Abstract

Fluorescence microscopy was applied to understand adhesion interfaces developed within laminated composite sandwiches formed between poly(lactic acid) (PLA) and wood veneers. Composites formed with maple veneer had greater tensile bond strength when manufactured at 200 °C (10.4 N/mm2) compared to formation at 140 °C (8.7 N/mm2), while significantly lower bond strength was achieved using spruce veneers, at 5.2 and 3.5 N/mm2, respectively. Qualitative and quantitative confocal microscopy assessments revealed differing bondline thicknesses and PLA ingress within the wood ultrastructure. Forming maple veneer composites at 200 °C promoted greater PLA mobility away from the bondline to reinforce the wood–PLA interface and deliver associated greater composite bond strength. The addition of 25% wood fibre to PLA led to fibre alignment and overlap within bondlines contributing to relatively thicker, heterogeneous bondlines. Study outcomes show that the composite processing temperature impacts the adhesion interface and composite performance and will have broad application over veneer overlays, laminates and wood plastic composites (WPCs) using wood, particles or fibres with PLA.

1. Introduction

Composite materials comprising natural fibres with thermoplastic matrixes are increasingly used across many sectors due to their formability, light weight, and design attributes [1]. It is common for wood plastic composites (WPCs) comprising wood-fibre-reinforced or -filled materials to be processed by compounding, extrusion, and injection and compression moulding for a range of product applications [2]. In addition to wood or other natural fibres, these composite materials can also contain renewable or sustainable matrixes such as poly(lactic acid) (PLA), a biodegradable polyester. As a replacement for the polyolefin plastics typically used in composites, such materials also offer additional economic and environmental advantages with respect to their end of life [3,4]. Poly(lactic acid) has been broadly considered for a range of applications including plastic components, films, packaging and paperboard products [3,4,5]. This includes PLA being evaluated in WPC materials for a range of applications [6]. Recently, the use of PLA in WPC materials has also been adapted to wood veneer to understand the adhesion developed at the wood–plastic interface [7,8]. In this wood laminate form, significant adhesion can be developed between the wood substrate and PLA on composite consolidation. This adhesion is developed over a range of scales from molecular- to macro-scale [8]. Initial evaluations of composite sandwiches formed with differing grades of PLA polymer and wood veneer species found a dependency between composite formation and performance with temperature [7]. However, it was also revealed at the micro-scale that the PLA bondline thickness between veneer surfaces within laminates may also dictate composite performance. Therefore, to develop the processing and performance of these promising composites, further understanding of the PLA adhesion, interactions and interphase at a wood cellular level is required.

In order to further develop a fundamental understanding of the PLA adhesion interface at a wood cellular level, further investigative analysis is required. A range of techniques are available to determine interfacial properties and behaviours at a wood ultrastructure level and include X-ray fluorescence microscopy, nanoindentation, scanning thermal microscopy and UV microscopy [9]. In the case of the latter, UV microscopy coupled with fluorescently tagged polyesters was initially applied to PLA-based WPCs to visualise interactions of PLA with wood fibre at microscale [10]. However, direct application of this methodology to composite sandwiches at a wood cellular level requires more investigation due to the challenges of distinguishing the PLA fluorescent chromophore from natural fibre components [7,11]. In the current paper a fluorescence microscopy methodology is further developed to quantify PLA polymer bondlines and interfacial adhesion developed between PLA and different wood species. By using two differing composite processing temperatures to alter PLA properties such as polymer flow and mobility, PLA migration into the ultrastructure of different wood species is characterised and compared with the composite performance. The outcomes of this study can be translated to the formation and integrity of wood interfaces with PLA or other polymers in a range of different WPCs, natural fibres and plastics applications.

2. Materials and Methods

Sycamore maple (Acer pseudoplatanus, hardwood) and spruce (Picea abies, softwood) sliced veneers (0.6 mm thickness) were used as wood substrates. Veneer specimens (100 × 20 mm2) were cut from veneer sheets and conditioned at 20 °C/65% relative humidity prior to sandwich composite formation. The amorphous grade of poly(lactic acid) (PLA) polymer was Ingeo 4060D and sourced from NatureWorks (Blair, NE, USA). This PLA was dried for 12 h under vacuum prior to any processing. Acriflavine, as acriflavine neutral chloride was obtained from Acros Organics (distributed by Thermo Fisher Scientific New Zealand Ltd.) and used as received. The wood fibres were generated by mechanically pulping Pinus radiata (softwood) chips using medium-density fibreboard processing conditions. These fibres were flash dried to <12% moisture content (mc) at the time of production and further dried (<8% mc) immediately prior to compounding with PLA.

