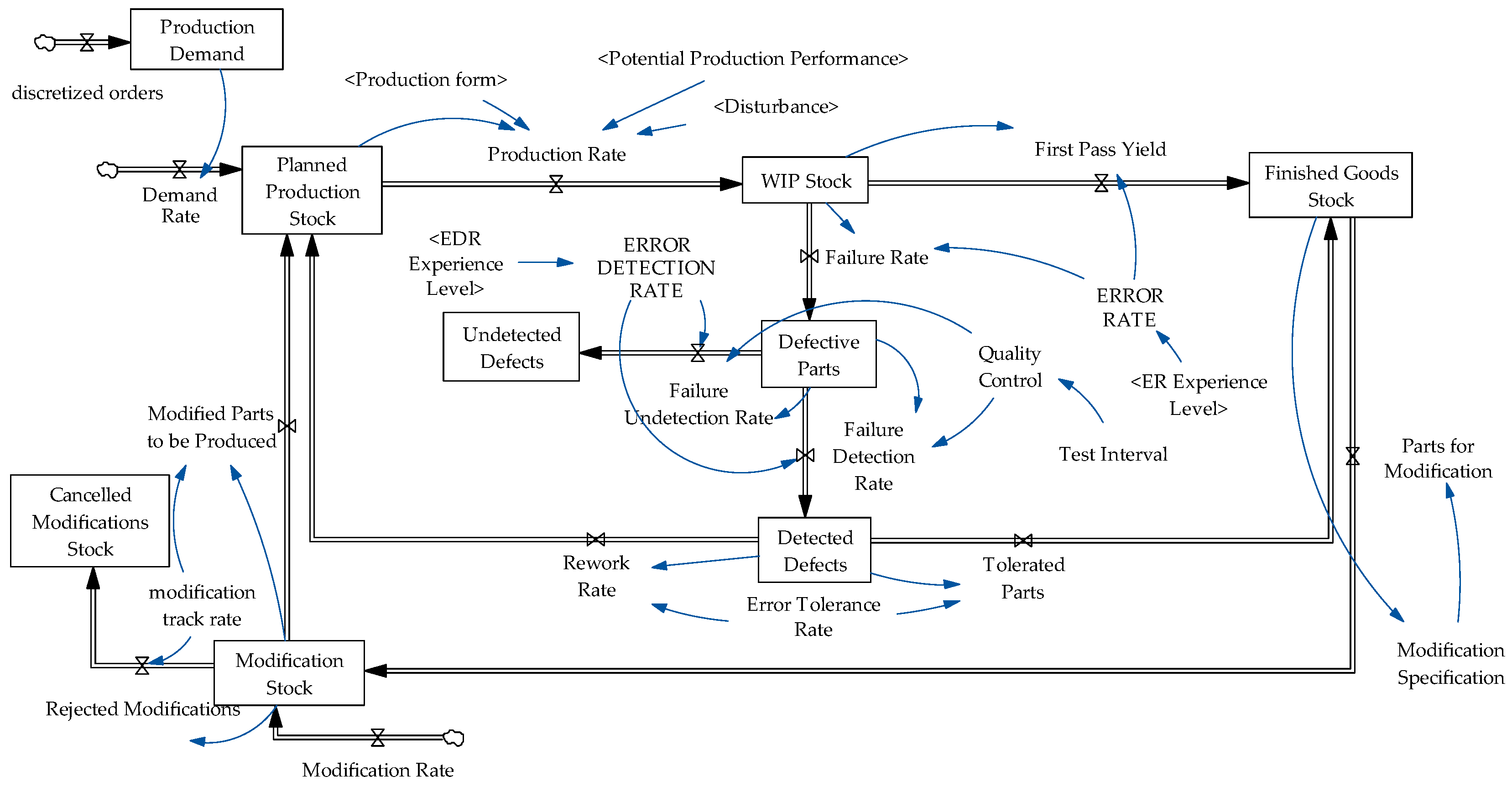

3.2.1. Base Module

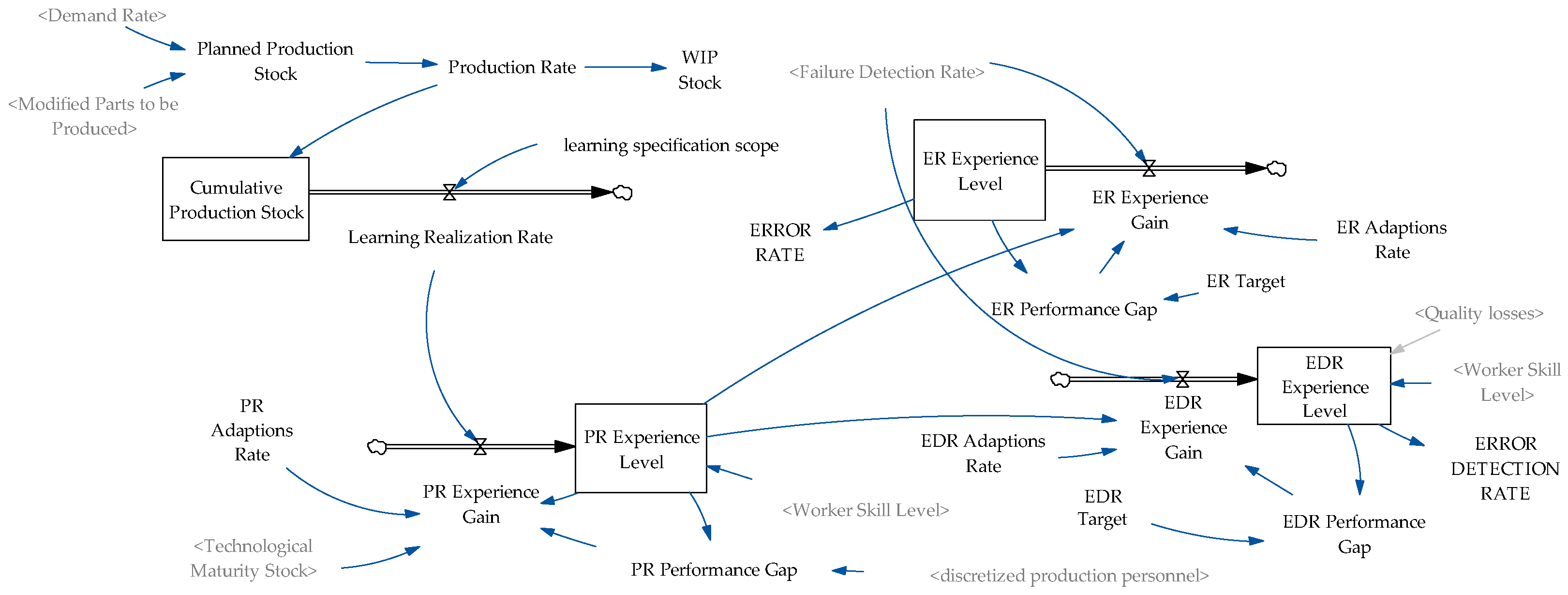

3.2.2. Learning Module

3.2.3. Disruptions Module

3.2.4. Control Factors

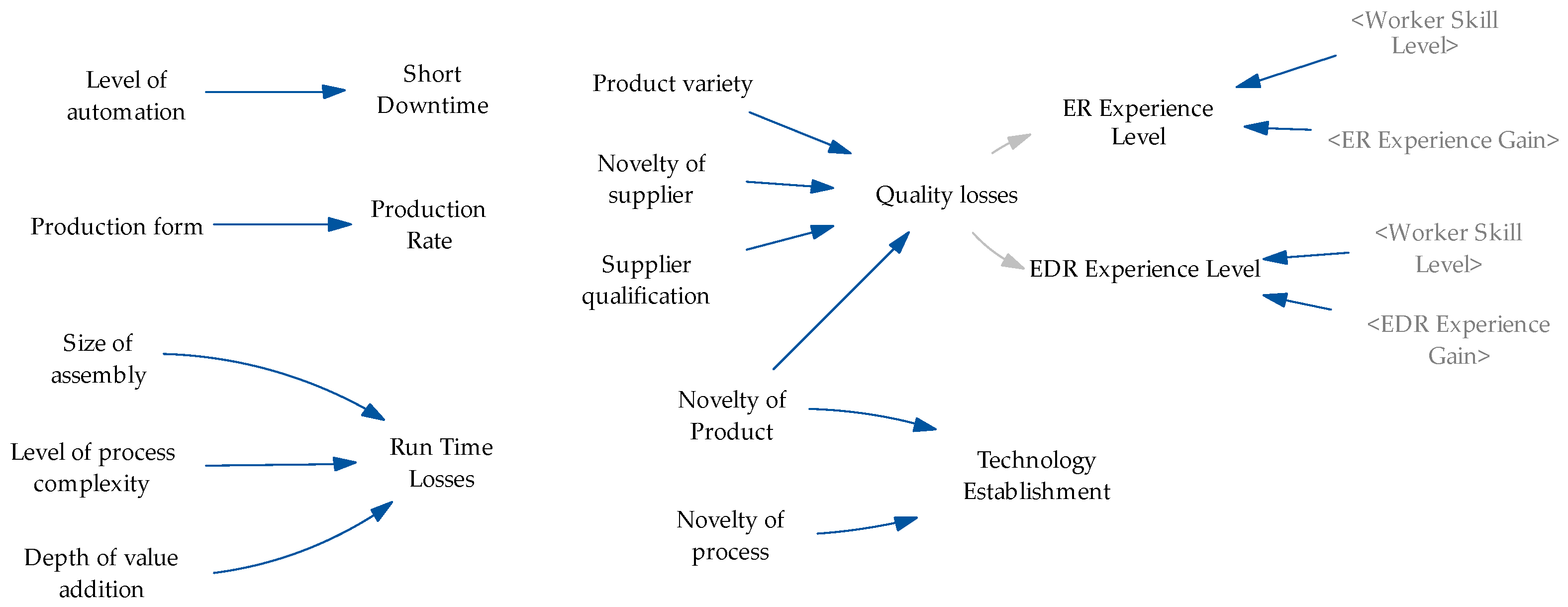

3.2.5. OEE Module

3.2.6. Breakdown Module

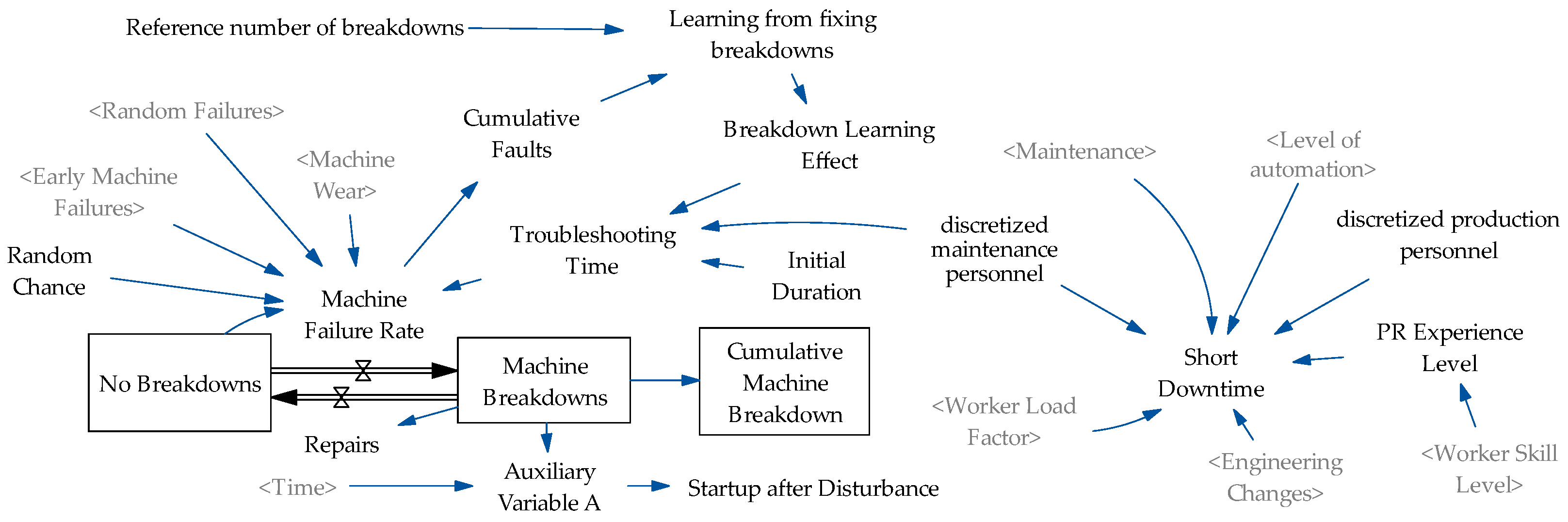

3.2.7. Technological Maturity Module

3.2.8. System Capacity Module

3.2.9. Process Maturity Module

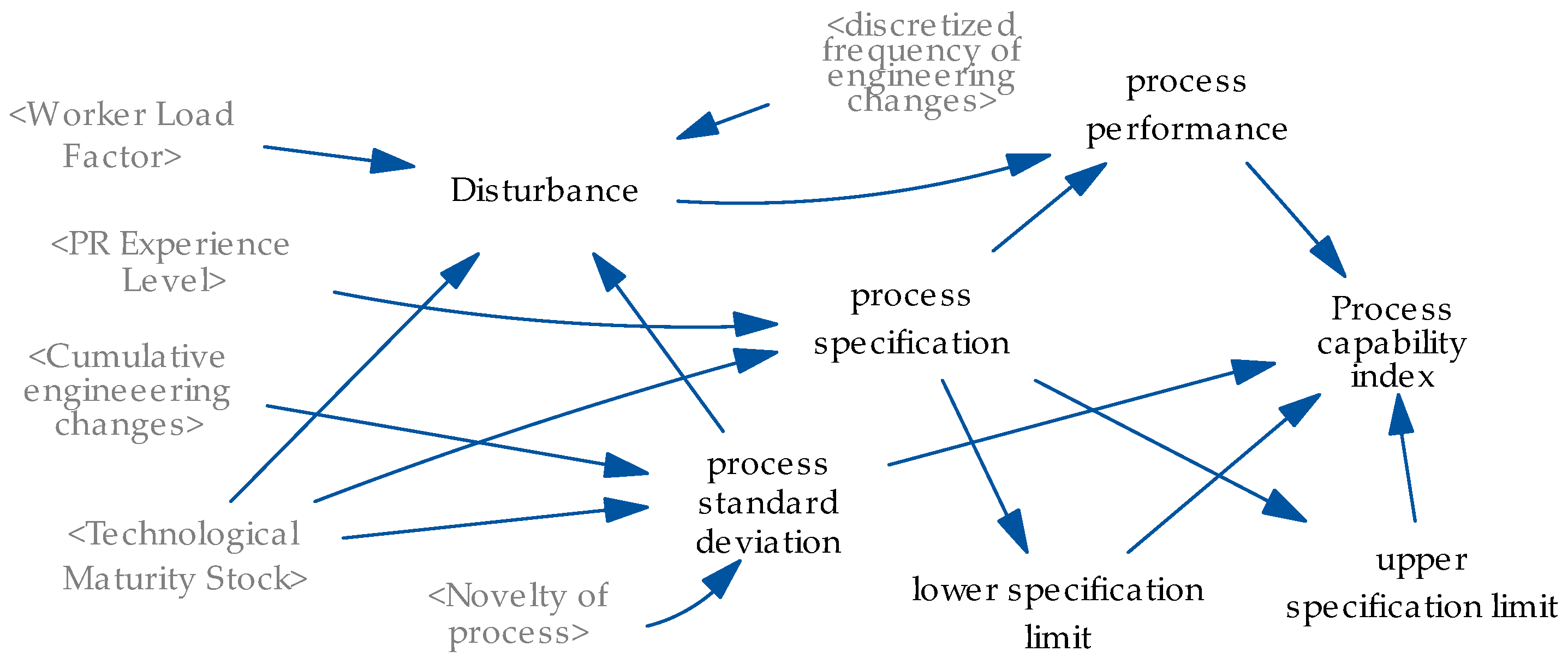

3.2.10. Worker Skill Module

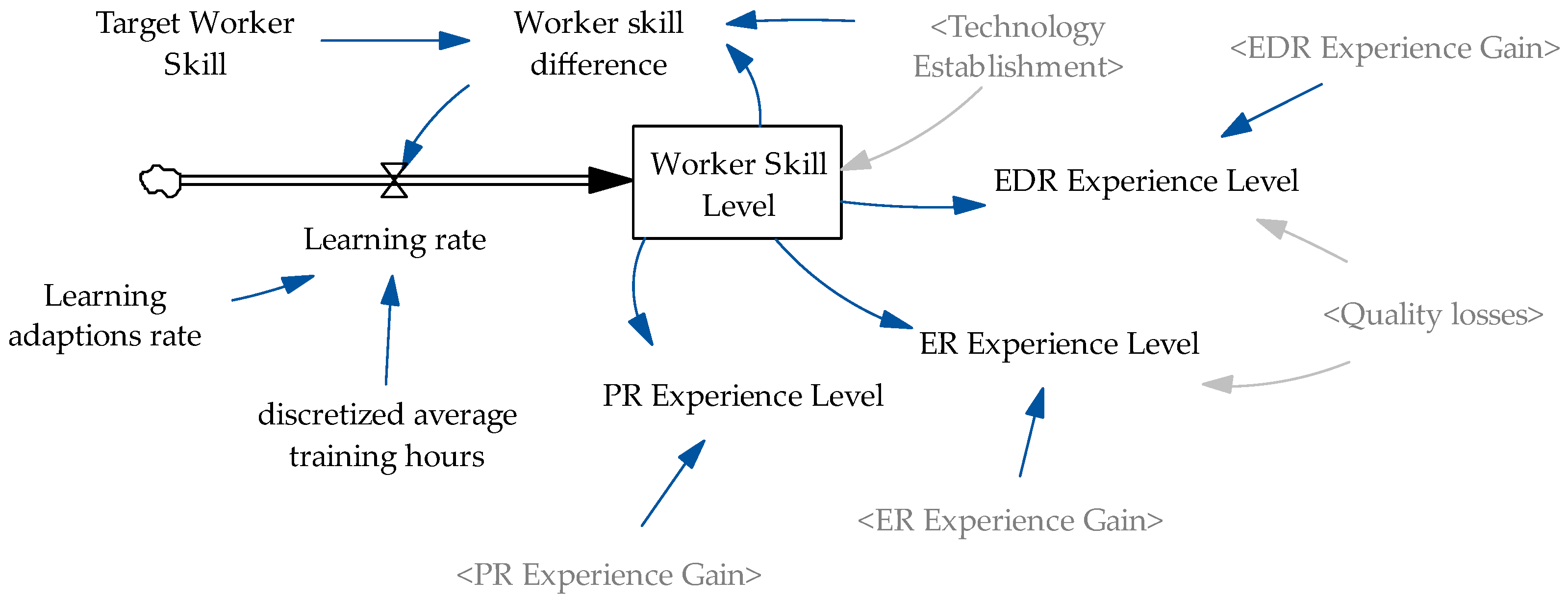

3.2.11. Structural Complexity Module

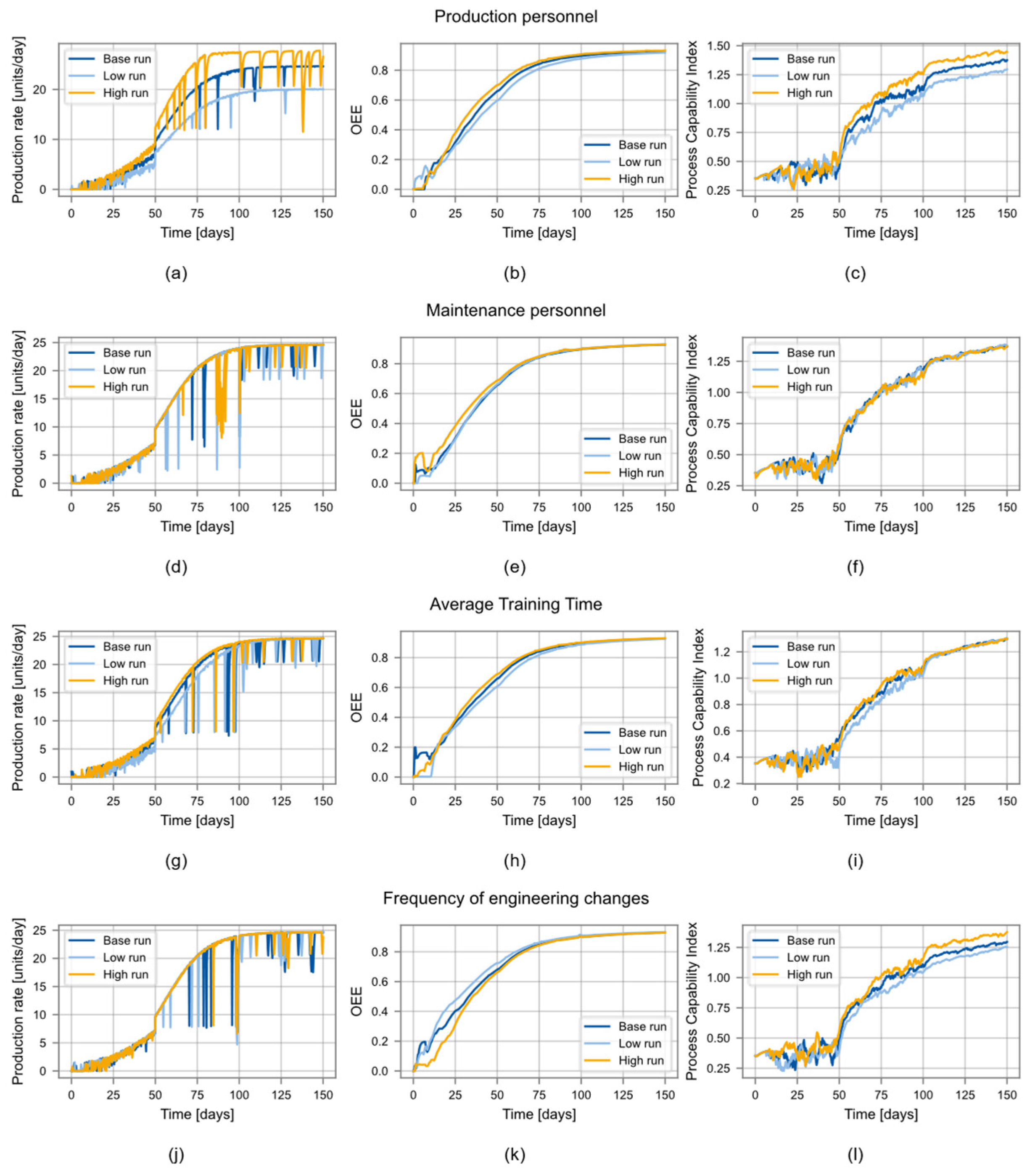

