Advances in the Development of Biofertilizers and Biostimulants from Microalgae

Abstract

Simple Summary

Abstract

1. Introduction

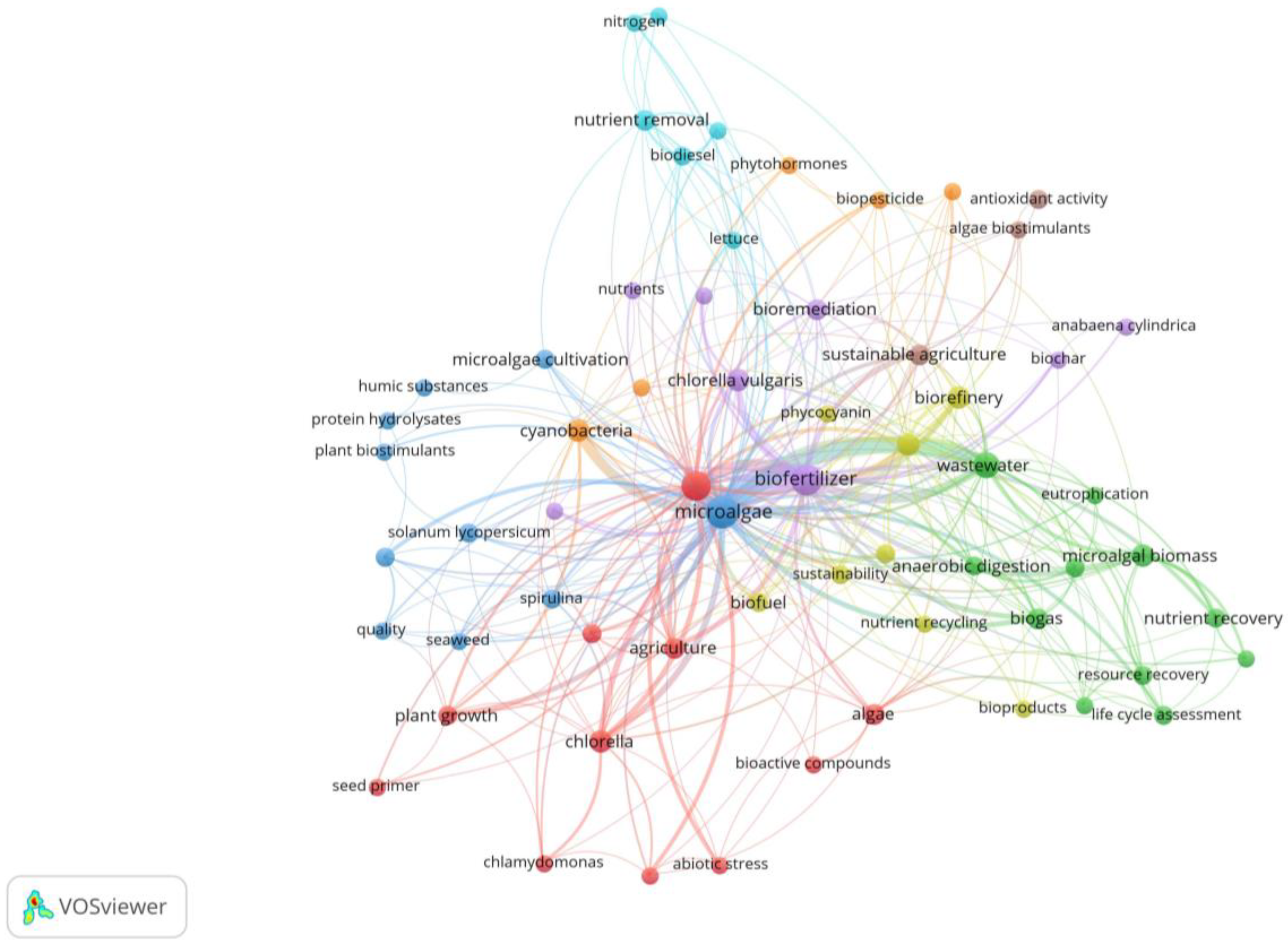

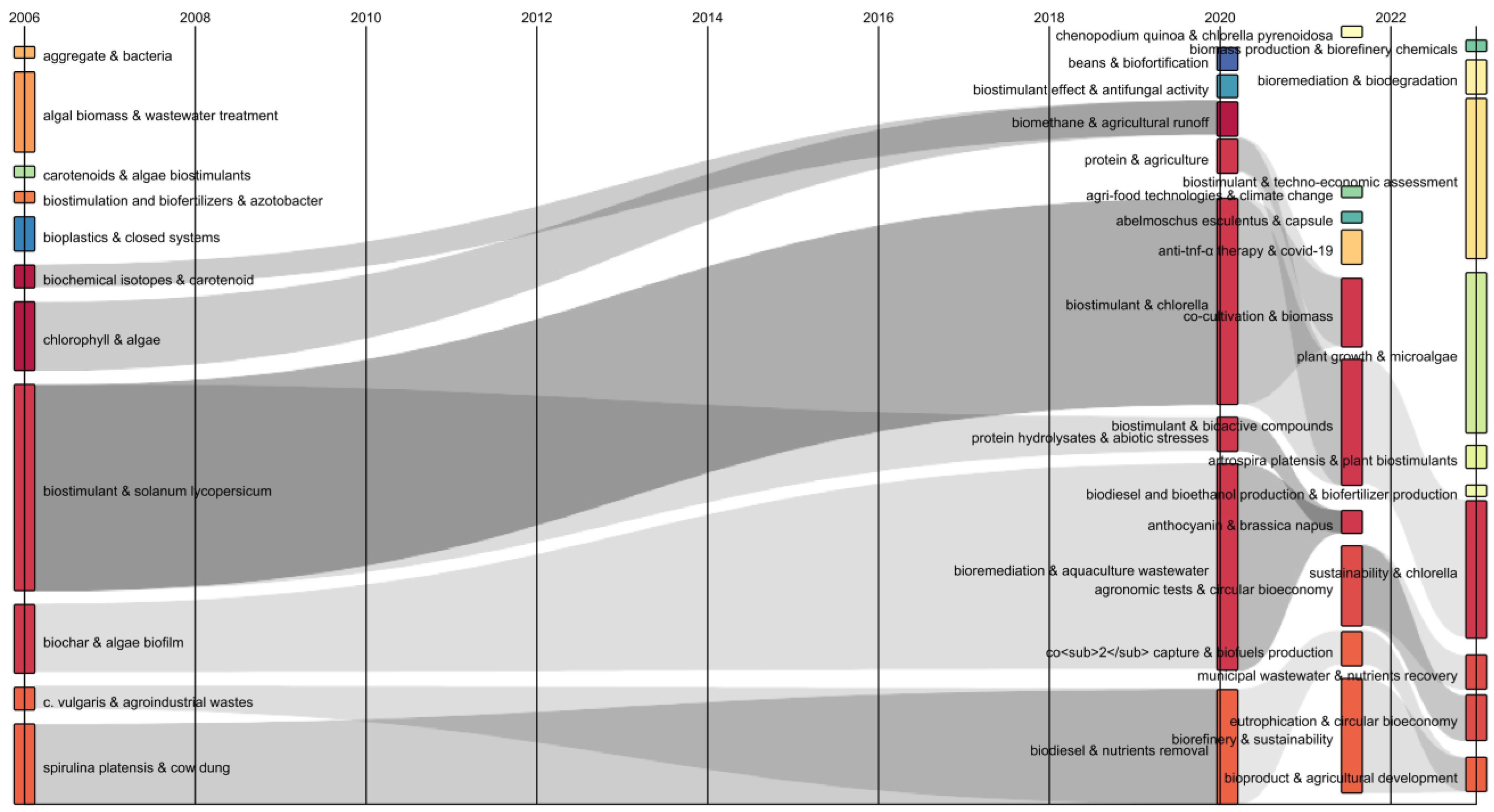

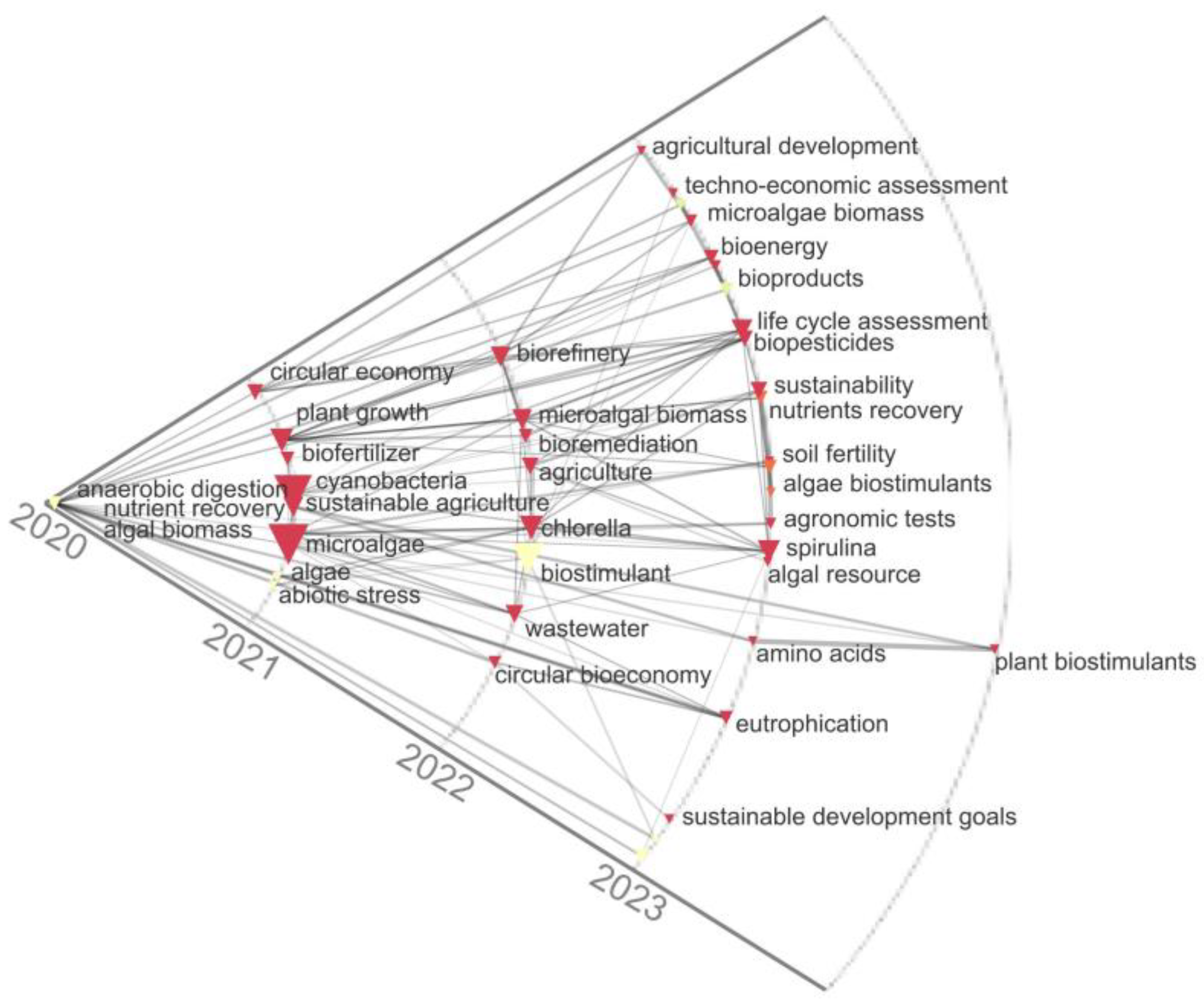

2. Bibliometric Analysis of Microalgae-Based Biofertilizers and Biostimulants

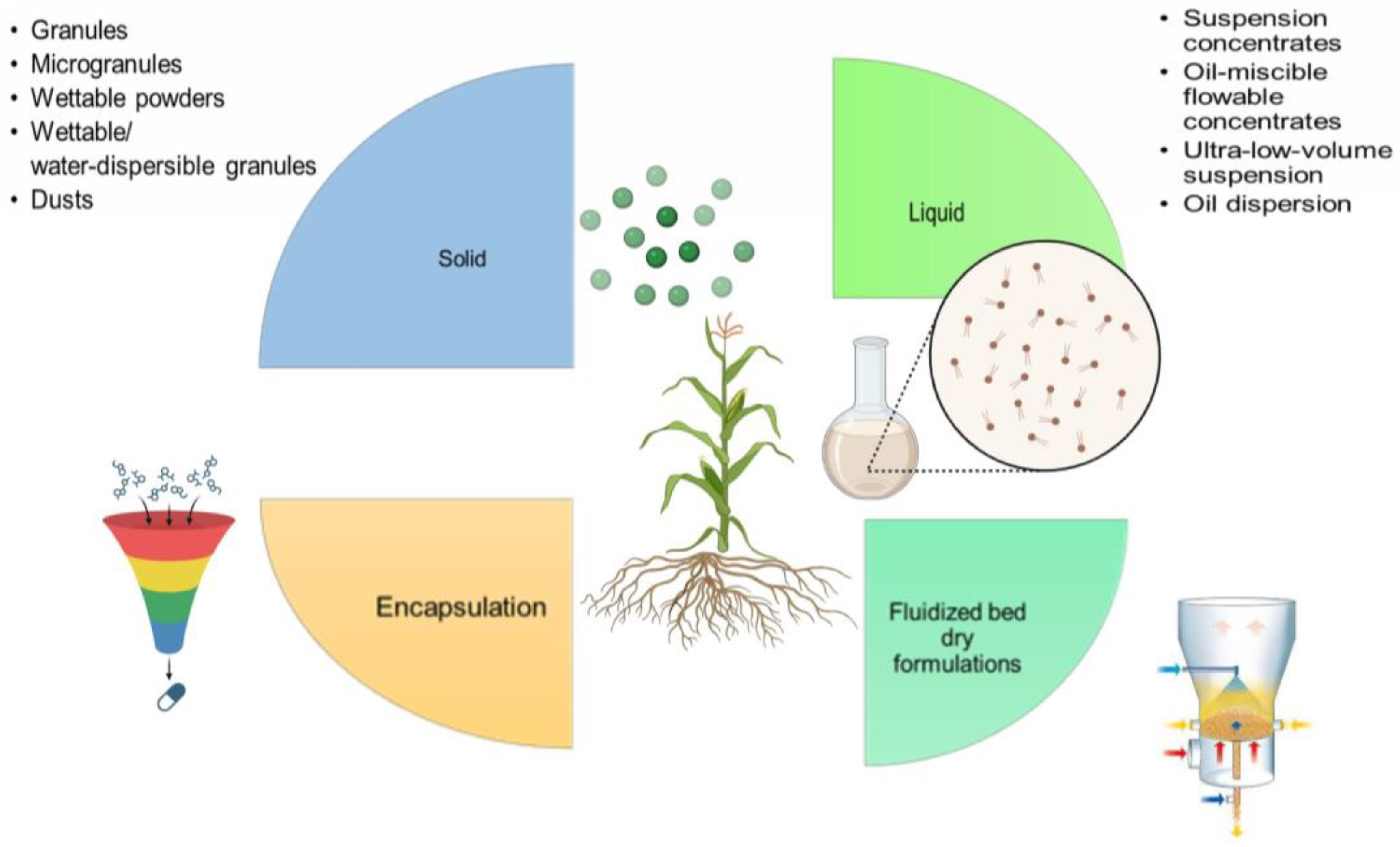

3. Potential Strategies for the Formulation of Biofertilizers and Biostimulants

4. Case Studies on the Application of Biofertilizers and Biostimulants Based on Microalgae

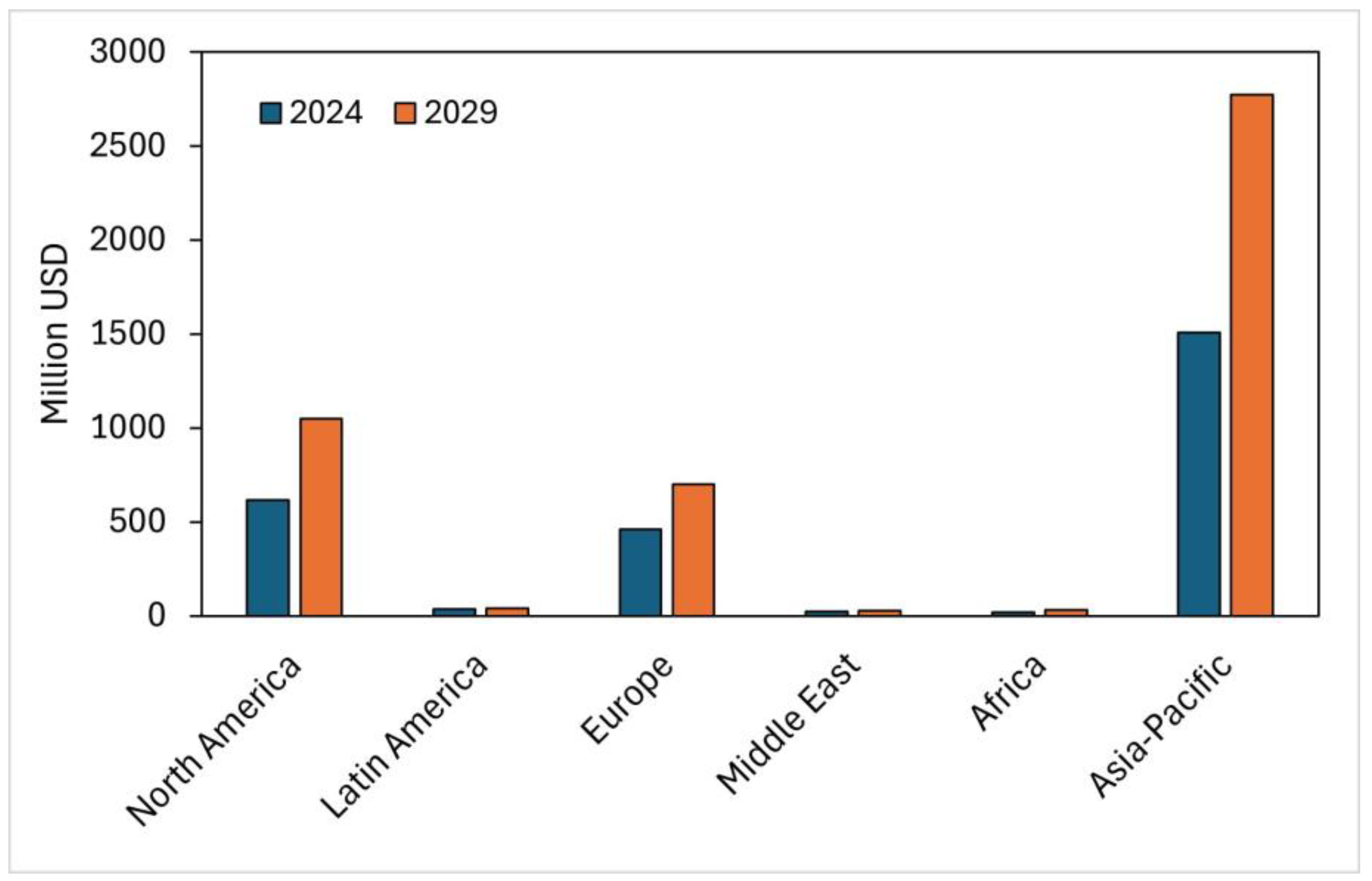

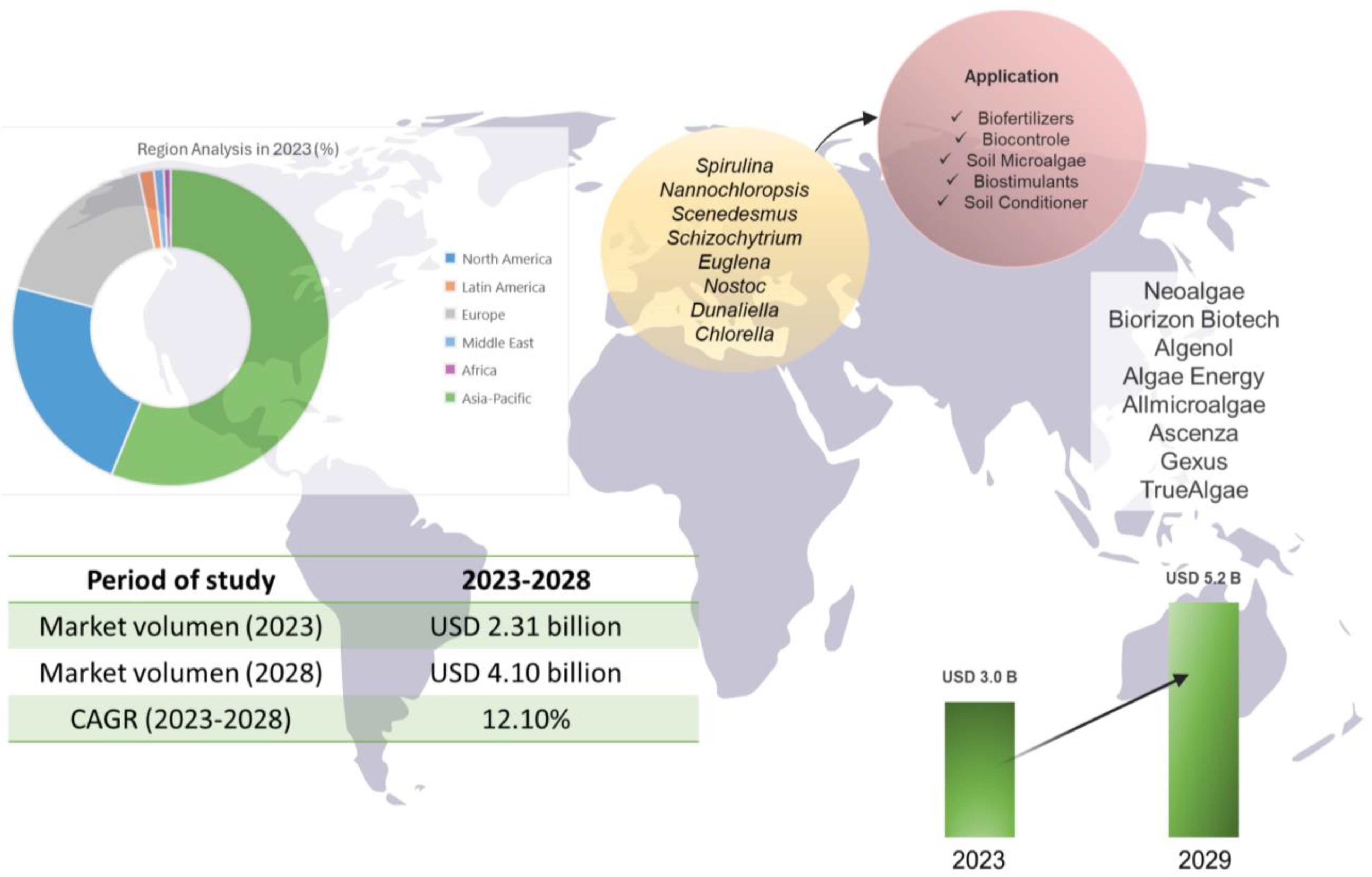

5. Microalgae in the Biofertilizer and Biostimulant Market

6. Overall Discussion and Perspectives

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ghorai, P.; Ghosh, D. Ameliorating the Performance of NPK Biofertilizers to Attain Sustainable Agriculture with Special Emphasis on Bioengineering. Bioresour. Technol. Rep. 2022, 19, 101117. [Google Scholar] [CrossRef]

- Kumar, S.; Diksha; Sindhu, S.S.; Kumar, R. Biofertilizers: An Ecofriendly Technology for Nutrient Recycling and Environmental Sustainability. Curr. Res. Microb. Sci. 2022, 3, 100094. [Google Scholar] [CrossRef]

