Carboxymethyl Cellulose Enhanced Production of Cellulose Nanofibrils

Abstract

:1. Introduction

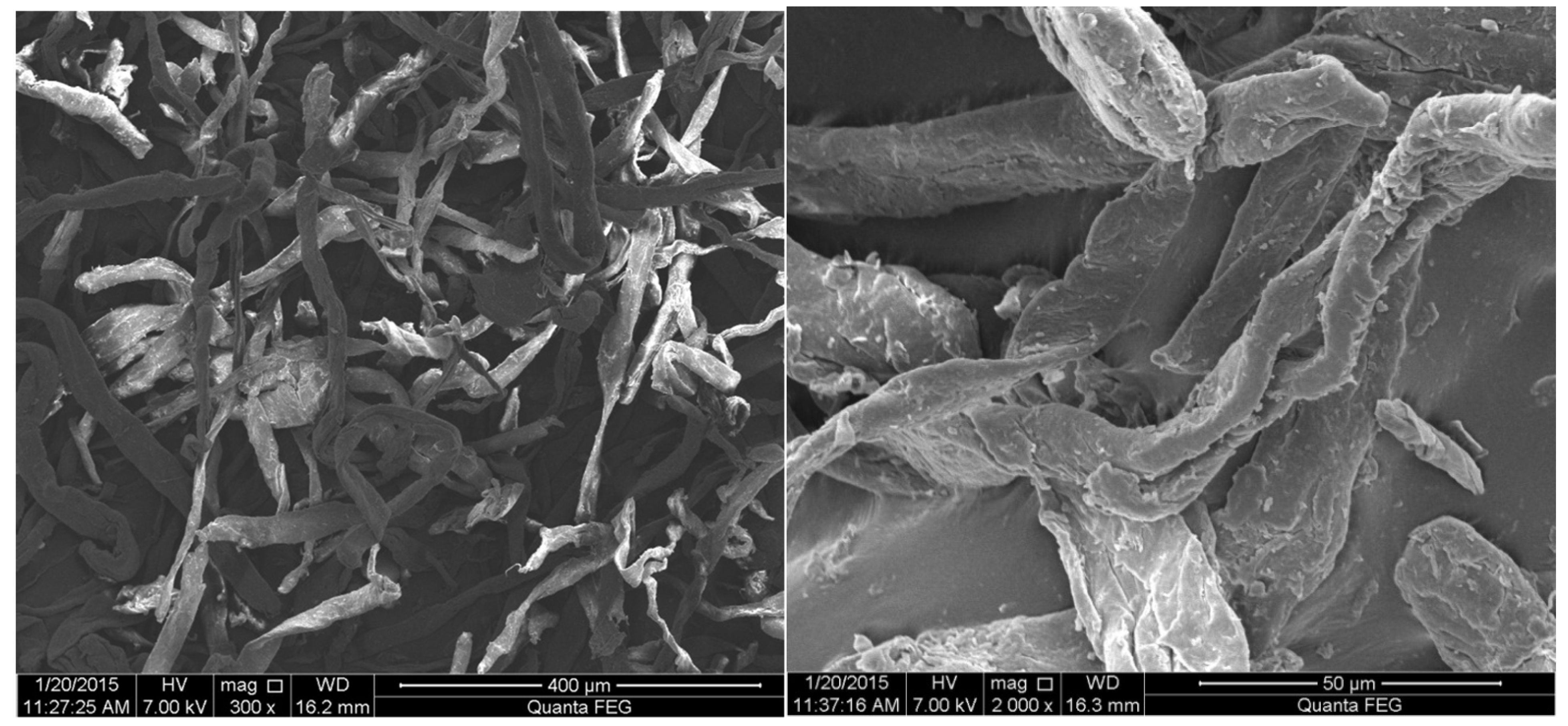

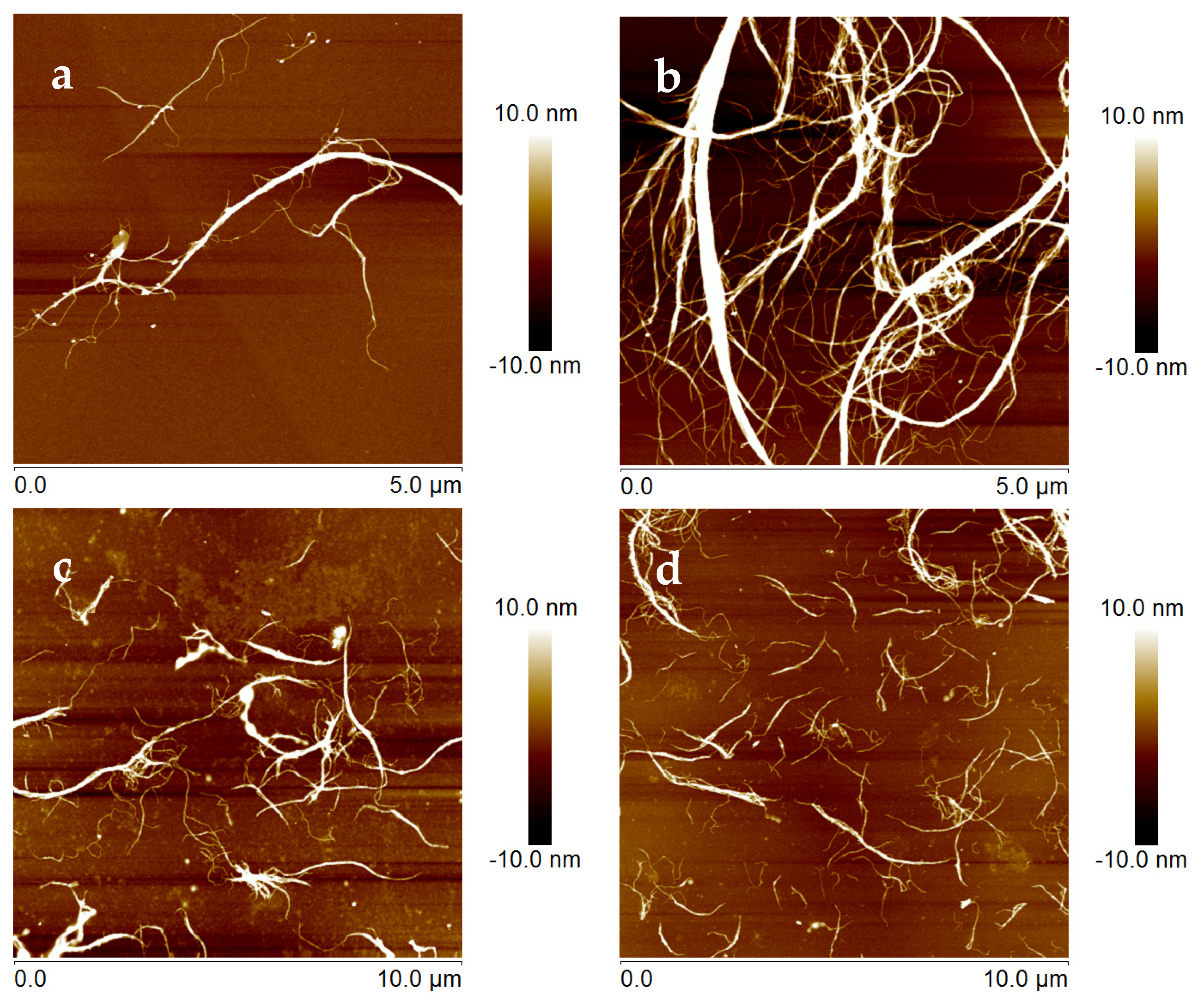

2. Materials and Methods

2.1. Production of CNF Hydrogels

2.2. Characterizations

2.3. SSA and WRV Measurements

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Klemm, D.; Kramer, F.; Moritz, S.; Lindström, T.; Ankerfors, M.; Gray, D.; Dorris, A. Nanocelluloses: A New Family of Nature-Based Materials. Angew. Chem. Int. Ed. 2011, 50, 5438–5466. [Google Scholar] [CrossRef] [PubMed]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941. [Google Scholar] [CrossRef] [PubMed]

