Effect of High Temperature on the Mechanical Properties of Steel Fiber-Reinforced Concrete

Abstract

1. Introduction

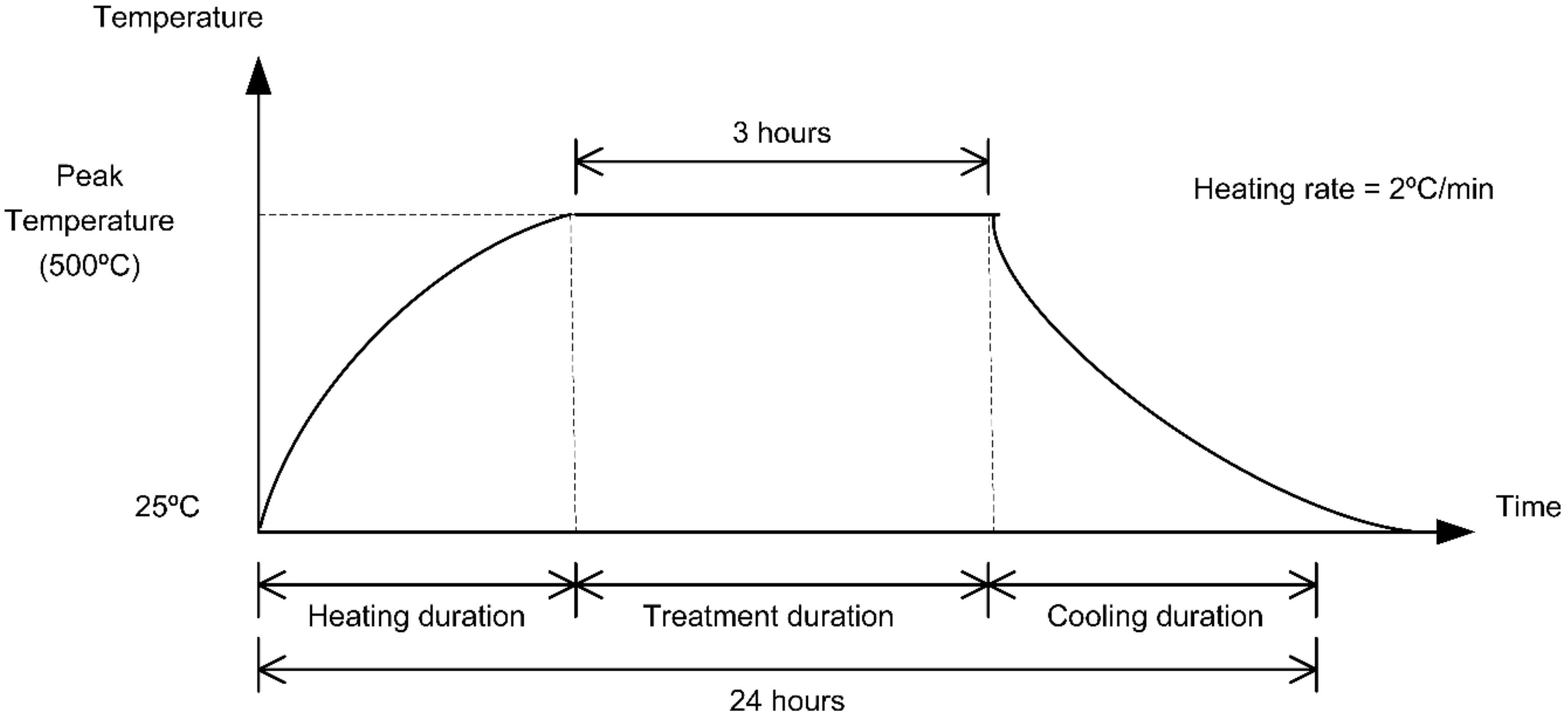

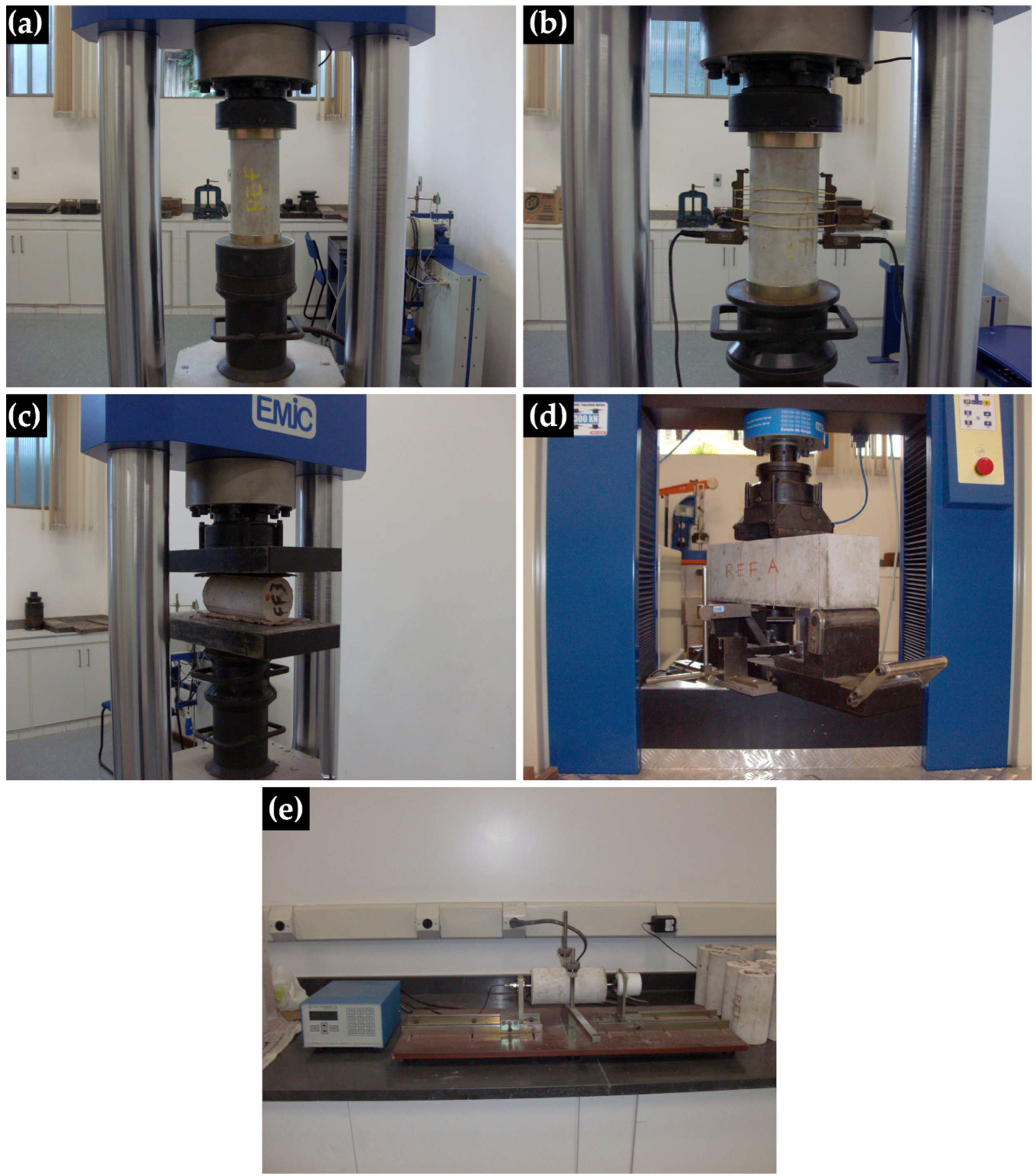

2. Materials and Methods

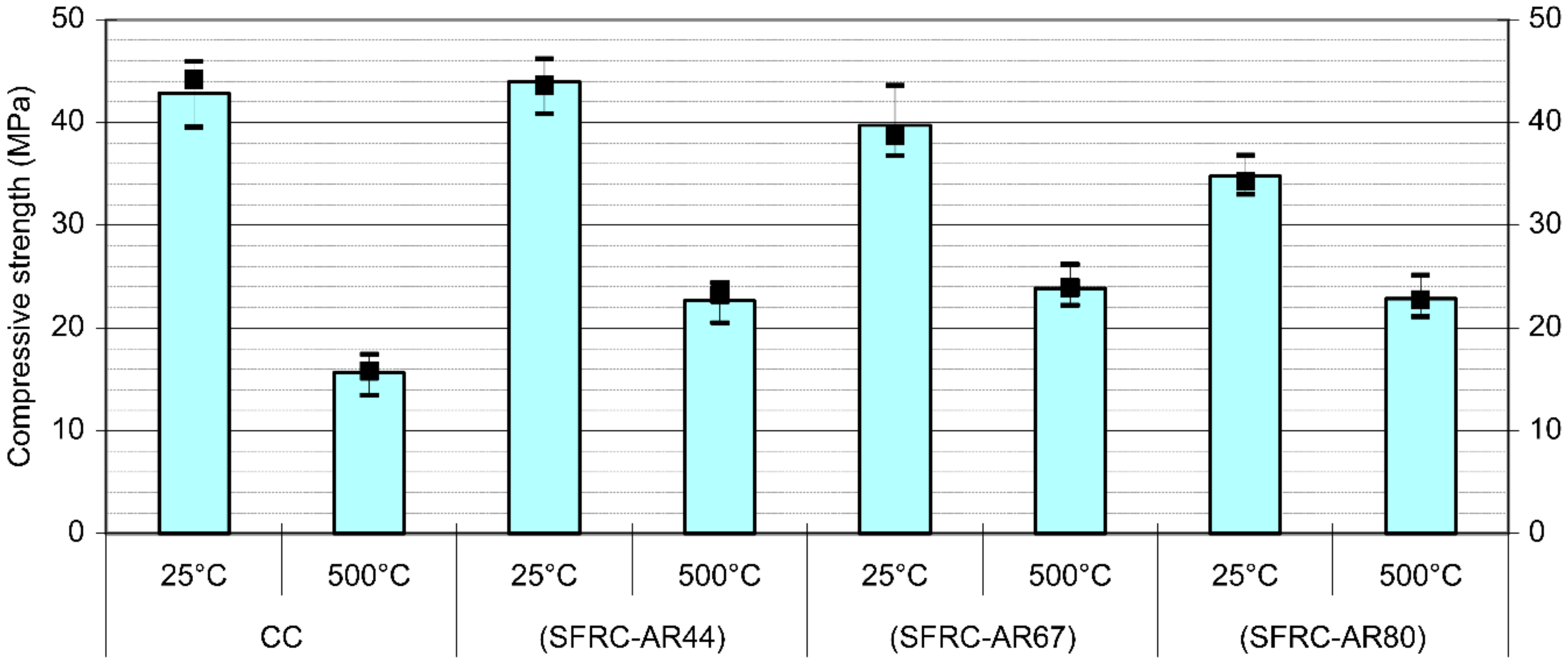

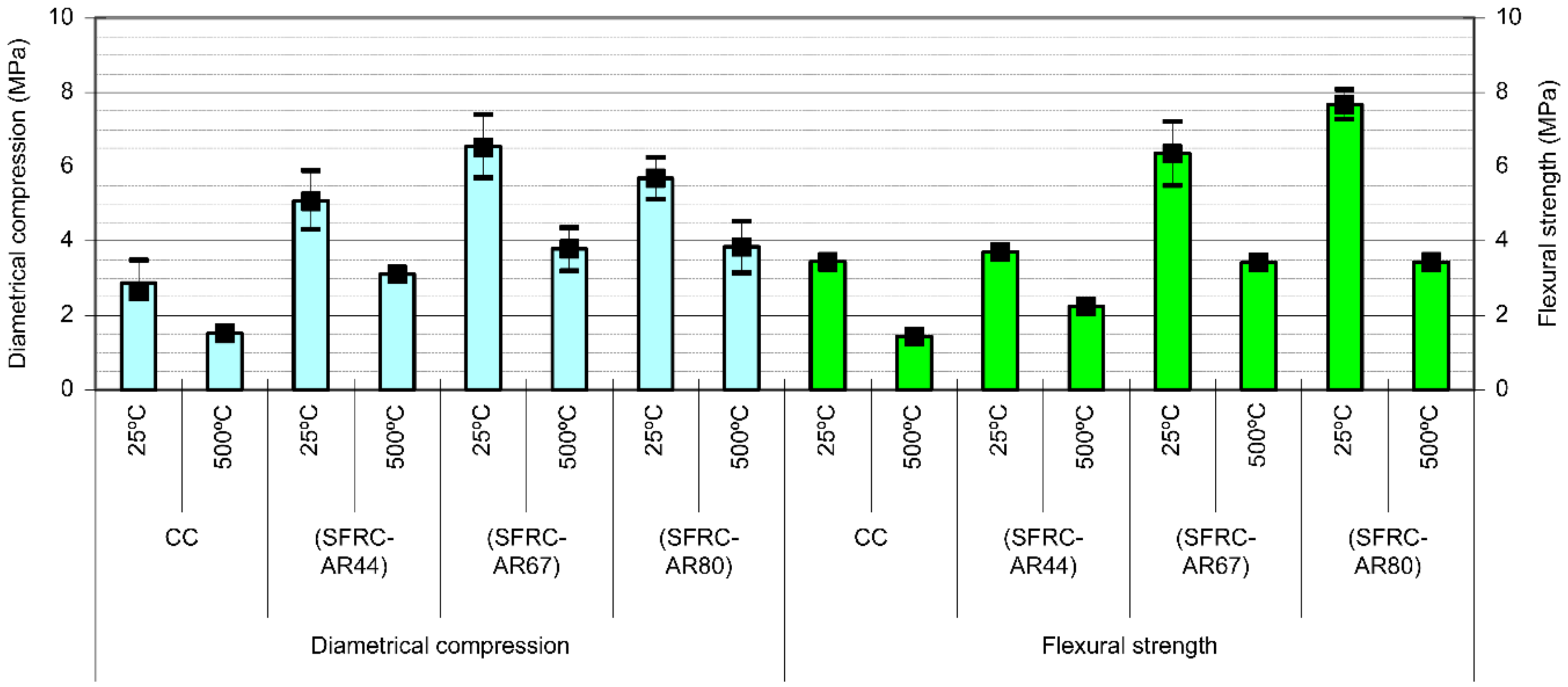

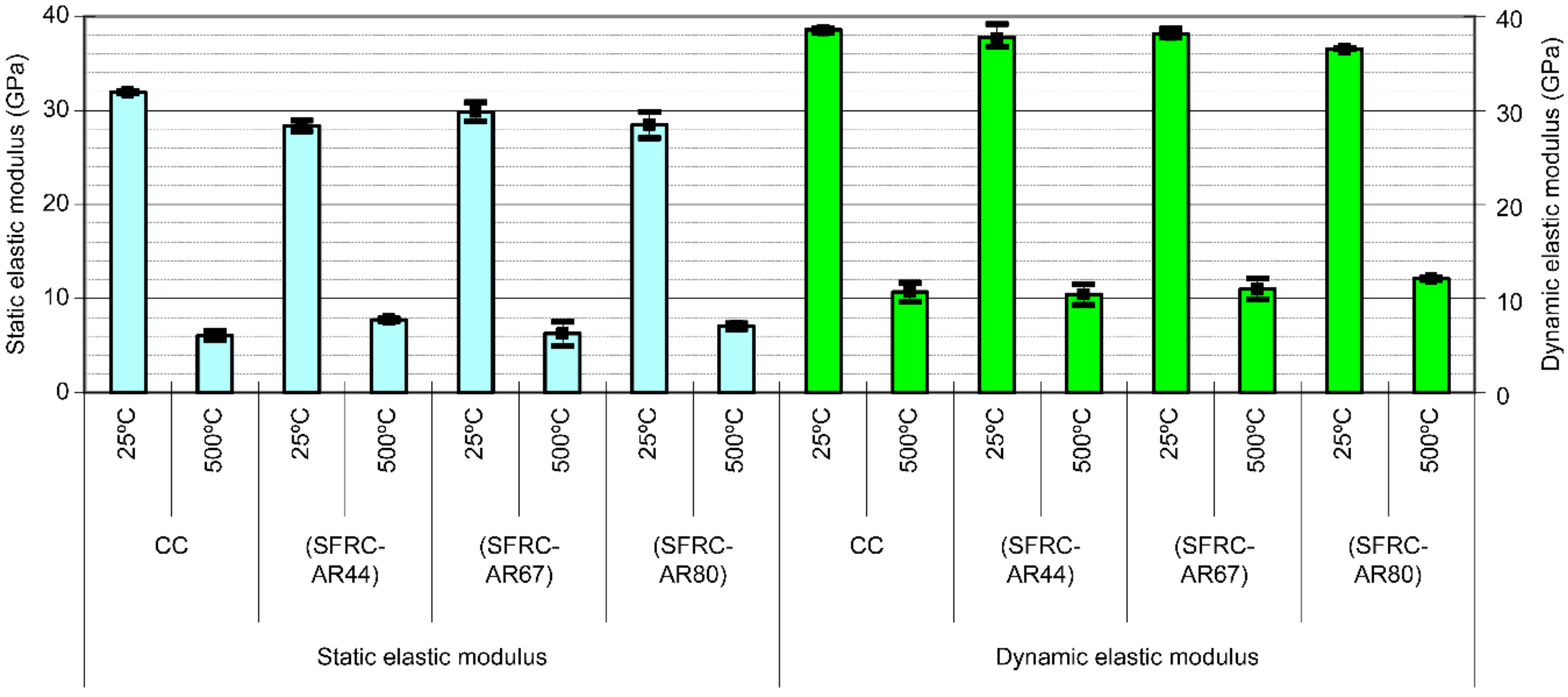

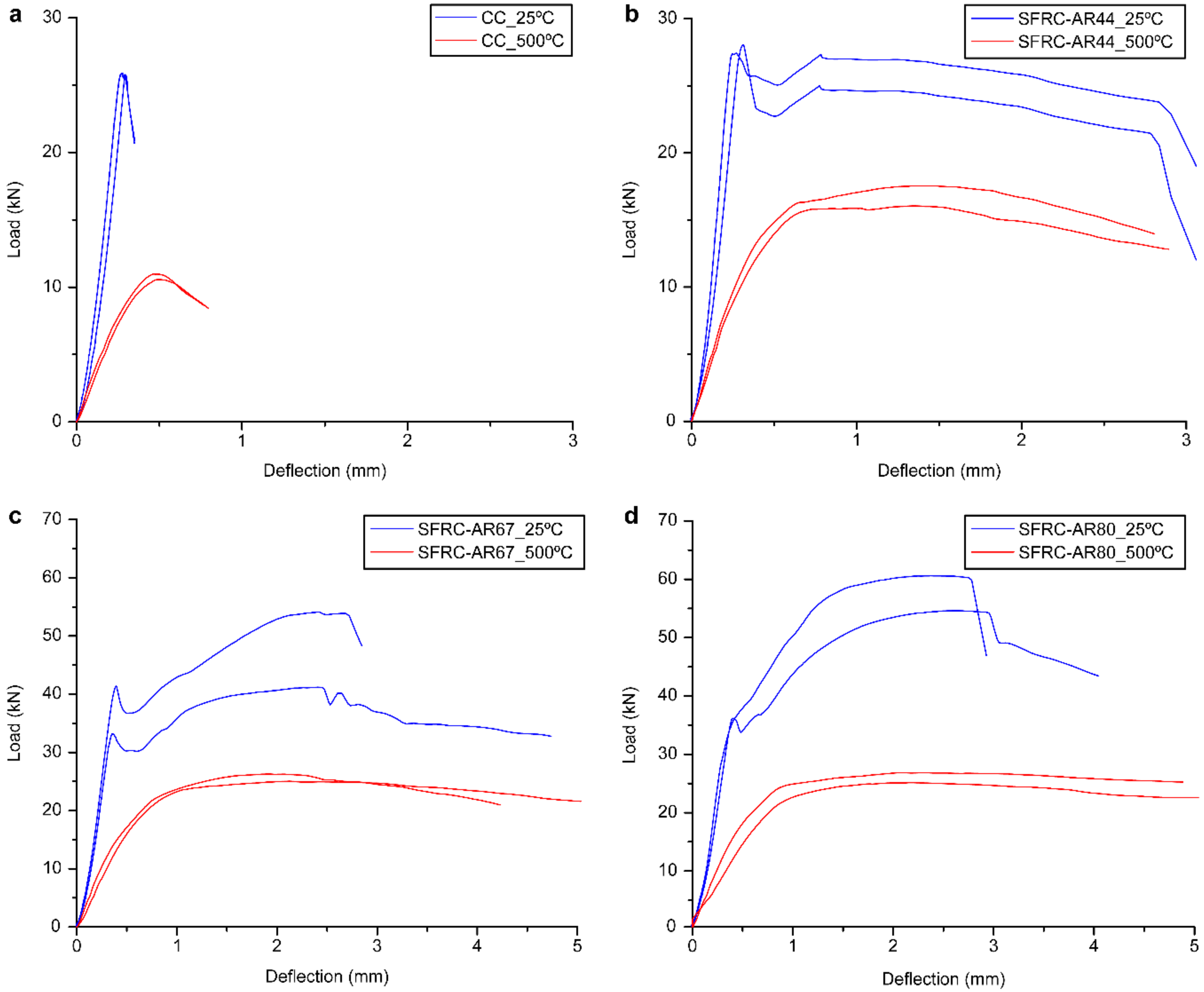

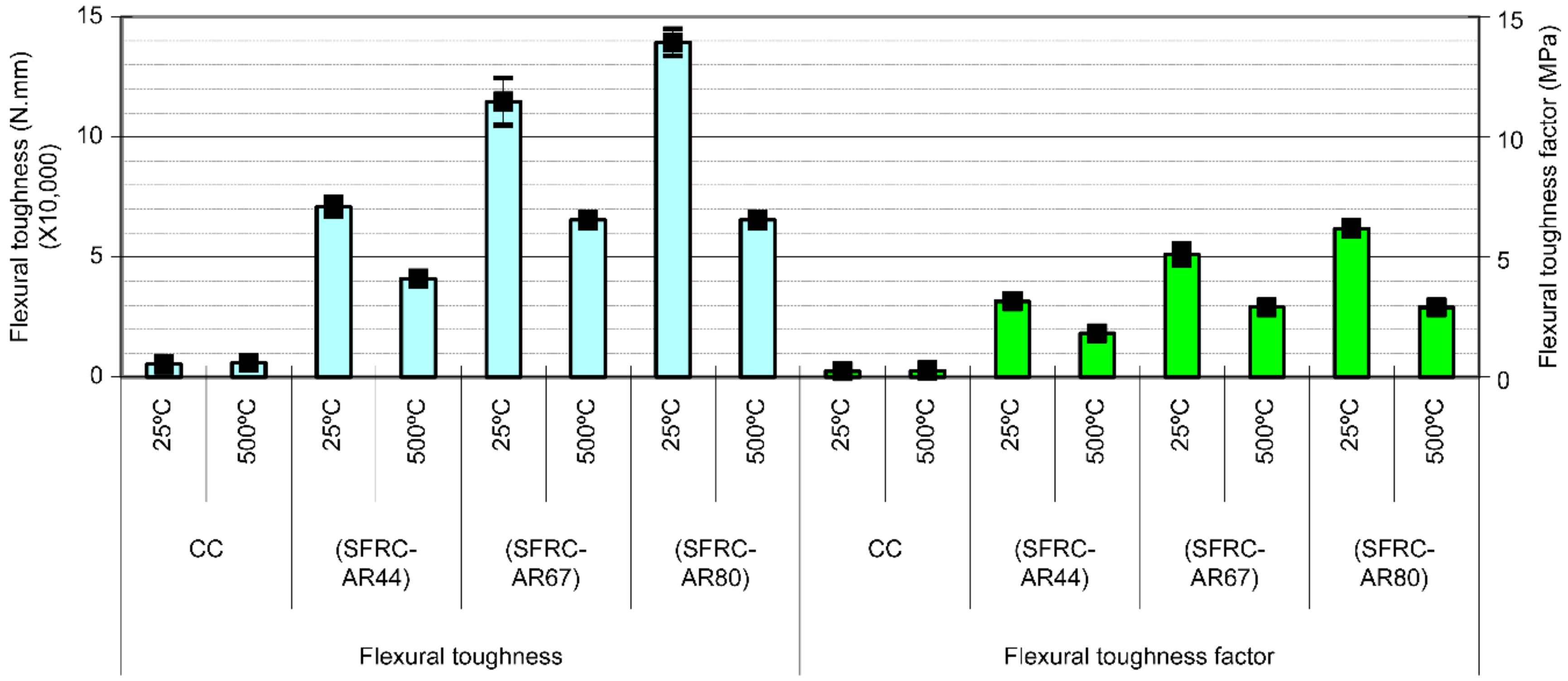

3. Results

4. Discussion

5. Conclusions

- The addition of steel fibers contributes to the increased tensile strength in diametrical compression;

- The addition of steel fibers contributes to the increase of the flexural strength;

- The investigation concluded that concrete reinforced with steel fibers has a much higher residual mechanical behavior after the fires when compared to non-reinforced concretes.

- The increase in fiber length leads to higher residual strength after fire.