- Sharma, G.K.; Khan, S.A.; Shrivastava, M.; Bhattacharyya, R.; Sharma, A.; Gupta, D.K.; Kishore, P.; Gupta, N. Circular Economy Fertilization: Phycoremediated Algal Biomass as Biofertilizers for Sustainable Crop Production. J. Environ. Manag. 2021, 287, 112295. [Google Scholar] [CrossRef]

- Yang, L.Y.; Zhou, S.Y.D.; Lin, C.S.; Huang, X.R.; Neilson, R.; Yang, X.R. Effects of Biofertilizer on Soil Microbial Diversity and Antibiotic Resistance Genes. Sci. Total Environ. 2022, 820, 153170. [Google Scholar] [CrossRef]

- Acién Fernández, F.G.; Gómez-Serrano, C.; Fernández-Sevilla, J.M. Recovery of Nutrients from Wastewaters Using Microalgae. Front. Sustain. Food Syst. 2018, 2, 59. [Google Scholar] [CrossRef]

- Sniatala, B.; Kurniawan, T.A.; Sobotka, D.; Makinia, J.; Othman, M.H.D. Macro-Nutrients Recovery from Liquid Waste as a Sustainable Resource for Production of Recovered Mineral Fertilizer: Uncovering Alternative Options to Sustain Global Food Security Cost-Effectively. Sci. Total Environ. 2023, 856, 159283. [Google Scholar] [CrossRef] [PubMed]