- Foster, E.J.; Moon, R.J.; Agarwal, U.P.; Bortner, M.J.; Bras, J.; Camarero-Espinosa, S.; Chan, K.J.; Clift, M.J.D.; Cranston, E.D.; Eichhorn, S.J.; et al. Current characterization methods for cellulose nanomaterials. Chem. Soc. Rev. 2018, 47, 2609–2679. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lavoine, N.; Desloges, I.; Dufresne, A.; Bras, J. Microfibrillated cellulose—Its barrier properties and applications in cellulosic materials: A review. Carbohydr. Polym. 2012, 90, 735–764. [Google Scholar] [CrossRef]

- Kim, Y.; McCoy, L.T.; Lee, E.; Lee, H.; Saremi, R.; Feit, C.; Hardin, I.R.; Sharma, S.; Mani, S.; Minko, S. Environmentally sound textile dyeing technology with nanofibrillated cellulose. Green Chem. 2017, 19, 4031–4035. [Google Scholar] [CrossRef]

- Liyanapathiranage, A.; Peña, M.J.; Sharma, S.; Minko, S. Nanocellulose-Based Sustainable Dyeing of Cotton Textiles with Minimized Water Pollution. ACS Omega 2020, 5, 9196–9203. [Google Scholar] [CrossRef]

- Rai, S.; Saremi, R.; Sharma, S.; Minko, S. Environment-friendly nanocellulose-indigo dyeing of textiles. Green Chem. 2021. [Google Scholar] [CrossRef]

- Wei, H.; Rodriguez, K.; Renneckar, S.; Vikesland, P.J. Environmental science and engineering applications of nanocellulose-based nanocomposites. Environ. Sci. Nano 2014, 1, 302. [Google Scholar] [CrossRef] [Green Version]

- Carpenter, A.W.; de Lannoy, C.-F.; Wiesner, M.R. Cellulose Nanomaterials in Water Treatment Technologies. Environ. Sci. Technol. 2015, 49, 5277–5287. [Google Scholar] [CrossRef]

- Ma, J.; Li, X.; Bao, Y. Advances in cellulose-based superabsorbent hydrogels. RSC Adv. 2015, 5, 59745–59757. [Google Scholar] [CrossRef]

- Liu, H.; Geng, B.; Chen, Y.; Wang, H. Review on the Aerogel-Type Oil Sorbents Derived from Nanocellulose. ACS Sustain. Chem. Eng. 2017, 5, 49–66. [Google Scholar] [CrossRef]

- Berglund, L.A.; Peijs, T. Cellulose Biocomposites—From Bulk Moldings to Nanostructured Systems. MRS Bull. 2010, 35, 201–207. [Google Scholar] [CrossRef]

- Dufresne, A. Nanocellulose: A new ageless bionanomaterial. Mater. Today 2013, 16, 220–227. [Google Scholar] [CrossRef]

- Taipale, T.; Österberg, M.; Nykänen, A.; Ruokolainen, J.; Laine, J. Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 2010, 17, 1005–1020. [Google Scholar] [CrossRef]

- Kedzior, S.A.; Gabriel, V.A.; Dubé, M.A.; Cranston, E.D. Nanocellulose in Emulsions and Heterogeneous Water-Based Polymer Systems: A Review. Adv. Mater. 2020, 2002404. [Google Scholar] [CrossRef] [PubMed]

- Hoeng, F.; Denneulin, A.; Bras, J. Use of nanocellulose in printed electronics: A review. Nanoscale 2016, 8, 13131–13154. [Google Scholar] [CrossRef]

