Osage Orange, Honey Locust and Black Locust Seed Meal Adhesives Employed to Fabricate Composite Wood Panels

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Processing Employed

2.2. Preparation of Composite Panels

2.3. Analysis of Matrix Ingredients

2.4. Composite Panel Evaluation

3. Results and Discussion

3.1. Seed Meal Chemical Composition

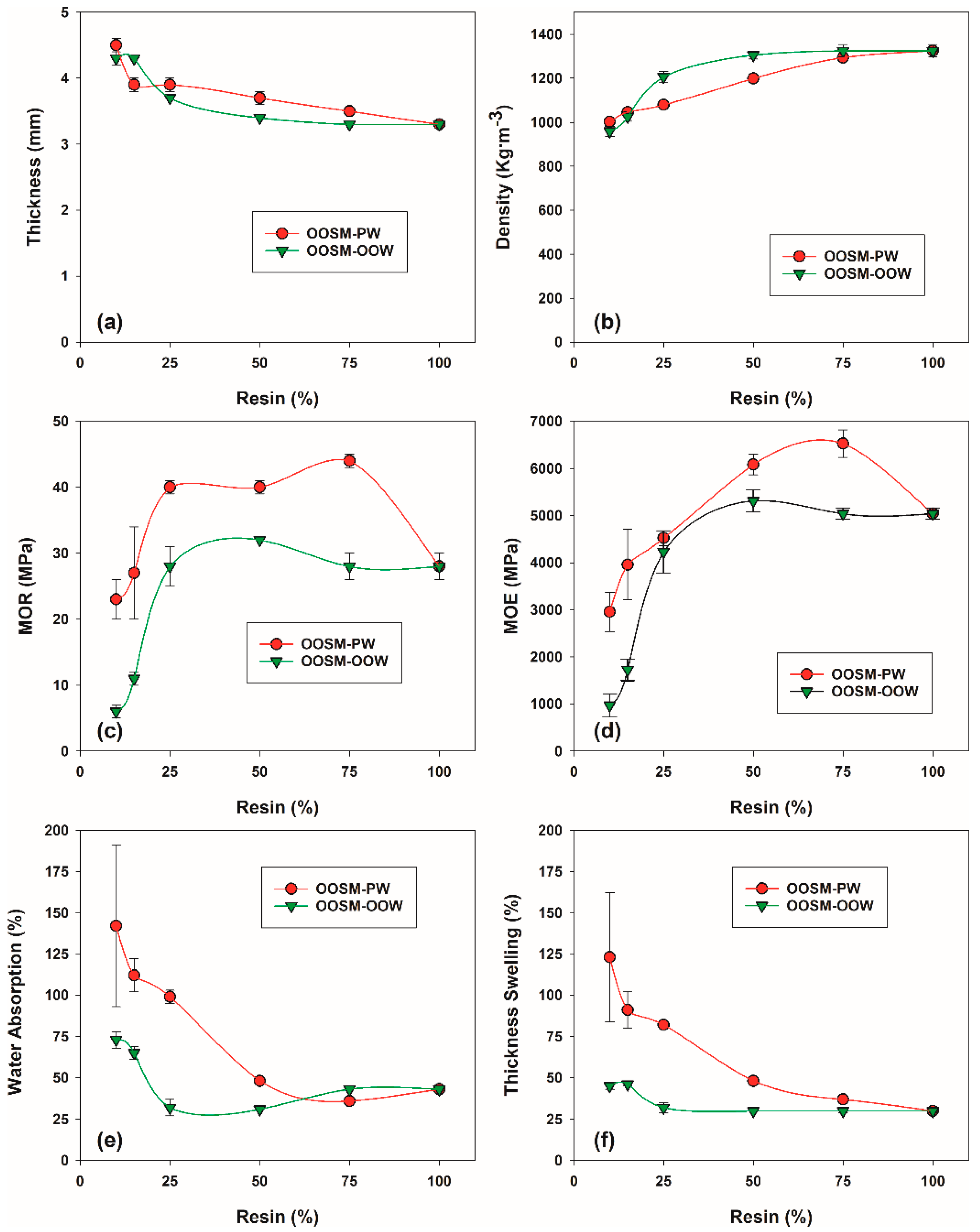

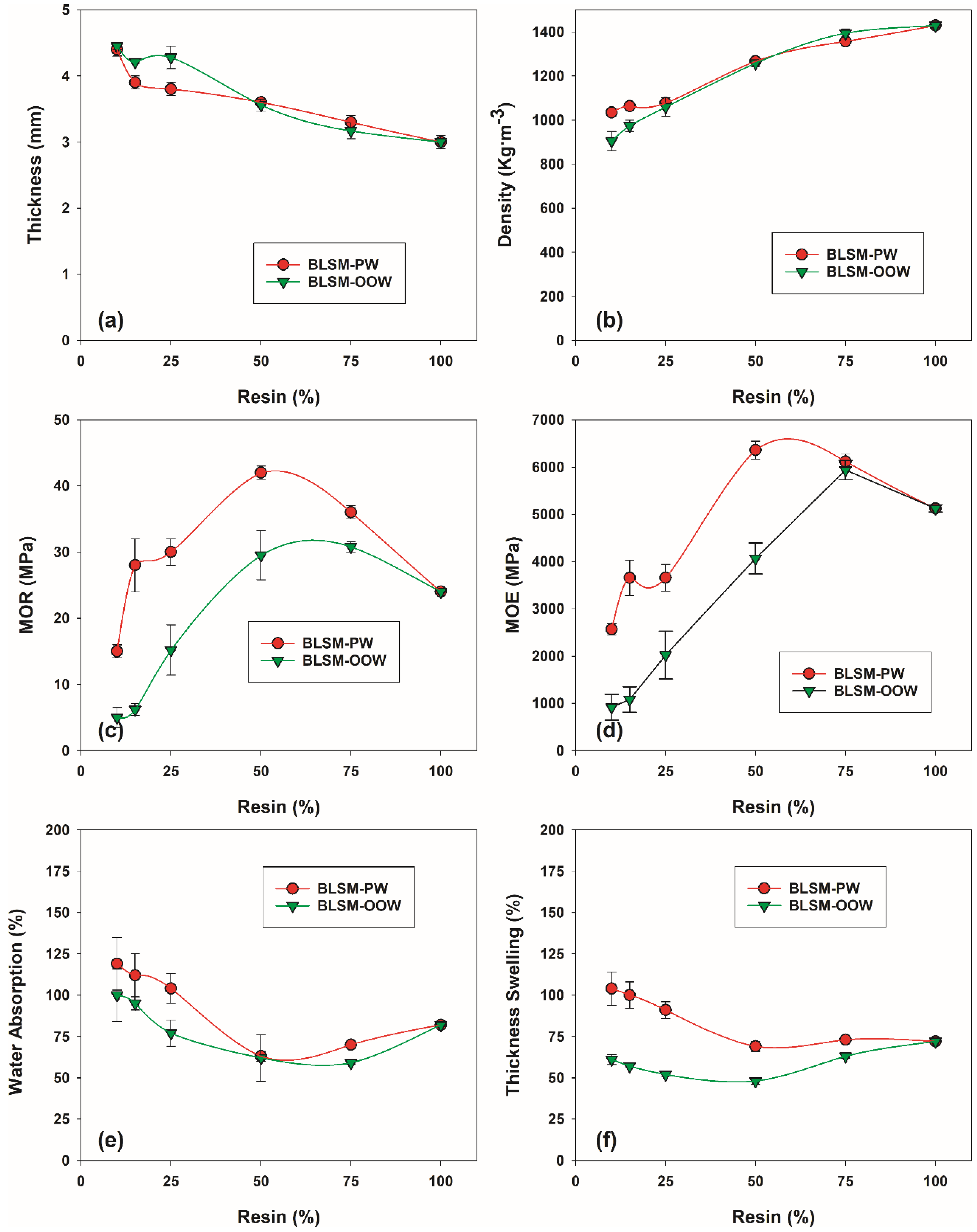

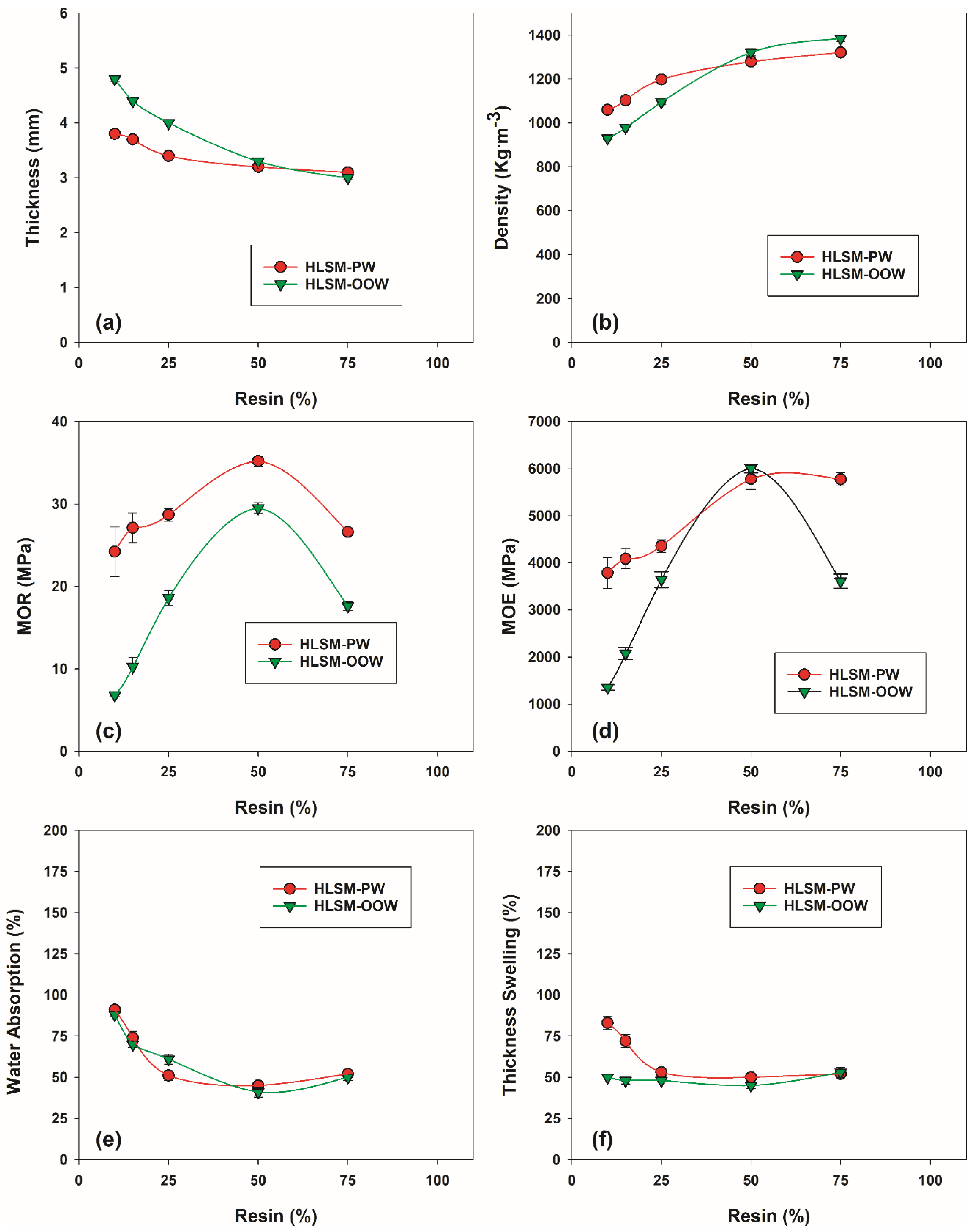

3.2. Lignocellulosic Panel Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Austin, A. Black Locust; Bellarmine University: Louisville, KY, USA, 2005; Available online: https://www.bellarmine.edu/faculty/drobinson/BlackLocust.asp (accessed on 6 July 2018).

- Burton, J.D. Osage-Orange. USDA-FS, FS-248. Available online: https://www.srs.fs.usda.gov/pubs/misc/ag_654/volume_2/maclura/pomifera.htm (accessed on 16 July 2019).