- de Paula Pereira, A.S.A.; de Siqueira Castro, J.; Ribeiro, V.J.; Calijuri, M.L. Organomineral Fertilizers Pastilles from Microalgae Grown in Wastewater: Ammonia Volatilization and Plant Growth. Sci. Total Environ. 2021, 779, 146205. [Google Scholar] [CrossRef] [PubMed]

- Ammar, E.E.; Aioub, A.A.A.; Elesawy, A.E.; Karkour, A.M.; Mouhamed, M.S.; Amer, A.A.; EL-Shershaby, N.A. Algae as Bio-Fertilizers: Between Current Situation and Future Prospective: The Role of Algae as a Bio-Fertilizer in Serving of Ecosystem. Saudi J. Biol. Sci. 2022, 29, 3083–3096. [Google Scholar] [CrossRef]

- Ronga, D.; Biazzi, E.; Parati, K.; Carminati, D.; Carminati, E.; Tava, A. Microalgal Biostimulants and Biofertilisers in Crop Productions. Agronomy 2019, 9, 192. [Google Scholar] [CrossRef]

- Del Buono, D. Can Biostimulants Be Used to Mitigate the Effect of Anthropogenic Climate Change on Agriculture? It Is Time to Respond. Sci. Total Environ. 2021, 751, 141763. [Google Scholar] [CrossRef] [PubMed]

- Tolisano, C.; Del Buono, D. Biobased: Biostimulants and Biogenic Nanoparticles Enter the Scene. Sci. Total Environ. 2023, 885, 163912. [Google Scholar] [CrossRef]

