Lot-Streaming Workshop Scheduling with Operation Flexibility: Review and Extension

Abstract

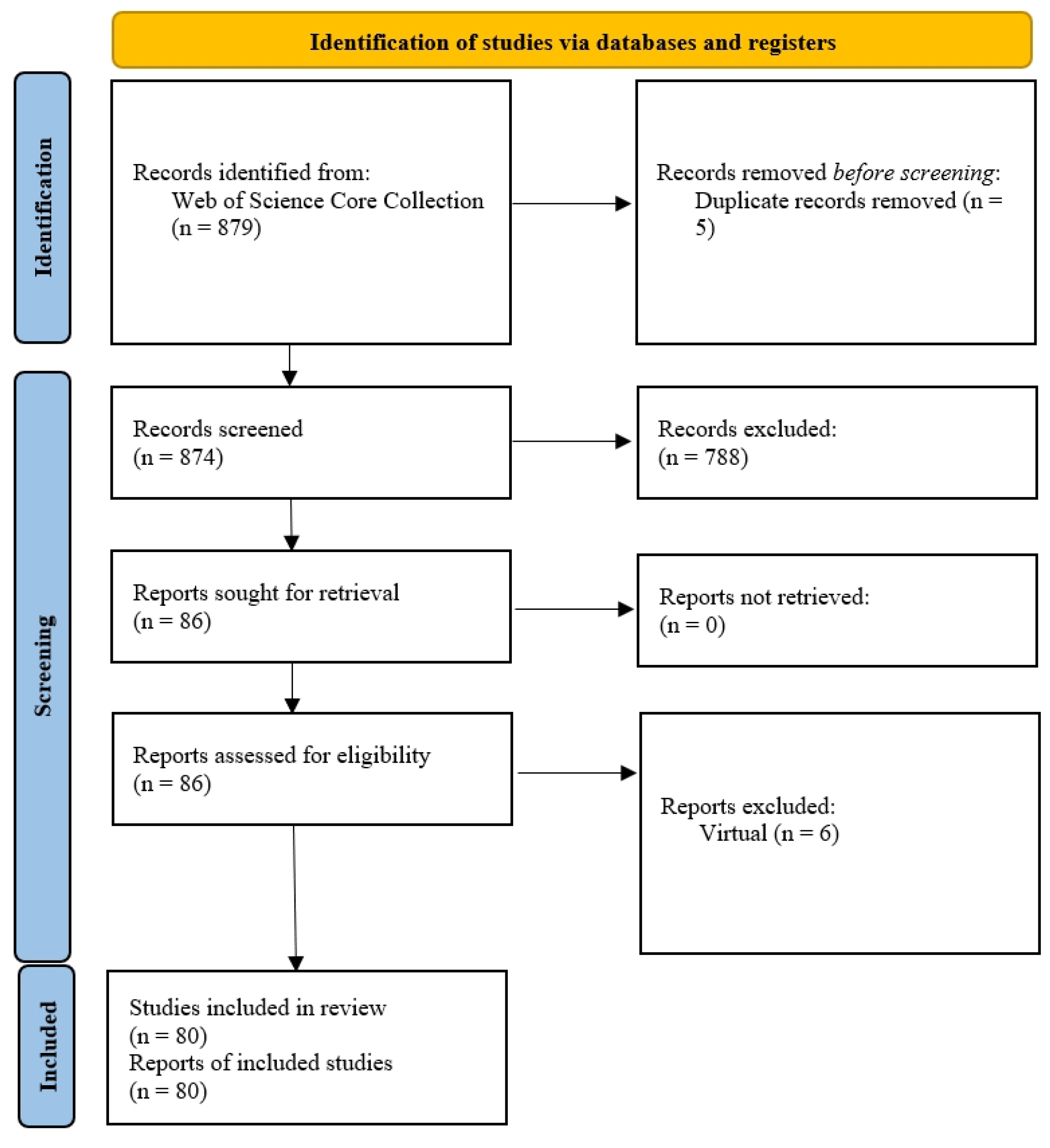

1. Introduction

2. The Framework of LWSOF

2.1. Lot-Splitting Methods

2.2. Objectives and Constraints

2.3. Problem Models

2.4. Solution Approaches

3. Research Trends

3.1. From Single Objective to Multi-Objective Considering Energy Consumption

3.2. Perfecting of Mathematical Programming Models

3.3. Extending of Problem Feature-Oriented EAs or SIAs

4. Future Directions

4.1. Knowledge and Greedy-Based Lot-Splitting Strategies

4.2. Practice in Actual Scheduling Environments with Multi-Constraint and Explore the Interaction Between Constraints

4.3. Developing of Highly Accurate Mathematical Planning Models and Graph-Based Models

4.4. Improvement of EAs and SIAs as Well as Deep Learning Methods

4.5. Exploiting of Digital-Twin Based Optimization Frameworks

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

List of Abbreviations

| ABC | Artificial bee colony | MILP | Mixed integer linear programming |

| ACO | Ant colony optimization | MINLP | Mixed integer non-Linear programming |

| CP | Constraint programming | MIP | Mixed integer programming |

| DE | Differential evolution algorithm | NILP | Non-integer linear programming |

| EA | Evolutionary algorithm | NN | Neural network |

| ECS | Equal consistent sub-lots | NSGA | Non-dominated sorting genetic algorithm |

| EDA | Estimation of distribution algorithm | PSO | Particle swarm optimization |

| GA | Genetic algorithm | MBO | Migrating birds optimization |

| IG | Iterated greedy | SA | Simulated annealing |

| KMA | Knowledge-based memetic algorithm | ER-GA | Early release GA |

| TS-ISMO | Two-stage improved spider monkey optimization | CHS-GPHH | Collaborative Harmony Searchbased Genetic Programming Hyper Heuristic |

| ILP | Integer linear programming | SVM | Support vector machine |

| IP | Integer programming | TS | Tabu search |

| LP | Linear programming | UCS | Unequal consistent sub-lots |

| UVS | Unequal variable sub-lots | VNS | Variable neighborhood search |

| VND | Variable neighborhood descent | EVS | Equal variable sub-lots |

References

- Gao, K.Z.; Cao, Z.G.; Zhang, L.; Chen, Z.H.; Han, Y.Y.; Pan, Q.K. A review on swarm intelligence and evolutionary algorithms for solving flexible job shop scheduling problems. IEEE CAA J. Autom. Sin. 2019, 6, 904–916. [Google Scholar] [CrossRef]