- CABI. Gleditsia triacanthos (honey Locust). Invasive Species Compendium. 2019. Available online: https://www.cabi.org/isc/datasheet/25272#tosummaryOfInvasiveness (accessed on 16 July 2019).

- Dean, M. Councils Combine to Combat Invasive Honey Locust Plant. Available online: https://www.bundabergnow.com/2019/06/11/honey-locust-invasive-plant/ (accessed on 30 July 2019).

- Duke, J.A. Gleditsia triacanthos L. Handbook of Energy Crops; Center for New Crops & Plant Products, Purdue University: West Lafayette, IN, USA, 1983. [Google Scholar]

- Greene, W. Black Locust: The Tree on Which the US was Built. Available online: https://www.livescience.com/50732-black-locust-tree-shaped-the-united-states.html (accessed on 23 July 2019).

- Smith, J.L.; Perino, J.V. Osage orange (Maclura pomifera): History and economic uses. Econ. Bot. 1981, 35, 24–31. [Google Scholar] [CrossRef]

- Stone, K.R. Robinia pseudoacacia. Fire Effects Information System, USDA-FS-RMRS. 2009. Available online: https://www.fs.fed.us/database/feis/plants/tree/robpse/all.html (accessed on 28 June 2019).

- Sullivan, J. Gleditsia triacanthos. Fire Effects Information System, USDA-FS-RMRS. 1994. Available online: https://www.fs.fed.us/database/feis/plants/tree/gletri/all.html (accessed on 28 June 2019).

- Hart, J.H. Morphological and chemical differences between sapwood, discolored sapwood, and heartwood in black locust and Osage orange. For. Sci. 1968, 14, 334–338. [Google Scholar]

- Heuzé, V.; Tran, G.; Savant, D.; Lebas, F. Honey locust (Gleditsia tricanthos) Feedipedia, a Programme by INRA, CIRAD, AFZ and FAO. 2018. Available online: https://www.feedipedia.org/node/295 (accessed on 2 July 2019).

- HenoftheWood. Foraging: Identifying & Harvesting Black Locust. Available online: https://foragedfoodie.blogspot.com/2013/05/foraging-identifying-harvesting-black.html (accessed on 23 July 2019).