- Del Buono, D.; Regni, L.; Proietti, P. Abiotic Stresses, Biostimulants and Plant Activity. Agriculture 2023, 13, 191. [Google Scholar] [CrossRef]

- Drobek, M.; Frąc, M.; Cybulska, J. Plant Biostimulants: Importance of the Quality and Yield of Horticultural Crops and the Improvement of Plant Tolerance to Abiotic Stress–A Review. Agronomy 2019, 9, 335. [Google Scholar] [CrossRef]

- Soni, R.; Suyal, D.C.; Yadav, A.N.; Goel, R. Trends-of-Applied-Microbiology-for-Sustainable-Economy; Academic Press: Cambridge, MA, USA, 2022. [Google Scholar]

- Behera, B.; Venkata Supraja, K.; Paramasivan, B. Integrated Microalgal Biorefinery for the Production and Application of Biostimulants in Circular Bioeconomy. Bioresour. Technol. 2021, 339, 125588. [Google Scholar] [CrossRef]

- Alvarez, A.L.; Weyers, S.L.; Goemann, H.M.; Peyton, B.M.; Gardner, R.D. Microalgae, Soil and Plants: A Critical Review of Microalgae as Renewable Resources for Agriculture. Algal Res. 2021, 54, 102200. [Google Scholar] [CrossRef]

- Naik, K.; Mishra, S.; Srichandan, H.; Singh, P.K.; Sarangi, P.K. Plant Growth Promoting Microbes: Potential Link to Sustainable Agriculture and Environment. Biocatal. Agric. Biotechnol. 2019, 21, 101326. [Google Scholar] [CrossRef]

