Comparative Life Cycle Assessment of Cotton and Other Natural Fibers for Textile Applications

Abstract

:1. Introduction

1.1. The Cotton Industry and the Environment

1.2. Potential Alternatives

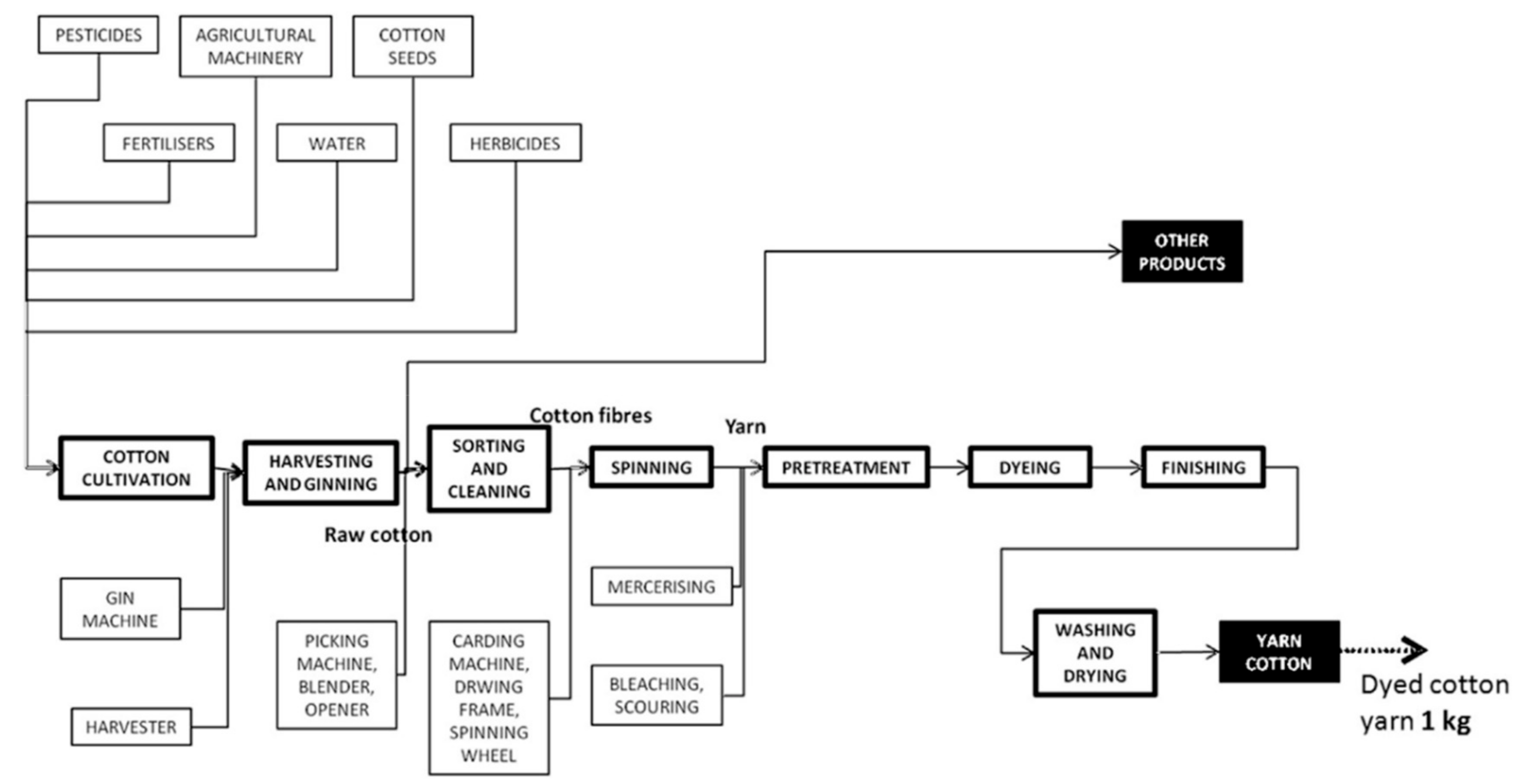

2. Materials and Methods

Rationale of the Work

- Average data, from the database Ecoinvent 3 provided by the software SimaPro (version 8.0.5.13, PRé Consultants, The Netherlands), were used for the evaluation of the impacts of the cultivation phase and the yarn production of the following fibers: cotton, kenaf, jute.

- Literature from life cycle impact assessment (LCIA) results were used for the impact of organic cotton cultivation and production;

- Literature data were used for the comparison with hemp cultivation and fiber production.