4. Results and Model Validity

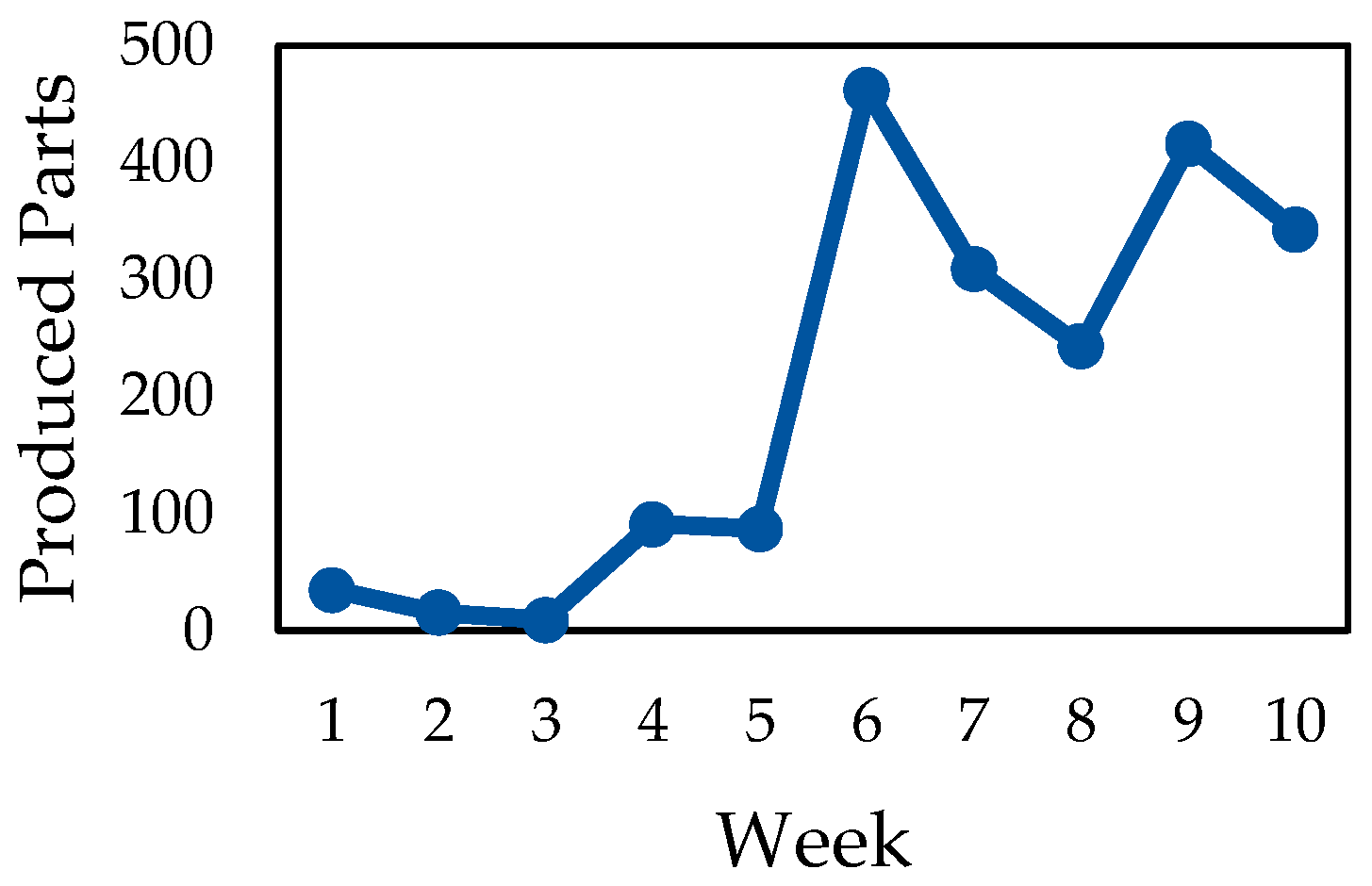

4.1. Stability Model Validation

4.2. Simulation Model Validation

5. Discussion

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Control Factors | Low Run | Base Run | High Run |

|---|---|---|---|

| Avg. Training Time | 2–0.67–0.2 | 3–1–0.3 | 4–1.33–0.4 |

| Engineering Changes | 4–2–1 | 6–2–1 | 8–3–1 |

| Production Personnel | 14–18–18 | 15–20–20 | 16–22–22 |

| Maintenance Personnel | 4–4–8 | 5–5–10 | 6–6–12 |

References