- Barros-Rodríguez, A.; Rangseekaew, P.; Lasudee, K.; Pathom-aree, W.; Manzanera, M. Regulatory Risks Associated with Bacteria as Biostimulants and Biofertilizers in the Frame of the European Regulation (EU) 2019/1009. Sci. Total Environ. 2020, 740, 140239. [Google Scholar] [CrossRef] [PubMed]

- Stirk, W.A.; Bálint, P.; Vambe, M.M.; Kulkarni, M.G.; van Staden, J.; Ördög, V. Effect of Storage on Plant Biostimulant and Bioactive Properties of Freeze-Dried Chlorella Vulgaris Biomass. J. Appl. Phycol. 2021, 33, 3797–3806. [Google Scholar] [CrossRef] [PubMed]

- Braun, J.C.A.; Colla, L.M. Use of Microalgae for the Development of Biofertilizers and Biostimulants. Bioenergy Res. 2023, 16, 289–310. [Google Scholar] [CrossRef]

- Cao, T.N.D.; Mukhtar, H.; Le, L.T.; Tran, D.P.H.; Ngo, M.T.T.; Pham, M.D.T.; Nguyen, T.B.; Vo, T.K.Q.; Bui, X.T. Roles of Microalgae-Based Biofertilizer in Sustainability of Green Agriculture and Food-Water-Energy Security Nexus. Sci. Total Environ. 2023, 870, 161927. [Google Scholar] [CrossRef]

- Chittora, D.; Meena, M.; Barupal, T.; Swapnil, P. Cyanobacteria as a Source of Biofertilizers for Sustainable Agriculture. Biochem. Biophys. Rep. 2020, 22, 100737. [Google Scholar] [CrossRef]

- Fernández-Rojas, B.; Hernández-Juárez, J.; Pedraza-Chaverri, J. Nutraceutical Properties of Phycocyanin. J. Funct. Foods 2014, 11, 375–392. [Google Scholar] [CrossRef]

- Varia, J.; Kamaleson, C.; Lerer, L. Biostimulation with Phycocyanin-Rich Spirulina Extract in Hydroponic Vertical Farming. Sci. Hortic. 2022, 299, 111042. [Google Scholar] [CrossRef]

- Sierra-López, L.D.; Hernandez-Tenorio, F.; Marín-Palacio, L.D.; Giraldo-Estrada, C. Coffee Mucilage Clarification: A Promising Raw Material for the Food Industry. Food Humanit. 2023, 1, 689–695. [Google Scholar] [CrossRef]

- Morillas-España, A.; Ruiz-Nieto, Á.; Lafarga, T.; Acién, G.; Arbib, Z.; González-López, C.V. Biostimulant Capacity of Chlorella and Chlamydopodium Species Produced Using Wastewater and Centrate. Biology 2022, 11, 1086. [Google Scholar] [CrossRef]

- Kapoore, R.V.; Wood, E.E.; Llewellyn, C.A. Algae Biostimulants: A Critical Look at Microalgal Biostimulants for Sustainable Agricultural Practices. Biotechnol. Adv. 2021, 49, 107754. [Google Scholar] [CrossRef] [PubMed]

- Marcel, Y.A.; Nadège, A.A.; Agossou, P.N.; Olaréwadjou, A.; Adolphe, A.; Lamine, B.-M. Bioformulations Based on Plant Growth Promoting Rhizobacteria for Sustainable Agriculture: Biofertilizer or Biostimulant? Afr. J. Agric. Res. 2021, 17, 1256–1260. [Google Scholar] [CrossRef]

- Parađiković, N.; Teklić, T.; Zeljković, S.; Lisjak, M.; Špoljarević, M. Biostimulants Research in Some Horticultural Plant Species—A Review. Food Energy Secur. 2019, 8, e00162. [Google Scholar] [CrossRef]

- Mahmud, M.S.; Chong, K.P. Formulation of Biofertilizers from Oil Palm Empty Fruit Bunches and Plant Growth-Promoting Microbes: A Comprehensive and Novel Approach towards Plant Health. J. King Saud. Univ. Sci. 2021, 33, 101647. [Google Scholar] [CrossRef]

- Bargaz, A.; Lyamlouli, K.; Chtouki, M.; Zeroual, Y.; Dhiba, D. Soil Microbial Resources for Improving Fertilizers Efficiency in an Integrated Plant Nutrient Management System. Front. Microbiol. 2018, 9, 1606. [Google Scholar] [CrossRef]

- Namasivayam, S.K.R.; Saikia, S.L.; Bharani, R.S.A. Evaluation of Persistence and Plant Growth Promoting Effect of Bioencapsulated Formulation of Suitable Bacterial Biofertilizers. Biosci. Biotechnol. Res. Asia 2014, 11, 407–415. [Google Scholar] [CrossRef][Green Version]

- Mącik, M.; Gryta, A.; Frąc, M. Biofertilizers in Agriculture: An Overview on Concepts, Strategies and Effects on Soil Microorganisms. Adv. Agron. 2020, 162, 31–87. [Google Scholar] [CrossRef]

- Gopal, S.; Baby, A. Enhanced Shelf-Life of Azospirillum and Psb Through. Int. J. Sci. Environ. Technol. 2016, 5, 2023–2029, ISSN 2278-3687. [Google Scholar]

- Mousa, M.; Allouzi, A.; Mousa, S.; Allouzi, A.; Xiang, Z.; Vimala, C.; Singh, A.; Chong, S. Heliyon Liquid Biofertilizers as a Sustainable Solution for Agriculture. Heliyon 2023, 8, e12609. [Google Scholar] [CrossRef]

- Lee, S.; Lur, H.; Lo, K.; Cheng, K. Evaluation of the Effects of Different Liquid Inoculant Formulations on the Survival and Plant-Growth-Promoting Efficiency of Rhodopseudomonas Palustris Strain PS3. Appl. Microbiol. Biotechnol. 2016, 100, 7977–7987. [Google Scholar] [CrossRef] [PubMed]

- Arora, N.K.; Mehnaz, S.; Balestrini, R. Preface; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 9788132227793. [Google Scholar]

- Brar, S.K.; Verma, M.; Tyagi, R.D.; Valéro, J.R. Recent Advances in Downstream Processing and Formulations of Bacillus Thuringiensis Based Biopesticides. Process Biochem. 2006, 41, 323–342. [Google Scholar] [CrossRef]

- Muñoz, J.; Alfaro, C. Avances En La Formulación de Emulsiones. Grasas y Aceites 2007, 3495, 64–73. [Google Scholar]

- Hernandez-Tenorio, F.; Miranda, A.M.; Rodríguez, C.A.; Giraldo-Estrada, C.; Sáez, A.A. Potential Strategies in the Biopesticide Formulations: A Bibliometric Analysis. Agronomy 2022, 12, 2665. [Google Scholar] [CrossRef]

- Vandergheynst, J.; Scher, H.; Guo, H. Water-in-Oil Emulsions That Improve the Storage and Delivery of the Biolarvacide Lagenidium Giganteum. BioControl 2007, 52, 207–229. [Google Scholar] [CrossRef]

- Pavela, R.; Benelli, G.; Pavoni, L.; Bonacucina, G.; Cespi, M.; Cianfaglione, K.; Bajalan, I.; Reza, M.; Lupidi, G.; Romano, D.; et al. Industrial Crops & Products Microemulsions for Delivery of Apiaceae Essential Oils—Towards Highly Effective and Eco-Friendly Mosquito Larvicides? Ind. Crops Prod. 2019, 129, 631–640. [Google Scholar] [CrossRef]