- -

- Functional unit 1: 1 kg of fiber (cotton, kenaf and jute)

- -

- Functional unit 2: 1 kg of textile (cotton, kenaf and jute)

3. Results

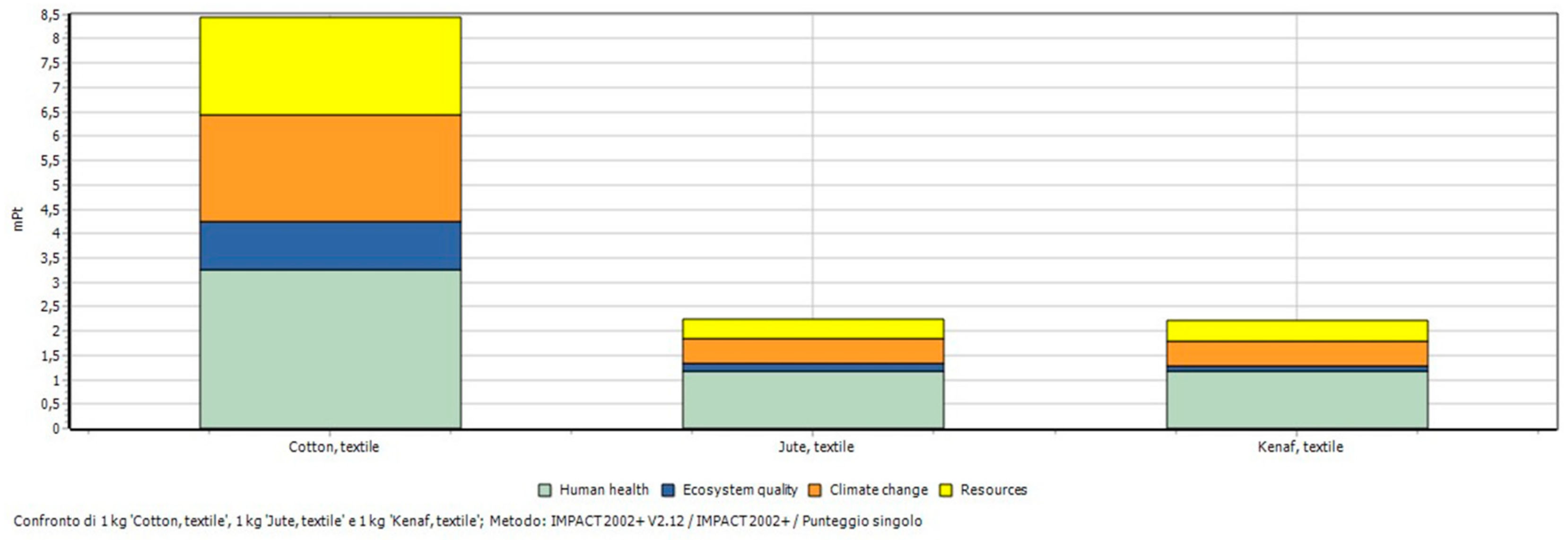

LCA Results and Discussion

- -

- GWP: (978) kgCO2-eq

- -

- Acidification Potential (AP): (5.7) kgSO2-eq

- -

- Eutrophication Potential (EP): (2.8) kgPO43−

- -

- Blue water consumption: (182) m3

- -

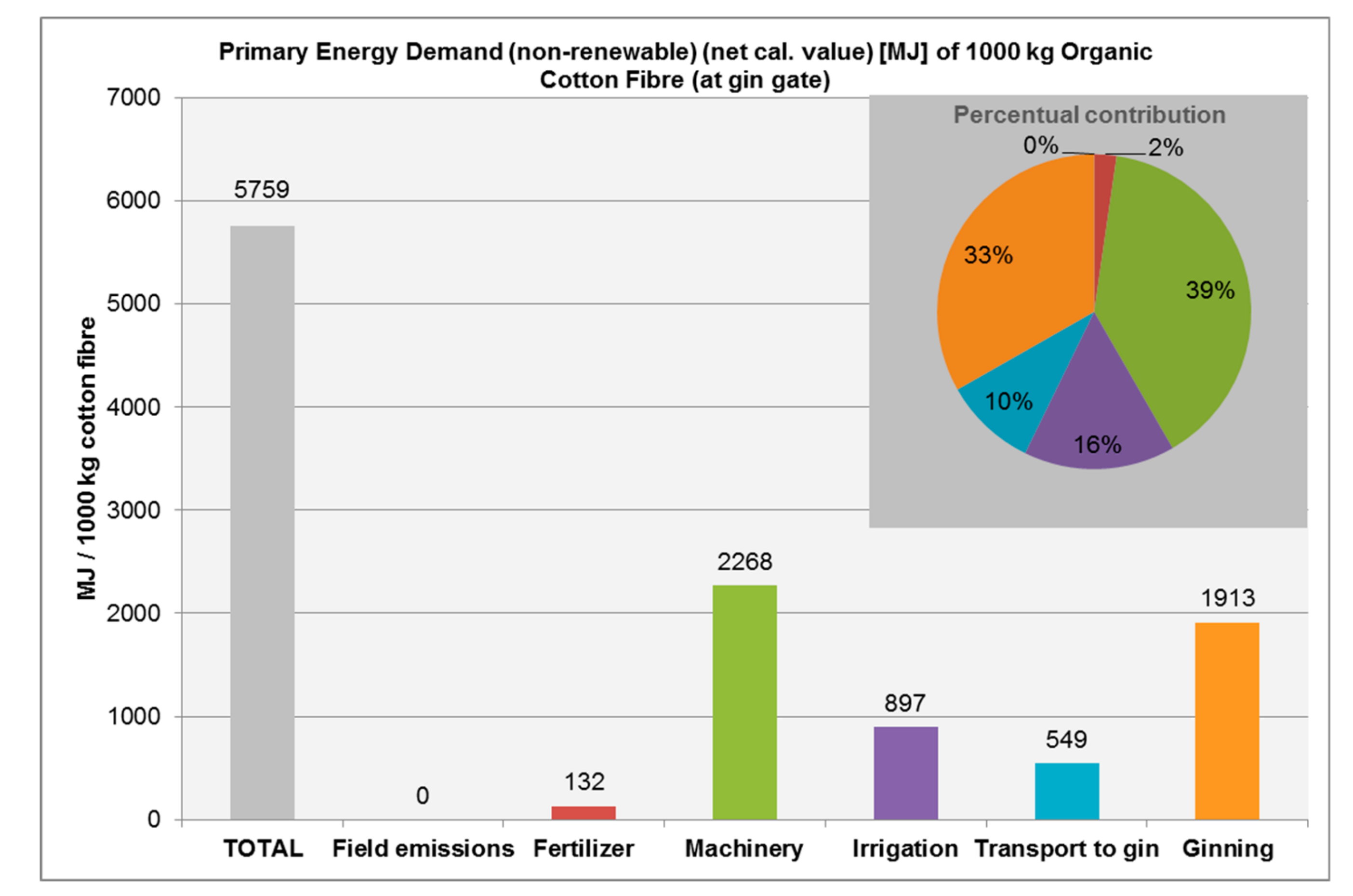

- PED (non renew): (5759) MJ

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Report, Textile Exchanges. 2014. Available online: https://textileexchange.org/downloads/life-cycle-assessment-of-organic-cotton/ (accessed on 15 November 2019).

- Scheffer, M.R. A sustainable vision on the cotton industry after 2005. In Proceedings of the Speech Held at the General Assembly of EUROCOTON, Brussels, Belgium, 30 May 2001. [Google Scholar]

- Clay, J. World Agriculture and the Environment. In Cotton Incorporated; Island Press: Washington, DC, USA, 2009; Available online: http://www.cottoninc.com/ (accessed on 15 November 2019).

- Stockle, C.O. Environmental Impact of Irrigation: A Review. 2001. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.488.4861&rep=rep1&type=pdf. (accessed on 15 November 2019).

- Roos, S.; Zamani, B.; Sandin, G.; Peters, G.M.; Svanstrom, M. A life cycle assessment (LCA)-based approach to guiding an industry sector towards sustainability: The case of the Swedish apparel sector. J. Clean. Prod. 2016, 133, 691–700. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Ciarapica, F.E.; Mazzuto, G.; Paciarotti, C. Environmental analysis of a cotton yarn supply chain. J. Clean. Prod. 2014, 82, 154–165. [Google Scholar] [CrossRef]

- Summerscales, J.; Dissanayakea, N.P.J.; Virka, A.S.; Hal, W. A Review of Bast Fibers and their Composites. Part 1—Fibers as reinforcements. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1329–1335. [Google Scholar] [CrossRef]

- Velden, N.M.; Patel, M.K.; Vogtlander, J.G. LCA benchmarking study on textiles made of cotton, polyester, nylon, acryl, or elastane. Int. J. Life Cycle Assess. 2013. [Google Scholar] [CrossRef]