- Dombrowski, U.; Wullbrandt, J.; Krenkel, P. Industrie 4.0 in production ramp-up management. Procedia Manuf. 2018, 17, 1015–1022. [Google Scholar] [CrossRef]

- Fogliatto, F.S.; da Silveira, G.J.; Borenstein, D. The mass customization decade: An updated review of the literature. Int. J. Prod. Econ. 2012, 138, 14–25. [Google Scholar] [CrossRef]

- Zikopoulos, C. On the effect of upgradable products design on circular economy. Int. J. Prod. Econ. 2022, 254, 108629. [Google Scholar] [CrossRef]

- Kim, T.; Glock, C.H.; Emde, S. Production planning for a ramp-up process in a multi-stage production system with worker learning and growth in demand. Int. J. Prod. Res. 2021, 59, 6002–6021. [Google Scholar] [CrossRef]

- Fjällström, S.; Säfsten, K.; Harlin, U.; Stahre, J. Information enabling production ramp-up. J. Manuf. Technol. Manag. 2009, 20, 178–196. [Google Scholar] [CrossRef]

- Terwiesch, C.; Xu, Y. The Copy-Exactly Ramp-Up Strategy: Trading-Off Learning with Process Change. IEEE Trans. Eng. Manag. 2004, 51, 70–84. [Google Scholar] [CrossRef]

- Winkler, H.; Heins, M.; Nyhuis, P. A controlling system based on cause–effect relationships for the ramp-up of production systems. Prod. Eng. 2007, 1, 103–111. [Google Scholar] [CrossRef]

- Surbier, L.; Alpan, G.; Blanco, E. A comparative study on production ramp-up: State-of-the-art and new challenges. Prod. Plan. Control 2014, 25, 1264–1286. [Google Scholar] [CrossRef]

- Scrimieri, D.; Oates, R.F.; Ratchev, S.M. Learning and reuse of engineering ramp-up strategies for modular assembly systems. J. Intell. Manuf. 2015, 26, 1063–1076. [Google Scholar] [CrossRef]

- Basse, I.; Schmitt, S.; Gartzen, T.; Schmitt, R. Solution Principles for Managing Instabilities in Ramp-up. Procedia CIRP 2014, 20, 93–97. [Google Scholar] [CrossRef]