2.1. Fluorescence Chromophore Label Grafting to PLA

Using a modified methodology [10], PLA polymer was first dissolved in chloroform in a round-bottom flask. This flask was immersed in an oil bath and heated at 60–70 °C while maintaining stirring. In a separate flask, acriflavine (nominally 0.1% w/w on PLA) was dissolved in water and then neutralised to ca. pH 8 with 1 M sodium hydroxide. The aqueous solution was poured into the chloroform solution to form a heterogeneous reaction mixture. Heating of this reaction mixture was continued at 60–70 °C under reflux for 17 h. After cooling, the solution was separated by centrifuging and washing the chloroform phase with water. Water washing was continued until the washings were deemed colourless. The residual PLA/chloroform solution was then poured onto an aluminium tray and allowed to evaporate at ambient temperature for at least 24 h. After evaporating, the fluorescently labelled PLA was recovered and further dried under vacuum at 45 °C for 24 h to produce an estimated 0.07% acriflavine loading on PLA as a PLA master batch (Supplementary Materials).

2.2. Labelled PLA Compounding and Sheet (Foil) Preparation

A Haake Rheomix Rheomex 600 OS mixer equipped with Roller Rotors from Thermo Scientific (Germany) was employed to process the fluorescence-labelled PLA master batch with varying quantities of pure PLA. Mixing was performed at 170 °C for 1 min to obtain final fluorescence chromophore concentrations ranging from 0.005% to 0.015% acriflavine (w/w on PLA). These fluorescently labelled PLAs were produced on ca. 50 g scale.

This melt mixing procedure was also applied to mix the labelled PLA with wood fibre. One extrusion run was sufficient to mix the fluorescently labelled PLA master batch, pure PLA and wood fibres with compounding also undertaken at 170 °C for 1 min to minimise any fluorescence degradation. The final PLA/wood fibre contents were 95/5 and 75/25 on an oven dry basis.

PLA sheets/foils were formed on a hot press (300 × 300 mm2) (Weverk, Sweden) using a platen temperature of 180 °C. A small amount of labelled PLA (1–5 g) was placed between two 0.8 mm aluminium plates covered with Teflon sheets and separated by 0.3 mm spacer bars. A pressure of 50 kN was applied for ca. 45 s (<1 min total pressing time). The recovered PLA foils were typically 200–300 µm thickness.

2.3. Composite Sandwich Formation and Automated Bond Evaluation System (ABES) Testing

A modified ABES instrument from Adhesive Evaluation Systems (Corvallis, OR, USA) was used to prepare and test composite sandwiches in situ [8]. The wood veneer strips (20 × 100 mm2) were mounted with a 5 mm overlap and a PLA foil section (2.7 × 20 mm2) was positioned between the overlapped veneer strips. The press heads were then closed and composite sandwich assembly hot-pressed at either 140 or 200 °C for 20 s with a constant pressing force (190 N) for each variation. At the completion of the hot-pressing step, the press heads were rapidly cooled to 45 °C with the press heads still closed. After achieving 45 °C for 10 s, the press heads were opened and the composite sandwich then tested (pulled) in tension recording the break load. At least 8 replicates were prepared and tested for each sample set. Samples for microscopy-only evaluation were prepared as above, but after cooling to 45 °C each specimen was removed from the ABES equipment untested.

2.4. Confocal Microscopy Analysis

A confocal TCS SP5 microscope (Leica, Germany) was used for all assessments of PLA fluorescence, PLA/wood fibres combinations (as foils) and composite sandwich bondlines. Samples from foils or sectioning bondlines from composite sandwiches were prepared by either cutting 2–3 mm sections or microtoming 20–30 µm sections of bonded veneers, respectively. Bondline images were acquired with a 10× or 60× lens at a resolution of 1024 × 1024 pixels and a stepwise depth of 2–3.5 µm. Excitation wavelengths were 476 nm and 561 nm (Argon laser) and fluorescence was recorded at 488–507 nm and 570–707 nm. Photomultiplier gain settings were adjusted for every image to avoid overexposure. Typically, 10 images of each bondline were obtained per sample. The image stacks were projected to a single image using maximum intensity projection (Leica Application Suite Advanced Fluorescence Lite (LAS AF Lite software, Germany). Emissions in the 488–507 nm region are represented in green and emissions in the 570–707 nm region are represented in red in microscopy images (Figure 1). Additional, selected images are also available in Supplementary Materials.

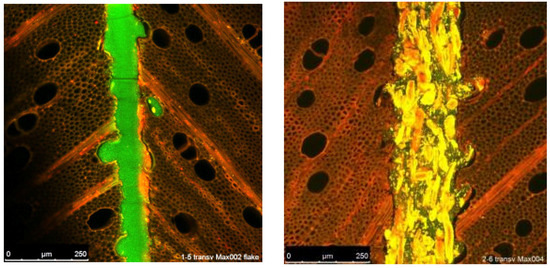

Figure 1.

Representative images of bondlines formed with maple veneer and poly(lactic acid) (PLA) foil produced by microtoming a 20–30 µm section (left), and maple veneer and PLA foil containing 25% wood fibres cut as a 2–4 mm section from the composite (right). PLA is green and wood and wood fibre is red-yellow. The bondline thickness is defined as the distance between the two veneer faces.