- Hui, A.; Marraffa, J.M.; Stork, C.M. A rare ingestion of the black locust tree. J. Toxicol. Clin. Toxicol. 2004, 42, 94–95. [Google Scholar] [CrossRef] [PubMed]

- MDOT. Minnesota Noxious Weeds. Minnesota Department of Transportation, 2019. Available online: https://www.dot.state.mn.us/roadsides/vegetation/pdf/noxiousweeds.pdf (accessed on 23 July 2019).

- MDNR. Black Locust-Invasive Species-Best Control Practices. Michigan Department of Natural Resources, 2012. Mich. Nat. Features Inventory 2/2012. Available online: https://mnfi.anr.msu.edu/invasive-species/BlackLocustBCP.pdf (accessed on 23 July 2019).

- Hanover, J.W. Black locust: An excellent fiber crop. In New Crops; Janick, J., Simon, J.E., Eds.; Wiley: New York, NY, USA, 1993; pp. 432–435. [Google Scholar]

- Minnesota Wildflowers. Gleditsia triacanthos (Honey Locust). 2019. Available online: https://www.minnesotawildflowers.info/tree/honey-locust (accessed on 23 July 2019).

- Oranges.com. The Osage Orange Tree. 2016. Available online: https://oranges.com/the-osage-orange-tree (accessed on 28 June 2019).

- Nesom, G.; Guala, G. Plant Guide: Honey Locust. USDA-NRCS. 2003. Available online: https://plants.usda.gov/plantguide/pdf/pg_gltr.pdf (accessed on 28 June 2019).

- PFAF.org. Maclura pomifera—(Raf.) C.K. Schneid. Plants for a Future. 2016. Available online: https://www.pfaf.org/user/Plant.aspx?LatinName=Maclura+pomifera (accessed on 28 June 2019).

- Usvast, L. Reforestation and Medicinal Use of the Trees-Legume Trees Fix the Soil. Available online: https://lilianausvat.blogspot.com/2014/02/legume-trees-fix-soil.html#.XRuaPXF7ncs (accessed on 28 June 2019).

- Reed, C. About Locust Trees Bean Pods. Available online: https://www.gardenguides.com/12471117-about-locust-trees-bean-pods.html (accessed on 28 June 2019).

- Invasive.org. Illinois Invasive Plant List. 2016. Available online: https://www.invasive.org/species/list.cfm?id=152 (accessed on 23 July 2019).

- Wilson, A. Nitrogen Fixation in Honeylocust Roots!?! Available online: https://faculty.virginia.edu/honeylocust-agroforestry/agroforestry/Honeylocust%20Research%20Newsletter%20No.%202.htm (accessed on 28 June 2019).

- Woodweb.com. Toxicity of Black Locust. Available online: https://www.woodweb.com/knowledge_base/Toxicity_of_Black_Locust.html (accessed on 18 June 2019).

- Grace Communications Foundation. Industrial Crop Production. 2016. Available online: https://www.sustainabletable.org/804/industrial-crop-production (accessed on 23 July 2019).

- Padulosi, S.; Eyzaquirre, P.; Hodgkin, T. Challenges and strategies in promoting conservation and use of neglected and underutilized crop species. In Perspectives on New Crops and Uses; Janick, J., Ed.; ASHS Press: Alexandria, VA, USA, 1999; pp. 140–144. [Google Scholar]

- Harry-O’Kuru, R.E.; Tisserat, B.; Gordon, S.H.; Gravett, A. Osage orange (Maculura pomifera L.) seed oil poly(α-hydroxydibutylamine) triglycerides: Synthesis and characterization. J. Agric. Food Chem. 2015, 63, 6588–6595. [Google Scholar] [CrossRef]

- Moser, B.R.; Eller, F.J.; Tisserat, B.H.; Gravett, A. Preparation of fatty acid methyl ester from Osage orange (Maclura pomifera) oil and evaluation as biodiesel. Energy Fuels 2011, 25, 1869–1877. [Google Scholar] [CrossRef]

- Tisserat, B.; Eller, F.; Mankowski, M.E. Properties of composite wood panels fabricated from Eastern Redcedar employing various bio-based green adhesives. BioResources 2019, 14, 6666–6685. [Google Scholar] [CrossRef]

- Tisserat, B. Fabrication of natural fiber composites consisting of Osage orange seed flour reinforced with non-woven hemp mats. J. Polym. Environ. 2018, 26, 3957–3966. [Google Scholar] [CrossRef]

- Carll, C. Wood Particleboard and Flakeboard. USDA-FS-FPRL-Gen. Tech. Rpt. FPL-GTR-53. 1986. Available online: https://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr53.pdf (accessed on 16 July 2018).

- Kurtz, C. Experts Talk about Engineered Wood. Available online: https://www.networx.com/article/experts-talk-about-engineered-wood (accessed on 23 July 2019).

- MarketsandMarkets.com. Bioadhesive Market by Type (Plant Based, and Animal Based) by Application (Packaging & Paper, Construction, Wood, Personal Care, Medical, and Others)—Global Forecast to 2019. April 2015. Report Code CH 3015. Available online: https://www.marketsandmarkets.com/Market-Reports/bioadhesive-market-16386893.html (accessed on 23 July 2019).