- Schuh, G.; Gartzen, T.; Wagner, J. Complexity-oriented ramp-up of assembly systems. CIRP J. Manuf. Sci. Technol. 2015, 10, 1–15. [Google Scholar] [CrossRef]

- Glock, C.H.; Grosse, E.H. Decision support models for production ramp-up: A systematic literature review. Int. J. Prod. Res. 2015, 53, 6637–6651. [Google Scholar] [CrossRef]

- ElMaraghy, H.; Monostori, L.; Schuh, G.; ElMaraghy, W. Evolution and future of manufacturing systems. CIRP Ann. 2021, 70, 635–658. [Google Scholar] [CrossRef]

- Elstner, S.; Krause, D. Methodical approach for an e cient transition from development to production. In DS 71, Proceedings of NordDesign 2012, the 9th NordDesign Conference, Aalborg, Denmark, 22–24 August 2012; Aarlborg University: Aalborg, Denmark, 2012. [Google Scholar]

- Biffl, S.; Kropatschek, S.; Kiesling, E.; Meixner, K.; Luder, A. Risk-Driven Derivation of Operation Checklists from Mul-ti-Disciplinary Engineering Knowledge. In Proceedings of the 2022 IEEE 20th International Conference on Industrial Informatics (INDIN), Perth, Australia, 25–28 July 2022; pp. 7–14. [Google Scholar]

- Christensen, I.; Rymaszewska, A. Lean Application to Manufacturing Ramp-Up: A Conceptual Approach. Qual. Manag. J. 2016, 23, 45–54. [Google Scholar] [CrossRef]

- Dombrowski, U.; Hanke, T. Lean Ramp-up: Ein Organisationsmodell für das Anlaufmanagement. Z. Wirtsch. Fabr. 2017, 112, 387–391. [Google Scholar] [CrossRef]

- Slattery, O.; Trubetskaya, A.; Moore, S.; McDermott, O. A Review of Lean Methodology Application and Its Integration in Medical Device New Product Introduction Processes. Processes 2022, 10, 2005. [Google Scholar] [CrossRef]

- Kremsmayr, M.; Dronhofer, A.; Mitterer, N.; Ramsauer, C. On the Application of Agility Principles in Ramp-up Management: Approaching the Challenges in the High-end Powder Metallurgy Industry. Procedia CIRP 2016, 51, 85–92. [Google Scholar] [CrossRef]

- Schuh, G.; Gartzen, T.; Basse, F.; Schrey, E. Enabling Radical Innovation through Highly Iterative Product Expedition in Ramp up and Demonstration Factories. Procedia CIRP 2016, 41, 620–625. [Google Scholar] [CrossRef]

- Rapp, S.; Heimicke, J.; Weber, J.; Albers, A. Development of strategic guidelines for agile Parts Ma- turity Management of engine subsystems in the automotive industry during series ramp-up. In Proceedings of the DS 101: Proceedings of NordDesign 2020, Lyngby, Denmark, 12–14 August 2020; pp. 1–12. Available online: https://www.designsociety.org/publication/42552/development+of+strategic+guidelines+for+agile+parts+ma-+turity+management+of+engine+subsystems+in+the+automotive+industry+during+series+ramp-up (accessed on 7 October 2024).

- Bergs, T.; Apelt, S.; Beckers, A.; Barth, S. Agile ramp-up production as an advantage of highly iterative product development. Manuf. Lett. 2021, 27, 4–7. [Google Scholar] [CrossRef]

- Heraud, J.; Medini, K.; Andersen, A.-L. Managing agile ramp-up projects in manufacturing—Status quo and recommendations. CIRP J. Manuf. Sci. Technol. 2023, 45, 125–137. [Google Scholar] [CrossRef]

- Brecher, C.; Müller, S.; Breitbach, T.; Lohse, W. Viable System Model for Manufacturing Execution Systems. Procedia CIRP 2013, 7, 461–466. [Google Scholar] [CrossRef]

- Bauer, W.; Ganschar, O.; Pokorni, B.; Schlund, S. Concept of a Failures Management Assistance System for the Reaction on Unforeseeable Events during the Ramp-up. Procedia CIRP 2014, 25, 420–425. [Google Scholar] [CrossRef]

- Ordaz, N.; Romero, D.; Gorecky, D.; Siller, H.R. Serious Games and Virtual Simulator for Automotive Manufacturing Education & Training. Procedia Comput. Sci. 2015, 75, 267–274. [Google Scholar] [CrossRef]

- Bußwolder, P.; Burgahn, F.; Hübner, M.; Werker, M. Classification of Company-specific Influence Factors as Part of a Knowledge Management System for Ramp-up Projects. Procedia CIRP 2016, 51, 44–50. [Google Scholar] [CrossRef]

- Willmann, R.; Kastner, W. A Deterministic Product Ramp-up Process: How to Integrate a Multi-Disciplinary Knowledge Base. In Multi-Disciplinary Engineering for Cyber-Physical Production Systems: Data Models and Software Solutions for Handling Complex Engineering Projects; Biffl, S., Lüder, A., Gerhard, D., Eds.; Springer: Cham, Switzerland, 2017; pp. 399–431. [Google Scholar]

- Wlazlak, P.; Hussmo, D.; Säfsten, K. Integration Across Knowledge Boundaries During New Product Introduction. In Advances in Transdisciplinary Engineering Ser, v.16, Transdisciplinary Engineering for Resilience, Proceedings of the 28th ISTE International Conference on Transdisciplinary Engineering, Virtual, 5–9 July 2021, 1st ed.; Newnes, L., Ed.; IOS Press Incorporated: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Doltsinis, S.C.; Lohse, N. A Model-Free Reinforcement Learning Approach Using Monte Carlo Method for Production Ramp-Up Policy Improvement—A Copy Exactly Test Case. IFAC Proc. Vol. 2012, 45, 1628–1634. [Google Scholar] [CrossRef]