- It was observed that the addition of fibers did not promote relevant variations in the compressive strength of the analyzed models. The addition of fibers of different aspect ratios did not significantly change the compressive strength when compared to the variations observed in the literature given by the different molding processes, curing, and load application speed.

- Therefore, it can be concluded that the use of steel fibers in concrete-based materials significantly enhances their fire and hear-resistant characteristics.

- Evaluation of the chipping inhibition of concretes in fire situations by the addition of steel fibers;

- Evaluation of the mechanical properties of steel fiber-reinforced concrete during fires; and

- Finite element simulation of the mechanical behavior of steel fiber-reinforced concrete during fires.

Author Contributions

Funding

Conflicts of Interest

References

- Nawy, E.G. Fundamentals of High Strength High Performance Concrete; Longman: Hong Kong, China, 1996. [Google Scholar]

- Kinnunen, S.; Nylander, H.S.E. Punching of Concrete Slabs Without Shear Reinforcement; Royal Institute of Technology: Stockholm, Sweden, 1960. [Google Scholar]

- Mckee, D.C. The Properties of an Expansive Cement Mortar Reinforced with Random Wire Fibers. Ph.D. Thesis, University of Illinois, Urbana-Champaign, IL, USA, 1969. [Google Scholar]

- Nielsen, L.E.; Chen, P.E. Young’s modulus of composites filled with randomly oriented fibers. J. Mater. 1968, 3, 352–358. [Google Scholar]

- Romualdi, J.P.; Mandel, J.A. Tensile Strength of Concrete Affected by Uniformly Distributed and Closely Spaced Short Lengths of Wire Reinforcement. J. Proc. 1964, 61, 657–672. [Google Scholar]

- Shah, S.P.; Rangan, B.V. Fiber Reinforced Concrete Properties. J. Proc. 1971, 68, 126–137. [Google Scholar]

- Shah, A.A.; Ribakov, Y. Recent trends in steel fibered high-strength concrete. Mater. Des. 2011, 32, 4122–4151. [Google Scholar] [CrossRef]