- Gross, M. Getting Stuck in. Chemistry World. Available online: https://www.rsc.org/images/Bioadhesives%20-%20Getting%20Stuck%20In_tcm18-210693.pdf (accessed on 23 July 2019).

- Frihart, C.R.; Lorenz, L. Protein Modifiers Generally Provide Limited Improvement in Wood Bond Strength of Soy Flour Adhesives. For. Prod. J. 2013, 63, 138–142. [Google Scholar] [CrossRef]

- Frihart, C.R.; Hunt, C.; Birkeland, M.J. Chapter 16: Soy proteins as wood adhesives. In Recent Advances in Adhesion Science and Technology; Gutowski, W., Dodiuk, H., Eds.; CRC Press: Boca Raton, FL, USA, 2014; pp. 277–294. [Google Scholar] [CrossRef]

- Elbadawi, M.; Osman, Z.; Paridah, T.; Nasroun, T.; Kantiner, W. Mechanical and physical properties of particleboards made from Ailanthus wood and UF resin fortified by Acacias tannins blend. J. Mater. Environ. Sci. 2015, 6, 1016–1021. [Google Scholar]

- Huei, R.O.; Prasad, D.M.R.; Khan, M.R.; Rao, D.S.; Jeyaratnam, N.; Raman, D.K. Effect of Jatropha Seed Oil Meal and Rubber Seed Oil Meal as Melamine Urea Formaldehyde Adhesive Extender on the Bonding Strength of Plywood. J. Appl. Sci. 2012, 12, 1148–1153. [Google Scholar] [CrossRef][Green Version]

- Hunt, C.G.; Frihart, C.; O’Dell, J. Heat resistant soy adhesives for structural wood products. In Proceedings of the 32nd Annual Meeting of the Adhesion Society, Savannah, GA, USA, 15–18 February 2009; pp. 74–76. [Google Scholar]

- Khosravi, S. Protein-Based Adhesives for Particleboards. Doctoral Thesis, KTH Royal Institute of Technology, Department of Fibre and Polymer Technology, Stockholm, Sweden, 2016. Available online: https://www.diva-portal.org/smash/get/diva2:878500/FULLTEXT01.pdf (accessed on 1 August 2019).

- Pervaiz, M.; Sain, M. Protein extraction from secondary sludge of paper mill wastewater and its utilization as a wood adhesive. Bioresources 2011, 6, 961–970. [Google Scholar] [CrossRef]

- Wrede, K. Progress in Eco-Friendly Adhesives. Available online: https://www.european-coatings.com/layout/set/print/Publications/Blog/Progress-in-eco-friendly-adhesives (accessed on 28 June 2019).

- Pijak, J. This Potato Starch Paper Glue Boasts no Harmful Additives. Available online: https://www.trendhunter.com/trends/paper-glue (accessed on 28 June 2019).

- Peltola, M.; Neu, T.R.; Raulio, M.; Kolari, M.; Salkinoja-Salonen, M.S. Architecture of Deinococcus geothermalis biofilms on glass and steel: A lectin study. Environ. Microbiol. 2008, 10, 1752–1759. [Google Scholar] [CrossRef] [PubMed]

- Nur Farahain, K. Jatropha Oil Based Bio-Adhesive for Plywood Application. Master’s Thesis, University Malaysia Pahang, Pahang, Malaysia, 2013. [Google Scholar]

- Olympic-adhesives.com. Natural Adhesives. Olympic Adhesives, Inc., 2016. Available online: https://olympic-adhesives.com/Nat_Adhes.html (accessed on 28 June 2019).

- Dumé, B. ‘Glue’ in English Ivy Contains Glycoprotein Nanoparticles. Available online: https://nanotechweb.org/cws/article/tech/65147 (accessed on 5 July 2018).

- Ong, H.R.; Prasad, R.; Khan, M.M.R.; Chowdhury, M.N.K. Effect of palm kernel meal as melamine urea formaldehyde adhesive extender for plywood application: Using a Fourier Transform Infrared Spectroscopy (FTIR) study. Appl. Mech. Mater. 2011, 121, 493–498. [Google Scholar] [CrossRef]

- He, Z.; Chapital, D.C. Preparation and Testing of Plant Seed Meal-based Wood Adhesives. J. Vis. Exp. 2015, 97, e52557. [Google Scholar] [CrossRef]

- Gao, Q.; Li, J.; Shi, S.Q.; Liang, K.; Zhang, X. Soybean meal-based adhesive reinforced with cellulose nano-whiskers. Bioresources 2012, 7, 5622–5633. [Google Scholar] [CrossRef]

- Gao, Q.; Shi, S.Q.; Zhang, S.; Li, J.; Wang, X.; Ding, W.; Liang, K.; Wang, J. Soybean meal-based adhesive enhanced by MUF resin. J. Appl. Polym. Sci. 2012, 12, 3676–3681. [Google Scholar] [CrossRef]

