Determination and Review of Physical and Mechanical Properties of Raw and Treated Coconut Fibers for Their Recycling in Construction Materials

Abstract

1. Introduction

2. Material and Methods

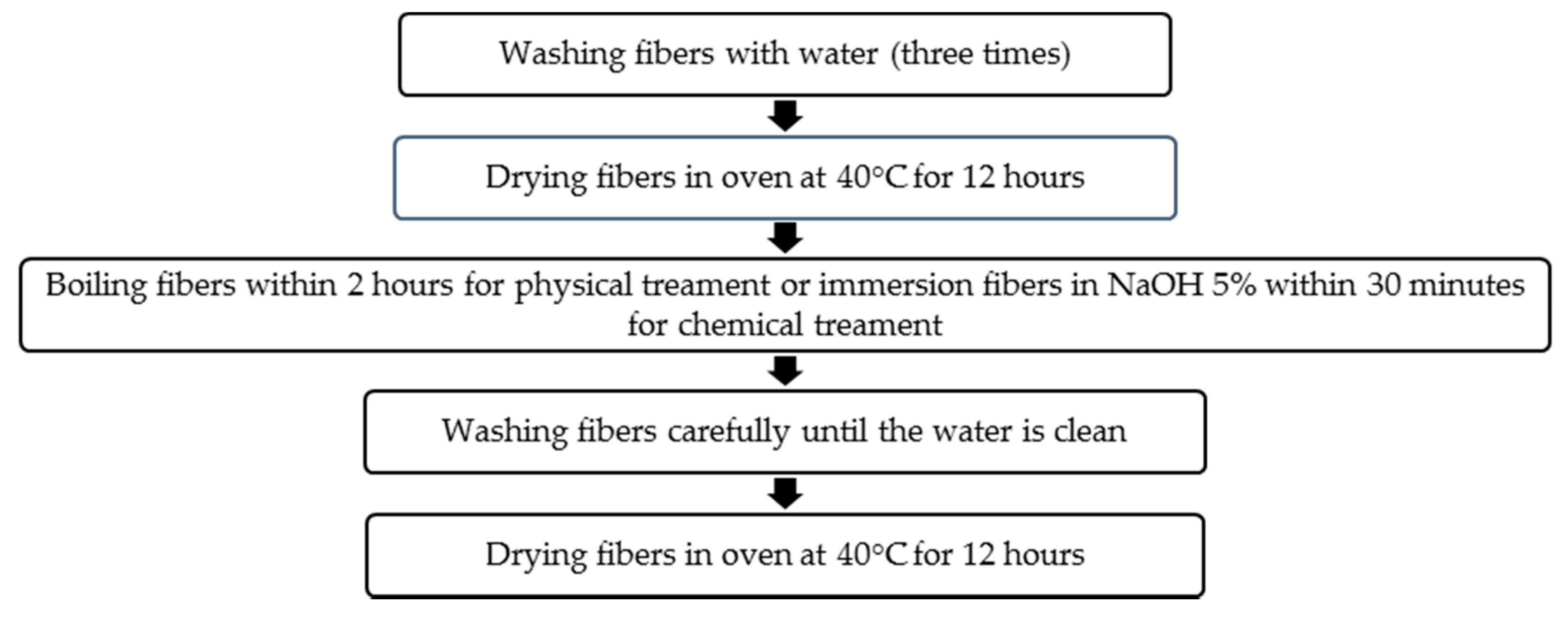

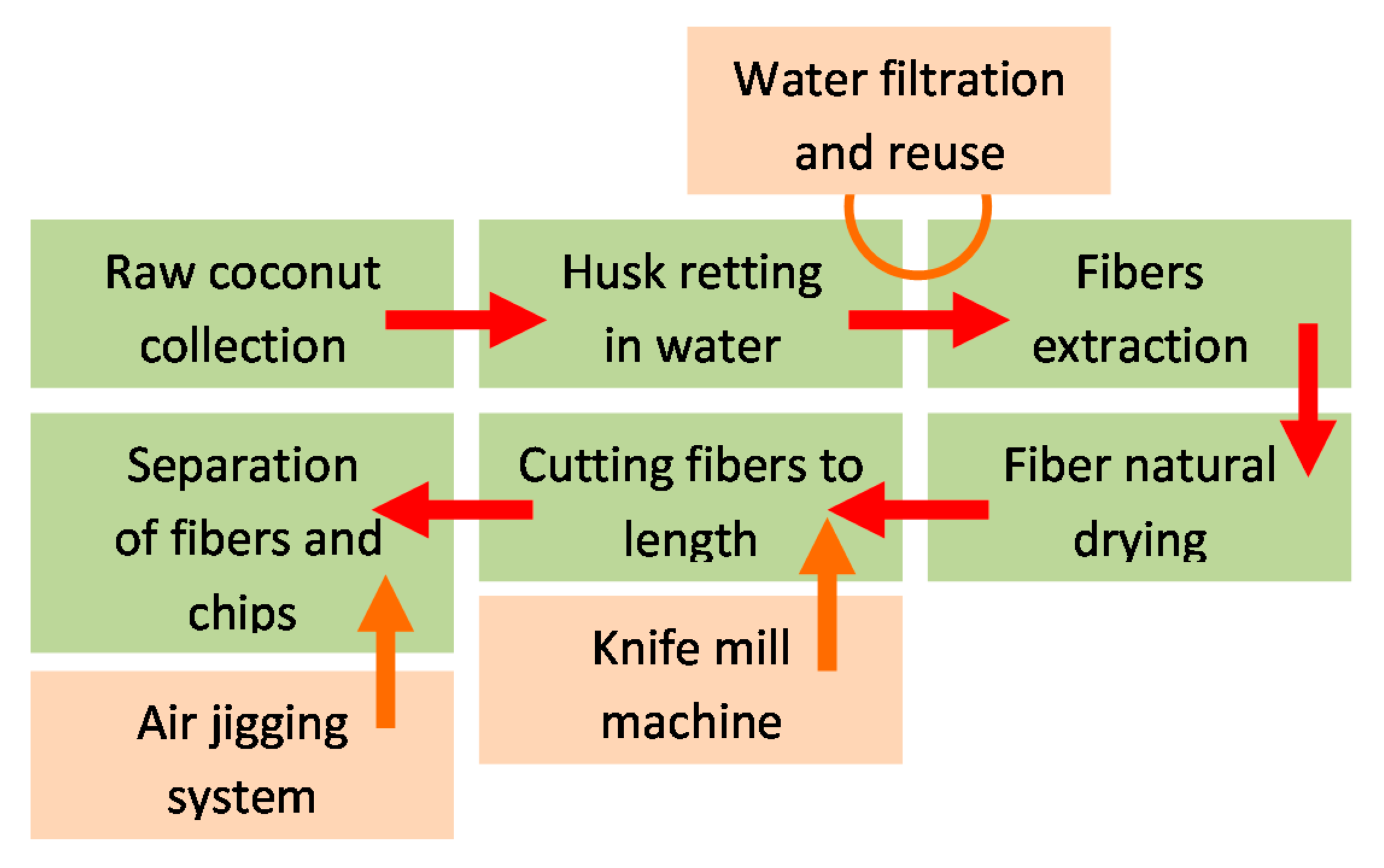

2.1. Preparation of Fibers

2.2. Testing Methods for the Determination of Fiber Properties

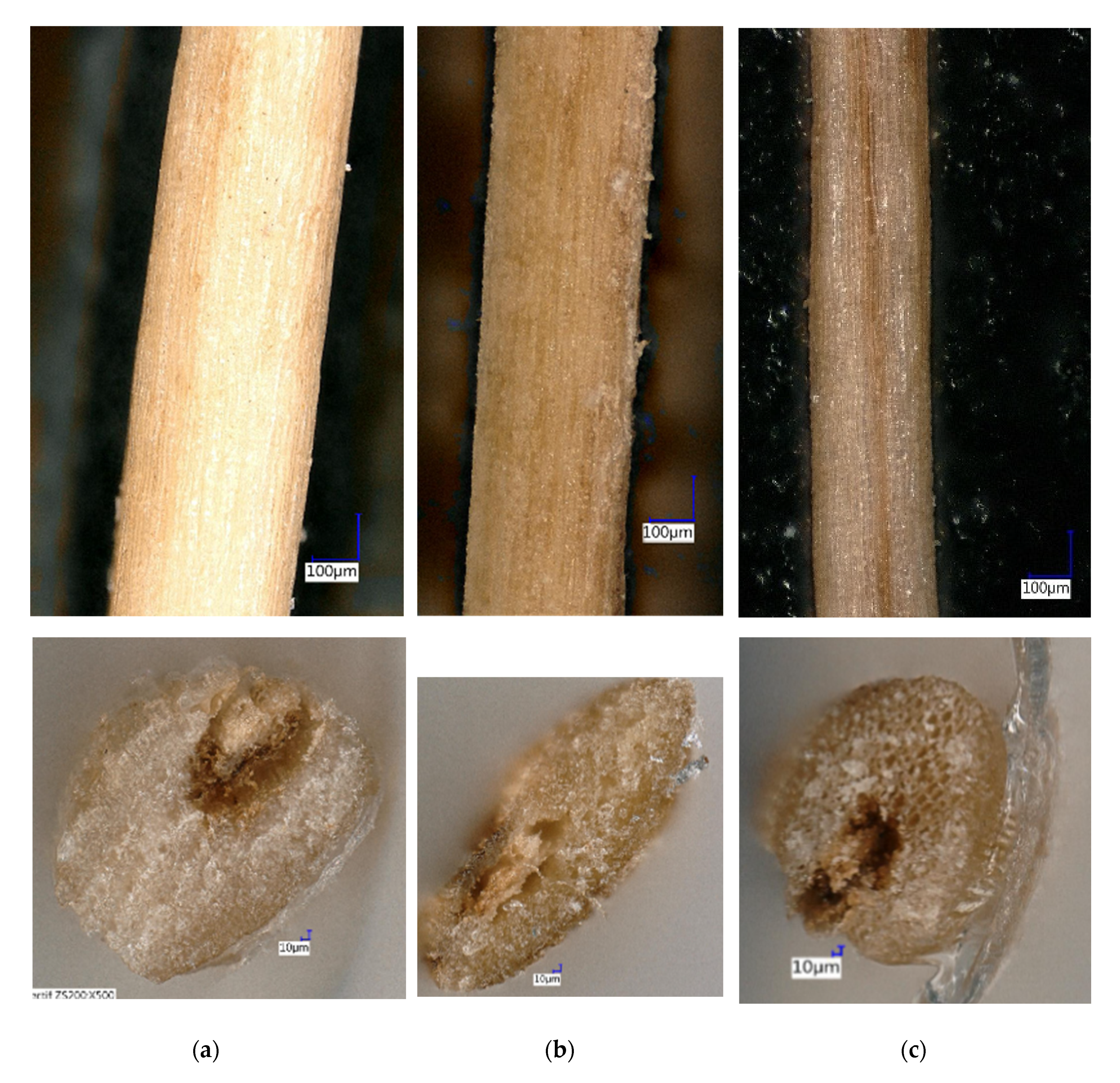

2.2.1. Microscope Image

2.2.2. Absolute Density

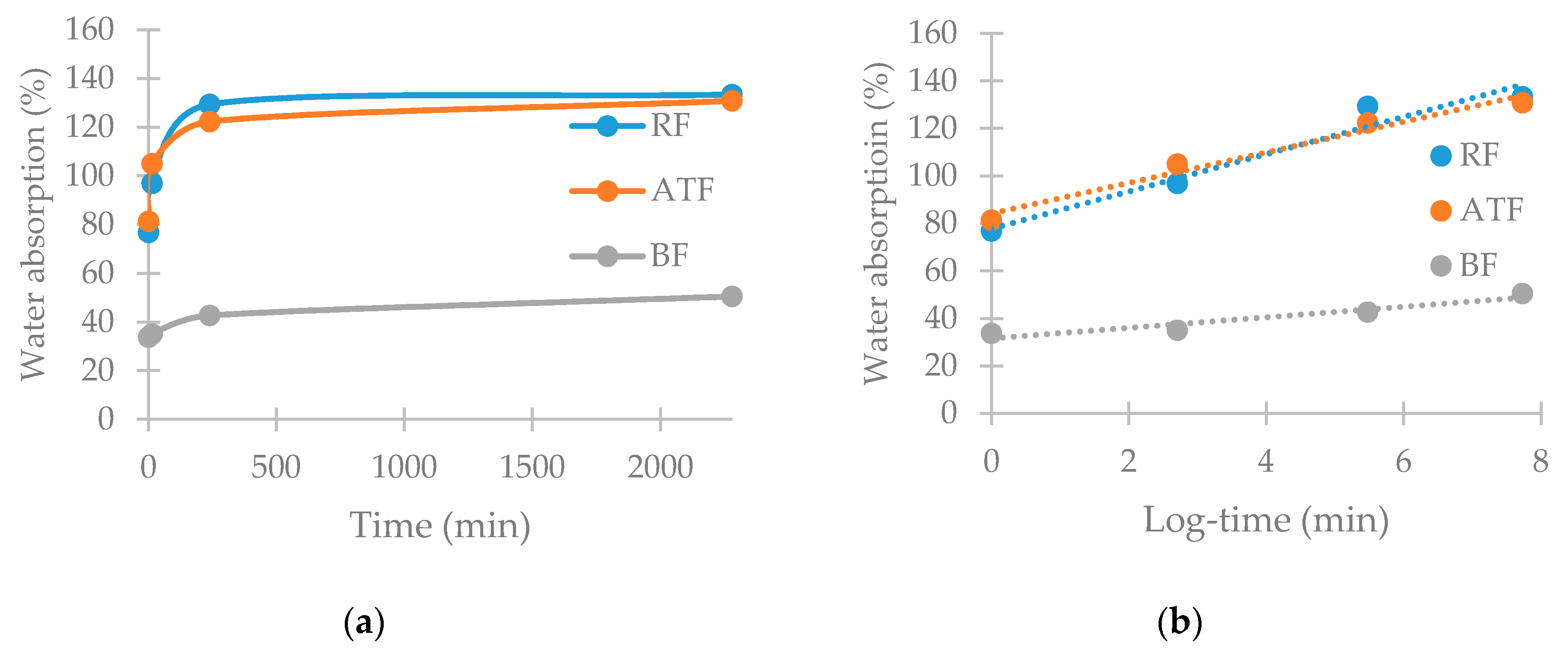

2.2.3. Water Absorption

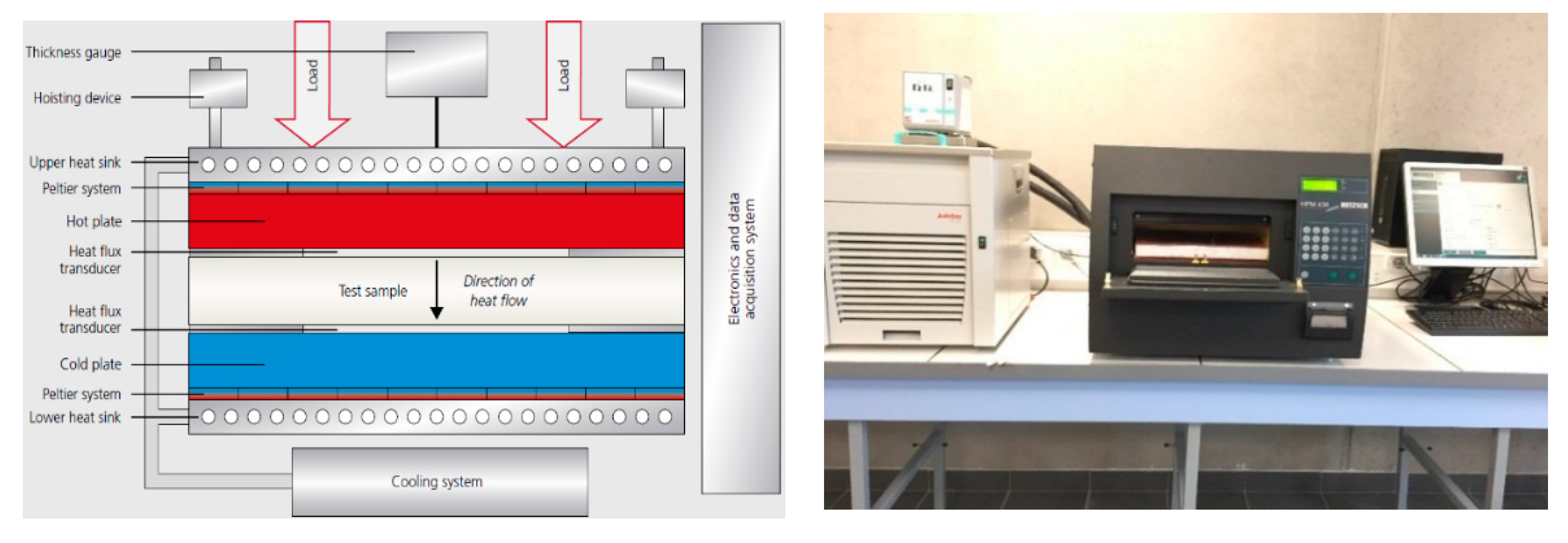

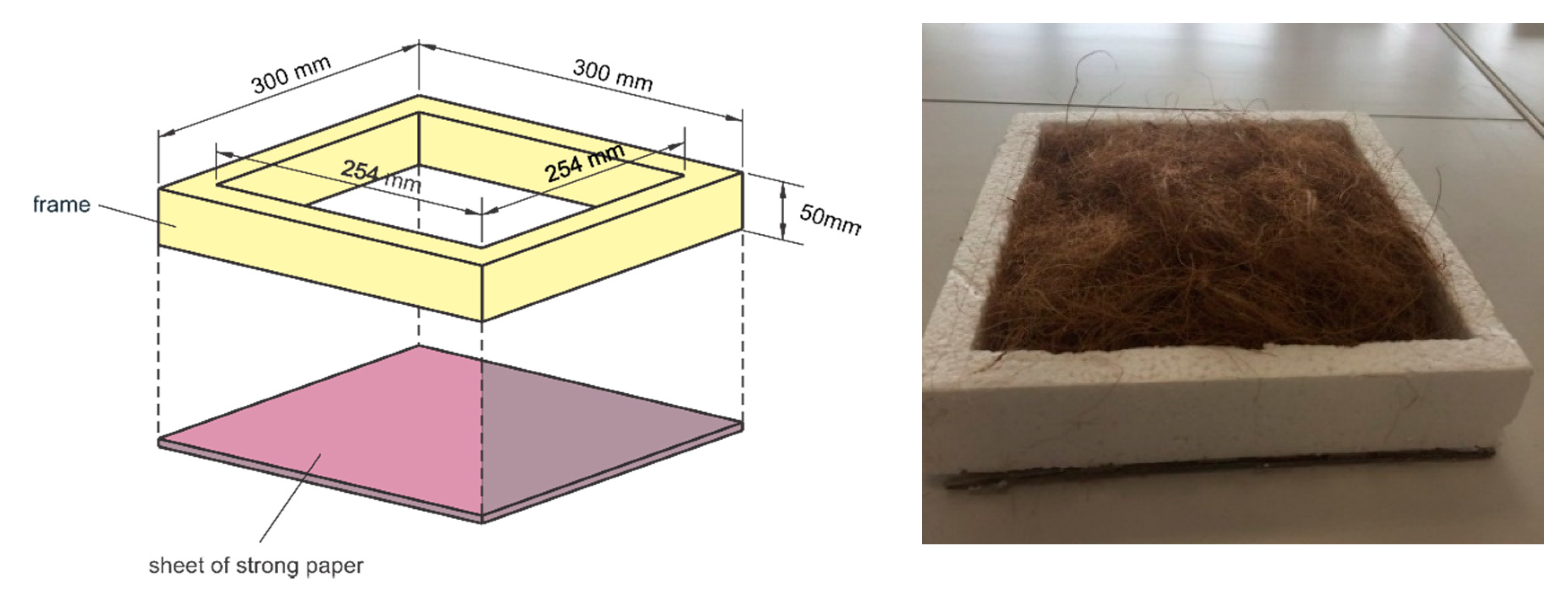

2.2.4. Thermal Conductivity

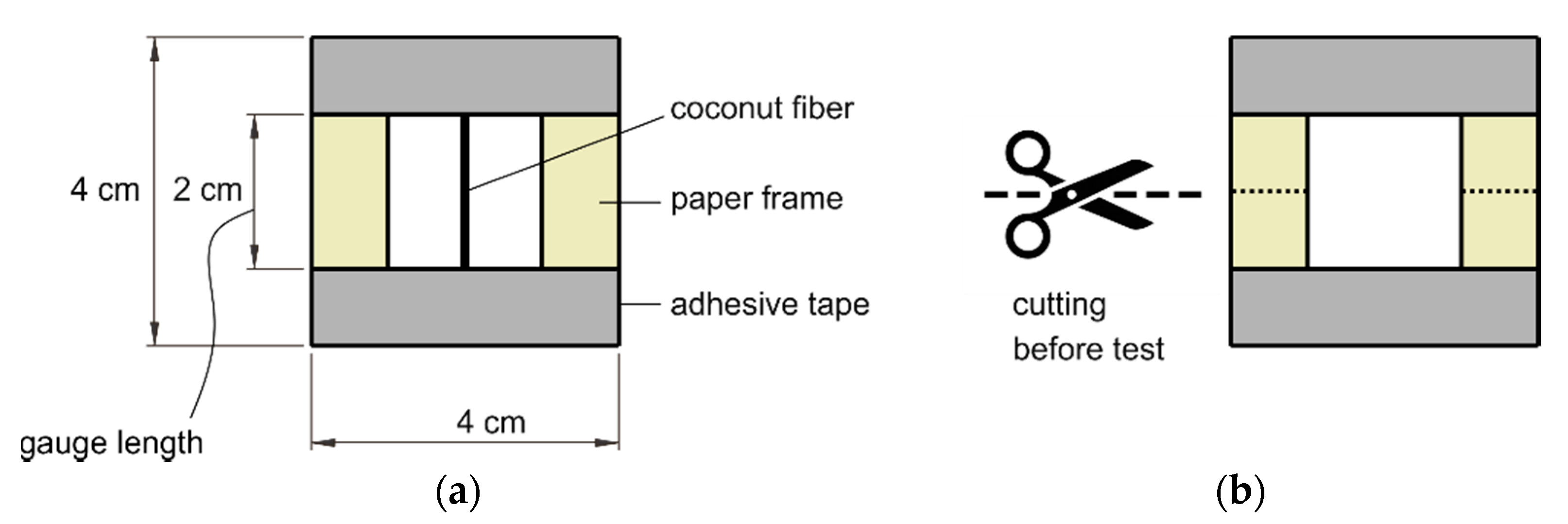

2.2.5. Direct Tensile Test

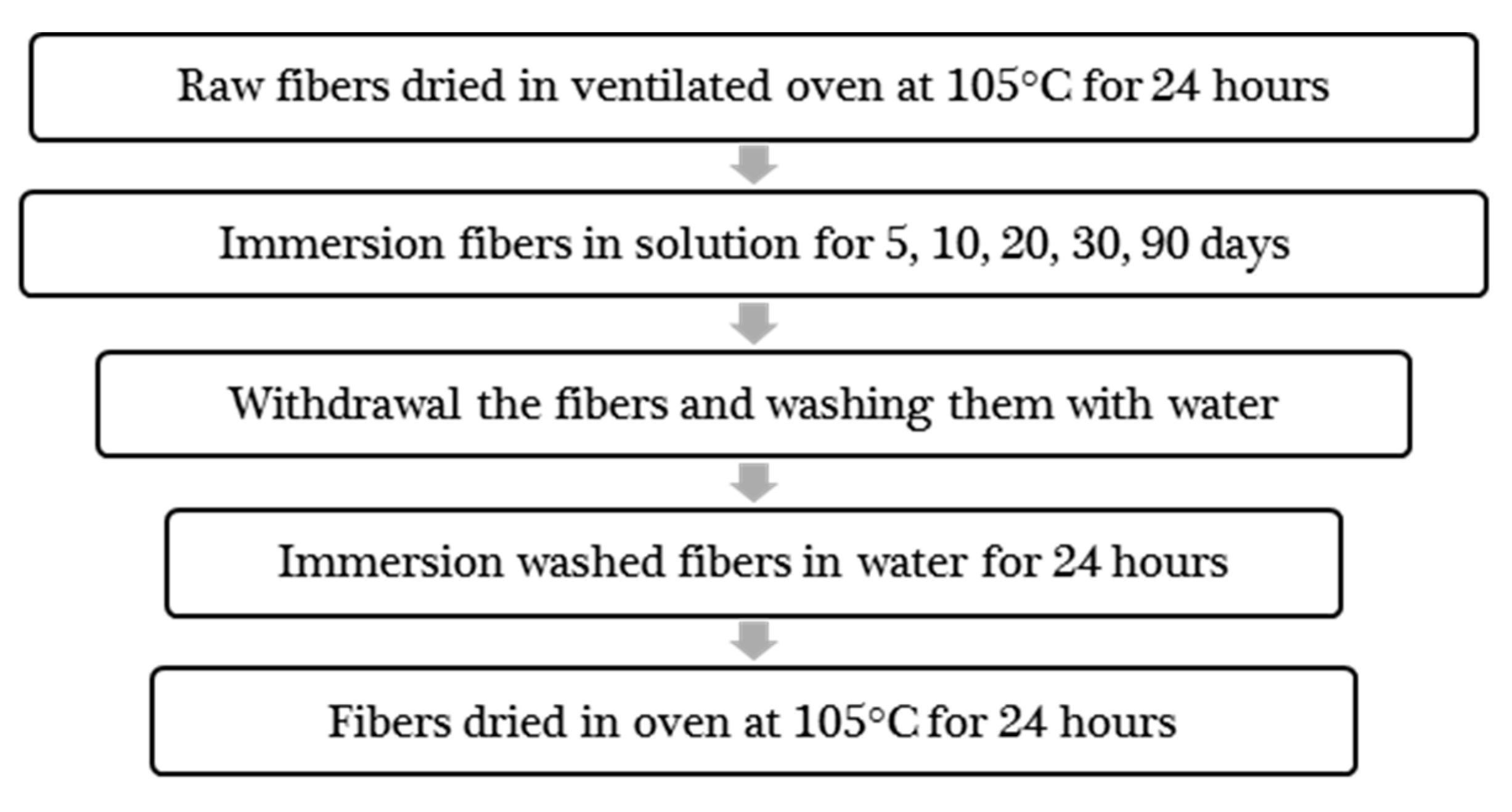

2.2.6. Durability

2.2.7. Thermal Stability

2.2.8. Chemical Stability