- Mohammadi, Y.; Singh, S.P.; Kaushik, S.K. Properties of steel fibrous concrete containing mixed fibres in fresh and hardened state. Constr. Build. Mater. 2008, 22, 956–965. [Google Scholar] [CrossRef]

- Khorami, M.; Ganjian, E. Comparing flexural behaviour of fibre–cement composites reinforced bagasse: Wheat and eucalyptus. Constr. Build. Mater. 2011, 25, 3661–3667. [Google Scholar] [CrossRef]

- Shafigh, P.; Mahmud, H.; Jumaat, M.Z. Effect of steel fiber on the mechanical properties of oil palm shell lightweight concrete. Mater. Des. 2011, 32, 3926–3932. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Heidari-Rarani, M.; Shakouri, M.; Kashizadeh, E. Effects of thermal cycles on mechanical properties of an optimized polymer concrete. Constr. Build. Mater. 2011, 25, 3540–3549. [Google Scholar] [CrossRef]

- Won, J.-P.; Park, C.-G.; Lee, S.-J.; Kang, J.-W. Bonding characteristics of recycled polyethylene terephthalate (PET) fibers coated with maleic anhydride grafted polypropylene in cement-based composites. J. Appl. Polym. Sci. 2011, 121, 1908–1915. [Google Scholar] [CrossRef]

- Grandhaie, F.; Granju, J.L.; Ringot, E. Durability of pavement repairs: Point of view about the role of fibers. In Proceedings of the 5th International Conference on Concrete Pavement Design and Rehabilitation, West Lafeyette, IN, USA, 23–25 April 1993; Volume 2, pp. 195–202. [Google Scholar]

- Granju, J.L. Thin bonded overlays: About the role of fiber reinforcement on the limitation of their debonding. Adv. Cem. Based Mater. 1996, 4, 21–27. [Google Scholar] [CrossRef]

- Holanda, K.M.A. Análise Dos Mecanismos Resistentes E Das Similaridades De Efeitos Da Adição De Fibras De Aço Na Resistência E Na Ductilidade à Punção De Lajes-Cogumelo E Ao Cisalhamento De Vigas De Concreto [Analysis of Resistant Mechanisms and Similarities of the Effect of Added Steel Fibres on the Strength and Ductility to both the Punching Shear of Flat Slabs and the Shear Of Concrete Beams]. Ph.D. Thesis, University of São Paulo, São Paulo, Brazil, 2002. [Google Scholar]