- Morton, J. Carob. In Fruits of Warm Climates; Morton, J.F., Ed.; Florida Flair Books: Miami, FL, USA, 1987; pp. 65–69. [Google Scholar]

- Xi, U.; Wng, C.; Chu, F.; Frihart, C.R.; Lorenz, L.F.; Stark, N.M. Chemical modification of soy flour protein and its properties. Adv. Mater. Res. 2012, 343–344, 875–881. [Google Scholar] [CrossRef]

- Wescott, J.; Frihart, C. Sticking Power from Soya Beans: Higher Fossil Fuel Prices and Concerns Over Formaldehyde In Existing Glue Formulations Have Led To A Resurgence In Interest In Soya-Based Adhesives. Chem. Ind. 2011, 3, 21–23. [Google Scholar]

- Tisserat, B.; Hwang, H.-S.; Vaughn, S.F.; Berhow, M.A.; Peterson, S.C.; Joshee, N.; Vaidya, B.N.; Harry-O’Kuru, R. Fiberboard created using the natural adhesive properties of distillers dried grains with solubles. BioResources 2018, 13, 2678–2701. [Google Scholar] [CrossRef]

- Wood-database.com. Osage Orange. Available online: https://www.wood-database.com/?s=Osage+Orange (accessed on 28 June 2019).

- Salem, M.Z.M.; Mohamed, N.H. Physico-chemical characterization of wood from Maclura pomifera (Raf.) C.K. Schneid. adapted to the Egyptian environmental conditions. J. For. Prod. Ind. 2013, 2, 53–57. [Google Scholar]

- San, H.P.; Long, L.K.; Zhang, C.Z.; Hui, T.C.; Seng, W.Y.; Lin, F.S.; Hun, A.T.; Fong, W.K. Anatomical features, fiber morphological, physical and mechanical properties of three years old new hybrid Paulownia: Green Paulownia. Res. J. For. 2016, 1, 30–35. [Google Scholar] [CrossRef]

- Kaymakci, A.; Bektas, I.; Bal, B.C. Some mechanical properties of Paulownia (Paulownia elongate) wood. In Proceedings of the International Caucasian Forestry Symposium, Artvin, Turkey, 24–26 October 2013; Available online: https://www.researchgate.net/publication/275287592_Some_Mechanical_Properties_of_Paulownia_Paulownia_elongata_Wood/link/55373d670cf2058efdeab04c/download (accessed on 8 October 2019).

- Wood-database.com. Paulownia. Available online: https://www.wood-database.com/paulownia/ (accessed on 28 June 2019).

- El-Showk, S.; El-Showk, N. The Paulownia Tree—An Alternative for Sustainable Forestry. Available online: https://www.cropdevelopment.org/docs/PaulowniaBrochure_print.pdf (accessed on 23 July 2019).

- WPI.com. Technical Characteristics of Paulownia Wood & the Physical Properties of Paulownia. 2019. Available online: https://worldpaulownia.com/technical/ (accessed on 28 June 2019).

- Ates, S.; Ni, Y.; Akgul, M.; Tozluoglu, A. Characterization and evaluation of Paulownia elongata as a raw material for paper production. Afr. J. Biotechnol. 2008, 7, 4153–4158. [Google Scholar]

- Kalaycioglu, H.; Deniz, I.; Hiziroglu, S. Some of the properties of particleboard made from Paulownia. J. Wood Sci. 2005, 51, 410–414. [Google Scholar] [CrossRef]

- European Committee for Standardization. Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength; EN 310:1993; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- European Committee for Standardization. Particleboards and Fibreboards—Determination of Swelling in Thickness after Immersion in Water; EN 317:1993; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- Tisserat, B.; Eller, F.; Harry-O’kuru, R. Various extraction methods influence the adhesive properties of dried distiller’s grains and solubles, and press cakes of pennycress (Thlaspi arvense L.) and Lesquerella [Lesquerella fendleri (A. Gary) S. Watson] in the fabrication of lignocellulosic composites. Fibers 2018, 6, 16. [Google Scholar] [CrossRef]

- Hojilla-Evangelista, M.P. Adhesive qualities of soybean protein-based foamed plywood glues. JAOCS 2002, 79, 1145–1149. [Google Scholar] [CrossRef]

- Li, C.; Li, H.; Zhang, S.; Li, J. Silane coupling agent soy adhesive. Bioresources 2014, 9, 5448–5460. [Google Scholar] [CrossRef]

- Frihart, C.R.; Yelle, D.J.; Wiedenhoeft, A.C. Enhancing bondline performance. In Proceedings of the Final Conference in COST E34, Bonding of Timber, Sopron, Hungary, 6–7 May 2008. [Google Scholar]

- Baharoğlu, M.; Nemli, G.; Sari, B.; Birtürk, B.S. Effects of anatomical and chemical properties of wood on the quality of particleboard. Compos. Part B 2013, 52, 282–285. [Google Scholar] [CrossRef]