- Knopp, S.; Dauzere-Peres, S.; Yugma, C. A batch-oblivious approach for complex job-shop scheduling problems. Eur. J. Oper. Res. 2017, 263, 50–61. [Google Scholar] [CrossRef]

- Tian, G.D.; Ren, Y.P.; Feng, Y.X.; Zhou, M.C.; Zhang, H.H.; Tan, J.R. Modeling and planning for dual-objective selective disassembly using and/or graph and discrete artificial bee colony. IEEE Trans. Ind. Inform. 2019, 15, 2456–2468. [Google Scholar] [CrossRef]

- Daneshamooz, F.; Fattahi, P.; Hosseini, S.M.H. Scheduling in a flexible job shop followed by some parallel assembly stations considering lot streaming. Eng. Optim. 2022, 54, 614–633. [Google Scholar] [CrossRef]

- Riaz, F.; Ali, K.M. Applications of graph theory in computer science. In Proceedings of the 2011 Third International Conference on Computational Intelligence, Bali, Indonesia, 26–28 July 2011; Volume 26–28, pp. 142–145. [Google Scholar]

- Mousavian, S.; Erol-Kantarci, M.; Mouftah, H.T. Cyber-Security and Resiliency of Transportation and Power Systems in Smart Cities. In Transportation and Power Grid in Smart Cities: Communication Networks and Services; Wiley: Hoboken, NJ, USA, 2019; pp. 507–527. [Google Scholar]

- Otala, J.; Minard, A.; Madraki, G. Graph-based modeling in shop scheduling problems: Review and extensions. Appl. Sci. 2021, 11, 4741. [Google Scholar] [CrossRef]

- 3D Simulation Modeling & Analysis Software. FlexSim. 2023. Available online: https://www.flexsim.com/ (accessed on 15 April 2023).

- Plant Simulation Software. Siemens Software. 2023. Available online: https://plm.sw.siemens.com/en-US/tecnomatix/products/plant-simulation-software/ (accessed on 15 April 2023).

- AnyLogic: Simulation Modeling Software Tools. AnyLogic. 2023. Available online: https://www.anylogic.cn/ (accessed on 15 April 2023).

- Global Operations Software. DELMIA-Dassault Systèmes. 2023. Available online: https://www.3ds.com/products/delmia (accessed on 15 April 2023).

- WITNESS Simulation Modeling Software. Lanner. 2023. Available online: https://www.lanner.com/en-us/technology/witness-simulation-software.html (accessed on 15 April 2023).

- Defersha, F.M.; Movahed, S.B. Linear programming assisted (not embedded) genetic algorithm for flexible jobshop scheduling with lot streaming. Comput. Ind. Eng. 2018, 117, 319–335. [Google Scholar] [CrossRef]

- Omid, S.; Rasaratnam, L.; Madjid, T. An efficient model-based branch-and-price algorithm for unrelated-parallel machine batching and scheduling problems. J. Sched. 2022, 25, 589–821. [Google Scholar] [CrossRef]

- Karimi-Nasab, M.; Seyedhoseini, S.M. Multi-level lot sizing and job shop scheduling with compressible process times: A cutting plane approach. Eur. J. Oper. Res. 2013, 231, 598–616. [Google Scholar] [CrossRef]

- Jalilvand-Nejad, A.; Fattahi, P. A mathematical model and genetic algorithm to cyclic flexible job shop scheduling problem. J. Intell. Manuf. 2015, 26, 1085–1098. [Google Scholar] [CrossRef]

- Defersha, F.M. A simulated annealing with multiple-search paths and parallel computation for a comprehensive flowshop scheduling problem. Int. Trans. Oper. Res. 2015, 22, 669–691. [Google Scholar] [CrossRef]

- Liu, Y.; Tiwari, A. An investigation into minimising total energy consumption and total makespan in a flexible job shop for recycling carbon fiber reinforced rolymer. In Proceedings of the 22nd CIRP Conference on Life Cycle Engineering (LCE), Sydney, Australia, 7–9 April 2015; Volume 29, pp. 722–727. [Google Scholar]

- Mohsen, N.; Iraj, M.; Reza, H.; Nezam, M.-A. Lot streaming in a two-stage assembly hybrid flow shop scheduling problem with a work shift constraint. J. Ind. Prod. Eng. 2016, 33, 459–471. [Google Scholar] [CrossRef]

- Chen, M.; Li, J.L. Genetic algorithm combined with gradient information for flexible job-shop scheduling problem with different varieties and small batches. In Proceedings of the 3rd International Conference on Mechatronics and Mechanical Engineering (ICMME), Shanghai, China, 21–23 October 2016; p. 95. [Google Scholar]

- Cheng, M.; Sarin, S.C.; Singh, S. Two-stage, single-lot, lot streaming problem for a hybrid flow shop. J. Glob. Optim. 2016, 66, 263–290. [Google Scholar] [CrossRef]

- Li, X.P.; Jiang, T.Z.; Ruiz, R. Heuristics for periodical batch job scheduling in a mapreduce computing framework. Inf. Sci. 2016, 326, 119–133. [Google Scholar] [CrossRef]

- Shahvari, O.; Logendran, R. Hybrid flow shop batching and scheduling with a bi-criteria objective. Int. J. Prod. Econ. 2016, 179, 239–258. [Google Scholar] [CrossRef]

- Vivek, P.; Saravanan, R.; Chandrasekaran, M.; Pugazhenthi, R. Heuristic for critical machine based a lot streaming for two-stage hybrid production environment. In Proceedings of the 2nd International Conference on Emerging Trends in Engineering Research (ICETER), Chennai, India, 20–21 October 2016; p. 183. [Google Scholar]