- Turatsinze, A.; Granju, J.-L.; Sabathier, V.; Farhat, H. Durability of bonded cement-based overlays: Effect of metal fibre reinforcement. Mater. Struct. 2005, 38, 321–327. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Liu, Q.; Li, B.; Schlangen, E.; Sun, Y.; Wu, S. Research on the Mechanical, Thermal, Induction Heating and Healing Properties of Steel Slag/Steel Fibers Composite Asphalt Mixture. Appl. Sci. 2017, 7, 1088. [Google Scholar] [CrossRef]

- Corradi, M.; Castori, G.; Sisti, R.; Borri, A.; Pesce, G.L. Repair of Block Masonry Panels with CFRP Sheets. Materials 2019, 12, 2363. [Google Scholar] [CrossRef] [PubMed]

- Jeong, Y.; Kim, W.; Gribniak, V.; Hui, D. Fatigue Behavior of Concrete Beams Prestressed with Partially Bonded CFRP Bars Subjected to Cyclic Loads. Materials 2019, 12, 3352. [Google Scholar] [CrossRef]

- Li, L. Stress-Rupture of Fiber-Reinforced Ceramic-Matrix Composites with Stochastic Loading at Intermediate Temperatures. Part I: Theoretical Analysis. Materials 2019, 12, 3123. [Google Scholar] [CrossRef]

- Kotsovos, G.; Zeris, C.; Kotsovos, M. The effect of steel fibres on the earthquake-resistant design of reinforced concrete structures. Mater. Struct. 2007, 40, 175–188. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Sfiri, E.F. Shear Performance of Steel Fibrous Concrete Beams. Procedia Eng. 2011, 14, 2064–2068. [Google Scholar] [CrossRef]

- Chalioris, C.E. Analytical approach for the evaluation of minimum fibre factor required for steel fibrous concrete beams under combined shear and flexure. Constr. Build. Mater. 2013, 43, 317–336. [Google Scholar] [CrossRef]

- Park, J.-S.; Kim, Y.; Cho, J.-R.; Jeon, S.-J. Early-Age Strength of Ultra-High Performance Concrete in Various Curing Conditions. Materials 2015, 8, 5537–5553. [Google Scholar] [CrossRef]

- Kang, S.-H.; Lee, J.-H.; Hong, S.-G.; Moon, J. Microstructural Investigation of Heat-Treated Ultra-High Performance Concrete for Optimum Production. Materials 2017, 10, 1106. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Panagiotopoulos, T.A. Flexural analysis of steel fibre-reinforced concrete members. Comput. Concr. 2018, 22, 11–25. [Google Scholar]

- Guerini, V.; Conforti, A.; Plizzari, G.; Kawashima, S. Influence of Steel and Macro-Synthetic Fibers on Concrete Properties. Fibers 2018, 6, 47. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Kosmidou, P.-M.K.; Karayannis, C.G. Cyclic Response of Steel Fiber Reinforced Concrete Slender Beams; an Experimental Study. Materials 2019, 12, 1398. [Google Scholar] [CrossRef] [PubMed]

- Soares Junior, P.R.R.; Maciel, P.S.; Barreto, R.R.; da Silva Neto, J.T.; Siqueira Corrêa, E.C.; da Bezerra, A.C.S. Thin Slabs Made of High-Performance Steel Fibre-Reinforced Cementitious Composite: Mechanical Behaviour, Statistical Analysis and Microstructural Investigation. Materials 2019, 12, 3297. [Google Scholar] [CrossRef]

- Gencel, O.; Brostow, W.; Datashvili, T.; Thedford, M. Workability and Mechanical Performance of Steel Fiber-Reinforced Self-Compacting Concrete with Fly Ash. Compos. Interfaces 2011, 18, 169–184. [Google Scholar] [CrossRef]

- Joshua, D.B.; Ostertag, O. Deflection Hardening and Workability of Hybrid Fiber Composites. ACI Mater. J. 2009, 106, 265–272. [Google Scholar]

- Chen, B.; Liu, J. Contribution of hybrid fibers on the properties of the high-strength lightweight concrete having good workability. Cem. Concr. Res. 2005, 35, 913–917. [Google Scholar] [CrossRef]

- Sahmaran, M.; Yurtseven, A.; Ozgur Yaman, I. Workability of hybrid fiber reinforced self-compacting concrete. Build. Environ. 2005, 40, 1672–1677. [Google Scholar] [CrossRef]

- Hull, W.A.; Ingberg, S.H. Fire resistance of concrete columns. J. Frankl. Inst. 1925, 200, 379–381. [Google Scholar] [CrossRef]

- Ingberg, S.H.; Griffin, H.K.; Robinson, W.C.; Wilson, R.E. Fire tests of building columns. J. Frankl. Inst. 1921, 191, 823–827. [Google Scholar] [CrossRef]

- Handoo, S.K.; Agarwal, S.; Agarwal, S.K. Physicochemical, mineralogical, and morphological characteristics of concrete exposed to elevated temperatures. Cem. Concr. Res. 2002, 32, 1009–1018. [Google Scholar] [CrossRef]

- Khoury, G.A. Compressive strength of concrete at high temperatures: A reassessment. Mag. Concr. Res. 1992, 44, 291–309. [Google Scholar] [CrossRef]

- Barragán, B.E.; Gettu, R.; Martín, M.A.; Zerbino, R.L. Uniaxial tension test for steel fibre reinforced concrete––A parametric study. Cem. Concr. Compos. 2003, 25, 767–777. [Google Scholar] [CrossRef]

- Barros, J.A.O.; Figueiras, J.A. Model for the analysis of steel fibre reinforced concrete slabs on grade. Comput. Struct. 2001, 79, 97–106. [Google Scholar] [CrossRef]

- Fu, C.Q.; Jin, X.Y.; Jin, N.G. Numerical Experiment on Flexural Properties of Steel Fiber Reinforced Concrete Beam. In Proceedings of the 2009 WRI World Congress on Computer Science and Information Engineering, Los Angeles, CA, USA, 31 March–2 April 2009; Volume 7, pp. 755–759. [Google Scholar]