- Baharoğlu, M.; Nemli, G.; Sari, B.; Birtürk, B.S.; Ayrilmis, N. The influence of moisture content of raw material on the physical and mechanical properties, surface roughness, wettability, and formaldehyde emission of particleboard composite. Compos. Part B 2012, 43, 2448–2451. [Google Scholar] [CrossRef]

- Rathke, J.; Sinn, G.; Harm, M.; Teischinger, A.; Weigl, M.; Müller, U. Effects of alternative raw materials and varying resin content on mechanical and fracture mechanical properties of particle board. Bioresources 2012, 7, 2970–2985. [Google Scholar] [CrossRef]

- Rathke, J.; Sinn, G.; Weigl, M.; Müller, U. Analysing orthotropy in the core layers of wood based panels by means of fracture mechanics. Eur. J. Wood Prod. 2012, 70, 851–856. [Google Scholar] [CrossRef]

- Vital, B.R.; Lehmann, W.F.; Boone, R.S. How species and board densities affect properties of exotic hardwood particleboards. For. Prod. J. 1980, 24, 37–45. [Google Scholar]

- Khanjanzadeh, H.; Bahmani, A.A.; Rafighi, A.; Tabarsa, T. Utilization of bio-waste cotton (Gossypium hirsutum L.) stalks and underutilized Paulownia (Paulownia fortunie) in wood-based composite particleboard. Afr. J. Biotechnol. 2012, 11, 8045–8050. [Google Scholar] [CrossRef]

- Hiziroglu, S. Overlaying Properties of Particleboard Panels Made from Eastern Redcedar and Osage Orange. 2007. Available online: https://www.swst.org/wp/meetings/IUFRO/pdfs/D505%20Session%20C%20-%20Environmental%20impacts%20and%20benefits%20of%20WBC/5.05%20C_5%20Salim%20HIZIROGLU.pdf (accessed on 23 July 2019).

- Hiziroglu, S. Some of the properties of three-layer particleboard panels made from under-utilized species in Oklahoma. J. Compos. Mater. 2007, 41, 467–476. [Google Scholar] [CrossRef]

- European Committee for Standardization. Fibreboards—Specifications—Part. 2: Requirements for Hardboards; EN 622-2:1997; European Committee for Standardization: Brussels, Belgium, 1997. [Google Scholar]

- European Committee for Standardization. Particleboard—Specifications. Particleboard—Specifications; EN 312:2003; European Committee for Standardization: Brussels, Belgium, 2003. [Google Scholar]

- European Committee for Standardization. Fibreboards—Specifications—Part. 5: Requirements for Dry Process Boards (MDF); EN 622-5:2006; European Committee for Standardization: Brussels, Belgium, 2006. [Google Scholar]