- Doltsinis, S.; Ferreira, P.; Lohse, N. An MDP Model-Based Reinforcement Learning Approach for Production Station Ramp-Up Optimization: Q-Learning Analysis. IEEE Trans. Syst. Man Cybern. Syst. 2014, 44, 1125–1138. [Google Scholar] [CrossRef]

- Bobka, P.; Heyn, J.; Henningson, J.-O.; Römer, M.; Engbers, T.; Dietrich, F.; Dröder, K. Development of an automated assembly process supported with an artificial neural network. J. Mach. Eng. 2018, 18, 28–41. [Google Scholar] [CrossRef]

- Meiners, M.; Franke, J. Concept of a Machine Learning supported Cross-Machine Control Loop in the Ramp-Up of Large Series Manufacturing. In Proceedings of the 2020 IEEE 11th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT 2020), Cape Town, South Africa, 20–22 January 2020; pp. 155–160. [Google Scholar]

- Lanza, G.; Sauer, A. Simulation of personnel requirements during production ramp-up. Prod. Eng. 2012, 6, 395–402. [Google Scholar] [CrossRef]

- Schmid, F.; Schneidewind, J.; Wild, T.; Galka, S.; Schuhegger, L.; Vogl, T. Simulation Based Approach for Reconfiguration and Ramp Up Scenario Analysis in Factory Planning. In Proceedings of the 2022 Winter Simulation Conference (WSC), Singapore, 11–14 December 2022; pp. 2842–2852. [Google Scholar]

- Spath, D.; Pokorni, B.; Ganschar, O.; Schlund, S. Intelligenter Störungsassistent im Serienanlauf als Industrie 4.0-Anwendungsfall. Industrie 2014, 4, 343–371. [Google Scholar]

- Haller, J.; Kaven, L.; Göppert, A.; Schmitt, R.H. Industry 4.0 advancements in discrete production ramp-ups: A systematic literature review. J. Intell. Manuf. 2024. under revision. [Google Scholar]

- Padrón, M.; Haller, J.; Schmitt, R.H. Production ramp-up in discrete manufacturing systems: A systematic literature review of modelling methods. Procedia CIRP 2024. in print. [Google Scholar]

- Forrester, J.W. Industrial Dynamics. J. Oper. Res. Soc. 1997, 48, 1037–1041. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, 71. [Google Scholar] [CrossRef]

- Pufall, A.; Fransoo, J.C.; de Kok, A.G. What Determines Product Ramp-Up Performance?: A Review of Characteristics Based on a Case Study at Nokia Mobile Phones; Beta, Research School for Operations Management and Logistics; Technische Universiteit Eindhoven: Eindhoven, The Netherlands, 2007. [Google Scholar]

- Calantone, R.J.; Randhawa, P.; Voorhees, C.M. Breakeven Time on New Product Launches: An Investigation of the Drivers and Impact on Firm Performance. J. Prod. Innov. Manag. 2014, 31, 94–104. [Google Scholar] [CrossRef]

- Kampker, A.; Kreiskother, K.; Lutz, N.; Gauckler, V.; Hehl, M. Re-Ramp-Up Management of Scalable Production Systems in the Automotive Industry. In Proceedings of the 2019 8th International Conference on Industrial Technology and Management: ICITM 2019, Cambridge, UK, 2–4 March 2019; pp. 137–141. [Google Scholar]

- Stauder, J.; Buchholz, S.; Klocke, F.; Mattfeld, P. A New Framework to Evaluate the Process Capability of Production Technologies during Production Ramp-Up. Procedia CIRP 2014, 20, 126–131. [Google Scholar] [CrossRef]

- Kornas, T.; Knak, E.; Daub, R.; Bührer, U.; Lienemann, C.; Heimes, H.; Kampker, A.; Thiede, S.; Herrmann, C. A Multivariate KPI-Based Method for Quality Assurance in Lithium-Ion-Battery Production. Procedia CIRP 2019, 81, 75–80. [Google Scholar] [CrossRef]

- Islam, M.H.; Chavez, Z.; Birkie, S.E.; Bellgran, M. Key Factors on Utilizing the Production System Design Phase for Increasing Operational Performance. In Springer eBook Collection, Volume 592, Advances in Production Management Systems. Towards Smart and Digital Manufacturing, Proceedings of the IFIP WG 5.7 International Conference, APMS 2020, Novi Sad, Serbia, 30 August–3 September 2020, 1st ed.; Proceedings, Part II; Lalic, B., Majstorovic, V., Marjanovic, U., von Cieminski, G., Romero, D., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 740–748. [Google Scholar]

- Verhaelen, B.; Martin, M.; Peukert, S.; Lanza, G. Practice-oriented methodology for increasing production ramp-up efficiency in global production networks of SME. Prod. Eng. 2022, 17, 145–177. [Google Scholar] [CrossRef]

- Carrillo, J.E.; Franza, R.M. Investing in product development and production capabilities: The crucial linkage between time-to-market and ramp-up time. Eur. J. Oper. Res. 2006, 171, 536–556. [Google Scholar] [CrossRef]

- Hansen, K.R.; Grunow, M. Modelling ramp-up curves to reflect learning: Improving capacity planning in secondary pharmaceutical production. Int. J. Prod. Res. 2015, 53, 5399–5417. [Google Scholar] [CrossRef]

- Terwiesch, C.; Bohn, R.E. Learning and process improvement during production ramp-up. Int. J. Prod. Econ. 2001, 70, 1–19. [Google Scholar] [CrossRef]

- Doltsinis, S.C.; Ratchev, S.; Lohse, N. A framework for performance measurement during production ramp-up of assembly stations. Eur. J. Oper. Res. 2013, 229, 85–94. [Google Scholar] [CrossRef]

- Safri, S.B.; Bazin, N.E.N.B. Conceptualization of factors influencing new product introduction within shorter product life cycle. In Proceedings of the 2012 4th Conference on Data Mining and Optimization (DMO), Langkawi, Malaysia, 2–4 September 2012; pp. 143–148. [Google Scholar]