- Lucia, A.; Guzmán, E. Emulsions containing essential oils, their components or volatile semiochemicals as promising tools for insect pest and pathogen management. Adv. Colloid. Interface Sci. 2020, 287, 102330. [Google Scholar] [CrossRef]

- Vandergheynst, J.; Dooley, T.; Guo, H.; Scher, H.; Cheng, Y. Storage and Release of Solutes and Microalgae from Water-in-Oil Emulsions Stabilized by Silica Nanoparticles. Process Biochem. 2010, 45, 1–6. [Google Scholar] [CrossRef]

- Tadros, T.F. Emulsion Formation, Stability, and Rheology. In Emulsion Formation and Stability; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Kumar, A.; Raman, Y.; Venkataramani, D.; Bhagwat, S.; Martin, T.; Clark, P.E.; Aichele, C.P. Colloids and Surfaces A: Physicochemical and Engineering Aspects Emulsion Stability of Surfactant and Solid Stabilized Water-in-Oil Emulsions after Hydrate Formation and Dissociation. Colloids Surf. A Physicochem. Eng. Asp. 2016, 506, 607–621. [Google Scholar] [CrossRef]

- Rezaul, M.; Shishir, I.; Xie, L.; Sun, C.; Zheng, X. Food Technology and Equipment, Key Laboratory for Agro-Products Postharvest Handling. Trends Food Sci. Technol. 2018, 78, 34–60. [Google Scholar] [CrossRef]

- Nedovic, V.; Kalusevic, A.; Manojlovic, V.; Levic, S. Procedia Food Science an Overview of Encapsulation Technologies for Food Applications. Procedia Food Sci. 2011, 1, 1806–1815. [Google Scholar] [CrossRef]

- Mcclements, D.J. Delivery by Design (DbD): A Standardized Approach to the Development of Efficacious Nanoparticle- and Microparticle-Based Delivery Systems. Compr. Rev. Food Sci. Food Saf. 2017, 17, 200–219. [Google Scholar] [CrossRef]

- Vieira, M.V.; Pastrana, L.M.; Fuciños, P. Microalgae Encapsulation Systems for Food, Pharmaceutical and Cosmetics Applications. Mar. Drugs 2020, 18, 644. [Google Scholar] [CrossRef]

- John, R.P.; Tyagi, R.D.; Brar, S.K.; Surampalli, R.Y.; Prévost, D. Bio-Encapsulation of Microbial Cells for Targeted Agricultural Delivery. Crit. Rev. Biotechnol. 2011, 31, 211–226. [Google Scholar] [CrossRef]

- Tong, C.Y.; Derek, C.J.C. Science of the Total Environment Bio-Coatings as Immobilized Microalgae Cultivation Enhancement: A Review. Sci. Total Environ. 2023, 887, 163857. [Google Scholar] [CrossRef]

- Sahu, P.K.; Brahmaprakash, G.P. Formulations of Biofertilizers. In Microbial Inoculants in Sustainable Agricultural Productivity; Springer: New Delhi, India, 2016; pp. 179–198. [Google Scholar] [CrossRef]

- Fang, Z. Encapsulation of Polyphenols e a Review. Trends Food Sci. Technol. 2010, 21, 510–523. [Google Scholar] [CrossRef]

- Vasilieva, S.; Shibzukhova, K.; Morozov, A.; Solovchenko, A.; Bessonov, I.; Kopitsyna, M.; Lukyanov, A.; Chekanov, K.; Lobakova, E. Immobilization of Microalgae on the Surface of New Cross-Linked Polyethylenimine-Based Sorbents. J. Biotechnol. 2018, 281, 31–38. [Google Scholar] [CrossRef]

- Bakry, A.M.; Abbas, S.; Ali, B.; Majeed, H.; Abouelwafa, M.Y.; Mousa, A.; Liang, L. Microencapsulation of Oils: A Comprehensive Review of Benefits, Techniques, and Applications. Compr. Rev. Food Sci. Food Saf. 2016, 15, 143–182. [Google Scholar] [CrossRef]

- Martínez Rivas, C.J.; Tarhini, M.; Badri, W.; Miladi, K.; Greige-Gerges, H.; Nazari, Q.A.; Galindo Rodríguez, S.A.; Román, R.Á.; Fessi, H.; Elaissari, A. Nanoprecipitation Process: From Encapsulation to Drug Delivery. Int. J. Pharm. 2017, 532, 66–81. [Google Scholar] [CrossRef]

- Mansour, H.M.; Sohn, M.J.; Al-Ghananeem, A.; DeLuca, P.P. Materials for Pharmaceutical Dosage Forms: Molecular Pharmaceutics and Controlled Release Drug Delivery Aspects. Int. J. Mol. Sci. 2010, 11, 3298–3322. [Google Scholar] [CrossRef]

- Sengar, R.S.; Singh, A. Bioformulation and Fluid Bed Drying: A New Approach Towards an Improved Biofertilizer Formulation. In Eco-Friendly Agro-Biological Techniques for Enhancing Crop Productivity; Springer Science and Business Media: Dordrecht, The Netherlands, 2018; pp. 1–282. [Google Scholar] [CrossRef]

- Berninger, T.; González López, Ó.; Bejarano, A.; Preininger, C.; Sessitsch, A. Maintenance and Assessment of Cell Viability in Formulation of Non-Sporulating Bacterial Inoculants. Microb. Biotechnol. 2018, 11, 277–301. [Google Scholar] [CrossRef]

- Rai, P.K.; Rai, A.; Sharma, N.K.; Singh, T.; Kumar, Y. Limitations of Biofertilizers and Their Revitalization through Nanotechnology. J. Clean. Prod. 2023, 418, 138194. [Google Scholar] [CrossRef]

- Kumari, R.; Singh, D.P. Nano-Biofertilizer: An Emerging Eco-Friendly Approach for Sustainable Agriculture. Proc. Natl. Acad. Sci. India Sect. B Biol. Sci. 2020, 90, 733–741. [Google Scholar] [CrossRef]

- Thirugnanasambandan, T. Advances and Trends in Nano-Biofertilizers. SSRN 2018. [Google Scholar] [CrossRef]

- Sharma, B.; Tiwari, S.; Kumawat, K.C.; Cardinale, M. Nano-Biofertilizers as Bio-Emerging Strategies for Sustainable Agriculture Development: Potentiality and Their Limitations. Sci. Total Environ. 2023, 860, 160476. [Google Scholar] [CrossRef]

- Bello, A.S.; Saadaoui, I.; Ben-Hamadou, R. “Beyond the Source of Bioenergy”: Microalgae in Modern Agriculture as a Biostimulant, Biofertilizer, and Anti-Abiotic Stress. Agronomy 2021, 11, 1610. [Google Scholar] [CrossRef]

- Coppens, J.; Grunert, O.; Van Den Hende, S.; Vanhoutte, I.; Boon, N.; Haesaert, G.; De Gelder, L. The Use of Microalgae as a High-Value Organic Slow-Release Fertilizer Results in Tomatoes with Increased Carotenoid and Sugar Levels. J. Appl. Phycol. 2016, 28, 2367–2377. [Google Scholar] [CrossRef]