- Zhu, H.; Luo, W.; Ciesielski, P.N.; Fang, Z.; Zhu, J.Y.; Henriksson, G.; Himmel, M.E.; Hu, L. Wood-Derived Materials for Green Electronics, Biological Devices, and Energy Applications. Chem. Rev. 2016, 116, 9305–9374. [Google Scholar] [CrossRef] [PubMed]

- Abdul Khalil, H.P.S.; Davoudpour, Y.; Islam, M.N.; Mustapha, A.; Sudesh, K.; Dungani, R.; Jawaid, M. Production and modification of nanofibrillated cellulose using various mechanical processes: A review. Carbohydr. Polym. 2014, 99, 649–665. [Google Scholar] [CrossRef]

- Nechyporchuk, O.; Belgacem, M.N.; Bras, J. Production of cellulose nanofibrils: A review of recent advances. Ind. Crop. Prod. 2016, 93, 2–25. [Google Scholar] [CrossRef]

- Rol, F.; Belgacem, M.N.; Gandini, A.; Bras, J. Recent advances in surface-modified cellulose nanofibrils. Prog. Polym. Sci. 2019, 88, 241–264. [Google Scholar] [CrossRef]

- Walecka, J.A. An Investigation of Low Degree of Substitution Carboxymethylcelluloses; Institute of Paper Chemistry in Appleton: Appleton, WI, USA, 1956. [Google Scholar]

- Wågberg, L.; Decher, G.; Norgren, M.; Lindström, T.; Ankerfors, M.; Axnäs, K. The Build-Up of Polyelectrolyte Multilayers of Microfibrillated Cellulose and Cationic Polyelectrolytes. Langmuir 2008, 24, 784–795. [Google Scholar] [CrossRef] [PubMed]

- Henriksson, M.; Henriksson, G.; Berglund, L.A.; Lindström, T. An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur. Polym. J. 2007, 43, 3434–3441. [Google Scholar] [CrossRef]

- Pääkkö, M.; Ankerfors, M.; Kosonen, H.; Nykänen, A.; Ahola, S.; Österberg, M.; Ruokolainen, J.; Laine, J.; Larsson, P.T.; Ikkala, O.; et al. Enzymatic Hydrolysis Combined with Mechanical Shearing and High-Pressure Homogenization for Nanoscale Cellulose Fibrils and Strong Gels. Biomacromolecules 2007, 8, 1934–1941. [Google Scholar] [CrossRef] [PubMed]

- Saito, T.; Nishiyama, Y.; Putaux, J.-L.; Vignon, M.; Isogai, A. Homogeneous Suspensions of Individualized Microfibrils from TEMPO-Catalyzed Oxidation of Native Cellulose. Biomacromolecules 2006, 7, 1687–1691. [Google Scholar] [CrossRef]

- Saito, T.; Kimura, S.; Nishiyama, Y.; Isogai, A. Cellulose Nanofibers Prepared by TEMPO-Mediated Oxidation of Native Cellulose. Biomacromolecules 2007, 8, 2485–2491. [Google Scholar] [CrossRef]

- Isogai, A.; Saito, T.; Fukuzumi, H. TEMPO-oxidized cellulose nanofibers. Nanoscale 2011, 3, 71–85. [Google Scholar] [CrossRef] [PubMed]

- Habibi, Y. Key advances in the chemical modification of nanocelluloses. Chem. Soc. Rev. 2014, 43, 1519. [Google Scholar] [CrossRef]

- Li, Q.; McGinnis, S.; Sydnor, C.; Wong, A.; Renneckar, S. Nanocellulose Life Cycle Assessment. ACS Sustain. Chem. Eng. 2013, 1, 919–928. [Google Scholar] [CrossRef]