3. Results and Discussion

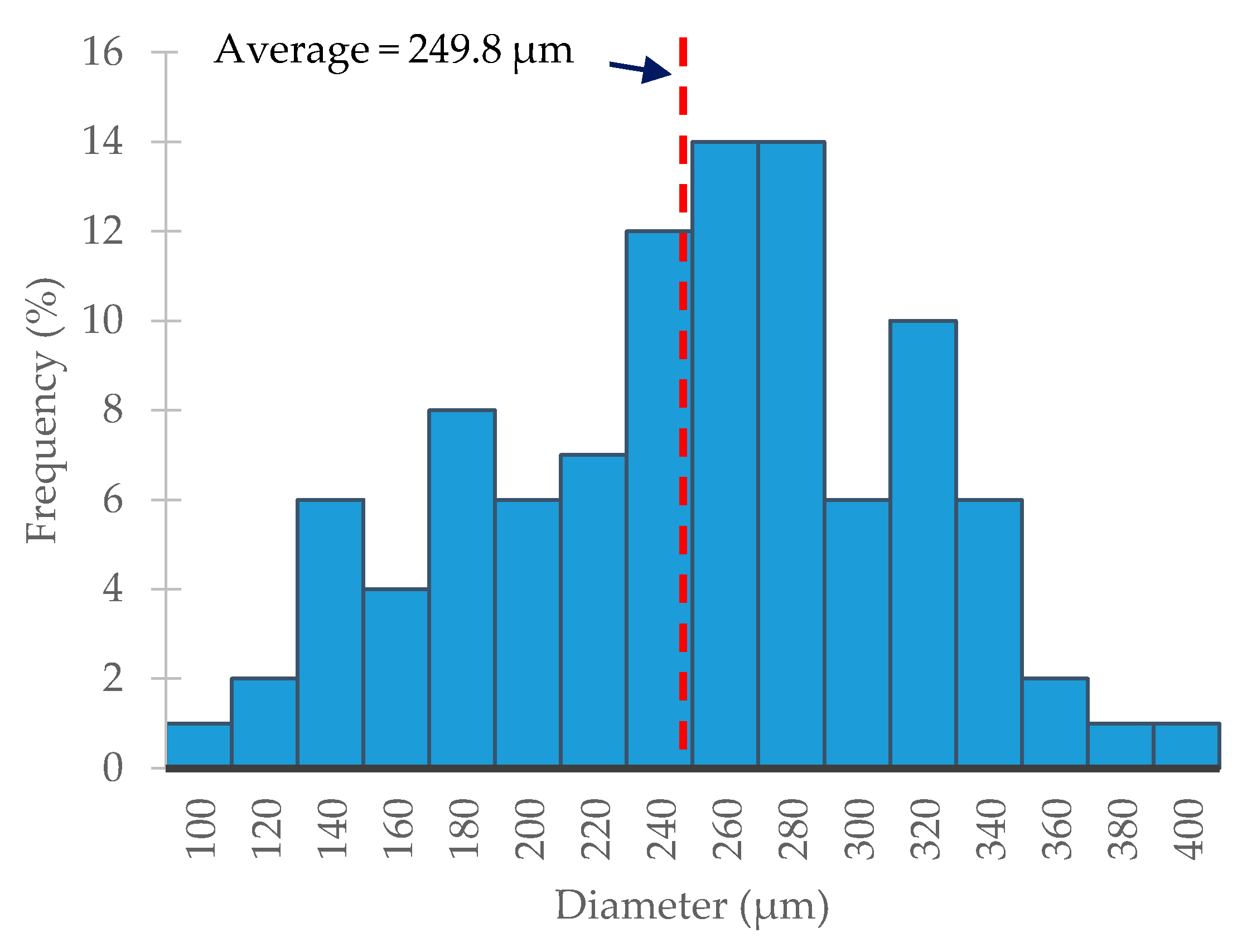

3.1. Geometrical Properties

3.2. Physical Properties

3.3. Thermal Conductivity

3.4. Mechanical Properties

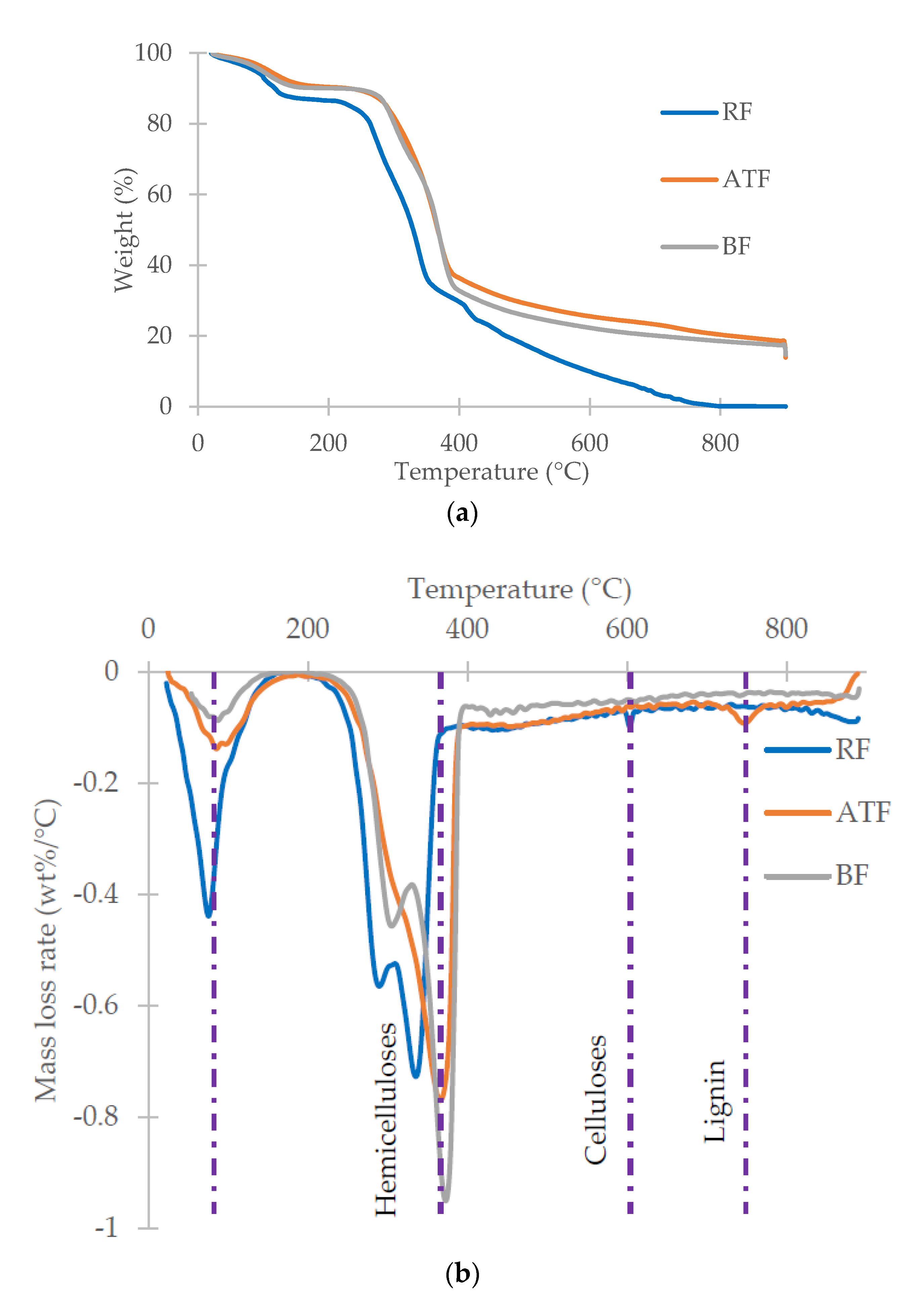

3.5. Thermogravimetric Analysis

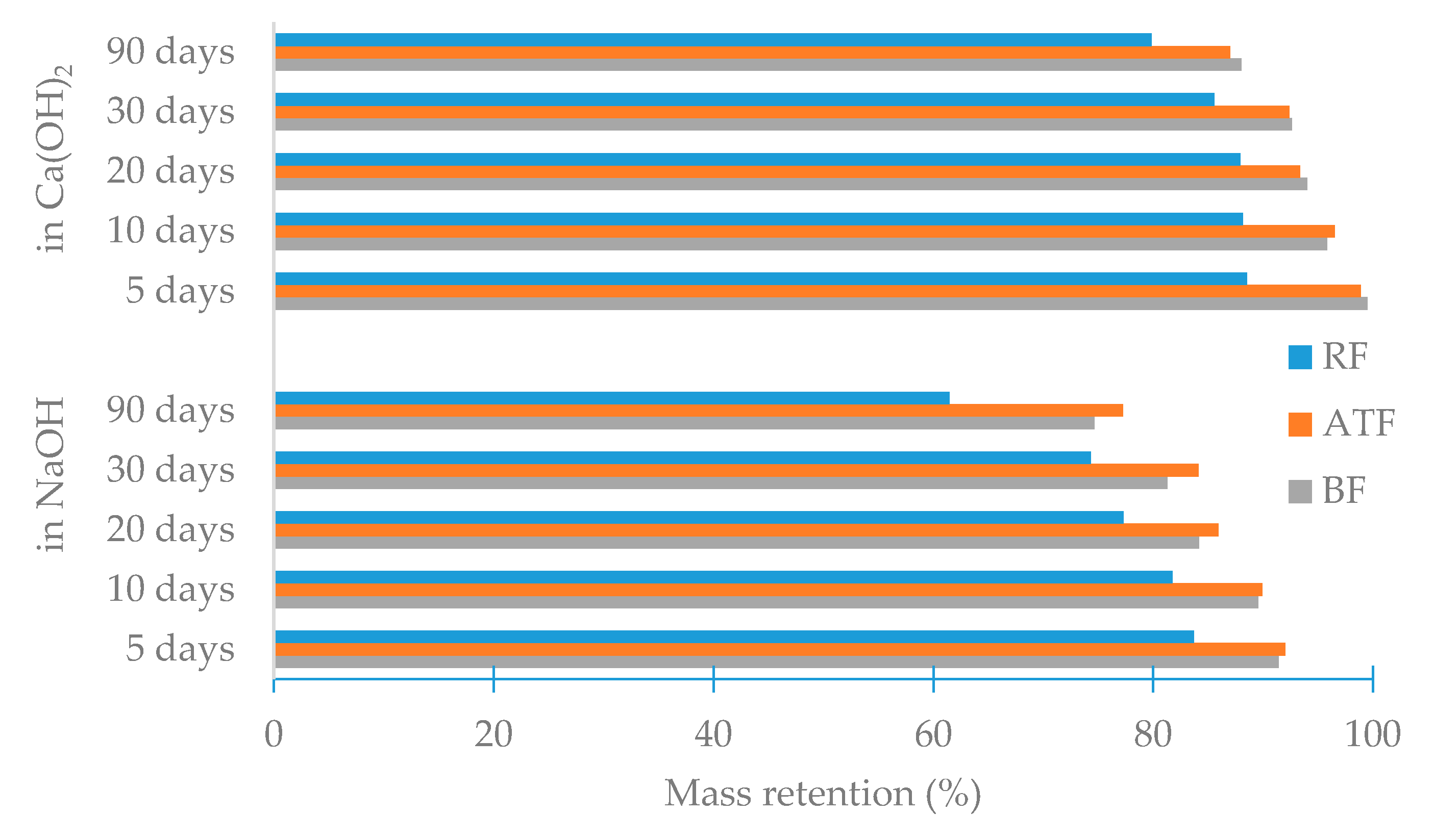

3.6. Chemical Durability

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liew, K.M.; Sojobi, A.O.; Zhang, L.W. Green concrete: Prospects and challenges. Constr. Build. Mater. 2017. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Suntijitto, A. Properties of natural fiber cement materials containing coconut coir and oil palm fibers for residential building applications. Constr. Build. Mater. 2015, 664–669. [Google Scholar] [CrossRef]