Composite sandwich bondline thickness was also measured using the LAS AF Lite software. The bondline thickness was determined as the distance between the two wood veneer surfaces, perpendicular to the direction of the bondline (Figure 1, and also see Supplementary Materials). Regions where PLA was present in vesicular structures or surface defects were not included in these measurements.

3. Results and Discussion

3.1. Fluorescence Chromophore Grafting to PLA

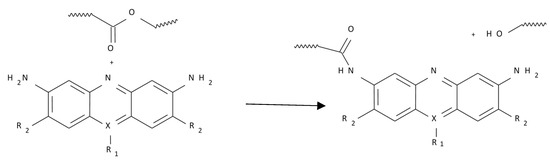

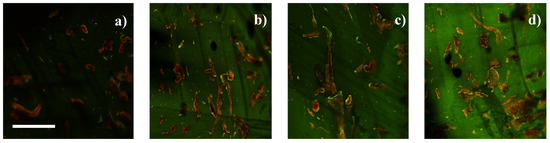

An appropriate fluorescence label concentration for poly(lactic acid) (PLA) foils was required to achieve the quality microscopy images produced in this study. The fluorescence of labelled PLA needed to match the inherent autofluorescence intensities of wood components within the hardwood and softwood veneer sandwiches and fibres, respectively [12]. Higher acriflavine chromophore concentrations (>0.05% w/w) have been used previously for polyester wood–plastic composites [10], but with wood veneer laminates this chromophore concentration and a lower degree of thermomechanical processing led to undesirably high PLA fluorescence intensity relative to the lignin autofluorescence [7]. This necessitated improving the acriflavine–PLA grafting via amido-functionalisation (Scheme 1) and better anticipating any thermally induced fluorophore degradation. Coupled with efficient washing [11], master batches of fluorescently labelled PLA could be readily produced at >60 °C without significant PLA hydrolysis or polymer de-esterification and impact to PLA polymer properties. At softwood fibre loadings of 5% w/w in PLA, the wood fibres could be distinguished across a range of acriflavine loadings from 0.007 to 0.015% on PLA (w/w, Figure 2). To ensure sufficient distinctions between PLA and the different wood species used in this study a chromophore concentration of 0.0075% was used and facilitated by microscope photomultiplier adjustments. The lack of any discernible chromophore leaching at this loading was also evident in images such as Figure 1 and Figure 2. Furthermore, polymer analysis indicated that the grafting, compounding, and master batching had minimal effect on fluorescently labelled PLA properties including further processing to combine with wood fibre, PLA foil production and ABES testing (Supplementary Materials).

Scheme 1.

Proposed modification of poly(lactic acid) polymer with acriflavine. Conditions: water/chloroform, 60 °C.

Figure 2.

Confocal laser scanning microscopy images showing differing acriflavine concentrations in PLA. Labelled PLA (green) compounded with softwood medium-density fibreboard wood fibres (red): (a) 0.005% labelled PLA; (b) 0.0075% labelled PLA; (c) 0.01% labelled PLA; (d) 0.015% labelled PLA. Scale bar is 500 µm.

3.2. Composite Sandwich Formation and In Situ Testing

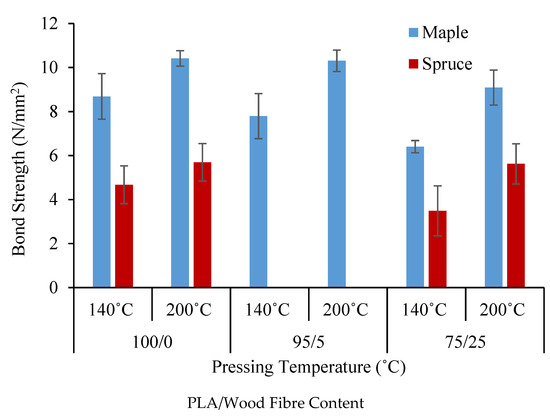

Composite sandwiches were prepared using maple or spruce veneers and labelled PLA foils containing 0% to 25% wood fibre using the established ABES processing methodology [8]. Composite sandwiches were manufactured at two temperatures, 140 and 200 °C, and then evaluated in situ via ABES tensile testing. Pressing temperature and wood fibre content both influenced the bond strength of maple veneer composites (Figure 3). With PLA only, pressing at 140 °C gave a bond strength value of 8.7 N/mm2, whereas composites formed at 200 °C had significantly greater values (10.4 N/mm2). This distinction in performance with temperature has been observed previously for a range of thermoplastic composite sandwiches [8] and was also consistent with the results obtained for semi-crystalline and amorphous grades of PLA [7]. With PLA being a relatively rigid, brittle polymer, these composite sandwiches were also evaluated with 5% and 25% wood fibre added to the PLA to understand any beneficial reinforcing effects of the fibres. An increase in strength and stiffness is typically seen in WPCs with natural fibre use [13]. Addition of 5% wood fibre to the PLA foil did not impact the bond strength developed at either temperature. At 25% wood fibre content, bondlines formed at 140 °C have lower bond strength values (6.4 N/mm2) compared with pure PLA. When pressed at 200 °C the 25% wood fibre content does not reduce the bondline strength (9.1 N/mm2).