- Arvidsson, R.; Nguyen, D.; Svanström, M. Life Cycle Assessment of Cellulose Nanofibrils Production by Mechanical Treatment and Two Different Pretreatment Processes. Environ. Sci. Technol. 2015, 49, 6881–6890. [Google Scholar] [CrossRef]

- Laine, J.; Lindström, T. Studies on topochemical modification of cellulosic fibres: Part 1. Chemical conditions for the attachment of carboxymethyl cellulose onto fibres. Nord. Pulp Pap. Res. J. 2000, 15, 520–526. [Google Scholar] [CrossRef]

- Liu, Z.; Choi, H.; Gatenholm, P.; Esker, A.R. Quartz Crystal Microbalance with Dissipation Monitoring and Surface Plasmon Resonance Studies of Carboxymethyl Cellulose Adsorption onto Regenerated Cellulose Surfaces. Langmuir 2011, 27, 8718–8728. [Google Scholar] [CrossRef] [PubMed]

- Filpponen, I.; Kontturi, E.; Nummelin, S.; Rosilo, H.; Kolehmainen, E.; Ikkala, O.; Laine, J. Generic Method for Modular Surface Modification of Cellulosic Materials in Aqueous Medium by Sequential “Click” Reaction and Adsorption. Biomacromolecules 2012, 13, 736–742. [Google Scholar] [CrossRef] [PubMed]

- Kargl, R.; Mohan, T.; Bračič, M.; Kulterer, M.; Doliška, A.; Stana-Kleinschek, K.; Ribitsch, V. Adsorption of Carboxymethyl Cellulose on Polymer Surfaces: Evidence of a Specific Interaction with Cellulose. Langmuir 2012, 28, 11440–11447. [Google Scholar] [CrossRef] [PubMed]

- Mikael, A.; Tom, L. Method for Providing a Nanocellulose Involving Modifying Cellulose Fibers. U.S. 8911591 B2, 16 December 2014. [Google Scholar]

- Naderi, A.; Lindström, T.; Sundström, J.; Pettersson, T.; Flodberg, G.; Erlandsson, J. Microfluidized carboxymethyl cellulose modified pulp: A nanofibrillated cellulose system with some attractive properties. Cellulose 2015, 22, 1159–1173. [Google Scholar] [CrossRef]

- Butchosa, N.; Zhou, Q. Water redispersible cellulose nanofibrils adsorbed with carboxymethyl cellulose. Cellulose 2014, 21, 4349–4358. [Google Scholar] [CrossRef]

- Agarwal, D.; MacNaughtan, W.; Foster, T.J. Interactions between microfibrillar cellulose and carboxymethyl cellulose in an aqueous suspension. Carbohydr. Polym. 2018, 185, 112–119. [Google Scholar] [CrossRef]

- Kaewprasit, C.; Hequet, E.; Abidi, N.; Gourlot, J.P. Quality measurements: Application of Methylene Blue Adsorption to Cotton Fiber Specific Surface Area Measurement, Part I. Methodology. J. Cotton Sci. 1998, 2, 164–173. [Google Scholar]

- Santamarina, J.C.; Klein, K.A.; Wang, Y.H.; Prencke, E. Specific surface: Determination and relevance. Can. Geotech. J. 2002, 39, 233–241. [Google Scholar] [CrossRef]

- Nechyporchuk, O.; Belgacem, M.N.; Pignon, F. Current Progress in Rheology of Cellulose Nanofibril Suspensions. Biomacromolecules 2016, 17, 2311–2320. [Google Scholar] [CrossRef]

- Sodium Carboxymethyl Cellulose, Average Mw ~90,000. Specification Sheet. Available online: https://www.sigmaaldrich.com/specification-sheets/160/380/419273-BULK_______ALDRICH__.pdf (accessed on 7 September 2021).

- Sodium Carboxymethyl Cellulose, Average Mw ~250,000. Specification Sheet. Available online: https://www.sigmaaldrich.com/specification-sheets/238/551/419303-BULK_______ALDRICH__.pdf (accessed on 7 September 2021).