- Lalitha, J.L.; Mohan, N.; Pillai, V.M. Lot streaming in N-1 (1)+N(m) hybrid flow shop. J. Manuf. Syst. 2017, 44, 12–21. [Google Scholar] [CrossRef]

- Yu, J.M.; Huang, R.; Lee, D.H. Iterative algorithms for batching and scheduling to minimise the total job tardiness in two-stage hybrid flow shops. Int. J. Prod. Res. 2017, 55, 3266–3282. [Google Scholar] [CrossRef]

- Zhang, B.; Pan, Q.K.; Gao, L.; Zhang, X.L.; Sang, H.Y.; Li, J.Q. An effective modified migrating birds optimization for hybrid flowshop scheduling problem with lot streaming. Appl. Soft Comput. 2017, 52, 14–27. [Google Scholar] [CrossRef]

- Zhong, Y.; Li, J.M.; Zhu, S.Z. Research on the multi-objective optimized scheduling of the flexible job-shop considering multi-resource allocation. Int. J. Simul. Model. 2018, 16, 517–526. [Google Scholar] [CrossRef]

- Bozek, A.; Werner, F. Flexible job shop scheduling with lot streaming and sublot size optimisation. Int. J. Prod. Res. 2018, 56, 6391–6411. [Google Scholar] [CrossRef]

- Liu, Y.; Farnsworth, M.; Tiwari, A. Energy-efficient scheduling of flexible flow shop of composite recycling. Int. J. Adv. Manuf. Technol. 2018, 97, 117–127. [Google Scholar] [CrossRef]

- Meng, T.; Duan, J.H.; Pan, Q.K.; Chen, Q.D.; Guo, J.T. An enhanced fruit fly optimization for the flexible job shop scheduling problem with lot streaming. In Proceedings of the 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; pp. 2345–2349. [Google Scholar]

- Meng, T.; Pan, Q.K.; Chen, Q.D. An enhanced migrating birds optimization for the flexible job shop scheduling problem with lot streaming. In Proceedings of the 14th International Conference on Intelligent Computing (ICIC), Wuhan, China, 15–18 August 2018; Volume 10954, pp. 769–779. [Google Scholar]

- Romero, M.A.F.; Garcia, E.A.R.; Ponsich, A.; Gutierrez, R.A.M. A heuristic algorithm based on tabu search for the solution of flexible job shop scheduling problems with lot streaming. In Proceedings of the Genetic and Evolutionary Computation Conference (GECCO), Kyoto, Japan, 15–19 July 2018; pp. 285–292. [Google Scholar]

- Shahvari, O.; Logendran, R. A comparison of two stage-based hybrid algorithms for a batch scheduling problem in hybrid flow shop with learning effect. Int. J. Prod. Econ. 2018, 195, 227–248. [Google Scholar] [CrossRef]

- Zhang, H.P.; Ye, J.H.; Yang, X.P.; Muruve, N.W.; Wang, J.T. Modified binary particle swarm optimization algorithm in lot-splitting scheduling involving multiple techniques. Int. J. Simul. Model. 2018, 17, 534–542. [Google Scholar] [CrossRef]

- Gong, D.W.; Han, Y.Y.; Sun, J.Y. A novel hybrid multi-objective artificial bee colony algorithm for blocking lot-streaming flow shop scheduling problems. Knowl. Based Syst. 2018, 148, 115–130. [Google Scholar] [CrossRef]

- Gu, H.Y.; Memar, J.; Zinder, Y. Improved lagrangian relaxation based optimization procedure for scheduling with storage. In Proceedings of the 9th IFAC/IFIP/IFORS/IISE/INFORMS Conference on Manufacturing Modelling, Management and Control (IFAC MIM), Berlin, Germany, 27–30 August 2019; Volume 52, pp. 100–105. [Google Scholar]

- Novas, J.M. Production scheduling and lot streaming at flexible job-shops environments using constraint programming. Comput. Ind. Eng. 2019, 136, 252–264. [Google Scholar] [CrossRef]

- Wang, S.S.; Kurz, M.; Mason, S.J.; Rashidi, E. Two-stage hybrid flow shop batching and lot streaming with variable sublots and sequence-dependent setups. Int. J. Prod. Res. 2019, 57, 6893–6907. [Google Scholar] [CrossRef]

- Yang, M.S.; Ba, L.; Xu, E.B.; Li, Y.; Gao, X.Q.; Liu, Y.; Li, Y. Batch optimization in integrated scheduling of machining and assembly. Int. J. Simul. Model. 2019, 18, 689–698. [Google Scholar] [CrossRef]

- Zacharias, M.; Tonnius, A.; Gottschling, J. Machine learning in hybrid flow shop scheduling with unrelated machines. In Proceedings of the International Conference on Industrial Engineering and Systems Management (IESM), Shanghai, China, 25–27 September 2019; pp. 318–323. [Google Scholar]

- Chen, T.L.; Cheng, C.Y.; Chou, Y.H. Multi-objective genetic algorithm for energy-efficient hybrid flow shop scheduling with lot streaming. Ann. Oper. Res. 2020, 290, 813–836. [Google Scholar] [CrossRef]

- Li, J.Q.; Tao, X.R.; Jia, B.X.; Han, Y.Y.; Liu, C.; Duan, P.; Zheng, Z.X.; Sang, H.Y. Efficient multi-objective algorithm for the lot-streaming hybrid flowshop with variable sub-lots. Swarm Evol. Comput. 2020, 52, 100600. [Google Scholar] [CrossRef]

- Wang, P.; Sang, H.Y.; Tao, Q.Y.; Guo, H.W.; Li, J.Q.; Gao, K.Z.; Han, Y.Y. Improved migrating birds optimization algorithm to solve hybrid flowshop scheduling problem with lot-streaming. IEEE Access 2020, 8, 89782–89792. [Google Scholar] [CrossRef]

- Zhang, M.; Tan, Y.T.; Zhu, J.H.; Chen, Y.N.; Chen, Z.T. A competitive and cooperative migrating birds optimization algorithm for vary-sized batch splitting scheduling problem of flexible job-shop with setup time. Simul. Model. Pract. Theory 2020, 100, 102065. [Google Scholar] [CrossRef]