Figure 3.

Comparisons of average tensile bond strength values for composites produced with maple and spruce veneers with 0% to 25% wood fibre content in PLA foils. Error bars are 0.05 significance level.

Using spruce veneer and PLA led to lower bondline performance with or without wood fibre (Figure 3). The pure PLA composites prepared at 200 °C appeared to have greater average bond strength (5.7 N/mm2) than the composite prepared at 140 °C (4.7 N/mm2), but due to high testing variability, these values were not significantly different (significance level: 0.05). At 25% wood fibre content, the spruce sandwich composites had bond strength values of 5.2 and 3.5 N/mm2 when formed at 200 °C and 140 °C, respectively. Like maple, the presence of 25% wood fibre reduced the bondline strength at the lower press temperature. Pressing spruce samples at 200 °C with 25% wood fibre in PLA did not significantly change bondline performance, consistent with the observation for maple.

3.3. Fluorescence Microscopy

The bondlines formed with PLA and maple or spruce veneers were visualised by confocal microscopy (CLSM, Figure 1, Figure 4, Figure 5, Figure 6 and Figure 7). Fluorescently labelling the PLA produced clear distinctions of this polymer from both wood species as well as any wood fibres additionally contained within each bondline (Figure 1 and Figure 4, with additional images available in Supplementary Materials). The microscopy cross sections of bondlines profile PLA mobility and migration into vesicular structures of the wood, similar to more traditional adhesive bondlines formed in plywood [9,14]. Examples of bondlines contrasting pure PLA and PLA containing 25% softwood fibres are shown in Figure 1. In addition to changes in bondline thickness between veneer surfaces, images contain other pertinent information such as PLA migration away from the bondline, wood fibre distributions and how these fibres were deposited within the bondline in terms of anisotropy and alignment of fibres in the X–Y plane of the bondline.

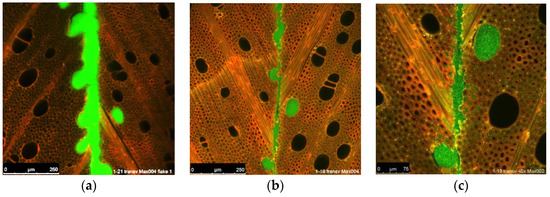

Figure 4.

Representative confocal microscopy (CLSM) images of maple–PLA composite sandwiches formed at (a) 140 °C, transverse view; (b) 200 °C, transverse view; and (c) 200 °C, transverse view at higher magnification.

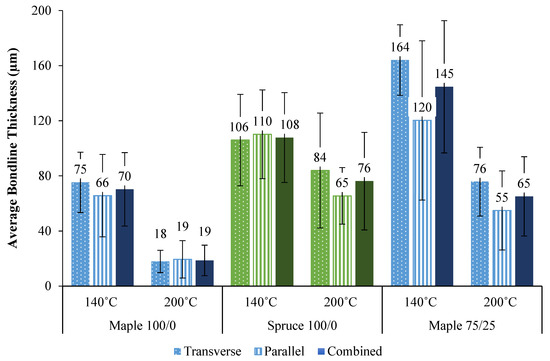

Figure 5.

Comparisons of average bondline thickness values for composites produced with maple and spruce veneers with 0% to 25% wood fibre content in PLA foils. Error bars are 0.05 significance level.

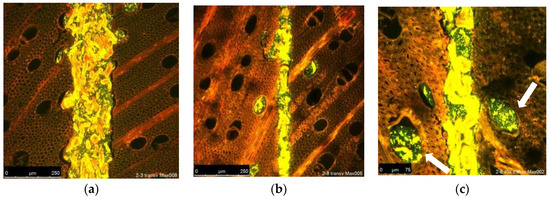

Figure 6.

Representative CLSM images of maple–PLA/25% wood fibre composite sandwiches formed at (a) 140 °C, transverse view; (b) 200 °C, transverse view; and (c) 200 °C, transverse view at higher magnification with arrows showing deposition of wood fines.

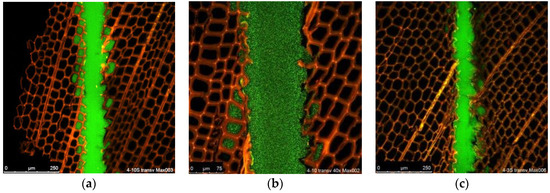

Figure 7.