- Sodium Carboxymethyl Cellulose, Average Mw ~700,000. Specification Sheet. Available online: https://www.sigmaaldrich.com/specification-sheets/160/780/419338-BULK_______ALDRICH__.pdf (accessed on 7 September 2021).

- Motornov, M.; Roiter, Y.; Tokarev, I.; Minko, S. Stimuli-responsive nanoparticles, nanogels and capsules for integrated multifunctional intelligent systems. Prog. Polym. Sci. 2010, 35, 174–211. [Google Scholar] [CrossRef]

- Sehaqui, H.; Zhou, Q.; Ikkala, O.; Berglund, L.A. Strong and Tough Cellulose Nanopaper with High Specific Surface Area and Porosity. Biomacromolecules 2011, 12, 3638–3644. [Google Scholar] [CrossRef] [PubMed]

- Hu, C.; Zhao, Y.; Li, K.; Zhu, J.Y.; Gleisner, R. Optimizing cellulose fibrillation for the production of cellulose nanofibrils by a disk grinder. Holzforschung 2015, 69, 993–1000. [Google Scholar] [CrossRef]

- Gu, F.; Wang, W.; Cai, Z.; Xue, F.; Jin, Y.; Zhu, J.Y. Water retention value for characterizing fibrillation degree of cellulosic fibers at micro and nanometer scales. Cellulose 2018, 25, 2861–2871. [Google Scholar] [CrossRef]

- Jiang, F.; Hsieh, Y.-L. Chemically and mechanically isolated nanocellulose and their self-assembled structures. Carbohydr. Polym. 2013, 95, 32–40. [Google Scholar] [CrossRef] [PubMed]

- Fernandes Diniz, J.M.B.; Gil, M.H.; Castro, J.A.A.M. Hornification—its origin and interpretation in wood pulps. Wood Sci. Technol. 2004, 37, 489–494. [Google Scholar] [CrossRef] [Green Version]