- Zhang, S.C.; Li, X.; Zhang, B.W.; Wang, S.Y. Multi-objective optimisation in flexible assembly job shop scheduling using a distributed ant colony system. Eur. J. Oper. Res. 2020, 283, 441–460. [Google Scholar] [CrossRef]

- Hadi, A.S.; Mehdi, R.B. Solving a flexible job shop lot sizing problem with shared operations using a self-adaptive COA. Int. J. Prod. Res. 2021, 59, 483–515. [Google Scholar] [CrossRef]

- Wu, X.L.; Peng, J.J.; Xie, Z.R.; Zhao, N.; Wu, S.M. An improved multi-objective optimization algorithm for solving flexible job shop scheduling problem with variable batches. J. Syst. Eng. Electron. 2021, 32, 272–285. [Google Scholar] [CrossRef]

- Zhang, B.; Pan, Q.K.; Meng, L.L.; Zhang, X.L.; Ren, Y.P.; Li, J.Q.; Jiang, X.C. A collaborative variable neighborhood descent algorithm for the hybrid flowshop scheduling problem with consistent sub-lots. Appl. Soft Comput. 2021, 106, 107305. [Google Scholar] [CrossRef]

- Zhang, C.J.; Wang, K.X.; Ma, Q.J.; Li, X.Y.; Gao, L. Adiscrete grey wolf optimizer for solving flexible job shop scheduling problem with lot-streaming. In Proceedings of the 24th IEEE International Conference on Computer Supported Cooperative Work in Design (IEEE CSCWD), Dalian, China, 5–7 May 2021; pp. 969–974. [Google Scholar]

- Chiu, C.C.; Lai, C.M.; Chen, C.M. An evolutionary simulation-optimization approach for the problem of order allocation with flexible splitting rule in semiconductor assembly. Appl. Intell. 2022, 53, 2593–2615. [Google Scholar] [CrossRef]

- Han, Y.Y.; Chen, X.H.; Xu, M.M.; An, Y.J.; Gu, F.S.; Ball, A.D. A multi-objective flexible job-shop cell scheduling problem with sequence-dependent family setup times and intercellular transportation by improved NSGA-II. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 236, 540–556. [Google Scholar] [CrossRef]

- Jiang, X.Y.; Tian, Z.Q.; Liu, W.J.; Suo, Y.Q.; Chen, K.Q.; Xu, X.W.; Li, Z.W. Energy-efficient scheduling of flexible job shops with complex processes: A case study for the aerospace industry complex components in China. J. Ind. Inf. Integr. 2022, 27, 100293. [Google Scholar] [CrossRef]

- Li, L.L. Research on discrete intelligent workshop lot-streaming scheduling with variable sub-lots under engineer to order. Comput. Ind. Eng. 2022, 165, 107928. [Google Scholar] [CrossRef]

- Zhang, B.; Pan, Q.K.; Meng, L.L.; Zhang, X.L.; Jiang, X.C. A decomposition-based multi-objective evolutionary algorithm for hybrid flowshop rescheduling problem with consistent sub-lots. Int. J. Prod. Res. 2022, 61, 1013–1038. [Google Scholar] [CrossRef]

- Li, X.L.; Lu, J.S.; Yang, C.X.; Wang, J.L. Research of flexible assembly job-shop batch-scheduling problem based on improved artificial bee colony. Front. Bioeng. Biotechnol. 2022, 10, 909548. [Google Scholar] [CrossRef]

- Yilmaz, B.G.; Yilmaz, O.F. Lot streaming in hybrid flowshop scheduling problem by considering equal and consistent sublots under machine capability and limited waiting time constraint. Comput. Ind. Eng. 2022, 173, 108745. [Google Scholar] [CrossRef]

- Meng, T.; Pan, Q.K. A distributed heterogeneous permutation flowshop scheduling problem with lot-streaming and carryover sequence-dependent setup time. Swarm Evol. Comput. 2021, 60, 100804. [Google Scholar] [CrossRef]

- Meng, T.; Pan, Q.K.; Wang, L. A distributed permutation flowshop scheduling problem with the customer order constraint. Knowl. Based Syst. 2019, 184, 104894. [Google Scholar] [CrossRef]

- Wang, S.; Hui, J.; Zhu, B.; Liu, Y. Adaptive genetic algorithm based on fuzzy reasoning for the multilevel capacitated lot-sizing problem with energy consumption in synchronizer production. Sustainability 2022, 14, 5072. [Google Scholar] [CrossRef]

- Li, C.S.; Zhang, B.; Han, Y.Y.; Wang, Y.T.; Li, J.Q.; Gao, K.Z. Energy-efficient hybrid flowshop scheduling with consistent sublots using an improved cooperative coevolutionary algorithm. Mathematics 2023, 11, 77. [Google Scholar] [CrossRef]

- Yang, Y.F.; Song, Y.C.; Guo, W.F.; Lei, Q.; Sun, A.H.; Fan, L.H. Guided shuffled frog-leaping algorithm for flexible job shop scheduling problem with variable sublots and overlapping in operations. Comput. Ind. Eng. 2023, 180, 109209. [Google Scholar] [CrossRef]

- Lu, Y.L.; Tang, Q.H.; Pan, Q.K.; Zhao, L.P.; Zhu, Y.Y. A heuristic-based adaptive iterated greedy algorithm for lot-streaming hybrid flow shop scheduling problem with consistent and intermingled sub-Lots. Sensors 2023, 23, 2808. [Google Scholar] [CrossRef]

- Zhu, Y.Y.; Tang, Q.H.; Zhang, L.P.; He, M.; Kapenda, J. Improved multi-objective artificial bee colony algorithm for parallel machine lot-streaming scheduling problem with limited and unequal sub-lots. Comput. Ind. Eng. 2023, 183, 109428. [Google Scholar] [CrossRef]

- Tian, Z.Q.; Jiang, X.Y.; Tian, G.D.; Li, Z.W.; Liu, W.J. Knowledge-based lot-splitting optimization method for flexible job shops considering energy consumption. IEEE Trans. Autom. Sci. Eng. 2024, 21, 4864–4875. [Google Scholar] [CrossRef]