Representative CLSM images of spruce–PLA composite sandwiches formed at (a) 140 °C, transverse view; (b) 140 °C, transverse view at higher magnification; and (c) 200 °C, transverse view.

3.4. Maple

Shown in Figure 4 are qualitative comparisons of bondlines formed with pure PLA and maple veneer at 140 °C and 200 °C. On pressing at 140 °C, it was evident that the PLA filled the relatively uneven veneer surfaces and was able to flow into the maple vesicular structure. This indicates that PLA possesses some degree of mobility promoted by this pressing temperature and pressure used. At 200 °C, PLA was also observed to migrate into the maple vessels with images showing PLA contained within the vesicular structure. At higher magnification (Figure 4c), which details a relatively rough veneer surface, PLA was observed to have migrated through a range of pores, including vessels, ray cells and within fibre lumens. Moreover, this PLA movement and penetration was via pits and vessels within the wood ultrastructure and appears not to enter fibre cell walls. This flow and behaviour is distinct from those of adhesives and resins which typically exhibit resin migration into cell walls [12,15]. Additionally, across the images (Figure 1 and Figure 4), it was evident that PLA migrated further from the bondline, providing a greater interface with the wood for those samples pressed at 200 °C than for those at the lower temperature.

In addition to visual differences in PLA flow and mobility behaviours, the thickness of maple bondlines pressed at 140 °C typically ranged between 50 µm and 100 µm (Figure 5). This variation in pure PLA bondline thicknesses is evident in Figure 4a. Visually, this thickness was relatively greater than the width of a maple vessel, as observed in Figure 3. Compared to bondlines formed at 140 °C, those formed at 200 °C (Figure 4b) were relatively thinner (10–30 µm) with this attributable to pressing above the PLA melt temperature. Moreover, this relatively thin bondline was consistent with the observed greater PLA migration into the vesicular structure away from the bondline.

For those composite sandwiches formed with PLA containing wood fibres, the images distinguish these softwood fibres from the maple veneer (Figure 1 and Figure 6). For samples pressed at 140 °C (Figure 6), wood fibres appear evenly distributed within the bondline formed between the veneer surfaces. In both transverse and parallel orientations (Figure 6) the expected alignment of fibres parallel with the direction of the bondline is evident. However, this appears to be associated with a high degree of fibre anisotropy within the bondline which was likely induced during both pressing as a foil sheet and then as the composite sandwich. The images also show significant fibre overlaps which appear not to allow veneer surfaces to compress together along the bondline as well as the deposition of fibre debris within the entrances to vessels. It is evident from the images that PLA was still able to migrate into and along open vessels adjacent to the bondline, as observed with pure PLA bondlines (Figure 1 and Figure 4). At higher magnification (Figure 6), wood fines (very small wood fibre particles) within the PLA were observed to have passed into maple vessels during pressing. From these images it is difficult to estimate whether the deposition of this fine material acts to influence PLA mobility away from the bondline. As above, the poor dispersion of wood fibres, together with their overlaps, also inhibits closer contact between veneer surfaces in areas along the bondline, which may be considered a contributor to the large variation observed in bondline thicknesses which range from 50 to 230 µm (Figure 5).

Forming composite sandwiches with PLA/25% wood fibre at higher temperature (Figure 6b) led to a decrease in bondline thickness, as found when using pure PLA foil (Figure 4). Additionally, PLA migrated further into the vessels, as was seen with maple/PLA pressed at 200 °C. As above with the 140 °C sample, fibres align parallel to the bondline. The images show greater PLA migration into the veneer substrate and regions where wood fibres were unevenly spaced and clustered, with some PLA regions dominated by wood fibre fines. At higher magnification (Figure 4c), there were instances where wood fibres may have restricted PLA from entering adjacent veneer wood cell lumens. Moreover, with transversal views of the bondline (Figure 6c), there were relatively fewer areas where PLA was observed within lumens near the bondline compared to with pure PLA use at 200 °C. From these images (Figure 6b,c, Supplementary Materials) it is evident that there was a wide range of bondline thicknesses, but these generally appeared thinner (30–100 µm, Figure 5) than those of the corresponding PLA/25% wood fibre sample pressed at 140 °C (Figure 6a).

3.5. Spruce

Imaging composite sandwiches formed with spruce veneer provided greater visual contrast between this softwood lignin autofluorescence and the acriflavine chromophore compared to those with the maple veneer (Figure 6). In addition to exhibiting earlywood and latewood cell deposition, composite bondlines formed with spruce veneer and pure PLA at 140 °C (Figure 7a) appeared thicker (65–140 µm) than those of composites formed with maple (Figure 4a). Microscopy also revealed evidence of PLA flow into exposed spruce lumens adjacent to the bondline, with higher magnification (Figure 7b) revealing PLA migration up to ca. 100 µm away from the bondline.