| Properties | Osage Orange Wood (OOW) | Paulownia elongata L. Wood (PW) |

|---|---|---|

| Physical: | ||

| Tree Height (m) | 15–18 [57] | 10–20 [59,61] |

| Density (Kg·m−3) | 620–855 [57,58] | 179–280 [59,61,62,63] |

| Modulus of rupture (MOR) (MPa) | 128.6 [57] | 29.4–37.8 [59,60,61] |

| Modulus of elasticity (MOE) (MPa) | 11,640 [57] | 838–5480 [59,60,61,62,63] |

| Crushing Strength (MPa) | 64.7 [57] | 20.7 [61] |

| Specific gravity | 0.76 [57] | 0.21–0.3 [61,62] |

| Janka Hardness (N) | 11,640 [57] | 1310–1330 [59,61] |

| Heartwood Color | Yellow/bright yellow [57,58] | Pale/whitish [61,63] |

| Chemical: | ||

| Cellulose (%) | 31–36 [58] | 43–49 [62,63,64] |

| Hemicellulose (%) | 16–18 [58] | 22–25 [62,63] |

| Lignin (%) | 32.5–37.5 [58] | 21–23 [62,63,64] |

| Extractives (%) | 7–9 [58] | 4–12 [64,65] |

| Tree Type | Wt. | Length | Diam | Meal | Coat |

|---|---|---|---|---|---|

| (g) | (mm) | (mm) | (%) | (%) | |

| Honey Locust | 0.24 ± 0.004 | 10.4 ± 0.38 | 6.4 ± 0.10 | 29 | 71 |

| Black Locust | 0.03 ± 0.001 | 3.9 ± 0.24 | 2.6 ± 0.05 | 67 | 33 |

| Osage Orange | 0.04 ± 0.003 | 8.3 ± 0.44 | 4.5 ± 0.09 | 73 | 27 |

| Percent | Filler/Reinforcement * | |

|---|---|---|

| Matrix | PW | OOW |

| 10OOSM,15OOSM,25OOSM,50OOSM,75OOSM,100OOSM | x | x |

| 10HLSM,15HLSM,25HLSM,50HLSM,75HLSM,100HLSM | x | x |

| 10BLSM,15BLSM,25BLSM,50BLSM,75BLSM,100BLSM | x | x |

| Composition | HLSM | BLSM | OOSM |

|---|---|---|---|

| Oil * | 0.9 | 4 | 25 |

| Crude Protein | 23.5 | 37.3 | 44.1 |

| Moisture | 7.8 | 8.6 | 5.8 |

| Crude Fiber | 10.3 | 8.9 | 4.9 |

| Cellulose | 10.6 | 8.9 | 3.3 |

| Starch | 0.4 | 0.4 | 0.8 |

| Lignin | 1.8 | 1.5 | 2.6 |

| Total Sugars | 3.2 | 5.6 | 2.3 |

| Ash | 3.7 | 5.3 | 3.1 |

| Amino Acids | Functional Group Characteristics | HLSM | BLSM | OOSM |

|---|---|---|---|---|

| Nonpolar: | ||||

| Alanine | hydrophobic | 4.2 | 4.3 | 4.1 |

| Isoleucine | hydrophobic | 3.7 | 4.0 | 4.2 |

| Leucine | hydrophobic | 6.5 | 6.6 | 6.9 |

| Methionine | hydrophobic | 1.1 | 1.2 | 1.1 |

| Phenylalanine | hydrophobic | 3.5 | 3.4 | 4.9 |

| Tryptophan | Hydrophobic | 0.8 | 0.8 | 1.2 |

| Tyrosine | hydrophobic | 2.9 | 3.2 | 3.0 |

| Valine | hydrophobic | 4.8 | 5.2 | 5.4 |

| Total: | 27.6 | 28.8 | 30.9 | |

| Polar: | ||||

| Arginine | positive charged/basic | 12.3 | 11.8 | 16.2 |

| Histidine | positive charged/basic | 2.4 | 2.5 | 2.2 |

| Lysine | positive charged/basic | 5.7 | 5.7 | 2.6 |

| Aspartic acid | negative charged/acidic | 11.8 | 9.8 | 10.7 |

| Glutamic acid | negative charged/acidic | 24.2 | 24.1 | 21.6 |

| Serine | polar uncharged | 5.1 | 5.1 | 5.6 |

| Threonine | polar uncharged | 3.0 | 3.1 | 3.1 |

| Total: | 61.4 | 59.0 | 59.0 | |

| Other: | ||||

| Cystine | thiol | 1.4 | 1.5 | 1.4 |

| Glycine | Hydrogen | 6.6 | 7.6 | 5.6 |

| Total: | 8.0 | 9.1 | 7.0 | |

| All Totals: | 97 | 96.9 | 96.9 | |

| Description | Density * | MOR ** | MOE ** | Thickness Swelling (TS) ** |

|---|---|---|---|---|

| (Panel Type, Thickness) | (Kg·m−3) | (MPa) | (MPa) | (mm) |

| PB, 3–6 mm | 160–800 | 13–20 | 1800–2550 | 14–23 |

| MDF, ≥2.5–6 mm | 450–800 | 23–34 | 2700–3000 | 18–35 |

| HB, ≥3.5–5.5 mm | 600–1450 | 30–44 | 2500–4500 | 10–35 |

| OOSM-PW, 3.5–4.5 mm | 1002–1294 | 23–44 | 2950–6080 | 37–91 |

| BLSM-PW, 3–4 mm | 1034–1429 | 15–42 | 1063–6357 | 69–100 |

| HLSM-PW, 3.1–3.8 mm | 1057–1321 | 24–35 | 1057–1421 | 50–83 |

| OOSM-OOW, 3.4–4.5 mm | 920–1206 | 6–32 | 970–4230 | 30–54 |

| BLSM-OOW, 2.8–4.5 mm | 905–1436 | 5–31 | 917–5936 | 48–61 |

| HLSM-OOW, 3.0–4.8 mm | 930–1385 | 7–30 | 1353–6005 | 45–53 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tisserat, B.; Harry-O’kuru, R. Osage Orange, Honey Locust and Black Locust Seed Meal Adhesives Employed to Fabricate Composite Wood Panels. Fibers 2019, 7, 91. https://doi.org/10.3390/fib7100091

Tisserat B, Harry-O’kuru R. Osage Orange, Honey Locust and Black Locust Seed Meal Adhesives Employed to Fabricate Composite Wood Panels. Fibers. 2019; 7(10):91. https://doi.org/10.3390/fib7100091

Chicago/Turabian StyleTisserat, Brent, and Rogers Harry-O’kuru. 2019. "Osage Orange, Honey Locust and Black Locust Seed Meal Adhesives Employed to Fabricate Composite Wood Panels" Fibers 7, no. 10: 91. https://doi.org/10.3390/fib7100091

APA StyleTisserat, B., & Harry-O’kuru, R. (2019). Osage Orange, Honey Locust and Black Locust Seed Meal Adhesives Employed to Fabricate Composite Wood Panels. Fibers, 7(10), 91. https://doi.org/10.3390/fib7100091