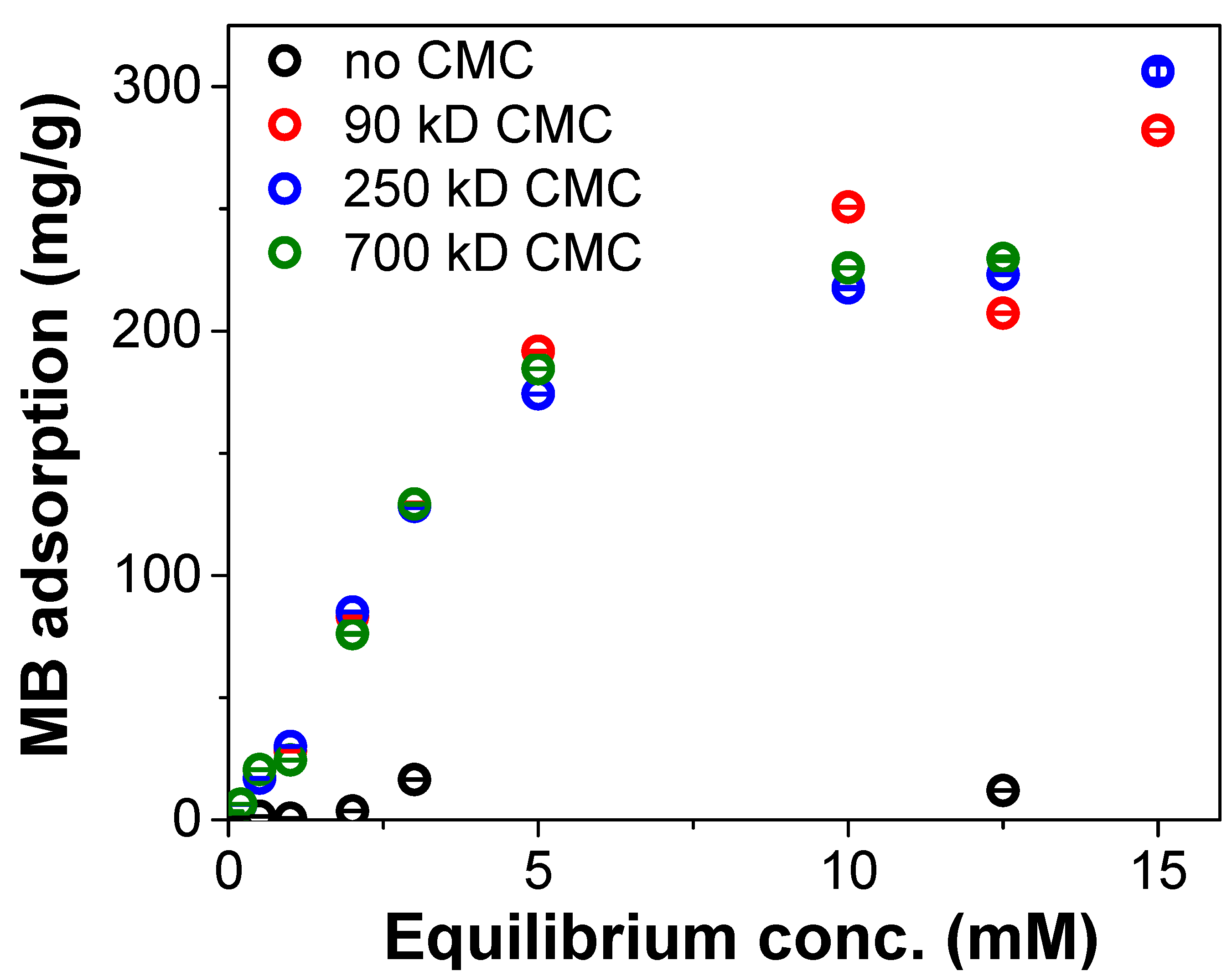

| No CMC | CMC, 90 kD | CMC, 250 kD | CMC, 700 kD | |

|---|---|---|---|---|

| MB adsorption on CNF (mg/g) | 16.4 | 282 | 306 | 229 |

| SSA of CNF (m2/g) | 34.5 | 591 | 641 | 481 |

| No CMC | CMC, 90 kD | CMC, 250 kD | CMC, 700 kD | |

|---|---|---|---|---|

| WRV (%) | 60 ± 58 | 870 ± 19 | 977 ± 132 | 1446 ± 6 |

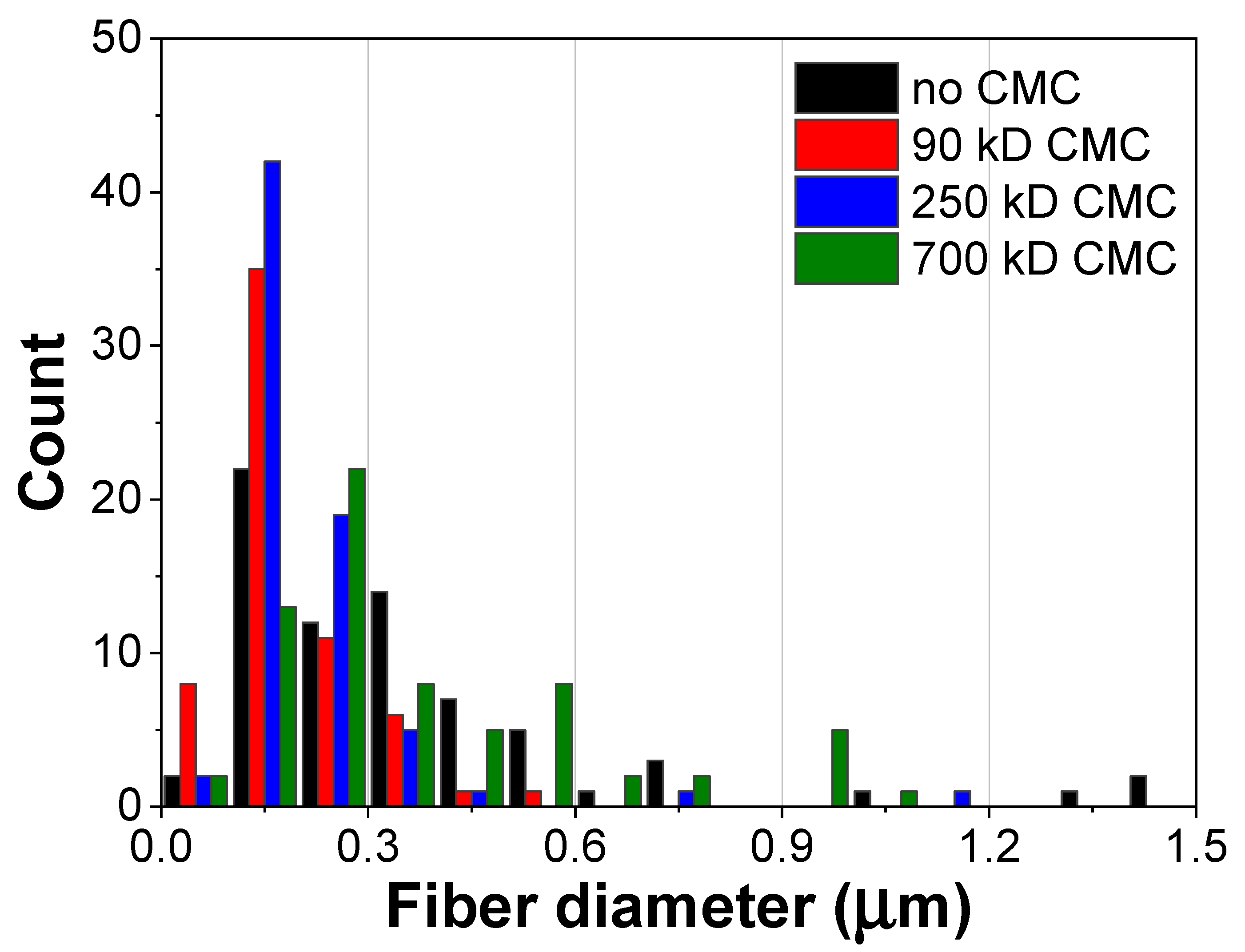

| No CMC | CMC, 90 kD | CMC, 250 kD | CMC, 700 kD | |

|---|---|---|---|---|

| Fiber diameter of CNF (μm) | 0.36 ± 0.30 | 0.19 ± 0.093 | 0.21 ± 0.14 | 0.38 ± 0.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.; McCoy, L.T.; Feit, C.; Mubarak, S.A.; Sharma, S.; Minko, S. Carboxymethyl Cellulose Enhanced Production of Cellulose Nanofibrils. Fibers 2021, 9, 57. https://doi.org/10.3390/fib9090057

Kim Y, McCoy LT, Feit C, Mubarak SA, Sharma S, Minko S. Carboxymethyl Cellulose Enhanced Production of Cellulose Nanofibrils. Fibers. 2021; 9(9):57. https://doi.org/10.3390/fib9090057

Chicago/Turabian StyleKim, Yunsang, Lauren T. McCoy, Corbin Feit, Shuaib A. Mubarak, Suraj Sharma, and Sergiy Minko. 2021. "Carboxymethyl Cellulose Enhanced Production of Cellulose Nanofibrils" Fibers 9, no. 9: 57. https://doi.org/10.3390/fib9090057

APA StyleKim, Y., McCoy, L. T., Feit, C., Mubarak, S. A., Sharma, S., & Minko, S. (2021). Carboxymethyl Cellulose Enhanced Production of Cellulose Nanofibrils. Fibers, 9(9), 57. https://doi.org/10.3390/fib9090057