- Tian, Z.Q.; Jiang, X.Y.; Liu, W.J.; Li, Z.W. Dynamic energy-efficient scheduling of multi-variety and small batch flexible job-shop: A case study for the aerospace industry. Comput. Ind. Eng. 2023, 178, 109111. [Google Scholar] [CrossRef]

- Shao, W.S.; Shao, Z.S.; Pi, D.C. Lot sizing and scheduling problem in distributed heterogeneous hybrid flow shop and learning-driven iterated local search algorithm. IEEE Trans. Autom. Sci. Eng. 2024, 21, 6483–6497. [Google Scholar] [CrossRef]

- Tutumlu, B.; Saraç, T. A MIP model and a hybrid genetic algorithm for flexible job-shop scheduling problem with job-splitting. Comput. Oper. Res. 2023, 155, 106222. [Google Scholar] [CrossRef]

- Chen, S.Y.; Wang, X.W.; Wang, Y.; Gu, X.S. A modified adaptive switching-based many-objective evolutionary algorithm for distributed heterogeneous flowshop scheduling with lot-streaming. Swarm Evol. Comput. 2023, 81, 101353. [Google Scholar] [CrossRef]

- Rohaninejad, M.; Hanzálek, Z. Multi-level lot-sizing and job shop scheduling with lot-streaming: Reformulation and solution approaches. Int. J. Prod. Econ. 2023, 263, 108958. [Google Scholar] [CrossRef]

- Wang, W.W.; Zhang, B.; Jia, B.X. A multiobjective optimization approach for multiobjective hybrid flowshop green scheduling with consistent sublots. Sustainability 2023, 15, 2622. [Google Scholar] [CrossRef]

- Tian, G.D.; Wang, W.J.; Zhang, H.H.; Zhou, X.W.; Zhang, C.; Li, Z.W. Multi-objective optimization of energy-efficient remanufacturing system scheduling problem with lot-streaming production mode. Expert Syst. Appl. 2023, 237, 121309. [Google Scholar] [CrossRef]

- Li, C.S.; Han, Y.Y.; Zhang, B.; Wang, Y.T.; Li, J.Q.; Gao, K.Z. A novel collaborative iterative greedy algorithm for hybrid flowshop scheduling problem with batch processing machines and variable sublots. Int. J. Prod. Res. 2024, 62, 4076–4096. [Google Scholar] [CrossRef]

- Li, Y.B.; Liao, C.; Wang, L.; Xiao, Y.; Cao, Y.; Guo, S.S. A reinforcement learning-artificial bee colony algorithm for flexible job-shop scheduling problem with lot streaming. Appl. Soft Comput. 2023, 146, 110658. [Google Scholar] [CrossRef]

- Liu, Q.H.; Gao, Z.J.; Li, J.; Li, S.; Zhu, L.Z. Research on optimization of dual-resource batch scheduling in flexible job shop. Cmc Comput. Mater. Contin. 2023, 76, 2503–2530. [Google Scholar] [CrossRef]

- Yunusoglu, P.; Yildiz, S.T. Solving the flexible job shop scheduling and lot streaming problem with setup and transport resource constraints. Int. J. Syst. Sci. Oper. Logist. 2023, 10, 2221072. [Google Scholar] [CrossRef]

- Abdollahzadeh-Sangroudi, H.; Moazzam-Jazi, E.; Tavakkoli-Moghaddam, R.; Ranjbar-Bourani, M. Dynamic opportunistic maintenance grouping in a lot streaming based job-shop scheduling problem. Comput. Ind. Eng. 2023, 183, 109424. [Google Scholar] [CrossRef]

- Shao, W.S.; Shao, Z.S.; Pi, D.C. Modelling and optimization of distributed heterogeneous hybrid flow shop lot-streaming scheduling problem. Expert Syst. Appl. 2023, 214, 119151. [Google Scholar] [CrossRef]

- Chen, Y.; Du, J.; Mumtaz, J.; Zhong, J.; Rauf, M. An efficient Q-learning integrated multi-objective hyper-heuristic approach for hybrid flow shop scheduling problems with lot streaming. Expert Syst. Appl. 2025, 262, 125616. [Google Scholar] [CrossRef]

- Duan, J.; Liu, F.; Zhang, Q.; Qin, J. Tri-objective lot-streaming scheduling optimization for hybrid flow shops with uncertainties in machine breakdowns and job arrivals using an enhanced genetic programming hyper-heuristic. Comput. Oper. Res. 2024, 172, 106817. [Google Scholar] [CrossRef]

- Fan, J.; Zhang, C.; Tian, S.; Shen, W.; Gao, L. Flexible job-shop scheduling problem with variable lot-sizing: An early release policy-based matheuristic. Comput. Ind. Eng. 2024, 193, 110290. [Google Scholar] [CrossRef]

- Fan, J.; Zhang, C.; Yang, F.; Shen, W.; Gao, L. A matheuristic with re-lot-sizing strategies for flexible job-shop rescheduling problem with lot-streaming and machine reconfigurations. Eur. J. Oper. Res. 2024, 319, 747–762. [Google Scholar] [CrossRef]

- Lu, B.; Gao, K.; Ren, Y.; Li, D.; Slowik, A. Combining meta-heuristics and Q-learning for scheduling lot-streaming hybrid flow shops with consistent sublots. Swarm Evol. Comput. 2024, 91, 101731. [Google Scholar] [CrossRef]

- Singh, S.; Sarin, S.C.; Cheng, M. Single-lot, lot-streaming problem for a 1+m hybrid flow shop. J. Glob. Optim. 2024, 89, 435–455. [Google Scholar] [CrossRef]

- Zhu, Y.; Tang, Q.; Cheng, L.; Zhao, L.; Jiang, G.; Lu, Y. Solving multi-objective hybrid flowshop lot-streaming scheduling with consistent and limited sub-lots via a knowledge-based memetic algorithm. J. Manuf. Syst. 2024, 73, 106–125. [Google Scholar] [CrossRef]