- Verma, D.; Gope, P.C.; Shandilya, A.; Gupta, A.; Maheshwari, M.K. Coir fibre reinforcement and application in polymer composites: A review. J. Mater. Environ. Sci. 2013, 4, 263–276. [Google Scholar]

- Abdullah, A.; Jamaludin, S.B.; Anwar, M.I.; Noor, M.M.; Hussin, K. Assessment of physical and mechanical properties of cement panel influenced by treated and untreated coconut fiber addition. Phys. Procedia 2011. [Google Scholar] [CrossRef]

- Kanning, R.C.; Portella, K.F.; Bragança, M.O.G.P.; Bonato, M.M.; Santos, J.C.M.D. Banana leaves ashes as pozzolan for concrete and mortar of Portland cement. Constr. Build. Mater. 2014, 460–465. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Recycling woven plastic sack waste and PET bottle waste as fiber in recycled aggregate concrete: An experimental study. Waste Manag. 2018, 79–93. [Google Scholar] [CrossRef]

- FAO. International Year of Natural Fibres. 2009. Available online: http://www.naturalfibres2009.org/ (accessed on 15 December 2017).

- Abraham, E.; Deepa, B.; Pothen, L.A.; Cintil, J.; Thomas, S.; John, M.J.; Anandjiwala, R.; Narine, S.S. Environmental friendly method for the extraction of coir fibre and isolation of nanofibre. Carbohydr. Polym. 2013, 1477–1483. [Google Scholar] [CrossRef]

- FAO. Jute, kenaf, sisal, abaca, coir and allied fibres. In Statistical Bulletin 2016; CCP: JU/HF/ST/2016/1, Market and Policy Analysis of Raw Materials, Horticulture and Tropical (RAMHOT) Products Team, Trade and Markets Division; Food and Agriculture Organization of the United Nations: Rome, Italy, 2017; 33p, Available online: http://www.fao.org/economic/futurefibres/resources2/en/ (accessed on 15 December 2017).