- Hartman, T. Steel Fiber Reinforced Concrete. Ph.D. Thesis, Royal Institute of Technology (KTH), Stockholm, Sweden, 1999. [Google Scholar]

- Holschemacher, K.; Mueller, T.; Ribakov, Y. Effect of steel fibres on mechanical properties of high-strength concrete. Mater. Des. 1980-2015 2010, 31, 2604–2615. [Google Scholar] [CrossRef]

- Kang, S.-T.; Lee, Y.; Park, Y.-D.; Kim, J.-K. Tensile fracture properties of an Ultra High Performance Fiber Reinforced Concrete (UHPFRC) with steel fiber. Compos. Struct. 2010, 92, 61–71. [Google Scholar] [CrossRef]

- Lee, D.H.; Hwang, J.-H.; Ju, H.; Kim, K.S.; Kuchma, D.A. Nonlinear finite element analysis of steel fiber-reinforced concrete members using direct tension force transfer model. Finite Elem. Anal. Des. 2012, 50, 266–286. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. Combined effect of silica fume and steel fibers on the impact resistance and mechanical properties of concrete. Int. J. Impact Eng. 2010, 37, 879–886. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. Property assessment of steel–fibre reinforced concrete made with silica fume. Constr. Build. Mater. 2012, 28, 664–669. [Google Scholar] [CrossRef]

- Özcan, D.M.; Bayraktar, A.; Şahin, A.; Haktanir, T.; Türker, T. Experimental and finite element analysis on the steel fiber-reinforced concrete (SFRC) beams ultimate behavior. Constr. Build. Mater. 2009, 23, 1064–1077. [Google Scholar] [CrossRef]

- Balázs, G.L.; Lublóy, É. Post-heating strength of fiber-reinforced concretes. Fire Saf. J. 2012, 49, 100–106. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Longman: London, UK, 1995; Volume 4. [Google Scholar]

- De Sousa Coutinho, A. Fabrico e Propriedades do Betão, 3rd ed.; Laboratório Nacional de Engenharia civil—LNEC: Lisboa, Portugal, 1997. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J. Concrete: Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Cánovas, M.F. Patologia e Terapia do Concreto Armado [Pathology and Therapy of Reinforced Concrete], 1st ed.; PINI: São Paulo, Brazil, 1988. [Google Scholar]

- Costa, C.N.; de Figueiredo, A.D.; Silva, V.P. Aspectos Tecnológicos dos Materiais de Concreto em Altas Temperaturas; University of São Paulo-Faculty of Architecture and Urbanism-Department of Architecture Technology: São Paulo, Brazil, 2002. [Google Scholar]

- Georgali, B.; Tsakiridis, P.E. Microstructure of fire-damaged concrete. A case study. Cem. Concr. Compos. 2005, 27, 255–259. [Google Scholar] [CrossRef]

- Naaman, A.E. Half a century of progress leading to ultra)high performance fiber reinforced concrete: Part 1-Overall review. In Proceedings of the 2nd International RILEM Conference on Strain Hardening Cementitious Composites, Rio de Janeiro, Brazil, 12–14 December 2011; pp. 27–36. [Google Scholar]

- Naaman, A.E. Half a century of progress leading to ultra-high performance fiber reinforced concrete: Part 2-Tensile stress-strain response. In Proceedings of the 2nd International RILEM Conference on Strain Hardening Cementitious Composites, Rio de Janeiro, Brazil, 12–14 December 2011; pp. 17–26. [Google Scholar]

- Tuyan, M.; Yazıcı, H. Pull-out behavior of single steel fiber from SIFCON matrix. Constr. Build. Mater. 2012, 35, 571–577. [Google Scholar] [CrossRef]

- Elavarasi, D.; Saravana Raja Mohan, K.; Parthasarathy, P.; Dinesh, T. Effects of slag on flexural strength of slurry infiltrated fibrous concrete. IOP Conf. Ser. Earth Environ. Sci. 2017, 80. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Gashti, S.H.; Tahmouresi, B. Residual strength and microstructure of fiber reinforced self-compacting concrete exposed to high temperatures. Constr. Build. Mater. 2020, 230, 116969. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New advancements, challenges and opportunities of multi-storey modular buildings-A state-of-the-art review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Ferdous, W.; Ngo, T.D.; Nguyen, K.T.Q.; Ghazlan, A.; Mendis, P.; Manalo, A. Effect of fire-retardant ceram powder on the properties of phenolic-based GFRP composites. Compos. Part B Eng. 2018, 155, 414–424. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Van Erp, G.; Aravinthan, T.; Ghabraie, K. Evaluation of an Innovative Composite Railway Sleeper for a Narrow-Gauge Track under Static Load. J. Compos. Constr. 2018, 22. [Google Scholar] [CrossRef]

- Japan Society of Civil Engineers (JSCE). JSCE-SF4: Method of Tests for Flexural Strength and Flexural Toughness of Fiber Reinforced Concrete; Concrete Library of JSCE, Part III-2; Standards for Test Method of Fiber Reinforced Concrete; Japan Society of Civil Engineers: Tokyo, Japan, 1984; pp. 58–61. [Google Scholar]

- Figueiredo, A.D. de Concreto Reforçado Com Fibras [Fiber-Reinforced Concrete]. Ph.D. Thesis, University of São Paulo, São Paulo, Brazil, 2011. [Google Scholar]

- American Concrete Institute (ACI). Design Considerations for Steel Fiber Reinforced Concrete. Struct. J. 1988, 85, 563–579. [Google Scholar]

- De Figueiredo Maia, A.L.; Oliveira Sena, N.; de Oliveira, L.L.M.S.; Melo Pereira, G.; da Silva, M.J.; Resende, D.S.; da Silva Neto, J.T.; de Aguilar, M.T.P.; Bezerra, A.C.S. Evaluation of Sample Preparation Parameters in the Compressive Strength of Cementitious Composites. Mater. Sci. Forum 2016, 869, 93–97. [Google Scholar] [CrossRef]