- Chen, S.Y.; Wang, X.W.; Wang, Y.; Gu, X.S. A knowledge-driven many-objective algorithm for energy-efficient distributed heterogeneous hybrid flowshop scheduling with lot-streaming. Swarm Evol. Comput. 2024, 91, 101771. [Google Scholar] [CrossRef]

- Chen, J.C.; Chen, T.L.; Chen, Y.Y.; Chung, M.Y. Multi-resource constrained scheduling considering process plan flexibility and lot streaming for the CNC machining industry. Flex. Serv. Manuf. J. 2024, 36, 946–993. [Google Scholar] [CrossRef]

- Yilmaz, B.G.; Yilmaz, O.F.; Yeni, F.B. Comparison of lot streaming division methodologies for multi-objective hybrid flowshop scheduling problem by considering limited waiting time. J. Ind. Manag. Optim. 2024, 20, 3373–3414. [Google Scholar] [CrossRef]

- Shao, S.; Xu, G.C.; Liu, Z.Q.; Jin, Z.J. A job assignment scheduling algorithm with variable sublots for lot-streaming flexible job shop problem based on NSGAII. Comput. Oper. Res. 2025, 173, 106866. [Google Scholar] [CrossRef]

- Tang, H.T.; Huang, J.W.; Ren, C.H.; Shao, Y.P.; Lu, J.S. Integrated scheduling of multi-objective lot-streaming hybrid flowshop with AGV based on deep reinforcement learning. Int. J. Prod. Res. 2025, 63, 1275–1303. [Google Scholar] [CrossRef]

- Wang, H.; Peng, T.; Li, X.Y.; He, J.K.; Liu, W.P.; Tang, R.Z. An integrated simulation-optimization method for flexible assembly job shop scheduling with lot streaming and finite transport resources. Comput. Ind. Eng. 2025, 200, 110790. [Google Scholar] [CrossRef]

- Yilmaz, B.G.; Yilmaz, O.F.; Akçali, E.; Çevikcan, E. Seru scheduling problem with lot streaming and worker transfers: A multi-objective approach. Comput. Oper. Res. 2025, 177, 106967. [Google Scholar] [CrossRef]

- Zhu, Y.Y.; Tang, Q.H.; Zhang, Z.K.; Meng, R.H.; Huang, S.W. An effective cooperative coevolutionary algorithm with global and local-oriented cooperative mechanisms for multi-objective hybrid flowshop lot-streaming scheduling with limited and flexible sub-lots. Swarm Evol. Comput. 2025, 93, 101815. [Google Scholar] [CrossRef]

- Jiang, X.; Tian, Z.; Liu, W.; Tian, G.; Gao, Y.; Xing, F.; Suo, Y.; Song, B. An energy-efficient method of laser remanufacturing process. Sustain. Energy Technol. Assess. 2022, 52, 102201. [Google Scholar] [CrossRef]

- Liu, W.J.; Suo, Y.Q.; Jiang, X.Y.; Tian, Z.Q.; Zhang, D.; Yang, G.Z.; Wang, H.Y.; Han, Q.B. Low-carbon modeling and process parameter optimization for laser cleaning process. J. Mech. Eng. 2023, 59, 276–294. (In Chinese) [Google Scholar] [CrossRef]

- Gao, K.Z.; Huang, Y.; Sadollah, A.; Wang, L. A review of energy-efficient scheduling in intelligent production systems. Complex Intell. Syst. 2020, 6, 237–249. [Google Scholar] [CrossRef]

- ILOG CPLEX Optimization Studio. IBM. 2024. Available online: https://www.ibm.com/products/ilog-cplex-optimization-studio (accessed on 15 April 2023).

- Voice and Data Solutions for Small Businesses. Lingo Communications. 2023. Available online: https://www.lingo.com (accessed on 15 April 2023).

- NX Software Including CAD and CAM. Siemens Software. 2023. Available online: https://plm.sw.siemens.com/en-US/nx/ (accessed on 15 April 2023).

| Article | Shop Floor Category | Lot Splitting Method | Model | Objective | Approach (Algorithm) | Constraint |

|---|---|---|---|---|---|---|

| Jalilvand-Nejad et al., 2015 [16] | Job-shop | Unknown | MILP | Cost | GA and SA | Setup times and costs |

| Defersha et al., 2015 [17] | Flow-shop | UCS | MILP | Makespan | Parallel multiple-search path SA | Setup times |

| Liu et al., 2015 [18] | Job-shop | Unknown | Others | Processing energy consumption and makespan | Modified GA | Routing problem |

| Mohsen et al., 2016 [19] | Flow-shop | ECS | MINLP | Weighted mean makespan | GA and SA | Setup times |

| Chen et al., 2016 [20] | Job-shop | ECS | Unknown | Makespan | Modified GA | None |

| Cheng et al., 2016 [21] | Flow-shop | UCS | MIP | Makespan | Heuristic | None |

| Li et al., 2016 [22] | Flow-shop | Unknown | IP | Makespan | Heuristic | Periodical job |

| Shahvari et al., 2016 [23] | Flow-shop | UVS | MILP | Total makespan and weighted tardiness | TS/path-relinking algorithms | Setup times |

| Vivek et al., 2016 [24] | Flow-shop | UCS | Simulation-based | Makespan | Extend V6 | None |

| Lalitha et al., 2017 [25] | Flow-shop | UCS | MILP | Makespan | Heuristic and mathematical programming | None |

| Yu et al., 2017 [26] | Flow-shop | ECS | MIP | Total job tardiness | Iterative algorithms | Due-date and setup times |

| Zhang et al., 2017 [27] | Flow-shop | ECS | MIP | Total flow time | Effective modified MBO | Overlapping in operations |

| Zhong et al., 2017 [28] | Job-shop | UCS | Unknown | Makespan, labour distribution, equipment compliance and production cost | Improved NSGA-II | Worker allocation |

| Bozek et al., 2018 [29] | Job-shop | ECS | MILP and Graph-based | Makespan and sizes of the sub-lots | TS and Greedy constructive algorithm | None |

| Defersha et al., 2018 [13] | Job-shop | Unknown | LP | Makespan | LP assisted GA | None |

| Liu et al., 2018 [30] | Flow-shop | UCS | Unknown | Makespan and TEC | NSGA-II | Composite recycling and energy consumption |