- Munawar, S.S.; Umemura, K.; Kawai, S. Characterization of the morphological, physical, and mechanical properties of seven nonwood plant fiber bundles. J. Wood Sci. 2007, 108–113. [Google Scholar] [CrossRef]

- Sengupta, S.; Basu, G.; Chakraborty, R.; Thampi, C.J. Stochastic analysis of major physical properties of coconut fibre. Indian J. Fibre Text. Res. 2014, 39, 14–23. [Google Scholar]

- Tran, L.Q.N.; Minh, T.N.; Fuentes, C.A.; Chi, T.T.; van Vuure, A.W.; Verpoest, I. Investigation of microstructure and tensile properties of porous natural coir fibre for use in composite materials. Ind. Crops Prod. 2015, 437–445. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Huang, L.; Kasal, B. Effect of alkali treatment on microstructure and mechanical properties of coir fibres, coir fibre reinforced-polymer composites and reinforced-cementitious composites. Constr. Build. Mater. 2016. [Google Scholar] [CrossRef]

- Ramli, M.; Kwan, W.H.; Abas, N.F. Strength and durability of coconut-fiber-reinforced concrete in aggressive environments. Constr. Build. Mater. 2013, 554–566. [Google Scholar] [CrossRef]

- Ezekiel, N.; Ndazi, B.; Nyahumwa, C.; Karlsson, S. Effect of temperature and durations of heating on coir fibers. Ind. Crops Prod. 2011, 638–643. [Google Scholar] [CrossRef]

- Oda, S.; Fernandes, J.L.; Ildefonso, J.S. Analysis of use of natural fibers and asphalt rubber binder in discontinuous asphalt mixtures. Constr. Build. Mater. 2012, 13–20. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Pereira, T.V.C.; Gomes, O.D.F.M.; Silva, F.D.; Filho, R.D.T. The effect of fiber morphology on the tensile strength of natural fibers. J. Mater. Res. Technol. 2013, 149–157. [Google Scholar] [CrossRef]