- Da Bezerra, A.C.S.; Aguilar, M.T.P.; Cetlin, P.R. The influence of specimen capping on the results of compression strength tests of cementitious composites. Rem Rev. Esc. Minas 2012, 65, 291–296. [Google Scholar] [CrossRef]

- Bergamini, E.; Colombo, M.; Felicetti, R.; Manzoni, M. On the bending behaviour of SFRC exposed to high temperature. In Proceedings of the 6th International RILEM Symposium on Fibre-Reinforced Concretes (BEFIB’2004), Varenna, Italy, 20–22 September 2005; Di Prisco, M., Felicetti, R.M., Plizzari, G.A., Eds.; pp. 647–658. [Google Scholar]

- Yazıcı, Ş.; İnan, G.; Tabak, V. Effect of aspect ratio and volume fraction of steel fiber on the mechanical properties of SFRC. Constr. Build. Mater. 2007, 21, 1250–1253. [Google Scholar] [CrossRef]

- Jo, B.-W.; Shon, Y.-H.; Kim, Y.-J. The evalution of elastic modulus for steel fiber reinforced concrete. Russ. J. Nondestruct. Test. 2001, 37, 152–161. [Google Scholar] [CrossRef]

- Wang, Z.L.; Wu, J.; Wang, J.G. Experimental and numerical analysis on effect of fibre aspect ratio on mechanical properties of SRFC. Constr. Build. Mater. 2010, 24, 559–565. [Google Scholar] [CrossRef]

- Sarzalejo, A.G.; Rossi, B.; Perri, G.; Winterberg, R.; Aristeguieta, R.E.P. Fibras Como Elemento Estrutural Para Reforço de Concreto, (Manual Técnico) [Fibres as Structural Elements for Concrete Reinforcement (Technical Manual)]; Maccaferri do Brasil Ltda: Jundiaí, Brazil, 2009. [Google Scholar]

- Da Silva Bezerra, A.C.; Corrêa, E.C.S.; Aguilar, M.T.P.; Cetlin, P.R. Post-fire Behavior of Ordinary Concrete Reinforced with Short Steel Fibers. J. Civ. Eng. Archit. 2015, 9, 262–267. [Google Scholar]

| Physical | Mechanical | Chemical (wt %) | |||||

|---|---|---|---|---|---|---|---|

| Particle size | #200–75 mm (%) | 0.28 | Compressive strength (MPa) | 1 d | 25.7 | Insoluble residue | 0.72 |

| #325–45 mm (%) | 2.75 | 3 d | 36.1 | Loss on ignition | 3.79 | ||

| Blaine (cm2/g) | 5.232 | 7 d | 41.2 | MgO | 2.91 | ||

| Density (g/cm3) | 3.070 | 28 d | 49.7 | SO3 | 3.63 | ||

| Setting time (min) | Initial | 130 | Expansibility (mm) | Cold | - | ||

| Final | 160 | Hot | 0.4 | ||||

| Notation | Manufacturing Material | Type | Section | Diameter (d) (mm) | Length (l) (mm) | Aspect Ratio (AR) (l/d) |

|---|---|---|---|---|---|---|

| AR 44 | Drawn low-carbon steel wire | Hooked | Circular | 0.75 | 33.00 | 44 |

| AR 67 | Drawn low-carbon steel wire | Hooked | Circular | 0.75 | 50.00 | 67 |

| AR 80 | Drawn low-carbon steel wire | Hooked | Circular | 0.75 | 60.00 | 80 |

| Component | Description | Density (kg/dm3) | Unit Weight (kg/dm3) | Finesses |

|---|---|---|---|---|

| Binder | High early strength Portland cement | 3.070 | - | - |

| Fine aggregates | Sand | 2.591 | 1.541 | 2.672 |

| Coarse aggregates | Crushed limestone (Max size: 19 mm) | 2.692 | 1.503 | 5.966 |

| Water | - | - | - | - |

| Component | Description | Content (kg/m3) | Proportion (kg) |

|---|---|---|---|

| Binder | High early strength Portland cement | 391.5 | 1.00 |

| Fine aggregates | Sand | 742.0 | 1.90 |

| Coarse aggregates | Crushed limestone | 972.5 | 2.49 |

| Water (w/c = 0.55) | - | 214.8 | 0.55 |

| Fibers (1% by volume) | Steel fibers | 81.2 | 0.21 |

| Element | %Fe | %C | %Mn | %Si | %P | %S |

|---|---|---|---|---|---|---|

| Specification | >99.19 | 0.06% max | 0.25% to 0.40% | 0.10% to 0.30% | 0.025% max | 0.025% max |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bezerra, A.C.S.; Maciel, P.S.; Corrêa, E.C.S.; Soares Junior, P.R.R.; Aguilar, M.T.P.; Cetlin, P.R. Effect of High Temperature on the Mechanical Properties of Steel Fiber-Reinforced Concrete. Fibers 2019, 7, 100. https://doi.org/10.3390/fib7120100

Bezerra ACS, Maciel PS, Corrêa ECS, Soares Junior PRR, Aguilar MTP, Cetlin PR. Effect of High Temperature on the Mechanical Properties of Steel Fiber-Reinforced Concrete. Fibers. 2019; 7(12):100. https://doi.org/10.3390/fib7120100

Chicago/Turabian StyleBezerra, Augusto C. S., Priscila S. Maciel, Elaine C. S. Corrêa, Paulo R. R. Soares Junior, Maria T. P. Aguilar, and Paulo R. Cetlin. 2019. "Effect of High Temperature on the Mechanical Properties of Steel Fiber-Reinforced Concrete" Fibers 7, no. 12: 100. https://doi.org/10.3390/fib7120100

APA StyleBezerra, A. C. S., Maciel, P. S., Corrêa, E. C. S., Soares Junior, P. R. R., Aguilar, M. T. P., & Cetlin, P. R. (2019). Effect of High Temperature on the Mechanical Properties of Steel Fiber-Reinforced Concrete. Fibers, 7(12), 100. https://doi.org/10.3390/fib7120100