| Meng et al., 2018 [31] | Job-shop | ECS | Others | Total flowtime | Enhanced fruit fly optimization | None |

| Meng et al., 2018 [32] | Job-shop | ECS | Others | Total flowtime | Enhanced monarch butterfly optimization | None |

| Romero et al., 2018 [33] | Job-shop | UCS | IP | Makespan | TS and heuristic | None |

| Shahvari et al., 2018 [34] | Flow-shop | UVS | MILP | Total weighted makespan and tardiness | PSO and TS | Machine availability times, job release times, machine capability and eligibility, stage skipping, learning effect and setup times |

| Zhang et al., 2018 [35] | Job-shop | ECS | Others | Makespan and cost | Binary PSO | Alternative process plans |

| Gong et al., 2018 [36] | Flow-shop | ECS | Unknown | Makespan and earliness time | Hybrid multi-objective discrete ABC | Due-date and operation blocking |

| Gu et al., 2019 [37] | Flow-shop | Unknown | IP | Total weighted tardiness | Mathematical programming | Capacity constraints |

| Novas et al., 2019 [38] | Job-shop | UCS | CP | Makespan | Mathematical programming | Setup times |

| Wang et al., 2019 [39] | Flow-shop | UVS | MILP | Total weighted makespan | Mathematical programming and heuristic | Setup times |

| Yang et al., 2019 [40] | Job-shop | ECS | Unknown | Makespan | GA | Setup times |

| Zacharias et al., 2019 [41] | Flow-shop | Unknown | MILP | Makespan | NN, SVM and heuristic | Transportation resource |

| Chen et al., 2020 [42] | Flow-shop | UCS | MIP | Makespan and TEC | GA | Energy consumption and setup times |

| Li et al., 2020 [43] | Flow-shop | EVS | Unknown | Penalty caused by the average sojourn time, energy consumption in the last stage and earliness and tardiness values | Right-shift heuristic and multi-objective evolutionary algorithm based on decomposition | Energy consumption |

| Wang et al., 2020 [44] | Flow-shop | ECS | Others | Makespan | MBO and heuristic | None |

| Zhang et al., 2020 [45] | Job-shop | UCS | Unknown | Makespan | Competitive and cooperative MBO algorithm | Setup times |

| Zhang et al., 2020 [46] | Job-shop | Unknown | Unknown | Makespan, total tardiness and total workload | ACO | Setup times and transportation resource |

| Hadi et al., 2021 [47] | Job-shop | UVS | MILP | Total production, setup, and tardiness penalty costs | Self-adaptive cuckoo optimisation algorithm | Setup times, initial inventory and safety stock levels |

| Wu et al., 2021 [48] | Job-shop | UVS | MILP | Makespan and transportation time | Improved multi-objective optimization algorithm | None |

| Zhang et al., 2021 [49] | Flow-shop | ECS | MILP | Makespan | Collaborative VND | Setup times |

| Zhang et al., 2021 [50] | Job-shop | EVS | Unknown | Makespan | Discrete grey wolf optimizer | Setup and transportation times |

| Chiu et al., 2022 [51] | Job-shop | ECS | Simulation-based | Expected flow time | Enhanced GA and heuristic | Processing time variability and setup times |

| Daneshamooz et al., 2022 [4] | Job-shop | ECS | MILP | Makespan | Mathematical programming and VNS | Parallel assembly and setup times |

| Han et al., 2022 [52] | Job-shop | ECS | Unknown | Makespan, TEC and total costs | Improved NSGA-II | Intracellular transportation, energy consumption and setup times |

| Jiang et al., 2022 [53] | Job-shop | ECS | MILP and Simulation-based | TEC, makespan, and processing cost | Improved crossover ABC | Setup times and energy consumption |

| Li et al., 2022 [54] | Job-shop | UVS | MILP | Makespan | Hyper-heuristic improved GA | Setup times |

| Zhang et al., 2022 [55] | Flow-shop | ECS | Unknown | Makespan, starting time deviations of operations, and average adjustment of sublot sizes | Multi-objective MBO algorithm based on decomposition | Machine breakdown |

| Li et al., 2022 [56] | Job-shop | UCS | MILP | Average flow time | Improved ABC | Setup times |

| Yilmaz et al., 2022 [57] | Flow-shop | ECS | Unknown | Makespan | Mathematical | None |

| Meng et al., 2021 [58] | Flow-shop | ECS | MIP | Makespan | Enhanced ABC | Setup times |

| Meng et al., 2019 [59] | Flow-shop | ECS | MIP | Makespan | Discrete ABC | Order constraint |

| Omid et al., 2022 [14] | Flow-shop | UVS | MILP | Total weighted job makespan and tardiness | Random forest and branch-and-price | Setup times, dynamic machine availability and job release times |

| Wang et al., 2022 [60] | Flow-shop | Unknown | MIP | Cost | Fuzzy-GA | Multilevel capacitated |

| Li et al., 2023 [61] | Flow-shop | UCS | MILP | TEC | Improved cooperative coevolutionary algorithm and VND | Energy consumption and setup times |

| Yang et al., 2023 [62] | Job-shop | UVS | MILP | Makespan | Guided shuffled frog-leaping algorithm | Overlapping in operations and setup times |

| Lu et al., 2023 [63] | Flow-shop | UCS | MILP | Makespan | Heuristic-based adaptive iterated greedy algorithm | Setup times |

| Zhu et al., 2023 [64] | Flow-shop | UCS | MILP | Makespan and due time deviations | Improved multi-objective ABC | Due-date |

| Tian et al., 2024 [65] | Job-shop | ECS and UCS | MILP | Makespan and TEC | Knowledge-based lot-splitting method | Energy consumption and setup times |

| Tian et al., 2023 [66] | Job-shop | ECS | MILP | Makespan, TEC and Cost | Bi-population differential ABC | Energy consumption and setup times |

| Shao et al., 2024 [67] | Flow-shop | ECS | MILP | Total tardiness | Learning-driven iterated local search algorithm | Setup times |