- Rana, S.; Fangueiro, R. Fibrous and textile materials for composite applications. In Textile Science and Clothing Technology; Springer: Singapore, 2016. [Google Scholar] [CrossRef]

- Adekunle, K.F. Surface Treatments of Natural Fibres—A Review: Part 1. Open J. Polym. Chem. 2015, 41–46. [Google Scholar] [CrossRef]

- Basu, G.; Mishra, L.; Jose, S.; Samanta, A.K. Accelerated retting cum softening of coconut fibre. Ind. Crops Prod. 2015, 66–73. [Google Scholar] [CrossRef]

- Khan, G.M.A.; Alam, M.S.; Terano, M. Thermal characterization of chemically treated coconut husk fibre. Indian J. Fibre Text. Res. 2012, 37, 20–26. [Google Scholar]

- da Silva, E.J.; Marques, M.L.; Velasco, F.G.; Junior, C.F.; Luzardo, F.M.; Tashima, M.M. A new treatment for coconut fibers to improve the properties of cement-based composites—Combined effect of natural latex/pozzolanic materials. Sustain. Mater. Technol. 2017. [Google Scholar] [CrossRef]

- Sood, M.; Dwivedi, G. Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egypt. J. Pet. 2017. [Google Scholar] [CrossRef]

- Rodríguez, N.J.; Yáñez-Limón, M.; Gutiérrez-Miceli, F.A.; Gomez-Guzman, O.; Matadamas-Ortiz, T.P.; Lagunez-Rivera, L.; Feijoo, J.A.V. Assessment of coconut fibre insulation characteristics and its use to modulate temperatures in concrete slabs with the aid of a finite element methodology. Energy Build. 2011. [Google Scholar] [CrossRef]

- Haque, M.M.; Hasan, M.; Islam, M.S.; Ali, M.E. Physico-mechanical properties of chemically treated palm and coir fiber reinforced polypropylene composites. Bioresour. Technol. 2009. [Google Scholar] [CrossRef] [PubMed]

- Manohar, K. Experimental Investigation of Building Thermal Insulation from Agricultural By-products. Br. J. Appl. Sci. Technol. 2012, 227–239. [Google Scholar] [CrossRef]

- Alavez-Ramirez, R.; Chiñas-Castillo, F.; Morales-Dominguez, V.; Ortiz-Guzman, M.; Lara-Romero, J. Thermal lag and decrement factor of a coconut-ferrocement roofing system. Constr. Build. Mater. 2014. [Google Scholar] [CrossRef]

- Damfeu, J.C.; Meukam, P.; Jannot, Y. Modeling and measuring of the thermal properties of insulating vegetable fibers by the asymmetrical hot plate method and the radial flux method: Kapok, coconut, groundnut shell fiber and rattan. Thermochim. Acta 2016, 64–77. [Google Scholar] [CrossRef]

- Danso, H. Properties of Coconut, Oil Palm and Bagasse Fibres: As Potential Building Materials. Procedia Eng. 2017, 1–9. [Google Scholar] [CrossRef]

- Khedari, J.; Charoenvai, S.; Hirunlabh, J. New insulating particleboards from durian peel and coconut coir. Build. Environ. 2003, 38, 435–441. [Google Scholar] [CrossRef]

- Babu, G.L.S.; Vasudevan, A.K. Strength and Stiffness Response of Coir Fiber-Reinforced Tropical Soil. J. Mater. Civ. Eng. 2008, 571–577. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 100–116. [Google Scholar] [CrossRef]

- Stevulova, N.; Estokova, A.; Cigasova, J.; Schwarzova, I.; Kacik, F.; Geffert, A. Thermal degradation of natural and treated hemp hurds under air and nitrogen atmosphere. J. Therm. Anal. Calorim. 2017, 1649–1660. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Aubert, J.E.; Magniont, C.; Tribout, C.; Bertron, A. Plant aggregates and fibers in earth construction materials: A review. Constr. Build. Mater. 2016, 719–734. [Google Scholar] [CrossRef]

- Amziane, S.; Collet, F.; Lawrence, M.; Magniont, C.; Picandet, V.; Sonebi, M. Recommendation of the RILEM TC 236-BBM: Characterisation testing of hemp shiv to determine the initial water content, water absorption, dry density, particle size distribution and thermal conductivity. Mater. Struct. Constr. 2017, 1–11. [Google Scholar] [CrossRef]

- Sair, S.; Oushabi, A.; Kammouni, A.; Tanane, O.; Abboud, Y.; el Bouari, A. Mechanical and thermal conductivity properties of hemp fiber reinforced polyurethane composites. Case Stud. Constr. Mater. 2018, 203–212. [Google Scholar] [CrossRef]

- Zimniewska, M.; Wladyka-Przybylak, M. Natural Fibers for Composite Applications. In Textile Science and Clothing Technology; Fibrous and Textile Materials for Composite Applications; Rana, S., Fangueiro, R., Eds.; Springer: Singapore, 2016. [Google Scholar] [CrossRef]

- Afroz, M.; Patnaikuni, I.; Venkatesan, S. Chemical durability and performance of modified basalt fiber in concrete medium. Constr. Build. Mater. 2017, 191–203. [Google Scholar] [CrossRef]

- Alavez-Ramirez, R.; Chiñas-Castillo, F.; Morales-Dominguez, V.J.; Ortiz-Guzman, M. Thermal conductivity of coconut fibre filled ferrocement sandwich panels. Constr. Build. Mater. 2012, 425–431. [Google Scholar] [CrossRef]

- Hwang, C.L.; Tran, V.A.; Hong, J.W.; Hsieh, Y.C. Effects of short coconut fiber on the mechanical properties, plastic cracking behavior, and impact resistance of cementitious composites. Constr. Build. Mater. 2016. [Google Scholar] [CrossRef]

- Nguyen, X.T.; Hou, S.; Liu, T.; Han, X. A potential natural energy absorption material—Coconut mesocarp: Part A: Experimental investigations on mechanical properties. Int. J. Mech. Sci. 2016. [Google Scholar] [CrossRef]

- Sengupta, S.; Basu, G. Chapter 04122—Properties of Coconut Fiber, Ref. Modul. Mater. Sci. Mater. Eng. 2017, 1–20. [Google Scholar] [CrossRef]

- Andiç-Çakir, Ö.; Sarikanat, M.; Tüfekçi, H.B.; Demirci, C.; Erdoǧan, Ü.H. Physical and mechanical properties of randomly oriented coir fiber-cementitious composites. Compos. Part B Eng. 2014, 49–54. [Google Scholar] [CrossRef]

- Liu, K.; Lu, L.; Wang, F.; Liang, W. Theoretical and experimental study on multi-phase model of thermal conductivity for fiber reinforced concrete. Constr. Build. Mater. 2017. [Google Scholar] [CrossRef]

- Sindhu, K.; Joseph, K.; Joseph, J.M.; Mathew, T.V. Degradation studies of coir fiber/polyester and glass fiber/polyester composites under different conditions. J. Reinf. Plast. Compos. 2007, 1571–1585. [Google Scholar] [CrossRef]

- Asasutjarit, C.; Hirunlabh, J.; Khedari, J.; Charoenvai, S. Development of coconut coir-based lightweight cement board. Constr. Build. Mater. 2007, 277–288. [Google Scholar] [CrossRef]