Spruce veneer sandwiches pressed at 200 °C (Figure 7c) generally had thinner bondlines with greater PLA migration away from bondlines than found in those pressed at 140 °C (Figure 5 and Figure 7a). Also evident in the transverse views are variations in bondline thickness typical of this sample. Bondline thicknesses ranged between 40 and 130 µm across CLSM images. A greater rate of PLA migration away from bondlines, up to four cells deep, was evident at 200 °C with this migration also extending into ray cells. Although spruce samples were produced with PLA containing wood fibres (Figure 2), only some were imaged (see Supplementary Materials), and these were not extensively analysed as above for maple samples.

3.6. Bondline Thickness Quantification

A summary of average PLA bondline thickness, defined as the distance between veneer surfaces (Supplementary Materials), is provided in Figure 5 and includes bondlines evaluated in both transverse and parallel bondline orientations. Along with the qualitative observations above, bondline measurements undertaken for all images revealed that those samples pressed at 200 °C had relatively thinner bondlines than the corresponding samples pressed at lower temperature. Although the maple–pure PLA sample pressed at 200 °C had the thinnest average bondline thickness (19 µm) of all samples, there was high variability in the thickness values. Bondline thicknesses were 3 times greater for 140 °C samples (70 µm) than for those formed at 200 °C. Furthermore, despite the high variability visually evident in images, these average bondline thickness values were statistically different between the two pressing temperatures. Imaging in both transverse and parallel views also revealed a relative consistency in these bondline measurements. As observed with qualitative observations, addition of wood fibre to PLA led to bondlines which were 3 times thicker (76 µm) than pure PLA bondlines when pressed at 200 °C. In the case of pressing at 140 °C, the presence of wood fibre in PLA produced a 50% greater thickness (108 µm) than pure PLA. However, evident in these quantitative measurements was the substantial variation in bondline thicknesses observed in the qualitative image assessments above (Figure 1 and Figure 6). With spruce veneer, image analysis revealed relatively thicker PLA bondlines than those with maple at both pressing temperatures. While these averaged 76 µm and 108 µm for 200 °C and 140 °C, respectively, these values were not statistically significant, indicative of the high variability across the bondlines surveyed. Moreover, these average thicknesses were more comparable to those observed with maple and PLA with 25% wood fibre.

4. Discussion

Across the microscopy images it was evident that PLA polymer flow and mobility at temperature dictated the PLA bondline thicknesses observed previously in composite sandwich formation [7]. The initial PLA foil thickness (ca. 300 µm) did not define the bondline thickness or the extent of migration into the wood substrate as PLA was additionally squeezed out on pressing; this can also occur when gluing wood with traditional adhesives [16]. While flow of PLA into wood vesicular structures was generally observed (Figure 1, Figure 2, Figure 3, Figure 4, Figure 5, Figure 6 and Figure 7), there was no defined PLA infiltration into wood cell walls of the veneer surface or individual softwood fibres. This is distinct from liquid wood adhesive behaviours where cell wall infiltration is commonly observed [12,14]. This suggests that the greater molecular weight of PLA [14], together with polymer hydrophobicity [9] and/or high viscosity, may restrict PLA mobility into the wood cell wall compared to that of the water-soluble condensation polymers of typical wood adhesive systems [12,14]. Moreover with liquid wood adhesives, adhesive flow can be parameterised to measure adhesive penetration depth from bondlines. However, this can be difficult given the randomness of the wood structure, particularly in hardwoods [14], which was also apparent across the various bondline images in this study. Nonetheless, both the qualitative observations and the quantitative information obtained in this study can be combined to describe how bondline strength is developed during composite sandwich formation and the effect of wood fibre inclusion with PLA.

On pressing composite sandwiches at 200 °C, the PLA has a lower viscosity more comparable to that of liquid adhesives [7]; this contributes to greater PLA mobility into the wood and correspondingly thinner bondlines due to the extent of this ingress (Figure 4 and Figure 7). This presence of PLA in the wood matrix provides a greater interface between the PLA polymer and wood matrix, contributing to better interfacial adhesion as well as the benefit of physical interlocking of PLA within the wood ultrastructure to reinforce the wood–PLA interface. At the same time, the thickness of bondlines being generally less than 100 µm may challenge liquid adhesives’ requirements for thicker (100–800 µm), gap-filling bondlines to achieve good adhesion between wood surfaces [16]. In contrast, at 140 °C, greater PLA viscosity reduces flow and ingress into the wood matrix and was associated with the retention of a thicker bondline. In assessing the tensile strength of bondlines, the relative thickness of the PLA matrix may impact the stress transfer across PLA bondlines, particularly given that PLA is a hard, rigid polymer below its glass transition when tested [17,18]. However, with tensile testing, a thinner PLA bond appeared able to transfer stress and, in combination with greater interfacial adhesion and mechanical interlocking, provided higher performance of composites formed at 200 °C.