| Tutumlu et al., 2023 [68] | Job-shop | UVS | MIP | Makespan | Hybrid GA | Setup times |

| Chen et al., 2023 [69] | Flow-shop | ECS | MIP | Makespan, idle time of machines, total production cost and total flow time | Modified adaptive switching-based many-objective evolutionary algorithm | Transportation resource and setup times |

| Rohaninejad et al., 2023 [70] | Job-shop | UCS | MILP | The sum of setup, production, and inventory holding costs | Decomposition heuristic | Setup times and capacitated machines |

| Wang et al., 2023 [71] | Flow-shop | UCS | MILP | Makespan and TEC | Multi-objective discrete ABC | Energy consumption and setup times |

| Tian et al., 2023 [72] | Flow-shop | UCS | MILP | Makespan and TEC | Hybrid multi-objective fruit fly optimization algorithm | Energy consumption |

| Li et al., 2024 [73] | Flow-shop | UVS | MILP | Total penalty values | Novel collaborative iterative greedy | Setup and transportation times |

| Li et al., 2023 [74] | Job-shop | UCS and ECS | Unknown | Makespan | Reinforcement learning and ABC | None |

| Liu et al., 2023 [75] | Job-shop | ECS | Unknown | Makespan | GA and SA | Transportation resource |

| Yunusoglu et al., 2023 [76] | Job-shop | ECS | CP | Makespan | Mathematical programming and large neighbourhood search | Setup times and transport resource |

| Hadi et al., 2023 [77] | Job-shop | UCS | MINLP | Total production costs and total maintenance costs | Self-adaptive cuckoo optimization algorithm | Dynamic opportunistic maintenance and setup times |

| Shao et al., 2023 [78] | Flow-shop | ECS | MILP | Makespan | Iterated local search algorithm and heuristic | Setup times |

| Chen et al., 2025 [79] | Flow-shop | ECS | MILP | Makespan, TEC, and total tardiness time | TS-ISMO and heuristic | Energy consumption |

| Duan et al., 2024 [80] | Flow-shop | UCS | MILP | Maximum tardiness, total idle energy consumption, and makespan | CHS-GPHH | Arrival of new workpieces, machine breakdown, and setup times |

| Fan et al., 2024 [81] | Job-shop | UVS | MILP | Makespan | ER-GA and heuristic | Setup times |

| Fan et al., 2024 [82] | Job-shop | UCS | MILP | Total weighted tardiness | GA-based matheuristic, VNS, and heuristic | Setup times |

| Lu et al., 2024 [83] | Flow-shop | UCS | MILP | Makespan | GA, Q-learning, and heuristic | None |

| Singh et al., 2024 [84] | Flow-shop | UCS | MIP | Makespan and small penalty proportional to the total number of machines | Mathematical programming | None |

| Zhu et al., 2024 [85] | Flow-shop | UCS | MILP | Makespan and due time deviation | KMA | Setup times |

| Chen et al., 2024 [86] | Flow-shop | ECS | MILP | Makespan, total earliness and total energy consumption | knowledge-driven many-objective optimization evolutionary algorithm | Transportation resource, due-date, energy consumption and setup times |

| Chen et al., 2024 [87] | Job-shop | ECS | MINLP | Tardiness, makespanand total setup time | Hybrid multi-objective GA | Alternative process plans, due-date and setup times |

| Yilmaz et al., 2024 [88] | Flow-shop | ECS | Unknown | Makespan, average flow time and total workload imbalance | Improved NSGA-II | Limited waiting time |

| Shao et al., 2025 [89] | Job-shop | EVS | Unknown | Makespan and utilization rate of machines | Adaptive job scheduling NSGA-II and heuristic | Setup times and operator limitations |

| Tang et al., 2025 [90] | Flow-shop | ECS | Markov chain | Makespan, total machine idle time and total travel distance | Multi-objective double deep Q-network | Transportation resource |

| Wang et al., 2025 [91] | Job-shop | EVS | MILP and simulatio-based | Makespan | Self-repair GA | Transportation resource and setup times |

| Yilmaz et al., 2025 [92] | Job-shop | ECS and EVS | MILP | Makespan, average flow time and total workload imbalance | Improved NSGA-II | Worker allocation |

| Zhu et al., 2025 [93] | Flow-shop | UCS | MILP | Makespan and due time deviation | Cooperative coevolutionary algorithm with global and local-oriented cooperative mechanisms, heuristic | Two types of time-overlaps |

| Lot-Splitting Strategy | Sizes of Different Sub-Lots of a Job | Sub-Lot Sizes of a Job in Different Stages |

|---|---|---|

| ECS | Same | Consist |

| UCS | Different | Consist |

| EVS | Same | Variable |

| UVS | Different | Variable |

| Region | Carbon Emission Factor (kgCO2/kw·h) |

|---|---|

| North China | 0.4578 |

| Northeast China | 0.3310 |

| East China | 0.4923 |

| Central China | 0.3112 |

| Northwest China | 0.3232 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Z.; Jiang, X.; Liu, W.; Zhao, B.; Liu, S.; Tan, Q.; Tian, G. Lot-Streaming Workshop Scheduling with Operation Flexibility: Review and Extension. Systems 2025, 13, 271. https://doi.org/10.3390/systems13040271

Tian Z, Jiang X, Liu W, Zhao B, Liu S, Tan Q, Tian G. Lot-Streaming Workshop Scheduling with Operation Flexibility: Review and Extension. Systems. 2025; 13(4):271. https://doi.org/10.3390/systems13040271

Chicago/Turabian StyleTian, Zhiqiang, Xingyu Jiang, Weijun Liu, Baohai Zhao, Shun Liu, Qingze Tan, and Guangdong Tian. 2025. "Lot-Streaming Workshop Scheduling with Operation Flexibility: Review and Extension" Systems 13, no. 4: 271. https://doi.org/10.3390/systems13040271

APA StyleTian, Z., Jiang, X., Liu, W., Zhao, B., Liu, S., Tan, Q., & Tian, G. (2025). Lot-Streaming Workshop Scheduling with Operation Flexibility: Review and Extension. Systems, 13(4), 271. https://doi.org/10.3390/systems13040271