- Peters, G.; Svanström, M.; Roos, S.; Sandin, G.; Zamani, B. Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing; Woodhead Publishing Series in Textiles; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- La Rosa, A.D.; Cozzo, G.; Latteri, A.; Recca, A.; Björklund, A.; Parrinello, E.; Cicala, G. Life cycle assessment of a novel hybrid glass-hemp/thermoset composite. J. Clean. Prod. 2013, 44, 69–76. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Summerscales, J.; Recca, G.; Latteri, A.; Cozzo, G.; Cicala, G. Bio-based versus traditional polymer composites. A life cycle assessment perspective. J. Clean. Prod. 2014, 74, 135–144. [Google Scholar] [CrossRef]

| Cumulative Energy Demand (CED) (MJ) | COTTON | JUTE | KENAF | |||

|---|---|---|---|---|---|---|

| Fiber | Textile | Fiber | Textile | Fiber | Textile | |

| 68.5 | 368 | 29.55 | 97 | 31 | 98.5 | |

| Category | Unit | Method | Cotton Textile | Jute Textile | Kenaf Textile |

|---|---|---|---|---|---|

| Water Resource Depletion | m3 water eq | ILCD 2011 Midpoint + V1.06/EU27 2010 | 1736 | 188 | 257 |

| Cumulative Energy Demand | MWh | V1.09/CED | 95 | 27 | 27 |

| Acidification | kg SO2 eq | CML-IA baseline V3.02/West Europe, 1995 | 165 | 41 | 41 |

| Eutrophication | kg PO4 eq | CML-IA baseline V3.02/West Europe, 1995 | 70.84 | 14.93 | 14.72 |

| Impact Category | Unit | Cotton Textile | Jute Textile | Kenaf Textile |

|---|---|---|---|---|

| Abiotic depletion | kg Sb eq | 0.05 | 0.00 | 0.00 |

| Abiotic depletion (fossil fuels) | MJ | 227 | 56.632 | 57.797 |

| Global warming (GWP100a) | kg CO2 eq | 23.395 | 5515 | 5590 |

| Ozone layer depletion (ODP) | kg CFC-11 eq | 0.10 | 0.00 | 0.00 |

| Human toxicity | kg 1,4-DB eq | 9570 | 1924 | 1970 |

| Fresh water aquatic ecotox | kg 1,4-DB eq | 48.391 | 1353 | 1381 |

| Marine aquatic ecotoxicity | kg 1,4-DB eq | 38.399 | 6.840 | 6.935 |

| Terrestrial ecotoxicity | kg 1,4-DB eq | 2761 | 5.86 | 4.51 |

| Photochemical oxidation | kg C2H4 eq | 4.86 | 2.89 | 2.93 |

| Acidification | kg SO2 eq | 165 | 41 | 41 |

| Eutrophication | kg PO4 eq | 70.84 | 14.93 | 14.72 |

| Impact Category | Unit | Cotton | Jute | Kenaf | |||

|---|---|---|---|---|---|---|---|

| Fiber | Textile | Fiber | Textile | Fiber | Textile | ||

| Terrestrial acid/nutri | kg SO2 eq | 154 | 562 | 57 | 162 | 52 | 158 |

| Land occupation | m2org.arable | 7261 | 8290 | 1210 | 1603 | 1040 | 1403 |

| Aquatic acidification | kg SO2 eq | 28 | 163 | 7.7 | 41 | 7.5 | 41 |

| Aquatic eutrophication | kg PO4 P-lim | 2 | 6.8 | 2.3 | 3.6 | 2.3 | 3.5 |

| Global warming | kg CO2 eq | 2446 | 20.338 | 294 | 5032 | 360 | 5110 |

| Non-renew. Energy | MJ primary | 32.643 | 279.777 | 2776 | 60.935 | 3873 | 62.223 |

| Mineral extraction | MJ surplus | 149 | 1116 | 20 | 69 | 29 | 80 |

| Impact Category | Organic Cotton (1000 kg) | Traditional Cotton (1000 kg) |

|---|---|---|

| (GWP) kgCO2 eq | 978 | 2446 |

| (Non-renew. Energy) MJ | 5759 | 32.643 |

| (Acidification) kgSO2 eq | 5.7 | 28 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

La Rosa, A.D.; Grammatikos, S.A. Comparative Life Cycle Assessment of Cotton and Other Natural Fibers for Textile Applications. Fibers 2019, 7, 101. https://doi.org/10.3390/fib7120101

La Rosa AD, Grammatikos SA. Comparative Life Cycle Assessment of Cotton and Other Natural Fibers for Textile Applications. Fibers. 2019; 7(12):101. https://doi.org/10.3390/fib7120101

Chicago/Turabian StyleLa Rosa, Angela D., and Sotirios A. Grammatikos. 2019. "Comparative Life Cycle Assessment of Cotton and Other Natural Fibers for Textile Applications" Fibers 7, no. 12: 101. https://doi.org/10.3390/fib7120101

APA StyleLa Rosa, A. D., & Grammatikos, S. A. (2019). Comparative Life Cycle Assessment of Cotton and Other Natural Fibers for Textile Applications. Fibers, 7(12), 101. https://doi.org/10.3390/fib7120101