- Renuka, N.; Guldhe, A.; Prasanna, R.; Singh, P.; Bux, F. Microalgae as Multi-Functional Options in Modern Agriculture: Current Trends, Prospects and Challenges. Biotechnol. Adv. 2018, 36, 1255–1273. [Google Scholar] [CrossRef] [PubMed]

- Paudel, Y.; Pradhan, S. Role of Blue Green Algae in Rice Productivity. Agric. Biol. J. N. Am. 2012, 3, 332–335. [Google Scholar] [CrossRef]

- Shalaby, T.A.; El-Ramady, H. Effect of Foliar Application of Bio-Stimulants on Growth, Yield, Components, and Storability of Garlic (Allium sativum L.). Aust. J. Crop Sci. 2014, 8, 271–275. [Google Scholar]

- Zhang, Z.; Xu, M.; Fan, Y.; Zhang, L.; Wang, H. Using Microalgae to Reduce the Use of Conventional Fertilizers in Hydroponics and Soil-Based Cultivation. Sci. Total Environ. 2024, 912, 169424. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, W.; Duan, H.; Dong, H.; Li, J.; Zhang, S.; Zhang, J.; Ding, S.; Xu, T.; Guo, B. Improved Effects of Combined Application of Nitrogen-Fixing Bacteria Azotobacter Beijerinckii and Microalgae Chlorella Pyrenoidosa on Wheat Growth and Saline-Alkali Soil Quality. Chemosphere 2023, 313, 137409. [Google Scholar] [CrossRef]

- Singh, A.K.; Singh, A.P.; Gaurav, N.; Srivastava, A.; Kumar, A. A Review on Blue Green Algae as Biofertilizer (Site Characteristics, Location and Boundaries of Vindhya Basin, Geology of Rewa, Physiography, Climatology). Int. J. Bot. Stud. 2016, 1, 1–7. [Google Scholar]

- Dineshkumar, R.; Duraimurugan, M.; Sharmiladevi, N.; Lakshmi, L.P. Microalgal Liquid Biofertilizer and Biostimulant Effect on Green Gram (Vigna radiata L.) an Experimental Cultivation. Biomass Convers. Biorefinery 2020, 12, 3007–3027. [Google Scholar] [CrossRef]

- Garcia-Gonzalez, J.; Sommerfeld, M. Biofertilizer and Biostimulant Properties of the Microalga Acutodesmus Dimorphus. J. Appl. Phycol. 2016, 28, 1051–1061. [Google Scholar] [CrossRef]

- Godlewska, K.; Michalak, I.; Pacyga, P.; Baśladyńska, S.; Chojnacka, K. Potential Applications of Cyanobacteria: Spirulina Platensis Filtrates and Homogenates in Agriculture. World J. Microbiol. Biotechnol. 2019, 35, 80. [Google Scholar] [CrossRef] [PubMed]

- Navarro-López, E.; Ruíz-Nieto, A.; Ferreira, A.; Gabriel Acién, F.; Gouveia, L. Biostimulant Potential of Scenedesmus Obliquus Grown in Brewery Wastewater. Molecules 2020, 25, 664. [Google Scholar] [CrossRef]

- Mógor, Á.F.; Ördög, V.; Lima, G.P.P.; Molnár, Z.; Mógor, G. Biostimulant Properties of Cyanobacterial Hydrolysate Related to Polyamines. J. Appl. Phycol. 2018, 30, 453–460. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Zhou, Q. Co-Cultivation of Chlorella Spp and Tomato in a Hydroponic System. Biomass Bioenergy 2017, 97, 132–138. [Google Scholar] [CrossRef]

- El Arroussi, H.; Benhima, R.; Elbaouchi, A.; Sijilmassi, B.; El Mernissi, N.; Aafsar, A.; Meftah-Kadmiri, I.; Bendaou, N.; Smouni, A. 6th Congress of the International Society for Applied Phycology Dunaliella Salina Exopolysaccharides: A Promising Biostimulant for Salt Stress Tolerance in Tomato (Solanum Lycopersicum). J. Appl. Phycol. 2018, 30, 2929–2941. [Google Scholar] [CrossRef]

- Faheed, F.A. Effect of Chlorella Vulgaris as Bio-Fertilizer on Growth Parameters and Metabolic Aspects of Lettuce Plant. ISSN OnlineAWB J. Agri. Soc. Sci. 2008, 4, 1813–2235. [Google Scholar]

- Mutale-joan, C.; Redouane, B.; Najib, E.; Yassine, K.; Lyamlouli, K.; Laila, S.; Zeroual, Y.; Hicham, E.A. Screening of Microalgae Liquid Extracts for Their Bio Stimulant Properties on Plant Growth, Nutrient Uptake and Metabolite Profile of Solanum lycopersicum L. Sci. Rep. 2020, 10, 2820. [Google Scholar] [CrossRef]

- Dmytryk, A.; Rój, E.; Wilk, R.; Chojnacka, K. Innowacyjne Biopreparaty Do Zaprawiania Nasion: Wstępna Ocena Właściwości Użytkowych w Początkowej Fazie Wzrostu Roślin. Przemysł Chem. 2014, 93, 959–963. [Google Scholar]

- Michalak, I.; Chojnacka, K.; Dmytryk, A.; Wilk, R.; Gramza, M.; Rój, E. Evaluation of Supercritical Extracts of Algae as Biostimulants of Plant Growth in Field Trials. Front. Plant Sci. 2016, 7, 1591. [Google Scholar] [CrossRef] [PubMed]

- Al-saman, M.A.; Farfour, S.A.; Hamouda, R.A. Effects of Some Red Algae on Antioxidant and Phytochemical Contents of Maize (Zea mays L.) Plants. Int. J. Agric. Sci. ISSN 2015, 5, 393–398. [Google Scholar]

- Barone, V.; Baglieri, A.; Stevanato, P.; Broccanello, C.; Bertoldo, G.; Bertaggia, M.; Cagnin, M.; Pizzeghello, D.; Moliterni, V.M.C.; Mandolino, G.; et al. Root Morphological and Molecular Responses Induced by Microalgae Extracts in Sugar Beet (Beta vulgaris L.). J. Appl. Phycol. 2018, 30, 1061–1071. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, X.; Laipan, M.; Wei, T.; Guo, J. Soil Health Improvement by Inoculation of Indigenous Microalgae in Saline Soil. Environ. Geochem. Health 2024, 46, 23. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.A.; Sharma, G.K.; Malla, F.A.; Kumar, A.; Rashmi; Gupta, N. Microalgae Based Biofertilizers: A Biorefinery Approach to Phycoremediate Wastewater and Harvest Biodiesel and Manure. J. Clean. Prod. 2019, 211, 1412–1419. [Google Scholar] [CrossRef]

- Wuang, S.C.; Khin, M.C.; Chua, P.Q.D.; Luo, Y.D. Use of Spirulina Biomass Produced from Treatment of Aquaculture Wastewater as Agricultural Fertilizers. Algal Res. 2016, 15, 59–64. [Google Scholar] [CrossRef]

- Perry/Hope Partners 2023 Global: Biofertilizers Market–Innovative Markets Forecast (2029) Report. Available online: https://www.marketresearch.com/PerryHope-Partners-v4032/Global-Biofertilizers-Innovative-Forecast-33730701/ (accessed on 28 October 2023).