With wood fibre incorporation, bondline thickness variously increased by some 100% at 140 °C and ca. 240% at 200 °C pressing temperature. The variable strength of these composite sandwiches suggests that the deposition of wood fibres within the X–Y plane of testing did not readily act to transfer stress across the bondline as expected for fibre-reinforced plastics [6]. Instead, wood fibre alignment and overlap in the heterogeneous bondline contributed to greater bondline thickness and potentially a lower degree of PLA ingress. A resulting impact was lower strength of the maple–PLA composite sample with 25% wood fibre pressed at 140 °C. However, thinner bondlines and sufficient PLA ingress were evident for the corresponding 200 °C/25% wood fibre sample which had comparable performance to pure PLA (Figure 2) or other polymers [8]. For spruce samples, the presence of wood fibre in PLA does not appear to significantly impact composite performance.

With spruce veneer, the contrasting cellular structures of spruce and maple led to distinctions in bondline thickness, with spruce–PLA bondlines being generally thicker (Figure 5); this was attributable to lower PLA mobility and ingress away from the bondline. A greater bondline thickness together with lower PLA ingress arguably contributed to reduced interfacial adhesion, resulting in lower bond strength in spruce samples than in those of maple. However, along with surface morphology, differences in wood chemistry and surface polarity may also contribute to this weaker PLA–spruce wood interface. The effect of polymer polarity has previously been demonstrated by significantly lower composite sandwich bond strengths for polyethylene or polypropylene polymer foils which have relatively similar melting points and melt flow to PLA [8]. Any impact of wood chemistry and polymer surface polarity may also extend to using softwood wood fibre in PLA, which potentially may have impacted interfacial adhesion, reinforcement and stress transfer within the PLA matrix. However, as above, wood fibre inclusion with PLA did not significantly impact spruce composite performance. Furthermore, polymer crystallinity around wood–polymer interfaces and within the plastic/polymer matrix will also impact performance, so must also be considered in the context of interfacial properties [6,17,18]. In related adhesion studies, nano- and molecular-scale interactions have also been found to be important [14], and these will also need to be considered in sandwich composite formation and performance. Further studies will be required to understand these complexities across differing scales in the formation and performance of plastic–wood interfaces.

Overall, we find bond strength increases with temperature and, through the promotion of PLA flow into the wood vesicular structure, provides improved mechanical adhesion and reinforcement of bondlines. At the same time, any need to maintain a minimum bondline thickness may not be a requirement as wood–wood contacts increase due to a lack of gap filling [16]. The addition of wood fibres may present a way to achieve both greater polymer flow at higher temperature and, acting as a “spacer”, the impediment of excessive flow into the wood vesicular structure, which may ensure a sufficient adhesive layer between the veneer substrates. Nonetheless, composite strength requirements will be dependent on applications, and study findings suggest that if higher strength is needed, higher processing temperatures should be employed.

5. Concluding Remarks

A microscopy methodology was developed for qualitative and quantitative assessments of bondlines formed in composite sandwich manufacture with wood veneer and PLA. The use of ca. 0.0075% fluorescent chromophore in PLA matched to the lignin autofluorescence of veneer sandwiches allowed the visualisation of PLA flow and ingress at the wood cell level. The use of higher sandwich formation temperatures promoted PLA mobility further into the wood ultrastructure, acting as anchor points for the reinforcement of bondlines. This was demonstrated with both maple and spruce composite sandwiches formed at 140 and 200 °C with the higher processing temperature resulting in greater composite bond strength. The study results reiterated that relatively higher bond strengths can be achieved by bonding wood veneer with PLA. It is the PLA/wood interface which promotes this bond strength and associated stress transfer across the PLA matrix. Maple veneer revealed greater PLA ingress and bond strength compared with spruce veneer use. Overall, the study findings and, particularly, the impact of processing temperature on laminate strength and adhesion will have broad applications across the manufacture of veneer overlays, laminate composites and WPCs using wood substrates, particles or fibre with PLA.

Supplementary Materials

The following are available online at http://www.mdpi.com/2079-6439/7/2/15/s1.

Author Contributions

These include conceptualization, W.G., A.K., J.L. and M.G.; formal analysis, W.G. and M.G., A.K. and J.L.; investigation, W.G., V.G., K.R., M.G.; writing—original draft preparation, W.G.; writing—review and editing, W.G., A.K., J.L. and M.G.; supervision, M.G. and W.G.; funding acquisition, W.G., A.K., J.L. and M.G.

Funding

“This research was funded by the New Zealand–Germany Science and Technology Programme administered by the New Zealand Royal Society and the Bundesministerium für Landwirtschaft und Ernährung.