- Hasan, N.M.; Sobuz, H.R.; Sayed, M.S.; Islam, M.S. The use of coconut fiber in the production of structural lightweight concrete. Appl. Sci. 2012, 12, 831–839. [Google Scholar]

- Asasutjarit, C.; Charoenvai, S.; Hirunlabh, J.; Khedari, J. Composites: Part B Materials and mechanical properties of pretreated coir-based green composites. Compos. Part B 2009, 633–637. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Silva, F.D.A.; Lima, P.R.L.; Filho, R.D.T. Effect of fiber treatments on the sisal fiber properties and fiber-matrix bond in cement based systems. Constr. Build. Mater. 2015, 730–740. [Google Scholar] [CrossRef]

- Arsyad, M.; Wardana, I.; Irawan, Y.S. The morphology of coconut fiber surface under chemical treatment. Rev. Mater. 2015, 169–177. [Google Scholar] [CrossRef]

- Rawangkul, R.; Khedari, J.; Hirunlabh, J.; Zeghmati, B. Characteristics and performance analysis of a natural desiccant prepared from coconut coir. ScienceAsia 2010, 216–222. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Cementitious building materials reinforced with vegetable fibres: A review. Constr. Build. Mater. 2011, 575–581. [Google Scholar] [CrossRef]

- Page, J.; Khadraoui, F.; Boutouil, M.; Gomina, M. Multi-physical properties of a structural concrete incorporating short flax fibers. Constr. Build. Mater. 2017, 344–353. [Google Scholar] [CrossRef]

- Sen, T.; Reddy, H.N.J. Application of sisal, bamboo, coir and jute natural composites in structural upgradation. Int. J. Innov. Manag. Technol. 2011, 186–191. [Google Scholar] [CrossRef]

- Millogo, Y.; Aubert, J.E.; Hamard, E.; Morel, J.C. How properties of kenaf fibers from Burkina Faso contribute to the reinforcement of earth blocks. Materials 2015, 2332–2345. [Google Scholar] [CrossRef]

- Pinto, J.; Cruz, D.; Paiva, A.; Pereira, S.; Tavares, P.; Fernandes, L.; Varum, H. Characterization of corn cob as a possible raw building material. Constr. Build. Mater. 2012, 28–33. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 1–17. [Google Scholar] [CrossRef]

- Guillou, J.; Lavadiya, D.N.; Munro, T.; Fronk, T.; Ban, H. From lignocellulose to biocomposite: Multi-level modelling and experimental investigation of the thermal properties of kenaf fiber reinforced composites based on constituent materials. Appl. Therm. Eng. 2018, 1372–1381. [Google Scholar] [CrossRef]

- Gu, H. Tensile behaviours of the coir fibre and related composites after NaOH treatment. Mater. Des. 2009, 3931–3934. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 939–948. [Google Scholar] [CrossRef]

- Kumar, S.M.S.; Duraibabu, D.; Subramanian, K. Studies on mechanical, thermal and dynamic mechanical properties of untreated (raw) and treated coconut sheath fiber reinforced epoxy composites. Mater. Des. 2014, 63–69. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 2883–2892. [Google Scholar] [CrossRef]

- Li, Y.; Mai, Y.W.; Ye, L. Sisal fibre and its composites: A review of recent developments. Compos. Sci. Technol. 2000, 2037–2055. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Improving degradation resistance of sisal fiber in concrete through fiber surface treatment. Appl. Surf. Sci. 2014, 511–523. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem. Concr. Res. 2015, 1–16. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 1781–1788. [Google Scholar] [CrossRef]

| Fiber | Average Value (g/cm3) | Standard Deviation (g/cm3) |

|---|---|---|

| Raw fiber (RF) | 1.41 | 0.0014 |

| Alkali-treated fiber (ATF) | 1.51 | 0.0014 |

| Boiled fiber (BF) | 1.50 | 0.0010 |

| Type of Fiber | Initial Rate of Absorption IRA in % | The Slope of the Curve K1 |

|---|---|---|

| RF | 77.82 | 7.86 |

| ATF | 84.28 | 6.42 |

| BF | 31.67 | 2.21 |

| Reference | Type of Fiber | Water Absorption in % |

|---|---|---|

| [29] | Oil palm | 54 |

| [53] | Flax | 132 |

| Present study | Coconut | 133 |

| [54] | Bamboo | 145 |

| [29] | Bagasse | 153 |

| [49] | Sisal | 180 |

| [55] | Kenaf | 307 |

| [56] | Corn cob | 327 |

| Type of Fiber | Tensile Strength at Failure (MPa) | Tensile Strain at Failure (%) |

|---|---|---|

| RF | 123.6 ± 37.6 | 26.9 ± 9.9 |

| ATF | 111.2 ± 16.3 | 31.8 ± 10.6 |

| BF | 105.9 ± 10.3 | 40.7 ± 11.7 |

| Reference | Type of Fiber | Tensile Strength at Failure (MPa) | Tensile Strain (%) |

|---|---|---|---|

| Present study | Coconut fiber | 123.6 ± 37.6 | 26.9 ± 9.9 |

| [62] | Jute fiber | 393.0–773.0 | 1.1–1.5 |

| [63] | Sisal fiber | 530.0–640.0 | 3.0–7.0 |

| [53] | Flax fiber | 1254.0 ± 456.0 | ±0.6 |

| Type of Fiber | Transition Temperature Range (°C) | Mass Loss (%) | Residue Left at 900 °C (%) |

|---|---|---|---|

| RF | 20–140 | 12.39 | 0.05 |

| 140–390 | 44.40 | ||

| 390–600 | 33.31 | ||

| 600–900 | 9.85 | ||

| ATF | 20–140 | 8.02 | 13.94 |

| 140–390 | 46.16 | ||

| 390–600 | 20.28 | ||

| 600–900 | 11.60 | ||

| BF | 20–140 | 9.37 | 14.63 |

| 140–390 | 45.60 | ||

| 390–600 | 22.76 | ||

| 600–900 | 7.64 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bui, H.; Sebaibi, N.; Boutouil, M.; Levacher, D. Determination and Review of Physical and Mechanical Properties of Raw and Treated Coconut Fibers for Their Recycling in Construction Materials. Fibers 2020, 8, 37. https://doi.org/10.3390/fib8060037

Bui H, Sebaibi N, Boutouil M, Levacher D. Determination and Review of Physical and Mechanical Properties of Raw and Treated Coconut Fibers for Their Recycling in Construction Materials. Fibers. 2020; 8(6):37. https://doi.org/10.3390/fib8060037

Chicago/Turabian StyleBui, Huyen, Nassim Sebaibi, Mohamed Boutouil, and Daniel Levacher. 2020. "Determination and Review of Physical and Mechanical Properties of Raw and Treated Coconut Fibers for Their Recycling in Construction Materials" Fibers 8, no. 6: 37. https://doi.org/10.3390/fib8060037

APA StyleBui, H., Sebaibi, N., Boutouil, M., & Levacher, D. (2020). Determination and Review of Physical and Mechanical Properties of Raw and Treated Coconut Fibers for Their Recycling in Construction Materials. Fibers, 8(6), 37. https://doi.org/10.3390/fib8060037