- Xu, X.G.; Shen, D.B. Research on Enterprises Knowledge Transfer under NPI Model Based on the System Dynamics. Adv. Mater. Res. 2014, 945–949, 2977–2981. [Google Scholar] [CrossRef]

- Chen, Y.; Lee, T.R.; Wang, J.W. Two-stage decision support for production ramp-up. Int. J. Agil. Syst. Manag. 2011, 4, 364. [Google Scholar] [CrossRef]

- Ali-Qureshi, Z.; ElMaraghy, W.H. Procurement of Reconfigurable Assembly System a Justification for Effective Production Ramp-up Planning. Procedia CIRP 2014, 16, 164–169. [Google Scholar] [CrossRef]

- Stiller, S. Qualitätsorientierte Produktionstheorie zur Beherrschung Dynamischer Produktrealisierender Prozesse. Ph.D. Thesis, Apprimus, Aachen, Germany, 2015. [Google Scholar]

- Ngo, Q.H. Gestaltungsmodell für Qualitätsorientierte Produktionsanläufe; Apprimus: Aachen, Germany, 2020. [Google Scholar]

- Haller, J.; Beckschulte, S.; Padrón, M.; Ngo, Q.H.; Schmitt, R.H. Framework for Target Classification and Strategy Derivation during Production Ramp-up. In Proceedings of the 2023 IEEE International Systems Conference (SysCon), Vancouver, BC, Canada, 17–20 April 2023; pp. 1–5. [Google Scholar]

- Kampker, A.; Deutskens, C.; Deutschmann, K.; Maue, A.; Haunreiter, A. Increasing Ramp-up Performance By Implementing the Gamification Approach. Procedia CIRP 2014, 20, 74–80. [Google Scholar] [CrossRef]

- Almgren, H. Pilot production and manufacturing start-up: The case of Volvo S80. Int. J. Prod. Res. 2000, 38, 4577–4588. [Google Scholar] [CrossRef]

- Jürging, J.; Milling, P.M. Manufacturing Start-Ups in the Automobile Industry. 2006. Available online: https://proceedings.systemdynamics.org/2006/proceed/papers/JUERG310.pdf (accessed on 7 October 2024).

- Bultó, R.; Viles, E.; Mateo, R. Overview of ramp-up curves: A literature review and new challenges. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 755–765. [Google Scholar] [CrossRef]

- Klocke, F.; Stauder, J.; Mattfeld, P.; Müller, J. Modeling of Manufacturing Technologies During Ramp-up. Procedia CIRP 2016, 51, 122–127. [Google Scholar] [CrossRef]

- Kukulies, J.; Schmitt, R. Stabilizing production ramp-up by modeling uncertainty for product design verification using Dempster–Shafer theory. CIRP J. Manuf. Sci. Technol. 2018, 23, 187–196. [Google Scholar] [CrossRef]

- Gartzen, T. Diskrete Migration als Anlaufstrategie für Montagesysteme; Apprimus: Aachen, Germany, 2012. [Google Scholar]

- Javadi, S.; Bruch, J.; Bellgran, M. Characteristics of product introduction process in low-volume manufacturing industries. J. Manuf. Technol. Manag. 2016, 27, 535–559. [Google Scholar] [CrossRef]

- Burggräf, P.; Dannapfel, M.; Voet, H. Potentials of Factory Standards in Production Ramp-Ups. Procedia CIRP 2016, 51, 134–139. [Google Scholar] [CrossRef]

- Viles, E.; Bultó, R.; Mateo, R.; Jurburg, D. Production ramp-up in European automotive production systems: A performance analysis. Prod. Plan. Control 2021, 32, 34–51. [Google Scholar] [CrossRef]

- Haller, M.; Peikert, A.; Thoma, J. Cycle time management during production ramp-up. Robot. Comput. Manuf. 2003, 19, 183–188. [Google Scholar] [CrossRef]

- Bohn, R.E.; Terwiesch, C. The economics of yield-driven processes. J. Oper. Manag. 1999, 18, 41–59. [Google Scholar] [CrossRef]

- Jackson, M.C. Systems Thinking: Creative Holism for Managers; Wiley: Chichester, UK, 2003. [Google Scholar]

- Zeugträger, K. Anlaufmanagement für Großanlagen; VDI: Düsseldorf, Germany, 1998. [Google Scholar]

- Nakajima, S. Introduction to TPM: Total Productive Maintenance; Productivity Press: Cambridge, MA, USA, 1988. [Google Scholar]

- Chatzimichali, A.P.; Tourassis, V.D. Hierarchies of adaptable learning during product development. In Proceedings of the 2011 IEEE International Conference on Systems, Man and Cybernetics—SMC, Anchorage, AK, USA, 9–12 October 2011; pp. 458–464. [Google Scholar]

| Control Factors | Quality Phase | Production Output Phase | Organization Phase |

|---|---|---|---|

| Avg. Training Time | 1 | 0.33 | 0.1 |

| Engineering Changes | 1 | 0.33 | 0.1 |

| Production Personnel | 0.75 | 1 | 1 |

| Maintenance Personnel | 0.5 | 0.5 | 1 |

| Orders | 0.4 | 0.8 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haller, J.; Kumar, B.; Göppert, A.; Schmitt, R.H. A System Dynamics Stability Model for Discrete Production Ramp-Up. Systems 2024, 12, 575. https://doi.org/10.3390/systems12120575

Haller J, Kumar B, Göppert A, Schmitt RH. A System Dynamics Stability Model for Discrete Production Ramp-Up. Systems. 2024; 12(12):575. https://doi.org/10.3390/systems12120575

Chicago/Turabian StyleHaller, Julian, Bharath Kumar, Amon Göppert, and Robert H. Schmitt. 2024. "A System Dynamics Stability Model for Discrete Production Ramp-Up" Systems 12, no. 12: 575. https://doi.org/10.3390/systems12120575

APA StyleHaller, J., Kumar, B., Göppert, A., & Schmitt, R. H. (2024). A System Dynamics Stability Model for Discrete Production Ramp-Up. Systems, 12(12), 575. https://doi.org/10.3390/systems12120575