- Mordor Intelligence Biofertilizer Market Size & Share Analysis-Growth Trends & Forecasts up to 2029. Available online: https://www.mordorintelligence.com/industry-reports/global-biofertilizers-market-industry (accessed on 28 October 2023).

- Sharma, N.K.; Tiwari, S.P.; Tripathi, K.; Rai, A.K. Sustainability and Cyanobacteria (Blue-Green Algae): Facts and Challenges. J. Appl. Phycol. 2011, 23, 1059–1081. [Google Scholar] [CrossRef]

- Jose, S.; Renuka, N.; Ratha, S.K.; Kumari, S.; Bux, F. Microalgal Bioinoculants for Sustainable Agriculture and Their Interaction with Biotic and Abiotic Components of the Soil. Pedosphere, 2023; in press. [Google Scholar] [CrossRef]

- Gonçalves, A.L. The Use of Microalgae and Cyanobacteria in the Improvement of Agricultural Practices: A Review on Their Biofertilising, Biostimulating and Biopesticide Roles. Appl. Sci. 2021, 11, 871. [Google Scholar] [CrossRef]

- Credence Research Microalgae Fertilizers Market. Available online: https://www.credenceresearch.com/report/microalgae-fertilizers-market#summary (accessed on 28 October 2023).

- Future Market Insights Demand for Microalgae in Fertilizers Sector Outlook (2023 to 2033). Available online: https://www.futuremarketinsights.com/reports/microalgae-fertilizers-sector (accessed on 28 October 2023).

- Neoalgae Spiragro: El Fertilizante ECO Natural a Base de Spirulina. Available online: https://neoalgae.es/spiragro/ (accessed on 25 October 2023).

- Biorizon Biobalance. Available online: https://www.biorizon.es/productos_biorizon/biobalance/ (accessed on 25 October 2023).

- Algenol Algae Product Development and Manufacturing. Available online: https://www.algenol.com/ (accessed on 25 October 2023).

- Algaenergy Microalgae a Quality Raw Material with an Immense Potential of Application. Available online: https://www.algaenergy.com/ (accessed on 25 October 2023).

- Allmicroalgae Cultivating Sustainable Microalgae Solutions. Available online: https://www.allmicroalgae.com/en/ (accessed on 25 October 2023).

- Ascenza Ascenza Cultivamos El Futuro. Available online: https://ascenza.com/es (accessed on 25 October 2023).

- Gexus Biosoluciones Para El Sector Agropecuario. Available online: https://www.gexus.com.mx/ (accessed on 25 October 2023).

- TrueAlgae Revolutionizing Algae. Available online: https://truealgae.com/ (accessed on 25 October 2023).

- Dębowski, M.; Zieliński, M.; Kazimierowicz, J.; Kujawska, N.; Talbierz, S. Microalgae Cultivation Technologies as an Opportunity for Bioenergetic System Development—Advantages and Limitations. Sustainability 2020, 12, 9980. [Google Scholar] [CrossRef]

- Gonçalves, J.; Freitas, J.; Fernandes, I.; Silva, P. Microalgae as Biofertilizers: A Sustainable Way to Improve Soil Fertility and Plant Growth. Sustainability 2023, 15, 12413. [Google Scholar] [CrossRef]

| Type of Formulation | Description | Advantages | Ref. |

|---|---|---|---|

| Granules/Microgranules | Dry particles composed of biomass (active ingredient with 5–20%), binder and carrier. | Non-dusty, non-caking, high disintegration capacity, easy to store and apply, non-inhalable, and used for soil treatments. | [33,37] |

| Wettable Powders | Composed of 50–80% technical powder, 15–45% filler, 1–10% dispersant, and 3–5% surfactant. | These powders are easily miscible with water and can be suspended in a liquid carrier; their shelf life can exceed 18 months. | [33,37,38] |

| Water-wettable/dispersible granules | Non-dusty solid formulation, with wetting and dispersing agents, but in higher concentrations than wettable powders. | Non-dusty solid formulation and disperses quickly in water. | [14] |

| Powders | Contain a very finely ground mixture of the active ingredient (usually 10%). They are used with adhesives and desiccants. | Ease of storage, greater ease of transportation, and greater chemical stability. | [33,37,38] |

| Suspension concentrates | Made by combining solid active ingredients with low water solubility and acceptable hydrolysis. | Do not generate dust, are easy to measure, and can be poured into spray tanks. | [35] |

| Ultra-low-volume suspensions | Solid particles dispersed in a liquid in small quantities. Can be dispersed by ultra-low-volume aerial or ground spray machinery into a very fine spray. | Can be dispersed using aerial or ground spray machinery. The spray is very fine. | [33,35] |

| Oil-miscible concentrated fluids | A suspension containing active ingredient(s) dispersed in an organic fluid. | Extremely fine spray. | [33] |

| Oil dispersion | Contains active ingredients in oil or in a water-immiscible solvent. | Due to the oil, the active ingredient remains in contact with the plants for a longer time. | [33,35] |

| Species | Biostimulation | Crop | References |

|---|---|---|---|

| Chlorella vulgaris Spirulina platensis | Leaf, root, height, and dry weight | Green gram Vigna radiata (L.) | [73] |

| Acutodesmus dimorphus | Seed germination, root, and leaf | Tomato | [74] |

| Spirulina platensis | Leaf and dry weight | Radishes | [75] |

| Scenedesmus obliquus | Germination, stem, roots, and leaf | Watercress, bean, and cucumber | [76] |

| Arthrospira platensis | Leaf, root | Lettuce | [77] |

| Year-to-Year Change | Market Sales (Million USD) | |

|---|---|---|

| 2018–2019 | 10.8% | 1642.6 |

| 2019–2020 | 4.7% | 1719.3 |

| 2020–2021 | 14.6% | 1979.1 |

| 2021–2022 | 19.6% | 2355.5 |

| 2022–2023 | 13.2% | 2667.2 |

| 2023–2024 | 13.2% | 3019.0 |

| CAGR 2024–2029 | 15.6% | 5377.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miranda, A.M.; Hernandez-Tenorio, F.; Villalta, F.; Vargas, G.J.; Sáez, A.A. Advances in the Development of Biofertilizers and Biostimulants from Microalgae. Biology 2024, 13, 199. https://doi.org/10.3390/biology13030199

Miranda AM, Hernandez-Tenorio F, Villalta F, Vargas GJ, Sáez AA. Advances in the Development of Biofertilizers and Biostimulants from Microalgae. Biology. 2024; 13(3):199. https://doi.org/10.3390/biology13030199

Chicago/Turabian StyleMiranda, Alejandra M., Fabian Hernandez-Tenorio, Fabian Villalta, Gabriel J. Vargas, and Alex A. Sáez. 2024. "Advances in the Development of Biofertilizers and Biostimulants from Microalgae" Biology 13, no. 3: 199. https://doi.org/10.3390/biology13030199

APA StyleMiranda, A. M., Hernandez-Tenorio, F., Villalta, F., Vargas, G. J., & Sáez, A. A. (2024). Advances in the Development of Biofertilizers and Biostimulants from Microalgae. Biology, 13(3), 199. https://doi.org/10.3390/biology13030199