Acknowledgments

The authors are grateful to the following organisations for assistance with funding for the New Zealand–Germany Science and Technology Programme. This was contributed to by the New Zealand Royal Society and Catalyst Seed funding [FRG-FRI1402] and the Bundesministerium für Landwirtschaft und Ernährung (Federal Ministry of Food and Agriculture) [02/14-15-NZL], together with resourcing provided by the Thünen Institute of Wood Research, Scion and the University of Hamburg. K.R. was a recipient of a University of Waikato summer studentship scholarship and, along with V.G., studentship placements also supported and resourced by Scion.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mertens, O.; Gurr, J.; Krause, A. The utilization of thermomechanical pulp fibers in WPC: A review. J. Appl. Polym. Sci. 2017, 134, 45161. [Google Scholar] [CrossRef]

- Kilyosov, A.A. Wood Plastic Composites; Wiley & Sons: Hoboken, NJ, USA, 2007; p. 726. [Google Scholar]

- Chen, Y.; Geever, L.M.; Killion, J.A.; Lyons, J.G.; Higginbotham, C.L.; Devine, D.M. Review of multifarious applications of poly (lactic acid). Polym.-Plast. Technol. Eng. 2016, 55, 1057–1075. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Perspective on polylactic acid (PLA) based sustainable materials for durable applications: Focus on toughness and heat resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Garlotta, D. A literature review of poly(lactic acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Peltola, H.; Pääkkönen, E.; Jetsu, P.; Heinemann, S. Wood based PLA and PP composites: Effect of fibre type and matrix polymer on fibre morphology, dispersion and composite properties. Compos. Part A Appl. Sci. Manuf. 2014, 61, 13–22. [Google Scholar] [CrossRef]

- Luedtke, J.; Gaugler, M.; Grigsby, W.J.; Krause, A. Understanding the development of interfacial bonding within PLA/wood-based thermoplastic sandwich composites. Ind. Crop. Prod. 2019, 127, 129–134. [Google Scholar] [CrossRef]

- Gaugler, M.; Luedtke, J.; Grigsby, W.J.; Krause, A. A new methodology for rapidly assessing interfacial bonding within fibre-reinforced thermoplastic composites. Int. J. Adhes. Adhes. 2019, 89, 66–71. [Google Scholar] [CrossRef]

- Paris, J.L.; Kamke, F.A. Quantitative wood–adhesive penetration with X-ray computed tomography. Int. J. Adhes. Adhes. 2015, 61, 71–80. [Google Scholar] [CrossRef]

- Grigsby, W.J.; Thumm, A.; Klepser, H. Assessing interfacial behaviours of natural fibre-plastic composites by fluorescent microscopy. In Proceedings of the 8th International Conference on Woodfiber-Plastic Composites, Madison, WI, USA, 19–13 May 2005. [Google Scholar]

- Can, H.K.; Karakus, G.; Tuzcu, N. Synthesis, characterization and in vitro antibacterial assessments of a novel modified poly[maleic anhydride-alt-acrylic acid]/acriflavine conjugate. Polym. Bull. 2014, 71, 2903–2921. [Google Scholar] [CrossRef]

- Grigsby, W.J.; Thumm, A. Resin and wax distribution and mobility during medium density fibreboard manufacture. Eur. J. Wood Wood Prod. 2012, 70, 337–348. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Progress report on natural fiber reinforced composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Jakes, J.E.; Frihart, C.R.; Hunt, C.G.; Yelle, D.J.; Plaza, N.Z.; Lorenz, L.; Grigsby, W.; Ching, D.J.; Kamke, F.; Gleber, S.C.; et al. X-ray methods to observe and quantify adhesive penetration into wood. J. Mater. Sci. 2019, 54, 705–718. [Google Scholar] [CrossRef]

- Jakes, J.E.; Hunt, C.G.; Yelle, D.J.; Lorenz, L.; Hirth, K.; Gleber, S.C.; Vogt, S.; Grigsby, W.; Frihart, C.R. Synchrotron-based x-ray fluorescence microscopy in conjunction with nanoindentation to study molecular-scale interactions of phenol-formaldehyde in wood cell walls. ACS Appl. Mater. Interfaces 2015, 7, 6584–6589. [Google Scholar] [CrossRef] [PubMed]

- Marra, A.A. Technology of Wood Bonding: Principles in Practice; Van Nostrand Reinhold: New York, NY, USA, 1992. [Google Scholar]

- Filgueira, D.; Holmen, S.; Melbø, J.K.; Moldes, D.; Echtermeyer, A.T.; Chinga-Carrasco, G. Enzymatic-assisted modification of thermomechanical pulp fibers to improve the interfacial adhesion with poly(lactic acid) for 3D printing. ACS Sustain. Chem. Eng. 2017, 5, 9338–9346. [Google Scholar] [CrossRef]

- Mukherjee, T.; Tobin, M.J.; Puskar, L.; Sani, M.A.; Kao, N.; Gupta, R.K.; Pannirselvam, M.; Quazi, N.; Bhattacharya, S. Chemically imaging the interaction of acetylated nanocrystalline cellulose (NCC) with a polylactic acid (PLA) polymer matrix. Cellulose 2017, 24, 1717–1729. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).